Thiele TWN 1320, TWN 1920 Mounting Instructions

B09117-A 1 EN-050117

Mounting Instructions

Original in compliance with 2006/42/EG

Connecting links

TWN 1320 and TWN 1920

Grades 8 and 10/XL

Manufacturer:

THIELE GmbH & Co. KG

Tel: +49 (0) 2371 / 947 - 0

58640 Iserlohn

www.thiele.de

1 Beschreibung und bestimmungsgemäße Verwendung

Connecting links are intended for use with sling chain assemblies for the

attachment and lifting of loads according EN 818-4 or for lashing chains

according EN 12195-3.

They are exclusively meant to connect individual chain sections/legs to each

other or to intermediate links or other attachment elements with eyelets and

must only be arranged in one load-carrying chain section.

A connecting link consists of two symmetrical halves attached to each other by

means of a secured pin. The link is marked with nominal chain size and quality

grade, manufacturer’s symbol and traceability code.

THIELE connecting links meet EG Machinery Directive 2006/42/EG

requirements and feature a safety factor of at least 4 based on Working Load

Limit (WLL).

The connecting links are designed to withstand 20 000 dynamic load changes

under maximum load conditions. In the event of higher loads (e.g. multishift/automatic operation, magnetic spreaders) the Working Load Limit (WLL)

must be reduced before the links are put to use.

Connecting links must exclusively be used

within the limits of their permissible working load limit,

for permissible attachment methods and inclination angles,

within the temperature limits prescribed,

by trained and authorized persons.

Any alternating use for lifting and lashing purposes is impermissible!

Connecting links are as a rule not permitted for the transportation of persons.

2 Safety Notes

Risk of Injury!

Never walk or stay under lifted loads!

Make sure to use connecting links free

from defects.

Operators, fitters, and maintenance personnel must especially observe the

Operating Instructions of the sling chain assembly into which the connecting

links are to be installed. They have to observe the documentations DGUV V 1,

DGUV R 100-500 Chapter 2.8, DGUV R 109-004, DGUV I 209-013 and

DGUV I 209-021 issued by the German Employer’s Liability Association as

well as standard specifications DIN 685-5 and DIN EN 818-6.

The directions given in these Mounting Instructions and specified

documentations relating to safety, assembly, operation, inspection and

maintenance must be made available to the respective persons.

Outside the Federal Republic of Germany the specific provisions issued

locally in the country where the items are used must also be observed.

Make sure these Mounting Instructions are available in a place nearby the

product during the time the equipment is used.

Please contact the manufacturer if replacements are needed.

When performing work make sure to wear your personal protective

equipment!

Improper assembly and use may cause personal injury and/or damage

to property.

Assembly and disassembly as well as inspection and maintenance must

exclusively be carried out by skilled and authorized persons.

Structural changes are impermissible (e.g. welding, bending).

Visually inspect the equipment prior to each use.

Never use worn-out, bent or otherwise damaged connecting links.

Never expose connecting links to loads exceeding the specified Working Load

Limit.

When used as locking link in endless chains of identical nominal size the

Working Load Limit must be reduced by 20%.

Do not use force when mounting/positioning the attachment components.

Avoid sharp edges.

Do not twist or knot the chains together.

In the event of doubts about use, inspection, maintenance or similar things

contact your safety officer or the manufacturer.

Usage without split sleeves is not allowed. Split sleeve do not stay in contact

to other parts.

THIELE will not be responsible for damage caused through non-

observance of the instructions, rules, standards and notes indicated!

As regards quality grade 10/XL THIELE does not give its general approval

to the assembly of components stemming from different manufacturers!

Working under the influence of drugs or alcohol is strictly forbidden.

3 Commissioning

Prior to using the components for the first time make sure that

the components comply with the order and have not been damaged,

test certificate and installation instructions have been provided,

markings correspond with what is indicated in the documentation,

documentations are safely kept in an orderly manner.

Dispose of the packing in an environmentally compatible way according to local

rules.

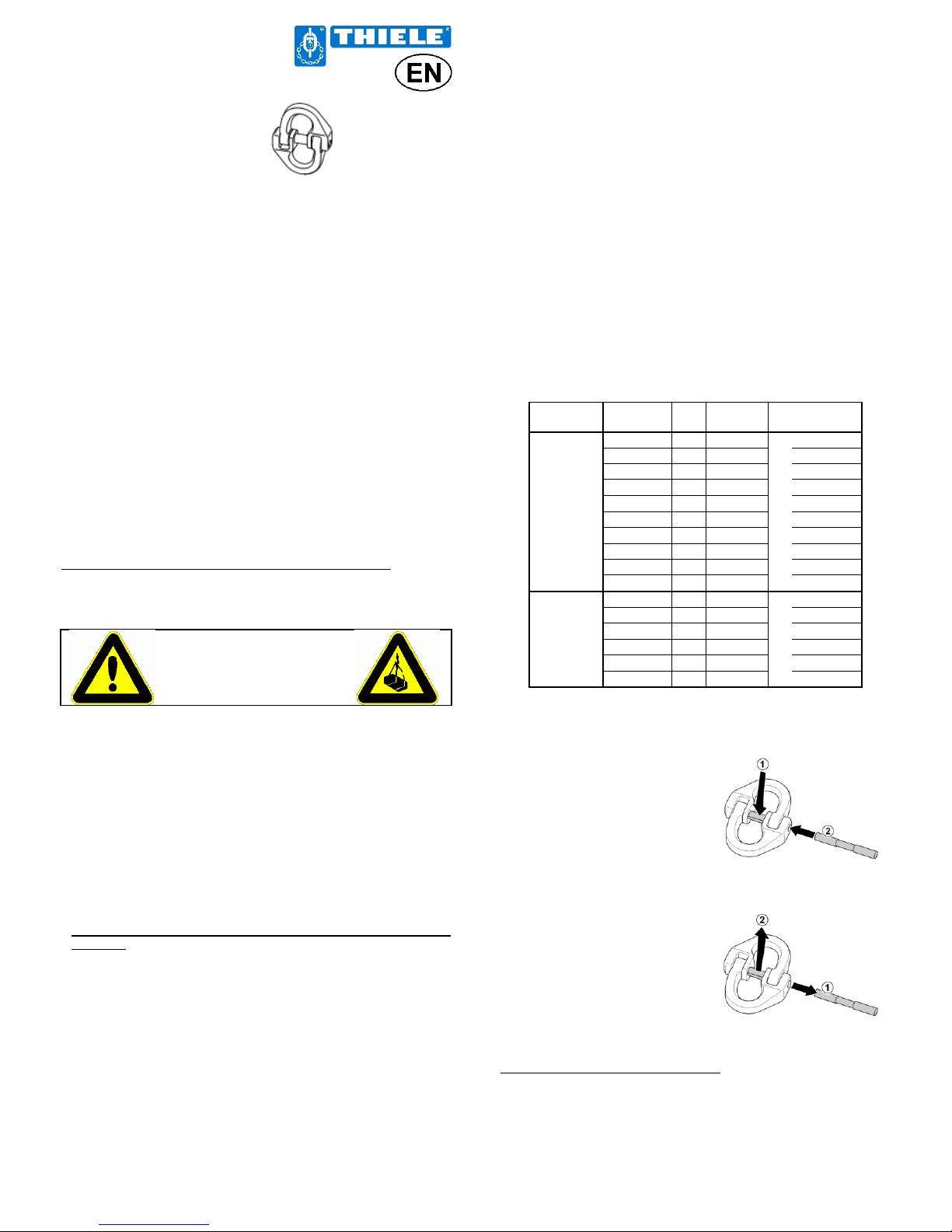

4 Technical Data

Table includes only series and not customized editions.

Each spare part set includes pin and split sleeve.

Type

Size

WLL

[t]

complete

Spare part sets

THI-LOK

TWN 1320

6-8

1,12

F30806

TWN 1920

F486012

7/8-8

1,5

F30816

F486042

10-8

3,15

F30826

F486072

13-8

5,3

F30836

F486102

16-8

8,0

F30846

F486132

18-8

10

F30850

F48615

20-8

12,5

F30855

F48617

22-8

15

F30860

F48619

26-8

21,2

F30870

F48622

32-8

31,5

F30880

F48625

XL-LOK

TWN 1820

6-10/XL

1,4

F30807

TWN 1921

F486013

8-10/XL

2,5

F30817

F486043

10-10/XL

4,0

F30827

F486073

13-10/XL

6,7

F30837

F486103

16-10/XL

10

F30847

F486133

22-10/XL

26

F30861

F486191

5 Assembly and Disassembly

Assembly

Install the connecting link halves in the components to be connected and join

both halves.

1. Position split sleeve as shown.

2. Push pin up to the split sleeve, align pin

bevels to suit split sleeve and drive the

pin in using a hammer.

3. Check to make sure split sleeve safely

embraces the pin centrally.

Check the parts to be connected are able to move freely within the

connector halves.

Disassembly

1. Use drift to drive the pin out.

2. Remove the split sleeve.

3. Separate connecting link halves from the

components they joined.

A set of drifts to TWN 0945 is available by Article No. Z03303.

The split sleeves must only be installed once.

6 Storage

Connecting links must be stored in dry spaces at temperatures ranging between

0 and +40 °C.

B09117-A 2 EN-050117

7 Conditions of Use

In mounted sling/suspension chain assemblies the chains are for example

joined to other components by means of connecting links. This way components

can be mounted the nominal size of which deviates from that of the chain.

Trade sizes and quality grades of chain and connecting link must always

coincide!

When attaching components observe correct position of the connecting link.

Relevant forces must act in longitudinal direction.

If two chain legs are arranged in one connecting link half for alternate use,

only one chain leg must be subjected to loads!

Connecting links must not be used in environments where acids, aggressive or

corrosive chemicals or their fumes are present. Hot-dip galvanizing or a galvanic

treatment is prohibited as well.

Application temperature

Type

Temperature

Remaining Working Load Limit

THI-LOK

TWN 1320

Gkl. 8

-40 °C < 200 °C

100 %

200 °C < 300 °C

90 %

300 °C < 400 °C

75 %

XL-LOK

TWN 1820

Gkl. 10/XL

-30 °C < 200 °C

100 %

200 °C < 300 °C

90 %

300 °C < 380 °C

60 %

Should the connecting links be exposed to temperatures exceeding the

maximum values specified they must no longer be used.

8 Inspection, Maintenance, Disposal

Inspections and maintenance and inspection intervals must be arranged for by

the Owner!

Inspections must be carried out regularly by competent persons and at least

once a year, or more frequently if the links are in heavy-duty service.

After three years at the latest the links must additionally be examined for cracks.

A load test shall never be considered a substitute for this examination.

The condition of all attachment components must be documented in the record

file during these inspections.

The results of the inspection shall be entered into a document to be prepared

when the sling/suspension chain assembly is first used. This document will

show characteristic data of the chains and components as well as identity

details.

Immediately stop using connecting links that show the following defects:

Limited hinging capability (halves get stuck),

Wear in excess of 10%, e.g. in the receiving area of the connecting link halves

and of the pin diameter,

Deformation, elongation, cuts, notches, cracks, pinches,

Links heated beyond permissible limits,

Severe corrosion,

Missing or illegible identification/marking.

Maintenance

Maintenance work must only be performed by competent persons.

Minor notches and cracks may be eliminated by careful grinding observing the

maximum cross section reduction requirement of 10 % and avoid making more

severe cuts or scores.

All maintenance activities are to be documented.

Inspection Service

THIELE offers inspection, maintenance and repair services by trained and

competent personnel.

Disposal

All components and accessories of steel taken out of service are to be scrapped

in line with local regulations and provisions.

9 Spare Parts

Only use original THIELE-spare parts.

See chapter 5, Technical data.

10 Publishing information

THIELE GmbH & Co. KG, Werkstraße 3, 58640 Iserlohn, Deutschland

Tel.: +49(0)2371/947-0 // Email: info@thiele.de

© THIELE GmbH & Co. KG, 2015. All rights reserved.

„#“ Changes to previous edition.

Loading...

Loading...