Page 1

Ultrasonic Anemometer 2D

Operating Instructions 4.3801.00.000

1. Range of Application

The Ultrasonic Anemometer 2D is designed to detect

the horizontal components of wind speed and wind

direction in two dimensions as well as the virtual

temperature. Due to its very short measurement

intervals, the instrument is ideal for the inertia-free

measurement of gusts and peak values.

In certain weather situations the accuracy of the air

temperature measurement (virtual-temperature)

surpasses that one of the classic method where the

temperature transmitter is used a weather and thermal

radiation shield.

The measured data are available as analogue signals

and as a data telegram via a serial interface. The

ultrasonic transducers as well as its carrying arms are

automatically heated so that the measuring results, in

case of critical ambient temperatures, are not affected

by icing rain or snow, and the risk of operation trouble,

caused by icing, is minimized.

2. Mode of Operation

The Ultrasonic Anemometer 2D consists of 4 ultrasonic transducers, in pairs of 2 which are opposite each

other at a distance of 200 mm.

The two measurement paths thus formed are vertical to each other.

The transformers act both as acoustic transmitters and acoustic receivers.

The respective measurement paths and their measurement direction are selected via the electronic control.

When a measurement starts, a sequence of 4 individual measurements in all 4 directions of the

measurement paths is carried out at maximum possible speed.

The measurement directions (acoustic propagation directions) rotate clockwise, first from south to north, then

from west to east, from north to south and finally from east to west.

The mean values are formed from the 4 individual measurements of the path directions and used for further

calculations.

A measurement sequence takes approx. 10 msec at +20°C.

.

1 - 10 021280/04/02

Page 2

3. Measurement Principle

3.1 Wind speed and direction

Wind from NNE

Y-Component

X-Component

E

N

W

S

The speed of propagation of the sound in calm air is

superposed by the speed components of an air flow in

wind direction.

A wind speed component in the direction of the

propagation of the sound supports the speed of

propagation, thus leading to an increase in the speed. A

wind speed component opposite to the direction of

propagation, on the contrary, leads to a reduction of the

speed of propagation.

The speed of propagation resulting from the

superposition leads to different propagation times of the

sound at different wind velocities and directions over a

fixed measurement path.

As the speed of sound is very dependent on the air

temperature, the propagation time of the sound is

measured on both of the measurement paths in both

directions. In this way, the influence of the temperaturedependent speed of sound on the measurement result

can be eliminated.

By combining the two measuring paths which are at right angles to each other, one obtains the

measurement results of the sum and the angle of the wind speed vector in the form of rectangular

components.

After the rectangular speed components have been measured, they are then transformed by the µ-processor

of the anemometer into polar co-ordinates and output as sum and angle of wind speed.

3.2 Acoustic-Virtual Temperature

As previously mentioned, the speed of the propagation of sound is shows a radix dependency on the

absolute air temperature, but is rather independent of air pressure, and only slightly dependent of humidity.

Thus these physical properties of gases can be used to measure air temperature at constant and known

chemical composition.

It is a measurement of gas temperature which is made without thermal coupling to a solid state sensor.

The advantages of this measured variable is, on the one hand, its inertia free reaction to the actual gas

temperature, and, on the other hand, the avoidance of measurement errors such as those which occur when

a solid state temperature sensor is heated up by radiation.

Due to the low dependency of the speed of propagation of the sound on the air humidity, the “Virtual

Temperature” refers to dry air (0% humidity) under the same pressure conditions as that one actually

measured.

The deviation of the measured “acoustic-virtual temperature”, compared with the real air temperature, is

linear-dependent from the absolute humidity content of the air.

The part of water vapour in the air increases proportionally the sonic speed, as H

2

O-molecules have approx.

only half of the mass of the remaining air-molecules (O

2

and N2).

The rise of the sonic speed leads to an apparent (virtual) rising of the measured temperature in humid air

compared with dry air of the same temperature.

The deviation of the measured virtual temperature in humid air, compared with real air temperature, can be

corrected according to the following correlation, when the value of absolute humidity is given:

Tr = Tv – Tv * 0,135 K * m3 / g * H

abs

and Tr represents the real air temperature, T

v

the measured acoustic-virtual temperature and H

abs

the

absolute humidity in grams H

2

O per m³ of air.

The virtual temperature at 100 % is too high by approx. 2 Kelvin with an air temperature of 20°C.

2 - 10 021280/04/02

Page 3

4. Technical Data

Wind Speed

Measurement range 0...65 m/s

Accuracy

± 0.1 m/s , at the range 0 ... 5 m/s

resp. ± 2 % rms from measured value at > 5 m/s

Resolution 0.1 m/s

Wind Direction

Meas. range 0...360°

Accuracy

± 1.0°

Resolution 1°

Virtual Temperature

Meas. range - 40 .... + 70 °C

Accuracy

± 0.5 K

Resolution 0.1 K

Data output digital

Interface RS 485 / RS 422

Baud rate 1200, 2400, 4800, 9600, 19200 selectable

Output

Instantaneous values of speed, direction and temperature

Gliding mean values 1sec.; 10sec.; 1min.; 2min.; 10min.

Output rate Spontaneous 1 per 100 msec up to 1 per 25.5 sec,

selectable

On request, asynchronous or synchronous measurement

Status identification

Heater status, path disturbance, δT temperature path to path

General

Internal meas. rate 400 measurements per second, at 25 °C

Temp. range - 40 ... + 70 °C

Operating voltage Supply 20…28 V

rms

AC/DC, max. 70 VA

Idling voltage when heating is switched-off: max. 32 V

rms

Protection IP 65

Icing according to THIES STD 012001

Corrosion No corrosion after 3 month of salt fog and condensation

EMV EN 55022 5/95 class B; EN50082-2 2/96

Model V4A Stainless steel for housing and sensor arms

Mounting to a mast tube 1

½ ”, for ex. DIN 2441

Type of connection 8 pole plug connector in the shaft

Weight approx. 2.5 kg

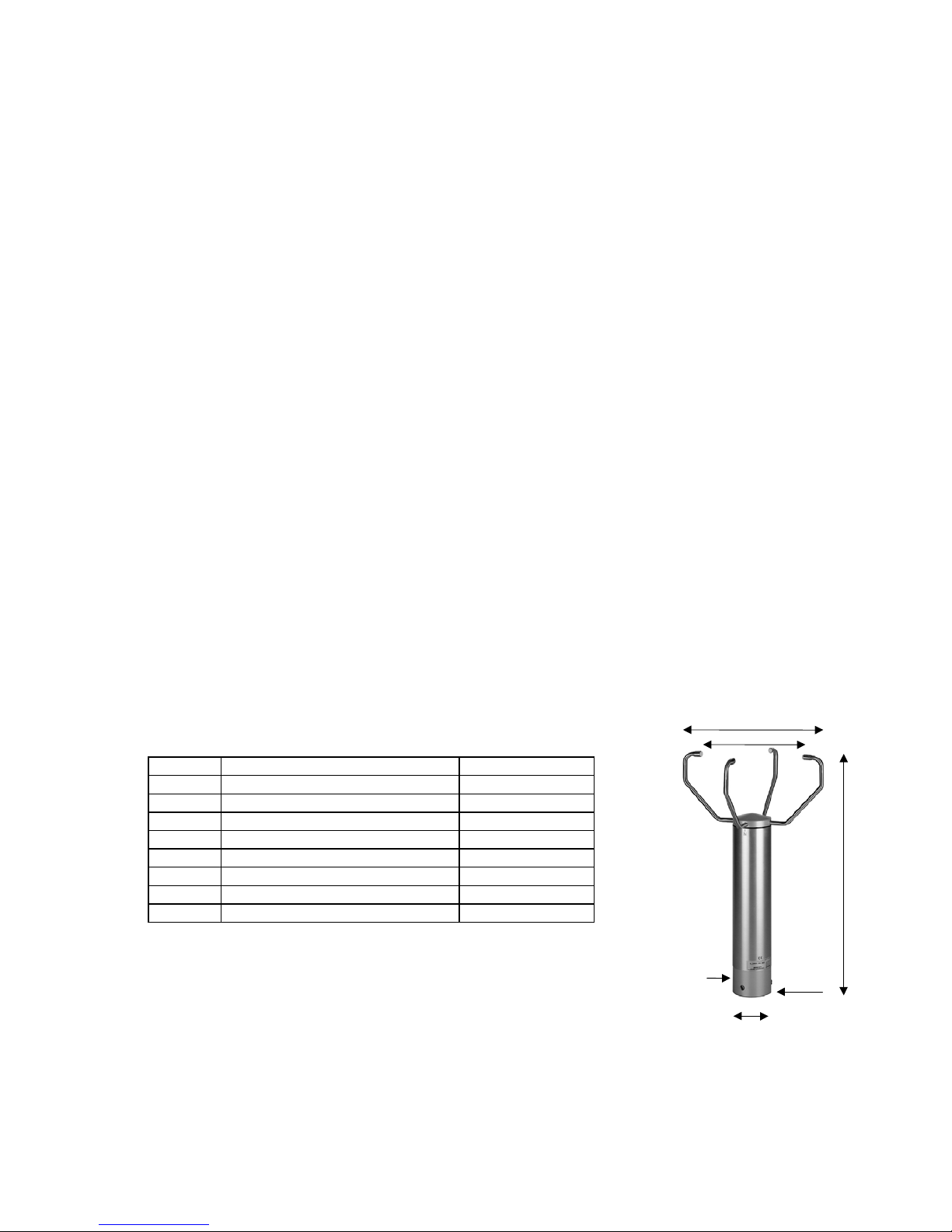

Scale Drawing

3 - 10 021280/04/02

5. Plug Connection Assignment

Pin-No. Function Remark

1 (A)

Selection Instr.-ID (Low active), bit 0 Pull up 10 KΩ intern

2 (B)

Selection Instr.-ID (Low active), bit 2 Pull up 10 KΩ intern.

3 (C)

TX− / RX− (Z) RS 485 / RS 422 Serial interface

4 (D)

Selection Instr.-ID (Low active), bit 1 Pull up 10 KΩ intern.

5 (E)

TX+ / RX+ (Y) RS 485 / RS 422 Serial interface

6 (F)

GND Serial interface

7 (G)

Supply 20−28 VAC, nom. 24 VAC Idling volt. 32 VAC

8 (H)

Supply 20−28 VAC, nom. 24 VAC Idling volt. 32 VAC

5.1 Hints for supplying the instrument:

The instrument must be supplied by 24 volts DC or AC

rms

, In order to guarantee the complete heating power.

Mounting sha ft

for Mast tube 1½“

40 mm depth

Ø 70

200

275

422

8 pole

plug

In the shaft

In order to protect the heating winding the supply voltage must not succeed an absolute value of 28v ac or

dc.

The maximum permissible idling voltage with switched-off heating is effectively 32 V DC or AC

rms

.

Page 4

6. Interface Description

6.1. Telegram „VESTAS“ ! I I V V V D D D S T T T B C R

4 - 10 021280/04/02

6.2 Definition of Checksum and Status byte

6.2.1 Forming of Checksum

The checksum is the result of the byte-wise EXOR-combination of the bytes in the telegram acc. following

definitions.

CSTEMP = XOR-Combination of Bytes 1..13 starting with 0 (Character '!' is not part of the

checksum)

Checksum = (High-Nibble(CSTEMP) XOR Low-Nibble(CSTEMP) ) + ASCII(0)

6.2.2 Definition of Status Byte

The status byte contains information about the current state of the system.

The information comprises:

• error events with the measurement value acquisition

• a possible de-calibration caused, e.g., by a change in the measurement path length

(due to mechanical deformation of the transducer carrying arms)

• the operation state of the instrument heating.

6.2.3 Structure of Status Byte

Bit 0 0 = data valid 1 = data invalid

Bit 1 temperature difference between X and Y measurement path (LSB)

Bit 2 temperature difference between X and Y measurement path (MSB)

Bit 3 Number of required measuring cycles for an error-free measurement value acquisition (LSB)

Bit 4 Number of required measuring cycles for an error-free measurement value acquisition (MSB)

Bit 5 Exceeding measuring range(counter overflow)

Bit 6 Reserved

Bit 7 0 = heating off 1 = heating on

6.2.4 Definition of Temperature Difference in Status Byte

Bit 2 Bit 1 Temperature difference x-path to y-path in Kelvin

0 0 0,0 K to 3,1 K

0 1 3,2 K to 6,3 K

1 0 6,4 K to 7,9 K

1 1 ≥ 8,0 K → invalid measurement

6.2.5 Definition of required measuring cycles in Status Byte

Bit 4 Bit 3 Number of required measuring cycles

0 0 = 16 measuring cycles

0 1 16 < measuring cycles < 32

1 0 32 < measuring cycles < 64

1 1 ≥ 64 measuring cycles, invalid measurement

CHARACT.NO CHARACTER AVAILABLE

FUNCTION

1 (!) ! Response character

2 (I) 0 ••• 9 Identifier Characters

3 (I) 0 ••• 9 Identifier characters

4 (V) 0 ••• 9 Wind speed * 10 1m/s

5 (V) 0 ••• 9 Wind speed * 10 0m/s

6 (V) 0 ••• 9 Wind speed * 10

-1

m/s

7 (D) 0 ••• 9 Wind direction * 10 2 degree

8 (D) 0 ••• 9 Wind direction * 10 1 degree

9 (D) 0 ••• 9 Wind direction * 10 0 degree

10 (S) + ••• − Sign

11 (T) 0 ••• 9 Temperature * 10 1 °C

12 (T) 0 ••• 9 Temperature * 10 0 °C

13 (T) 0 ••• 9 Temperature * 10

-1

°C

14 (B) ASCII Status byte, see item 6.2.2

15 (C) ASCII Check sum, see item 6.2.1

Page 5

5 - 10 021280/04/02

7. Averaging Procedure:

The Ultrasonic 2D forms the gliding mean value through a FIFO-memory the capacity of which comprises up

to 600 values.

In the free running measurement mode the measurement data rate is exactly 10 Hz or 100msec, and forms,

at the same time, the updating rate for the averaging memory (FIFO-memory).

If averaging is requested the measured data are recorded in the FIFO-memory stated above, the capacity of

which is built-up depending on the selected averaging period.

If the averaging period is, for example, 10 seconds, 100 memory cells are used, and in case of an averaging

period of 1 minute 600 cells.

From a selected averaging period > 1 minute up the data flow will be pre-averaged; because the memory

capacity of 600 values cannot be exceeded.

The Ultrasonic 2 D combines two different and useful procedures of mean value forming:

• The forming of vectorial mean values

• The forming of scalar mean values

These different procedures can be selected for the averaging of both the wind speed and wind direction,

depending on the application.

The procedure of forming the vectorial mean value takes the wind direction into account when averaging the

wind speed and vice versa.

Thus, the averaged dimensions of wind speed and wind direction are valued each one with the other.

This procedure of forming the mean value is well suited, for example, for measurements and analysis of

pollutant-propagation.

The procedure of forming the scalar mean value averages both dimensions of wind speed and wind direction

independently from each other.

These averaging procedures lead to results comparable with mechanical wind speed- and wind direction

transmitters.

The scalar averaging procedure is suited, for example, for location-analysis for wind power plants, where only

the dimension of the wind vector – important for power generation – is interesting but not its direction.

The vectorial and scalar procedure can be used independently with wind speed and wind direction within an

output telegram.

For this, you have to select one of the four possible combinations through the command AM (Average

Method).

Command for selecting the averaging procedure:

AM00000 (Average Method) vectorial averaging of speed and direction

AM00001 scalar averaging of speed and direction

AM00002 scalar averaging of speed and vectorial averaging of direction

AM00003 vectorial averaging of speed and scalar averaging of direction

Page 6

6 - 10 021280/04/02

8. Bus-Ability, Synchronisation of the Measurement on the Query Telegram:

8.1 Bus-Ability

The Ultrasonic supports absolutely any operation at an RS485/RS422 data bus in co-operation with further

instruments (bus operation).

The line drivers of the ultrasonic are contemporarily active only for each transmission-period of the

instrument.

The remaining time the line drivers are off-line (“three-state-mode”).

The direct connection to a PC with RS232 interface makes an interface-converter RS 485 / RS 232

necessary, e.g. our accessories order-no. 9.1702.20.000

In case of bus operation respond only those instruments with instrument-specific “ID” on request of the bus

masters

Spontaneous telegram output by selecting a respective telegram type (TT0000x) is suppressed when semiduplex operation is set, as this could lead to a blocking of the receivers at slow baud rates.

8.2 Synchronisation on Data Query

Certain application make it necessary to interrogate cyclically a collective of instruments within a short time

(e.g. 5 instruments within 100 ms).

There might be the following problem: the Ultrasonic can be contacted during a measurement by the

asynchronous query and is then not ready for transmission.

In order to guarantee an immediate instrument response without delay, the possibility of temporal

measurement synchronisation on the query is used.

In case the instrument receives, with active synchronisation, a telegram inquiry through the command

TR0000x, and further inquiry follow with intervals of less than 2,5 seconds, the instrument runs

synchronously to the inquiries and responds with smallest possible delay.

If there are no queries for more than 2,5 seconds, the instrument leaves the synchronous mode and changes

into a spontaneous measurement value acquisition.

This return to the spontaneous mode of measurement guarantees that all control functions derived from the

measurement data (e.g. switch-on heating etc.) will be able to operate also in case of a failure of query

telegram.

As soon as a new query occurs in the spontaneous mode the instrument synchronises immediately on the

query telegram.

8.3 Averaging with Active Synchronisation

In case the measurement values should be averaged please take care that – with active synchronisation –

the exact, internal time basis of 100 ms for forming the measurement values is not used. In this case, the

time is determined by the query-repetition-rate.

Page 7

7 - 10 021280/04/02

9. List of control commands

The Anemometer 2D can be controlled via its serial data interface using the commands in the following list.

Any standard terminal program such as “procomm“ , “telix“ or a Windows terminal program (e.g. “Hyper

Terminal” ) can be used.

All adjustments are stored in a E²ROM so that the adjusted parameters cannot get lost after switching

off or failure of power supply.

9.1 List of commands

Command Function Remark

<ID> AM 00000 Vectorial averaging

Vectorial averaging of wind speed and direction

<ID> AM 00001 Scalar averaging

Scalar averaging of wind speed and direction

<ID> AM 00002 Scalar / vectorial

averaging

Scalar averaging of speed / vectorial averaging of direction

<ID> AM 00003 Vectorial / Scalar

averaging

Vectorial averaging of speed / scalar averaging of direction

<ID> AV 00000 Instantaneous value

Output of the instantaneous values

<ID> AV 00001 Mean value over 1 second

Output of the gliding mean value over 1 second

<ID> AV 00002 Mean value over 10

seconds

Output of the gliding mean value over 10 seconds

<ID> AV 00003 Mean value over 1 minute

Output of the gliding mean value over 1 minute

<ID> AV 00004 Mean value over 2 minutes

Output of the gliding mean value over 2 minutes

<ID> AV 00005 Mean value over 10

minutes

Output of the gliding mean value over 10 minutes

<ID> BR 00002 1200 Baud N 8 1

Data rate 1200 Baud, 8 Data bits, No Parity, 1 Stop bit

<ID> BR 00010 1200 Baud E 7 1

Data rate 1200 Baud, 7 Data bits, Parity Even, 1 Stop bit

<ID> BR 00003 2400 Baud N 8 1

Data rate 2400 Baud, 8 Data bits, No Parity, 1 Stop bit

<ID> BR 00011 2400 Baud E 7 1

Data rate 2400 Baud, 7 Data bits, Parity Even, 1 Stop bit

<ID> BR 00004 4800 Baud N 8 1

Data rate 4800 Baud, 8 Data bits, No Parity, 1 Stop bit

<ID> BR 00012 4800 Baud E 7 1

Data rate 4800 Baud, 7 Data bits, Parity Even, 1 Stop bit

<ID> BR 00005 9600 Baud N 8 1

Data rate 9600 Baud, 8 Data bits, No Parity, 1 Stop bit

<ID> BR 00013 9600 Baud E 7 1

Data rate 9600 Baud, 7 Data bits, Parity Even, 1 Stop bit

<ID> BR 00006 19200 Baud N 8 1

Data rate 19200 Baud, 8 Data bits, No Parity, 1 Stop bit

<ID> BR 00014 19200 Baud E 7 1

Data rate 19200 Baud, 7 Data bits, Parity Even, 1 Stop bit

<ID> DV Device version request

Query of the software version of the instrument

<ID> ES 00000 Sign-echo switched off

Echo operation of transmitted characters (to Sonic) switched off

<ID> ES 00001 Sign-echo switched on

Echo operation of transmitted characters switched on

<ID> HT 00000 Heating locked

Switching on of heating suppressed

<ID> HT 00001 Heating energised

Heating operation possible

<ID> KY 00000 Key, no access

Software-key, access to EEPROM closed

<ID> KY 00001 Key, open access

Software-key, access to EEPROM open

<ID> NC 00xxx North correction in 1°

units

Input of north correction, value range 00000 up to 00360

<ID> OS 00000 Wind speed in m/s

Scale of Wind speed in meter per second

<ID> OS 00001 Wind speed in Km/h

Scaling of Wind speed in kilo meter per hour

<ID> OS 00002 Wind speed in mph

Scaling of Wind speed in miles per hour

<ID> OS 00003 Wind speed in Knots

Scaling of Wind speed in knots (nautically)

<ID> SH Serial number “High

Word”

Query of serial number, upper 4 characters

<ID> SL Serial number “Low

Word”

Query of serial number, lower 4 characters

<ID> SV Software version, SW-

Date, Hardware version,

SH, SL

Query of software version, of the date of making out the software, of

hardware version, of serial number high word and low word

<ID> TR 00009 VESTAS Telegram

Output of VESTAS telegram on request

Page 8

8 - 10 021280/04/02

9.2 Command Input

Please find your ID (identifier-number) in the works certificate included in the delivery.

For the input of commands and parameters please open first the access to the EEPROM by entering the

command (ID) KY00001.

After all inputs have been made the access to the EEPROM should be locked again through the command

(ID) KY00000 in order to avoid unauthorised changes of the system parameters.

The command is input by entering the instrument identification number (ID) followed by two letters which

specify the actual command followed by a 5-digit code number respective value.

The characters are entered without a space and are activated with Return.

All letters must be capitalised, otherwise they will not be accepted.

Correcting the command word during input when an error has occurred is not allowed and the command

will not be accepted.

Entering the command without the 5-digit code number is interpreted as a query of the command status and

leads to the output of the current command status.

Example :

Correcting an angle of displacement while setting up the anemometer by entering a corrective

angle:

Instrument ID is accepted as 12. The necessary angular correction is 47°. The angle stored in

the system up to that time was 15°. Attention: Input and representation in units of 1°.

The correction angle is added clockwise to the measured wind direction angle.

First, opening of the EE-prom access:

Input into the system: 12KY00001 response of the system: user access

Input into the system: 12NC response of the system: !12NC00015

Input into the system: 12NC00047 response of the system: !12NC00047

Input into the system: 12KY00000 response of the system: protect

The system verifies the accepted input and displays the set value.

Attention: After the supply voltage of the instrument has been switched on or switched off the

locking is automatically activated.

The ID-number selects the requested instrument.

Page 9

9 - 10 021280/04/02

10. Preparation for Use

10.1 Selecting the Site

As already described above the ultrasonic anemometer transmits sonic bursts which are necessary for the

measurement of the propagation speed. If these sonic bursts hit a well sonic-reflecting surface they are

reflected as echo and might cause error measurements – under unfavourable conditions.

It is, therefore, advisable to install the US-anemometer with a minimum distance of 1 meter to objects in

the measurement area.

In general wind measurement instruments should be able to detect the wind conditions over a wide area. In

order to obtain comparative values when determining the surface wind, measurements should be taken at a

height of 10 meters above a plane, unobstructed area. An unobstructed area is one where the distance

between the wind transmitter and any obstacle is at least 10 times greater than the height of the obstacle. (s.

VDI (German Engineers Association) 3786). If this requirement cannot be fulfilled, then the wind

measurement instrument should be set up at a height where the measured values are not influenced by any

local obstacles (approx. 6-10 m above the level of the obstacle). The anemometer should be set up in the

center of flat roofs, not at the edge in order to avoid possible preferred directions.

10.2 Mounting the wind transmitter

The wind transmitter can be mounted to a pipe piece of R 1 ½" (Ø 48.3 mm) which is 50 mm long. The

internal diameter of the pipe must be at least 40 mm as the wind transmitter is connected electrically from

below with a plug. Solder a flexible control line LiYCY with the corresponding number of cores to the

enclosed plug. After the wind transmitter has been connected, set it onto the pipe piece respectively the mast

piece. The branch of the red marked sonic transducer must be aligned to North. To do this, take a bearing via

the ultrasonic transducer of the North/South path onto an object to the North, for example a building or a

special geographic feature. Use the four screws with hexagonal recessed holes (SW 4 mm) to attach the

instrument to the shaft.

Note : When using a lightning rod please take care that it is mounted always in an angle of

45° to the measuring distance, as otherwise there might be deviations of measuring

value.

10.3 North Alignment

For the alignment of the anemometer the branch of the red marked sonic transducer must indicate to

North. For this, you select an obvious point in a northerly or southerly direction in the surroundings with the

aid of a compass; then turn the mast or the anemometer into this direction until both arms opposite are

situated in a straight line.

It is also possible that oneself stands in a northerly or southerly direction with respective distance, and a

partner turns the anemometer or mast by command until both sensor arms are situated in a straight line.

In this case, it is advisable to use a pair of field glasses.

11. Accessories

Connecting cable, complete 506 702

15 m cable with connecting plug at the

sensor, the other end open

PC Software Meteo-Online 9.1700.98.000

For graphic visualization of measured values

on PC screen

Power Supply Unit 9.3388.00.000

For the power supply of the Ultrasonic

Anemometer

Interface converter 9.1702.20.000

For signal conversion of interface

Lightning Rod 4.3100.99.150

For lightning protection

Page 10

12. Maintenance

As the instrument has no moving parts i.e. operates without wear or tear, only minimal maintenance is

required. As the sensor surface is permanently washed up by the falling rain it is only occasionally necessary

to clean the surface with non-aggressive cleansing agent and soft cloth. These cleansing activities can be

carried out – as far as necessary – on occasion of the routine checks.

13. Calibration

The ultrasonic anemometer does not contain any adjustable components such as electrical or mechanical

trimming elements. All of the components and materials are invariant in time. Thus, regular calibration

because of ageing is not required. Only a mechanical deformation of the transformer arms and the resulting

changes in the length of the measurement paths lead to errors in the measured values.

The virtual temperature can be used to check the length of the measurement path. A change in the

measurement path length of 0.17% and consequently a measurement error of 0.17% of the wind speed

corresponds to a 1 K deviation of the virtual temperature at 20 °C, thus at 6 K deviation, the measurement

error of wind speed is approx. 1%.

If the distance of measuring path of the anemometer is de-aligned please contact the producer for a recalibration of the instrument.

14. Warranty

Damages resulting from improper handling or caused by external influences, e.g. lightning, are excluded from

the warranty. The warranty expires if the instrument has been opened.

Attention :

A return of the instruments must be effected in the original packing as otherwise the

guarantee expires in case of mechanical damages e.g. by deformation of the

transducer arms.

ADOLF THIES GmbH & Co. KG

Hauptstraße 76 37083 Göttingen Germany

P.O. Box 3536 + 3541 37025 Göttingen

Phone ++551 79001-0 Fax ++551 79001-65

www.thiesclima.com info

@

thiesclima.com

- Alterations reserved -

10 - 10 021280/04/02

Loading...

Loading...