INSTRUCTION MANUAL

E

A

D

R

-

Y

T

-

T

S

O

O

-

F

M

L

L

Y

A

Wing Span

39.5 in / 1000mm

Wing Area

Flying Weight

Fuselage Length

25 5 oz / 720g.

305 sq in / 19 7 sq dm.

39 in / 990mm

Specifications

3D EP

3D EP

Requires : 4-channel radio w/ 4 micro servos,

Outrunner Motor KM0283010

w/ Propeller Adaptor HW2340100

20A brushless ESC, 3 cells 11.1V

2100 mAh Li - Po battery & charger.

E217XM0 806

Warning! This model is not a toy.

It is designed for maximum performance. Please seek advice if one is not familiar with this kind

of electric powered precision model. Operating this model without prior preparation may cause

injuries. Remember, safety is the most important thing. Always keep this instruction manual at

hand for quick reference.

FACTORY PRE-FABRICATED

ALMOST-READY-TO-FLY(ARF) SERIES

MADE IN CHINA

The World Models

Manufacturing Co., LTD.

www.theworldmodels.com

*Specifications are subject to change without not ice.*

P.1

3D EP

3D EP

Appl

y

thread locke

r

Apply epoxy glue.

Pierce the shaded portion

covering film.

Apply instant glue

(C.A.glue, super glue.)

Ensure smooth non-bindin g

movement while assembling .

Do not overlook this symbol !

P. 3 -10

IN D E X

BEFORE YOU BEGIN

PARTS LIST

ASSEMBLY

SAFETY PRECAUTIONS

P. 1

P. 2

P.10

BEFORE YOU BEGIN

Check all parts. If you find any defective or missing parts contact your local dealer. Please DRY FIT

and check for defects for all parts that will require CA or Epoxy for final assembly. Any parts you

find to be defective after the gluing process may be difficult to remove for warranty replacement. The

manufacturer will replace any defective parts, but will

not

extend to the parts that are good before

gluing to defective parts during assembly. Warranty will not cover any parts modified by customer.

Read through the manual before you begin, so you will have an overall idea of what to do.

Symbols used throughout this instruction manual comprise of the following : -

1

2

3

Assemble left and right

sides the same way.

Peel off shade d portion

covering film.

Drill holes with the specified

diameter (here: 3mm) .

Pay close attention here!

Cu

t

of

f

shaded

portion

.

Mus

t

b

e

purchase

d

separatel

y

!

Warning!

3mm

E217XM0 806

Parts List

P. 2

1. MAIN WING -- 1 pair

2. PUSHROD Ø1.4x80mm w/ Threads (For Aileron) -- 2 pcs

STRAPER (S) -- 2 pcs

CLEVIS (S) -- 2 pcs

FUEL TUBE d2xD4x4mm -- 4 pcs

HORN (S) -- 2 sets

SCREW PM2x20mm -- 4 pcs

SCREW PA1.7x8mm -- 8 pcs

SERVO MOUNTING PANEL -- 1 pair

3. FUSELAGE -- 1 pc.

STABILIZER & ELEVATOR -- 1 set

4. VERTICAL FIN & RUDDER -- 1 set

5. TAIL LANDING GEAR -- 1 set

TAIL WHEEL Ø23mm -- 1 pc.

PLASTIC COLLAR d1xd5x2mm -- 2 pcs

SCREW PA2x8mm -- 2 pc.

SCREW PM2x8mm -- 1pc.

M2 NUT -- 1 pc.

ALUMINUM PLATE 0.5mm -- 1pc.

6. MAIN LANDING GEAR -- 1 set

MAIN WHEEL Ø40mm -- 2 pcs

COLLAR Ø2.6mm w/set screw -- 2 sets

LANDING WIRE STRAPS PL4114030 -- 3 pcs

SCREW PA2.3x10mm -- 6 pcs

7. PUSHROD Ø1.4x470mm w/ Threads (For Elevator) -- 2 pcs

CLEVIS (S) -- 2 pcs

HORN (S) -- 2 sets

SCREW PM2x10mm -- 4 pcs

FUEL TUBE d2xD4x4mm -- 2 pcs

8. PUSHROD Ø1.4x540mm w/ Threads (For Rudder) -- 1 pc.

CLEVIS (S) -- 1 pc.

FUEL TUBE d2xD4x4mm -- 1 pc.

HORN (S) -- 1 set

SCREW PM2x10mm -- 2 pcs

9. FOLDING PROPELLER SET -- 1 set

SPINNER Ø45mm -- 1 set

SCREW PM3x6mm -- 4 pcs

WASHER d3xD7mm -- 4 pcs

COWLING -- 1 pc.

SCREW PWA2x8mm -- 4 pcs

10. EYE SCREW PA2.5x10x23mm -- 2 pcs

WING TUBE Ø9.6x227 mm -- 1 pc.

RUBBER BAND D30x1mm -- 2 pcs

11. PUSHROD Ø1.4x76mm (For Elevator) -- 1 pc.

PUSHROD CONNECTOR PL4410020 -- 1 set

FUEL TUBE d2xD4x4mm -- 2 pcs

STRAPER (S) -- 2 pcs

SPONGE 10x50x150mm -- 1 pc.

BATTERY TIE 200mm -- 1 pc.

DOUBLE-SIDED TAPE 30x35mm -- 1 pc.

SCREW PM2x10mm -- 1 pc.

WASHER d2xD5mm -- 1 pc.

M2 NYLON INSERT LOCK NUT -- 1 pc.

MOUNTING PLATE PL4114015 -- 1 pc.

12. CANOPY -- 1 pc.

SCREW PWA2x8mm -- 4 pcs

13. DECALS E217XMDEC -- 1 set

COVERING:- LIGHTEX SGX100 WHITE

LIGHTEX SGX311 FERRARI RED

LIGHTEX SGX550 PEARL BLUE

LIGHTEX SGX217000

E217XM0 806

P.3

1

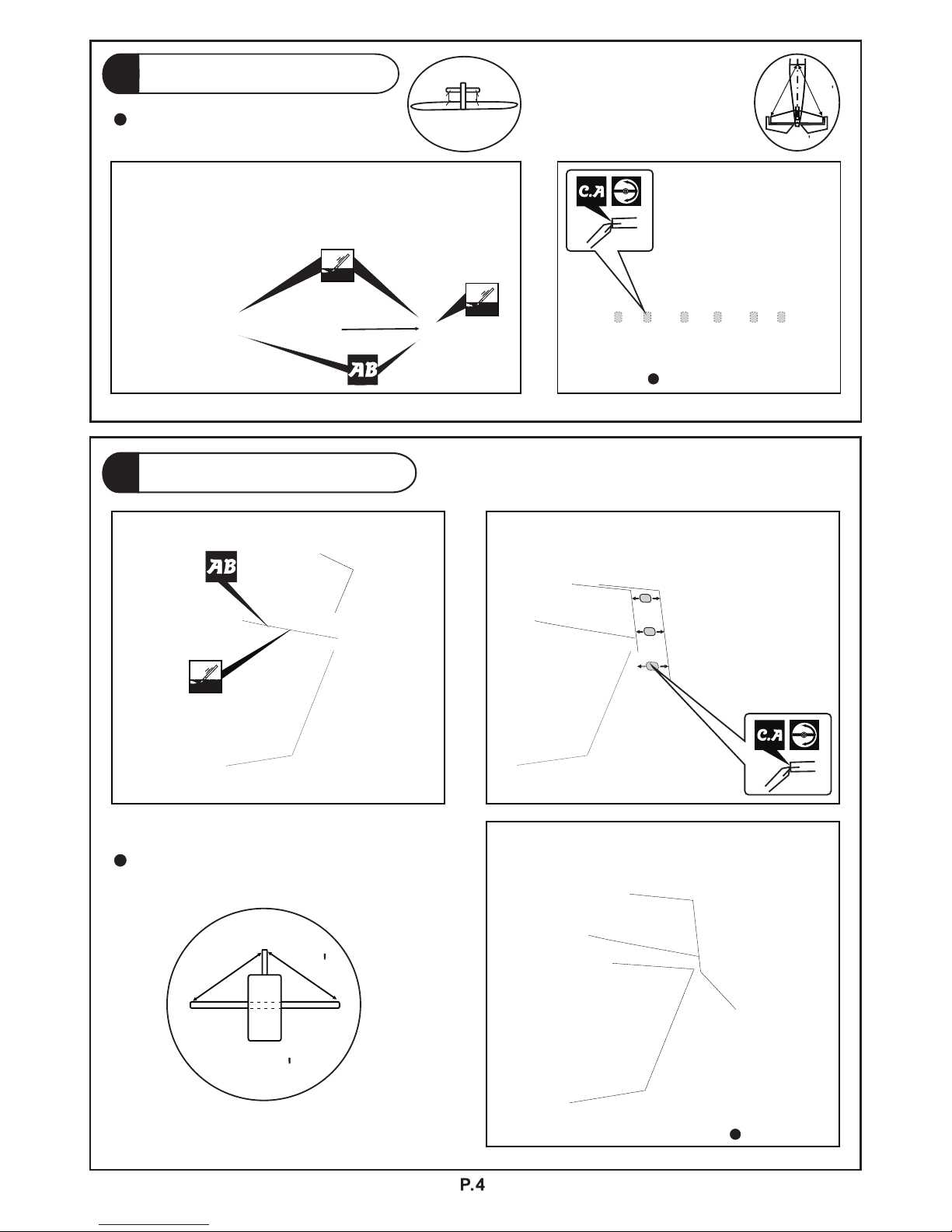

Aileron Servo

2

Main Wing

Aileron S ervo leadAileron S ervo lead

Apply instant type CA

glue to both sides of

each hinge.

Bottom View

Ø1mm pilot holes for

World Models tri-horn are

pre-drilled. Please look for

pin-hole marks at under

side of control surfaces.

02L

03L

04L

02R

03R

04R

PA1.7x 8mm Screw

8

4

PM2x20m m Screw

Straper

Fuel Tu be

d2xD4x4 mm

PA1.7x 8mm

Please choose either 02L & 02R or 03L & 03R or 04L & 04R that suits your servo.

2mm

PM2x20m m

Fuel Tu be

d2xD4x4 mm

Clevis

Horn

Pushrod

Ø1.4x80 mm

Bottom View

E217XM0 806

4

Vertical Fin & Rudder

C=C

C

C

Stabilizer & Elevator

3

Temp or ar y ins ta ll the ma in wi ng , adj us t

level in g of th e sta bi li ze r t o ma ke it as

paral le l to th e mai n wi ng as p oss ib le .

(St abili zer)

(Ma in Wing )

A A’

A=A’

B=B

B

B

Apply instant type CA glue to

both sides of each hinge.

Apply instant type CA glue to both

sides of each hinge.

Completed

Completed

E217XM0 806

P.5

6

Elevator Pushrod

7

Main Landing Gear

M3x3mm Set Screw

2.6mm Collar

PA2.3x 10mm Screw

6

2.6mm Collar

2

Front

4

PA2.3x 10mm

Landing W ire Straps

80mm

23mm

Tail Landing Gear

5

PA2x8mm S crew

M2 Nut

2

1

Pla stic

Col lar

PM2x8mm S crew

1

Bottom View

Bottom View

1.5mm

1.5mm

Ø1mm pilot holes for World Models horn are pre-drilled.

Please look for pin-hole marks at under side of control surfaces.

PM2x10m m Screw

PM2x10mm

Horn

Elevator Pushrod

Ø1.4x470mm

2mm

Fuel Tube

d2xD4x4mm

Bottom View

Wheel Ø23 mm

M2 Nut

PM2x8mm

PA2x8mm

E217XM0 806

P.6

Rudder Pushrod

8

2

PM2x10m m Screw

Ø1mm pilot holes for World Models horn are pre-drilled.

Please look for pin-hole marks at under side of control surfaces.

4mm

90mm

Bottom View

PM2x10mm

Elevator Pushrod

Ø1.4x540mm

2mm

Fuel Tube

d2xD2x4mm

9

Outrunner Motor & Cowling

PA2.6 x8 mm

Spinner

PWA 2 x 8mm

1.5mm

PM3x6mm S crew

PA2.6x8 mm Screw

d3xD7mm Washer

4

2

4

Make sure rotating

motor casing is not

in contact with

wirings or anything.

PWA2x8mm Screw

4

Outrunner Motor 28/ 30

KM0283010

Propeller Adaptor

(d3xD5) HW2340100

Optional Parts

Don't ov er-tigh ten t he PM3

screws , too much st res s on

the scre ws could sp lit t he

firewa ll.

Don’t ov er-tigh ten t he PM2 s cre ws, let the

propel ler b lade s ali gn themse lves when s pinning .

PM3x6mm

d3xD7mm

Washer

Completed

PM2x12m m

PM2x12m m

1

2 3

4 5

M5 N ut

E217XM0 806

Main Wing

10

Bottom View

Rubber Band

Eye Screw

PA2.5x10x23mm

90°

Bot tom

Up

Botto m Vie w

Lead to Aileron Servo

Wing Tub e

D9.6x 227mm

P.7

E217XM0 806

Radio Equipment

11

Canopy

12

PWA2x8mm Screw

4

PM2 x10mm S crew

1

M2 Nylon In sert Lock Nut

1

d2 x D5mm Washer

1

d2xD5mm

Was her

M2 Nylon Ins ert L ock N ut

Rudde r Pus hrod

Ø1.4x5 40m m

Straper

Fuel Tube

d2xD4x4m m

Rudder Servo

Elevator S erv o

Sponge

Front

Install and arrange the servo as shown in the diagram.

Front

P.8

Bottom View

Front

Batte ry

Batte ry Tie

Double-Sided Tape

20A Bru shless ESC

Elevator Servo

Pushrod

Connector

J2(Pushrod Ø1.4x470)

J1(Pushrod Ø1.4x76)

J1

J2

Bottom View

KM2 x8mm

M2 Nu t

Ele vator P ushro d

Ø1.4 x470m m

Receiver

2mm

PWA2x8mm

1mm

E217XM0 806

P.9

13

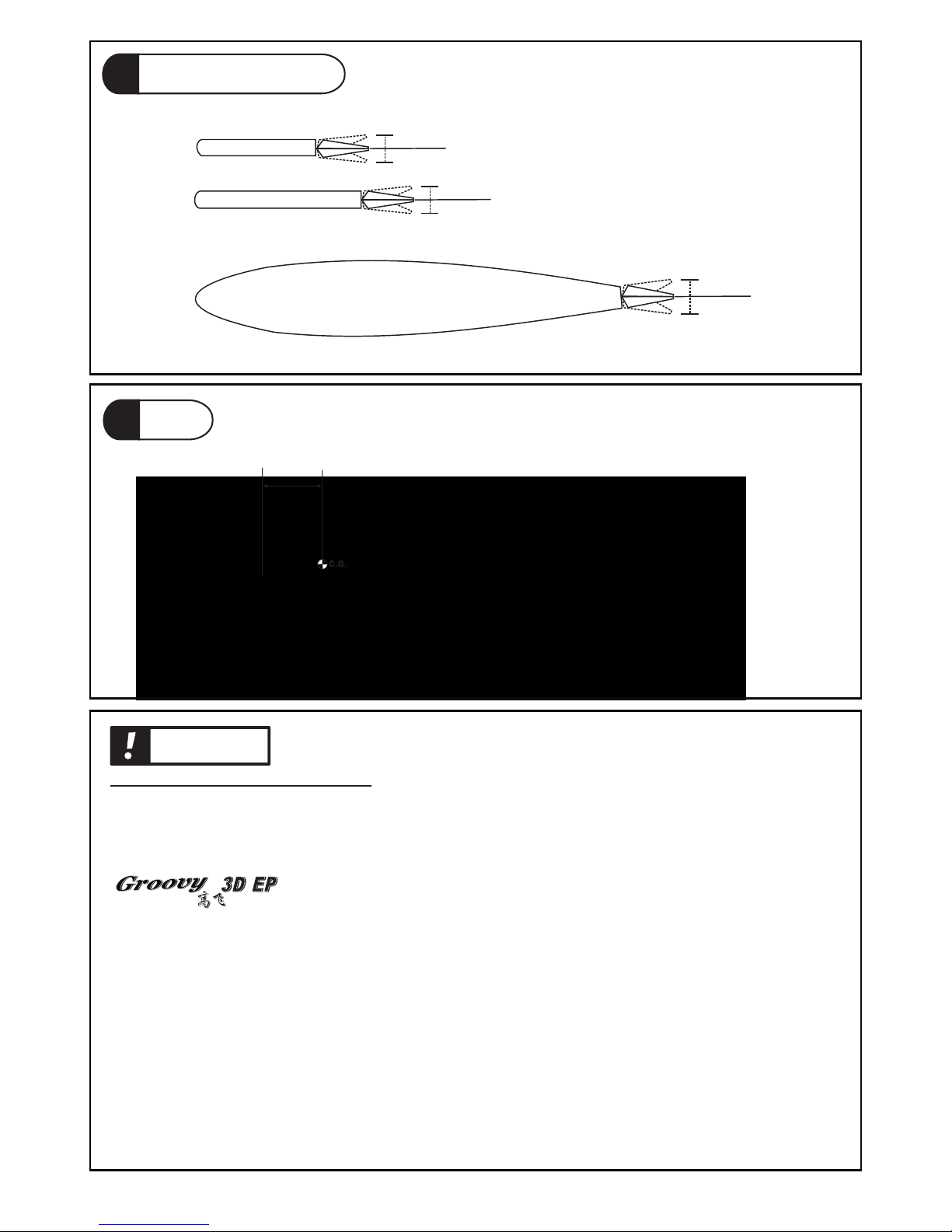

Wing Setting

A

A'

B B'

C

C'

A=A' B=B' C=C'

Adjust the wi ng and fusela ge configuration as shown in the diagrams.

E217XM0 806

85mm

3.35 in.

P.10

Adjust the control throws as shown in the diagram.

These throws are good for general flying. You can

adjust according to your personal preference.

Eleva tor

Rudde r

Ailer ons

14mm

14mm

20mm

20mm

12mm

12mm

The ideal C.G. position is 85mm (3.35 in.) behind

the leading edge measured at where the wing

meets the fuselage. In order to obtain the C.G.

specified, add weight to the fuselage or move

the battery position. Check the C.G. before

flying.

E217XM0 806

Warning!

Important Safety Precautions

# First time flyer should never fly by himself / herself. Assistance from experienced flyer is absolutely necessary.

# Pre-flight adjustment must be done before flying, it is very dangerous to fly a badly pre-adjusted aircraft.

# is specially designed to be powered by KM0283010 Outrunner Motor.

# Make sure the air field is spacious, never fly the plane too close to people and never get too close to a running

propeller. Extreme caution should be exercised when working with electric powered models. Make sure the

propeller is cleared of all objects, especially your hands before connecting the battery to the model. Make sure

you understand the operation of the ESC (Electronic Speed Control) by studying the ESC manual. Once you

plug in the battery for electric powered model, always treat the propeller as a rotating one, as accidental

movement of the throttle stick will spin the propeller and could cause injuries.

# If you find wrinkles on the covering as a result of weather changes, you can use hot iron to remove the wrinkles.

Please begin with lower temperature setting and gradually raise the temperature until the wrinkles are gone.

Too hot an iron may damage the covering. Don't use hot iron near the seams or edges, hot iron will melt the

glue and shrink the covering at the same time, causing the seams to pull away.

# Check and re-tighten up all factory assembled screws, use thread locker if necessary.

14

Control Throws

15

C.G.

The World Models

Manufacturing Co., LTD.

www .t hew or ldm od els .c om

E217XM0 806

Loading...

Loading...