Summary of XC series PLC

XC Series Programmable Controller

User's Manual

Xinje Electronic Co., Ltd.

1

CONTENTS

XC series

Programmable controll er

Summary of XC series PLC

Preface

—————————————

Summary of XC series PLC

Chapter

1

Operating Manual

V2.5

—————————————

Spec., Input/output and layout

—————————————

Function of each device

—————————————

Basic SFC instructions

—————————————

Applied instructions

—————————————

Special function

2

3

4

5

6

—————————————

Applied examples

—————————————

Appendix

2

7

8

Summary of XC series PLC

This manual includes some basic precautions which you should follow to keep you safe and

protect the products. These precautions are underlined with warning triangles in the manual.

About other manuals that we do not mention please follow basic electric operating rules.

Precautions

Please follow the precautions. If not, it may lead incorrect or

abnormal the control system, even cause fortune lose.

Correct

Application

The models could only be used according to the manual, and can

only be used along with the peripheral equipments recognized or

recommended by Xinje Electronic. They could only work

normally in the condition of be transported, kept and installed

correctly, also please operate and maintain them according to the

recommendations.

We have checked the manual; its content fits the hardware and software of the products. As

mistakes are unavoidable, we couldn’t promise all correct. However, we would check the data in

the manual frequently, and in the next edition, we will correct the necessary information. Your

recommendation would be highly appreciated.

3

Summary of XC series PLC

Preface

—— Specialties of programmable controller

The programming of XC series programmable controller has the following characteristics:

• Support two kinds of program languages

In XC series PLC, besides statement format, you can also adopt ladder chart on the

screen and these two formats could convert to the other.

• Rich basic functions

Based on the theory of “Basic functions, High speed dispose, convenient to use”, XC

series PLC supports not only functions relative to sequence control, but also basic

application instructions of data transfer and compare, arithmetic and logic control

loop and shift of data etc., besides, it can support interrupt, high-speed counter

exclusive compare instructions, high-speed impulse output and other high-speed

dispose instructions.

• Offset function (Indirect addressing)

Add offset suffix after the coil, data register (e.g. X3[D100], D0[D100]) to realize

indirect addressing. E.g. when D100=0, X3[D100] means X3, D0[D100] means D0;

when D100=9, X3[D100] means X14, D0[D100] means D9;

• Single phase or AB high speed counter

The high speed counters in XC series PLC carry on interrupt disposal with the high

speed pulse from special input points. So it is independent with the scan cycle, the

count speed can reach 200 KHz.

• Convenient MODBUS communication instructions

With Modbus communication instruction, PLC can easily communicate with every

kind of peripheral device as long as they have Modbus protocol.

• High speed pulse output

The main units have two routes pulse output, output can be sequencial segments, and

each segment of pulse number could be set freely. The pulse could reach 400 KHz

XC series PLC are divided into XC1, XC3 and XC5 sub series:

• XC1 economic type: This sub-series has specifications of 16 I/O, 24 I/O and 32 I/O.

The function is simple, suitable for common, small scale applications. They don’t

support high speed count, pulse output, free communication these advanced functions;

also they can not connected with the expansions. For the details, please refer to the

appendix 8-3 “XC1 using description”.

• XC3 Standard type: This sub-series belongs to the standard models of XC series

PLC. They could fulfill most using requirements. If no special demonstrate, this

manual’s content are all written for XC3 series PLC.

• XC5 strength type: This sub-series has specifications of 32 I/O, 48 I/O and 60 I/O.

Besides the functions of XC3-PLC, XC5-32 has function of 4 channels pulse output,

XC5-48, XC5-60 support CANBUS instructions, they can realize CAN bus network

function. For the details, please refer to the appendix 8-4 “XC5 using description”.

.

4

Summary of XC series PLC

1. Summary of XC series PLC

XC series PLC are mini type PLC with powerful function. These series products can satisfy

diverse control requirement. With compact design excellent extend capability, cheap price and

powerful function, XC series PLC has become perfect solution of small size control.

1-1. Summary of XC series PLC and program format

1-2. XC series PLC’s model and type

1-3. Expansion’s constitution and ID assignment

1-4. General specification

1-5. Shape and Size

1-6. Terminal arrangement

1-7. Communication ports definition

5

1-1. Summary of XC series PLC and program format

Introduction

Program

Format

Alternation

XC series programmable controller

z I/O 14~60 points

z FlashROM memory inside

z Real time clock: With clock inside, Li battery power drop memory

z Multi-COM ports can connect with inverters, instruments, printers etc.

z Rich instructions, convenient to program

Statement Program

Statement program is the format which use“LD”, “AND”, “OUT”

etc. These SFC instructions to input this format is the basic input

form to compile the SFC program

E.g: Step Instruction ID

0 LD X000

1 OR Y005

2 ANI X002

3 OUT Y005

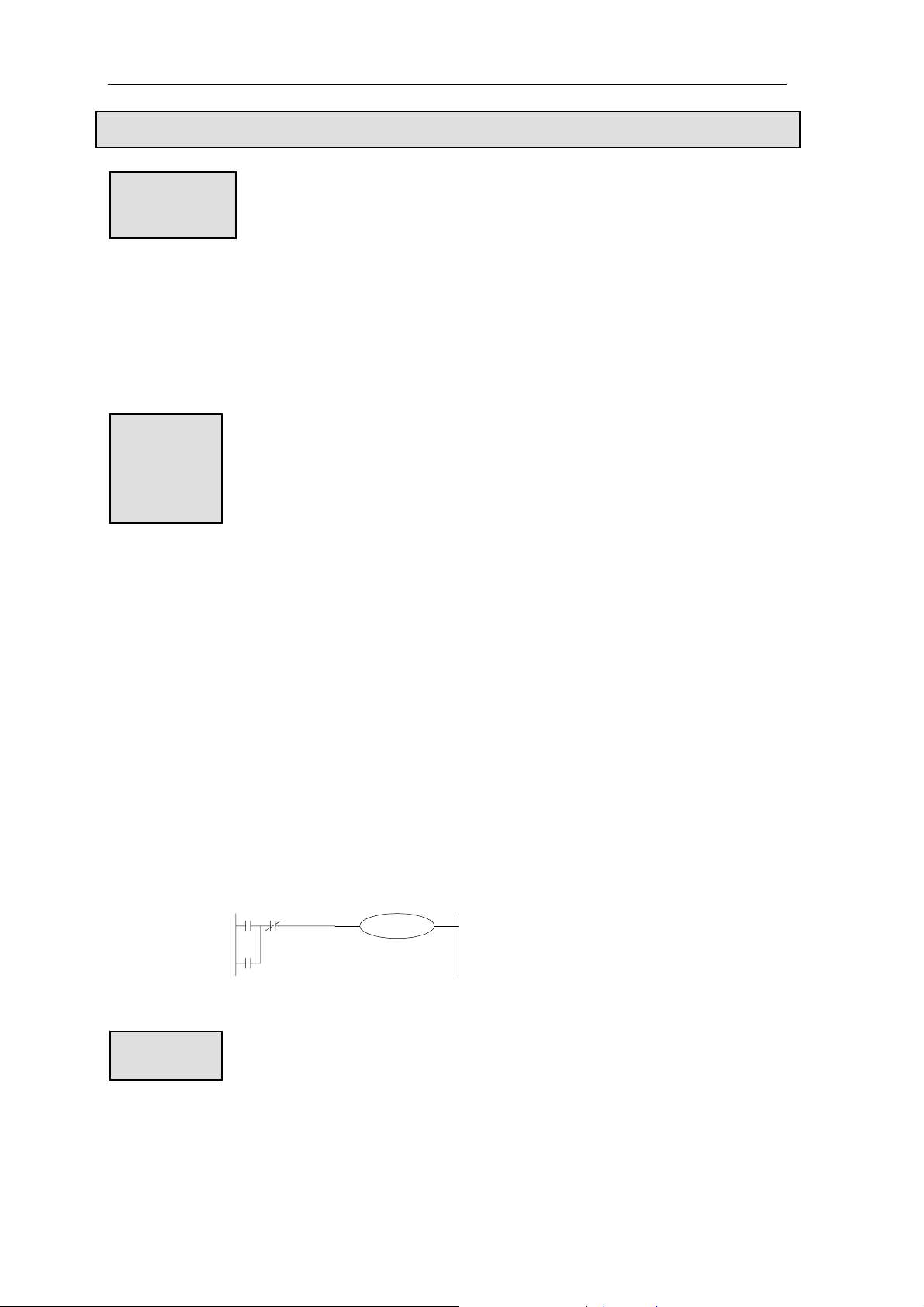

Ladder Program

Use sequencial control signal and soft unit’s ID to draw the

sequencial circuit’s graph on the screen, which is called ladder

program. As this method uses trigger point’s symbols and coil

symbols to denote the sequencial control circuit, so it is easy to

understand the program’s contents. At the same time it’s also

available to monitor the PLC’s action via the status displayed in the

circuit.

E.g:

X0 X2

Y5

Y5

The programs compiled with the preceding two methods are both

stored in the PLC’s program memory in the format of instruction

table. So, the denotion and edition of this two program format can

convert to the other.

Summary of XC series PLC

6

Summary of XC series PLC

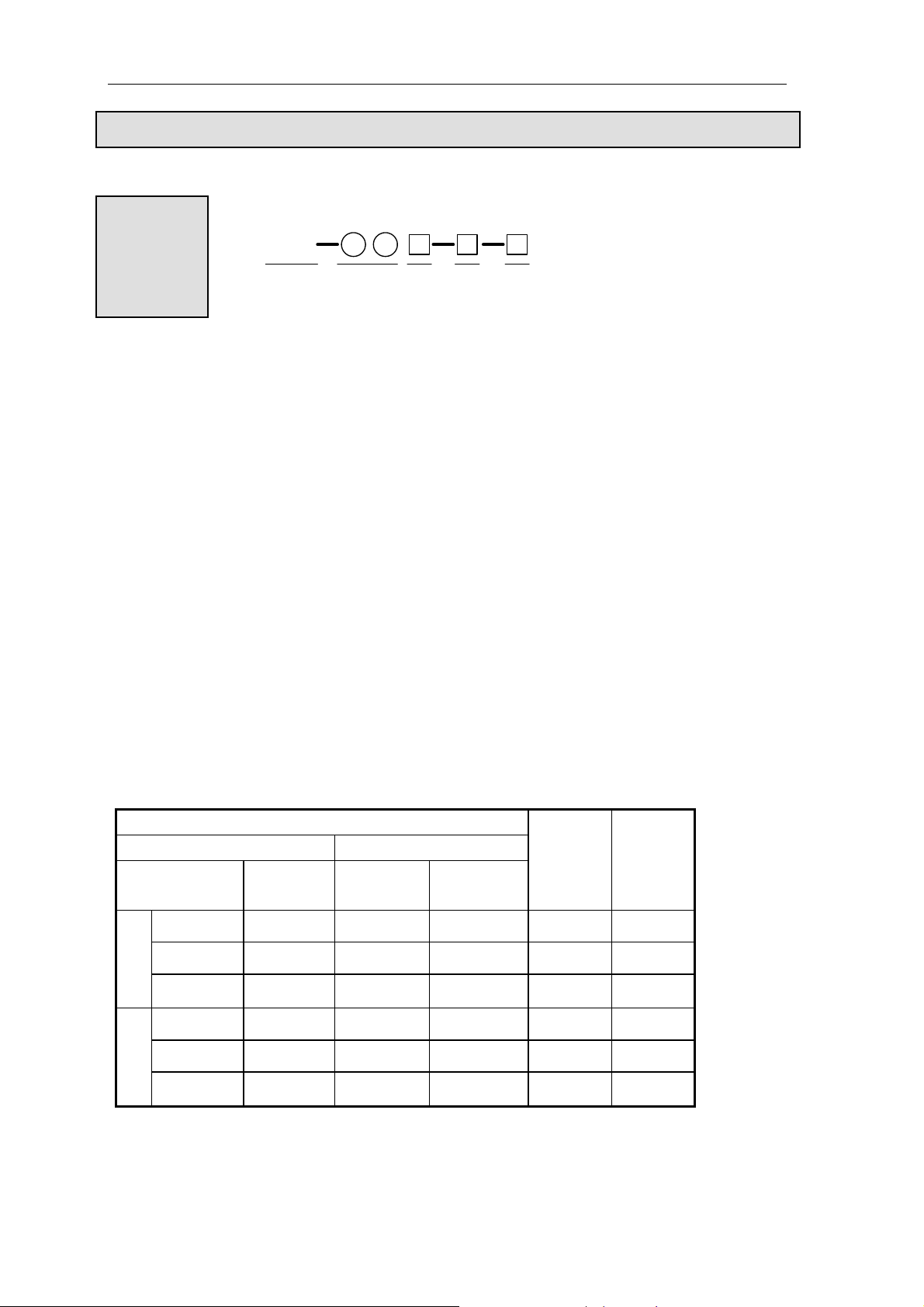

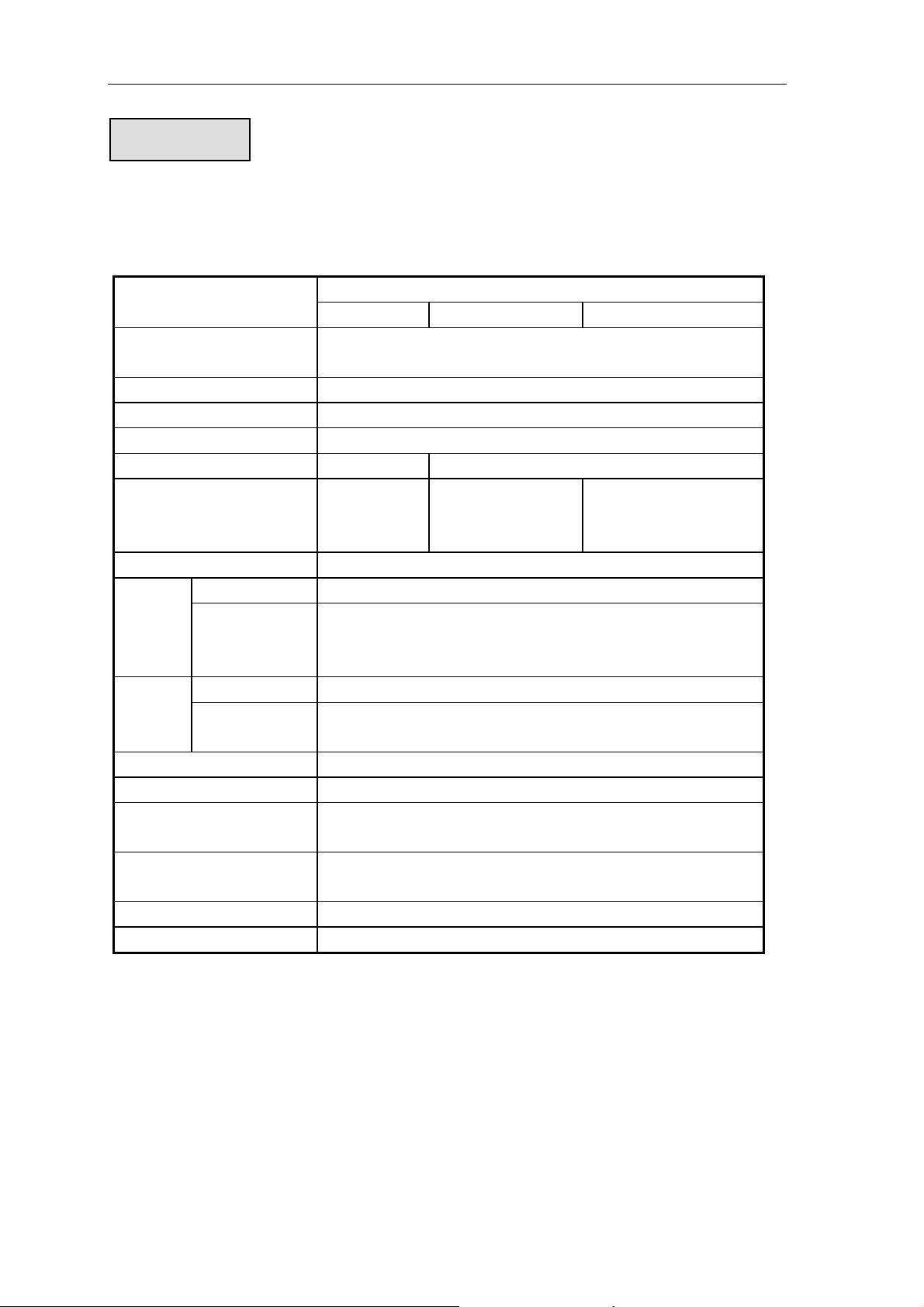

1-2. XC series PLC’s Model and Type

XC Series

XC3

Main Units

1234 5

1 Series Name XC1 series, XC3 series and XC5 series

2 I/O points

3 Input Format(NPN) R: Relay output

T: Transistor output

RT: Mix output of Transistor /Relay (Y0, Y1 are transistor)

Output Format(PNP) PR: Relay output

PT: Transistor output

PRT: Mix output of Transistor /Relay(Y0, Y1 are transistor)

4 Supply Power E: AC Power(220V)

C: DC Power(24V)

5 Clock S: With clock and RS485 COM port inside

: Without clock and RS485 COM port inside

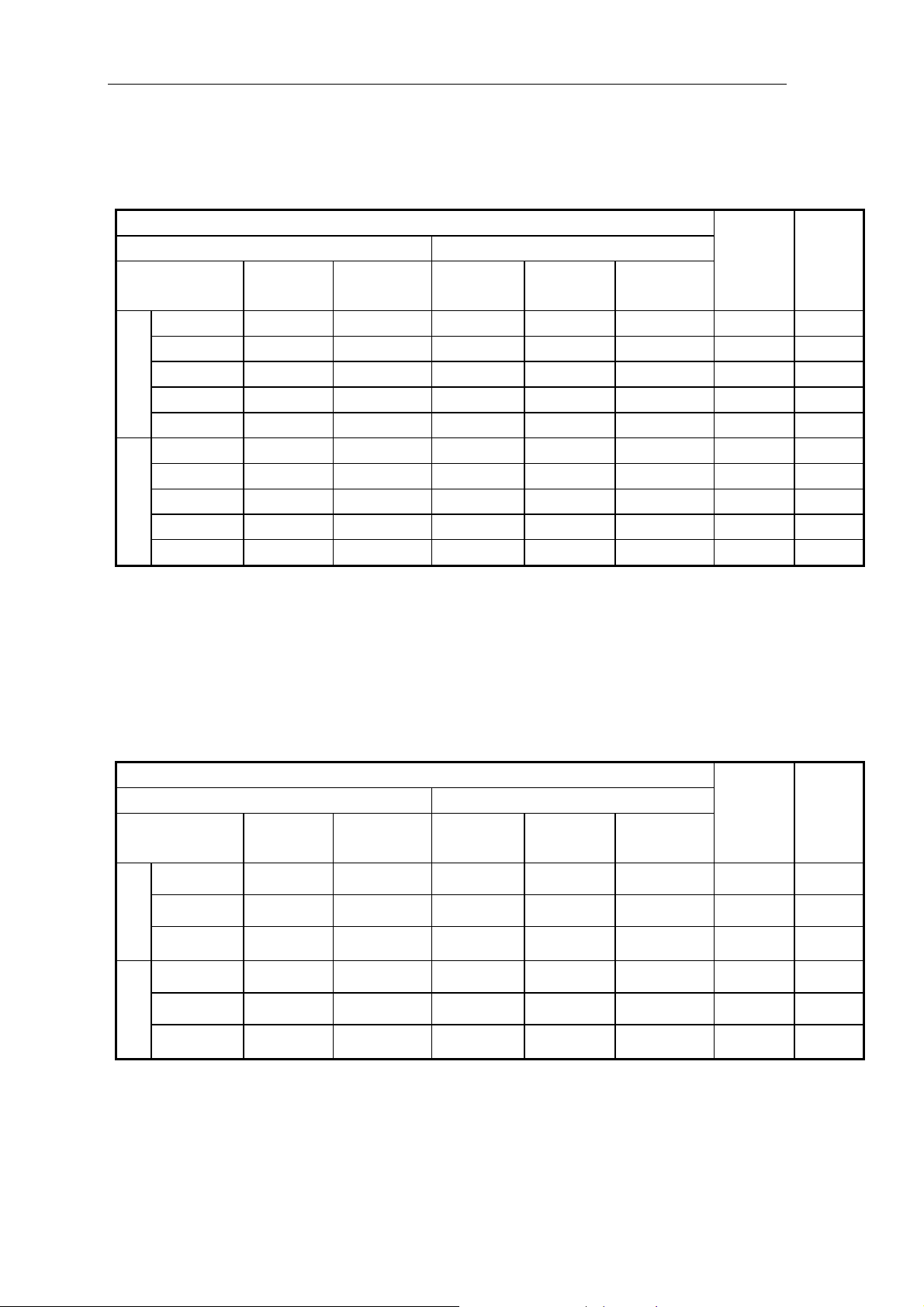

XC1 series models:

Model

AC Power DC Power

Relay Output

N

XC3-16R-E XC3-16T-E XC3-16R-C XC3-16T-C 8 points 8 points

P

XC3-24R-E XC3-24T-E XC3-24R-C XC3-24T-C 12 points 12 points

N

XC3-32R-E XC3-32T-E XC3-32R-C XC3-32T-C 16 points 16 points

Type

P

XC3-16PR-E XC3-16PT-E XC3-16PR-C XC3-16PT-C 8 points 8 points

N

XC3-24PR-E XC3-24PT-E XC3-24PR-C XC3-24PT-C 12 points 12 points

P

XC3-32PR-E XC3-32PT-E XC3-32PR-C XC3-32PT-C 16 points 16 points

Type

Transistor

Output

Relay Output

Transistor

Output

Input

(DC24V)

Output

(R, T)

7

Summary of XC series PLC

XC3 series models:

Model

AC Power DC Power

Relay Output Transistor

Output

XC3-14R-E XC3-14T-E XC3-14RT-E XC3-14R-C XC3-14T-C XC3-14RT-C 8 points 6 points

N

XC3-24R-E XC3-24T-E XC3-24RT-E XC3-24R-C XC3-24T-C XC3-24RT-C 14 points 10 points

P

XC3-32R-E XC3-32T-E XC3-32RT-E XC3-32R-C XC3-32T-C XC3-32RT-C 18 points 14 points

N

XC3-48R-E XC3-48T-E XC3-48RT-E XC3-48R-C XC3-48T-C XC3-48RT-C 28 points 20 points

Type

XC3-60R-E XC3-60T-E XC3-60RT-E XC3-60R-C XC3-60T-C XC3-60RT-C 36 points 24 points

XC3-14PR-E XC3-14PT-E XC3-14PRT-E XC3-14PR-C XC3-14PT-C XC3-14PRT-C 8 points 6 points

P

XC3-24PR-E XC3-24PT-E XC3-24PRT-E XC3-24PR-C XC3-24PT-C XC3-24PRT-C 14 points 10 points

N

XC3-32PR-E XC3-32PT-E XC3-32PRT-E XC3-32PR-C XC3-32PT-C XC3-32PRT-C 18 points 14 points

P

XC3-48PR-E XC3-48PT-E XC3-48PRT-E XC3-48PR-C XC3-48PT-C XC3-48PRT-C 28 points 20 points

Type

XC3-60PR-E XC3-60PT-E XC3-60PRT-E XC3-60PR-C XC3-60PT-C XC3-60PRT-C 36 points 24 points

Mix output

(R&T)

Relay Output Transistor

Output

Mix output

(R&T)

Input

(DC24V)

Output

(R, T)

XC5 series models:

Model

AC Power DC Power

Relay Output

N

P

N

Type

P

N

P

Type

- XC5-32T-E XC5-32RT-E - XC5-32T-C XC5-32RT-C 18 points 14 points

XC5-48R-E XC5-48T-E XC5-48RT-E XC5-48R-C XC5-48T-C XC5-48RT-C 28 points 20 points

XC5-60R-E XC5-60T-E XC5-60RT-E XC5-60R-C XC5-60T-C XC5-60RT-C 36 points 24 points

- XC5-32PT-E XC5-32PRT-E - XC5-32PT-C XC5-32PRT-C 18 points 14 points

XC5-48PR-E XC5-48PT-E XC5-48PRT-E XC5-48PR-C XC5-48PT-C XC5-48PRT-C 28 points 20 points

XC5-60PR-E XC5-60PT-E XC5-60PRT-E XC5-60PR-C XC5-60PT-C XC5-60PRT-C 36 points 24 points

Transistor

Output

Mix output

(R&T)

Relay Output

Transistor

Output

Mix output

(R&T)

Input

(DC24V)

Output

(R, T)

8

Summary of XC series PLC

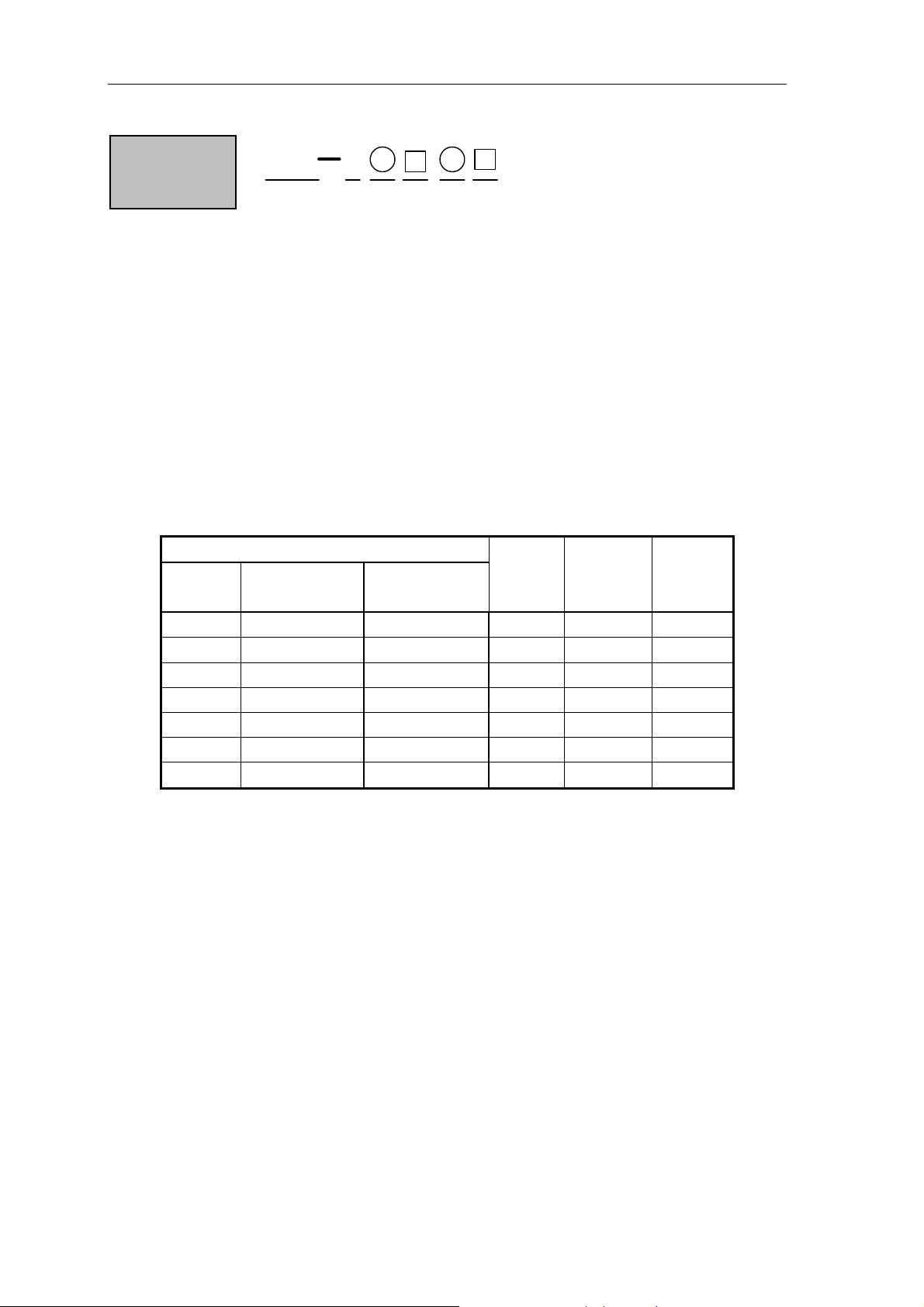

Digital I/O

Expansions

1. Series name

2. E: Expansion

3. Input points

4. X: Input

5. Output points

6. Output format YR: Relay output YT: Transistor output

XC-E16X - - 16 points 16 points -

XC-E32X - - 32 points 32 points -

XC

1234E56

Model

Input R

- XC-E8YR XC-E8YT 8 points - 8 points

- XC-E16YR XC-E16YT 16 points - 16 points

- XC-E 8YR XC-E 8YT 8 p s 8X 8X 16 points 8 points oint

X XC-E1 16YT 16 p ts C-E16X16YR 6X 32 points oin 16 points

- XC-E32YR - 32 points - 32 points

elay Output Transistor

Ou t

tpu

I/O

points

Input

(DC V)

24 (R, T)

Output

9

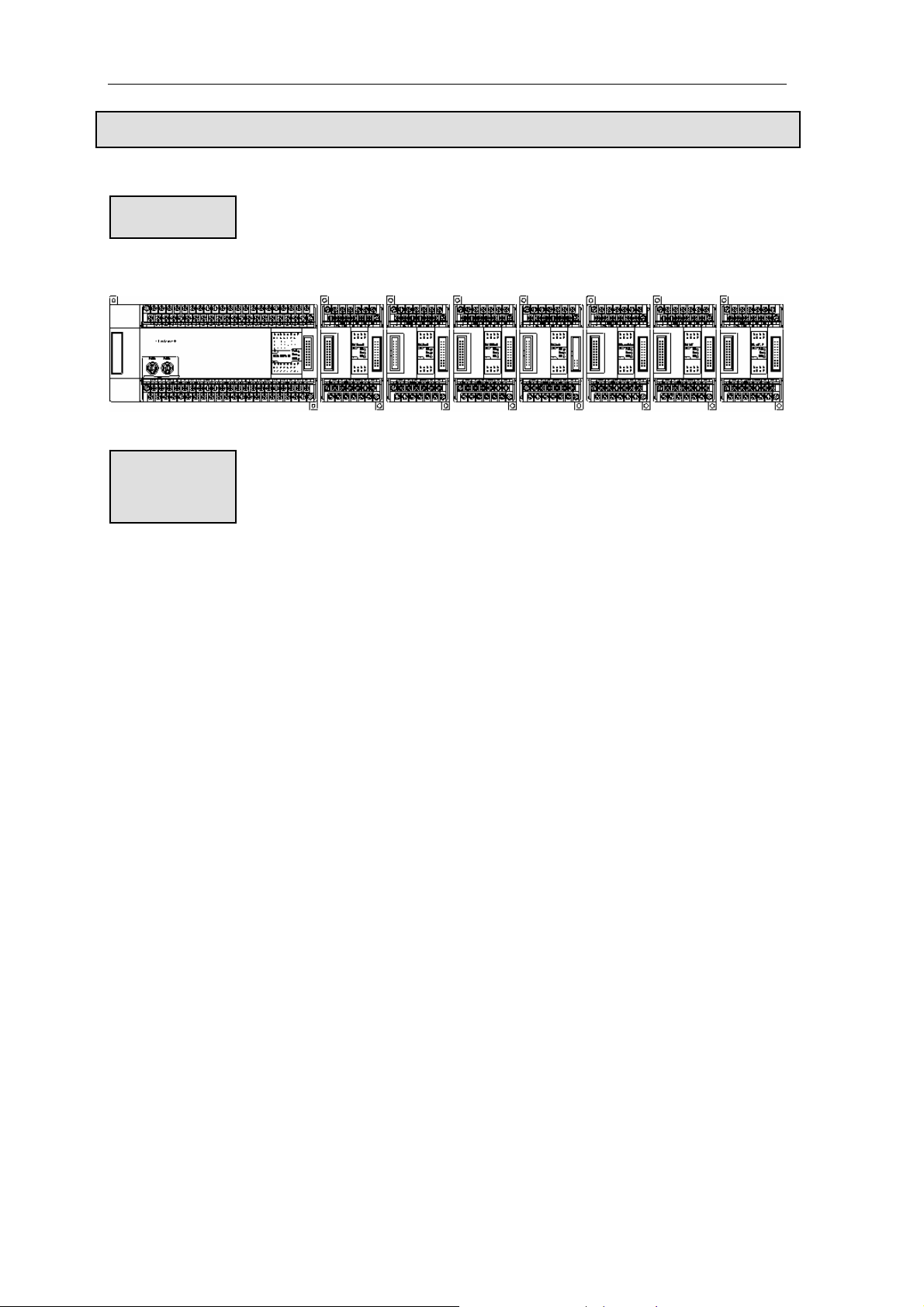

1-3. Expansion’s constitution and ID assignment

Expansion

• XC series PLC can be used independently or used along with

the expansions. The following is the chart of a basic unit with

seven expansions.

Constitution

Rules

• Digital Input/Output quantity is Octal

• Analogue Input/Output quantity is Decimal

• PLC main units can connect with 7 expansions and a BD

module. The input/output type is not limited, both switch and

analog quantity are available.

Summary of XC series PLC

10

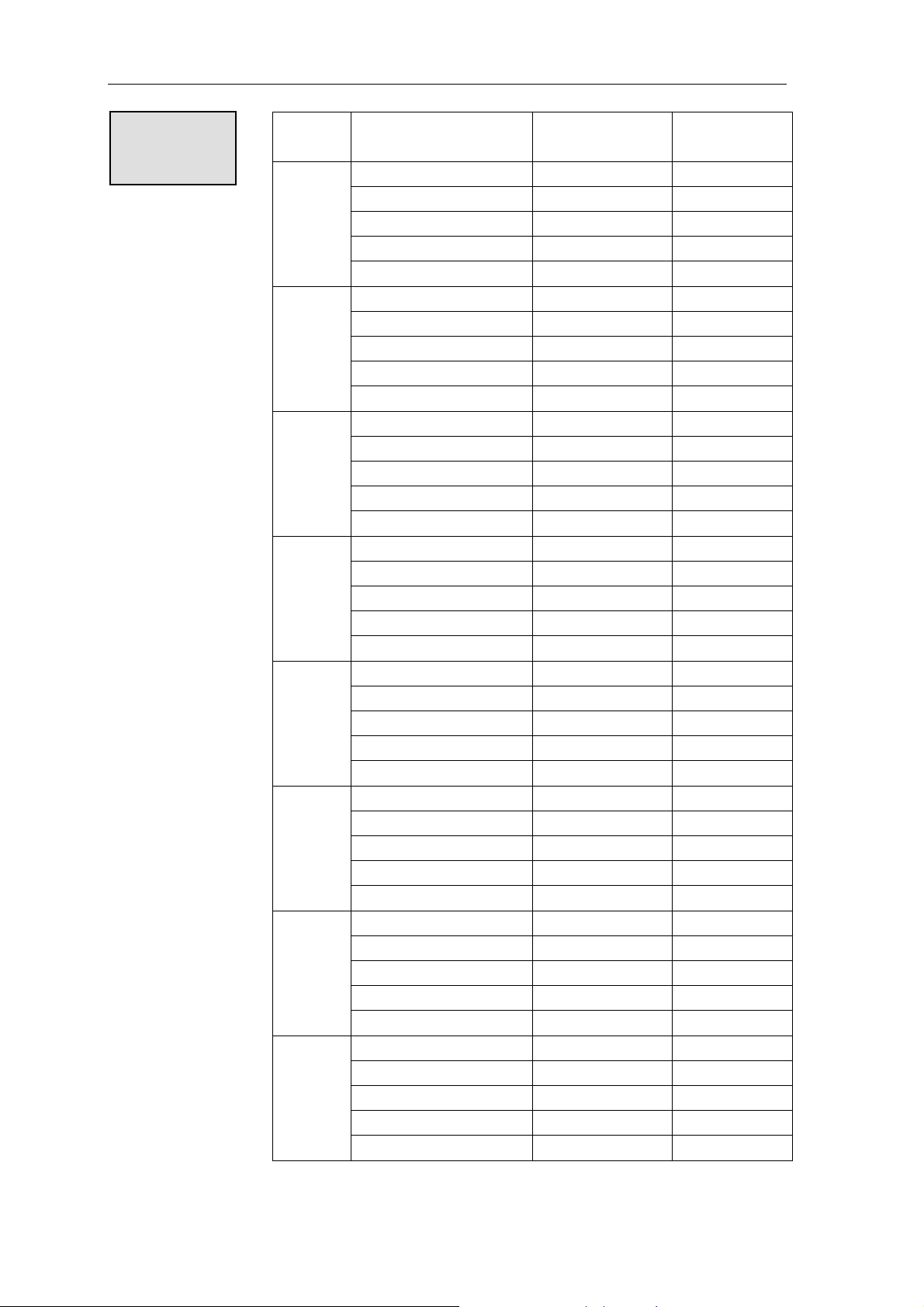

Summary of XC series PLC

ID

Assignment

Unit Type ID(As register)

Input switch quantity X X100~X137 32 points

Expansion

1#

Expansion

2#

Expansion

3#

Expansion

4#

Expansion

5#

Expansion

6#

Expansion

7#

BD Board

Output switch quantity Y Y100~Y137 32 points

Input analog quantity ID ID100~ID131 16 channels

Output analog quantity QD QD100~QD131 16 channels

Module’s set value D D8250~D8259 -

Input switch quantity X X200~X237 32 points

Output switch quantity Y Y200~Y237 32 points

Input analog quantity ID ID200~ID231 16 channels

Output analog quantity QD QD200~QD231 16 channels

Module’s set value D D8260~D8269 -

Input switch quantity X X300~X337 32 points

Output switch quantity Y Y300~Y337 32 points

Input analog quantity ID ID300~ID331 16 channels

Output analog quantity QD QD300~QD331 16 channels

Module’s set value D D8270~D8279 -

Input switch quantity X X400~X437 32 points

Output switch quantity Y Y400~Y437 32 points

Input analog quantity ID ID400~ID431 16 channels

Output analog quantity QD QD400~QD431 16 channels

Module’s set value D D8280~D8289 -

Input switch quantity X X500~X537 32 points

Output switch quantity Y Y500~Y537 32 points

Input analog quantity ID ID500~ID531 16 channels

Output analog quantity QD QD500~QD531 16 channels

Module’s set value D D8290~D8299 -

Input switch quantity X X600~X637 32 points

Output switch quantity Y Y600~Y637 32 points

Input analog quantity ID ID600~ID631 16 channels

Output analog quantity QD QD600~QD631 16 channels

Module’s set value D D8300~D8309 -

Input switch quantity X X700~X737 32 points

Output switch quantity Y Y700~Y737 32 points

Input analog quantity ID ID700~ID731 16 channels

Output analog quantity QD QD700~QD731 16 channels

Module’s set value D D8310~D8319 -

Input switch quantity X X1000~X1037 32 points

Output switch quantity Y Y1000~Y1037 32 points

Input analog quantity ID ID1000~ID1031 16 channels

Output analog quantity QD QD1000~QD1031 16 channels

Module’s set value D D8320~D8329 -

Max points/

Channels

11

1-4. General Specification

Summary of XC series PLC

General

Specification

Items Specifications

Insulate voltage Up to DC 500V 2MΩ

Anti-noise 1000V 1uS pulse per minute

Ambient

0°C~60°C

temperature

Ambient humidity 5%~95%

COM 1 RS-232, connect with host machine, HMI program or debug

COM 2 RS-232/RS-485, connect with network or aptitude instrument,

inverters etc.

COM 3 BD board COM port RS-232C/RS-485

COM 4 CANBUS COM port (XC5 series)

Installation Can use M3 screw to fix or install directly on DIN46277

(Width 35mm) orbit

Grounding The third type grounding (can’t public ground with strong

power system.)

12

Performance

XC3 series:

Summary of XC series PLC

Item

Specification

14 points 24/32 points 48/60 points

Program executing

Loop scan format, time scan format

format

Program format Both statement and ladder

Dispose speed 0.5us

Power cut retentive Use FlashROM and Li battery

User program’s capacity 2500 steps 8000 steps

I/O points 8 I / 6 O Input 14/18 points

Output 10/14

Input 28/36 points

Output 20/24 points

points

Interior coil’s points (M) 8512 points

Points 620 points

Timer

(T)

Spec.

100mS timer: Set time 0.1~3276.7 seconds

10mS timer: Set time 0.01~327.67 seconds

1mS timer: Set time 0.001~32.767 seconds

Points 635 points

Counter

(C)

Spec.

16 bits counter: set value K0~32767

32 bits counter: set value K0~2147483647

Data Register(D) 8512 words

FlashROM Register(FD) 2048 words

High speed dispose

High speed count, pulse output, external interrupt

function

Setting of time scan

0~99mS

space

Password protection 6 bits ASCII

Self diagnose function Power on self-diagnose, Monitor timer, grammar check

13

1-5. Shape and Size

Exterior Size

XC1 series 16 points main units

XC3 series 14 points main units (Including 16 points expansions)

Summary of XC series PLC

XC1 series 32 points main units (Including 24 points main units)

XC3 series 24 / 32 points main units (Including 32 points expansions)

XC5 series 32 points main units

139

131

X21

X13

X15X7X6X5X4X3X2X1

X12

X14 X16

2 3540 1

76

X

PWR

RUN

XC3-32R-E

ERR

Y

104532

67

COM 4

Y10

Y11Y6Y7Y5COM 3Y12

X17

X20

Y13

Y15

Y14

5

.

3

110

102

94

COM

X0COM

FG

POR T2POR T1

0V

AY0COM 0

COM 2Y3

24V

COM 1

B

Y1

X11

X10

Y2

Y4

Xi n j e El e ct r oni c Co. , Lt d

SN :0067032266

73.3

D A T E :20060410

TYPE:XC3-32R-E

14

XC3 series 60 points main units (Including 48 points main units)

XC5 series 60 points main units (Including 48 points main units)

207.4

199.4

Summary of XC series PLC

73.3

102

94

X1

COM

X0

X2X3X4X5X6X7X10

COM

POR T 2POR T 1

CAN+ CAN-

0V

24V

B

A

X11

X13

X15

X17

X21

X23

X25

X12

X14

X16

X20

COM5

Y3

Y4

Y2Y1

Y0

COM3

COM 1CO M0

COM 2

COM 6

Y6COM4

Y5

X27

X22

X24

X26

X30

COM7

Y12Y7

Y10

Y15

Y13

Y11

Y16

Y14

X37

X35

X33

X31 X41

Y17

X34

X32

X

XC3-60R- E

Y

0

1326754

Y20

COM8

Y21

X40X36

4

5762 310

PWR

RUN

ERR

COM 9

Y22

Y23

Y24

X43

X42

Xi nj e El ec t r oni c Co. , Lt d

SN :0067032266

D A T E:20060410

TYPE:XC3-60R-E

Y27

Y25

Y26

15

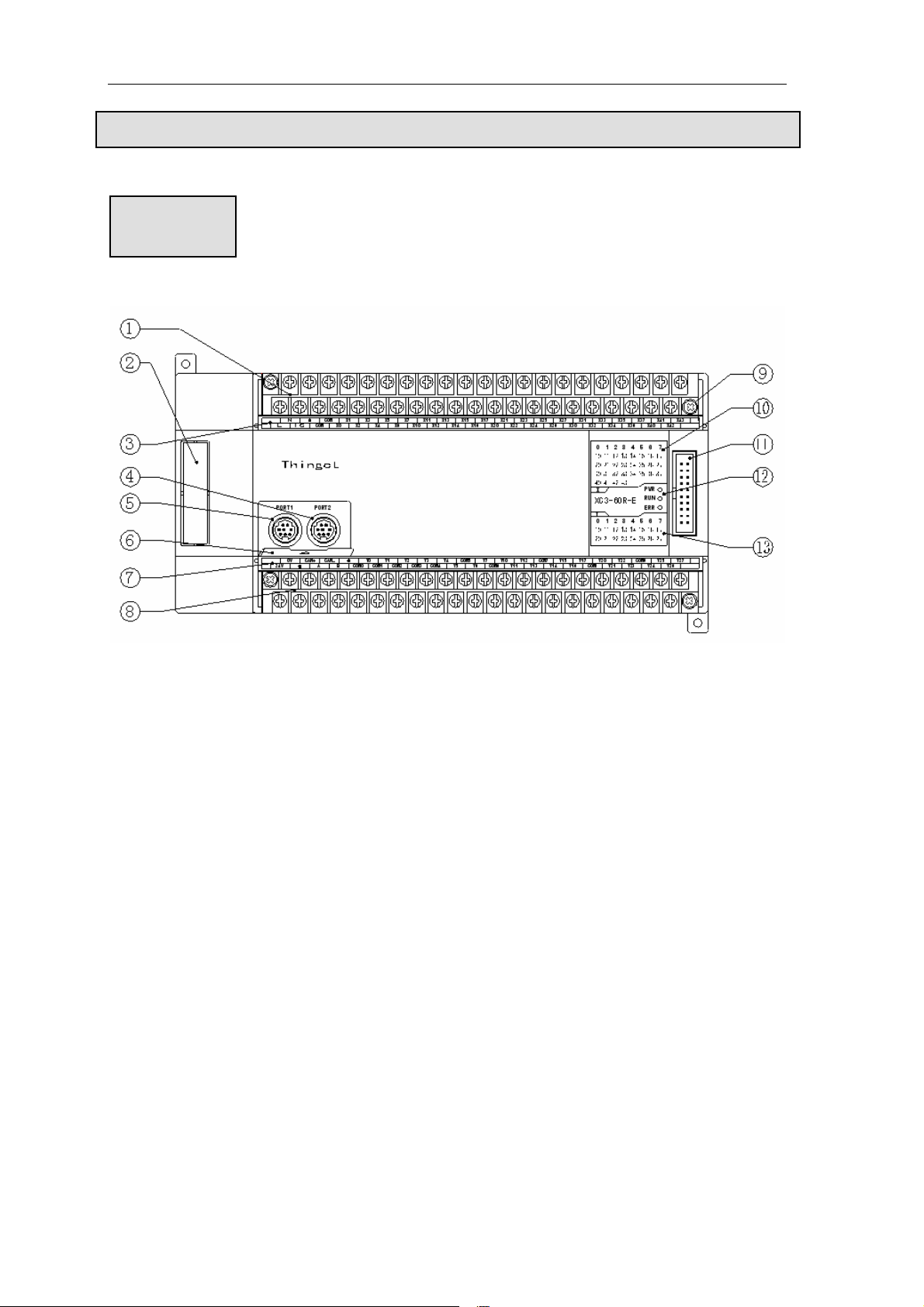

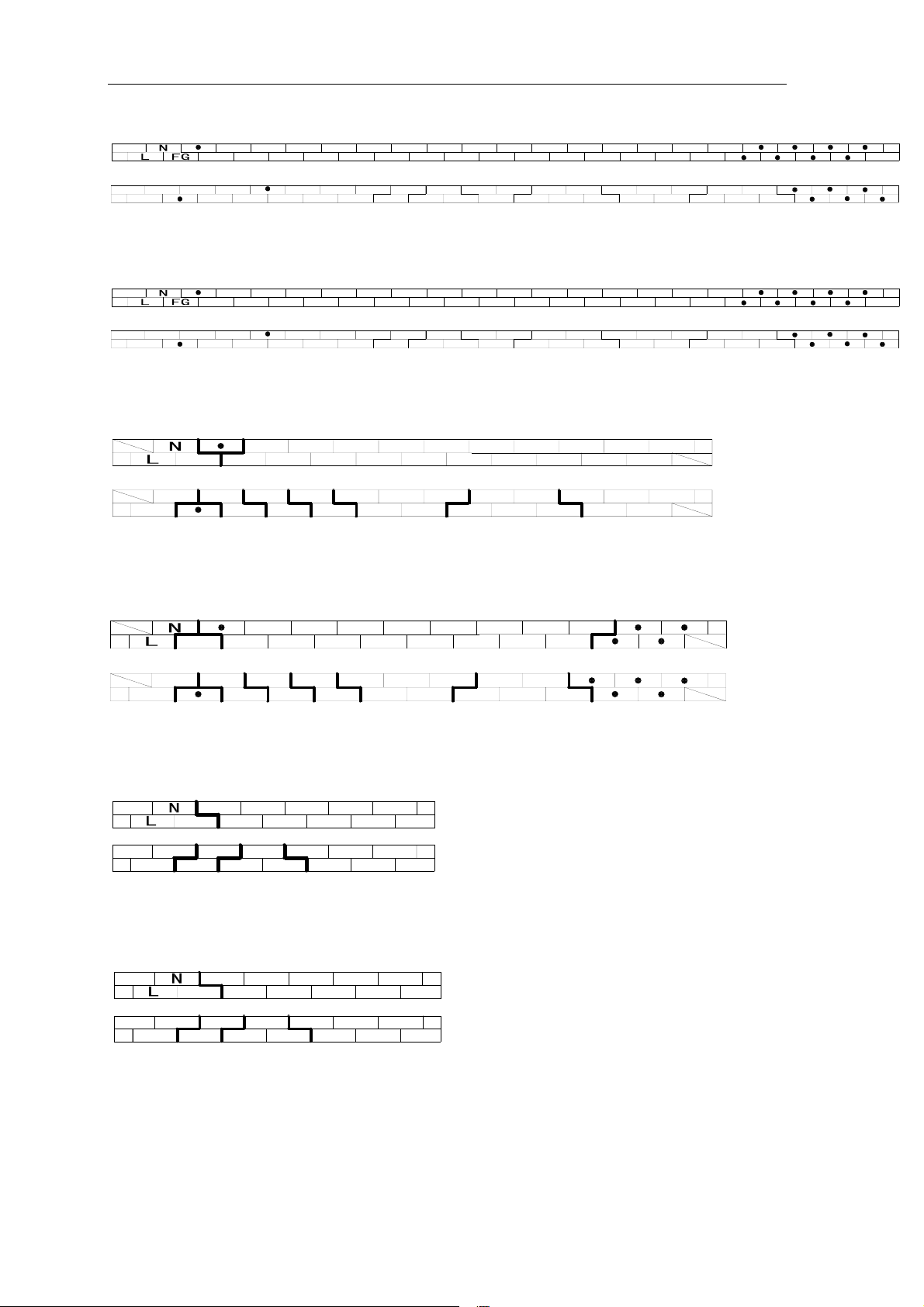

1-6. Terminal arrangement

Main Units

Summary of XC series PLC

1. Input terminals

2. BD expansion

3. Input label

4. COM port

5. COM port

6. COM port’s cover door

7. Output label

8. Output terminals

9. Screws

10. Input indicate LED

11. Extension port

12. Programming status indicate LED

13. Output indicate LED

16

XC3- 60 main units, XC5- 60 main units: 36 Input/24 Output

M

X21

X17

X15

X13

X11

X7

X5

X3

X1

CO M

COM

X14

X12

X10

X6

X4

X2

X0

X16

X20

X22

X23

Summary of XC series PLC

X27

X24

X25

X26

X30

X31

X32

X33

24V

0V

CAN+

CAN-

A

B

COM0COM1

Y1

Y0

COM2

Y2

COM3

Y4Y6COM5

Y3

COM4

Y5

COM6

Y10

Y11

Y12 COM7Y7

Y13

Y14 Y16

Y15

Y17

XC3- 48 main units, XC5- 48 main units: 28 Input /20 Output

X27

X25

X23

X21

X17

X15

X13

X11

X7

X5

X3

24V

X1

COM

CO M

0V

CAN+

CAN-

A

X0

B

X2

Y0

COM0COM1

X6

X4

Y1

Y2

COM2

X10

COM3

X12

Y4Y6COM5

Y3

COM4

X14

X16

Y5

X20

COM6

Y10

X22

Y11

Y12 COM7Y7

X24

Y13

X26

Y14 Y16

X31

X30

Y17

Y15 Y22

C1- 32 main units, XC3- 32 main units, XC5- 32 main units: 18 Input /14 Output

X

24V

0V

FG

CO M

CO M

CO M0

A

B

X1 X3 X5 X7 X1X13X11

X0 X2 X4 X6

Y0

CO M1

CO M2

Y1

Y2

Y3

Y4

CO M3Y5Y7Y6Y11

Y10

CO M4

5

X17

Y13

X21

X20

Y15

Y14

X16X14X12X10

Y12

C1- 24 main units, XC3- 24 main units: 14 Input /10 Output X

FG

CO M

CO M

X0

X1

X2

X3

X4

X5

X6

X11

X10

X12

X13

X15X7

X14

COM8

X32

COM8

Y20

X33

Y20

Y22

Y23

Y21

Y2

Y231

0V

24V

AY0CO M0

B

CO M1

Y1

CO M2

Y2

XC3- 14 main units: 8 Input /6 Output

CO M

FG

24V Y0 COM1Y3 Y5

0V

X1 X3 X5 X7

X6X4X2X0

A

Y4Y2Y1CO M0B

XC1- 16 main units: 8 Input /8 Output

CO

FG

24V Y0 COM1Y2 Y7

0V

CO M0

X1 X3 X5 X7

X6X4X2X0

Y5

Y4Y3Y1

Y6

Y3

Y4

Y5

CO M3

Y6

Y7

Y10

Y11

17

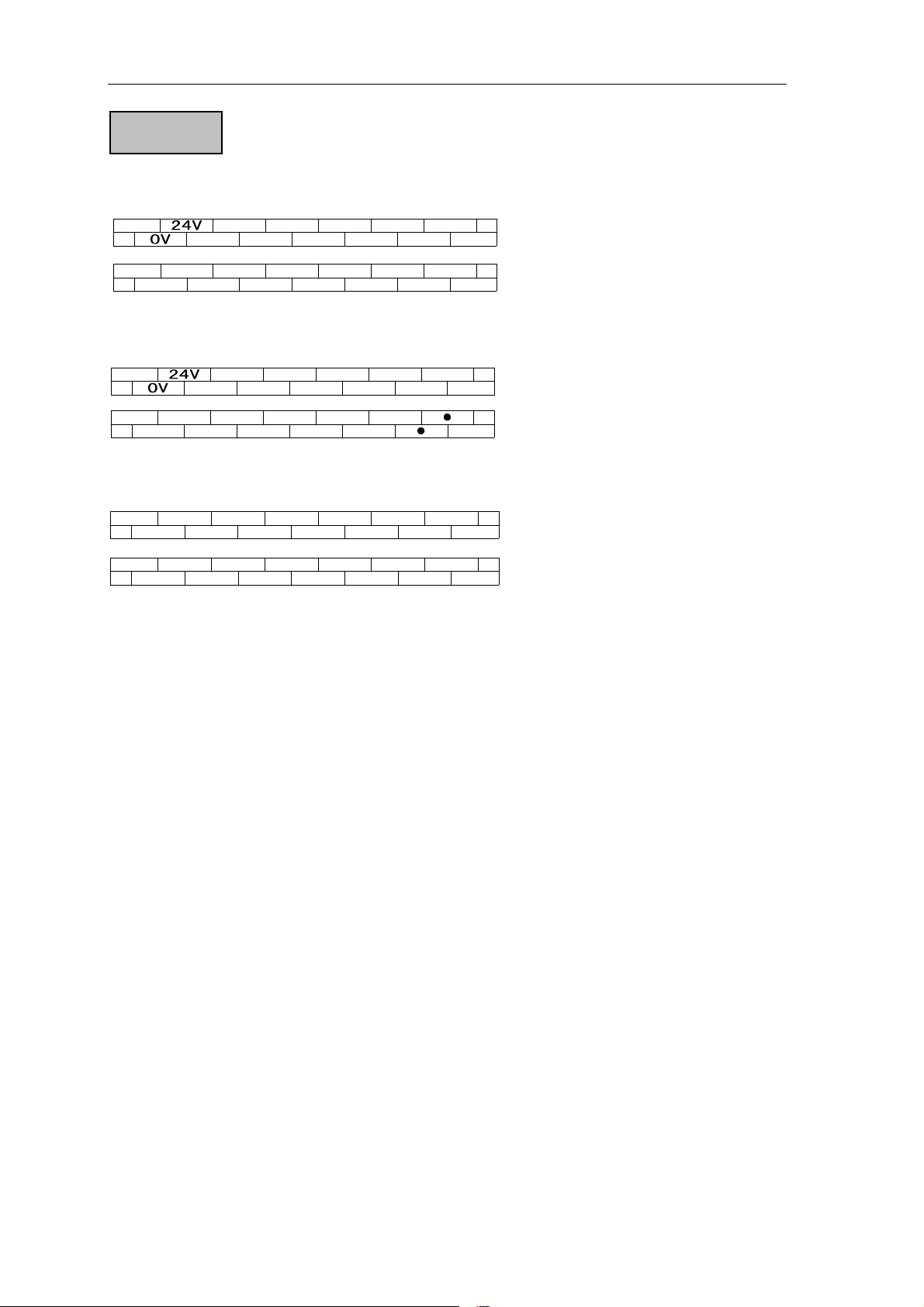

Expansions

XC-E8X8YR

Summary of XC series PLC

Y0

CO M 0

XC-E16X

CO M

CO M

XC-E16YR

Y0

CO M0COM1

CO M4

CO M

CO M

CO M1COM2Y3 Y4 Y6

CO M

CO M5COM6Y13 Y14 Y16

X0 X2 X4 X6

Y1

CO M

X11

Y1

Y11

X1 X3 X5 X7

X13 X15 X17

X16X14X12X10

CO M2Y3Y4Y6

X7X5X3X1

Y7Y5CO M3Y2

X6X4X2X0

Y7Y5CO M3Y2

Y17Y15CO M7Y12Y10

18

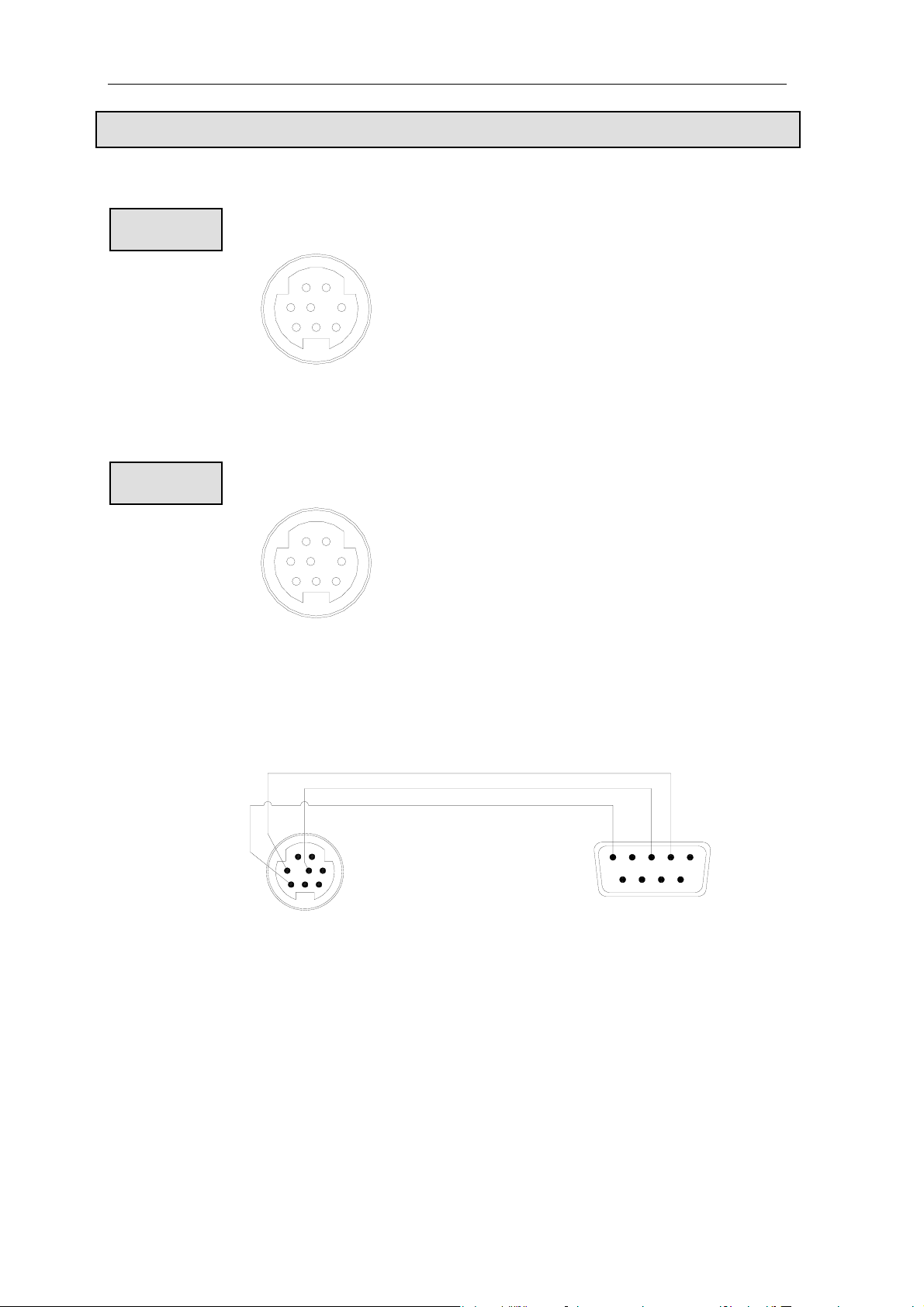

1-7. COM Port Definition

COM 1

Pin of COM 1

1

45

3

6

Mini Din 88 core socket (hole)

Summary of XC series PLC

2: PRG

备注

4: RxD

5: TxD

6: VCC

8: GND

2

8

7

COM 2

Pin of COM 2

4: RxD

1

45

3

6

2

8

7

5: TxD

8: GND

Mini Din 88 core socket (hole)

Connection of programmable cable is the following:

15

2

1

45

3

8

6

7

Mini Din 8 core socket (pin) DB9 pin (hole)

19

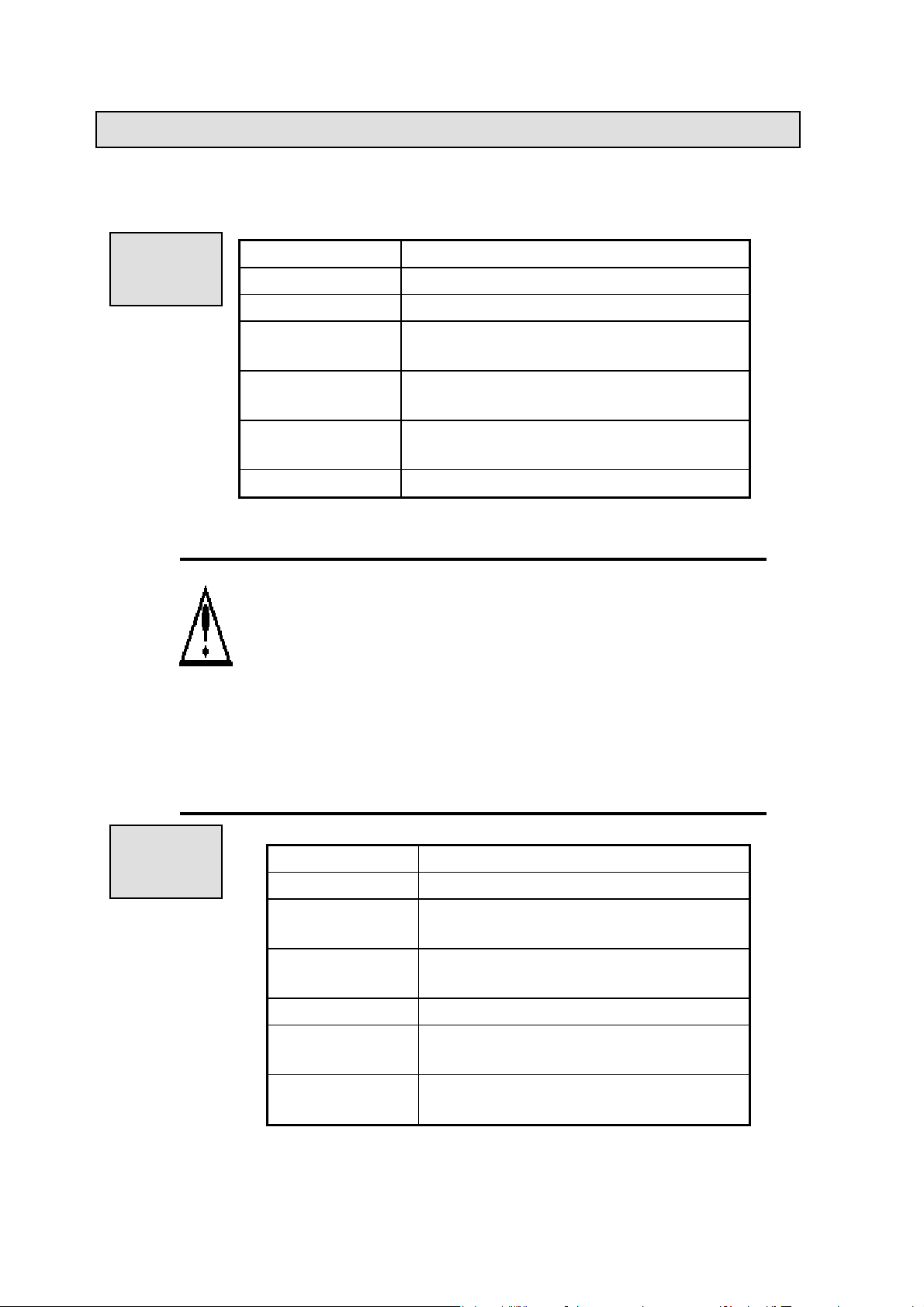

2-1. Power Specification

For the power specification of XC series programmable controller’s basic units, please see

the following table:

AC Power

Type

Rated voltage AC100V~240V

Voltage allow bound AC90V~265V

Rated frequency 50/60Hz

Allow momentary

power-cut time

Impact current Max 40A 5mS below/AC100V

Max power

consumption

Power for sensor use 24VDC±10% max 400mA

Interrupt time≤0.5 AC cycle, alternation≥1 sec

max 60A 5mS below /AC200V

12W

• To avoid voltage decrease, please use the power cable

thicker than 2mm2

• Even appear power cut within 10ms; PLC can still go on

working. But if long time power cut or abnormal power

decrease, PLC will stop working, output will also appear

OFF status, when recover power supply, the PLC will auto

start to work.

• Connect the grounding terminals of basic units and extend

modules together, then ground

DC power

type

Rated voltage DC24V

Voltage allow bound DC21.6V~26.4V

Input current

(Only basic unit)

Allow momentary

power-cut time

Impact current 10A DC26.4V

Max power

consumption

Power for sensor

use

120mA DC24V

10mS DC24V

12W

24VDC±10% Max 400mA

21

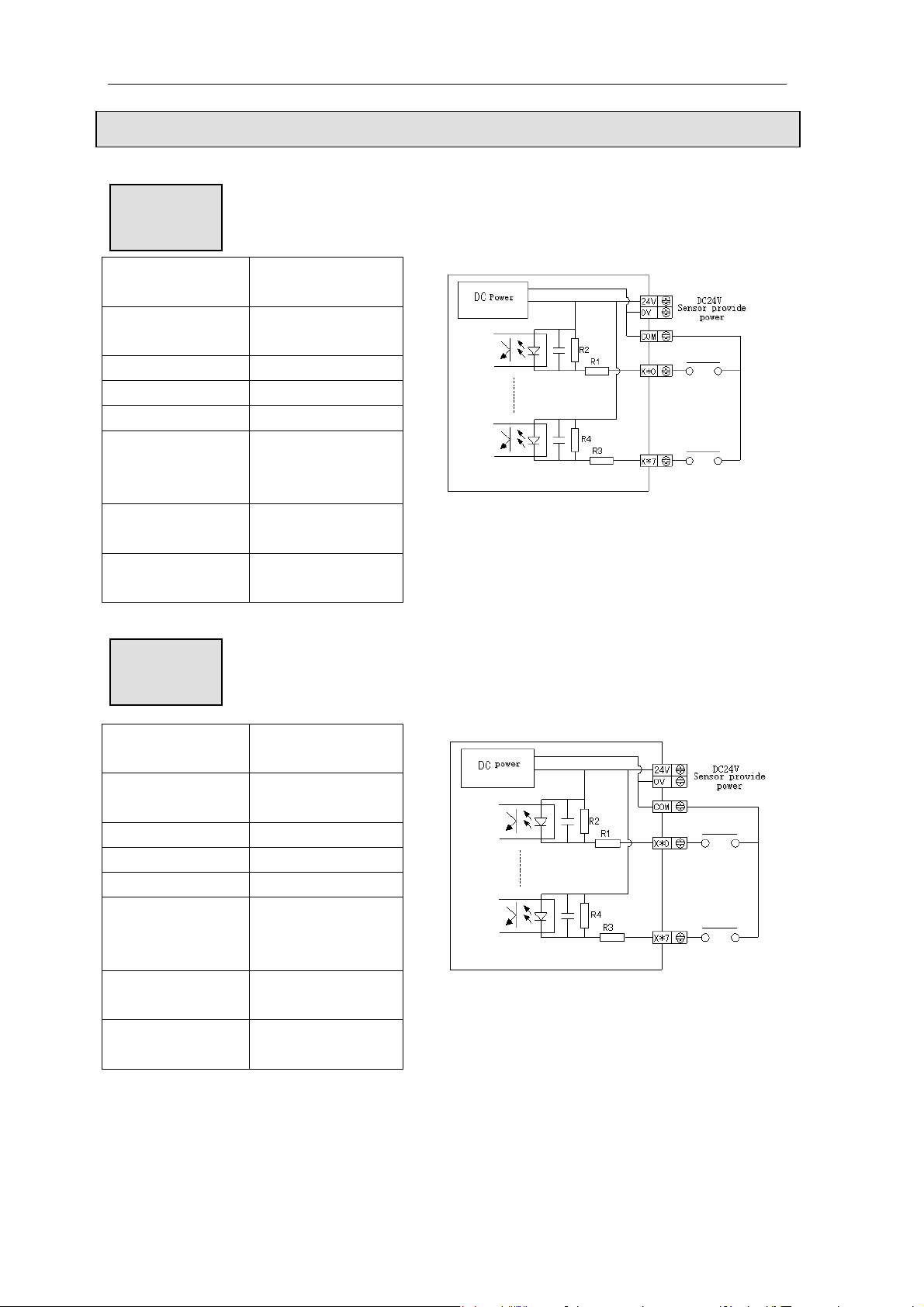

2-2. AC Power, DC Input Type

Constitution

and

Connection

Spec., Input/output and layout

·

• The Input power is connected between L and N terminals.

• 24+, COM terminals can be used to power 400mA/DC24V for sensor

·

supply. Besides, this terminal can’t be connected to external power.

• Terminal is NC terminal, please don’t go on exterior connection or

use it as relay terminal.

• Connect the basic unit with all expantions module’s COM terminal.

22

2-3. Input Specification

Basic Units

Input signal’s

voltage

Input signal’s

current

Input ON current Up to 4.5mA

Input OFF current Low than 1.5mA

Input response time About 10ms

Input signal’s

format

Circuit insulation Photo-electricity

Input action’s

display

Expansions

Input signal’s

voltage

Input signal’s

current

Input ON current Up to 4.5mA

Input OFF current Below 1.5mA

Input response time About 10ms

Input signal’s

format

Circuit insulation Photo-electricity

Input action’s

display

DC24V±10%

7mA/DC24V

Contact input or

NPN open collector

transistor

coupling insulation

LED light when

input ON

DC24V±10%

7mA/DC24V

Contacts input or

NPN open collector

transistor

coupling insulation

LED light when

input ON.

Spec., Input/output and layout

23

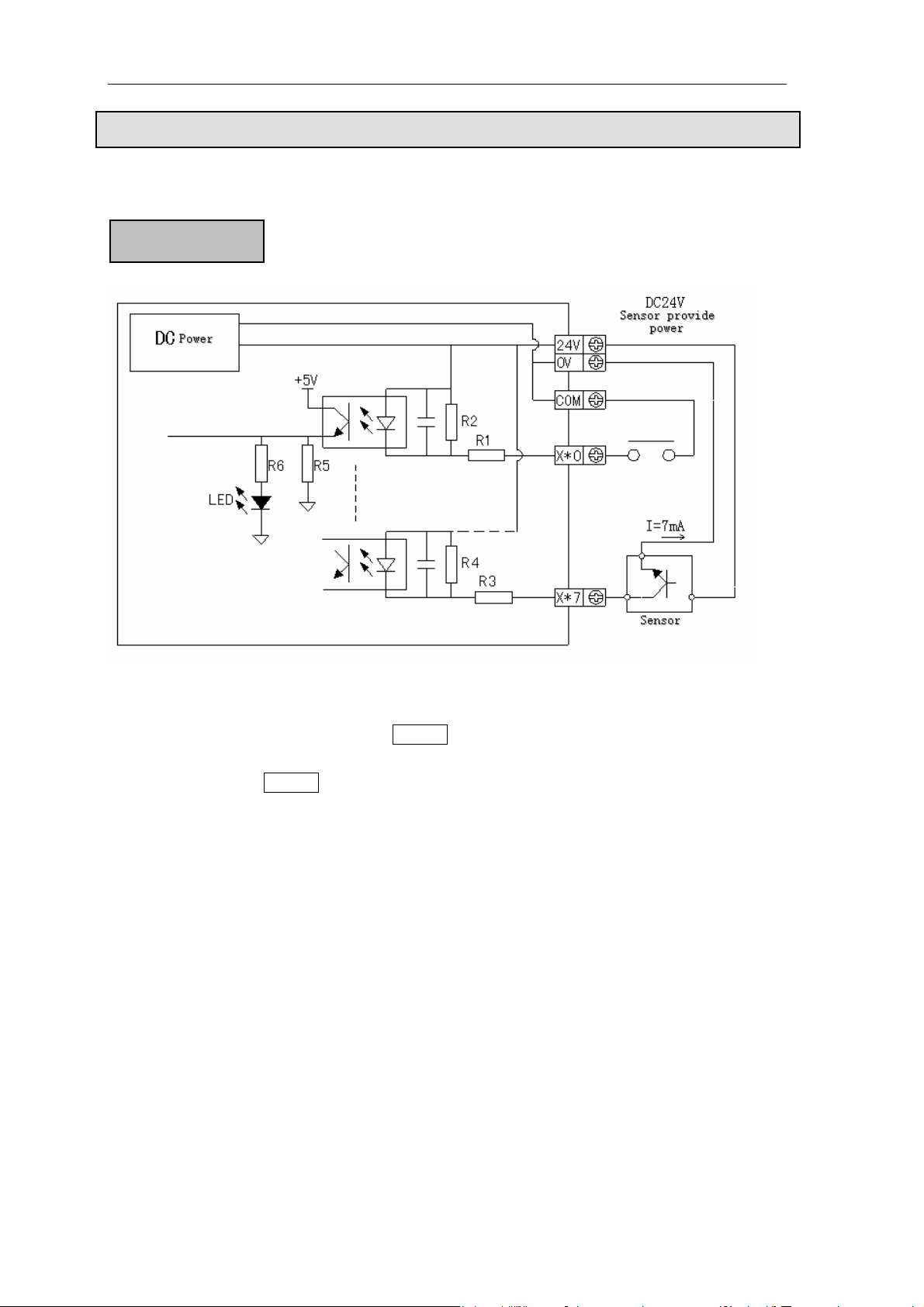

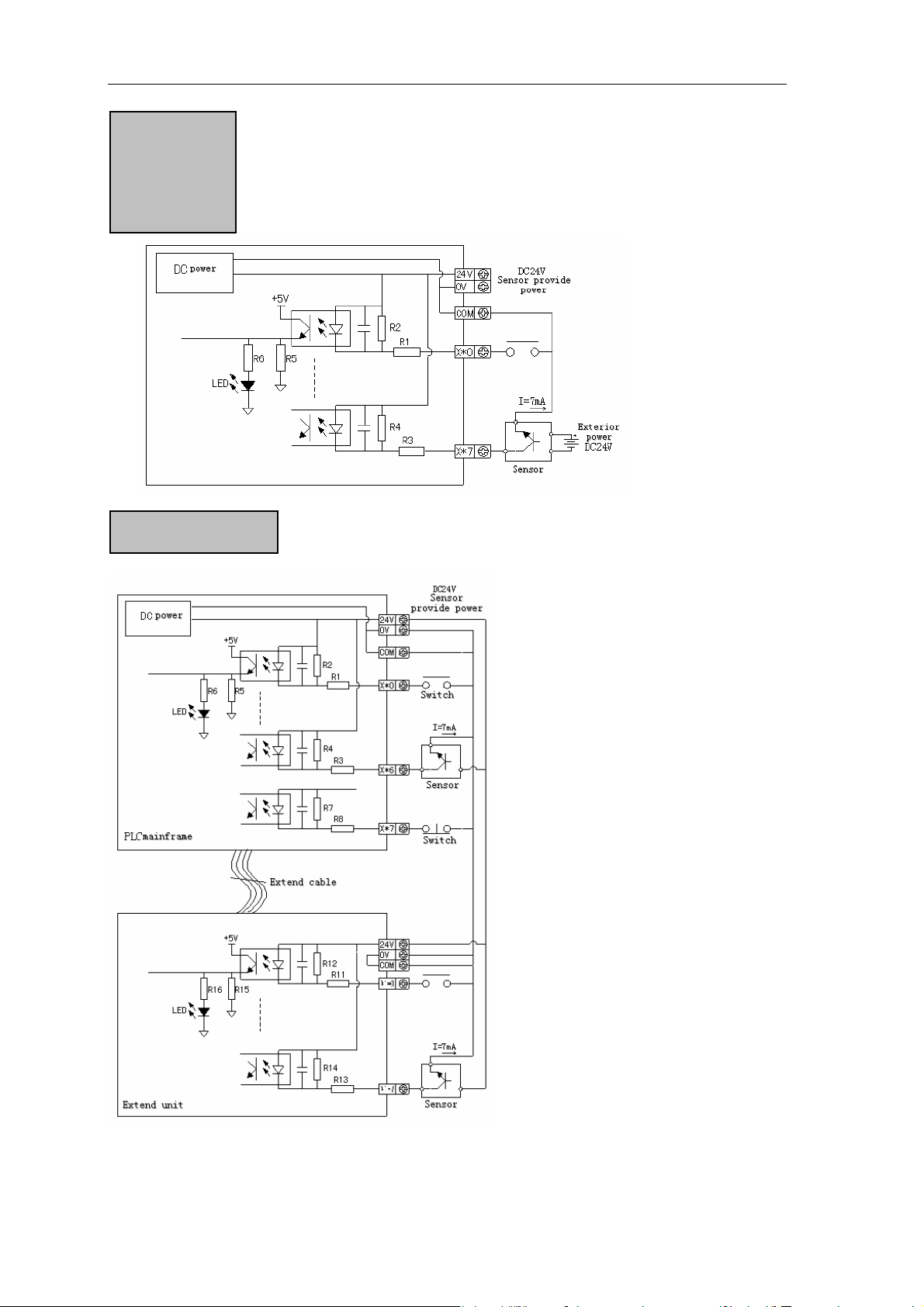

2-4. DC Input Signal’s Disposal(AC Power Type)

DC input signal

Spec., Input/output and layout

z Input terminal

When connect input terminal and COM terminal with contacts without voltage or

NPN open collector transistor, if input is ON,LED lamp lights, which indicates input。

There are many COM terminals to connect in PLC.

z Input circuit

Use optical coupling instrument to insulate the input once circuit and twice circuit,

There’s a C-R filter in the twice circuit。It is set to avoid wrong operation caused by

vibration of input contacts or noise along with input signal. As the preceding reason, for

the changing of input ON→OFF,OFF→ON,in PLC, the response time delays about

10ms。There’s a digital filter inside X000~X015。This kind of filter can very from

0~15ms according to the special register (D8020).

z Input sensitive

The PLC’s input current is DC24V 7mA,but to be safe,it needs current up to 3.5mA

when it’s ON,lower than 1.5mA when it’s OFF.

24

Spec., Input/output and layout

Exterior

circuit used

Input Connection

XC series PLC’s input power is supplied by its interior 24V power,so if

use exterior power to drive photoelectricity sensor etc., this exterior

power should be DC24V±4V,please use NPN open collector type for

sensor’s output transistor

25

Spec., Input/output and layout

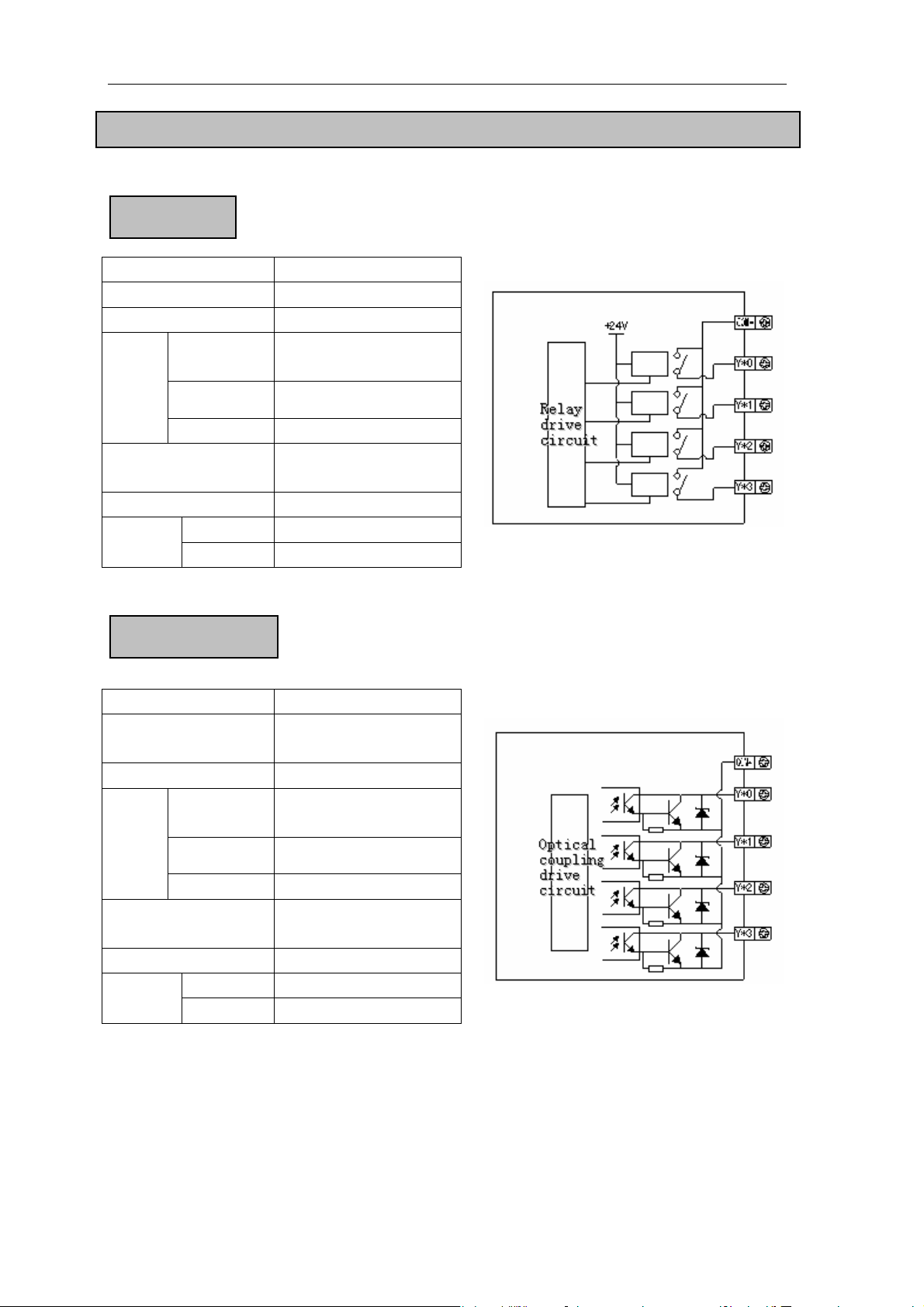

2-5. Output Specifica

Relay output

Interior power Be

Circuit insulation ion Mechanism insulat

Action deno mp te LED indicate la

Max

load

Open circuit’s leak

current

Mini load DC5V 2mA

me

ti

Interior power Below DC5~30V

Circuit insulation Optical coupling

Action denote Indicate lamp LED

Max

load

Resistant

load

Induce load 80VA

Lamp load 100W

OFF→ON 10ms Response

ON→OFF 10ms

Transistor Output

Restance

load

Induce load 12W/DC24V

tion

low AC250V, DC30V

3A

-

insulation

0.8A

Lamp load 1.5W/DC24V

Open circuit’s leak

urrent

c

Mini load DC5V 2mA

OFF→ON Below 0.2ms Response

time

ON→OFF Below 0.2ms

-

26

Spec., Input/output and layout

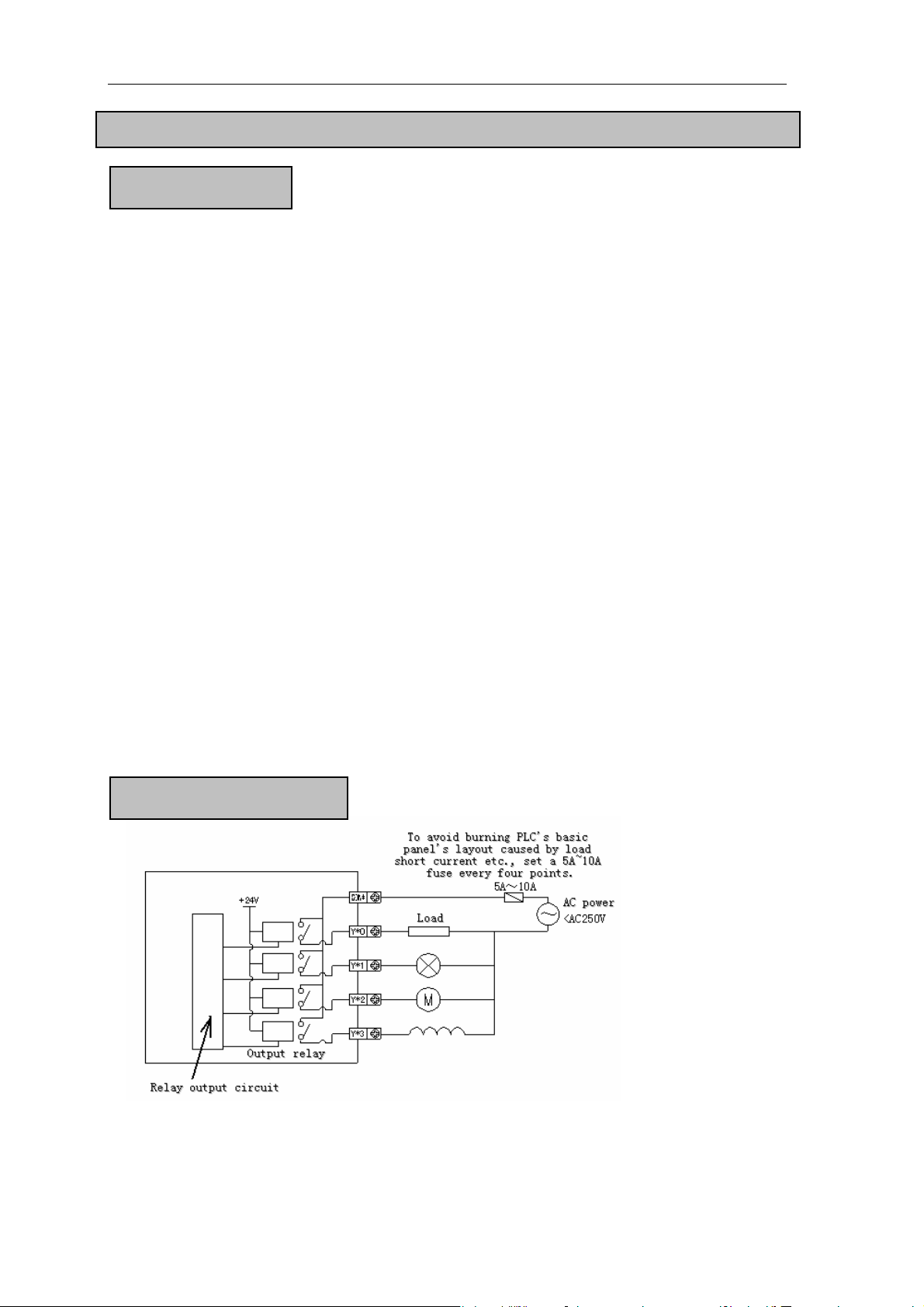

2-6. Disposal of Relay Output Circuit

Relay output circuit

z Output terminals

Relay output type includes 2~4 public terminals. So each public-end unit can drive different

power-voltage system’s (E.g.:AC200V,AC100V,DC24V etc.) load.

z Circuit’s insulation

Between the relay output coils and contacts,PLC’s interior circuits and exterior circuits, load

circuits are electric insulation. Besides, each public-end blocks are separate.

z Action display

LED lamp lights when output relay’s coils galvanize, output contacts are ON.

z Response time

From the output relay galvanize (or cut) to the output contacts be ON (or OFF), the response time is

about 10ms

z Output current

The current-voltage below AC250V can drive the load of pure resistace 2A/1 point、inductance load

below 80VA(AC100V or AC200V) and lam load below 100W(AC100V or AC200V).

z Open circuit’s leak current

When the output contact be OFF and there’s no leak current,can directly drive Ne lamp etc.

z The life of relay output contacts

Standard life of induce AC load such as cont ctor、electromagnetism valve:5 million times for

20VA load. Cut power device’s life according t the company’s test: for 80VA load, the action life is

up to 2 million times. But if the load parallel nnect with surge absorber, the life will be greatly

improved!

Output connection example

p

a

o

co

27

Spec., Input/output and layout

Constitution

of output

circuit

DC load

AC load

z For DC induce load, please parallel connect with commutate diode.

If not connect with the commutate diode, the contact’s life will be

decreased greatly. Please choose the commutate diode which allow

inverse voltage endurance up to 5~10 times of the load’s voltage,

ordinal current exceeds load current.

z Parallel connect AC induce load with surge absorber can reduce

noise.

28

Spec., Input/output and layout

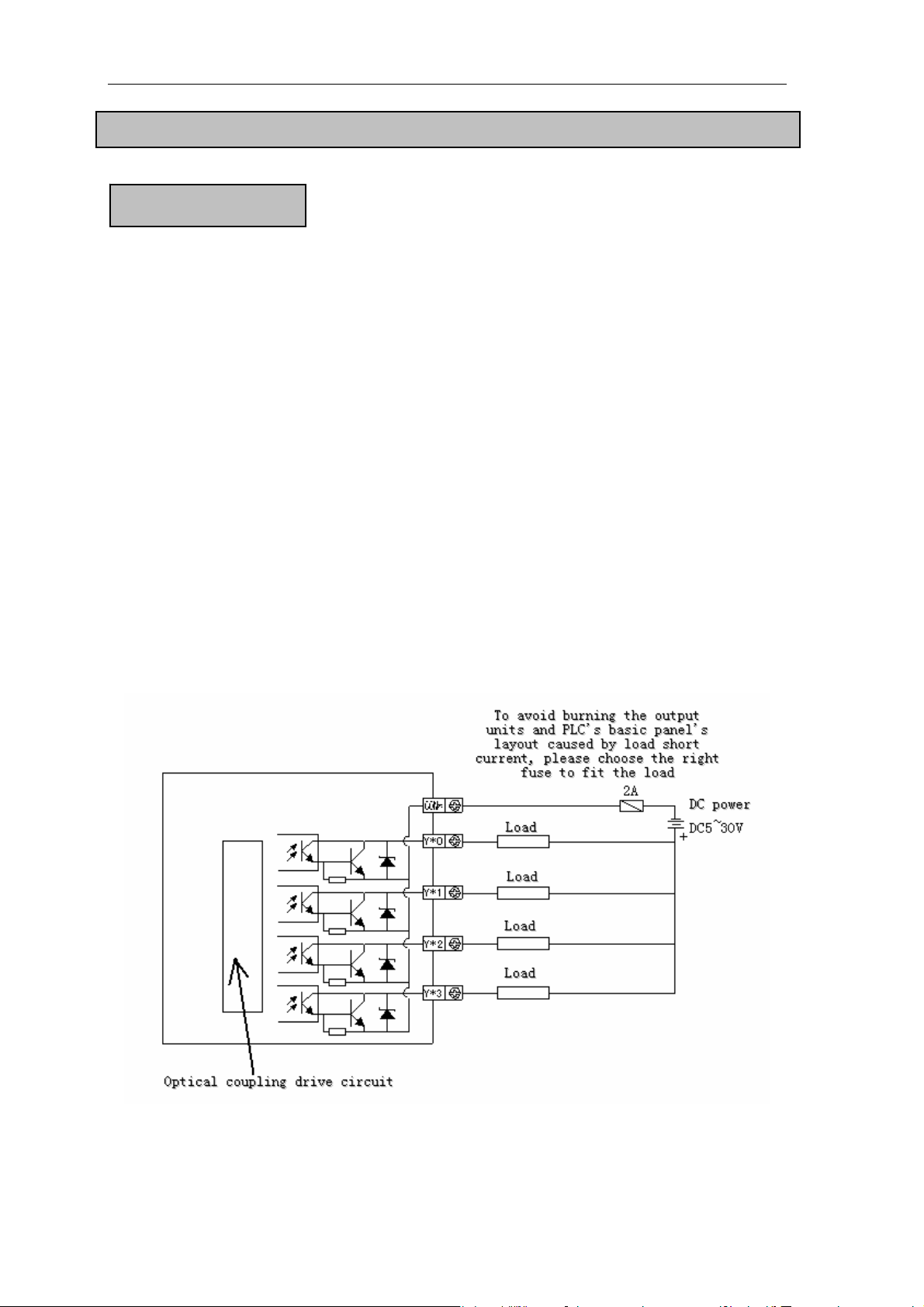

2-7. Disposal of Transistor Output Circuit

Transistor output circuit

¾

z Output terminal

Basic unit’s transistor output has 1~4 public-end output.

z Exterior power

Please use DC5~30V steady-voltage power for load drive,

z Circuit insulation

Use photoelectricity coupling device to insulate PLC’s interior circuit and output

transistor. Besides, each public block is separate.

z Action denote

When drive optical coupling,LED lights,output transistor is ON.

z Response time

From photoelectricity coupling device drive (or cut) to transistor ON (or OFF), the time

PLC uses is below 0.2ms.

z Output current

The current is 0.5A per point。But as restrict by temperature goes up, the current is 0.8A

every four points.

z Open circuit’s current

Below 0.1mA

29

3. Each Soft Unit’s Usage and Function

T his chapter, we’ll give some description of the PLC’s data and the function of interior input/output relay, auxiliary

lay, status, counter, data register etc. This item is the base to use PLC. re

3-1.Every Soft Unit of PLC

3-2.Soft Unit’s ID List

3-3.Disposal of Data

3-4.Some Encode Principle of Soft Units

3-5.Timer’s ID and Function [T]

3-6.Counter’s ID and Function [C]

3-7.Note Items

31

Function of each device

3-1. Every Soft Unit of Programmable Controller

In the programmable controller, there are many relays、timers and counters,they all have

countless “a” contacts(Normally open contacts)and “b” contacts(Normally closed contacts),

Connect these contacts and coils to constitute sequencial control circuit. The following, we’ll

briefly introduce each soft unit:

【Input(X)and output(Y)relay】

z In each basic unit, assign the ID of input relay, output relay in the format of

X000~X007,X010~X017…,Y000~Y007,Y010~Y017… this octal format. The ID of

extension is connected behind basic unit.

z The ID of expansion obeys the principle of channel 1 starts from X100/Y100, channel 2

starts from X200/Y200… 7 expansions could be connected totally.

z Use digital filter in the special input filter of input relay, so you can use the program to

change the sieve value. So in the high-speed receive application, you can assign this type

of relay’s ID No.

【Auxiliary relay(M)】

z Auxiliary relay is the relay inside the programmable controller,this type of output relay

is different from input/output relay,it can’t gain exterior input,it also can’t drive exterior

load,it can only be used in the program。

z The relay used for retentive can still save its ON/OFF status in the case of PLC power

cut.

【Status(S)】

z Relay used as step ladder chart.

z When not used as working procedure No.,it’s the same with auxiliary relay and can be

used as common contact/coil to carry on programming. Besides, it can also be signal

alarm to diagnose exterior trouble.

【Timer(T)】

z Timer could carry on plus operation to 1ms,10ms,100ms etc. time pulse in PLC, When

reach certain set value, output contact act.

z T100~T199 are timers with the unit of 100ms clock pulse,their current values are the

accumulate values. So, even though timer coil’s drive input is cut, they will still hold the

current value, go on accumulating the action.

32

Function of each device

【Counter(C)】

z The counters can be divided into the following sorts according the their usage and

purpose:

[Used for interior count] Common use / power failure retentive use

16 bits counter:Used for plus count,count bound: 1~32,767

32 bits counter:Used for add / minus count,count bound: -2,147,483,648~+2,

147,483,647

These counters are used for PLC’s interior signals, usually their response speed is below

10Hz.

[Used for high-speed count] For power failure retentive use

32 bits counter: For plus / minus count, count bound: -2,147,483,648~+2,147,483,6487

(Single phase plus count,single phase plus/minus count,AB phase

count) allocate to the special input points.

High-speed counter can count with the frequency below 200kHz,independent with the

PLC’s scan cycle.

【Data register(D)】

z Data register is the soft unit used by data register to save data. XC series PLC’s data

registers are all 16 bits (The high bit is the sign bit), Combine two registers can carry on

32 bits data disposal (The high bit is the sign bit).

Just the same with other soft units, data registers can also be divided to be two types: for

common use and power failure retentive use.

【Constant(K)、(H)】

z In the diverse value used by PLC, K means decimal integer,H means Hex. Value. They

are used to be the set value and current value for the timer and counter, or applied

instructions’ operands.

【Pointer(P)(I)】

z Pointers are used for branch and interrupt. The pointer (P) used by branch is the jump

aim used for condition jump or subroutine jump. Pointer used for interrupt is used for the

assigned input interrupt, time interrupt.

33

3-2. Device’s ID List

For the allocate of device’s ID, please see the following list:

Besides, when connect input / output expansions and special expansions on the basic units, for

the input / output relay’s No., please refer to the user manual.

Mnemonic Name

X Input relay X000~X007

Y Output relay Y000~Y005

M Interior relay

S Flow

T Timer

C Counter

D Data Register

FD

FlashROM

Register

Bound points

14 points 24\32 points 48 \60 points

X000~X015

X000~X021

Y000~Y011

Y000~Y015

M0~M2999【M3000~M7999】 8000

M8000~M8511 for special using 512

S0~S511

【S512~S1023】

T0~T99:100ms not accumulation

T100~T199:100ms accumulation

T200~T299:10ms not accumulation

T300~T399:10ms accumulation

T400~T499:1ms not accumulation

T500~T599:1ms accumulation

T600~T618:1ms with interruption precise time

C0~C299:16 bits forth counter

C300~C598:32 bits forth/back counter

C600~C634:high-speed counter

D0~D3999

【D4000~D7999】

For special usage D8000~D8511 512

FD0~FD1535 1536

For special usage FD8000~FD8511 512

X000~X033

X000~X043

Y000~Y023

Y000~Y027

Function of each device

14

24\32

points

8 points

6 points

points

14\18

points

10\14

points

1024

620

635

8000

48 \60

points

28\36

points

20\24

points

34

Function of each device

NOTE:

※1. The memorizer area in 【 】 is the defaulted power failure retentive area;soft

elements D、M、S、T、C can be set to change the power failure retentive area. For the

details, please see the following table

※2. FlashROM register needn’t set power failure retentive, its data won’t lose when power is

cut (No battery).

※3. The serial No. of input coil、output relay are octal data, other memorizers’ No. are all

algorism data.

Setting of soft unit’s power failure saving area:

Mnemonic Set area Function

D FD8202

M FD8203

T FD8204

C FD8205

S FD8206

Start denotation of D power

cut save area

Start denotation of M power

cut save area

Start denotation of T power

cut save area

Start denotation of C power

cut save area

Start denotation of S power

cut save area

System’s

defaulted

value

4000 D4000~D8000

3000 M3000~M8000

620 Not set

320 C320~C640

512 S512~S1024

Memory bound

of power drop

35

Function of each device

3-3. Data Disposal of Programmable Controller

According to different usage and purpose, XC series programmable controllers use 5 types of

count format. For their usage and function, see the following:

《DEC》(DEC:DECIMAL NUMBER)

¾ The set value of timer and counter(K constant)

¾ The ID of auxiliary relay(M),timer(T),counter(C),status(S)(Soft

unit’s number)

¾ Assign the value in the operands and instruction’s action(K constant)

《HEX》(HEX:HEXADECIMAL NUMBER)

¾ The same with DEC data,it is used to assign the value in the operands and

instruction’s action(H constant)

《BIN》(BIN:BINARY NUMBER)

¾ Just as said before,carry on data allocation to timer, counter or data register in

the format of DEC. or Hex., But in the PLC, these data are all be put in the

format of binary data. And, when carry on monitor on the peripherial device,

these soft units will auto switch to be DEC. data as shown in the graph.(they

can also switch to be Hex. Data.).

《OCT》(OCT:OCTAL NUMBER)

¾ The input relay, output relay’s soft units’ ID of XC series PLC are allocate in

the format of OCT data. So, it can go on carry of [1-7,10-17,...70-77,

100-107].

《BCD code》(BCD: BINARY CODE DECIMAL)

¾ BCD is the method which use 4 bits binary to denote decimal 0~9. It’s easy to

despose bit. So, BCD is available to denote digital switch or 7 segments display

control.

《Other data(float)》

¾ XC series PLC has the function of high precision floating point operation. Use binary

floating point data to execute floating point operation, use decimal floating value to

execute monitor.

36

3-4. Some encode principles of device

1、Data register could be used as offset(indirect assignment)

Format:Dn[Dm]、Xn[Dm] 、Yn[Dm] 、Mn[Dm] etc.

Function of each device

M8002

M2

M8000

MOV K0 D0

MOV K5 D0

MOV D10[D0] D100

Y0[D0]

In the preceding example, when D0=0, then D100=D10, Y0 is ON;

z Word’s offset composed by bit soft units:DXn[Dm] means DX[n+Dm];

z Soft units with offset, the offset could only be denoted with soft device D.

When M2 turns from OFF to be ON, D0=5, then D100=D15, Y5 is ON.

When D10[D0]=D[10+D0], Y0[D0]=Y[0+D0].

2、 Bit units compose word

Input X、output Y、middle coil M could compose 16 bits word. E.g. DX0 means

X0~X17compose to be a 16 bits data. DX20 means X20~X37 combines a 16 bits data.

Format:Add a D before bit device

Bit devices combine to be word devices:DX、DY、DM、DS、DT、DC

M0

M1

M8000

MOV K21 DY0

MOV K3 D0

MOV DX2[D0] D10

In the preceding example, when M0 turns from OFF to be ON, the value of the word DY0 composed

by Y0~Y17 equals 21,i.e. Y0、Y2、Y4 turns to be ON status.

Before M1 be activate, when D0=0, DX2[D0] means a word composed by X2~X21;

When M1turns from OFF to be ON, D0=3, then DX2[D0] means a word composed by X5~X24

z DXn(the bound of “n” is the exact bound of “X”),choose 16 points from the head to the end,

add 0 if not enough.

z Please note, the word composed by bit device couldn’t carry on bit searching address.

37

Function of each device

3、 Bit of word device

Format:Dn.m

Register could carry on bit searching address, e.g. Dn.m means number “m” bit of Dn data

register(0≤m≤15)。

D0.4

Y0

D5[D1].4

Y1

In the preceding example, D0.4 means when the No.4 bit of D0 is 1, Y0 set ON;

D5[D1].4 means bit searching address with offset, if D1=5,it says D5[D1] means the number 4

bit of D10.

z The bit of word device with offset is denoted as Dn[Dm].x

z Please note, to the bit of word device, they couldn’t combined to be word device.

4、 T/C means the difference of register’s word and bit

To T and C register, Tn/Cn means be a bit register or a word register should be

distinguished by the instructions.

T、C could denote the status of timer、counter, or the current value of time、counter, it is

distinguished by the instructions.

X0

T11

K99

M0

T11

MOV D0T11

Y1

In the preceding example,MOV T11 D0,T11 means word register;

LD T11,T11 means bit register.

5、 Tag type:P,I

e.g.:P means the tag which using CJ instruction or CALL instruction which could jump; I

means interrupt tag.

38

3-5. Timer’s Number and Function [T]

Timer’s number

100ms not accumulated(16 bits) T0~T99

100ms accumulated(16 bits) T100~T199

10ms not accumulated(16 bits) T200~T299

10ms accumulated(16 bits) T300~T399

1ms not accumulated(16 bits) T400~T499

1ms accumulated(16 bits) T500~T599

Function

The timer accumulates clock pulse of 1ms,10ms,10ms inside PLC. When

reach the set value, the output contact activates.

The common timers don’t set exclusive instructions, use OUT instruction

to time; use constant K in the program memory, also you could use

register’s content (D) to indirect assign.

Please see the following table for the timer’s [T] number (the

number is assigned according to Hex.)

Function of each device

Common format Accumulation format

If drive input X000 of time coil T200

is ON, T200 accumulates 10ms clock

pulse with the current value timer. If

this current value equals the set value

K200, timer’s output contact activates.

That is, output contact activates after 2

seconds of coil driving. Driving input

X000 cut or power cut, timer reset,

output contact reset.

If the drive input X001 of timer’s coil

T300 is ON, T300 accumulates 10ms

clock pulse with the current value

counter. When the value reaches the set

value K2000, counter’s output contact

activates. In the count process, even the

input X001 cut or drop power, when start

again, go on counting, its accumulation

time is 20 seconds. When reset input

X002 is ON, timer reset, output contact

reset.

39

Assign

method of

the set value

The Time

Value

Action

Function of each device

《Constant assignment (K)》

X0

T10 K100

T10 is a timer with the unit of

100ms. Assign 100 as a constant,

then 0.1s×100=10s timer work.

《Indirect assignment (D)》

X0

MOV K200 D5

X1

T10 D5

Write content in indirect data register

to program or input via data switch.

When assigned as power cut retentive

register, please note that voltage low

will cause the set value instable.

The count format of Timers T0~T599 is 16 bits linear increment mode

(0~K32 ,767). If the timer’s count value reaches the maximum value K32767,

the timer will stop timing , the timer’s status will remain the same status.

《Output delay on-off timer》

X0

Y0 X0

T2

Y0

T2

K200

X0

Y0

T2

When X000 is ON, output Y000;

If X000 changes from ON to be OFF, T2(20 seconds)will be delayed, the will

n

output Y000 cut.

《Flicker》

X0

T1

If X000 activates, Y000 starts flicker output.

T1 controls the OFF time of Y000, T2 controls the ON time of Y000.

T2

T1

T2

Y0

K20

K10

X0

T1 T2 T1

Y0

40

Function of each device

3-6. Counter’s ID and

Counter’s ID

Counter’s

characters

Items 16 bits counter 32 bits counter

Count direction Positive Positive/negative

The set value 1~32,767 -2,147,483,648~+2,147,483,647

The assigned set

value

Changing of the

current value

Output contact

Reset activates

The current value

register

For the counter’s number (C), ple r to the following table: ase refe

function [C]

16 bits positive counter 299

32 bits positive/negative

counter

High speed counter

The characters of 16 bits counter and 32 bits counter are shown below:

Constant K or data

register

Change after positive

count

Hold the action after

positive count

When executing RST command,counter’s current value is 0,

output contacts recover

16 bits 32 bits

C0~C

C300~C598 (C300, C302...C598) (Each one

engrosses 2 counter No.) The number must be

even.

C600~C634(C600,C602...C634) (Each one

engrosses 2 counter No.) The number must be

even

Same as the left, but data register

must be in a couple

Change after positive count (Loop

counter)

Hold the action after positive count,

reset if negative count

41

Function of each device

Function

About the assignment of normally used counter and power failure retentive

counter, they could be changed in the method of changing FD parameters’

settin via the peripheral device. g

16 bits counter For normally use or power count r etentive

16 bits binary increment counter, its valid setting value is K1~K32,767

(Decimal constant). The set value K0 and K1 have the same meaning, i.e. act

when output contacts at the beginning of first time count.

If cut the PLC’s power, then the value

X0

RST C0

X1

C0 K10

of the normally use counter will be

reset. However, counter used by power

cut retentive could save the count

value after power cut, and the counter

will go on counting from the value.

C0

Y0

z Every time when X001 drives coil C0, the counter’s current value will

increase. When execute the coil instruction the tenth time, output contact

acts. Later, even X001 activates, counter’s current value will not change.

z If reset input X000 is ON, execute RST instruction, counter’s current

value is 0, output contacts activates.

z For the counter’s set value, it could not only set by constant K, but also be

assigned by data register’s ID. E.g. assign D10, if the content of D10 is

123, it’s the same with setting K123.

z When write the set value to the current value register via MOV instruction

etc. When input next time, output coil gets, current value register turns to

the set value.

42

Function of each device

32 bits counter For normally use or power count r etentive

Assign

method of

the set value

For 32 bits binary increment counter, its valid bound is K1~K2,147,483,647

(Decimal constant). With special auxiliary relay M8238, assign the direction of

bits positive/negative counter’s (C300~C498) direction

z If X2 drives M8238, then it is

negative count;If no drive, then it is

X2

M8238

X3

RST C300

X4

C300 K10

positive count.

z According to constant K or to the

content of data register D, set the

value to be positive. Treat contents

in consecutive data register as a

pair, and dispose it as 32 bits data.

So, when assign D0, dispose D0

C300

Y1

and D1 as a 32 bits set data. If use

count input X004 to drive coil

C300, execute increase count.

z When reset input X3 is ON, execute RST instruction, counter’s current

value turns to be 0, output contact resets.

z When use counter as power cut retentive, counter’s current value, output

contact’s action and reset status cut power retentive.

z 32 bits counter can also be used as 32 bits data register. But 32 bits data

register can’t be used as device in 16 bits applied instructions.

16 bits counter

《Constant assignment(K)》

X001

C0

K100

《Indicate assignment(K)》

X000

X001

MOV K100 D5

C0 D5

43

Function of each device

32 bits counter

《Constant assignment(K)》

The count

value

X001

C300

K43,100

《Indicate assignment(K)》

X000

X001

DMOV K43100 D0

C300

D0

( D1)

The count mode of counters T0~T599 is 16 bits linear increment mode

(0~K32767). When counter’s count value reaches the max value K32767, the

counter will stop counting, the counter’s status will remain.

44

Function of each device

3-7. Some Points to Note

Action order of input/output relay and response delay》

《

Input disposal

Before PLC executing the program, read all the input terminal’s ON/OFF status of PLC to

the image area. In the process of executing the program, even the input changed, the content

in the input image area will not chang

read out the change.

Output disposal

Once finish executing all the instructions, transfer the ON/OFF status of output Y image

area to the output lock memory area. This will be the actual output of the PLC. The

contacts used for the PLC’s exterior output will act according to the device’s response

delay time.

When use this input/output f

filter and output device will also appear response delay.

ormat in a batch, the drive time and operation cycle of input

e. However, in the input disposal of next scan cycle,

《Not accept narrow input pulse signal》

PLC’s input ON/OFF time should be longer than its loop time. If consider input filter’s

response delay 10ms, loop time is 10ms,then ON/OFF time needs 20 ms separately. So, up to

1,000/(20+20)=25Hz input pulse can’t be disposed. But, this condition could be improved

when use PLC’s special function and applied instructions.

Dual output(Dual coils)action》

《

X1

Y3

X2

Y3

Y4

Y3

When executing dual output (use dual coil),

the back side act in prior

As shown in the left map, please consider

the things of using the same coil Y003 at

many positions:

E.g. X001=ON,X002=OFF

At first, X001 is ON, its image area is ON,

output Y004 is also ON.

But, as input X002 is OFF, the image area

of Y003 is OFF.

So, the actual output is : Y003=OFF,

Y004= ON.

45

4. Basic Program Instructions

In this chapter, we tell some basic instructions and their functions.

4-1.List of Basic Instructions

4-2.【LD】,【LDI】,【OUT】

4-3.【AND】,【ANI】

4-4.【OR】,【ORI】

4-5.【LDP】,【LDF】,【ANDP】,【ANDF】,【ORP】, 【ORF】

4-6.Compare Instructions

4-7.【ORB】

4-8.【ANB】

4-9.【MCS】,【MCR】

4-10.【ALT】

4-11.【PLS】, 【PLF】

4-12.【SET】, 【RST】

4-13.【OUT】, 【RST】 (Compare with counter’s soft unit)

4-14.【NOP】, 【END】

4-15.Note Items When Programming

46

4-1. List of Basic Instructions

XC1, XC3, XC5 series basic SFC instructions

Mnemonic Function Format and Device

LD

(LoaD)

LDI

(LoaD Inverse)

LDP

(LoaD Pulse)

LDF

(LoaD Falling Pulse)

AND

(AND)

ANI

(AND Inverse)

ANDP

(AND Pulse)

ANDF

(AND Falling pulse)

OR

(OR)

ORI

(OR Inverse)

ORP

(OR Pulse)

ORF

(OR Falling pulse)

ANB

(ANd Block)

ORB

(OR Block)

OUT

(OUT)

SET

(SET)

RST

(ReSeT)

PLS

(PuLSe)

PLF

(PuLse Falling)

Initial logical operation contact

type NO (normally open)

Initial logical operation contact

type NC (normally closed)

Initial logical operation-Rising

edge pulse

Initial logical operation-Falling

/trailing edge pulse

Serial connection of NO

(normally open) contacts

Serial connection of NC

(normally closed) contacts

Serial connection of rising edge

pulse

Serial connection of

falling/trailing edge pulse

Parallel connection of NO

(normally open) contacts

Parallel connection of NC

(normally closed) contacts

Parallel connection of rising edge

pulse

Parallel connection of

falling/trailing edge pulse

Serial connection of multiply

parallel circuits

Parallel connection of multiply

parallel circuits

Final logic operation type coil

drive

Set a bit device permanently ON Y, M, S, T, C, Dn.m

Reset a bit device permanently

OFF

Rising edge pulse X, Y, M, S, T, C, Dn.m

Falling/trailing edge pulse X, Y, M, S, T, C, Dn.m

Basic SFC Functions

X, Y, M, S, T, C, Dn.m, FDn.m

X, Y, M, S, T, C, Dn.m, FDn.m

X, Y, M, S, T, C, Dn.m, FDn.m

X, Y, M, S, T, C, Dn.m, FDn.m

X, Y, M, S, T, C, Dn.m, FDn.m

X, Y, M, S, T, C, Dn.m, FDn.m

X, Y, M, S, T, C, Dn.m, FDn.m

X, Y, M, S, T, C, Dn.m, FDn.m

X, Y, M, S, T, C, Dn.m, FDn.m

X, Y, M, S, T, C, Dn.m, FDn.m

X, Y, M, S, T, C, Dn.m, FDn.m

X, Y, M, S, T, C, Dn.m, FDn.m

None

None

Y, M, S, T, C, Dn.m

Y, M, S, T, C, Dn.m

47

Basic SFC Functions

MCS

(New bus line start)

MCR

(Bus line return)

ALT

(Alternate state)

NOP

(No Operation)

END

(END)

Connect the public serial contacts None

Clear the public serial contacts None

The status of the assigned device

X, Y, M, S, T, C, Dn.m

is inverted on every operation of

the instruction

No operation or null step None

Force the current program scan to

None

end

48

4-2. 【LD】,【LDI】,【OUT】

Mnemonic

Mnemonic Function Format and Devices

LD

(LoaD)

Initial logic operation

contact type NO (Normally

Open)

LDI

(LoaD Inverse)

Initial logic operation

contact type NC (Normally

Closed)

OUT

(OUT)

Final logic operation type

drive coil

Basic SFC Functions

Devices: X, Y, M, S, T, C, Dn.m,

FDn.m

M0

Devices: X, Y, M, S, T, C, Dn.m,

Dn.m F

D

evices: X, Y, M, S, T, C, Dn.m,

FDn.m

Statement

z Connect the LD and LDI instructions directly to the left bus bar. Or use

them to define a new block of program when using ANB instruction.

z OUT instruction is the coil drive instruction for the output relay、

auxiliary relay、status、timer、counter. For the input relay, cannot use.

z Can not sequentially use parallel OUT command for many times.

z For the timer’s time coil or counter’s count coil, after using OUT

instruction, set constant K is necessary.

z For the constant K’s set bound、actual timer constant、program’s step

relative to OUT instruction(include the set value)

See the following table

r Setting bound of K Timer/Counte The actual set value

1ms timer 0.001~32.767 seconds

1~32,767

10ms timer 0.01~32.767 seconds

100ms timer

0.1~32.767 seconds

16 bits counter 1~32,767 Same as the left

32 bits cou ter 1~2,147,483,647 Same as the left n

49

Basic SFC Functions

X0

Program

X1

T0

-3. 【AND】,【ANI】

4

Mnemonic Function Format and Devices

Mnemonic

AND

(AND)

ANI

(ANd Inverse)

Y100

M1203

T 0

Y 1

Serial connection of

NO (Normally Open)

contacts

Serial connection of

NC (Normally Closed)

contacts

K19

Devices

Devices

LD X0

OUT Y100

LDI X1

OUT M120

3

OUT T0

SP K19

LD T0

OUT Y1

M0

: X, Y, M, S, T, C, Dn.m, FDn.m

M0

: X, Y, M, S, T, C, Dn.m, FDn.m

Description

Program

z Use the AND and ANI instructions for serial connection of contacts.

As many contacts as required can be connected in series. They can

be used for many times.

z The output processing to a coil, through writing the initial OUT

instruction is called a “follow-on” output (For an example see the

program below: OUT M2 and OUT Y003). Follow-on outputs are

permitted repeatedly as long as th

no limit for the serial connected

e output order is correct. There’s

contacts’ No. and follow-on outputs’

number.

X2 M1

X3Y2

T1

Y2

M2

Y3

LD X2

AND M1

OUT Y2

LD Y2

ANI X3

50

4-4. 【OR】,【ORI】

Mnemonic

and

Function

Mnemonic Function Format and Devices

OR

(OR)

ORI

(OR Inverse)

Description

z Use the OR and ORI instructions for parallel connection of contacts.

z OR and ORI start from the instruction’s step, parallel connect with the

Basic SFC Functions

Parallel connection of

NO (Normally Open)

contacts

Devices: X, Y, M, S, T, C, Dn.m, FDn.m

Parallel connection of

NC (Normally Closed)

contacts

Devices: X, Y, M, S, T, C, Dn.m, FDn.m

To connect a block that contains more than one contact connected in

series to another circuit block in parallel, use an ORB instruction.

LD and LDI instruction’s step said before. There is no limit for the

parallel connect times.

Program

LD X5

OR X6

OR M11

OUT Y6

LDI Y6

AND M4

OR M12

ANI X7

OR M13

51

Basic SFC Functions

Relationship

with ANB

M11

M12

M13

X5

X6

Y6 M4 X7

Y6

M100

The parallel connection with

OR, ORI instructions should

connect with LD, LDI

instructions in principle. But

after the ANB instruction,

it’s available to add a LD or

LDI instruction.

4-5. 【LDP】,【L 【AND P ,【ORF】

DF】, P】,【ANDF】,【OR 】

52

Mnemonic

and

Function

Description

Program

Basic SFC Functions

Mnemonic Function Format and Devices

LDP

(LoaD Pulse)

Initial lo

operation-Rising edge

gical

pulse

Devices: X, Y, M, S, T, C, Dn.m, FDn.m

LDF

(LoaD Falling

pulse)

ANDP

(AND Pulse)

Initial logical

operation

Falling/trailing edge

pulse

Devices: X, Y, M, S, T, C, Dn.m, FDn.m

Serial connection of

Rising edge pulse

Devices: X, Y, M, S, T, C, Dn.m, FDn.m

ANDF Serial connection of

(AND Falling

pulse)

ORP

(OR Pulse)

ORF

(OR Falling

pulse)

Falling/trailing edge

pulse

Parallel connection of

Rising edge pulse

Parallel connection of

Falling/trailing edge

pulse

Devices: X, Y, M, S, T, C, Dn.m, FDn.m

Devices: X, Y, M, S, T, C, Dn.m, FDn.m

Devices: X, Y, M, S, T, C, Dn.m, FDn.m

z LDP、ANDP、ORP are active for one program scan after the

associated devices switch from OFF to ON.

z LDF、ANDF、ORF are active for on

associated devices switch from ON to

X5

X6

M8000 X7

M13

M15

e program scan after the

OFF.

LDP X5

ORP X6

OUT M13

LD M8000

ANDP X7

OUT M15

X5

X6

M8000 X7

M13

M15

In the preceding chart, when X005~X007 turns from ON t OFF or

om OFF to ON, M13 or M15 has only one scan cycle activates.

fr

o

LDF X5

ORF X6

OUT M13

LD M8000

ANDF X7

OUT M15

53

Basic SFC Functions

Output drive

In two conditions, when X0 turns from OFF to ON, M20 gets a scan cycle.

NOTE:

X10

X10

MOV

MOV

K10 D0

K10 D0

When X10 turns from OFF to ON,

only execute once MOV instruction.

When X10 turns from OFF to ON,

each scan cycle execute once MOV

instruction.

54

4-7. 【ORB】

Mnemonic

and

Function

Description

Basic SFC Functions

Mnemonic Function Format and Devices

ORB

(OR Block)

Parallel connection of

multiply parallel circuits

Devices: none

z To declare the starting point of the circuit (usually serial circuit blocks)

to the preceding circuit in parallel. Serial circuit blocks are those in

which more than one contacts in series or the ANB instruction is used.

z An ORB instruction is an independent instruction and is not associated

with any device number.

z There are no limitations to the number of parallel circuits when using an

ORB instruction in the sequential processing configuration.

z When using ORB instructions in a batch, use no more than 8 LD and

LDI instructions in the definition of the program blocks (to be

connected parallel).

Program

Recommended sequencial

programming method:

LD X0

AND X1

LD X2

AND X3

ORB

LDI X4

AND X5

ORB

Non-preferred batch

programming

method:

LD X0

AND X1

LD X2

AND X3

LDI X4

AND X5

ORB

55

4-8. 【ANB】

Mnemonic

Description

Basic SFC Functions

Mnemonic Function

ANB

(ANd Block)

Serial connection of

multiply parallel circuits

Format and Devices

Devices: none

z To declare the starting point of the circuit block, use a LD or LDI

instruction. After completing the parallel circuit block, connect it to the

preceding block in series using the ANB instruction.

z It is possible to use as many ANB instructions as necessary to connect a

number of parallel circuit blocks to the preceding block in series. When

using ANB instructions in a batch, use no more than 8 LD and LDI

instructions in the definition of the program blocks (to be connected in

parallel)

Program

Start of a branch

Start of a branch

End of a parallel circuit block

End of a parallel circuit block

Serial connect with the preceding circuit

LD X0

OR X1

LD X2

AND X3

LDI X

AND

X5

ORB

4

OR X6

ANB

OR X7

OUT Y20

56

4-9. 【MCS】,【MCR】

Mnemonic

Mnemonic

MCS

(Master control)

MCR

(Master control

Reset)

Description

z After the execution of an MCS instruction, the bus line(LD、LDI)shifts

to a point after the MCS instruction. An MCR instruction returns this to

the original bus line.

z MCS、MCR instructions should use in pair.

z The bus line could be used nesting. Between the matched MCS、MCR

instructions use matched MCS、 MCR instructions. The nest level

increase with the using of MCS instruction. The max nest level is 10.

When executing MCR instruction, go back to the upper bus line.

z When use flow program, bus line management could only be used in the

same flow. When end some flow, it must go back to the main bus line.

Function Format and Devices

Denotes the start

of a master control

block

Devices

: None

Denotes the end of

a master

control

block

Devices

: None

Basic SFC Functions

Y0

Y0

Description

X1 X2

M3M1

M2

Y0

Y1

Y2

MCS

LD X2

OUT Y0

LD M1

MCS

Bus line starts

Bus line nest

LD M3

OUT Y1

LD M2

OUT Y2

MCR

LD X1

MCR

Bus line back

57

4-10. 【ALT】

Mnemonic

and

Function

Description

Program

Basic SFC Functions

Mnemonic Function Format and Devices

ALT

(Alternate

status)

The status of the assigned

devices inverted on every

operation of the instruction

M0ALT

Devices: Y, M, S, T, C, Dn.m

The status of the destination device is alternated on every operation of the

ALT instruction.

M100

M0ALT

LDP M100

ALT M0

M0

Y0

M0

Y1

LD M0

OUT Y0

LDI M0

OUT Y1

58

4-11. 【PLS】,【PLF】

Mnemonic

and

Function

Mnemonic Function Format and Devices

PLS

(PuLSe)

PLF

(PuLse

Falling)

Description

z When a PLS instruction is executed, object devices Y and M operate

for one operation cycle after the drive in ut signal has turned ON.

z When a PLF instruction is executed, object devices Y and M operate

for one operation cycle after the drive input signal has turned OFF.

X0

Program

M0

X1

M1

Rising edge pulse

Falling/trailing edge pulse

PLS M0

SET Y0

PLF M1

RST Y0

Basic SFC Functions

Devices: Y, M, S, T, C, Dn.m

Devices: Y, M, S, T, C, Dn.m

p

LD X0

PLS M0

LD M0

SE

T Y0

----------------------

LD X1

PLF M1

LD M1

RST Y0

59

4-12. 【SET】,【RST】

Mnemonic

and

Function

Mnemonic

SET

(SET)

RST

(ReSeT)

Description

z Turning ON X010 causes Y000 to turn ON. Y000 remains ON even

after X010 turns OFF. Turning ON X 1 causes Y000 to turn OFF.

Y000 remains OFF even after X011 turns OFF. It’s the same with M、

S.

z SET and RST instructions can be used for the same device as many

times as necessary. However, the last instruction activated determines

the curre

After assignz

opera

z Be io

contents

Basic SFC Functions

Function

Format and Devices

Set a bit device permanently

ON

Devices: Y, M, S, T, C, Dn.m

Reset a bit device

permanently OFF

Devices: Y, M, S, T, C, Dn.m

01

nt status.

the start definition ID and e

nds available.

in one bound at the same time is

sides, ssible to use RST instruct n to reset the current

it’s also po

nd defi he

nition ID, operate t

of timer, counter and contacts.

Program

X10

X11

X12

X13

X14

X15

X10

X17

SET

RST

SET

RST

SET

RST

RST

Y0

Y0

M50

M50

S0

S0

K10

T250

T250

LD X10

SET Y0

LD X11

RST Y0

LD X12

SET M50

LD X13

RST M50

LD X14

SET S0

LD X15

RST S0

LD X10

OUT T250

SP K10

LD X17

RST T250

60

4-13. 【OUT】,【RST】for the counters

Mnemonic

and

Function

Mnemonic Function Format and Devices

OUT

(OUT)

RST

(ReSeT)

Final logic operation type

coil drive

Reset a bit device

permanently OFF

Programming

Counter used for ut retentive.

power c

Even when power is cut, hold the current

value and output contact’s action status

and reset status.

Basic SFC Functions

K or D

C0 carries on increase count for the

OFF→ON of X011. When reach the

value K10, output contact C0

set

activates. Afterwards, even X011 turns

m OFF to ON, counter’s current

fro

value will not change, output contact

keep on activating.

To clear this, let X010 be the activate

status and reset the output contact. It’s

necessary to assign constant K or

indirect data register’s ID behind OUT

instruction.

Programming

of high speed

counter

z In the preceding example, when M0 is ON, carry on positive count with OFF→ON

of X0.

z Counter’s current value increase, when reach the set value (K or D), the output

contact is reset.

z When M1 is ON, counter’s C600 output contact is reset, counter’s current value turns

to be 0.

61

4-14. 【NOP】,【END】

Mnemonic Function Format and Devices: None

NOP No operation

(No

Operation)

END Force t

(END)

Description

z When clear the whole program, all the instructions become NOP. If add

NOP instructions between the common instructions, they have no effect

and PLC will keep on working. If add NOP instructions in the program,

then whe

the program should have rest quantity.

z If replace the program’s instructions

AND→NOP ANI→NOP

Contacts short circuit

Basic SFC Functions

or null step

he

current

program scan

to end

Devices: None

Devices: None

n modify or add programs, the step vary will be decreased. But

with NOP instructions, then the

OUT→NOP

OR→NOP

ORI→NOP

Open circuit

PLC repeatedly carry on input disposal, program

executing and output disposal. If write END

instruction at the end of the program, then the

instructions behind END instruction won’t be

executed. If there’s no END instruction in the

program, the PLC executes the end step and then

repeat executing the program from step 0.

When debug, insert END in each program

segment to check out each program’s action.

Then, after confirm the correction of preceding

block’s action, delete END instruction.

Besides, the first execution of RUN begins with

END instruction.

When executing END instruction, refresh monitor timer. (Check if scan cycle is a long timer. )

62

Basic SFC Functions

4-15. Items To Note When Programming

, Contacts’ structure and step number

1

Even in the sequencial control circuit with the same action, it’s also available to simple the

program

a)write t

in the

and save program’s steps according to the contacts’ structure. General program principle is:

he circuit with many serial contacts on the top;b)write the circuit with many parallel contacts

left.

, Program’s executing sequence

2

Handle the sequencial control program by【From top to bottom】and【From left to right】

ncial control instructions also encode following this flow.

Seque

, Dual output dual coil’s activation and the solution

3

If carry on coil’s dual output (dual coil) in the sequencial control program, then the backward

z

action is prior.

Dual output (dual coil) doesn’t go against the input rule at the program side. But as the preceding

z

action is very complicate, please modify the program as in the following example.

X0 X2

X3 X4

Y0

Y0

X0 X2

X3 X4

X0 X2

X3 X4

M0

M1

Y0

M0

M1

Y0

There are other methods. E.g. jump instructions or step ladder. However, when use step ladder, if the

main program’s output coil is programmed, then the disposal method is the same with dual coil, please

note this.

63

5. Applied Instructions

In this chapter, we describe applied instruction’s function of XC series PLC.

5-1.Table of App ructions lied Inst

5-2.Reading Meth Applied Instructions od of

5-3.Flow Instructions

5-4.Contactors Co Instructions mpare

5-5.Move and Co nstructions mpare I

5-6.Arithmetic an on Instructions d Logic Operati

5-7.Loop and Shift tions Instruc

5-8.Data Convert

5-9.Floating Operation

5-10.Clock Operation

Applied Instructions

64

Applied Instructions

5-1. Applied Instruction List

The applied instructions’ sort a r correspond instructions are listed i ing table:

Common statements of XC1/ C5:

Sort ¾ Mnemonic Function

Program

Flow

Data

Compare

Data

Move

nd thei n the follow

XC3/X

CJ Co p ndition jum

CALL C e all subroutin

SRET Subro turn utine re

STL Flow start

STLE Flow end

SET Open the assi urrent flow gned flow, close the c

ST

FOR Start of a FOR-NEXT loop

NEXT End of a FOR-NEXT loop

FEND First end

LD= LD activates if (S1) = (S2)

LD> LD activates if (S1) > (S2)

LD< LD activates if (S1) =< (S2)

LD<> LD activates if(S1)≠(S2)

LD<= LD activates if(S1)≤(S2)

LD>= LD activates if(S1)≥(S2)

AND= AND activates if(S1)=(S2)

AND> AND activates if(S1)>(S2)

AND< AND activates if(S1)<(S2)

AND<> AND activates if(S1)≠(S2)

AND<= AND activates if(S1)≤(S2)

AND>= AND activates if(S1)≥(S2)

OR= OR activates if(S1)=(S2)

OR> OR activates if(S1)>(S2)

OR< OR activates if(S1)<(S2)

OR<> OR activates if(S1)≠(S2)

OR<= OR activates if(S1)≤(S2)

OR>= OR activates if(S1)≥(S2)

MOV Move

BMOV Block move

FMOV Fill move

FWRT FlashROM written

MSET Zone set

ZRST Zone reset

Open the assign ose the current ed flow, not cl

flow

65

Applied Instructions

Operation

Data

SWAP

XCH ange Exch

ADD tion Addi

SUB Subtraction

MUL iplication Mult

DIV Division

INC Increment

DEC Decrement

MEAN Mean

WAND Word And

WOR Word OR

WXOR Word exclusive OR

CML Compliment

NEG Negative

The high and low byte of the destinated devices

are exchanged

66

Common statements of XC3/XC5

SHL Arithmetic Shift Left

SHR Arithmetic Shift Right

LSL Logic shift left

LSR Logic shift right

Data Shift

Data

Convert

Float

Point

eration

Op

Clock

Operation

ROL Rotation shift left

ROR Rotation shift right

SFTL Bit shift left

SFTR Bit shift right

WSFL Word shift left

WSFR Word shift right

WTD Single word integer converts to double word integer

FLT 32 bits integer converts to float point

FLTD 64 bits integer converts to float point

INT Float point converts to binary

BIN BCD converts to binary

BCD Binary converts to BCD

ASC Hex. converts to ASCII

HEX ASCII converts to Hex.

DECO Coding

ENCO High bit coding

ENCOL Low bit coding

ECMP Float compare

EZCP Float Zone compare

EADD Float Add

ESUB Float Subtract

EMUL Float Multiplication

EDIV Float division

ESQR Float Square Root

SIN Sine

COS Cosine

TAN Tangent

TCMP Time Compare

TZCP Time Zone Compare

TADD Time Add

TSUB Time Subtract

TRD Read RTC data

TWR Set RTC data

Applied Instructions

67

5-2. Reading Method of Applied Instructions

nderstanding method of instruction understanding

U

this manual, the applied instructions are described in the following manner.

In

Applied Instructions

Note:

① Denote the instruction name

② 16 bits instruction and 32 bits instruction

③ Denotes the soft units which can be used as the operation object

④ Ladder Example

⑤ Flag after executing the instruction. Instructions without the direct flag will not display.

⑥ Suitable models for the instruction

S·

⑦ Source operand, its content won’t change after executing the instruction

D·

Destinate operand, its content changes with the execution of the instruction

(8) Tell the instruction’s basic action, using way, applied example, extend function, note items etc.

68

Applied Instructions

The related

description

z The assignment of the data

The data register of XC series PLC is a single word (16 bit) data register, single

word data only engross one data register which is assi singl

object instruction. The disposal bound is: Dec. –3 327,67, x.

0000~FFFF.

Single word object instruction

D(NUM)

Instruction D(NUM) Object data

Double word(32 bit)engrosses two data register, it’s composed by tw cutive dat