STOW

HIEMAN

N

TE

A

THE ASSOCIATION FOR THE WORK TRUCK INDUSTRY

TM

MEMBER

Tailgates By THIEMAN

AWAY

M, MLB, MDC, MDC LB

INSTALLATION INSTRUCTIONS

!

IMPORTANT! KEEP IN VEHICLE!

PLEASE READ AND UNDERSTAND THE CONTENTS OF THIS

MANUAL BEFORE OPERATING THE EQUIPMENT.

Phone: 419-586-7727 Fax: 419-586-9724

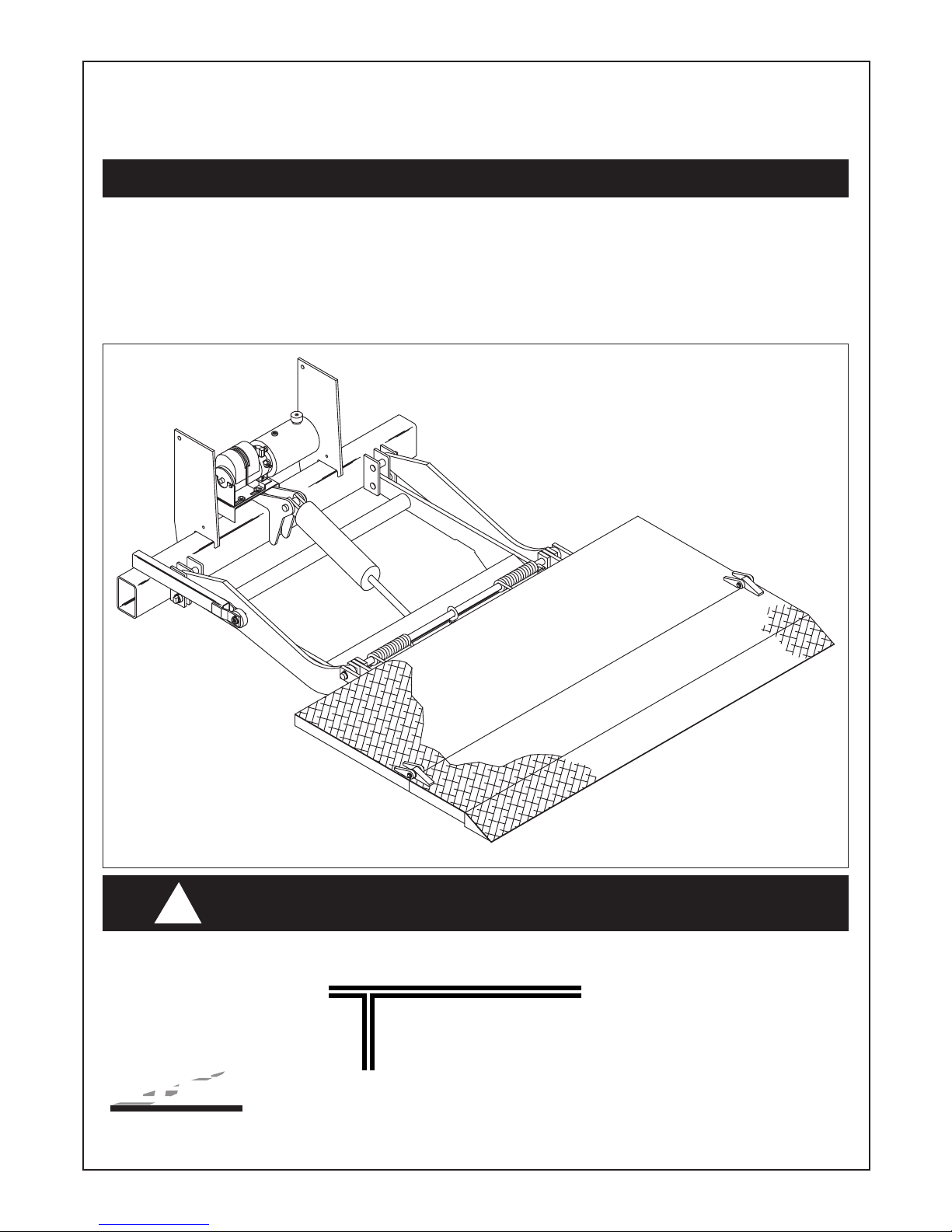

M-25 shown

TAILGATES, INC.

600 East Wayne Street

Celina, Ohio 45822

www.thiemantailgates.com

16, 20, 25, 30

M

ATTENTION INSTALLERS:

hanges are made periodically to the installation procedure to comply with engineering changes. To

C

ensure proper liftgate operation, it is VERY IMPORTANT

to read and understand the installation

instructions before attempting an installation. Installers also MUST read and understand the liftgate’s

Owner’s Manual before installing the liftgate, so they can operate the liftgate safely as required during

different stages of the installation process. NEVER perform a modification on the liftgate, which is not

specifically covered in the manual or which is unauthorized by Thieman. Modifications may result in

failure of the liftgate and may create hazards for liftgate installers, operators, or maintainers. Serious

damage, equipment failure, or operator injury could result from improper installation. This equipment

MUST have all decals applied properly. FAILURE to apply all decals properly will VOID all warranties!

Any installer with questions or doubts should contact Thieman before proceeding.

The M, MLB, MDC, and MDCLB are stow-away style liftgates for use on trucks and trailers. Before

mounting your liftgate, make sure that the model you have will work on the truck or trailer you intend to

mount it on. The loaded and unloaded bed height of your truck (with weight of liftgate figured in) MUST

fall within the bed height range of your liftgate. To determine the bed height range of your liftgate, you

must know the full model name, the platform material of both the main section and extension (i.e. both

steel, both aluminum, or steel main with aluminum extension), and the platform size (see charts and figures on pages 2 thru 4).

NOTES:

1. The tip of the platform will touch the ground on standard STOW-AWAY liftgates, but not on gates

designed for “level ride”. “Ramp ride” is standard, “level ride” is built for special order only.

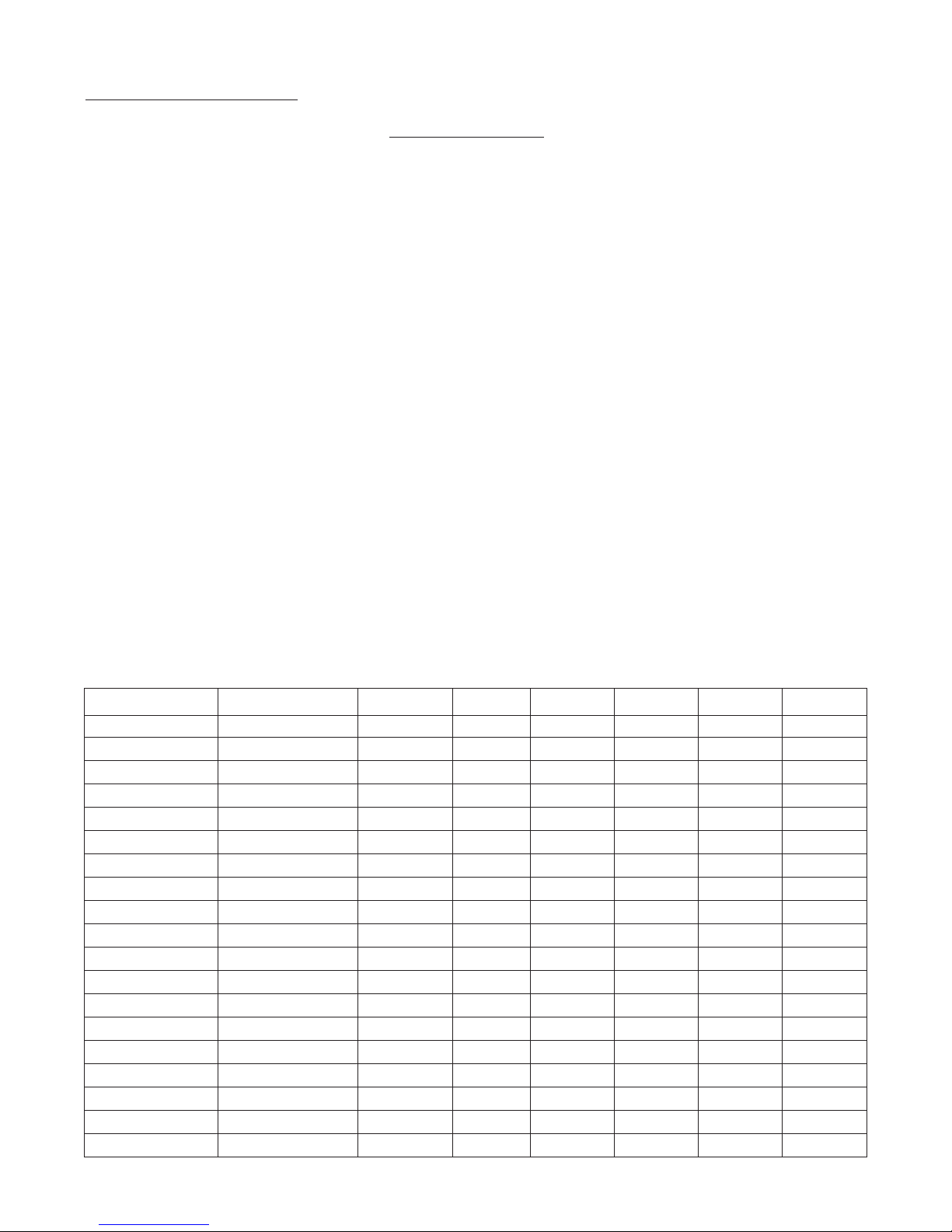

2. Reference figures 1 and 2 for charted dimensions on pages 2 thru 4.

3. All maximum mounting dimensions are shown with the vehicle empty; all minimum mounting dimensions are shown with the vehicle loaded.

4. Check bed height “H” when parked on a level surface.

5. Check “C” dimension for possible interference with spring hanger bracket before installation.

6. If the liftgate was ordered with the optional 216 receiver kit, use the loaded bed height (Hmin) to

determine what set of mounting dimensions to use. Bed height range for 216 Kit is 42" min. (vehicle

fully loaded) and 54" max. (vehicle empty).

ALL STEEL PLATFORMS (STEEL MAIN AND EXTENSION)

Platform Size Models H A B C D E

32+5 All Models 34"-40" 16.50 14.00 32.00 4.00 5.50

38W MLB 16/20 34"-40" 16.50 14.00 32.00 4.00 5.50

36+6 M 16/20 37"-44.99" 19.50 17.00 30.50 5.00 8.00

45"-50" 22.00 16.00 28.50 5.50 10.00

50"-54" 25.00 15.00 25.50 6.50 13.00

36+6 M 25/30 38"-44.99" 19.50 17.00 30.50 5.00 8.00

45"-50" 22.00 16.00 28.50 5.50 10.00

50"-54" 25.00 15.00 25.50 6.50 13.00

42+6 All Models 42"-45" 19.50 18.50 30.50 5.00 8.00

45"-50" 22.00 17.50 28.50 5.50 10.00

50"-54" 25.00 16.50 25.50 6.50 13.00

42+10 RET M 16/20 37"-45" 19.50 17.00 30.50 4.19 6.00

45"-50" 22.00 16.50 28.50 4.75 8.00

50"-54" 25.00 16.00 25.50 5.50 11.00

42+10 RET M/MDC 25/30 38"-45" 19.50 17.00 30.50 4.19 6.00

45"-50" 22.00 16.50 28.50 4.75 8.00

50"-54" 25.00 16.00 25.50 5.50 11.00

42W All Models 45"-50" 22.00 16.00 28.50 5.50 10.00

50"-54" 25.00 15.00 25.50 6.50 13.00

2.

STEEL MAIN SECTION/ALUMINUM EXTENSION PLATFORMS

Platform Size Models H A B C D E

48W M/MDC25 45"-49.99" 22.00 17.00 28.50 5.50 10.00

50"-54" 25.00 15.00 25.50 6.50 13.00

48W MDCLB 25 38"-45" 19.50 17.00 30.50 5.00 8.00

ALL ALUMINUM PLATFORMS (ALUMINUM MAIN AND EXTENSION)

Platform Size Models H A B C D E

27+6 MLB 16/20/25 34"-40" 16.50 13.00 32.00 4.50 5.50

37W MLB 16/20 34"-40" 16.50 13.00 32.00 4.50 5.50

36+6 M16/20 37"-44.99" 19.50 18.00 30.50 5.00 8.00

45"-50" 22.00 17.00 28.50 5.50 10.00

50"-54" 25.00 16.00 25.75 6.50 13.00

36+6 MDC/M25/30 38"-44.99" 19.50 19.00 30.50 5.00 8.00

45"-50" 22.00 18.00 28.50 5.50 10.00

50"-54" 25.00 16.50 25.75 6.50 13.00

40+6 All Models 42"-45" 19.50 19.00 30.50 5.00 8.00

45"-50" 22.00 18.00 28.75 5.50 10.00

50"-54" 25.00 16.50 26.00 6.50 13.00

42+10 RET M 16/20 37"-44.99" 19.50 19.00 30.50 4.50 6.50

45"-50" 22.00 18.00 28.50 5.00 8.50

50"-54" 25.00 16.50 25.75 6.00 11.50

42+10 RET M/MDC 25/30 38"-44.99" 19.50 19.00 30.50 4.50 6.50

45"-50" 22.00 18.00 28.50 5.00 8.50

50"-54" 25.00 16.50 25.75 6.00 11.50

48W M/MDC25 45"-49.99" 22.00 18.00 28.50 5.50 10.00

50"-54" 25.00 16.25 25.75 6.50 13.00

48W MDCLB25 39"-45" 19.50 19.00 30.50 5.00 8.00

A—Distance from top of bed to trunnion

tube.

B, D, E—Clearance needed for platform in

closed position.

C—Minimum distance needed for

mounting plates.

F, G, J, K—Rubrail notch dimension. See

figure 2.

H—Distance from ground to bed height.

3.

INSTALLATION INSTRUCTIONS

Step 1 Remove banding from gate undercarriage. Inspect for obvious shipping damage or

missing parts.

Step 2 If necessary notch rear of body as shown in figure 2.

Step 3 Center and level spacer at rear of body and tack weld into position. See figure 3.

4.

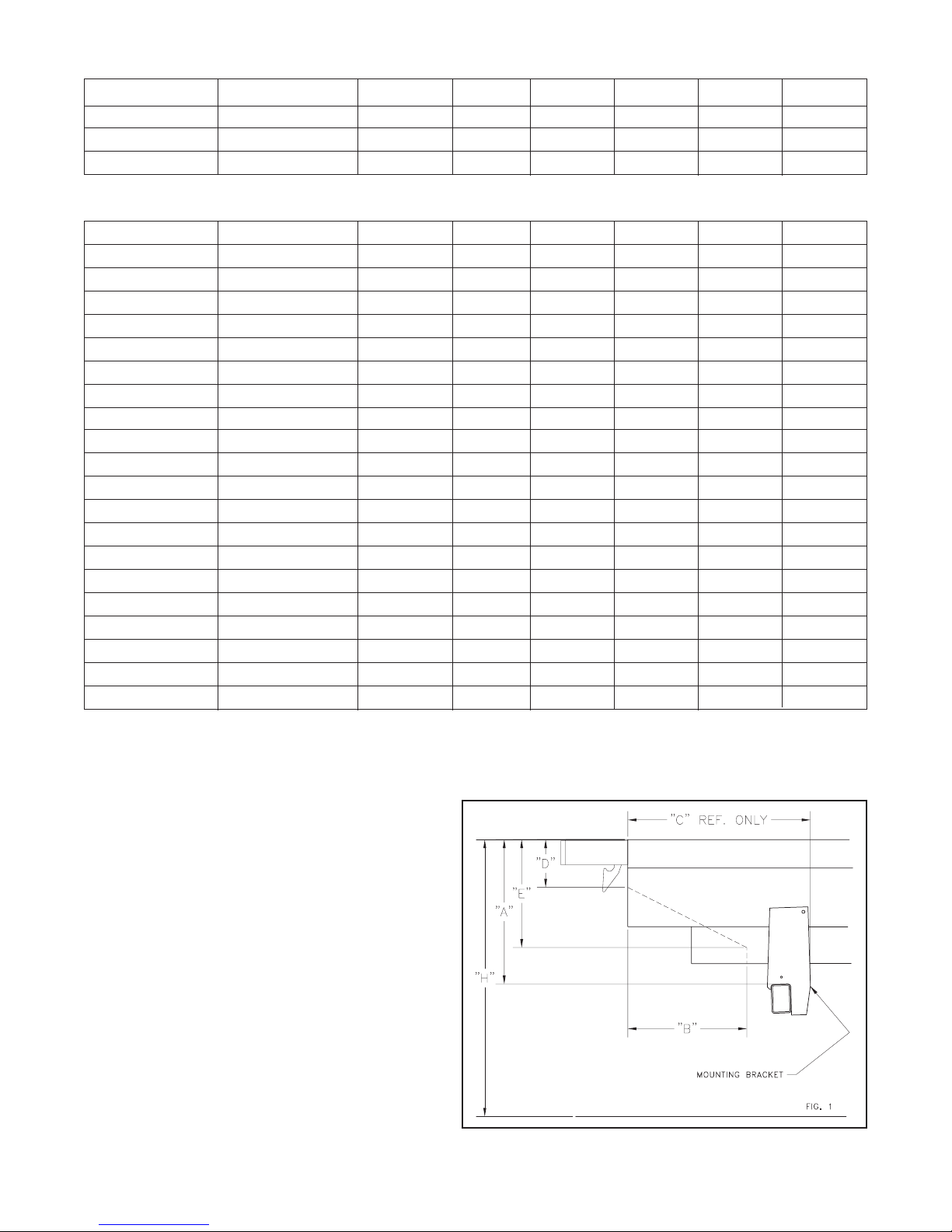

Step 4 Raise the liftgate by lifting under the main section of the folded platform with a forklift.

Make sure the platform is clamped securely to the forks. With the trunnion and liftarms

hanging from the platform, the platform rib and pivot assembly should make firm contact.

The installer may need to rotate the trunnion, as shown, to make this contact. Tack weld

the platform hinge to the pivot assembly to maintain contact. See figure 4.

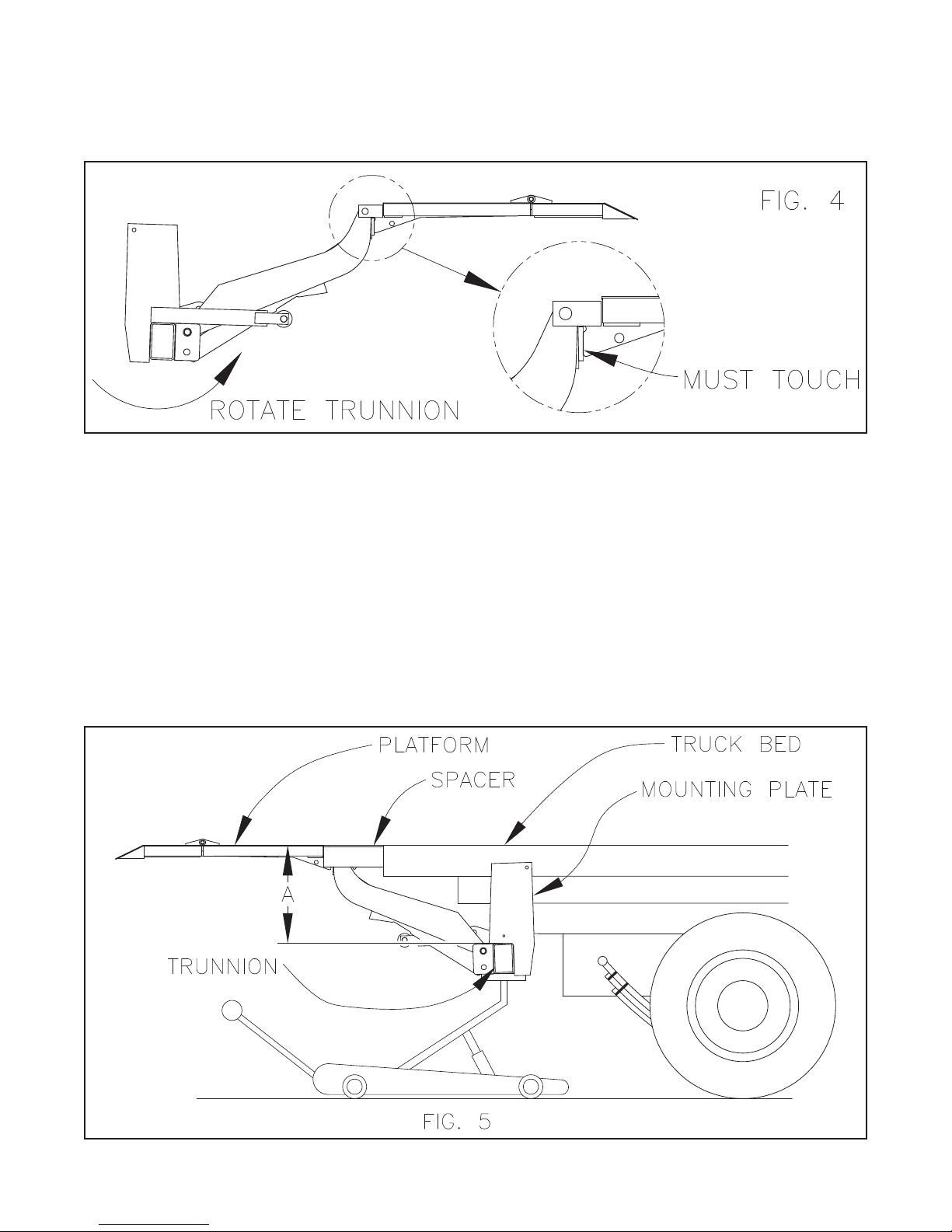

Step 5 Using a forklift or crane, center and position liftgate behind vehicle and jack trunnion into

position. See figure 5 and 1 for “A” dimension. Note: Do Not connect hydraulic lines at

this time, the M series liftgates are pre-assembled with cylinder and pump mounted. On

certain installations, for instance a truck with a rear fuel tank, the pump may get in the

way of obtaining the proper “A” dimension. In most of these cases, Except for the 50" to

54" bed height range, where the “A” dimension is 25.00, the pump may be removed and

then mounted to the second, more rearward, set of holes in the pump mounting bracket

to provide more clearance. Note: Do Not move pump when the “A” dimension is 25.00

because the platform will not stow properly.

Step 6 Cut a small post or similar item to the correct length and place it under the platform so

the platform and payload area are at the same height. Place barrels or other protective

equipment under the platform so that the gate will not accidentally fall and injure someone.

5.

Step 7 Attach mounting plates to truck by means of .62" Grade 8 screws or by a .38 fillet

weld all around. Weld the mounting plates to the trunnion tube all around in the same

manner.

Note: On installation where narrow underframe members are used, the liftgate mounting

plates will reach these frame members for mounting purposes; however, the space

between the frame members and trunnion now becomes quite large. This lengthy

unsupported area may contribute to undesirable ‘springiness’ under heavy loading.

Many installers when faced with this problem extend the underframe support on the

mounting plate closer to the trunnion by adding a channel section under the existing

frame member as shown in figure 6. On certain equipment such as a lengthened van

body, rebuilt trailer or other altered vehicle, where the underframe stops short of the

end of the vehicle body frame, extra support must be added to avoid any independent deflection. See figure 7 for bracing suggestions. Refer to figure 1 for clearances.

Step 8 Fasten the 150 amp circuit breaker provided within 2 ft. of the truck battery. Route the

battery cable from the liftgate toward the circuit breaker. AVOID SHARP CORNERS

AND HIGH HEAT AREAS. Use cable clips provided to secure the cable to the truck

frame every 2 ft. Cut the cable to the desired Length and strip .88" of the insulation

from the end. Slide the pre-cut heat shrink over the end of the cable. Secure the

cable lug in a vise and apply heat to the connector and insert the cable as the solder

melts. Allow connector to cool and install the heat shrink. Attach this end to one terminal on the 150 amp circuit breaker.

6.

Step 9 Many late model trucks have battery connections as shown in figure 8. The ground

cable from the battery may be connected directly to the engine block with only a light

braided ground strap connecting the block to the chassis. Where this is the case, the

factory installed cable does not provide an adequate ground circuit for operating battery powered liftgates. We recommend that the cables labeled with an “X” be not less

than #2 gauge cable as supplied in the installation kit. Also because of the high current draw (approximately 200A)we recommend that the alternator be a heavy duty

type and the battery must have a 150 AMP minimum reserve capacity.

7.

Step 10 Install breather cap on power unit and connect hydraulic hose from power unit to flow

control. Remove tack weld from Step 4. See figures 9 thru 12 for hose and battery

cable connections. On Gravity Down

liftgates, install return line in place of plugs

on butt end of cylinder and return port on pump reservoir. On Power Down

liftgates, the rod end port on cylinder must be plumbed to C1 port on pump.

(Note: Incorrectly plumbing rod end port on cylinder to C2 port will make gate drift

down and motor to spin backwards from raised position.) Attach ground cable to the

tapped hole in the pump base labeled “GND” and to the trunnion mounting plate with

the .38 hardware and internal lockwashers provided.

Step 11 Locate and mount the toggle switch assembly or pushbutton box in a convenient

place and wire the switch according to figure 13 or 14.

8.

9.

Step 12 Check all operations and trim excess where required for stow clearances. The M

series liftgate comes with a standard snubber kit to prevent excessive wear during

transport. See figure 15 for mounting instructions.

Step 13 To re-adjust the platforms spring assist, follow these steps:(See figure 16.)

1. Fold the platform for stowing and raise until the tension is relieved from spring

item C.

2. Remove snap ring item A from the groove and slide it to the left.

3. Remove the locknut item G from item E.

4. Slide spring support tube item B to the left and tilt right side up and remove from

assembly.

5. Remove long straight end of closing spring from hole in center rib of platform item

D. Moving the spring to the left decreases the tension and to the right increases

the tension.

6. Return spring support tube to position and replace snap ring.

10.

Step 14 After installation is complete lower platform to the ground and if a sag is present

between the platform and main section a shim must be added as shown in figure 17.

11.

Step 15 Now review the entire installation with the power source disconnected. With the

power connected again, check for possible interference of all moving parts. If interference occurs review the instructions and contact THIEMAN if the problem can not

be eliminated.

Step 16 Thieman recommends that the installer perform a weight test of the liftgate to check

the welds or mounting bolts and the structural integrity of the body or frame of the

truck or trailer. The load used should be the maximum weight rating of the particular

liftgate with the weight centrally located on the platform. A minimum of 20 cycles

should be made to insure the integrity of the mounting.

Step 17 Finish paint as required and remove the pre-mask on decals already applied by

Thieman. Apply the remaining decals in the appropriate locations as shown. When

painting, carefully grease or mask fittings and exposed portion of the piston rod. The

decals MUST be applied properly or all warranties are VOID!

Step 18 Any lights that were removed or obstructed must be replaced or relocated in such a

manner that the completed vehicle must be compliance with FMVSS 108 (49 CFR

571.108).

Step 19 It may be necessary to add Rear End Protection on this installation. Check your local

and state laws for requirements for FMCSR 49 CFR 393.86.

12.

Item Part Name Part Number

1 Warning Decal-off center 4671050

2 Fast Idle Decal 4650150

2 PTODecal 4650140

3 Danger Decal-no riding 4609

4 Operating Decal 4650890

5 Capacity Decal-1600# 4650750

5 Capacity Decal-2000# 4650100

5 Capacity Decal-2500# 4650110

5 Capacity Decal-3000# 4650120

6 Warning Decal-pinch point 4604

7 Handle Decal 4605

8 Thieman Nameplate (not shown) 4650800

9 Urgent Warning Decal 4681

10 Reflector (3) 5705

11 Wiring Diagram-Gravity Down 4612

11 Wiring Diagram-Power Down 4614

12 Warning Decal 4620

13 Caution Decal 4650770

14 Receiver Latch Decal (w/optional 216 Kit) 4683

13.

14.

15.

Rev. 12/17 • 5C • MP94438

Loading...

Loading...