Page 1

XC series expansions with special functions

Operate Manual

Thinget Electronic Co., Ltd.

Page 2

Catalog

Ⅰ 、 MODULE’S INFORMATION ....................................................................................................................... 3

Ⅱ 、 PID FUNCTION ............................................................................................................................................. 2

Ⅲ 、 ANALOG INPUT MODULE (XC-E8AD) .................................................................................................. 3

Ⅳ 、 ANALOG INPUT/OUTPUT MODULE XC-E4AD2DA ........................................................................ 12

Ⅴ 、 ANALOG OUTPUT MODULE XC-E4DA ............................................................................................... 19

Ⅵ 、 PT100 TEMPERATURE PID CONTROL MODULE XC-E6PT-P ...................................................... 24

Ⅶ 、 K TYPE THERMOCOUPLE TEMPERATURE PID CONTROL MODULE XC-E6TC-P ............ 30

VIII 、 XC-E3AD4PT2DA ................................................................................................................................. 36

ANALOG INPUT MODULE XC-E4AD .......................................................................................................... 46

Page 3

Ⅰ、Module’s information

1、Basic Characteristic

XC series PLC have not only strong functions of logic dispose 、data operation、high speed disposing

etc. but also functions of A/D 、 D/A convert、PID adjustment;With using expansions of analog input

module、analog output module 、temperature control module etc, XC series PLC are widely used in the

control system of temperature、flow、liquid level、pressure.

2、Module’s Name

The detailed information is the following:

Model Function

XC-E8AD

8 channels analog input (14bit);4 channels current input, 4 channels voltage input

XC-E4AD2DA

4 channels analog input (14bit); 2 channels analog output (12bit) ; current 、 voltage

selectable

XC-E4DA

4 channels analog output (12bit);current、voltage selectable

XC-E6PT-P

-150 ~350℃ ℃,6 channels Pt100 temperature sampling, 0.1 degree precision, include PID

operation

XC-E6TC-P

0 ~1000℃ ℃,6 channels K type thermocouple temperature sampling module, 0.1 degree

precision, include PID operation

3、Exterior Size

Page 4

4、General Specification

Operating Environment No Canker gas

Ambient Temperature 0 ~60℃ ℃

Store Temperature -20~70℃

Ambient Humidity 5~95%

Store Humidity 5~95%

Installation Can be fixed with M3 screws or directly installed on orbit of

DIN46277(width: 35mm)

Size 63mm×102mm×73.3mm

5、Items to note when using

Please confirm the specification, choose suitable module

When carry on processing the screws or layout project, please protect the scraps falling into the modules

Before connecting, please confirm again module’s specification and connected device

When connecting, please check if the connection is fastness, cable breaking off will cause data incorrect,

short circuit and other fault! Installation, layout should only be carried after cutting all power.

Page 5

Ⅱ、PID Function

1、Brief introduction of PID function

Among XC series PLC special modules, digital input module (A/D module) and temperature control

modules both have PID control function. It is widely used and flexible. When using, only four parameters

(Kp、 Ki、 Kd and Diff) should be set.

2、Parameter’s usage

Usage of four parameters: Proportion parameter(Kp)、Integral parameter(Ki)、Differential

parameter(Kd)、Control proportion band(Diff)

Kp—parameter P is proportion parameter, mainly reflect system’s wrap. When wrap occurs, carry on control to

decrease this wrap.

Ki—parameter I is integral parameter, mainly used to eliminate whisht difference, improving system’s no

difference degree.

Kd-- parameter D is differential parameter, mainly used to control signal’s changing trend, decrease system’s

shake.

Diff—Control bound means in the assigned bound, carry on PID control, out the bound, do not carry on PID

control.

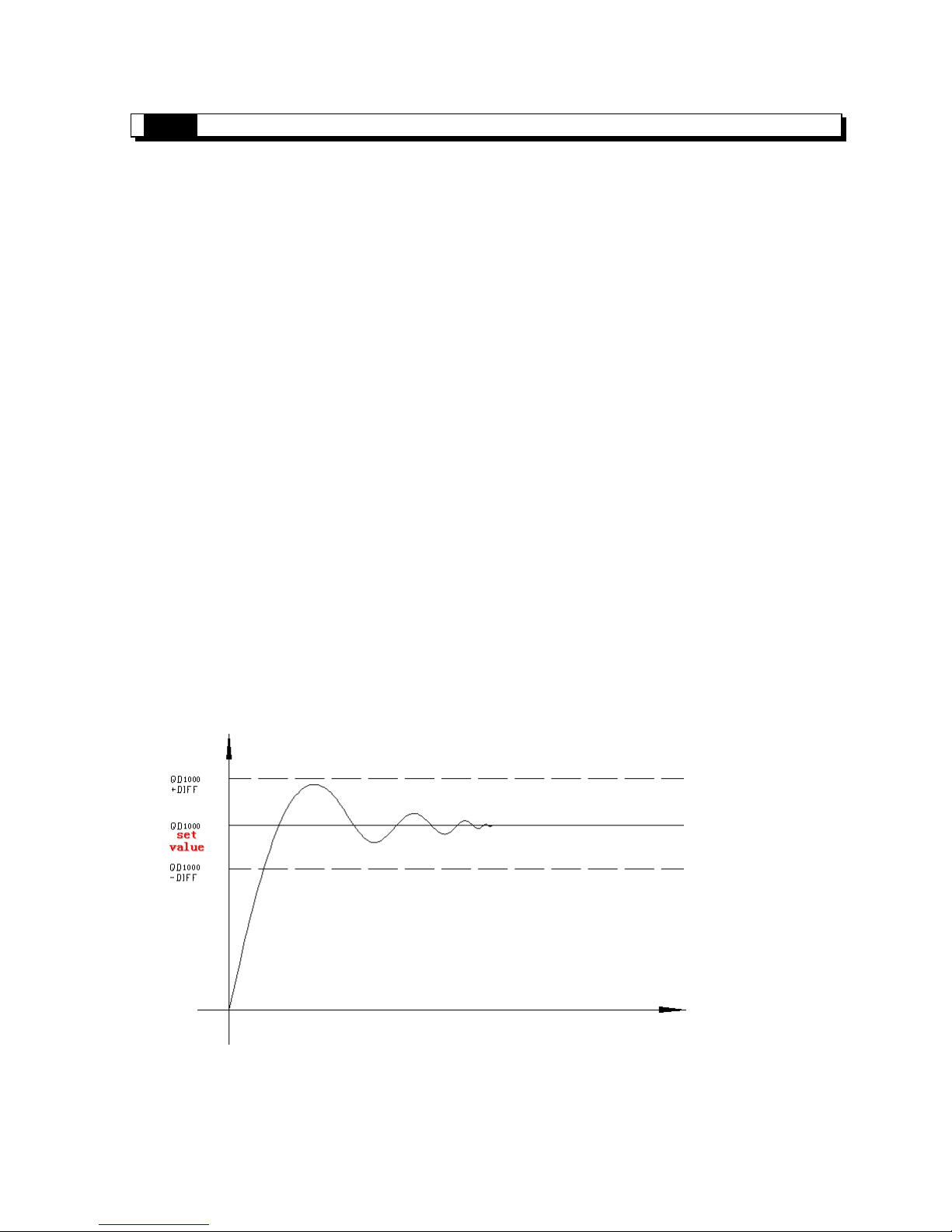

3、 Contr ol characteris tic

The bound of PID adjustment is, when the testing value is low than QD-Diff, controller output with the

full scale; when the testing value is larger than QD+Diff, the controller stop output; in the bound of(QD-

Diff,QD+Diff), carry on PID adjustment.

The control curve of PID is the following:

Each parameter’s reference value: Kp=20~100;Ki=5~20;Kd=200~700;DIFF=100~200.

Page 6

Ⅲ、Analog input module (XC-E8AD)

1.

Specification

Specialty:

14 bits high precision analog input

8 channels analog input : The first

four channels current input

(0~20mA 、 4~20 mA two kinds) ;

The left 4 channels voltage input

(0~5V、0~10V two kinds)

As special function module of XC, 7

models could be connected at most.

With PID adjustment function

Items

Current input(0CH~3CH) Voltage input(4CH~7CH)

Analog input bound

DC0~20mA、4~20mA DC0~5V、0~10V

Max input bound 0~40mA ±18V

Digital output bound 14 bits binary data

PID control value 0~4095

Distinguish Ratio 1/16383(14Bit)

Integrate Precision 0.8%

Convert speed 15ms per channel

Power used by analog DC24V±10%,100mA

Install format Can be fixed with M3 screws or directly installed on orbit of DIN46277 (width:

35mm)

Size 63mm×102mm×73.3mm

Page 7

2.

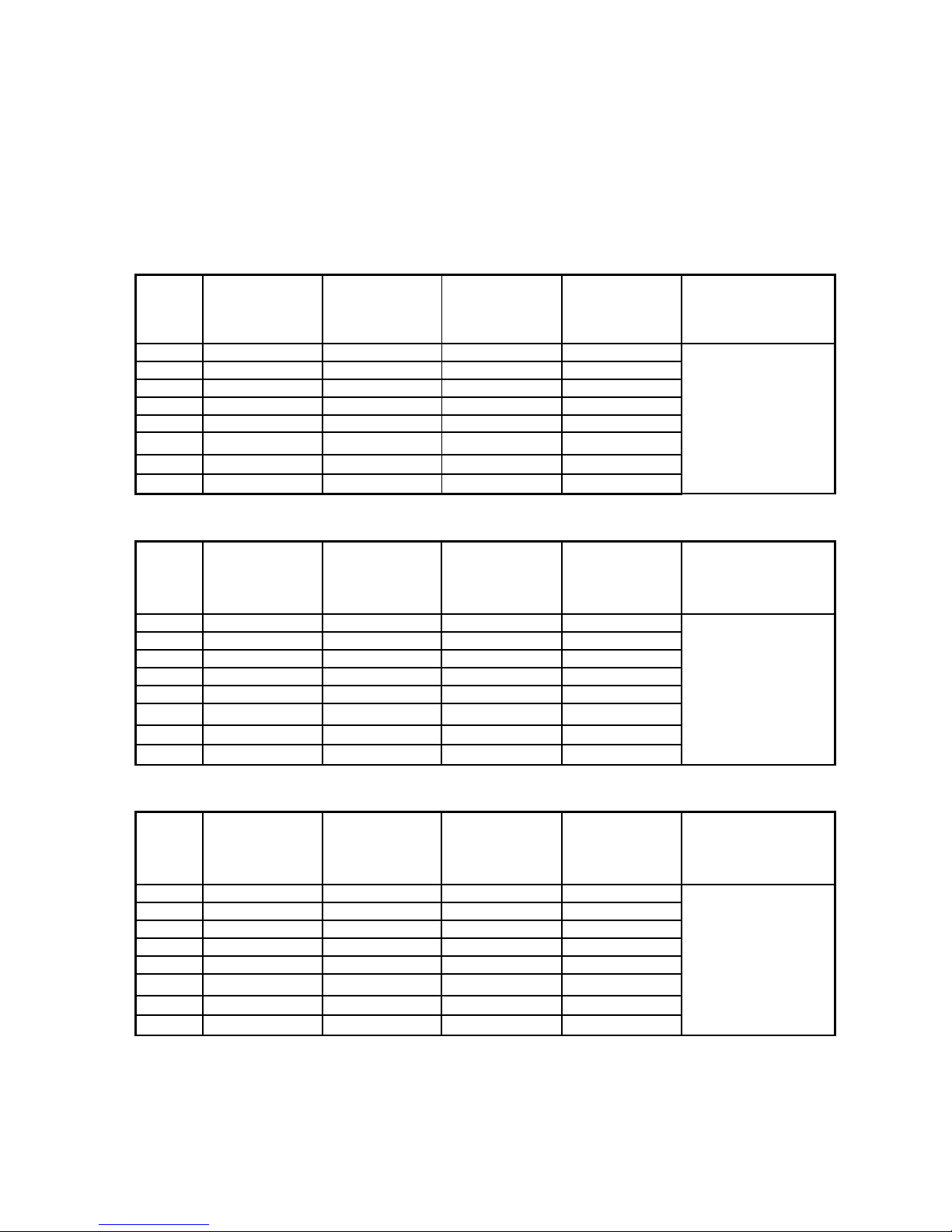

Input ID assignment

XC series analog module doesn’t engross I/O units, the converted data is directly transferred into PLC

register. Channels’ correspond PLC register ID is:

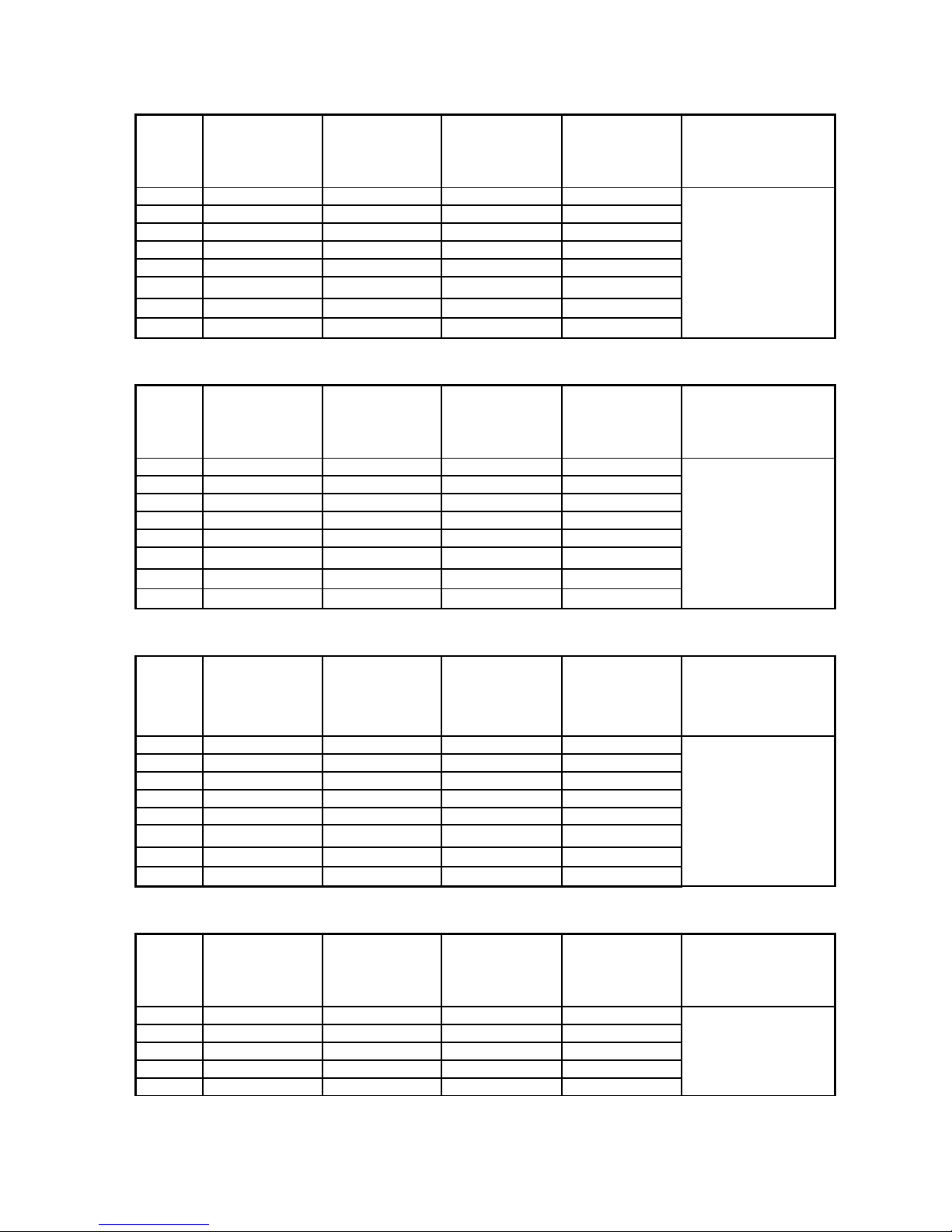

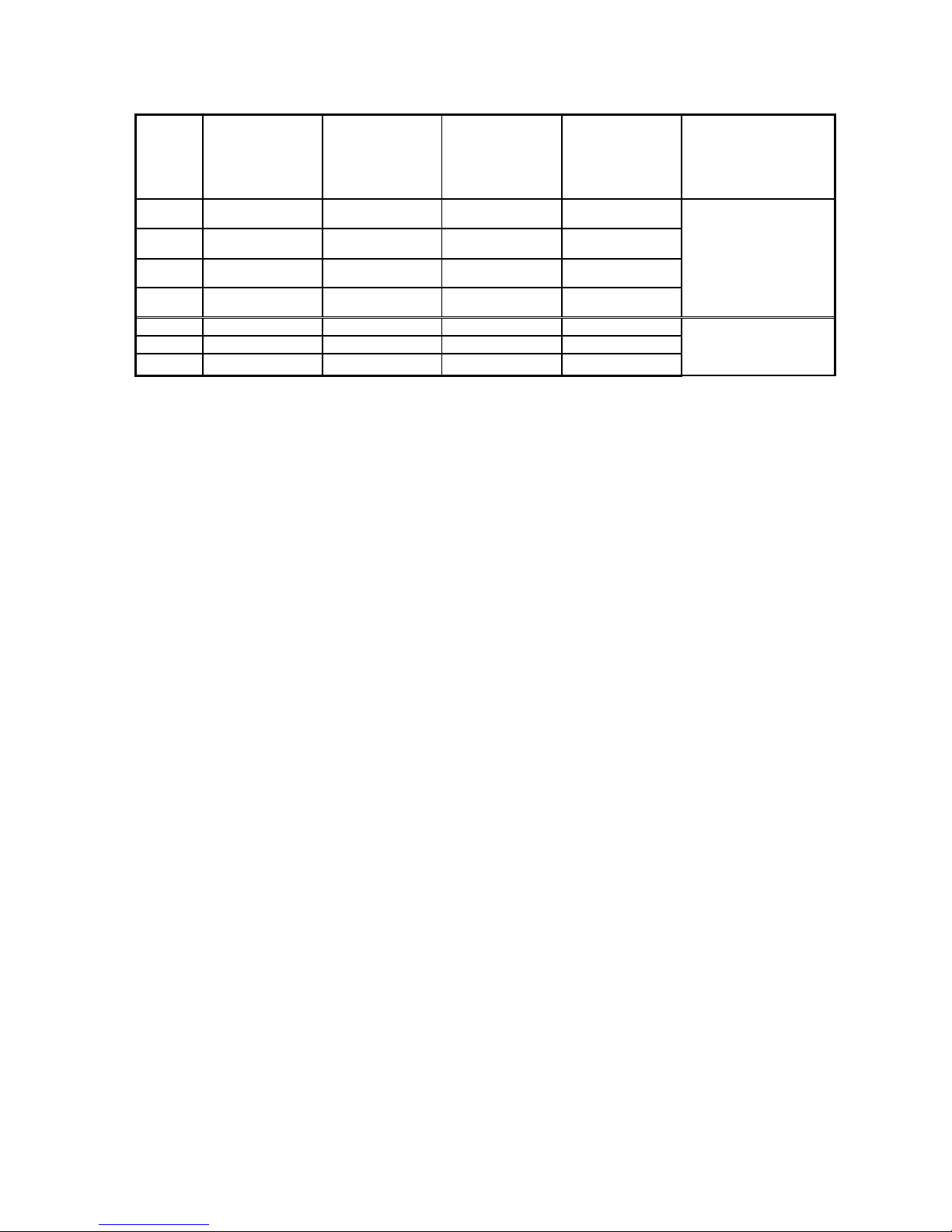

Input、output ID list

Register’s ID of expansion 1:

Channel AD signal PID output

value

PID start/stop

control bit

The set value PID Parameters: Kp,

Ki, Kd, control bound

Diff, dead bound

“Death”

0CH ID100 ID108 Y100 QD100

Kp:QD108

Ki:QD109

Kd:QD110

Diff:QD111

Death:QD112

1CH ID101 ID109 Y101 QD101

2CH ID102 ID110 Y102 QD102

3CH ID103 ID111 Y103 QD103

4CH ID104 ID112 Y104 QD104

5CH ID105 ID113 Y105 QD105

6CH ID106 ID114 Y106 QD106

7CH ID107 ID115 Y107 QD107

Register’s ID of expansion 2:

Channel AD signal PID output

value

PID start/stop

control bit

The set value

PID parameters: Kp,

Ki, Kd, control bound

Diff, dead bound

“Death”

0CH ID200 ID208 Y200 QD200

Kp:QD208

Ki:QD209

Kd:QD210

Diff:QD211

Death:QD212

1CH ID201 ID209 Y201 QD201

2CH ID202 ID210 Y202 QD202

3CH ID203 ID211 Y203 QD203

4CH ID204 ID212 Y204 QD204

5CH ID205 ID213 Y205 QD205

6CH ID206 ID214 Y206 QD206

7CH ID207 ID215 Y207 QD207

Register’s ID of expansion 3:

Channel AD signal PID output

value

PID start/stop

control bit

The set value

PID parameters: Kp,

Ki, Kd, control bound

Diff, dead bound

“Death”

0CH ID300 ID308 Y300 QD300

Kp:QD308

Ki:QD309

Kd:QD310

Diff:QD311

Death:QD312

1CH ID301 ID309 Y301 QD301

2CH ID302 ID310 Y302 QD302

3CH ID303 ID311 Y303 QD303

4CH ID304 ID312 Y304 QD304

5CH ID305 ID313 Y305 QD305

6CH ID306 ID314 Y306 QD306

7CH ID307 ID315 Y307 QD307

Register’s ID of expansion 4:

Page 8

Channel AD signal PID output

value

PID start/stop

control bit

The set value

PID parameters: Kp,

Ki, Kd, control bound

Diff, dead bound

“Death”

0CH ID400 ID408 Y400 QD400

Kp:QD408

Ki:QD409

Kd:QD410

Diff:QD411

Death:QD412

1CH ID401 ID409 Y401 QD401

2CH ID402 ID410 Y402 QD402

3CH ID403 ID411 Y403 QD403

4CH ID404 ID412 Y404 QD404

5CH ID405 ID413 Y405 QD405

6CH ID406 ID414 Y406 QD406

7CH ID407 ID415 Y407 QD407

Register’s ID of expansion 5:

Channel AD signal PID output

value

PID start/stop

control bit

The set value

PID parameters: Kp,

Ki, Kd, control bound

Diff, dead bound

“Death”

0CH ID500 ID508 Y500 QD500

Kp:QD508

Ki:QD509

Kd:QD510

Diff:QD511

Death:QD512

1CH ID501 ID509 Y501 QD501

2CH ID502 ID510 Y502 QD502

3CH ID503 ID511 Y503 QD503

4CH ID504 ID512 Y504 QD504

5CH ID505 ID513 Y505 QD505

6CH ID506 ID514 Y506 QD506

7CH ID507 ID515 Y507 QD507

Register’s ID of expansion 6:

Channel AD signal PID output

value

PID start/stop

control bit

The set value

PID parameters :

Kp、Ki 、Kd 、contr

ol bound Diff 、 dead

bound “Death”

0CH ID600 ID608 Y600 QD600

Kp:QD608

Ki:QD609

Kd:QD510

Diff:QD611

Death:QD512

1CH ID601 ID609 Y601 QD601

2CH ID602 ID610 Y602 QD602

3CH ID603 ID611 Y603 QD603

4CH ID604 ID612 Y604 QD604

5CH ID605 ID613 Y605 QD605

6CH ID606 ID614 Y606 QD606

7CH ID607 ID615 Y607 QD607

Register’s ID of expansion 7:

Channel AD signal PID output

value

PID start/stop

control bit

The set value

PID parameters: Kp,

Ki, Kd, control bound

Diff, dead bound

“Death”

0CH ID700 ID708 Y700 QD700

Kp:QD708

Ki:QD709

Kd:QD710

1CH ID701 ID709 Y701 QD701

2CH ID702 ID710 Y702 QD702

3CH ID703 ID711 Y703 QD703

4CH ID704 ID712 Y704 QD704

Page 9

Diff:QD711

Death:QD712

5CH ID705 ID713 Y705 QD705

6CH ID706 ID714 Y706 QD706

7CH ID707 ID715 Y707 QD707

Description:

Start signal(Y):when Y is 0, close PID control, when be 1 , start PID control

Parameter P:Proportion parameter, mainly reflex system’s difference, carry on control as soon as

difference occurs to improve the system’s no difference degree.

Parameter I:Integral parameter. Mainly used to remove whisht, improve the system’s no difference

degree.

Parameter D:Differential parameter, mainly used to control signal’s changing trend,minish system’s

shake.

Control bound Diff:In the assigned bound, carry on PID control. Beyond the bound, no PID control.

Dead area Death:When the current PID control value compares with the preceding PID control value. If

the difference between them is less than the set dead bound’s value, the module will

abnegate the current PID control value, send the preceding PID control value to the

PLC main unit.

Each parameter’s reference value:Kp=20~100;Ki=5~20;Kd=200~700;DIFF=100~200

3.Setting of working mode

1)Expansion’s

0CH~3CH channels have two modes to select: current 0~20mA、 4~20mA , 4CH~7CH

channels have two modes to select, voltage 0~5V 、 0~10V. Set via special FLASH data register FC inside

PLC. See the following table:

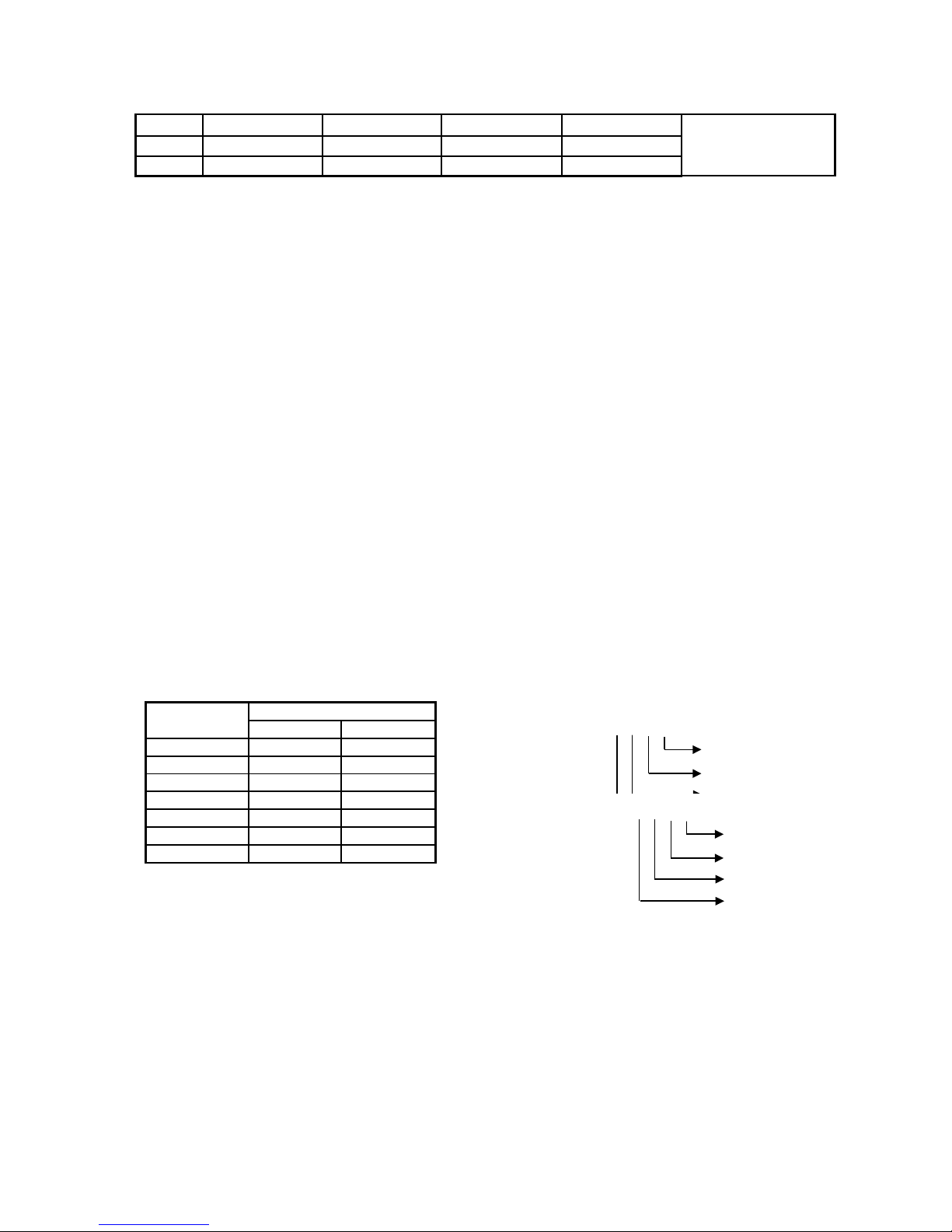

Module Channel’s ID

0CH~3CH 4CH~7CH

1# module FD8250 FD8251

2# module FD8258 FD8259

3# module FD8266 FD8267

4# module FD8274 FD8275

5# module FD8282 FD8283

6# module FD8290 FD8291

7# module FD8298 FD8299

Note:As showed in the preceding table, each register set 4 channels’ mode, each register has 16 bits. From

low bit to high bit, every 4 bits separately set 4 channels’ mode.

Each bit’s definition is showed in the following table:

The following, we take module 1 as example to describe the setting format:

Register FD8250:

Take 1# module as example:

FD8250 H O O O O

0CH

1CH

2CH

3CH

FD8251 H O O O O

4CH

5CH

6CH

7CH

Page 10

Register FD8251:

E.g. : 1 ) Set module 1’s No. 3 、 No.2 、 No.1 、 No.0 channel’s working mode separately as

0~20mA、4~20mA、0~20mA、4~20mA, filters are all 1/2 filter, data in FD8250 is 0101H

2 ) Set module 1’s No. 7 、 No.6 、 No.5 、 No.4 channel’s working mode separately as

0~10V、0~5V、0~10V、0~5V, all the four channels don’t filter, data in FD8251 is 4545H

4.Exterior connection

About exterior connection, you should note the following two items:

When connect+24V power outside, please use the 24V power on PLC main unit to avoid interfere.

To avoid interfere, please use the shield cable and single point grounding with the shield layer.

Layout chart:

Channel 1 Channel 0

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

-

0:0~20mA

1:4~20mA

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

-

0:0~20mA

1:4~20mA

- -

Channel 3 Channel 2

Bit15 Bit14 Bit13 Bit12 Bit11 Bit10 Bit9 Bit8

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

-

0:0~20mA

1:4~20mA

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

-

0:0~20mA

1:4~20mA

- -

Channel 5 Channel 4

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

-

0:0~10V

1:0~5V

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

-

0:0~10V

1:0~5V

- -

Channel 7 Channel 6

Bit15 Bit14 Bit13 Bit12 Bit11 Bit10 Bit9 Bit8

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

-

0:0~10V

1:0~5V

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

-

0:0~10V

1:0~5V

- -

Page 11

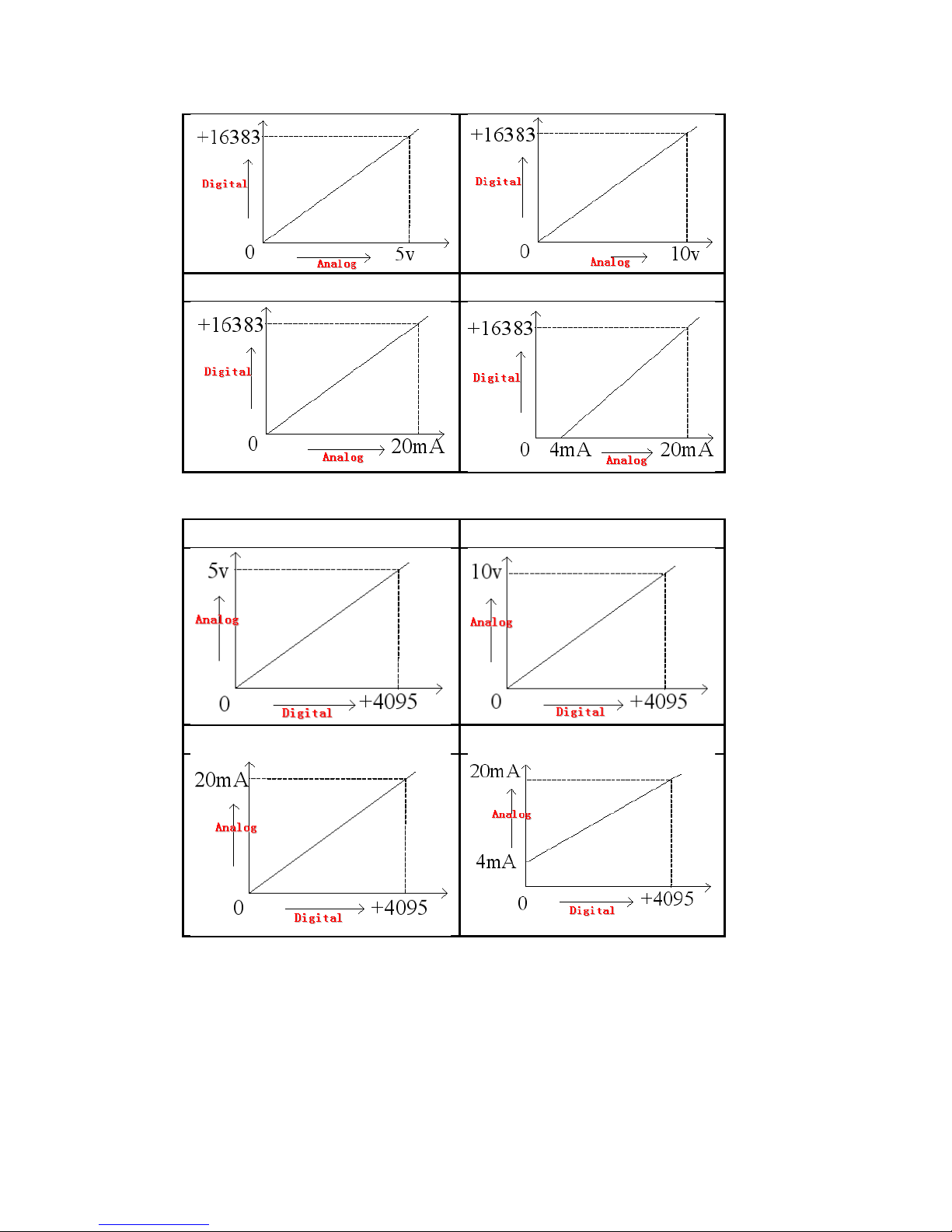

5.Analog/digital convert chart

The relationship between input analog and converted digital quantity is showed in the following chart:

Current mode of Channel 0~Channel 3:

0~20mA analog input 4~20mA analog input

Page 12

Voltage mode of Channel 4~Channel 7:

0~5V analog input 0~10V analog input

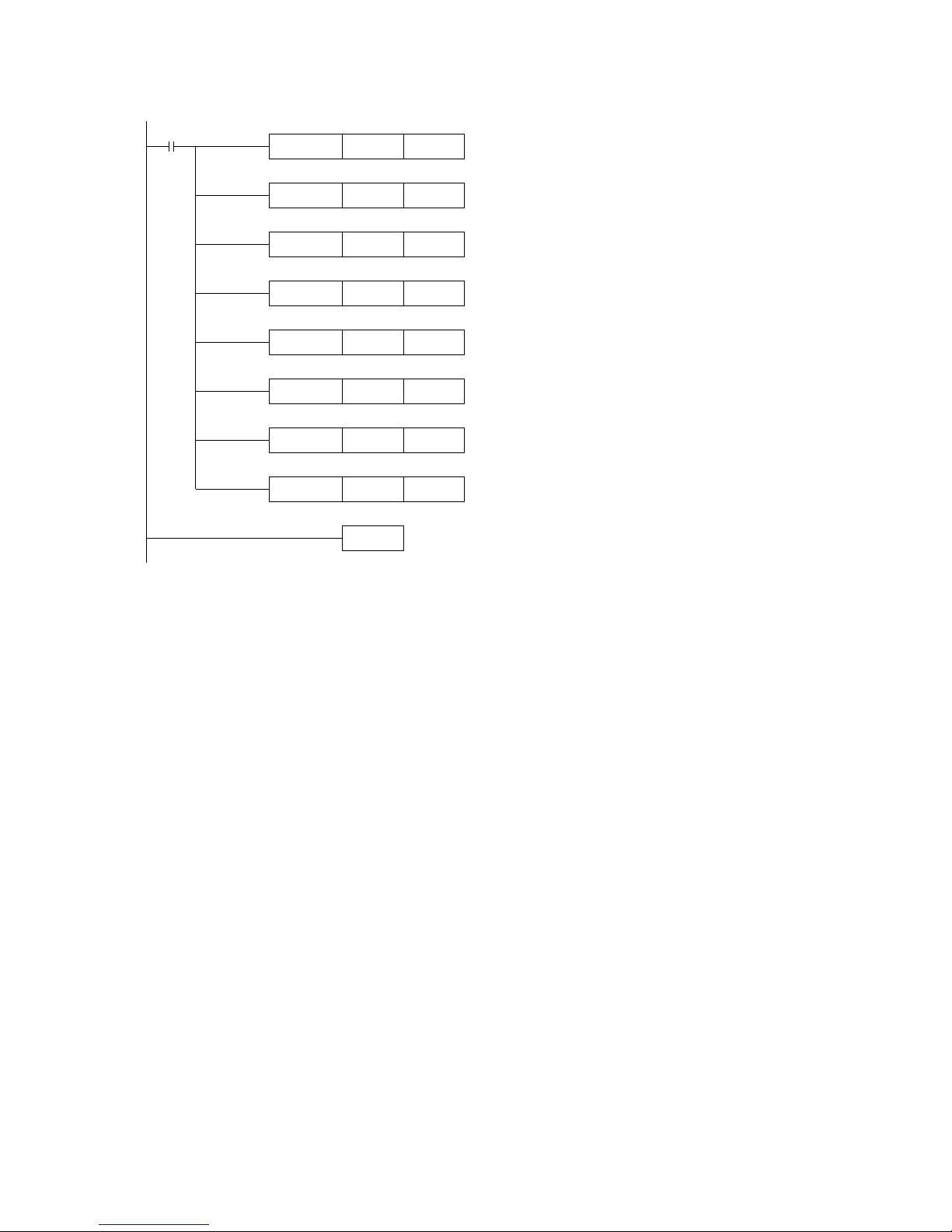

6.Programming

E.g. 1)Real time read unit 1 XC-E8AD module’s 8 channels’ data

Page 13

MOV ID100 D0

END

M8000

MOV ID101 D1

MOV ID102 D2

MOV ID103 D3

MOV ID104 D4

MOV ID105 D5

MOV ID106 D6

MOV ID107 D7

E.g.2)Application of PID control in AD modules

The following, we take channel 0 of XC-E8AD as the example:

Write channel 0’s data in to data register D0

Write channel 1’s data in to data register D1

Write channel 2’s data in to data register D2

Write channel 3’s data in to data register D3

Write channel 5’s data in to data register D5

Write channel 4’s data in to data register D4

Write channel 7’s data in to data register D7

Write channel 6’s data in to data register D6

Page 14

MOV ID100 D10

MOV ID108 D1000

M8000

MOV K30 QD108

MOV K10 QD109

MOV K300 QD110

MOV K100 QD111

MOV K200 QD112

MOV QD100D4000

END

Y100

M8000

Write channel 0’s data into data register D10

Channel 0’s set value is register D4000

Set proportion coefficient Kp as 30

Set proportion coefficient Ki as 10

Set proportion coefficient Kd as 300

Set adjustment bound Diff as 100

Set control dead area as 200

Write channel 0’s PID value into register D1000

PID start/stop signal

Page 15

Ⅳ、Analog input/output module XC-E4AD2DA

1.S pecificatio n

Characteristic:

4 channels 14 bits analog input and 2

channels 12 bits analog output

4 channels selectable voltage

0~5V 、 0~10V , current

0~20mA 、 4~20mA input and 2

channels selectable voltage

0~5V 、 0~10V , current

0~20mA 、 4~20mA output. Set via

host machine.

As special function module of XC, 7

modules could be connected at most

4 channels A/D have PID adjustment

function

Items

Analog input(AD) Analog output(DA)

Voltage input Current input Voltage output Current output

Analog input bound

DC0~5V、0~10V DC0~20mA 、4~20m

A

-

Max input bound

DC±18V DC0~40mA -

Analog output bound

-

DC0~5V、0~10V

(Exterior load

resistance

2KΩ~1MΩ)

DC0~20mA 、 4~20mA

(Exterior load

resistance is less

than 500Ω)

Digital input bound -

12 bits binary data(0~4095)

Digital output bound

14 bits binary data(0~16383)

-

Distinguish ratio 1/16383(14Bit); the converted data is

stored into PLC in the format of HEX

format (14Bit)

1/4095(12Bit); the converted data is

stored into PLC with the format of HEX.

(12Bit)

PID control value 0~4095 Integrate precision 0.8%

Convert speed 15ms per channel 2ms per channel

Power used by analog DC24V±10%,100mA

Install format Fixed with M3 screws or directly installed on orbit of DIN46277 (Width: 35mm)

Exterior size 63mm×102mm×73.3mm

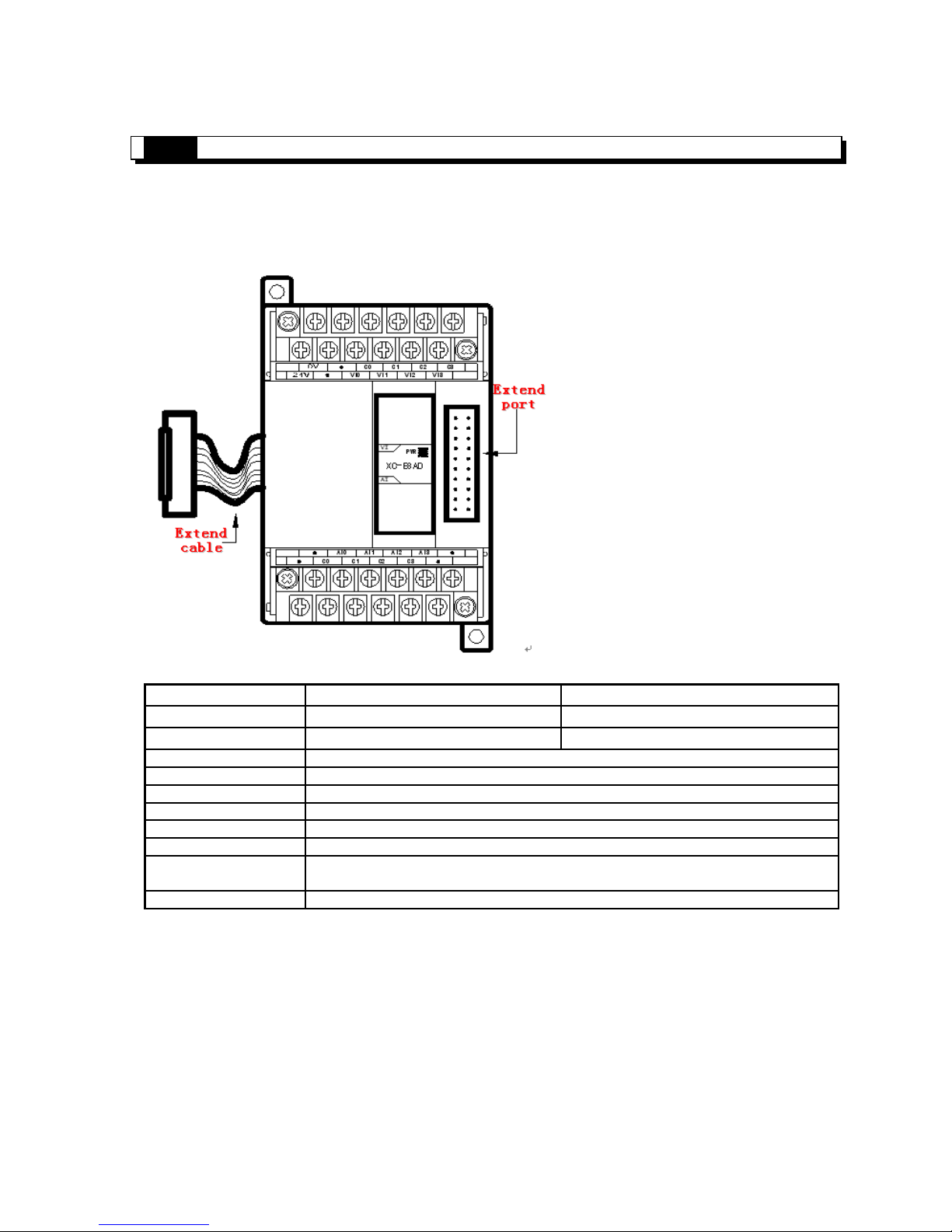

[Extend cable]: Realize data transfer via the connection of extend cable and PLC extend port

[Extend port]:Connect with other expansions

Page 16

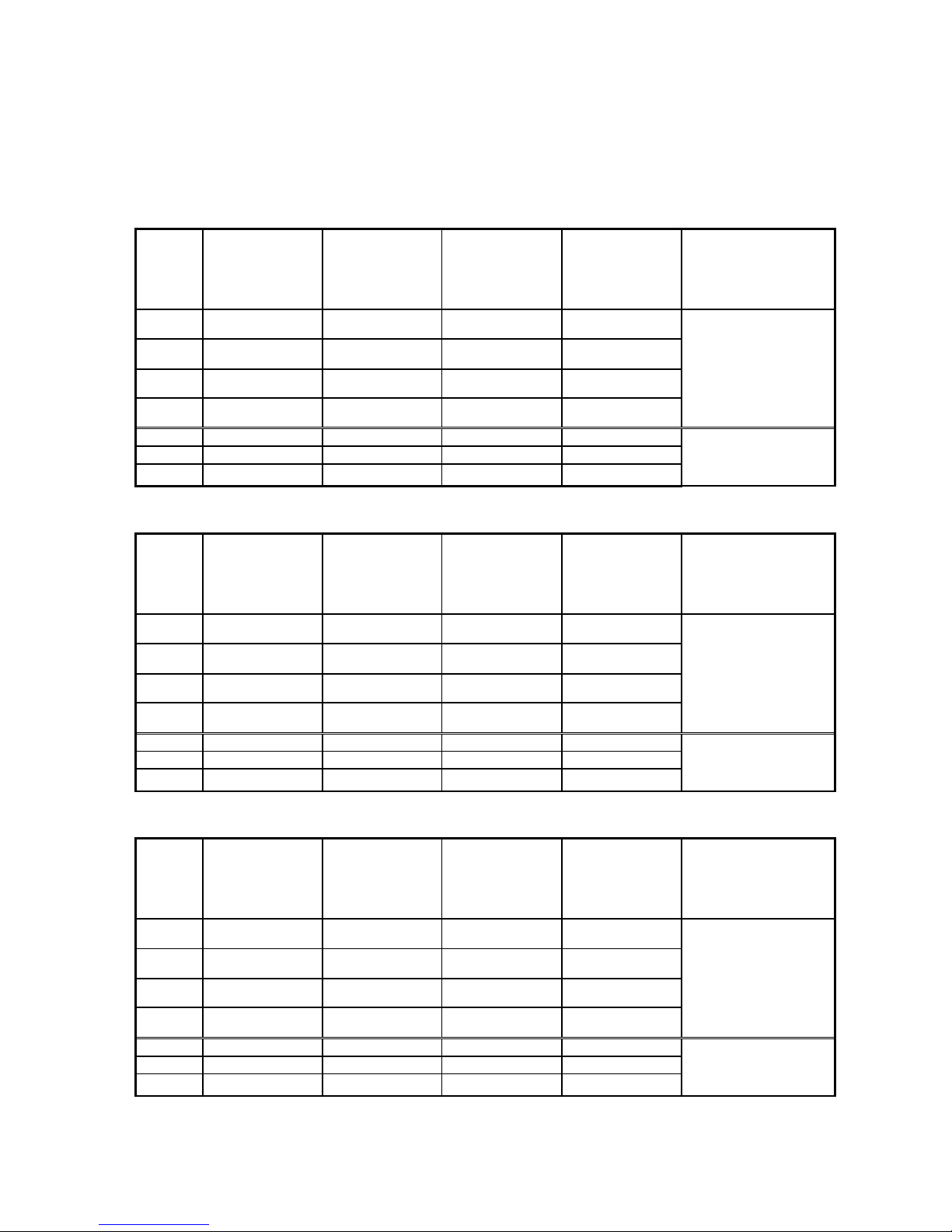

2.The assignment of input/output ID

XC series analog modules do not engross I/O units, the converted data is directly transferred into PLC

register, analog output is also directly offered by PLC register.

Register’s ID of expansion 1:

Channel AD signal PID output

value

PID start/stop

control bit

The set value

PID parameter : Kp,

Ki, Kd, control bound

Diff, dead bound

Death

0CH ID100 ID104 Y100 QD102

Kp:QD106

Ki:QD107

Kd:QD108

Diff:QD109

Death:QD110

1CH ID101 ID105 Y101 QD103

2CH ID102 ID106 Y102 QD104

3CH ID103 ID107 Y103 QD105

Channel DA signal - - - -

4CH QD100 - - 5CH QD101 - - -

Register’s ID of expansion 2:

Channel AD PID output

value

PID start/stop

control bit

The set value

PID parameter : Kp,

Ki, Kd, control bound

Diff, dead bound

Death

0CH ID200 ID204 Y200 QD202

Kp:QD206

Ki:QD207

Kd:QD208

Diff:QD209

Death:QD210

1CH ID201 ID205 Y201 QD203

2CH ID202 ID206 Y202 QD204

3CH ID203 ID207 Y203 QD205

Channel DA signal - - - -

4CH QD200 - - 5CH QD201 - - -

Register’s ID of expansion 3:

Channel AD signal PID output

value

PID start/stop

control bit

The set value

PID parameter : Kp,

Ki, Kd, control bound

Diff, dead bound

Death

0CH ID300 ID304 Y300 QD302

Kp:QD306

Ki:QD307

Kd:QD308

Diff:QD309

Death:QD310

1CH ID301 ID305 Y301 QD303

2CH ID302 ID306 Y302 QD304

3CH ID303 ID307 Y303 QD305

Channel DA signal - - - -

4CH QD300 - - 5CH QD301 - - -

Page 17

Register’s ID of expansion 4:

Channel AD signal PID output

value

PID start/stop

control bit

The set value

PID parameter : Kp,

Ki, Kd, control bound

Diff, dead bound

Death

0CH ID400 ID404 Y400 QD402

Kp:QD406

Ki:QD407

Kd:QD408

Diff:QD409

Death:QD410

1CH ID401 ID405 Y401 QD403

2CH ID402 ID406 Y402 QD404

3CH ID403 ID407 Y403 QD405

Channel DA signal - - - -

4CH QD400 - - 5CH QD401 - - -

Register’s ID of expansion 5:

Channel AD signal PID output

value

PID start/stop

control bit

The set value

PID parameter :

Kp、Ki 、Kd 、contr

ol bound Diff 、 dead

bound Death

0CH ID500 ID504 Y500 QD502

Kp:QD506

Ki:QD507

Kd:QD508

Diff:QD509

Death:QD510

1CH ID501 ID505 Y501 QD503

2CH ID502 ID506 Y502 QD504

3CH ID503 ID507 Y503 QD505

Channel DA signal - - - -

4CH QD500 - - 5CH QD501 - - -

Register’s ID of expansion 6:

Channel AD signal PID output

value

PID start/stop

control bit

The set value

PID parameter :

Kp、Ki 、Kd 、contr

ol bound Diff 、 dead

bound Death

0CH ID600 ID604 Y600 QD602

Kp:QD606

Ki:QD607

Kd:QD608

Diff:QD609

Death:QD610

1CH ID601 ID605 Y601 QD603

2CH ID602 ID606 Y602 QD604

3CH ID603 ID607 Y603 QD605

Channel DA signal - - - -

4CH QD600 - - 5CH QD601 - - -

Register’s ID of expansion 7:

Page 18

Channel AD signal PID output

value

PID start/stop

control bit

The set value

PID parameter :

Kp、Ki 、Kd 、contr

ol bound Diff 、 dead

bound Death

0CH ID700 ID704 Y700 QD702

Kp:QD706

Ki:QD707

Kd:QD708

Diff:QD709

Death:QD710

1CH ID701 ID705 Y701 QD703

2CH ID702 ID706 Y702 QD704

3CH ID703 ID707 Y703 QD705

Channel DA signal - - - -

4CH QD700 - - 5CH QD701 - - -

Description:

Start signal(Y):When Y is 0, close PID control; when being 1, start PID control

Parameter P:proportion parameter, mainly reflect system’s difference, control as soon as difference

occurs to decrease this difference.

Parameter I:Integral parameter, mainly used to remove the whisht and improve the system’s no

difference degree

Parameter D:differential parameter, mainly control signal’s changing trend and decrease the system’s

shake.

Temp. control bound Diff : in the assigned bound, carry on PID control, beyond that bound, no PID

control

Each parameter’s reference value:Kp=20~100;Ki=5~20;Kd=200~700;DIFF=100~200

3.

Setting of working mode

1)

Expansion’s input/output all have options of voltage 0~5V、0~10V, current 0~20mA、4~20mA modes.

Via setting of special FLASH data register FD in PLC. See the following table:

Page 19

Module Channel’s ID

0CH~3CH 4CH~5CH

1#

expansion

FD8250 FD8251 low byte

2#

expansion

FD8258 FD8259 low byte

3#

expansion

FD8266 FD8267 low byte

4#

expansion

FD8274 FD8275 low byte

5#

expansion

FD8282 FD8283 low byte

6#

expansion

FD8290 FD8291 low byte

7#

expansion

FD8298 FD8299 low byte

Note:As shown in the preceding table, every register set 4 channels mode, each register has 16 bits, from low

to high, every 4 bits set separately 4 channels mode.

Each channel’s working mode is assigned by correspond register’s 4 bits. Each bit’s definition is showed in the

following table:

The following, we take module 1 as example to show how to set:

Register FD8250:

Register FD8251 low byte:

Channel 1 Channel 0

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

0: voltage

input

0:0~10V

1:0~5V

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

0: voltage

input

0:0~10V

1:0~5V

1: current

input

0:0~20mA

1:4~20mA

1: current

input

0:0~20mA

1:4~20mA

Channel 3 Channel 2

Bit15 Bit14 Bit13 Bit12 Bit11 Bit10 Bit9 Bit8

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

0: voltage

input

0:0~10V

1:0~5V

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

0: voltage

input

0:0~10V

1:0~5V

1: current

input

0:0~20mA

1:4~20mA

1: current

input

0:0~20mA

1:4~20mA

Channel 5 Channel 4

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

0: voltage

input

0:0~10V

1:0~5V

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

0: voltage

input

0:0~10V

1:0~5V

1: current

input

0:0~20mA

1:4~20mA

1: current

input

0:0~20mA

1:4~20mA

Take 1# expansion as example :

FD8250 H O O O O

0CH

1CH

2CH

3CH

FD8251 H O O O O

4CH

5CH

Page 20

E,g. : 1 ) If set working mode 0~20mA 、 4~20mA 、 0~10V 、 0~5V of module 1’s channel 3 、 channel

2、channel 1、channel 0, filters are all 1/2 filter, value in FD8250 is 2301H

4.Exterior connection

When carry on exterior connection, please note the following two items:

When connect+24V power outside, please choose 24V power on PLC main unit to avoid interfere.

To avoid interfere, please use shield cable and single point grounding with the shield layer.

Module’s 0~20mA or 4~20mA output need 24V power from outside, according to the analog output

register QD’s value, the module adjusts the loop circuit’s current, but the module itself doesn’t produce

current.

5.Analog digital convert chart

The relationship between input analog and converted digital is showed in the following chart:

0~5V analog input 0~10V analog input

Page 21

0~20mA analog input 4~20mA analog input

The relationship between output digital and its correspond analog data is showed in the following chart:

0~5V analog output 0~10V analog output

0~20mA analog output 4~20mA analog output

When input data exceed K4095, D/A converted output analog data keep 5V、10V or 20mA.

6.Programming

E.g.1)Real time read 4 channels data, write 2 channels data (take expansion 1 as example)

Page 22

MOV ID100 D0

END

M8000

MOV ID101 D1

MOV ID102 D2

MOV ID103 D3

MOV D10 QD100

MOV D11 QD101

E.g.2)Applied method of PID (take expansion 1’s channel 0 as example)

MOV ID100 D10

MOV ID104 D1000

M8000

MOV K30 QD106

MOV K10 QD107

MOV K300 QD118

MOV K100 QD119

MOV K200 QD110

MOV QD100D4000

END

Y100

M8000

Ⅴ、Analog output module XC-E4DA

Write channel 0’s data into data register D0

Write channel 1’s data into data register D1

Write channel 2’s data into data register D2

Write channel 3’s data into data register D3

Write data into data register D10 and give channel 4

Write data into data register D10 and give channel 5

Write channel 0’s data into data register D10

Channel 0’s set value is register D4000

Set proportion coefficient Kp as 30

Set proportion coefficient Ki as 10

Set proportion coefficient Kd as 300

Set adjustment bound Diff as 100

Set control dead area as 200

Write channel 0’s PID output value into register D1000

PID start signal

Page 23

1、Specification

Characteristic:

12 bits high precision analog output

4 channels selectable voltage

0~5V 、 0~10V , current 0~20mA 、

4~20mA output

As special function module of XC, 7

modules could be connected

Items Voltage output Current output

Analog output bound

DC0~5V、0~10V DC0~20mA、4~20mA

Digital output bound 12 bits binary data

Distinguish Ratio 1/4096(12Bit); the converted data is stored into PLC with the format of HEX

Integrate precision 0.8%

Convert speed 2ms per channel

Insulate format DC/DC convert, optical coupling insulation

Power for analog using DC24V±10%,100mA

Install format Can be fixed with M3 screws or directly installed on orbit of DIN46277 (width:

35mm)

Exterior size 63mm×102mm×73.3mm

[Extend cable]:Realize data transfer via connecting of extend cable and PLC extend port

[Extend port]:Connect with other expansions

2.

Assignment of Output ID

Page 24

XC series analog module does not engross I/O units, the converted data is directly transferred into PLC

register. The output channel’s correspond PLC register ID is:

Output ID list

Channel No.1 unit No.2 unit No.3 unit No.4 unit No.5 unit No.6 unit No.7 unit

0CH QD100 QD200 QD300 QD400 QD500 QD600 QD700

1CH QD101 QD201 QD301 QD401 QD501 QD601 QD701

2CH QD102 QD202 QD302 QD402 QD502 QD602 QD702

3CH QD103 QD203 QD303 QD403 QD503 QD603 QD703

3.

Setting of working mode

1 )

Each expansions’ input/output have the choice of voltage

0~5V 、 0~10V , current

0~20mA、4~20mA modes. Via the setting of special FLASH data register FD inside PLC, see the following

table:

Module Channel’s ID

0CH~3CH

1# module D8250

2# module D8258

3# module D8266

4# module D8274

5# module D8282

6# module D8290

7# module D8298

Each channel’s working mode is assigned by the correspond register’s 4 bits. Each bit’s definition is listed in

the following table:

Take module 1 as the example:

Register FD8250:

4.Exterior connection

Channel 1 Channel 0

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

-

0:Voltage

input

0:0~10V

1:0~5V

-

0: Voltage

input

0:0~10V

1:0~5V

1:current

input

0:0~20mA

1:4~20mA

1:Current

input

0:0~20mA

1:4~20mA

Channel 3 Channel 2

Bit15 Bit14 Bit13 Bit12 Bit11 Bit10 Bit9 Bit8

-

0: Voltage

input

0:0~10V

1:0~5V

-

0: Voltage

input

0:0~10V

1:0~5V

1: current

input

0:0~20mA

1:4~20mA

1: current

input

0:0~20mA

1:4~20mA

Take expansion1 as the example:

FD8250 H O O O O

0CH

1CH

2CH

3CH

Page 25

When carry on exterior connection, please note the following two items:

When connect+24V power outside, please choose 24V power on PLC main unit to avoid interfere.

To avoid interfere, please use shield cable and single point grounding with the shield layer.

Module’s 0~20mA or 4~20mA output need 24V power from outside, according to the analog output

register QD’s value, the module adjusts the loop circuit’s current, but the module itself doesn’t produce

current.

Page 26

5.Analog digital convert chart

The relationship between PLC’s output digital and its correspond analog data is showed in the following

chart:

0~5V analog output 0~10V analog output

0~20mA analog output 4~20mA analog output

When the output data exceed K4095, D/A converted output analog data keep 5V、 10V or 20mA

6.

Programming

Real time write data into 4 channels

MOV D10 QD100

END

M8000

MOV D11 QD101

MOV D12 QD102

MOV D13 QD103

Write data into data register D10 and give channel 0

Write data into data register D11 and give channel 1

Write data into data register D13 and give channel 3

Write data into data register D12 and give channel 2

Page 27

Ⅵ、Pt100 temperature PID control module XC-E6PT-P

1.Specification

Characteristic:

Platinum thermo-resistance input, Pt100

6 channels input, 6 channels output

2 groups PID parameters (every 3

channels has a group of PID parameter)

1mA lasting current output, not affected

by the exterior environment

Distinguish ratio is 0.1℃

As special function module of XC, 7

modules could be connected

Item Content

Analog input signal Pt100 platinum thermo-resistance

Temperature testing

bound

-100 ~350℃ ℃

Digital output bound

-1000~3500,16 bits with sign bit, binary

Control precision ±0.5℃

Distinguish ratio

0.1℃

Integrate precision

±0.8%(relative to the max value)

Convert speed

100ms×6 channels

Analog using power

DC24V±10%,50mA

Install format Fixed with M3 screws or directly installed on orbit of DIN46277 (Width: 35mm)

Exterior size 63mm×102mm×73.3mm

[Extend cable]:Realize data transfer via the connection of extend cable and PLC extend port.

[Extend port]: Connect with other expansions

Note:1、Without signal input, the channel’s data is 3500

2、According to the actual requirement, connect with Pt100 platinum thermo-resistance

Page 28

2.Assignment of input definition ID

XC series analog modules don’t engross I/O units, the converted data is directly transferred into PLC

register, channel’s correspond PLC register’s ID is:

Table of input definition ID:

Channel 1#module 2#module 3#module 4#module 5#module 6#module 7#module

0CH ID100 ID200 ID300 ID400 ID500 ID600 ID700

1CH ID101 ID201 ID301 ID401 ID501 ID601 ID701

2CH ID102 ID202 ID302 ID402 ID502 ID602 ID702

3CH ID103 ID203 ID303 ID403 ID503 ID603 ID703

4CH ID104 ID204 ID304 ID404 ID504 ID604 ID704

5CH ID105 ID205 ID305 ID405 ID505 ID605 ID705

Table of output definition ID:

Channel

1#module 2#module3#module4#module5#module6#module7#modul

e

0CH set

temperature

QD100 QD200 QD300 QD400 QD500 QD600 QD700

1CH set

temperature

QD101 QD201 QD301 QD401 QD501 QD601 QD701

2CH set

temperature

QD102 QD202 QD302 QD402 QD502 QD602 QD702

3CH set

temperature

QD103 QD203 QD303 QD403 QD503 QD603 QD703

4CH set

temperature

QD104 QD204 QD304 QD404 QD504 QD604 QD704

5CH set

temperature

QD105 QD205 QD305 QD405 QD505 QD605 QD705

First 3

channels P

parameter

QD106 QD206 QD306 QD406 QD506 QD606 QD706

First 3

channels I

parameter

QD107 QD207 QD307 QD407 QD507 QD607 QD707

First 3

channels D

parameter

QD108 QD208 QD308 QD408 QD508 QD608 QD708

First 3

channels

temperature

control

bound

QD109 QD209 QD309 QD409 QD509 QD609 QD709

Last 3

channels P

parameter

QD110 QD210 QD310 QD410 QD510 QD610 QD710

Last 3

channels I

parameter

QD111 QD211 QD311 QD411 QD511 QD611 QD711

Last 3

channels D

parameter

QD112 QD212 QD312 QD412 QD512 QD612 QD712

Last 3

QD113 QD213 QD313 QD413 QD513 QD613 QD713

Page 29

channels

temperature

control

bound

Description:

Start signal(Y):When Y is 0, close PID control; when being 1, start PID control

Parameter P:proportion parameter, mainly reflect system’s difference, control as soon as difference

occurs to decrease this difference.

Parameter I:Integral parameter, mainly used to remove the whisht and improve the system’s no

difference degree

Parameter D:differential parameter, mainly control signal’s changing trend and decrease the system’s

shake.

Temp. control bound Diff : in the assigned bound, carry on PID control, beyond that bound, no PID

control

Each parameter’s reference value:Kp=20~100;Ki=5~20;Kd=200~700;DIFF=100~200

3.Setting of input filter

1)

Every input of expansion has option of filter, set via

special FLASH data register FD in PLC.

Seethe following chart:

Module channel’s ID

0CH~3CH 4CH~5CH

1#module FD8250 FD8251low byte

2# module FD8258 FD8259 low byte

3# module FD8266 FD8267 low byte

4# module FD8274 FD8275 low byte

5# module FD8282 FD8283 low byte

6# module FD8290 FD8291 low byte

7# module FD8298 FD8299 low byte

Each channel’s filter mode is assigned via correspond register’s 4 bits! Each bit’s definition is showed in the

following table:

Take module 1 as the example:

Register FD8250:

Take 1# module as example:

FD8250 H O O O O

0CH

1CH

2CH

3CH

FD8251 H O O O O

4CH

5CH

Page 30

Register FD8251:

When leave the factory, the defaulted value is 0, the initial filter format is 1/2 filter.

4.Exterior connection

About outside layout, you should note the following two items:

When carry on+24V power, please use 24V power on PLC main unit to avoid interfere.

To avoid interfere, please take shield measure with the signal cable.

Input connection:

Channel 2 Channel 1

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

00:1/2 filter

01:not filter

10:1/3 filter

11:1/4 filter

-

-

00:1/2 filter

01:not filter

10:1/3 filter

11:1/4 filter

-

-

-

-

-

-

Channel 4 Channel 3

Bit15 Bit14 Bit13 Bit12 Bit11 Bit10 Bit9 Bit8

00:1/2 filter

01:not filter

10:1/3 filter

11:1/4 filter

-

-

00:1/2 filter

01:not filter

10:1/3 filter

11:1/4 filter

-

-

-

-

-

-

Channel 5 Channel 4

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

00:1/4 filter

01:不 filter

10:1/2 filter

11:1/3 filter

-

-

00:1/4 filter

01:不 filter

10:1/2 filter

11:1/3 filter

-

-

-

-

-

-

Page 31

A0

C0 C1

A1C2A2 A3C3A4C4A5

C5

Y0

COM0Y2Y5COM2

Y1 Y4

Y3COM1

Y

AI

PWR

54

3210

Output terminals

Transistor output terminals, please choose DC5V~30V flat power.

Circuit insulation

Between PLC’s interior circuit and output transistor, use optical insulation. Each public module is also

separate.

Response time

The time from PLC drive (or cut) optical coupling device to transistor ON/OFF, no more than 0.2ms.

Output current

Each point has electricity 0.8A, but to avoid temperature rising, please use as every 4 points 1.2A or

every 8 points 2.0A

Open circuit leak current

Below 0.1mA

The output circuit is the following:

Take channel 0 and channel 1 as the example:

Page 32

6.Programming

Program with the first channel

K800MOV QD100

K500MOV QD108

K5MOV QD107

K30MOV QD106

M8000

FEND

K150MOV QD109

Y100

M0

Set channel 0’s set value as 800 (80 degrees)

Set channel 0’s proportion coefficient Kp as 30

Start/stop channel 0

Set channel 0’s proportion coefficient Ki as 5

Set channel 0’s proportion coefficient Kd as 500

Set channel 0’s proportion band Diff as 150

(enter PID operation at 650)

Page 33

Ⅶ、K type thermocouple temperature PID control module XC-E6TC-P

1.Specification

Characteristic:

Thermocouple K type analog input used

by temperature sensor

6 channels input, 6 channels output

2 groups PID parameters (one group

PID parameters every 3 channels)

Hide cold-terminal compensate circuit

inside

Distinguish precision is 0.1℃

As special function module of XC , 7

modules could be connected at most

Items Content

Analog input signal K type thermocouple

Temperature testing bound 0 ~1000℃ ℃

Digital output bound

0~10000,16 bits with sign bit, binary

Control precision ±0.5℃

Distinguish ratio

0.1℃

Integrate precision ±0.8% (compare with the max value)

Convert speed

100ms×6 channels

Power for analog using

DC24V±10%,50mA

Install format Fixed with M3 screws or directly installed on orbit of DIN46277 (Width:

35mm)

Exterior size 63mm×102mm×73.3mm

[Extend cable]:Realize data transfer via the connection of extend cable and PLC extend port

[Extend port]: Connect with other expansion

Note:1、If no signal input, the channel’s data is 0

2、According to the actual requirement, connect with K type thermocouple

Page 34

2.Assignment of input ID

XC series analog modules don’t engross I/O units, the converted data is directly transferred into PLC

register, channel’s correspond PLC register’s ID is:

Input ID list

Channel 1#

Expansion

2#

Expansion

3#

Expansion

4#

Expansion

5#

Expansion

6#

Expansion

7#

Expansion

0CH ID100 ID200 ID300 ID400 ID500 ID600 ID700

1CH ID101 ID201 ID301 ID401 ID501 ID601 ID701

2CH ID102 ID202 ID302 ID402 ID502 ID602 ID702

3CH ID103 ID203 ID303 ID403 ID503 ID603 ID703

4CH ID104 ID204 ID304 ID404 ID504 ID604 ID704

5CH ID105 ID205 ID305 ID405 ID505 ID605 ID705

Output ID list

Channel’s

ID and

parameter

1#

Expansion

2#

Expansion

3#

Expansion

4#

Expansion

5#

Expansion

6#

Expansion

7#

Expansion

0CH set

temperature

QD100 QD200 QD300 QD400 QD500 QD600 QD700

1CH set

temperature

QD101 QD201 QD301 QD401 QD501 QD601 QD701

2CH set

temperature

QD102 QD202 QD302 QD402 QD502 QD602 QD702

3CH set

temperature

QD103 QD203 QD303 QD403 QD503 QD603 QD703

4CH set

temperature

QD104 QD204 QD304 QD404 QD504 QD604 QD704

5CH set

temperature

QD105 QD205 QD305 QD405 QD505 QD605 QD705

First 3

channels P

para.

QD106 QD206 QD306 QD406 QD506 QD606 QD706

First 3

channels I

para.

QD107 QD207 QD307 QD407 QD507 QD607 QD707

First 3

channels D

para.

QD108 QD208 QD308 QD408 QD508 QD608 QD708

First 3 channels

temp. control

bound

QD109 QD209 QD309 QD409 QD509 QD609 QD709

Last 3

channels P

para.

QD110 QD210 QD310 QD410 QD510 QD610 QD710

Last 3

channels I

para.

QD111 QD211 QD311 QD411 QD511 QD611 QD711

Last 3

channels D

para.

QD112 QD212 QD312 QD412 QD512 QD612 QD712

Page 35

Last 3 channels

temp. control

bound

QD113 QD213 QD313 QD413 QD513 QD613 QD713

Description:

Start signal(Y):When Y is 0, close PID control; when being 1, start PID control

Parameter P:proportion parameter, mainly reflect system’s difference, control as soon as difference

occurs to decrease this difference.

Parameter I:Integral parameter, mainly used to remove the whisht and improve the system’s no

difference degree

Parameter D:differential parameter, mainly control signal’s changing trend and decrease the system’s

shake.

Temp. control bound Diff : in the assigned bound, carry on PID control, beyond that bound, no PID

control

Each parameter’s reference value:Kp=20~100;Ki=5~20;Kd=200~700;DIFF=100~200

3.Input filter setting

Every input of expansions has filter option, set via special FLASH data register FD inside PLC. See the

following chart:

Module Channel’s ID

0CH~3CH 4CH~5CH

1# module FD8250 FD8251 Low byte

2# module FD8258 FD8259 Low byte

3# module FD8266 FD8267 Low byte

4# module FD8274 FD8275 Low byte

5# module FD8282 FD8283 Low byte

6# module FD8290 FD8291 Low byte

7# module FD8298 FD8299 Low byte

Each channel’s filter mode is assigned by correspond register’s 4 bits. Each bit’s definition is showed in the

following table:

Take module 1 as example

Register FD8250:

Take 1# module as example :

FD8250 H O O O O

0CH

1CH

2CH

3CH

FD8251 H O O O O

4CH

5CH

Page 36

Register FD8251:

When leave the factory, their defaulted value is 0, i.e. the initial filter format is 1/4 filter

4.Exterior connection

About the exterior connection, you should pay attention to the following two items:

When connect with+24V power outside, please use the 24V power on PLC main unit to avoid interfere

To avoid interfere, shield measure is necessary for the signal cables

Input method:

Channel 1 Channel 0

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

00:1/4 filter

01:not filter

10:1/2 filter

11:1/3 filter

-

-

00:1/4 filter

01:not filter

10:1/2 filter

11:1/3 filter

-

-

-

-

-

-

Channel 3 Channel 2

Bit15 Bit14 Bit13 Bit12 Bit11 Bit10 Bit9 Bit8

00:1/4 filter

01:not filter

10:1/2 filter

11:1/3 filter

-

-

00:1/4 filter

01:not filter

10:1/2 filter

11:1/3 filter

-

-

-

-

-

-

Channel 5 Channel 4

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

00:1/4 filter

01:not filter

10:1/2 filter

11:1/3 filter

-

-

00:1/4 filter

01:not filter

10:1/2 filter

11:1/3 filter

-

-

-

-

-

-

Page 37

0 1 2 3

4 5

PWR

AI

Y

TC5-

TC5+

TC0-

TC0+ TC2+

TC1-

TC2- TC3- TC4-

TC4+TC3+TC1+

COM1 Y3

Y4Y1

COM2 Y5Y2COM0

Y0

Output terminal

For transistor output terminals, flat please use power of DC5V~30V.

Circuit insulation

Between PLC interior circuit and output transistor, carry on optical insulation with optical coupling

device. Each public modules are separate.

Response time

The time form PLC drive (or cut) optical coupling circuit to transistor’s ON/OFF, no more than 0.2ms

Output circuit

Each point’s current 0.8A. But to restrict the increase of temperature,, please use in the condition of

every 4 points 1.2A or every 8 points 2.0A

Open circuit leak current

Below 0.1mA.

The output circuit is the following:

Take channel 0 and channel 1 as the example:

Page 38

6.Program

Program with the first channel

K800MOV QD100

K500MOV QD108

K5MOV QD107

K30MOV QD106

M8000

FEND

K150MOV QD109

Y100

M0

Set channel 0’s value as 800 (80 degrees)

Set channel 0’s proportion coefficient Kp as 30

Start / stop channel 0

Set channel 0’s proportion coefficient Ki as 5

Set channel 0’s proportion coefficient Kd as 500

Set channel 0’s proportion band Diff as 150

(At 650, carry on PID operation)

Page 39

VIII、XC-E3AD4PT2DA

1.Specifications

Specilities:

3 channels 14 bits current input、4

channels PT100 temperature input and 2

channels 12 bits voltage output

3 channels current 0~20mA、4~20mA

input (selectable) and 2 channels voltage

0~5V、0~10V output (selectable), set via

the software

Pt resistor input (PT100)

3 channels A/D and 4 channels PT input,

with PID adjustment function

ITEMS

Analog Current Input

(AD)

Temperature Input (PT) Analog Voltage Output

(DA)

Analog Input

DC0~20mA、4~20mA

PT100

-

Temperature

Testing Bound

- -100~350℃

-

Maximum Output

Bound

DC0~40mA - -

Analog Output

Bound

- -

DC0~5V、0~10V

External load resistor

(2KΩ~1MΩ)

Digital Input

Bound

- - 12 bits binary (0~4095)

Digital Output

Bound

14 bits binary (0~16383) -1000~3500 -

Distinguish 1/16383(14Bit); the

converted data is stored

into PLC(14Bit) in the

form of Hex.

0.1℃ 1/4095(12Bit); the

converted data is stored

into PLC(12Bit) in the

form of Hex.

PID Output Value 0~K4095 General

Precision

0.8% ±0.5℃ 0.8%

Convert Speed 20ms per channel 3ms per channel

Power Supply for

Analog Using

DC24V±10%,100mA

Installation Fix with M3 screws or install on DIN46277 (Width: 35mm) leader directly

Dimension 63mm×102mm×73.3mm

[Extend Cable]: Via the connection of the extend cable and PLC’s extend port, realize data transfer

[Extend Port]: Connect with other expansions

Page 40

2.Input/Output Definition

XC series analog modules do not engross I/O units, the converted value is sent to PLC register

directly. Analog output is also offered by PLC register.

The first expansion’s register definition:

Channel AD Signal PID Output

Value

PID start/stop

bit

The Set Value

PID : Kp, Ki, Kd,

Diff, Death

0CH ID100 ID107 Y100 QD102 Kp-------

Ki-------

Kd-------

Diff------

Death----

QD109

QD110

QD111

QD112

QD113

1CH ID101 ID108 Y101 QD103

2CH ID102 ID109 Y102 QD104

Channel PT Signal PID Output

Value

PID start/stop

bit

The Set Value

3CH ID103 ID110 Y103 QD105

4CH ID104 ID111 Y104 QD106

5CH ID105 ID112 Y105 QD107

6CH ID106 ID113 Y106 QD108

Channel DA Signal - - - -

0CH QD100 - - 1CH QD101 - - -

The second expansion’s register definition:

Channel AD Signal PID Output

Value

PID start/stop

bit

The Set Value

PID : Kp, Ki, Kd,

Diff, Death

0CH ID200 ID207 Y200 QD202 Kp-------

Ki-------

Kd-------

Diff------

Death----

QD209

QD210

QD211

QD212

QD213

1CH ID201 ID208 Y201 QD203

2CH ID202 ID209 Y202 QD204

Channel PT Signal PID Output

Value

PID start/stop

bit

The Set Value

3CH ID203 ID210 Y203 QD205

4CH ID204 ID211 Y204 QD206

5CH ID205 ID212 Y205 QD207

6CH ID206 ID213 Y206 QD208

Channel DA Signal - - - -

0CH QD200 - - 1CH QD201 - - -

The third expansion’s register definition:

Page 41

Channel AD Signal PID Output

Value

PID start/stop

bit

The Set Value

PID : Kp, Ki, Kd,

Diff,Death

0CH ID300 ID307 Y300 QD302 Kp-------

Ki-------

Kd-------

Diff------

Death----

QD309

QD310

QD311

QD312

QD313

1CH ID301 ID308 Y301 QD303

2CH ID302 ID309 Y302 QD304

Channel PT Signal PID Output

Value

PID start/stop

bit

The Set Value

3CH ID303 ID310 Y303 QD305

4CH ID304 ID311 Y304 QD306

5CH ID305 ID312 Y305 QD307

6CH ID306 ID313 Y306 QD308

Channel DA Signal - - - -

0CH QD300 - - 1CH QD301 - - -

The fourth expansion’s register definition:

Channel AD Signal PID Output

Value

PID start/stop

bit

The Set Value

PID : Kp, Ki, Kd,

Diff, Death

0CH ID400 ID407 Y400 QD402 Kp-------

Ki-------

Kd-------

Diff------

Death----

QD409

QD410

QD411

QD412

QD413

1CH ID401 ID408 Y401 QD403

2CH ID402 ID409 Y402 QD404

Channel PT Signal PID Output

Value

PID start/stop

bit

The Set Value

3CH ID403 ID410 Y403 QD405

4CH ID404 ID411 Y404 QD406

5CH ID405 ID412 Y405 QD407

6CH ID406 ID413 Y406 QD408

Channel DA Signal - - - -

0CH QD400 - - 1CH QD401 - - -

The fifth expansion’s register definition:

Channel AD Signal PID Output

Value

PID start/stop

bit

The Set Value

PID : Kp, Ki, Kd,

Diff,Death

0CH ID500 ID507 Y500 QD502 Kp-------

Ki-------

Kd-------

Diff------

Death----

QD509

QD510

QD511

QD512

QD513

1CH ID501 ID508 Y501 QD503

2CH ID502 ID509 Y502 QD504

Channel PT Signal PID Output

Value

PID start/stop

bit

The Set Value

3CH ID503 ID510 Y503 QD505

4CH ID504 ID511 Y504 QD506

Page 42

5CH ID505 ID512 Y505 QD507

6CH ID506 ID513 Y506 QD508

Channel DA Signal - - - -

0CH QD500 - - 1CH QD501 - - -

The sixth expansion’s register definition:

Channel AD Signal PID Output

Value

PID start/stop

bit

The Set Value

PID : Kp, Ki, Kd,

Diff,Death

0CH ID600 ID607 Y600 QD602 Kp-------

Ki-------

Kd-------

Diff------

Death----

QD609

QD610

QD611

QD612

QD613

1CH ID601 ID608 Y601 QD603

2CH ID602 ID609 Y602 QD604

Channel PT Signal PID Output

Value

PID start/stop

bit

The Set Value

3CH ID603 ID610 Y603 QD605

4CH ID604 ID611 Y604 QD606

5CH ID605 ID612 Y605 QD607

6CH ID606 ID613 Y606 QD608

Channel DA Signal - - - -

0CH QD600 - - 1CH QD601 - - -

The seventh expansion’s register definition:

Channel AD Signal PID Output

Value

PID start/stop

bit

The Set Value

PID : Kp, Ki, Kd,

Diff, Death

0CH ID700 ID707 Y700 QD702 Kp-------

Ki-------

Kd-------

Diff------

Death----

QD709

QD710

QD711

QD712

QD713

1CH ID701 ID708 Y701 QD703

2CH ID702 ID709 Y702 QD704

Channel PT Signal PID Output

Value

PID start/stop

bit

The Set Value

3CH ID703 ID710 Y703 QD705

4CH ID704 ID711 Y704 QD706

5CH ID705 ID712 Y705 QD707

6CH ID706 ID713 Y706 QD708

Channel DA Signal - - - -

0CH QD700 - - 1CH QD701 - - -

Description:

Start signal (Y): when Y is 0, close PID control, when be 1 , start PID control

Parameter P:Proportion parameter, mainly reflex system’s difference, carry on control as soon

Page 43

as difference occurs to improve the system’s no difference degree.

Parameter I:Integral parameter. Mainly used to remove whisht, improve the system’s no

difference degree.

Parameter D:Differential parameter, mainly used to control signal’s changing trend,minish

system’s shake.

Control bound Diff:In the assigned bound, carry on PID control. Beyond the bound, no PID

control.

Dead area Death:When the current PID control value compares with the preceding PID control

value. If the difference between them is less than the set dead bound’s value,

the module will abnegate the current PID control value, send the preceding

PID control value to the PLC main unit.

Each parameter’s reference value:Kp=20~100;Ki=5~20;Kd=200~700;DIFF=100~200

3.

Working Mode Setting

1)Expansion’s input/output mode can be set via special FLASH data register FD

inside PLC.

Module Register’s ID

1# Module

FD8250 、FD8251、FD8252

2# Module

FD8258、FD8259、FD8260

3# Module

FD8266、FD8267、FD8268

4# Module

FD8274、FD8275、FD8276

5# Module

FD8282、FD8283、FD8284

6# Module

FD8290、FD8291、FD8292

7# Module

FD8298、FD8299、FD8270

Each bit’s definition is showed in the following table:

The following, we take module 1 as the example to show how to set:

Take 1# module as the example:

FD8250 H O O O O

0CH ( AD )

1CH ( AD )

2CH ( AD )

3CH ( PT )

FD8251 H O O O O

4CH ( PT )

5CH ( PT )

6CH ( PT )

0CH ( DA )

FD8252 H O O O O

1CH ( DA )

Note : As showed in the preceding table,

each register set 4 channels’ mode, each

register has 16 bits. From low bit to high

bit, every 4 bits separately set 4 channels’

mode.

Page 44

Register FD8250:

Low byte of register FD8251::

Low byte of register FD8252:

4.E xternal Connection

Please note the following two items about external connection:

When connect with external +24V power supply, please use 24V power supply on PLC main unit to

avoid intefere

To avoid intefere, please use shield cable, and single-point grounding with the shield layer.

Input CH 1 (AD)

Input CH 0(AD)

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

-

0:0~20mA

1:4~20mA

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

-

0:0~20mA

1:4~20mA

Input CH 3(PT) Input CH 2(AD)

Bit15 Bit14 Bit13 Bit12 Bit11 Bit10 Bit9 Bit8

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

- 00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

-

0:0~20mA

1:4~20mA

Input CH 5(PT) Input CH 4(PT)

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

- 00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

-

Output CH 0(DA) Input CH 6(PT)

Bit15 Bit14 Bit13 Bit12 Bit11 Bit10 Bit9 Bit8

- 0 :0~10V

1 :0~5V

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

-

-

Output CH 1(PT)

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

- - - - - 0 :0~10V

1 :0~5V

Page 45

Module’s 0~20mA or 4~20mA output should be offered 24V power supply from outside. According to the

QD value, adjust the circuit’s current. The module itself doesn’t generate current.

0V

24V+

AI0+

AI0-

AI1+

AI1-

AI2+

AI2-

VO0+

VO0-

VO1+

VO1-

C0

AI0

C1 C3

VO1AI 2

C2 C4

VO0AI 1

B3

C3

A0

B0 C1

C0 B1 A2 C2

A3B2A1

PWR

A

A

PT100

PT100

PT100

PT100

5.A nalog/Digit al convert Diagram

The relationship of the input analog quantity and the converted digital quantity is shown below:

0~20mA analog input 4~20mA analog input

The relationship of the output digital quantity and its correspond analog quantity is shown below:

Page 46

0~5V analog output 0~10V analog output

When the output value is larger than K4095, D/A converted analog value will remain 5V、10V.

The output specialty of PT100 is shown below:

PT100 Input

6.Program

E.g. 1)Real time read data from 7 channels, write data to 2 channels (take module 1 as the example)

Page 47

MOV ID100 D0

END

M8000

MOV ID101 D1

MOV ID102 D2

MOV ID103 D3

MOV D10 QD100

MOV D11 QD101

MOV ID104 D4

MOV ID105 D5

MOV ID106 D6

E.g.2) Application of PID (Take CH0 of module 1 as the example)

Write AD value in CH0 to data register D0

Write AD value in CH1 to data register D1

Write AD value in CH2 to data register D2

Write temperature value in CH3 to data register D3

Output value in register D10 to CH0

Output value in register D11to CH0

Write temperature value in CH4 to data register D4

Write temperature value in CH5 to data register D5

Write temperature value in CH6 to data register D6

Page 48

MOV ID100 D10

MOV ID107 D1000

M8000

MOV K30 QD109

MOV K10 QD110

MOV K300 QD111

MOV K100 QD112

MOV K200 QD113

MOV QD102D4000

END

Y100

M8000

Write AD value from CH0 into data register D10

Write the set AD value from CH0 into register D4000

Set proportion coefficient Kp as 30

Set proportion coefficient Ki as 10

Set proportion coefficient Kd as 300

Set adjustment bound Diff as 100

Set control dead area as 200

Write CH 0’s PID value into register D1000

PID start/stop signal

Page 49

Analog Input Module XC-E4AD

1.Specification

Specification:

4CH 14 bits analog input

4CH voltage (0~5V 、 0~10V),

current (0~20mA、4~20mA) input

selectable, set via the software.

As expansion of XC series PLC,

the PLC CPU unit can connect 7

modules

4CH A/D has PID adjustment

function

ITEMS

Analog Input (AD)

Voltage Input Current Input

Analog Input Range

DC0~5V、0~10V DC0~20mA、4~20mA

Maximun Input Range

DC±18V DC0~40mA-

Analog Output Range Digital Input Range -

Digital Outout Range 14 bits binary (0~16383)

Distinguish Ratio 1/16383(14Bit); the convert data is stored in PLC in the form of Hex. (14Bit)

PID Output Value 0~K4095Synthesis Precision 0.8%

Convert Speed 20ms per channel

Power Supply DC24V±10%,100mA

Installation Fix with M3 screw or install on DIN46277 guilder (Width: 35mm) directly

Dimension 63mm×102mm×73.3mm

[Expansion Cable]: Realize data transfer via the connection of expansion cable and PLC expansion port.

[Expansion Port]: Connect with other expansion module

2.Assignment of Input/Output ID

XC series expansions do not occupy the I/O units, the converted value is delivered to PLC register directly.

Page 50

Analog output is also offered by PLC register.

Register ID of expansion 1:

Channel AD Signal PID Output

Value

PID Start/Stop

Control Bit

The Set Value PID Parameters: Kp,

Ki, Kd, Control Range

Diff, Dead Range

“Death”

0CH ID100 ID104 Y100 QD102 Kp-------

Ki-------

Kd-------

Diff------

Death----

QD106

QD107

QD108

QD109

QD110

1CH ID101 ID105 Y101 QD103

2CH ID102 ID106 Y102 QD104

3CH ID103 ID107 Y103 QD105

Register ID of expansion 2:

Channel AD Signal PID Output

Value

PID Start/Stop

Control Bit

The Set Value PID Parameters: Kp,

Ki, Kd, Control Range

Diff, Dead Range

“Death”

0CH ID200 ID204 Y200 QD202 Kp-------

Ki-------

Kd-------

Diff------

Death----

QD206

QD207

QD208

QD209

QD210

1CH ID201 ID205 Y201 QD203

2CH ID202 ID206 Y202 QD204

3CH ID203 ID207 Y203 QD205

Register ID of expansion 3:

Channel AD Signal PID Output

Value

PID Start/Stop

Control Bit

The Set Value PID Parameters: Kp,

Ki, Kd, Control Range

Diff, Dead Range

“Death”

0CH ID300 ID304 Y300 QD302 Kp-------

Ki-------

Kd-------

Diff------

Death----

QD306

QD307

QD308

QD309

QD310

1CH ID301 ID305 Y301 QD303

2CH ID302 ID306 Y302 QD304

3CH ID303 ID307 Y303 QD305

Register ID of expansion 4:

Channel AD Signal PID Output

Value

PID Start/Stop

Control Bit

The Set Value PID Parameters: Kp,

Ki, Kd, Control Range

Diff, Dead Range

“Death”

0CH ID400 ID404 Y400 QD402 Kp-------

Ki-------

Kd-------

Diff------

Death----

QD406

QD407

QD408

QD409

QD410

1CH ID401 ID405 Y401 QD403

2CH ID402 ID406 Y402 QD404

3CH ID403 ID407 Y403 QD405

Register ID of expansion 5:

Page 51

Channel AD Signal PID Output

Value

PID Start/Stop

Control Bit

The Set Value PID Parameters: Kp,

Ki, Kd, Control Range

Diff, Dead Range

“Death”

0CH ID500 ID504 Y500 QD502 Kp-------

Ki-------

Kd-------

Diff------

Death----

QD506

QD507

QD508

QD509

QD510

1CH ID501 ID505 Y501 QD503

2CH ID502 ID506 Y502 QD504

3CH ID503 ID507 Y503 QD505

Register ID of expansion 6:

Channel AD Signal PID Output

Value

PID Start/Stop

Control Bit

The Set Value PID Parameters: Kp,

Ki, Kd, Control Range

Diff, Dead Range

“Death”

0CH ID600 ID604 Y600 QD602 Kp-------

Ki-------

Kd-------

Diff------

Death----

QD606

QD607

QD608

QD609

QD610

1CH ID601 ID605 Y601 QD603

2CH ID602 ID606 Y602 QD604

3CH ID603 ID607 Y603 QD605

Register ID of expansion 7:

Channel AD Signal PID Output

Value

PID Start/Stop

Control Bit

The Set Value PID Parameters: Kp,

Ki, Kd, Control Range

Diff, Dead Range

“Death”

0CH ID700 ID704 Y700 QD702 Kp-------

Ki-------

Kd-------

Diff------

Death----

QD706

QD707

QD708

QD709

QD710

1CH ID701 ID705 Y701 QD703

2CH ID702 ID706 Y702 QD704

3CH ID703 ID707 Y703 QD705

Description:

Start signal (Y): when Y is 0, close PID control, when be 1 , start PID control

Parameter P: Proportion parameter, mainly reflex system’s difference, carry on control as soon as

difference occurs to improve the system’s no difference degree.

Parameter I:Integral parameter. Mainly used to remove whisht, improve the system’s no difference

degree.

Parameter D:Differential parameter, mainly used to control signal’s changing trend,minish system’s

shake.

Control bound Diff:In the assigned bound, carry on PID control. Beyond the bound, no PID control.

Dead area Death:When the current PID control value compares with the preceding PID control value. If

the difference between them is less than the set dead bound’s value, the module will

abnegate the current PID control value, send the preceding PID control value to the

PLC main unit.

Each parameter’s reference value: Kp=20~100; Ki=5~20; Kd=200~700; DIFF=100~200

Page 52

3.Setting of working mode

1)Expansion’s input mode can be

voltage 0~5V 、0~10V or current 0~20mA 、4~20mA , Set via

special FLASH data register FD inside PLC. See the following table:

Module Channel’s ID

0CH~3CH

1# expansion FD8250

2# expansion FD8258

3# expansion FD8266

4# expansion FD8274

5# expansion FD8282

6# expansion FD8290

7# expansion FD8298

Note:As shown in the preceding table, every register set 4 channels mode, each register has 16 bits, from low

to high, every 4 bits set separately 4 channels mode.

Each channel’s working mode is assigned by correspond register’s 4 bits. Each bit’s definition is showed in the

following table:

The following, we take module 1 as example to show how to set:

Register FD8250:

Channel 1 Channel 0

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

0: voltage

input

0:0~10V

1:0~5V

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

0: voltage

input

0:0~10V

1:0~5V

1: current

input

0:0~20mA

1:4~20mA

1: current

input

0:0~20mA

1:4~20mA

Channel 3 Channel 2

Bit15 Bit14 Bit13 Bit12 Bit11 Bit10 Bit9 Bit8

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

0: voltage

input

0:0~10V

1:0~5V

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

0: voltage

input

0:0~10V

1:0~5V

1: current

input

0:0~20mA

1:4~20mA

1: current

input

0:0~20mA

1:4~20mA

Take 1# expansion as example :

FD8250 H O O O O

0CH

1CH

2CH

3CH

Page 53

E.g. : 1) If set working mode 0~20mA 、4~20mA 、 0~10V 、0~5V of module 1’s channel 3 、channel

2、channel 1、channel 0, filters are all 1/2 filter, value in FD8250 is 2301H

4.Exterior connection

When carry on external connection, please note the following two items:

When connect+24V power outside, please choose 24V power on PLC main unit to avoid interfere.

To avoid interfere, please use shield cable and single point grounding with the shield layer.

5.Analog digital convert chart

The relationship between input analog and converted digital is showed in the following chart:

0~5V analog input 0~10V analog input

0~20mA analog input 4~20mA analog input

Page 54

6.Programming

E.g.1 Real time read the 4 channels data, write 2 channels data (take expansion 1 as example)

MOV ID100 D0

END

M8000

MOV ID101 D1

MOV ID102 D2

MOV ID103 D3

MOV D10 QD100

MOV D11 QD101

E.g.2 Applied method of PID (take expansion 1’s channel 0 as example)

0 D0

1 D1

输入第 2 通道的数据写入数据寄存器 D2

Write data from CH3 into data register D3

数据寄存器 D10 写入数据给输出第 0

通

Output data in register D11 to CH1.

Page 55

MOV ID100 D10

MOV ID104 D1000

M8000

MOV K30 QD106

MOV K10 QD107

MOV K300 QD118

MOV K100 QD119

MOV K200 QD110

MOV QD100D4000

END

Y100

M8000

Write channel 0’s data into data register D10

Channel 0’s set value is register D4000

Set proportion coefficient Kp as 30

Set proportion coefficient Ki as 10

Set proportion coefficient Kd as 300

Set adjustment bound Diff as 100

Set control dead area as 200

Write channel 0’s PID output value into register D1000

PID start signal

Page 56

VIII 、XC-E3AD4PT2DA

VIII 、XC-E3AD4PT2DA

1.Specifications

Specilities:

3 channels 14 bits current input、4

channels PT100 temperature input and 2

channels 12 bits voltage output

3 channels current 0~20mA、4~20mA

input (selectable) and 2 channels voltage

0~5V、0~10V output (selectable), set via

the software

Pt resistor input (PT100)

3 channels A/D and 4 channels PT input,

with PID adjustment function

ITEMS

Analog Current Input

(AD)

Temperature Input (PT) Analog Voltage Output

(DA)

Analog Input

DC0~20mA、4~20mA

PT100

-

Temperature

Testing Bound

- -100~350℃

-

Maximum Output

Bound

DC0~40mA - -

Analog Output

Bound

- -

DC0~5V、0~10V

External load resistor

(2KΩ~1MΩ)

Digital Input

Bound

- - 12 bits binary (0~4095)

Digital Output

Bound

14 bits binary (0~16383) -1000~3500 -

Distinguish 1/16383(14Bit); the

converted data is stored

into PLC(14Bit) in the

form of Hex.

0.1℃ 1/4095(12Bit); the

converted data is stored

into PLC(12Bit) in the

form of Hex.

PID Output Value 0~K4095 General

Precision

0.8% ±0.5℃ 0.8%

Convert Speed 20ms per channel 3ms per channel

Power Supply for

Analog Using

DC24V±10%,100mA

Installation Fix with M3 screws or install on DIN46277 (Width: 35mm) leader directly

Dimension 63mm×102mm×73.3mm

[Extend Cable]: Via the connection of the extend cable and PLC’s extend port, realize data transfer

[Extend Port]: Connect with other expansions

Page 57

2.Input/Output Definition

XC series analog modules do not engross I/O units, the converted value is sent to PLC register

directly. Analog output is also offered by PLC register.

The first expansion’s register definition:

Channel AD Signal PID Output

Value

PID start/stop

bit

The Set Value

PID : Kp, Ki, Kd,

Diff, Death

0CH ID100 ID107 Y100 QD102 Kp-------

Ki-------

Kd-------

Diff------

Death----

QD109

QD110

QD111

QD112

QD113

1CH ID101 ID108 Y101 QD103

2CH ID102 ID109 Y102 QD104

Channel PT Signal PID Output

Value

PID start/stop

bit

The Set Value

3CH ID103 ID110 Y103 QD105

4CH ID104 ID111 Y104 QD106

5CH ID105 ID112 Y105 QD107

6CH ID106 ID113 Y106 QD108

Channel DA Signal - - - -

0CH QD100 - - 1CH QD101 - - -

The second expansion’s register definition:

Channel AD Signal PID Output

Value

PID start/stop

bit

The Set Value

PID : Kp, Ki, Kd,

Diff, Death

0CH ID200 ID207 Y200 QD202 Kp-------

Ki-------

Kd-------

Diff------

Death----

QD209

QD210

QD211

QD212

QD213

1CH ID201 ID208 Y201 QD203

2CH ID202 ID209 Y202 QD204

Channel PT Signal PID Output

Value

PID start/stop

bit

The Set Value

3CH ID203 ID210 Y203 QD205

4CH ID204 ID211 Y204 QD206

5CH ID205 ID212 Y205 QD207

6CH ID206 ID213 Y206 QD208

Channel DA Signal - - - -

0CH QD200 - - 1CH QD201 - - -

The third expansion’s register definition:

Page 58

Channel AD Signal PID Output

Value

PID start/stop

bit

The Set Value

PID : Kp, Ki, Kd,

Diff, Death

0CH ID300 ID307 Y300 QD302 Kp-------

Ki-------

Kd-------

Diff------

Death----

QD309

QD310

QD311

QD312

QD313

1CH ID301 ID308 Y301 QD303

2CH ID302 ID309 Y302 QD304

Channel PT Signal PID Output

Value

PID start/stop

bit

The Set Value

3CH ID303 ID310 Y303 QD305

4CH ID304 ID311 Y304 QD306

5CH ID305 ID312 Y305 QD307

6CH ID306 ID313 Y306 QD308

Channel DA Signal - - - -

0CH QD300 - - 1CH QD301 - - -

The fourth expansion’s register definition:

Channel AD Signal PID Output

Value

PID start/stop

bit

The Set Value

PID : Kp, Ki, Kd,

Diff, Death

0CH ID400 ID407 Y400 QD402 Kp-------

Ki-------

Kd-------

Diff------

Death----

QD409

QD410

QD411

QD412

QD413

1CH ID401 ID408 Y401 QD403

2CH ID402 ID409 Y402 QD404

Channel PT Signal PID Output

Value

PID start/stop

bit

The Set Value

3CH ID403 ID410 Y403 QD405

4CH ID404 ID411 Y404 QD406

5CH ID405 ID412 Y405 QD407

6CH ID406 ID413 Y406 QD408

Channel DA Signal - - - -

0CH QD400 - - 1CH QD401 - - -

The fifth expansion’s register definition:

Channel AD Signal PID Output

Value

PID start/stop

bit

The Set Value

PID : Kp, Ki, Kd,

Diff, Death

0CH ID500 ID507 Y500 QD502 Kp-------

Ki-------

Kd-------

Diff------

Death----

QD509

QD510

QD511

QD512

QD513

1CH ID501 ID508 Y501 QD503

2CH ID502 ID509 Y502 QD504

Channel PT Signal PID Output

Value

PID start/stop

bit

The Set Value

3CH ID503 ID510 Y503 QD505

4CH ID504 ID511 Y504 QD506

Page 59

5CH ID505 ID512 Y505 QD507

6CH ID506 ID513 Y506 QD508

Channel DA Signal - - - -

0CH QD500 - - 1CH QD501 - - -

The sixth expansion’s register definition:

Channel AD Signal PID Output

Value

PID start/stop

bit

The Set Value

PID : Kp, Ki, Kd,

Diff, Death

0CH ID600 ID607 Y600 QD602 Kp-------

Ki-------

Kd-------

Diff------

Death----

QD609

QD610

QD611

QD612

QD613

1CH ID601 ID608 Y601 QD603

2CH ID602 ID609 Y602 QD604

Channel PT Signal PID Output

Value

PID start/stop

bit

The Set Value

3CH ID603 ID610 Y603 QD605

4CH ID604 ID611 Y604 QD606

5CH ID605 ID612 Y605 QD607

6CH ID606 ID613 Y606 QD608

Channel DA Signal - - - -

0CH QD600 - - 1CH QD601 - - -

The seventh expansion’s register definition:

Channel AD Signal PID Output

Value

PID start/stop

bit

The Set Value

PID : Kp, Ki, Kd,

Diff, Death

0CH ID700 ID707 Y700 QD702 Kp-------

Ki-------

Kd-------

Diff------

Death----

QD709

QD710

QD711

QD712

QD713

1CH ID701 ID708 Y701 QD703

2CH ID702 ID709 Y702 QD704

Channel PT Signal PID Output

Value

PID start/stop

bit

The Set Value

3CH ID703 ID710 Y703 QD705

4CH ID704 ID711 Y704 QD706

5CH ID705 ID712 Y705 QD707

6CH ID706 ID713 Y706 QD708

Channel DA Signal - - - -

0CH QD700 - - 1CH QD701 - - -

Description:

Start signal (Y): when Y is 0, close PID control, when be 1 , start PID control

Parameter P:Proportion parameter, mainly reflex system’s difference, carry on control as soon

Page 60

as difference occurs to improve the system’s no difference degree.

Parameter I:Integral parameter. Mainly used to remove whisht, improve the system’s no

difference degree.

Parameter D:Differential parameter, mainly used to control signal’s changing trend,minish

system’s shake.

Control bound Diff:In the assigned bound, carry on PID control. Beyond the bound, no PID

control.

Dead area Death:When the current PID control value compares with the preceding PID control

value. If the difference between them is less than the set dead bound’s value,

the module will abnegate the current PID control value, send the preceding

PID control value to the PLC main unit.

Each parameter’s reference value:Kp=20~100;Ki=5~20;Kd=200~700;DIFF=100~200

3.

Working Mode Setting

1)Expansion’s input/output mode can be set via special FLASH data register FD

inside PLC.

Module Register’s ID

1# Module

FD8250 、FD8251、FD8252

2# Module

FD8258、FD8259、FD8260