Page 1

Instruction for Use

021579/06/09

Datalogger DLx-MET

9.1756.x0.x0x

Software Version V1.01

9.1756.00.000

9.1756.00.100

ADOLF THIES GmbH & Co. KG

Hauptstraße 76 37083 Göttingen Germany

Box 3536 + 3541 37025 Göttingen

Phone ++551 79001-0 Fax ++551 79001-65

www.thiesclima.com info@thiesclima.com

THE WORLD OF WEATHER DATA - THE WORLD OF WEATHER DATA - THE WORLD OF WEATHER DATA

Page 2

Contents

1 MODELS.................................................................................................................................... 4

2 CONSTRUCTION OF THE DATALOGGER .............................................................................. 4

2.1 MOUNTING......................................................................................................................... 8

2.1.1 Wall-mounting............................................................................................................... 9

2.1.2 Mast-installation for case version B ............................................................................ 11

2.1.3 Cable gland................................................................................................................. 12

2.1.4 Accumulator................................................................................................................ 13

2.1.5 Mains supply............................................................................................................... 13

2.1.6 Solar panel.................................................................................................................. 14

2.1.7 DCF-Active Antenna (9.1760.00.000)......................................................................... 15

2.1.8 Remove Front Plate.................................................................................................... 15

2.1.9 Setting Digital Input..................................................................................................... 16

2.1.10 Setting Resistors Serial Interfaces .......................................................................... 17

3 OPERATION............................................................................................................................ 18

3.1 DISPLAY OPTIONS .......................................................................................................... 18

3.2 CHANGING PARAMETERS ............................................................................................. 29

3.2.1 STATION NAME ......................................................................................................... 29

3.2.2 DATE .......................................................................................................................... 29

3.2.3 SENSOR CONFIGURATION...................................................................................... 29

3.2.4 MEASUREMENT / STORE CYCLE............................................................................ 29

3.2.5 ADJUST SERIAL INTERFACES MODE..................................................................... 31

3.2.5.1 SENSOR THIES SONIC ...................................................................................... 32

3.2.5.2 SENSOR-INTERFACE SIF .................................................................................. 33

3.2.6 SWITCH OUTPUT TIMER.......................................................................................... 33

3.2.7 DCF77 RECEIVING CONTROL ................................................................................. 34

3.2.8 DCF77 SYNCHRONIZATION..................................................................................... 35

4 MEASURING VALUE ACQUISITION ...................................................................................... 36

5 DATA OUTPUT........................................................................................................................ 38

5.1 DATA OUTPUT MANUALLY............................................................................................. 39

5.2 RECOMMENDATIONS ON SD-CARD ............................................................................. 41

5.3 CONNECTING RS232 CABLE OF COM1 ........................................................................ 42

5.4 USB ................................................................................................................................... 42

5.5 FORMAT OF THE COMMANDS....................................................................................... 43

5.5.1 Parameter for memory commands ............................................................................. 46

5.6 DATAFORMAT.................................................................................................................. 47

5.6.1 MEAN DATA............................................................................................................... 47

5.6.2 Extreme DATA............................................................................................................ 48

5.6.3 END LINE ................................................................................................................... 48

6 TECHNICAL DATA .................................................................................................................. 49

2 - 56 021579/06/09

Page 3

7 WIRING PLAN ......................................................................................................................... 52

8 EC-Declaration of Conformity .................................................................................................. 54

Figure

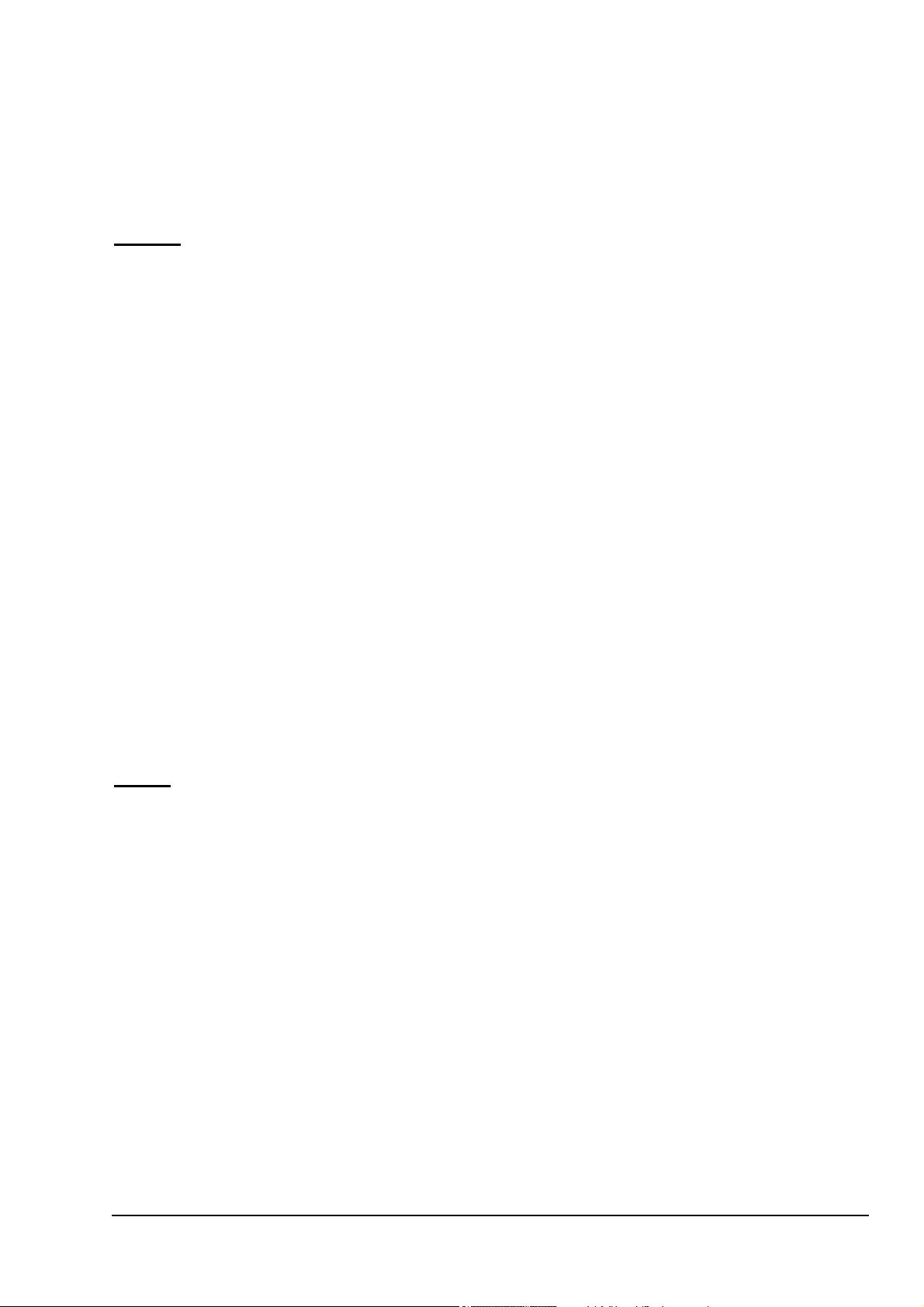

Figure 1: Connections ...................................................................................................................... 4

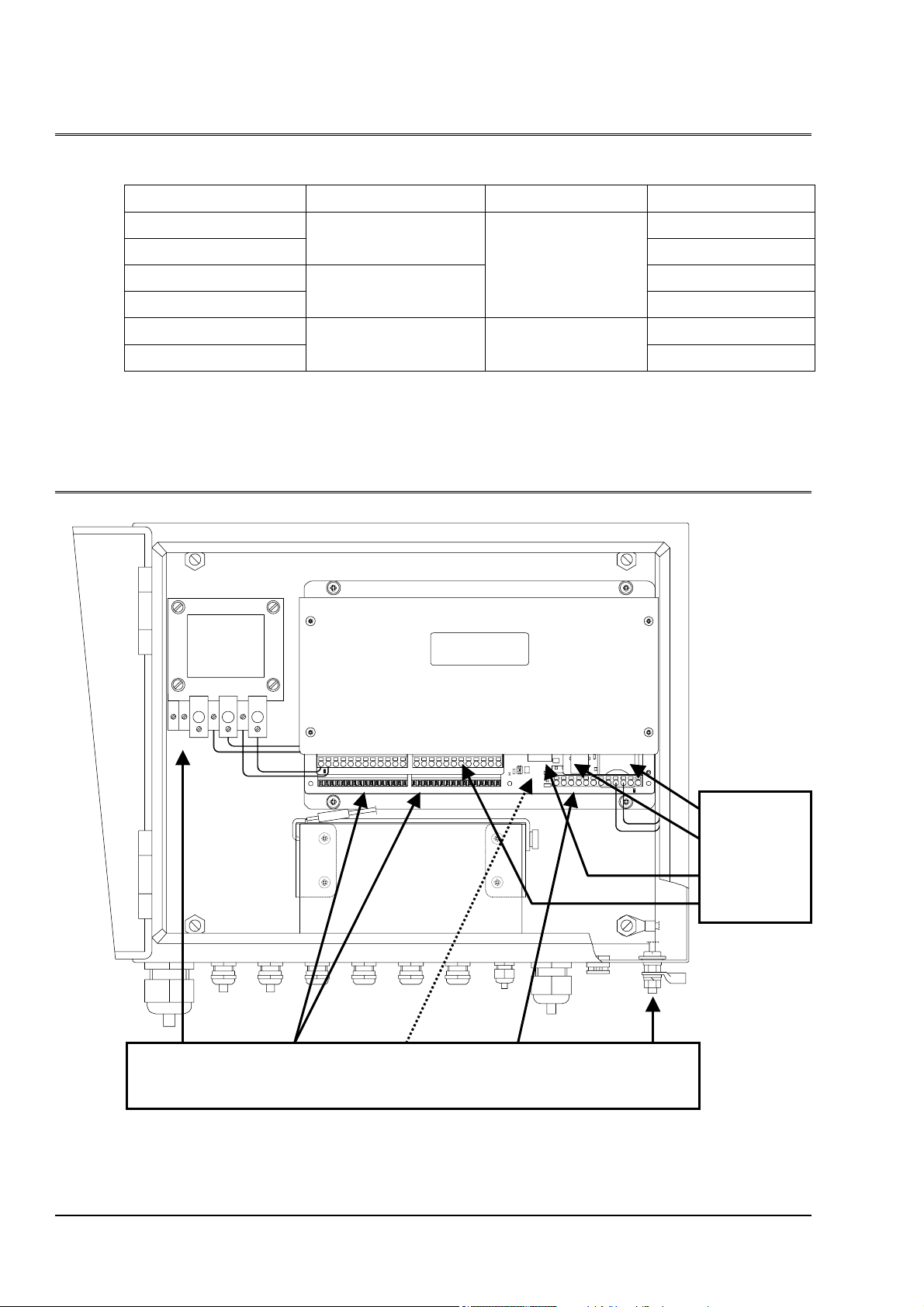

Figure 2: Assembly with Sensor-Interface (9.1756.x0.100).............................................................. 5

Figure 3: Interfaces of the datalogger .............................................................................................. 5

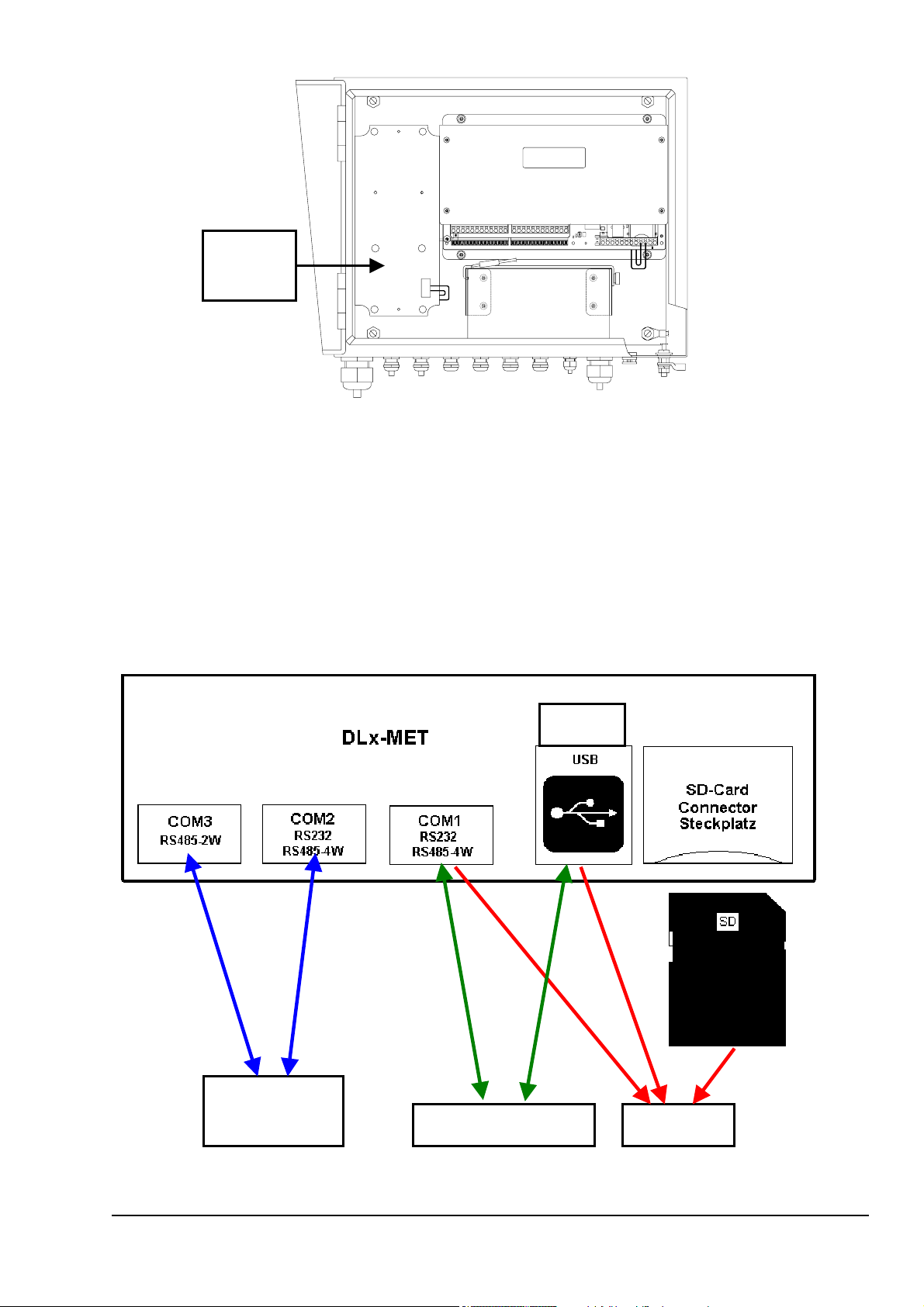

Figure 4: Block diagram supply ........................................................................................................ 6

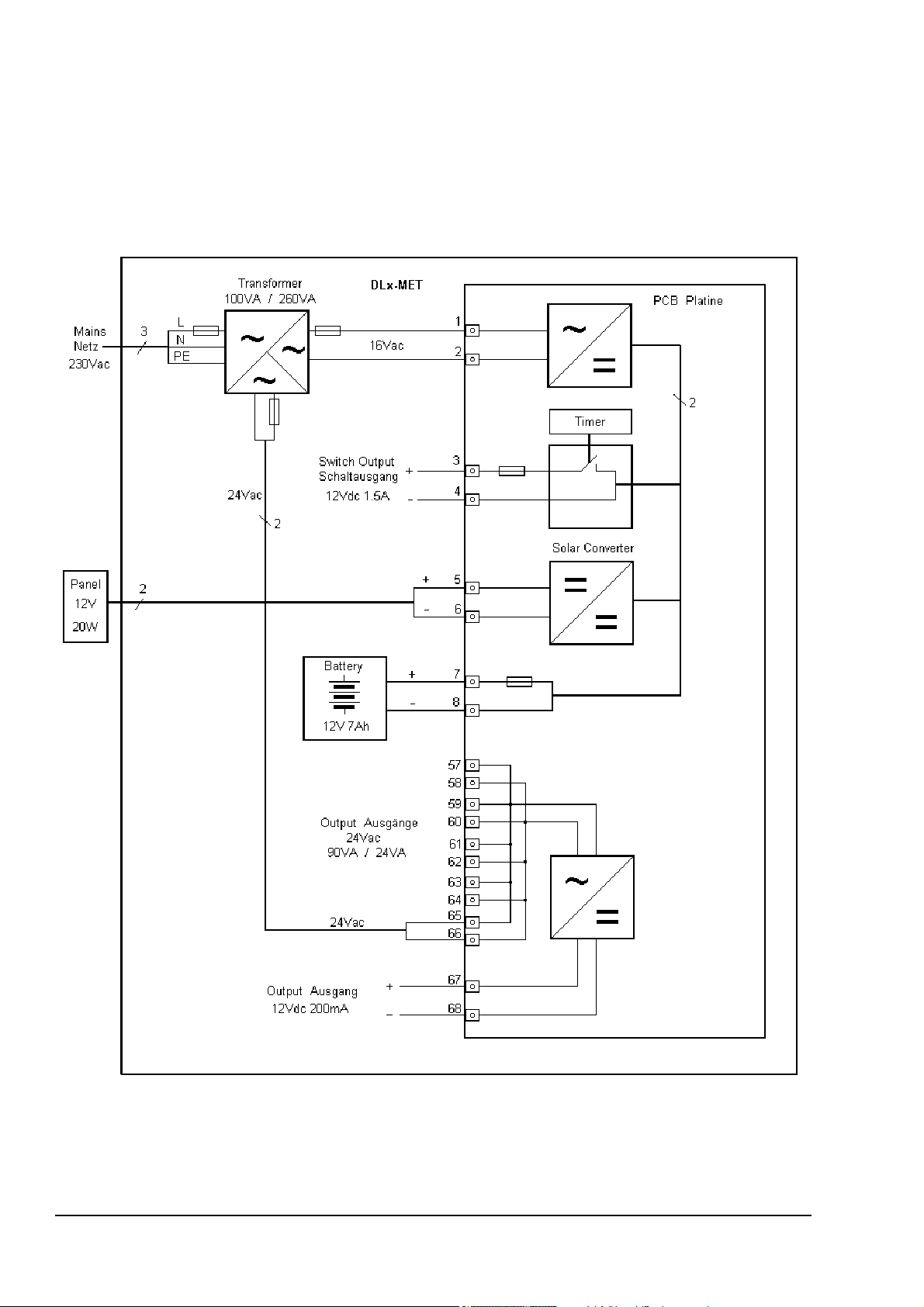

Figure 5: Front view.......................................................................................................................... 7

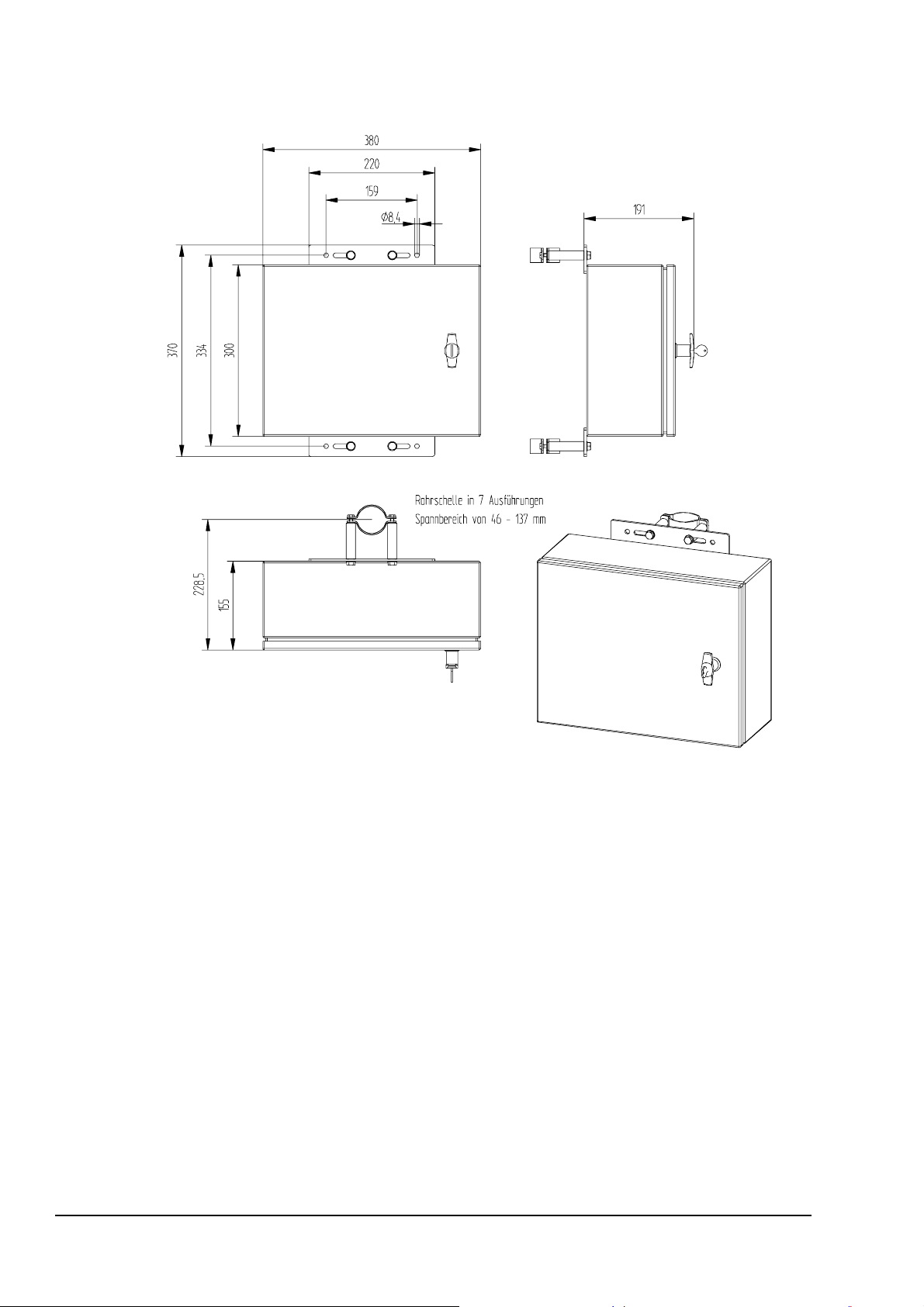

Figure 6: Dimension illustration of the case version B (in mm) ........................................................ 9

Figure 7: Dimension illustration of the case version A (in mm) ...................................................... 10

Figure 8: Strap Housing ................................................................................................................. 11

Figure 9: Mast with guy rope .......................................................................................................... 11

Figure 10: Screen cable connection to the cable gland ................................................................. 12

Figure 11: Tilt angle for solar panel (here 45°)............................................................................... 14

Figure 12: Jumper for Digital Input ................................................................................................. 16

Figure 13: Jumper for serial interfaces........................................................................................... 17

Figure 14: Flow diagram in the measuring mode (display off)........................................................ 36

Figure 15: Flow diagram in the display mode (display on) ............................................................. 37

Table

Table 1: Length of guy rope ........................................................................................................... 11

Table 2: Jumper for digital input ..................................................................................................... 16

Table 3: Serial Port RS485 termination selection........................................................................... 17

Table 4: Summary over memory time periods with 10 channels.................................................... 31

Table 5: Serial Interface Modes ..................................................................................................... 32

Table 6: Terminal Program Configuration COM1 ........................................................................... 38

Table 7: Tested SD-Cards.............................................................................................................. 41

Table 8: Connections COM1 for RS232......................................................................................... 42

Table 9: List of commands ............................................................................................................. 45

3 - 56 021579/06/09

Page 4

1 MODELS

Order-No. Sensor-Interface Transformer Case version

9.1756.00.000 B

9.1756.10.000

9.1756.00.100 B

9.1756.10.100

no

A

100VA

yes

A

9.1756.00.001 B

no 260VA

9.1756.10.001

2 CONSTRUCTION OF THE DATALOGGER

Prim. 230V 0,43A 50/60Hz

Prim.Sicherung 0,5 AT

Sek.: 1 x 24V 3,75A 100 VA

PE 0

Sek. Sicherung 1 x 4,0 AT

Sek.: 1 x 16V 0,6A

Sek. Sicherung 1 x 0,8 AT

BV 9951 nach VDE 0551

230V

24V

0

0,5AT

4,0 AT

Si

16V

0

0,8 AT

Si

Si

DLx MET

A

SD-Card slot

USB

Akku

COM 1

COM 2 + 3

4 - 56 021579/06/09

230VAC Clamps DCF77 Clamps Grounding

mains 1 … 56 (bottom side) 57 … 68 Earth

Figure 1: Connections

Page 5

DLx MET

Sensor-

Interface

Sensor - Int erface

Akku

Figure 2: Assembly with Sensor-Interface (9.1756.x0.100)

The datalogger DLx-MET is a complete measurement system serving for the acquisition and

storing of at minimum 10 meteorological parameters (e.g. temperature or radiation). Additionally in

the version 9.1756.x0.100 a so-called Sensor-Interface (SIF, see Figure 2) printed circuit board

with several measuring channels is connected to the serial interface COM2. Optional measuring of

other parameters or special sensors with serial output can be done by connecting the so-called

Sensor-Interface or a serial sensor to the serial interface COM2 or COM3 (RS485 2W, 2-Wire, halfduplex). The serial interfaces COM1 (used for commands and data output) and COM2 are

adjustable from operation mode RS232 to RS485-4W (4-Wire, full-duplex). See below Figure 3 for

a overview of all interfaces.

Device

IN: Sensor

Out: Telegram

IN/OUT: Commands

Out: Data

Figure 3: Interfaces of the datalogger

5 - 56 021579/06/09

Page 6

The instrument is battery-operated (12V), thus allowing it to be set up according to model and

sensor equipment at site without any mains supply for some hours or even days (applies not for

sensors measured by the Sensor-Interface). The exchangeable storage battery is situated in the

data logger case. With an optional 12V solar panel it is possible to load the battery.

Additionally a mains power supply (230VAC) can be used, which also supplies (24VAC) the heating

of sensors and the Sensor-Interface (apply only for 9.1756.x0.100). In this case the battery serves

for bridging in case of power failure. The following figure shows the supply possibilities.

Figure 4: Block diagram supply

In order to protect the accumulator against discharging the measurement of the sensors is

interrupted in case the voltage is below 10,5 V (thus the current consumption is minimized). Then,

6 - 56 021579/06/09

Page 7

the voltage is measured every 5 minutes; when it is higher than 11,0 V the normal measuring

routine is continued.

An integrated lithium battery buffers the contents of the data memory and the clock operation when

no other power supply is available. This means that the saved values and the time are not lost even

when there is no additional power supply.

The housing can be locked, is impermeable to jet-water (IP65), and is a very stable construction.

For shielding against electromagnetic fields the housing is made of stainless steel. In addition,

operation is guaranteed for temperatures ranging from – 30 °C to 60 °C.

The instrument can be easily operated either by means of three keys, via serial interface COM1 or

via USB. The three keys are referred to in the following as"<∆>", "<∇>"ON, and "<ENTER>" (see

Figure 5). A three-line, alphanumeric liquid crystal display (LCD) serves as indicating instrument.

ON

DATALOGGER DLx MET

EN TER

Figure 5: Front view

The scanning of the measuring values is selectable in the range from 1 second to 60 minutes. For

each of the 10 internal sensors the scanning, and further processing can be switched on or off

separately. The optional sensors connected to the Sensor-Interface are processed if the datalogger

receives a telegram over the serial interface COM2 (apply only for 9.1756.x0.100).

The measuring values are stored in a memory (CMOS-RAM) with a storing rate of 1 to 60 minutes

for mean values and 1 minute to 6 hours for extreme values. The memories are organized as socalled ring memory with a capacity of 1.4MB (mean) and 0.5MB (extreme) . If the capacity of the

ring memory is exhausted, the next step is to overwrite the oldest record. The reading-out of the

data can be carried out via the serial interface COM1, USB or via a Secure Digital Memory Card

(SD Card, see chap.5.2 for working types).

There is a so-called switch output available for the supply of an optional GSM-modem; by means of

this contact output the modem can be supplied at up to 6 selectable times a day.

It is possible to synchronize the internal time automatically by means of a separately connectable

DCF77-receiver module (reception range up to 2000km around Frankfurt(Main)/Germany).

For checking the sensors or the measuring inputs the datalogger can be turned into the

maintenance-mode. While this mode is active the measuring values of all the sensors cannot get

into the memory. I.e. values detected during the maintenance-mode are displayed, however, are

not taken into consideration for the calculation of mean- or extreme values.

7 - 56 021579/06/09

Page 8

2.1 MOUNTING

The datalogger is designed for wall-mounting or installation on a mast.

For proper protection against lightning strikes we strongly recommend to connect a preferably short

cable (≤1m) with a cross section greater than 6mm² between the case (see Figure 1, Grounding

Earth) and the mast (if used) with an earth terminal (e.g. grounding bound or main equipotential

bonding conductor). This connection is also necessary when mains (230VAC) is connected to the

datalogger.

It exists two case variants:

• 9.1756.10.x00x (case version A)

• 9.1756.00.x00x (case version B)

For the mast-installation of case version A seven different pipe clips with a diameter from 46 to

137mm are available. For mast-installation with case version B see chap. 2.1.2

8 - 56 021579/06/09

Page 9

2.1.1 Wall-mounting

For mounting on a wall or likewise use the 4 mounting holes:

• diameter 10mm, see

• (applies for 9.1756.00.x0x)

• diameter 8.4mm, see Figure 7 (applies for 9.1756.10.x0x)

Figure 6: Dimension illustration of the case version B (in mm)

9 - 56 021579/06/09

Page 10

Figure 7: Dimension illustration of the case version A (in mm)

10 - 56 021579/06/09

Page 11

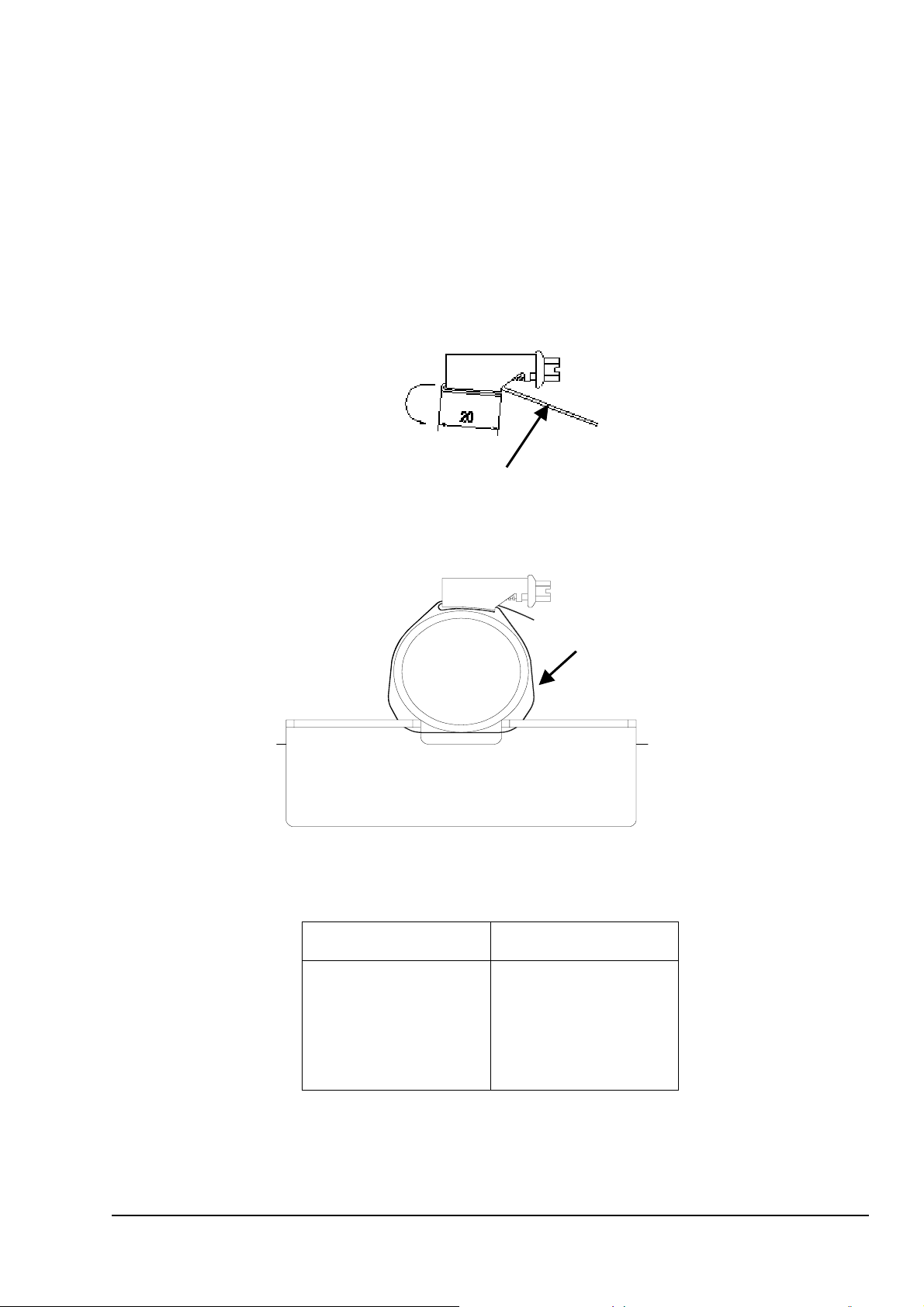

2.1.2 Mast-installation for case version B

The following instructions are only valid for case version B (9.1756.00.x0x).

1. Cut two piece in the requested length of the guy rope (1 meter) according to

table (see Table 1).

2. Insert the strap into the housing from the screw head side, and bend a projection of

20mm over the ridge (see Figure 8).

3. Put the free end of the prepared clamp around the mast and the mounting angle, and

screw it on (see Figure 9).

4. Two straps are provided for the datalogger.

Length of Guy Rope

Figure 8: Strap Housing

Mast Ø

Guy Rope

Mounting angle

Figure 9: Mast with guy rope

Mast Ø Length of Guy Rope

48 mm / 1.9 inch

60 mm / 2.4 inch

80 mm / 3.2 inch

90 mm / 3.5 inch

102 mm / 4 inch

250 mm / 10 inch

310 mm / 12.2 inch

370 mm / 14.6 inch

400 mm / 15.8 inch

440 mm / 17.3 inch

Table 1: Length of guy rope

11 - 56 021579/06/09

Page 12

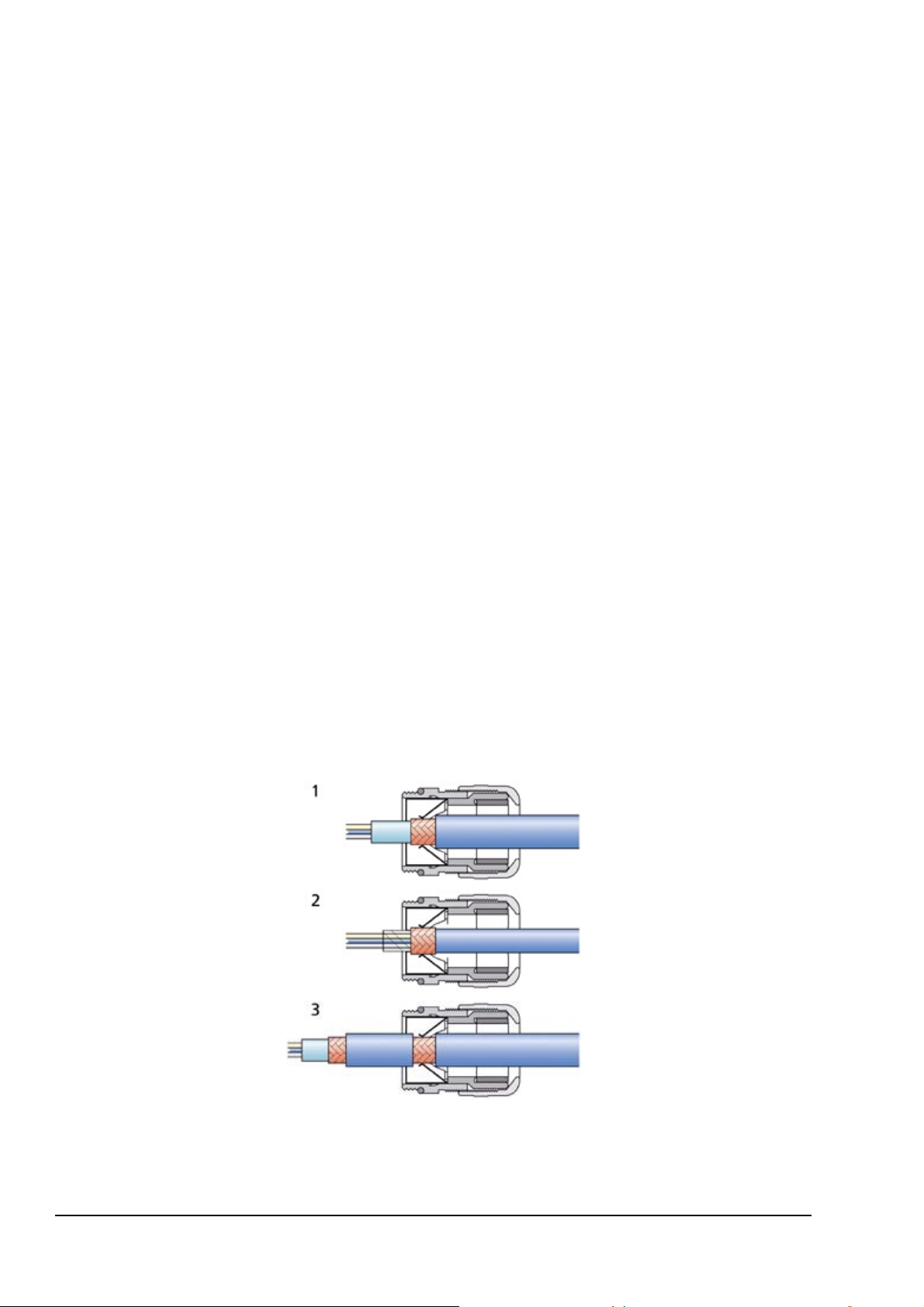

2.1.3 Cable gland

In order to carry out an EMC-compatible installation the cable screen (excepted the supply cable,

which is normally not shielded) is to be connected to the contact spring of the screwed cable gland

(see Figure 10) For wiring plan ref. to chap. 7.

1. With the Standard Contacting (see Figure 10-1)

- Strip back the outer sheath and screen (shielding)

- Make a round cut in the outer sheath approx. 15 mm along but do not remove the sheath

- Guide the cable through the cable gland

- Pull off the outer sheath

- Pull back the cable until the connection is made between the cable screen and contact spring

- Turn shut… and it is ready for use!

2. With thin Wires without an Inner Sheath (see

- Strip back the outer sheath

- Pull back the screen braid approx. 15-20mm over the outer sheath

- Insert the cables into the cable gland until the contact is made between the cable screen and

contact spring

- Turn shut ….and it is ready for use!

3. When Routing the Cable Screen to another Connection (see

- Expose the screen braid approx. 10 mm

-Guide the cable through the cable gland until the connection is made between the cable screen and

contact spring

- Turn shut…and it is ready for use!

Figure 10-2)

Figure 10-3)

Figure 10: Screen cable connection to the cable gland

12 - 56 021579/06/09

Page 13

2.1.4 Accumulator

The accumulator or battery is to be connected always. It is absolutely necessary to pay attention to

the specified polarity (red -> + ,black -> -)!

Remark:

When changing the accumulator, or with active power- or solar-supply please take care

that the red cable is not in contact with the housing parts (danger of short-cut)

During the installation please take care that all connections are voltage-free, and

that people and/or instruments are not endangered!

When replacing the accumulator with active power supply please take care that the red cable has

no contact with any part of the housing (danger of short-circuit).

A replacing or loading is necessary at the latest when the indicated accumulator voltage decreases

below 9.0V. However, a discharge of the accumulator below 11,0 V should be avoided, as no

considerable capacity is available any more. With operation below 10,5 V the life time of the

accumulator is reduced considerably! The new accumulator should be newly charged before

mounting, because, possibly, it might not have its maximum capacity due to self-discharge (approx.

3 % per month). The stored data are being secured during the replacement. Before disconnecting

the accumulator, the data should be saved. Without accumulator no measurements are being

carried out.

2.1.5 Mains supply

Safety Notes if using mains supply:

Attention! High Voltage. Mortal Danger!

The instrument must be mounted and wired only by qualified personnel, who

knows and observes the generalities of techniques, and applicable regulations

and norms.

Please keep in mind the local safety instructions.

Before carrying out any installation or service isolate unit from the mains supply!

in chapter 2.1.

When a Sensor-Interface(SIF, see Figure 2) board is installed (9.1756.x0.100), it is necessary to

swing open it to connect the 230V-power supply to the transformer or to check the fuses (see

Figure 1). When the both screws at the head of the SIF-board are removed you can turn the board.

When the 230V-power supply cable is installed, and connected, a red LED is active at the

datalogger between clamps 1 and 2 for the function control of the charging connection. In case this

LED does not light, the fuses of the 230VAC-input and the 16VAC-output of the transformer should

be checked.

13 - 56 021579/06/09

Page 14

Additionally a red LED lights up between clamp 67 and 68 for control the 24VAC supply (normally

used for heating of sensors). In case of malfunction check the fuses 230VAC and 24VAC.

Remark for 9.1756.x0.001:

The 26Vac output has no fuse, but a 135°C thermal trip switch which breaks the

primary supply.

2.1.6 Solar panel

Electric Connection:

The connection of the optional solar panel is to be carried out according the wiring plan

(see chap. 7). We recommend to earth the panel for protection against lightning strikes.

The integrated 12V solar regulator generates a temperature-controlled voltage for a

optimum load of the battery. The maximum power of the panel should not exceed 20W,

otherwise the regulator could be damaged. Due to the temperature-controlling the battery

should be always in the case of the datalogger.

Alignment:

• Direction: Always align the panel pointing to the sun at noon (south on the northern

hemisphere and vice versa) for an optimum performance. If necessary, refer to a compass.

• Angle: The optimum tilt angle (angle between the horizontal plane and the solar panel, (see

Figure 11) depends on the latitude of the site. If the datalogger is to be used all the year

round, we recommend a tilt angle for optimum winter performance :

Tilt Angle = Latitude + 15° (apply not for Arctic / Antarctic region, maximum tilt angle 90°)

Example: Berlin(Germany) Latitude: 50.3° ---> Tilt Angle = 50.3° + 15° = 65.3°

Figure

11: Tilt angle for solar panel (here 45°)

• Nearby obstacles (trees, sensors etc.) should not block the sun at the panel.

Maintenance:

• Dirt, snow, leaves etc. on the panel reduces the amount of light and decreases the energy

yield. Therefore regularly clean the glass of the panel depending on the vicinity.

14 - 56 021579/06/09

Page 15

2.1.7 DCF-Active Antenna (9.1760.00.000)

For installation of the optional DCF-Active Antenna (9.1760.00.000) it is necessary to notice the

following:

Generally, please take care that the position of the antenna is optimal. It should be aligned

horizontally to, and across the direction of the transmitter (situated near Frankfurt/M., N 50° 01’, E

09° 00’). The antenna should have a minimum distance of 1m from sources of interference such as

power lines, and a 20cm-distance from metal obstacles. For other information on the alignment of

the antenna ref. to chap. 3.2.7 .

2.1.8 Remove Front Plate

For changing or checking of the jumpers for the digital input (ref. to chap. 2.1.9) or for the resistors

of the serial interfaces (ref. to chap. 2.1.10) the front plate (see Figure 5) has to be removed.

First remove the 4 recessed head screws of the front plate. Then move the plate carefully because

otherwise the ribbon cable for the three keys can be damaged.

Before you tighten the screws check the 3 keys of the front plate. When the keys are not working

anymore you had to insert the ribbon cable into the 4-pin connector of the printed circuit board.

15 - 56 021579/06/09

Page 16

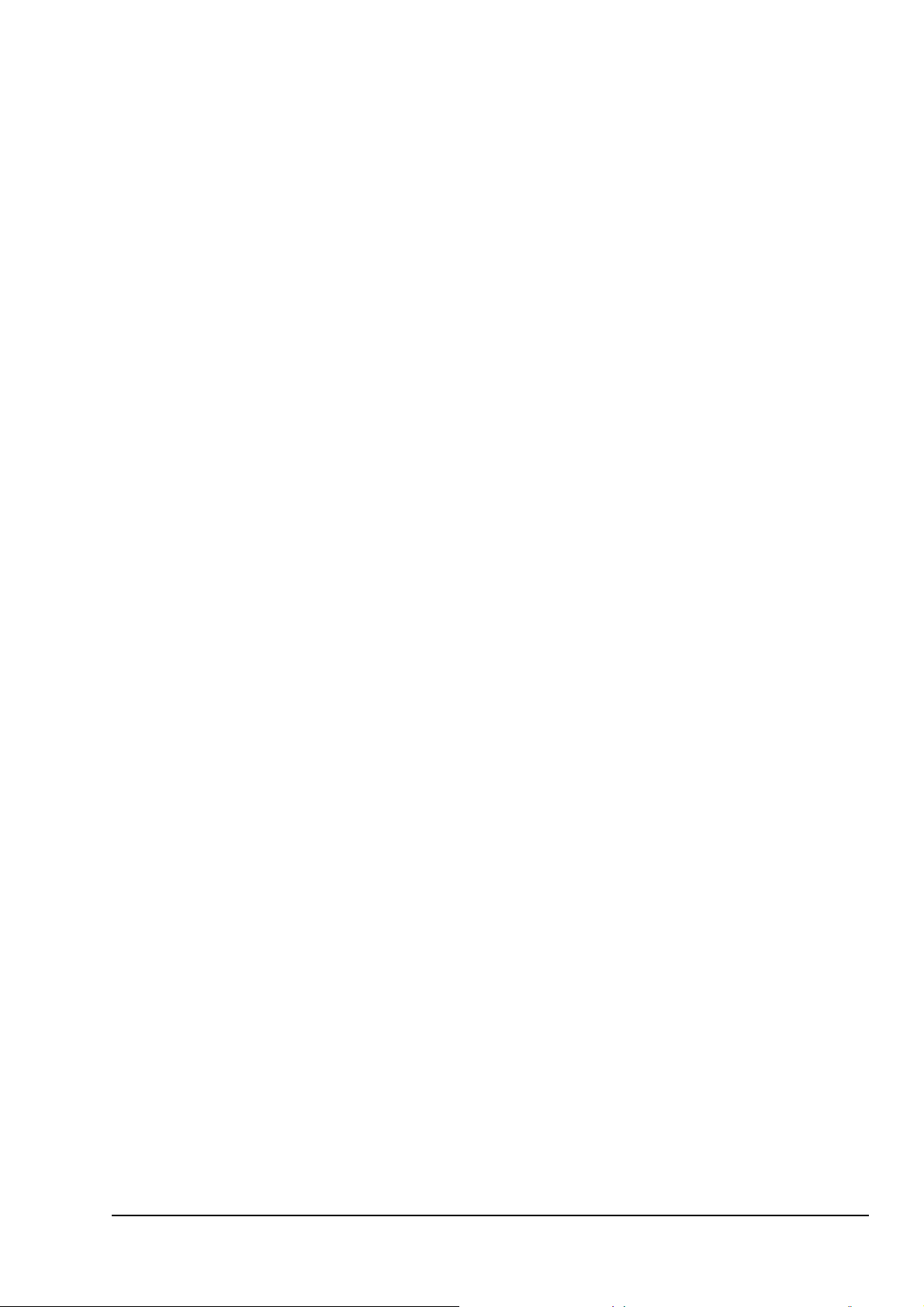

2.1.9 Setting Digital Input

The digital input „Event / Length of time” (Sensor 10) can be configured for two possibilities with the

Jumper P2:

Jumperposition P2 Logic * Inverse Level Miscellaneous

2 3.3V(5V TTL) No Pull-up Resistor 100kΩ to 3.3V

3 1V Yes ** Resistor > 1kΩ

Table 2: Jumper for digital input

* The corresponding switching levels are listed in the technical data (see chap. 6)

** Note that with jumper in position 3 the logic level is reversed by the electronic.

The jumper P2 is situated 2 cm above clamp 13 (see Figure 12). To change or check the position it

is necessary to remove the front plate (see Figure 5, ref. to chap. 2.1.8).

Figure 12: Jumper for Digital Input

16 - 56 021579/06/09

Page 17

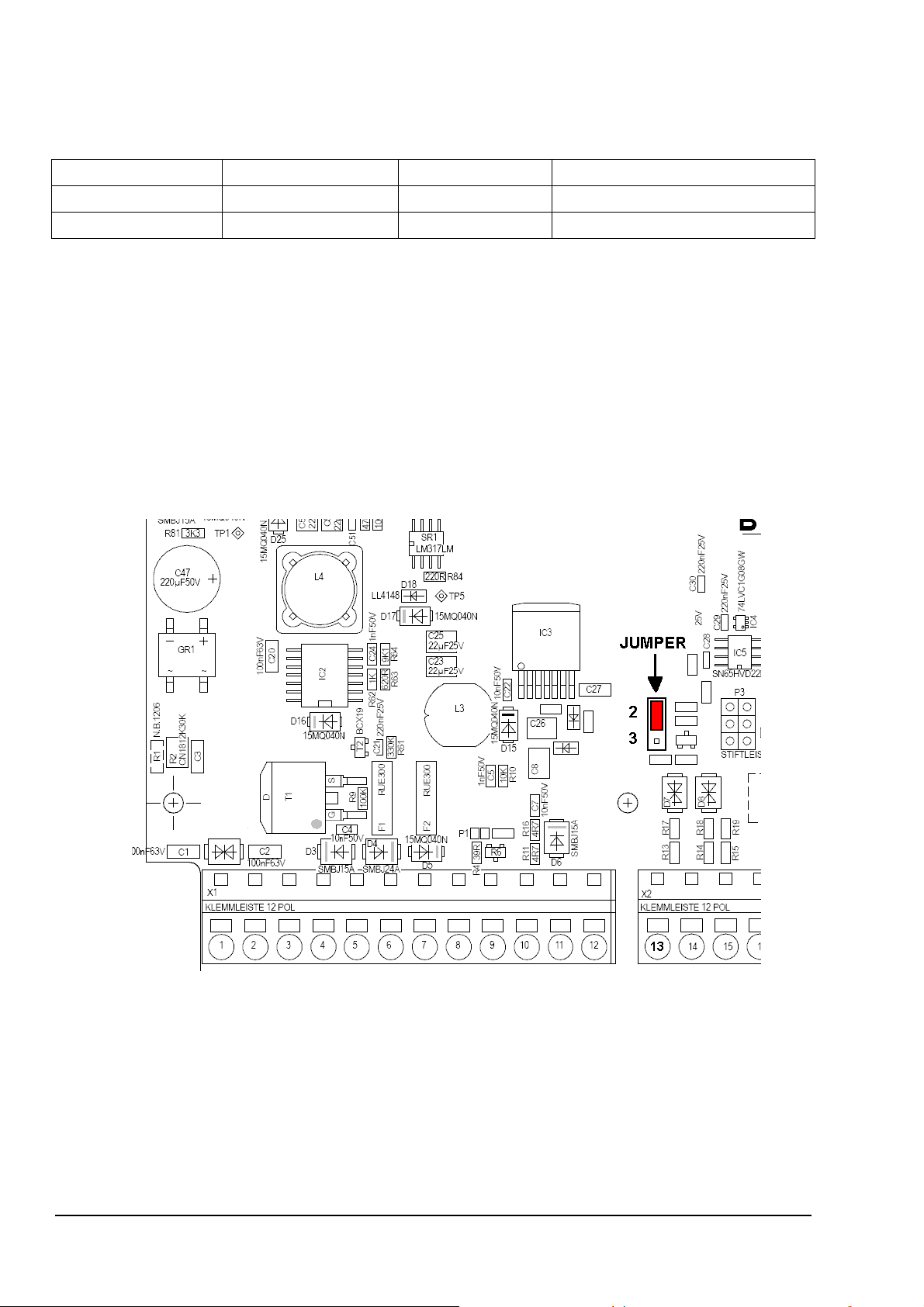

2.1.10 Setting Resistors Serial Interfaces

There are three multi-pin connectors for the serial interfaces when used in RS485 mode. To get the

lowest current consumption and no negative impacts when COM1(P5) or COM2(P4) are in the

RS232 mode all respective jumpers must be open. COM1 and COM2 are adjustable by firmware

between RS232 and RS485 (ref. to chap. 3.1 Baudrate setting). COM3 is always in the operation

mode RS485-2w (half-duplex).

To change or check the position of the jumpers it is necessary to remove the front plate (see

Figure 5, ref. to chap. 2.1.8). Figure 13 show the position of the multi-pin connectors:

COM1: 10-pin connecter P5 (above the 9 pin D-plug)

COM2: 10-pin connecter P4 (above clamp 20)

COM3: 6-pin connector P3 (above clamp 15)

Termination COM1(P5) COM2(P4) COM3(P3)

1000 Ω pull-down resistor

1000 Ω pull-up resistor

220 Ω termination resistor

T+/T- connected to R+/R- for 2 wire operation

(RS485-2w) (Remark: mode not available)

Table 3: Serial Port RS485 termination selection

J7-8 connected J3-4 connected

J9-10 connected J5-6 connected

J5-6 connected J1-2 connected

J1-2 and J3-4 connected --------------

Figure 13: Jumper for serial interfaces

17 - 56 021579/06/09

Page 18

3 OPERATION

When the accumulator is connected, the datalogger starts automatically with the so-called

Bootloader (uploads new Firmware), and re-initialises itself. The Bootloader waits 30 seconds and

start the actual Firmware automatically. After the first activation, time and date should be

controlled.

3.1 DISPLAY OPTIONS

The display is switched on through the button <∇> (press half a second at the most). The display

deactivates itself automatically, if – for 4 minutes – no button was pressed or no signal was sent or

received via the serial interfaces COM1 or USB. After the unit has been switched on the station

name appears on the display.

The character "*" as first character of the first line signifies for the user that it is possible to edit this

value or to get more information (ref. chapter 3.2). By pressing the <∇>-button you reach the next

indicated value, and get back respectively through button <∆>.

„M“ as first character of the second line with the sensor measuring values shows the maintenance

operation (see operation mode).

DLx Met

Bootloader V1.2

-

Remark:

The display can be read off up to a minimum temperature of –20°C . For

technology reasons, the time until the value appears on the display, is rather long

with low temperatures (approx. 10 seconds at –20 °C!).

18 - 56 021579/06/09

Page 19

SEQUENCE OF DISPLAY VALUES:

1. Station name

2. Date and time of datalogger

3. Data output

Internal sensor measured instantaneous values:

4. Sensor 1: Wind speed

5. Sensor 2: Wind direction

6. Sensor 3: Temperature 1

7. Sensor 4: rel. Humidity

8. Sensor 5: Precipitation

9. Sensor 6: Air pressure

10. Sensor 7: Radiation

11. Sensor 8: Temperature 2

12. Sensor 9: 20mA Input

13. Sensor 10: Event / Length of time

External sensor serial values, if configured:

14. Sensor 11 to ??

14. Sensor configuration

15. Sensor connection

16. Serial interfaces mode

17. Measuring cycle / storing cycle

18. Voltage of the accumulator / Status of power supply

19. DCF77 receiving control

20. DCF77 synchronisation

21. Switch output-timer

22. A/D-Converter State

23. State EEPROM

24. Baudrate COM1 / SD-Card

25. Baudrate COM2

26. Baudrate COM3

27. Operation Mode Normal / Maintenance

19 - 56 021579/06/09

Page 20

1. STATION NAME:

* Station: THIES

DLx(Met) V1.01a

USB:0 DE

The station name serves to distinguish the data from several stations. The name (here: "THIES")

can comprise up to 5 characters. On the readout, this name is output along with the data via the

serial interface. The instrument type(„DLx(Met)“) and the software version („V1.01a“) are mentioned

in the second line. The third line shows if a USB-connection is detected (USB:1) or not (USB:0) and

the “DE” indicate a German(Deutsch)/English version.

Serial command: “XXn” for input of the station name (ref. to chap.5.5)

Language:

When changing the station name (ref. to chap. 3.2.1) the second line turns to the language

selection for the display output („Language :English“ or „Sprache : Deutsch“); selecting between

both modes is possible, then.

2. DATE / TIME:

*Date: 01.01.08

Time: 13:00:00

Display of date and time of the logger.

Serial commands date: “DD”, “DT”, “DM”, “DJ” (ref. to chap.5.5)

Serial commands time: “ZZ”, “ZH”, “ZM”, “ZS” (ref. to chap.5.5)

3. DATA OUTPUT:

* Data Output

?

Starting the data output (ref. to chap. 5.1)

If there is no SD-Card in the slot of the datalogger, the output is carried out automatically via the

serial interface COM1.

Serial commands: “TS”,”ts”,”DS”,”ds”,”TE”,”te”,”DE”,”de”,”SS”,”GS”,”EE” (ref. to chap.5.5)

SENSOR MEASURED VALUES:

For display, all measuring values are detected, and updated every second.

General error message (exceeding of measuring range or sensor not connected) is the output of

„???.?“.

If a internal sensor is not configured (switched off) „---.-„ is output.

„M“ as first character of the second line with the sensor measuring values shows the maintenance

operation (see operation mode).

Serial commands: “mm” or “MM” (ref. to chap.5.5)

20 - 56 021579/06/09

Page 21

4. SENSOR 1 Wind speed:

* Windspeed:

NN.N m/s

Classic I:N

Line 2: Display of the instantaneously measured wind speed.

Line 3: Display and input type of sensor (Compact [4.3519.X], Classic [4.3303.X],

First Class [4.3350.X] and current flow test of sensor (I:0 -> off I:1 -> on)

Serial commands: “WV” and “WW” (ref. to chap.5.5)

Measuring range: 0.5 ... 65.0 m/s (Compact)

0.3 … 50.0 m/s (Classic)

0.3 … 75.0 m/s (First Class)

Resolution: 0.1 m/s

5. SENSOR 2 Wind direction:

* Winddirection:

NNN °

5-/8-Bit

Line 2: Display of the instantaneously measured wind direction.

Line 3: Display and input type of sensor (5-/8-Bit syn.ser. or 10-Bit syn.ser.)

Serial command: “WD” (ref. to chap.5.5)

5-Bit sensor: 8-Bit sensor: 10-Bit sensor:

Measuring range: 0 ... 349° 0 … 357° 0 … 359°

Resolution: <= 12° <= 3° 1°

6. SENSOR 3 Temperature 1:

Temperature 1:

NNN.N °C

Display of the instantaneously measured temperature1.

Measuring range: -40 ... 70 °C

Resolution: 0.1 °C

21 - 56 021579/06/09

Page 22

7. SENSOR 4 relative Humidity:

Rel.Humidity :

NNN.N %

Display of the instantaneously measured rel. Humidity.

Measuring range: 0.2 ... 100 % r.H. °C

Resolution: 0.1 % r.H.

8. SENSOR 5 Precipitation:

* Precipitation:

NNN.N mm

0.X I:N

Line 2: Display of the amount of precipitation which has fallen during the current day.

The sum of all precipitation since midnight, including the during the

maintenance mode.

Line 3: Display and input of the resolution of the sensor (0.1 -> 0.1mm, 0.2 ->

0.2mm) and current flow test of sensor (I:0 -> off I:1 -> on).

Serial commands: “NS” and “NT" (ref. to chap.5.5)

Measuring range: 0 ... 999.9 mm

Resolution: 0.1 / 0.2 mm

9. SENSOR 6 Air pressure:

* Air pressure :

NNNN.N hPa

Min:NNN Max:NNNNM

Line 2: Display of the instantaneously measured air pressure

Line 3: Display and input option for the measuring range of the air pressure sensor

Serial commands: “LM” and “LN" (ref. to chap.5.5)

Measuring range: (500-900)* ... (900-1100)* hPa

Resolution: 0.1 hPa

* Note: measuring range adjustable (see Line 3)

22 - 56 021579/06/09

Page 23

10. SENSOR 7 Radiation:

* Radiation :

NNNN.N W/sm

NN.NNNN uV/W

Line 2: Display of the instantaneously measured global radiation.

Line 3: Display and input of the radiation constant [µV/W]

Serial command: “SK1” (ref. to chap.5.5)

Measuring range: 0 ... >1428 W/m

Resolution : <1 W/m

2

2

11. SENSOR 8 Temperature 2:

Temperature 2:

NNN.N °C

Display of the instantaneously measured temperature 2.

Measuring range: -40 ... 70 °C

Resolution: 0.1 °C

12. SENSOR 9 20mA Input:

20mA Input:

NNN.N %

Display of the instantaneously measured 20mA Input.

Measuring range: 0 ... 100 %

Resolution: 0.1 %

23 - 56 021579/06/09

Page 24

13. SENSOR 10 Event / Length of time:

* Event/Length :

NNN.N

Event L:N

Line 2: Display of the instantaneously measured digital state input:

Mode Event: Level active (-> 1) / non-active (-> 0)

Mode Length: Length of time in minutes during the current day

Line 3: Display and input of the mode of the digital state input (Event or Length) and

the active logic (L:0 -> low active logic, L:1 -> high active logic)

Measuring range: 0,1 (Mode: Event) or 0 …. 9999 min (Mode : Length)

Resolution: 6 seconds (Mode : Length)

Serial command: “LS” and “LT” (ref. to chap.5.5)

Remark:

To setting up or check the logic level (3.3V or 1V) see chap. 2.1.8.

From here will displayed the instantaneous data of serial sensors if configured (e.g. Sensor-

interface or Sonic-windsensor). See following display 16 for adjustment and refer to chap. 3.2.5 for

additional information.

14. SENSOR CONFIGURATION:

x = “0” Sensor switched off

*Channel config:

xxxxx xxxxx

x = “1” Sensor switched on

Channels: 10+YY

YY= 00 to ??: Number of external channels

Sensor 1...10

Display of the configured internal measuring channel („1“→ switched on). Measuring channels

which are not configured („0“→ switched off) are marked by bars (for ex. „---.-“) in the display and in

the data output.

The first digit (from the left side) means the 1. measuring value of the sensor (wind speed) the last

one means sensor 10 (state/length).

For more information to change the sensor configuration ref. to chap. 3.2.3

Serial command: “KK” (ref. to chap.5.5)

24 - 56 021579/06/09

Page 25

15. SENSOR CONNECTION:

x = “+” Sensor connected

Sensor connec.:

xxxxx xxxxx

x = “-“ Sensor not connected

x = “0” Current flow test of sensor off

x = “X” Sensor not configured (see 14. sensor configuration)

Sensor 1…10 x = “?” Sensor not testable

This display shows whether a internal sensor is connected. A “-“ means that the datalogger not

detect the sensor, and the “+” stand for vice versa. A “+” means not mandatory that the sensor is

working respectively a good quality of the measurement.

16. SERIAL INTERFACES MODE:

* COM1: Command

COM2: Sonic R

COM3: SIF002

The display shows the settings of the three serial interfaces.

The COM1 interface is fix adjusted to operate the commands.

To get the lowest power consumption it is necessary to switch COM2 and COM3 off.

For more information to change the serial interface mode for COM2 and COM3 ref. to chap. 3.2.5

Serial command: “Cs” (ref. to chap.5.5)

17. MEASURING CYCLE / STORING CYCLE:

*Meas.Cyc. 1 sec

Memory C. 1 min

ExtremeC. 1 h

The display shows the adjustment of the measuring cycle (line 1), the mean (line 2) and the

extreme (line 3) value storing cycle. Refer to chap. 3.2.4 for additional explanation.

Setting options measuring cycle (applies only for the 10 internal sensors connected directly to the

datalogger):

1, 2, 3, 4, 5, 6, 10, 12, 15, 20, 30 seconds and

1, 2, 3, 4, 5, 6, 10, 12, 15, 20, 30, 60 minutes

Setting options mean storing cycle:

1, 2, 3, 4, 5, 6, 10, 12, 15, 20, 30 and 60 minutes

Setting options extreme storing cycle:

1, 2, 3, 4, 5, 6, 10, 12, 15, 20, 30 minutes and

1, 2, 3, 4, 6 hours

Serial commands: “MT”, “ST”, “ET” (ref. to chap.5.5)

25 - 56 021579/06/09

Page 26

18. VOLTAGE OF THE ACCUMULATOR / Status of Power Supply :

OK : voltage >11.5 V

Accumulator: OK

!!! voltage 10.6 ... 11.5 V

12.5 V

Low : voltage <10.5 V loading/replacing of the accumulator !

Mains AC: 1

Display of the measured voltage of the accumulator.

Line 3 displays the state of power supply (1: mains voltage present, 0: no mains voltage).

Remark:

Analogue measurements at a recorded voltage of below 9V are not accurate!

A discharge of the accumulator below 10,5 V should be avoided, as, firstly, no

considerable capacity is available any more, and secondly the life time of the

accumulator is reduced considerably ! Please replace or charge the accumulator,

if "!!!" is displayed. In order to protect the accumulator against further discharge

the query of the sensors is interrupted at a voltage of 10.5 V; thus the current

consumption is minimized . Then, the voltage is checked every 5 minutes; when it

is higher than 11,0 V the normal measuring routine is continued (ref. to chap.4).

19. DCF77 RECEIVING CONTROL:

DCF77 Test: ss nn

D:1.0s L:10 0

DCF77 Test: --

DCF-antenna on DCF-antenna off

For more information refer to chap.3.2.7.

20. DCF77 SYNCHRONISATION

*DCF: 1 !!.!!.!!

ffff n !!:!!:!!

!!.!!.!! !!:!! 0

*DCF77: 0

!!.!!.!! !!:!! 0

DCF-antenna on DCF-antenna off

For more information refer to chap. 3.2.8.

26 - 56 021579/06/09

Page 27

21. SWITCH OUTPUT TIMER:

*PROG-Timer: X

programmed

X= 1,2,3,4,5,6

*PROG-Timer:

deactivated

Display of the programmed timers for the connection of a consumer load (for ex. GSM-Modem,

refer to chap.3.2.6).

Serial command: “FS” (ref. to chap.5.5)

22. A/D-Converter State:

A/D: OK

State for service purposes only:

OK (A/D converter in order)

Err (A/D converter defect)

23. STATE EEPROM:

Estado EEPROM

Usuario:OK DL:OK

State of the EEPROM memory (parameter memory for user-settings and calibration values).

In case “OK” is not displayed here, the instrument might be defect.

24. BAUD RATE (COM1) / SD-Card:

No SD-Card in the slot

Display of the settings of COM1

Setting options:

300, 600, 1200, 2400, 4800,

9600, 19200, 38400, 57600

and 115200 Bd

8 data bits, no (none) parity,

1 stop bit, RS232 or RS485-4Wire

Serial commands: “CC1”, “CR1”

(ref. to chap.5.5)

* COM 1:Command

9600 Bd 8N1

RS232

SD-Card:

2 TM SD02G 3.2

xxxxxxxx 04.2008

SD-Card in the slot of the Datalogger

(Example, line 2 and 3 are specific for each SD-Card)

Display of the so-called “Card Identification

Register”(CID) of the SD-Card in the slot. The data of

the CID is necessary to differ the cards, since the label

on the card is normally of no relevance. Unfortunately

not all SD-Cards works with the datalogger (see chap.

5.2 for tested SD-Cards).

Line 2 : MID, OID, PNM, PRV of the CID

Line 3 : Product serial number (x) and manufacturing

date (month and year)

27 - 56 021579/06/09

Page 28

25. BAUD RATE (COM2)

* COM 2:SIF001

9600 Bd 8N1

RS232

Display of the settings of the serial interface COM2.

Setting options are the same like COM1 (see above).

In the first line the actual setting of the mode is displayed (here “SIF001”, see display 16: SERIAL

INTERFACES MODE for adjustment).

Serial commands: “CC2”,”CR2” (ref. to chap.5.5)

26. BAUD RATE (COM3)

* COM 3:Sonic

9600 Bd 8N1

485-2Wire

Display of the settings of the serial interface COM3.

Setting options are the same like COM1 (see above). except for fixed serial operation mode

(always RS485-2Wire).

Serial command: “CC3” (ref. to chap.5.5)

27. OPERATION MODE:

*Mode:

Normal

Display of the selected mode:

„Normal“: normal mode

„ Maintenance “: Maintenance mode (Measuring values are not stored in the memory)

Remark:

The maintenance mode is stopped automatically when the display is switched off!

28 - 56 021579/06/09

Page 29

3.2 CHANGING PARAMETERS

All display values which are output with a "*" to top left can be changed.

In order to be able to edit the displayed value, first simply press the <ENTER>-key and then the

<∇>-key. The value to be changed is then indicated by the flashing cursor. Now you can release

both keys. With the <∆> key the value can be raised, or decreased with the. <∇> key. If the set

value is o.k., simply press the <ENTER>-key again in order to leave the edit mode or to proceed to

the next changeable value.

3.2.1 STATION NAME

Station name identifies the measuring station. If several data loggers are in use, then each logger

should be given a different name. All letters and digits can be set as well as the underlining "_" and

the space key.

When the station name is changed in the second line the output language is displayed, and can be

selected through the arrow key.

3.2.2 DATE

If an invalid date is entered (for example.: 31.4.00), it is corrected automatically.

3.2.3 SENSOR CONFIGURATION

For changing the sensor configuration, it is necessary – after pressing the <ENTER>- and <∇> -key

at the same time – to proceed as follows:

The second line is cancelled, and an interrogation mark is output. Afterwards, press the <∇>- and

<∆> -key at the same time for 10 seconds. The „countdown“ is shown on the display. After the

„countdown“ has finished you can change the values as usual.

3.2.4 MEASUREMENT / STORE CYCLE

The measurement cycle indicates the time intervals at which the analogue sensor values are

measured by the data logger and the serial sensors (e.g. sensor-interface SIF) are requested. The

measurement cycle can be changed during operation without the preceding data being lost. All

digital inputs (wind speed, wind direction (every second) and precipitation) are continuously

measured independently from the measured value set.

There are 23 different measurement intervals available:

seconds: 1, 2, 3, 4, 5, 6, 10, 12, 15, 20, 30

minutes: 1, 2, 3, 4, 5, 6, 10, 12, 15, 20, 30, 60

The mean storing cycle indicates time interval for storing the measuring values. For this, the

measuring values are averaged, or accumulated.

The memory cycle is selectable in 12 steps.

Minutes : 1, 2, 3, 4, 5, 6, 10, 12, 15, 20, 30, 60

29 - 56 021579/06/09

Page 30

Example: meas. cycle 1 second

mean storing cycle 10 minutes

A mean value is calculated from 600 measuring values, and stored. The calculation of the mean

value is carried out as arithmetic mean with „normal“ sensors. Exceptions are the wind direction

(vectorial mean), and precipitation (formation of sums).

Remark:

When adjusting the measuring cycle the cycles of mean value memory and

extreme value possibly have to be corrected to an integral multiple!

The mean storing cycle influences the storing time period of the mean values (see following Table

4 for 9.1756.x0.000 without additional serial sensors (10 channels))

The extreme storing value cycle gives the time point when the extreme values are saved.

The extreme storing value cycle is selectable in 16 steps:

Minutes: 1, 2, 3, 4, 5, 6, 10, 12, 15, 20, 30

Hours: 1, 2, 3, 4, 6

The extreme value cycle influences the extreme value time period (see following Table 4 for 10

channels).

The storage period is the period of time until the old data are overwritten. The data logger has two

ring memories. Both time periods depend on the number of measured channels. Additionally the

time period of the mean value memory depends on the mean storing cycle set. The time period of

the extreme value memory depends similarly on the extreme storing value cycle set.

For other number of channels you can use the following formulas.

[ ]: means rounding down to integer

Calculation of quantity of mean ring memory dataset:

Quantity(Mean) = [32768 / (5 + 2 * Channels)] * 47

Calculation of quantity of extreme ring memory dataset:

Quantity(Extreme) = [32768 / (5 + 8 * Channels)] * 16

Example with 20 channels :

Quantity(Mean) = [32768 / (5 + 2 * 20)] * 47 = 34216 dataset

Quantity(Extreme) = [32768 / (5 + 8 * 20)] * 16 = 3168 dataset

That denote in this case the mean time period is 23.76 days (= 34216 / 1440) when the mean

storing cycle is 1 minute.

30 - 56 021579/06/09

Page 31

Mean storing cycle

Extreme storing cycle

1 min 28.8 2.7

2 min 57.6 5.4

3 min 86.4 8.1

4 min 115 10.8

5 min 144 13.5

6 min 172 16.2

10 min 288 27

12 min 345 32

15 min 432 (1.1 a) 40

20 min 576 (1.5 a) 54

30 min 864 (2.3 a) 81

1 h 1729 (4.7 a) 162

2 h --- 325

3 h --- 487 (1.2 a)

Mean value time period

[day]

Extreme value time period

[day]

4 h --- 650 (1.7 a)

6 h --- 975 (2.6 a)

Table 4: Summary over memory time periods with 10 channels

3.2.5 ADJUST SERIAL INTERFACES MODE

According to following Table 5 COM2 and COM3 can be switched off (lowest power consumption)

or adjusted for the input of serial sensors and output of telegrams. It is not possible to set both

serial interfaces to the same priority (e.g. COM2 to SIF001 and COM3 to SIF002). With this settings

the number of channels can be changed and in this case the ring memories (mean and extreme)

are new initialised.

To start the setting with the keys the procedure like sensor configuration (ref. to chap. 3.2.3) has to

be done.

Remarks:

Before change this settings save the measuring data of the logger!

In case of changing the number of channels the old mean and extreme data

is no more available!

The baudrate and mode (RS232 or RS485) parameters of a sensor must be same

as the corresponding serial port of the datalogger (COM2 or COM3).

31 - 56 021579/06/09

Page 32

If more than one sensor is selected, the order of the sensor values in the display and memories is

done according the priority in the following table. The sensor with the lowest priority value is output

first. E.g. when Sonic (priority 1) and SIF(priority 3) are set, the values from the Sonic are given out

before the data of the SIF.

The index of the table below shows the values needed for programming via the serial interface

(command “Cs”, ref. to chap.5.5).

To get the lowest power consumption it is necessary to switch COM2 and COM3 off.

Index Display text Priority Channel Function

0 Off/Aus - - COM not used (lowest power consumption)

1 Sonic R 1 3

THIES Windsensor SONIC (ref. to chap. 3.2.5.1)

2 LPM/LNM A 2 6 Soon available

3 T-WindLED - -

4 T-Online - -

6 T-Online 2 - -

7 SIF001 3 6

8 SIF002 3 9

Table 5: Serial Interface Modes

Soon available

Soon available

Soon available

THIES Sensor Interface 001 (ref. to chap. 3.2.5.2)

THIES Sensor Interface 002 (ref. to chap. 3.2.5.2)

3.2.5.1 SENSOR THIES SONIC

The THIES SONIC sensors (“Ultrasonic Anemometer 2D” with software version 3.09 and higher)

are connectable to the datalogger on COM2 (RS485-4Wire, full-duplex) or COM3 (RS485-2Wire,

half-duplex), if the following settings are done:

• ID = 0

• Baudrate 9600Bd 8N1 (BR = 5, command “00BR00005”)

• automatic output off (TT = 0)

• only for full-duplex : DM = 2 (or 1)

• only for half-duplex: DM = 0 and RD = 20

Preset THIES SONIC versions working with this datalogger:

• Full-duplex (COM2): 4.3820.00.300, 4.3820.30.300

• Half-duplex(COM3): 4.3820.01.301, 4.3820.31.301

The data of the SONIC are requested with the command “00TR00002” (VDT-telegram: Wind

speed, wind direction, acoustic-virtual temperature). With the command “SO2”(ref. to chap. 5.5) it

is possible to send a command to the sensor.

32 - 56 021579/06/09

Page 33

3.2.5.2 SENSOR-INTERFACE SIF

In the case of model 9.1756.X0.100 is a so-called sensor-interface SIF build in and is connected to

COM2 (9600Bd 8N1, RS232 mode) of the datalogger. Available are different SIF which separate

between number and type of channels. The data are requested with the command “mm”. The

command “SI2” (ref. to chap. 5.5) can be used to send a command to the SIF.

SIF001, 6 channels: Radiation 2 + 3, Direct-radiation 1 + 2, Temperature 3 + 4

SIF002, 9 channels: 10V-input, 1V-Input 1 + 2, 20mA-Input 2 + 3 + 4, Temperature 3 + 4 + 5

3.2.6 SWITCH OUTPUT TIMER

The timer activates up to 6 daily time slots for an externally connected GSM-modem.

By setting small time slots (for ex. 5 min) the average current consumption of the modem per day

(operating current approx. 200 mA) can be kept down.

During a data transmission via a timer-controlled modem, the remaining power-on-time is fixed on 5

min, thus a re-logging-in in case of a failure is guaranteed within this period.

In the edit mode all timers can be set in turn .

Selectable are the daily starting time, and the minimum power-on-period.

TIMERx: HH:MM

ONLINE: NN min

x = 1,2,3,4,5,6

„HH:MM“ indicates the starting time of the respective timer slot in the format hour:min.

The power-on-period is selectable in minute-increments from 5 to 31. When the power-on-time is

set to 0, the respective timer is deactivated.

Remark:

Only timer 1 is activated even if the discharge-protection for the accumulator is

active (voltage < 10.5V).

33 - 56 021579/06/09

Page 34

3.2.7 DCF77 RECEIVING CONTROL

DCF77 Test: ss nn

D:1.0s L:10 0

DCF77 Test: --

DCF-antenna on DCF-antenna off

This display serves for controlling and setting of the DCF77-antennna.

„ss“: indicates the seconds (0-60, with overflow „??“), after the minute mark has been

identified

„nn“: cycle counter (0-99) of the received second marks.

„D:D.Ds“: time difference of the second marks in seconds (ideal: 1.0s, except for the second

60 (minute mark): 2.0s)

„L:NN B“: length of the second marks in 10ms(NN).

B indicates the binary decoding (L= 6..13[10ms] -> „0“, L= 16...23[10ms] -> „1“,

other lengths are output with “?”)

After this output has been activated, the following values appear for example:

DCF77 Test: ??

2 D:1.0s L:19 1

The minute mark has not yet been identified („??“). The 2. second mark received has a length of

190 (19*10)ms.

The length of the second mark (optimal: L=10 resp. L=20, the length is shorter with weak reception)

is well suited for the optimal alignment of the antenna.

After the minute mark has been recognized (D:2.0s und L: 7...13[10ms]) „ss“ is output and is raised

every second up to a maximum of 60. When the reception is correct, “ss” and “nn” run almost

synchronously. A difference of more than 1 means, that error pulses or not enough pulses have

been received; thus a decoding of the DCF77 time information is impossible.

DCF77 Test: 32

32 D:1.0s L:08 0

Remark:

If the reception is very weak in the daytime, the antenna should be aligned at

night (broader reach). Never try to align the antenna during sunrise or sunset (site

of transmitter and receiver/datalogger) !

Possibly, there are several alignments (neither horizontal!) allowing a reception

(reflections).

The transmitter can be inactive for several hours (thunderstorm close to the

sender).

34 - 56 021579/06/09

Page 35

3.2.8 DCF77 SYNCHRONIZATION

*DCF: 1 !!.!!.!!

ffff n !!:!!:!!

!!.!!.!! !!:!! 0

*DCF77: 0

!!.!!.!! !!:!! 0

DCF-antenna on DCF-antenna off

This display serves for switching on and off the DCF-antenna, indicates the last time of

synchronization (third line) and the manual start of synchronization.

When the DCF-antenna is active, it tries to receive a time telegram at night from 01:30 h (max. 10

minutes) because of the better reception. This time telegram is sent during standard time as CET

(“Central European Time”, CET=UTC+1h), and during daylight saving time as CEST (“Central

European Summer Time”, CEST=UTC+2h). This time telegram is converted in UTC, and the

internal clock is synchronized.

In the edit mode the antenna can be activated and deactivated. Additionally in the third line the last

synchronised DCF77-Time is given out:

*DCF: 1

s = 0 CET/standard time

30.04.09 03:33 s

s = 1 CEST/daylight saving time

With active DCF-antenna, and sufficient reception, when you wait approx. 2 minutes or longer, the

DCF time telegram is displayed, and the internal clock is synchronized (provided that no error

occurs).

Example: Reception of a time telegram (year not yet received)

ffff = Error display in the hexadecimal (0 means “no error”)

*DCF: 1 30.04.!!

ffff n 09:06:52

n = 0...9 display of the received second pulses

When the minute mark has been received, the seconds are set to zero

Second 28: reception minute

Second 35: reception hour

Second 41: reception day

Second 49: reception month

Second 57: reception year

35 - 56 021579/06/09

Page 36

4 MEASURING VALUE ACQUISITION

For reasons of current consumption the display, and other control parts are switched off in case

that for 4 minutes no button has been pressed, or no data communication over COM1 or USB has

been proceeded.

When the display is on (display mode) all configured internal channels are scanned every second.

In the pure measuring mode (display off) the configured analogue measuring channels are

measured, depending on the set measuring cycle ( 1 second to 1 hour). The digital measuring

channels are measured every second.

The following figures will make clear the process of the measuring value acquisition:

Every 5 minutes:

measure supply

voltage

ON

Measuring mode

(display off)

Discharge protection ?

OFF

Depending on measuring cycle:

measure instantaneous value

Depending on storing cyle:

Calculate and store mean-, and extreme

values

36 - 56 021579/06/09

Voltage >

11.0V?

Yes

Discharge protection

OFF

Figure 14: Flow diagram in the measuring mode (display off)

Voltage <

10.5V?

Yes

Discharge protection

ON

Page 37

Display mode

(display on)

Measure instantaneous values

Every second:

Maintenance ?

No

Depending on storing cycle:

Calculate and store mean- and

extreme values

Figure 15: Flow diagram in the display mode (display on)

37 - 56 021579/06/09

Page 38

5 DATA OUTPUT

On principle, there are three interfaces existing at the datalogger for the data output:

serial interface COM1 (RS232/RS485)

serial interface USB

SD-Card (Secure Digital memory Card)

With the serial interfaces COM1 and USB it is possible to query the data of the datalogger via a

cable from another computer. Via the both serial interfaces it is possible to wake-up the datalogger

(Display on), with sending a byte, therefore it is not necessary to wake-up with the "<∇>"ON -key.

The serial data output can be carried out manually (only COM1) or by remote-control (ref. to chap.

5.5 for commands).

For the reading out of data you can use a usual terminal program (e.g. “Terminal” of WINDOWS,

general settings for COM1see following Table 6). For communication via USB also a terminal

program can be used, but here a configuration is not necessary (ref. to chap. 5.4)

The serially transmitted data are output as ASCII-files (clear text). Thus, you are in a position, to

see your data records with word processors, as well, to process them and to print them out.

Herewith, you are also in a position to follow up your data via the ASCII-interface with standardsoftware such as spread sheet, data bases etc.

Furthermore it is possible to upload a firmware over COM1.

The data written on the SD-Card are saved in the same ASCII form as over the serial interfaces.

Baud / Bits per second just like baudrate COM1 of the

datalogger

Databits 8

Parity none

Stopbit 1

Flow control / Handshaking none

Table 6: Terminal Program Configuration COM1

38 - 56 021579/06/09

Page 39

5.1 DATA OUTPUT MANUALLY

With the manually data output the complete ring memory (mean or extreme) will be given out on

serial port COM1 or on a SD-Card (ref. to chap. 5.2).

SD-Card:

1. Set the display to

* Data Output

?

2. Push and snap in the SD-Card into the slot of the datalogger.

3. First press <ENTER> and then <▼> -button, until

the cursor is flashing.

4. Press <▼> - or <▲> -button for at least 3 seconds.

5. Select mean or extreme value memory:

X: “M” Mean value: <▼>

X: “E” Extreme value: <▲>

* Data Output

X-data

6. Start output: Press <ENTER>

7. To cancel or end data output: Press <ENTER>

8. Finish of output: Output „ END “ on display (line 2)

Y: “M” (mean) or “E” (extreme)

ooo: “SD” or “COM1”

* Data Output

Y ooo: NNNNN END

sssssY00.TXT

NNNNN: number of scanned data

records

Line 3: Filename on SD-Card (ssss: station name)

9. Remove the card when the output is ready:

Push the Card until it releases, then pull it out (so called e

jector type

Push-In/Push- Out).

39 - 56 021579/06/09

Page 40

Serial (COM1):

As above but without SD-card in socket (number 2 and 9 do not apply).

Additional information’s for the using of SD-Cards:

The data files are stored on the SD-Card in the following tree structure:

D:\ Root-Directory (here drive D)

sssss\ Subdirectory (Station name)

sssssMnn.TXT Mean memory files (nn: 00..99)

sssssEnn.TXT Extreme memory files (nn: 00..99)

Example station “MET23”: “D:\MET23\MET23M00.TXT”

The data on a CD-Card is always written into the “00”-file. If a “00”-file is present in the subdirectory

the datalogger tries to append only the new data. Whenever the “00”-file is greater then ten million

bytes, the “00”-file is renamed to a not existing “01”- till “99”-file. Unless the renaming is possible,

the output of the data will be breaked.

Remarks:

The datalogger do not delete any data on the SD-Card.

The user is responsible to use a SD-Card with enough free memory and the

deleting of the old “01”- to “99”-files.

The write-protect tab of the SD-Card is not used by the datalogger.

We strongly recommend to backup the data on alternative media.

Do not eject the card while writing the data. Press the “ENTER”-Key for breaking

the output.

Liability is excluded for loss of data.

Refer to chapter 5.2 for recommended SD-Cards.

40 - 56 021579/06/09

Page 41

5.2 RECOMMENDATIONS ON SD-CARD

To display the so-called “Card Identification Register”(CID: MID, OID, PNM, PRV) of the SD-Card

refer to chap. 3.1 (Baudrate COM1 / SD-Card). The data of the CID is necessary to differ the

cards, since the label on the card is normally of no relevance.

List of tested SD-Cards (maximum size 2GB, sorted by manufacturer ID) see following table.

MID: Manufacturer ID OID: OEM/Application ID

PNM: Product name PRV: Product version

Work with

Datalogger

Platinum

Label Size Manufacturer MID OID PNM PRV

2GB Panasonic 1 __ _____ 0.0 YES

Kingston 512MB SD512 1.5 YES

Kingston

AgfaPhoto

2GB

Toshiba 2 TM

SD02G

2.8

3.2

YES

3.8

512MB SD512

SanDisk

1GB SD01G

2GB

SanDisk 3 SD

SD02G

8.0 no

Platinum 1GB ??? 27 SM UD___ 1.0 YES

PNY Technologies

extreme memory

1GB ??? 39 PH SD01G 2.0

YES

AgfaPhoto

extreme memory 1GB ??? 62 H- FLASH 0.0 YES

extreme memory 2GB ??? 136 __ NCARD 1.0 YES

Table 7: Tested SD-Cards

Remarks on SD-Card:

Use only positive tested SD-Cards. Refer to the above list. Not all cards are

compatible with the datalogger.

The SD-Cards must be preformatted with the standard “FAT16”-format (deliverer

condition of the SD-Card).

41 - 56 021579/06/09

Page 42

5.3 CONNECTING RS232 CABLE OF COM1

The serial interface COM1 in RS232 mode is designed as “three-wire”-connection. The

transmission line (TxD) and the receiving line (RxD) are to be crossed in the cable.

PC/TERMINAL

cable

Sub-D25 (25 pins)

TxD 2 2 RxD

RxD 3 3 TxD

Ground 7 5 Ground

Both sides Sub-D9 (9 pins)

RxD 2 2 RxD

TxD 3 3 TxD

Ground 5 5 Ground

Table 8: Connections COM1 for RS232

Datalogger DLx

Sub- D9

5.4 USB

For the communication via USB it is required to have a VCP (Virtual COM Port) driver on the used

PC. Virtual COM port drivers cause the USB device to appear as an additional COM port available

to the PC. Application software can access the USB device in the same way as it would access a

standard COM port.

The driver is available from FTDI (FT245R): http://www.ftdichip.com/Drivers

In addition installation guides for several operating systems can be downloaded from there.

The USB cable between PC and datalogger is a common so-called AB-plug-cable.

42 - 56 021579/06/09

Page 43

5.5 FORMAT OF THE COMMANDS

The following commands operate with the serial interfaces COM1 and USB of the datalogger.

The commands are 4 to 12 bytes long:

STX ? ? ? ? ? ? ? ? ? ? ETX

Begin of command:

0x02(Hex) / Ctrl-B

Command:

2 ... 10 Bytes

LIST OF THE COMMANDS:

"HH" Help: indicates the list of entering commands

“PD“ Turn Datalogger into “power down” (display off, Measuring-Mode)

“RS” Reset of the Datalogger. Start of Bootloader

„CC1“<0..9>

“CC2”<0..9>

“CC3”<0..9>

„CR“<n><0,1> Set operation mode COM n(n = 1,2) 0:RS232 1:RS485-4w

“Cs000 ”aaa’ ‘bbb Configure sensor or telegram for COM2 and COM3

„MT“<01s,02s,03s,04s,05s,06s,10

s,12s,15s,20s,30s,01m,02m,03m,

04m,05m,06m,10m,12m,15m,20

m,30m,60m>

„ST“<01m,02m,03m,04m,05m,06

m,10m,12m,15m,20m,30m,60m>

„ET“<01m,02m,03m,04m,05m,06

m,10m,12m,15m,20m,30m,01h,0

2h,03h,04h,06h>

„SS“ Output of all stored mean values

„GS“ Complete mean memory:

“EE” Output of all stored extreme values

"TS"<DdMoYy>

“ts”<d><m><y>

„DS“<DdMoYyHhMi>

“ds”<d><m><y><h><m>

"TE"<DdMoYy>

“te”<d><m><y>

Set baud rate COM1

Set baud rate COM2 0:300Bd … 5:9600Bd … 9:115200Bd

Set baud rate COM3

aaa:COM2 bbb:COM3 values according to index in Table 5

Example: STX “Cs000 008 001”ETX

COM2: 8 (-> SIF002) COM3: 1 (-> SONIC)

Ref. to chap.3.2.5 for additional remarks. Old data can be deleted!

Set measuring cycle in seconds or minutes

Set mean storing cycle in minutes

Set extreme storing cycle in minutes and hours

Reasonable only, when the logger has re-initialised itself, in order to

save data which have not been overwritten

Stored mean data of one day

Description of parameters: ref. to chap. 5.5.1

Output of stored mean data from a specific time

Description of parameters: ref. to chap. 5.5.1

Stored extreme data of one day

Description of parameters: ref. to chap. 5.5.1

End of command:

0x03(Hex) / Ctrl-C

43 - 56 021579/06/09

Page 44

„DE“<DdMoYyHhMi>

“de” ”<d><m><y><h><m>

Output of stored extreme data from a specific time

Description of parameters: refer to chap. 5.5.1

"EP" Output of EEPROM-data (parameter memory) for service purposes

Logger status:

Output station name, date and time , state of the AD-transducer,

"LL"

sensor configuration, measuring and storing rates, voltage of the

accumulator, state of power supply, radiation constant, EEPROMstatus, operation mode, contact output-Timer, last DCFsynchronisation time and appropriate logger time

"MM" Instant. measuring values: output with sensor identification (multiline)

"mm" Instantaneous measuring values: output as single-line data record

(sequence as in the display output)

"DD" Output Logger-date

"DT"<1..31>

Entering day: Setting of day for the logger-clock (*)

Response: entered day, logger date

"DM"<1..12>

Entering month: setting of month for the logger-clock (*)

Response: entered month, logger date

"DJ"<0..99>

Entering year: setting of year for logger-clock (*)

Response: entered year, logger date

"ZZ" output logger-time

"ZH"<0..23>

Entering hour: entering of hour for the logger-clock (*)

Response: entered hour, logger-time

"ZM" <0..59>

Entering minute: entering of minute for the logger-clock (*).

The second is set to zero.

Response: entered minute, logger-time

„ZS“ <0..59>

Entering second: setting of second for the logger-clock. (*)

Response: entered second, logger time

"XX" Output of the station name, instrument type, and software-version.

„XXn“<AAAAA> Entering station name

„LM“<500..900> Enter of the lower measuring range in hPa of the air pressure sensor

„LN“<500..900> Enter of the higher measuring range in hPa of the air pressure sensor

“WV”<0..3>

Wind speed sensor type

(0:COMx, 1:Compact, 2:Classic, 3:FirstClass)

“WW”<0,1> Wind speed sensor current flow test (0:Off)

“WD”<0..2> Wind direction sensor type (0:COMx, 1:5-/8-Bit, 2:10-Bit)

„NS“<1,2> Precipitation sensor type resolution (0.1mm / 0.2mm)

“NT“<0,1> Precipitation sensor current flow test (0:Off)

„LS“<0,1> Digital input mode: Event(0) or Length(1)

„LT“<0,1> Digital input logic: active logic low (0) or active logic high (1)

„SK“<n>’ ’<NN.NNNN>

Enter radiation constant n (n=1…5)

Example: STX „SK1 12.42“ ETX (set constant 1 to 12.42)

Entering sensor configuration of a internal sensor

“KK“<01..10>’ ’<0,1>

<01..10> sensor number

<0,1> 0 -> switch off 1 -> switch on

Example: STX “KK02 1“ ETX (switch on sensor 2)

“FF“ Output of all switch-output timers

“FS“<1..6><HH><MM><LL> Setting of a switch output-timer: <1..6> timer number,

<HH> starting hour, <MM> starting minute, <LL> power-on time in

minutes

Ex.: STX “FS2083005“ ETX (timer 2, start at 08:30 h, time: 5

minutes)

44 - 56 021579/06/09

Page 45

“SI2”<AAAAAAA> Transparent Gateway / Bridge command to Sensor-Interface SIF

(9.1756.x0.100)

The command <AAAAAAA> (up to 7 signs) is send to COM2 or COM3

and the answer is given back. STX and ETX is added automatically.

Operation only if SIF configured.

Example: STX “SI2HH” ETX -> Help (HH) from SensorInterface

“SO2”<AAAAAAAAA> Transparent Gateway / Bridge command to SONIC. Works only for

commands with a single-line answer and if SONIC is configured.

The command <AAAAAAAAA> (up to 9 signs) is send to COM2 or

COM3 and the answer is given back. CR is added automatically.

Example: STX”SO200TT00000”ETX -> TT parameter is set 0

CR LF"?"CR LF Response in case of unknown command or erroneous parameter

Table 9: List of commands

(*): The internal divider of the clock will be reset by each write into the register. That means the

internal 1/100 second-register is reset and therefore the change of the second is manipulated.

ADDITIONAL CHARACTERS AND THEIR MEANING:

STX (0x02 Hex) Start of command

ETX (0x03 Hex) End of command

EOT (0x04 Hex) End of memory data output by the commands:

"SS", "GS", “EE”, "ts", "ds", “TS”, “DS”, ”, "te", "de", “TE”, “DE”

XON (0x11 Hex) Software-Handshake (continue output)

XOFF (0x13 Hex) Software-Handshake (stop output; max. 4 minutes,

otherwise the logger turns itself off!)

45 - 56 021579/06/09

Page 46

5.5.1 Parameter for memory commands

Remark:

Time duration for searching mean data can be up to several seconds.

ASCII parameters (2 bytes per parameter, commands “TS”, “DS”, “TE”, DE”) :

Dd: day (01..31) Mo: month (01..12) Yy: year (00..99) w/o century

Hh: hour (00..23) Mi: minute (00..59)

Example: STX“DS0103041200“ETX

Mean data from 1.03.2004 12:00 are required.

Binary parameters (1 byte per parameter, commands “ts”, ”ds”, “te”, “de”):

d : day in binary + 28 (29..59)

m : month in binary + 28 (29..40)

y : year in binary + 28 (28..127) w/o century

h : hour in binary + 28 (28..52)

m : minute in binary + 28 (28..77)

Example: STX“ds“ 29 31 32 40 28 ETX

Mean data from 1.03.2004 12 :00 are required. Binary parameters have to enter without spaces!

46 - 56 021579/06/09

Page 47

5.6 DATAFORMAT

The data are output in tabular form with fixed telegram length. Separator is at least one space

(ASCII 32). Lines are concluded with "CR LF". Decimal separator is the point. Erroneous values are

marked by one or several "?" respectively “!”. Non-configured internal channels are marked by one

or more “-“. The end of the serial (COM1 and USB) data output is identified with the End Line (not

on SD.Card, ref. to chap. 5.6.3)

Remark:

The date and time in the data line refers to the end of the measurement.

5.6.1 MEAN DATA

Data Line Mean Data:

Sensor values:

Sequence as in display (ref. to chap. 3.1)

8.7333 30.0 11.1 …….. 8.09.08 8:44 CR LF

2.Sensor line feed

1.Sensor carriage return

Time in Time

decimals Date

Examples (9.1756.x0.100, Sensor-Interface with 6 additionally sensors):

15.0667 57.5 329 -1.5 ???.? 0.0 ????.? 1033.2 24.4 0.0 1.0

0.0 1.1 1.2 1.0 -5.0 51.6 27.10.08 15:04

15.0833 57.5 329 -1.5 ???.? 0.0 ????.? 1033.2 24.4 0.0 1.0

0.0 1.0 1.2 0.8 -5.0 51.6 27.10.08 15:05

15.1000 57.5 329 -1.5 ???.? 0.0 ????.? 1033.2 24.6 0.0 1.0

0.0 0.9 1.1 0.7 -5.0 51.6 27.10.08 15:06

15.1167 57.5 329 -1.5 ???.? 0.0 ????.? 1033.2 24.6 0.0 1.0

0.0 1.1 1.2 1.0 -5.0 51.6 27.10.08 15:07

47 - 56 021579/06/09

Page 48

5.6.2 Extreme DATA

Data Line Extreme Data:

Sensor values: Sequence as in display (ref. to chap. 3.1)

1. Sensor

11.0633 0.3 11:01 3.1 11:03 ..... 8.03.08 11:05 CR LF

line feed

carriage return

time

date

time of the maximum value

maximum value

time of the minimum value

minimum value

time in decimals

Remarks:

The time of minimum and maximum values are round up to the next minute.

Special case wind direction: The minimum value is always marked with “?”, and

the maximum value is the direction at the highest gust (maximum) of wind speed.

Examples (9.1756.x0.100, Sensor-Interface SIF001 with 6 additionally sensors):

13.0000 57.5 12:51 57.6 12:51 ??? 00:01 329 12:51 -1.5 12:51 -1.4 12:51

???.? 13:19 ???.? 13:19 0.0 12:51 0.0 12:51 ????.? 15:01 ????.? 15:01

1033.0 12:51 1033.5 12:51 24.5 13:00 24.7 12:51 0.0 12:51 0.0 12:51

1.0 12:51 1.0 12:51 0.0 12:51 0.8 12:55 0.0 12:56 2.0

12:51 0.2 12:56 2.1 12:52 0.0 12:52 2.3 12:52 -5.0 12:51 -5.0

12:51 51.6 12:51 51.6 12:51 27.10.08 13:00

13.1667 57.5 13:01 57.6 13:01 ??? 00:01 329 13:01 -1.5 13:01 -1.4 13:01

???.? 13:19 ???.? 13:19 0.0 13:01 0.0 13:01 ????.? 15:01 ????.? 15:01

1033.0 13:01 1033.5 13:01 24.3 13:09 24.5 13:01 0.0 13:01 0.0 13:01

1.0 13:01 1.0 13:01 0.0 13:01 0.3 13:04 0.0 13:02 2.1

13:08 0.0 13:07 2.2 13:09 0.0 13:02 2.0 13:10 -5.0 13:01 -5.0

13:01 51.6 13:01 51.6 13:01 27.10.08 13:10

5.6.3 END LINE

End line is only output by the serial interfaces COM1 and USB.

END OF DATA Station: THIES DLx(Met) V1.01a USB: 0

USB state (on/off)

Software-Version “V1.01a”

Instrument Type “DLx(Met)”

Station name „THIES

48 - 56 021579/06/09

“ e.g.

Page 49

6 TECHNICAL DATA

Housing : stainless steel

Protection class : IP 65

Power supply:

-Battery : 12V 7Ah (lead acid valve regulated VRLA), voltage is monitored

-Solar panel : 12V 20W max

-Switched Output : 12V 1.5A max. (e.g. for supplying a GSM-Modem)

-Buffer-battery : 3V 0.56Ah, buffering data memory and real time clock

-Mains operation : monitoring status of mains(On/Off)

Out all versions: 12Vdc 0.2A, powered by 24Vac output (e.g.

permanent supply for fan)

91756.x0.x00: In: 230Vac 100VA 0.5A

Out: 24Vac 90VA (e.g. heating of sensors)

16Vac 10VA (datalogger and sensors)

9.1756.x0.001: In: 230Vac 260VA 1.25A 135°C thermal trip switch

Out: 26Vac 220VA (e.g. heating of sensors)

24Vac 24VA

16Vac 10VA (datalogger and sensors)

Power consumption battery (COM2 and COM3 switch off):

approx. 12mA (Display active without Sensors)

max. 1mA (Display off)

Temperature range : -30...+60°C

Temperature Display : -20...+60°C (for reading)

Storage Temperature : -40...+85°C

Humidity : up to 100% RH, non-condensing

Analogue Measurement:

-A/D-Converter : 24 Bit theoretical resolution with fully differential inputs

-Accuracy analogue : ±0,1% of measuring span of the sensors, without long term drift

-Internal Channels : 6

1 Voltage for radiation sensor (0...40mV)

1 Voltage for humidity (0...1V)

1 Voltage for air pressure (0…5V)

1 Current (0…20mA)

2 Temperature Pt100 (-40...70°C)

-Input resistance internal channels :

0…40mV 100kΩ

0…1V 100kΩ

0…5V 200kΩ

0...20mA 120Ω

-Factory calibration 40mV-Input series resistance : 100Ω

Additional analogue channels (applies for 9.1756.x0.100):

49 - 56 021579/06/09

Page 50

Sensor-Interface SIF001 : 6 (4x Voltages for Radiation, 2x Temperatures Pt100)

Sensor-Interface SIF002 : 9 (10V, 2x 1V, 3x 20mA, 3x Temperatures Pt100)

Digital Measurement:

Channels : 4

synchronous-serial (wind direction: THIES 5, 8 or 10bit)

16 bit counter (wind speed: THIES compact, classic, first class)

8 bit counter (precipitation: resolution 0.1 or 0.2mm)

Event / Length of time 3.3V(5V-TTL)-logic (max. level 5V, pull-up

100kΩ to 3.3V, low level: <0.9V, high level:

>1.9V) or

1V-Logic (switch level: 0.58V ±0.1V)

Measurement cycle : 1, 2, 3, 4, 5, 6, 10, 12, 15, 20, 30 s,

1, 2, 3, 4, 5, 6, 10, 12, 15, 20, 30, 60 min

Memory cycle

-Mean values : 1, 2, 3, 4, 5, 6, 10, 12, 15, 20, 30, 60 min

-Extreme values : as mean values, 2h, 3h, 4h and 6h are additionally adjustable

Time base : Real time clock with leap year

automatically time synchronisation with optional DCF77-Radioclock (Thies

number: 9.1760.00.000)

Memory capacity : Flash: 128 KB (Firmware, Upload able COM1 XModem-CRC)

RAM: 2 MB (Data)

EEPROM: 256 Bytes (Parameter)

Number of data records:

-Mean values : 41500 (with 10 sensors)

-Extreme values : 3900 (with 10 sensors)

Memory period : refer to chap. 3.2.4 for more information

50 - 56 021579/06/09

Page 51

Data output :

-Serial 1 (COM1) : RS232 or RS485 full-duplex adjustable

Parameter: XON/XOFF-Handshake,

300...115200 Baud, 8 databits, no parity, 1 stopbit

-USB : USB 2.0 full speed device, Type B connector, Type FTDI (FT245R),

VIRTUAL COM PORT driver:

www.ftdichip.com

-Memory Card : SD-Card, Types (up to 2GB) ref. to chap. 5.2