Thiele TWN 0796 Mounting Instructions

Mounting Instructions

Master link assembly

3- and 4-leg sling

Oversized master

link assembly

Fixed size master

link assembly

TAA / TAB

Risk of Injury!

Never walk or stay under lifted loads!

Make sure to use hoisting/

attachment means free from defects.

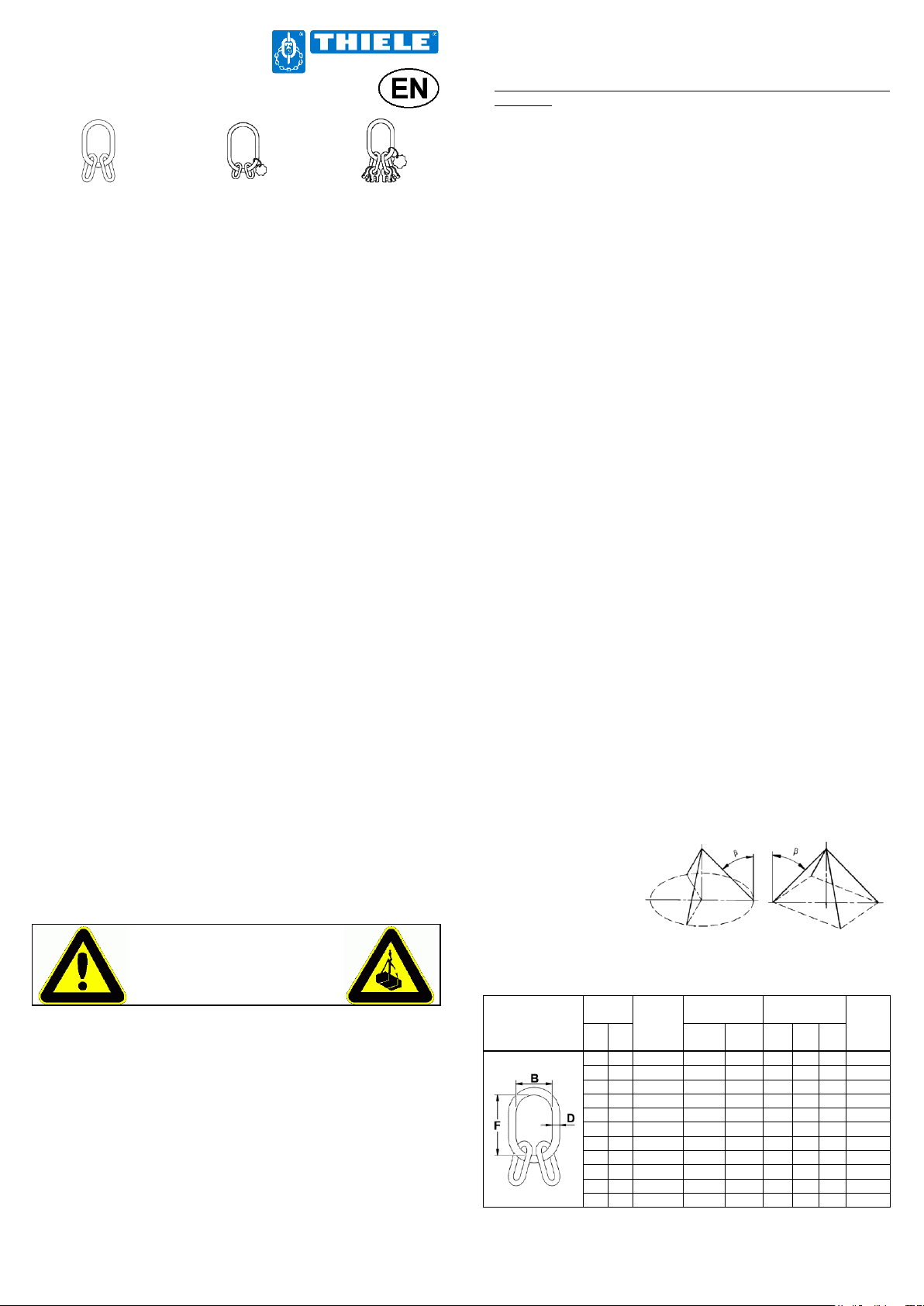

TWN 0796

Rope-Ø 3)

Article-

no.

WLL

[t]

Dimensions

[mm]

Mass

app. [kg]

1)

2)

β

0°≤45°

β

45°≤60°

D F B

11

10

F0796016

2,8

2,0

16

110

60

1,2

13

12

F0796018

4,0

2,8

18

130

70

1,9

14

14

F0796022

5,3

3,7

22

160

90

3,1

18

16

F0796026

7,5

5,3

26

180

100

5,3

22

20

F0796032

11,1

7,8

32

230

125

9,0

26

24

F0796036

16,0

11,3

36

250

140

15

28

28

F0796045

21,0

14,8

45

320

175

24

36

36

F0796050

31,6

22,3

50

340

190

40

40

40

F0796056

40,2

28,4

56

380

210

55

44

44

F0796063

50,1

35,4

63

430

240

79

60

60

F0796085

102

70

85

520

290

200

Original in compliance with 2006/42/EG

Master Link Assemblies for 3-/4-Leg Slings

Grades 8 and 10

Manufacturer:

THIELE GmbH & Co. KG

Tel: +49 (0) 2371 / 947 - 0

58640 Iserlohn

www.thiele.de

1 Description and Intended Use

Master link assemblies are intended to be built in sling chain assemblies for

lifting of loads according to EN 818-4.

They are prevalently used as upper end fittings to connect the sling chain

assemblies to the crane hooks.

Fixed size master link assemblies have integrated ringshackles for easy

attachments of sling chain and therefore they are predestinated for mounted

sling chain assemblies.

These Mounting Instructions apply to following products:

TWN 0796, TWN 1315, TWN 1815 #

Master link assemblies for 3- and 4-leg wire ropes slings according to

DIN EN 13414-1

TWN 0797

Master link assemblies for 3- and 4-leg offshore sling chain assemblies

TWN 0809, TWN 1809, TWN 1314, TWN 1814 #

Master link assemblies for 3- and 4-leg slings chain assemblies

TWN 0817

Oversized master link assemblies for 3- and 4-leg slings chain assemblies

used for crane hooks DIN15401

TWN 0810/4, TWN 0811/4, TWN 1810/4

Fixed size master link assemblies type TAA and TAB (with ringshackles)

The master link assemblies meet EG Machinery Directive 2006/42/EG

requirements and feature a safety factor of at least 4 based on Working Load

Limit (WLL).

THIELE master link assemblies are designed to withstand 20 000 dynamic

load changes under maximum load conditions. In the event of higher loads

(e.g. multi-shift/automatic operation) the WLL must be reduced.

Master link assemblies must exclusively be used

within the limits of their permissible Working Load Limit,

within the temperature limits prescribed,

for permissible attachment methods and inclination angles,

by trained and authorized persons.

Master link assemblies are as a rule not permitted for the transportation of

persons.

2 Safety Notes

Make sure these Mounting Instructions are available in a place near the

product during the time the equipment is used. Please contact the

manufacturer if replacements are needed. See chapter 12. #

When performing work make sure to wear your personal protective

equipment!

Improper assembly and use may cause personal injury and/or damage

to property.

Assembly and removal as well as inspection and maintenance must

exclusively be carried out by skilled and authorized persons.

Structural changes are impermissible (e.g. welding, bending).

Operators must carry out a visual inspection and, if necessary, a

functional test of the safety equipment before each use. #

Never put to use worn-out, bent or damaged master link assemblies.

Never expose master link assemblies to loads exceeding the specified

Working Load Limit.

Do not use force when mounting/positioning the master link assemblies.

Master link assemblies must be allowed to move freely in all tensile

directions.

Avoid bending loads to act on master link assemblies.

During lifting/hoisting make sure your hands or other body parts do not come

into contact with hoisting means. Only remove hoisting means manually (use

your hands).

Avoid impacts, e.g. due to abruptly lifting loads with chain in slack condition.

Usage of fixed site master link assemblies without working safety elements

(dowel pins) is not permissible.

In the event of doubts about the use, inspection, maintenance or similar

things contact your safety officer or the manufacturer!

THIELE will not be responsible for damage caused through nonobservance of the instructions, rules, standards and notes indicated!

As regards quality grade 10 THIELE does not give its general approval to

the assembly of components stemming from different manufacturers!

Working under the influence of drugs or alcohol is strictly forbidden!

3 Commissioning

Prior to using the parts for the first time make sure that

the parts comply with the order and have not been damaged,

test certificate, statement of compliance and Mounting Instructions are at

hand,

markings correspond with what is specified in the documentation,

inspection deadlines and the qualified persons for examinations are

determined, #

visibility and functional testing are carried out and documented, #

documentations are safely kept in an orderly manner.

Dispose of the packing in an environmentally compatible way according to

local rules.

4 Technical Data

Tables include only article numbers of standard and not customized parts.

WLL = Working Load Limit

For 3- or 4-leg slings the

data for WLL are depending

on the inclination angle:

4.1 Master Link Assemblies for Wire Ropes

TWN 0796, Grade 8 (as of October 2018 replaced by TWN 1313) #

Operators, fitters and maintenance personnel must in particular observe the

Operating Instructions of the sling chain assembly into which the master link

assemblies are to be installed, documentations DGUV V 1, DGUV R 100500 Chapter 2.8, DGUV R 109-004, DGUV I 209-013 and DGUV I 209-021

issued by the German Employers’ Liability Insurance Association as well as

standard specifications DIN 685-5, DIN 5688-3, EN 818-4 and EN 818-6.

In the Federal Republic of Germany, the Operational Safety Ordinance

(BetrSichV) has to be implemented and the Technical Rule for Industrial

Safety TRBS 1201, in particular Annex 1, Chapter 2 "Special regulations for

the use of working equipment for lifting loads" must be observed. #

Outside the Federal Republic of Germany the specific provisions issued

locally in the country where the items are used must also be observed.

The directions given in these Mounting Instructions and specified

documentations relating to safety, assembly, operation, inspection and

maintenance must be made available to the respective persons.

1) with fibre core [mm], 2) with steel core [mm], 3) acc. EN 13414-1

B10361-B 1 EN-161118

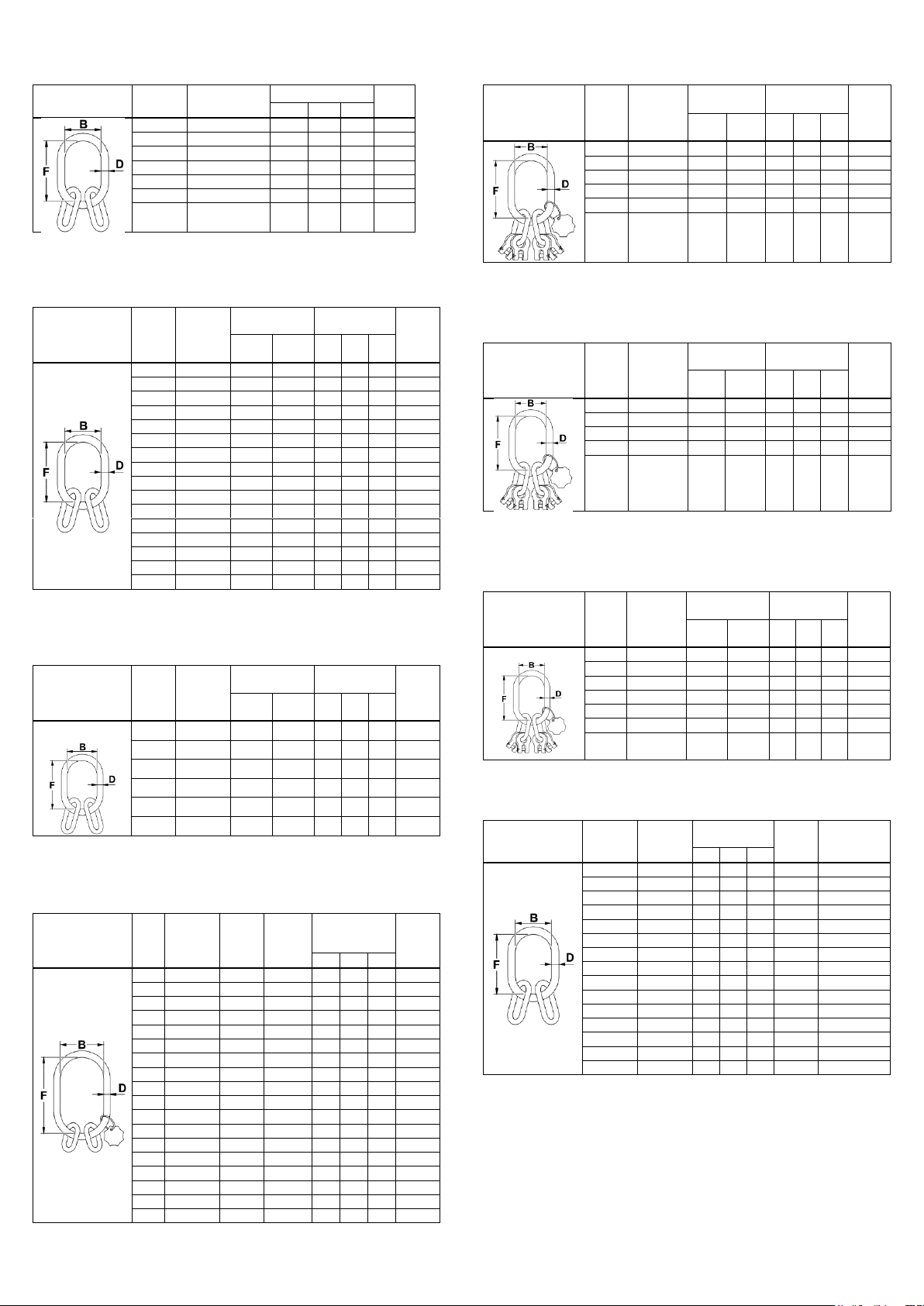

4.2 Master Link Assemblies for Offshore Sling Chain Assemblies

TWN 0797

(Offshore)

Article-

no.

WLL

[t]

0°< β ≤45°

Dimensions

[mm]

Mass

app. [kg]

D F B

F0797268

7,9

26

180

100

5,3

F0797328

11,3

32

230

125

9,0

F0797368

16

36

250

140

15

F0797458

22,6

45

320

175

24,4

F0797508

26,8

50

340

190

40

F0797568

40

56

380

210

55

F0797638 50

63 430 240 79

TWN 0809

Nominal

size

Article-

no.

WLL

[t]

Dimensions

[mm]

Mass

app. [kg]

β

0°≤45°

β

45°≤60°

D F B

6-8

F0809068

2,36

1,7

16

110

60

0,9

8-8

F0809088

4,25 3 20

140

80

1,8

10-8

F0809108

6,7

4,75

26

180

100

3,8

13-8

F0809138

11,2 8 32

230

125

7,7

16-8

F0809168

17

11,8

40

290

160

13

18-8

F0809188

21,2

15

45

320

175

18

20-8

F0809208

26,5

19

50

340

190

25

22-8

F0809228

31,5

22,4

50

340

190

28

26-8

F0809268

45

31,5

63

430

240

49

28-8

F0809288

50

37,5

63

430

240

49

32-8

F0809328

67

47,5

80

520

290

86

36-8

F0809368

85

60

85

520

290

106

40-8

F0809408

106

75

95

580

320

146

45-8

F0809458

132

95

110

680

380

223

50-8

F0809508

160

118

110

680

380

252

56-8

F0809568

200

150

125

720

400

350

TWN 1809

Nominal

size

Article-

no.

WLL

[t]

Dimensions

[mm]

Mass

app. [kg]

β

0°≤45°

β

45°≤60°

D F B

6-10

F180906

3,0

2,12

16

110

60

1,0

8-10

F180908

5,3

3,75

20

140

80

2,2

10-10

F180910

8,0

6,0

26

180

100

3,8

13-10

F180913

14

10

32

230

125

7,7

16-10

F180916

21,2

15

40

290

160

13

22-10

F180922

40

28

50

340

190

28

TWN 0817

Nom.

size

Article-

no.

Crane

hook

no.

WLL

[t]

0°<β≤45°

Dimensions

[mm]

Mass

app. [kg]

D F B

6-8

F08170616

16

2,36

22

260

140

2,9

8-8

F08170816

16

4,25

26

260

140

3,9

10-8

F08171016

16

6,7

30

260

140

5,

13-8

F08171316

16

11,2

36

250

140

9,43

16-8

F08171616

16

17

36

250

140

9,4

6-8

F08170625

25

2,36

24

340

180

4,1

8-8

F08170825

25

4,25

28

340

180

5,4

10-8

F08171025

25

6,7

32

340

180

7,7

13-8

F08171325

25

11,2

40

340

180

11,9

16-8

F08171625

25

17

40

340

180

13,2

20-8

F08172025

25

26,5

55

430

220

32,3

6-8

F08170640

40

2,36

26

430

220

5,7

8-8

F08170840

40

4,25

30

430

220

7,42

10-8

F08171040

40

6,7

34

430

220

10,1

13-8

F08171340

40

11,2

42

430

220

15,5

16-8

F08171640

40

17

42

430

220

16,8

18-8

F08171840

40

21,2

48

430

220

23,7

22-8

F08172240

40

31,5

55

430

220

32,3

TWN 0810/4

Nom.

size

Article-

no.

WLL

[t]

Dimensions

[mm]

Mass

app.

[kg]

β

0°≤45°

β

45°≤60°

D F B

6-8

F08104068

2,36

1,7

16

110

60

1,4

8-8

F08104088

4,25

3,0

22

160

90

3,1

10-8

F08104108

6,7

4,75

26

180

100

5,4

13-8

F08104138

11,2

8,0

32

230

125

11,1

16-8

F08104168

17,0

11,8

40

290

160

19

22-8

F08104228

31,5

22,4

50

340

190

43

TWN 1810/4

Nom.

size

Article-

no.

WLL

[t]

Dimensions

[mm]

Mass

app. [kg]

β

0°≤45°

β

45°≤60°

D F B

6-10

F1810406

3,0

2,12

16

110

60

1,4

8-10

F1810408

5,3

3,75

20

140

80

2,7

10-10

F1810410

8,0

6,0

26

180

100

5,4

13-10

F1810413

14

10

32

230

125

11,2

16-10

F1810416

21,2

15

40

290

160

19,4

TWN 0811/4

Nom.

size

Article-

no.

WLL

[t]

Dimensions

[mm]

Mass

app. [kg]

β

0°≤45°

β

45°≤60°

D F B

6-8

F08114068

2,36

1,7

16

70

35

1,2

8-8

F08114088

4,25 3 20

90

45

2,3

10-8

F08114108

6,7

4,75

22

100

50

4,1

13-8

F08114138

11,2 8 26

120

60

8,3

16-8

F08114168

17

11,8

32

140

70

13

18-8

F08114188

21,2

15

36

160

80

20

22-8 F08114228

31,5

22,4

40

180

90

32,6

TWN 1314

Article-

no.

WLL

[t]

Dimensions

[mm]

Mass

app. [kg]

for chain

slings of size

0°<β≤45°

D F B

3-/4-Leg 1)

F1314016

3,15

16

110

60

0,9

6-8

F1314020

4,75

20

140

80

1,8

8-8

F1314026

8,0

26

180

100

3,8

10-8

F1314032

12,5

32

230

125

7,7

13-8

F1314040

19

40

290

160

13

16-8

F1314045

25

45

320

175

18

18-8

F1314050

31,5

50

340

190

25

20-8

F1314050A

31,5

50

340

190

28

22-8

F1314063

50

63

430

240

49

26-8

F1314063A

50

63

430

240

49

28-8

F1314080

71

80

520

290

86

32-8

F1314085

85

85

520

290

106

36-8

F1314095

112

95

580

320

146

40-8

F1314110

132

110

680

380

223

45-8

F1314110A

160

110

680

380

252

50-8

TWN 0797, Grade 8

4.3 Master Link Assemblies for Slings Chain Assemblies

TWN 0809, Grade 8 (as of October 2018 replaced by TWN 1314) #

4.6 Fixed Size Master Link Assemblies Type TAA

TWN 0810/4, Grade 8

4.7 Fixed Size Master Link Assemblies Type TAA

TWN 1810/4, Grade 10

4.4 Master Link Assemblies for Slings Chain Assemblies

TWN 1809, Grade 10 (as of October 2018 replaced by TWN 1814) #

4.5 Oversized Master Link Assemblies Slings Chain Assemblies used for

Crane Hooks DIN15401 TWN 0817, Grade 8

4.8 Fixed Size Master Link Assemblies Type TAB

TWN 0811/4, Grade 8

4.9 Master Link Assemblies TWN 1314, Grade 8 #

1) The classification applies to the inclination angle range 0° < ≤ 45°.

B10361-B 2 EN-161118

Loading...

Loading...