Page 1

Motor Replacement Package

RV Toilet Service Parts

for Aria/Aria Deluxe

Tools needed

• Flat-blade screwdriver • Adjustable Wrench

• Small Flat-blade screwdriver • Pliers

Note:

• Read all instructions before beginning work.

To Remove Toilet From Floor

1. Turn off RV water supply per RV Owner’s Manual.

2. Press both keypad buttons at the same time, twice, to open

blade and drain bowl of water.

you will have to open the valve manually. Remove the Sound

Deadening insulation (if present) from the back of the

mechanism to access the mechanism lead screw. Use a

5/16” socket wrench to turn the screw and open the valve.

3. Pry off Bolt Caps with Flat-blade screwdriver. Use wrench

to remove 1/2-inch Lag Screws.

4. Swivel Toilet to gain access to back.

5. Turn off RV’s power supply to the Toilet.

6. Disconnect Toilet’s 12-volt power hookup to RV.

7. Disconnect Water Supply Line from elbow connector by

hand. Use Adjustable Wrench if necessary, with care.

8. Place an old towel or soft cloth on work surface. Remove

Toilet from floor and place upside-down on work surface.

9. Remove old Closet Flange Seal (may be found in toilet or in

floor at Closet Flange). Discard.

10. Cover Holding Tank opening to contain odor.

If mechanism does not work,

To Remove Old Part

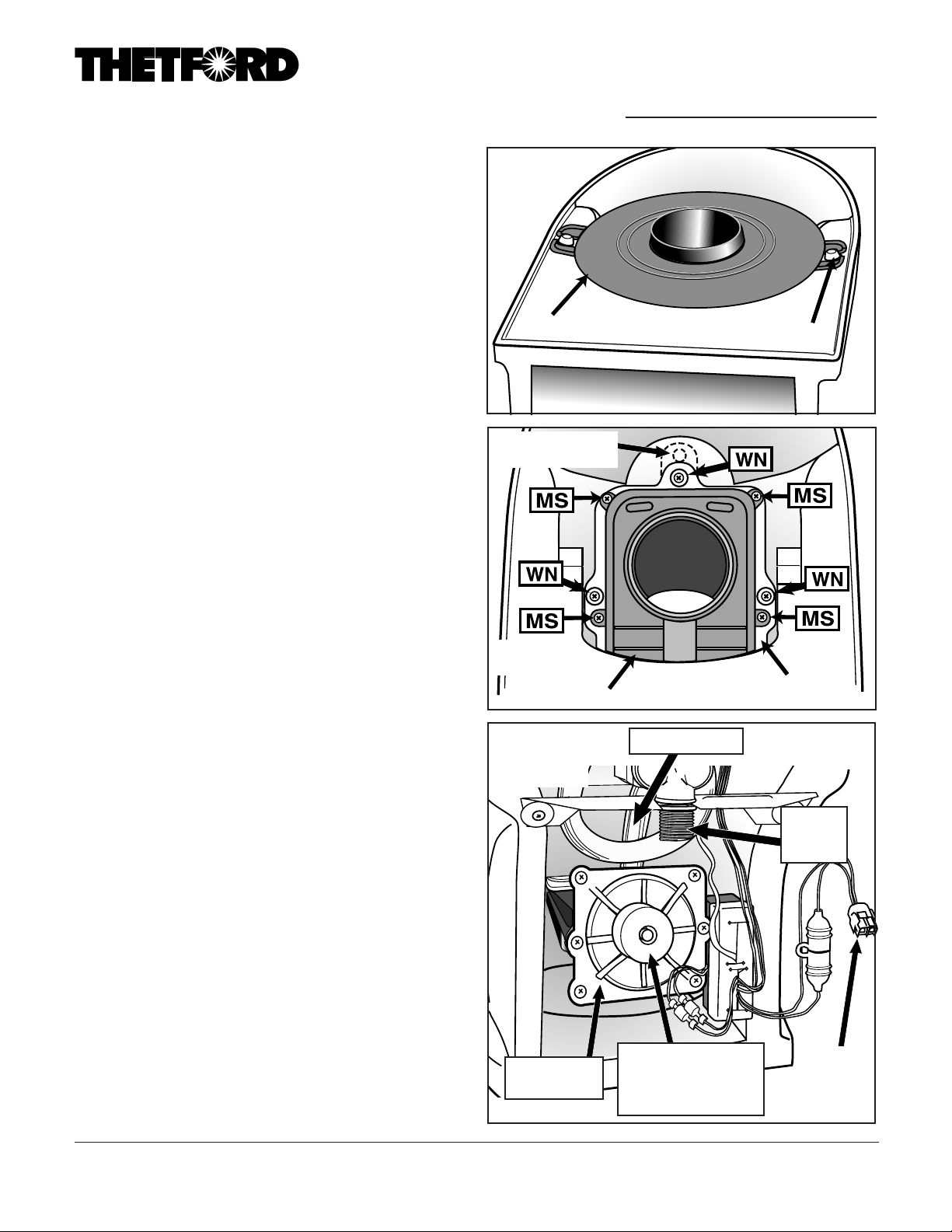

1. Tap out 2 Mounting Bushings (Fig. A).

2. Remove Mounting Flange (Fig. A).

3.

High Profile models only:

be found connected to Mounting Flange or to the Mechanism. Remove Tube Seal (Fig. G).

(You may want to turn the toilet right side up to continue.)

4. Remove and save Sound Deadening Kit insulation from

around mechanism. The cylindrical pad at the rear of the

Mechanism may be left in place (Fig. C).

5.

Remove 4 Mechanism Screws (without Washers) (MS, Fig. B).

6. Disconnect 2 green/yellow wires from Mechanism Assembly at spade connectors. Use pliers if necessary.

7. Lift Mechanism Assembly off. Pull carefully out through back

of Toilet.

8. Remove Overflow Tube from Mechanism Assembly (Fig. C).

9. Remove, save 6 End Cap Bolts. Remove End Cap (Fig. C).

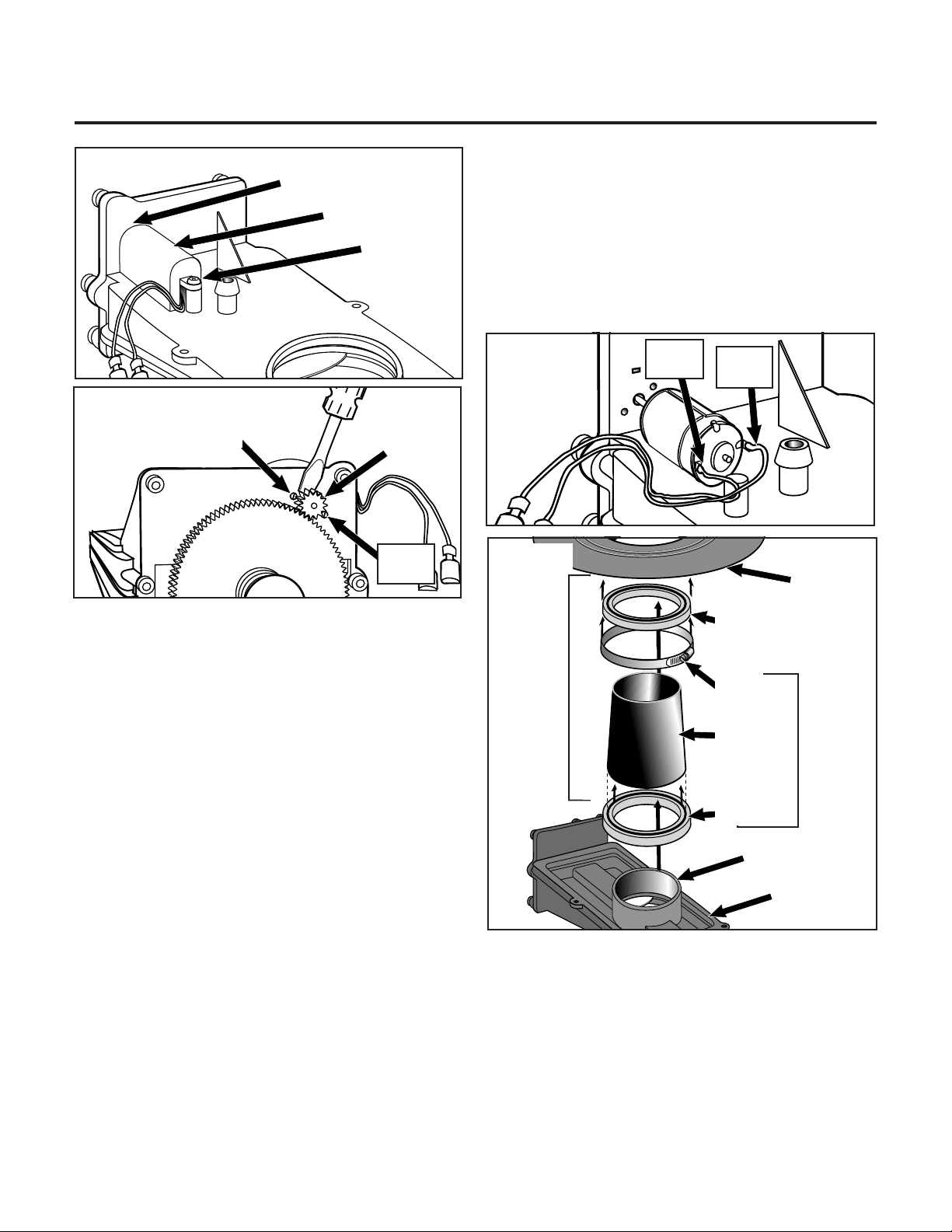

10. Remove screw to remove Motor Cover (Fig. D).

11.

Using Screwdriver, gently pry off small Pinion Gear (Fig. E). Discard.

Remove Extension Tube. It may

Fig. A

Mounting Flange

newer plates have

a 2nd hole at front

Fig. B

Mechanism

Fig. C

Mechanism

End Cap

Part #19622

Mounting Bushing

White Mechanism Plate

Overflow Tube

Sound Deadening

Cylindrical Insulator

(not present on all

models)

Water

supply

hookup

Power

supply

connector

Form #19640 Rev. 10.1.01

Page 2

Part #19622

Motor Replacement Package

Continued

Fig. D

Fig. E

Small

screw

Motor Cover Tab

Motor Cover

Screw

Small

screw

Pinion

Gear

cone Grease.

f. Install Mounting Flange and Seal assembly on Extension

Tube. Make sure there is at least a 1/2” overlap between the

Extension Tube and Mounting Flange Seal.

Low Profile:

of the Mounting Flange. Install Mounting Flange to Mechanism. (No extension tube is used.)

10. Replace 2 Mounting Bushings with flat surface out.

Fig. F

Fig. G

Replace the Mounting Flange Seal onto the lip

Green

Wire

Yellow

Wire

Mounting

Flange

12. Using small, Flat-blade screwdriver, remove 2 Screws that

connect Motor to Front Flange. Remove Motor. Discard.

To Replace Part

1. Position new Motor, lining up 2 Screw holes and with wires

as shown in Fig. F . Replace Screws and tighten.

2. To replace Pinion Gear, line up D shape of Motor shaft and

Gear. Rotate Drive Gear slightly to align teeth of Pinion Gear.

Press on. Must be fully engaged with Drive Gear.

3. Replace Motor Cover, lining up tab with slot (Fig. D). Do not

pinch wires. Reinstall Motor Cover Screw.

4. Reinstall End Cap. Secure 6 Screws.

5. Reattach Overflow Tube to Mechanism.

6.

Reattach 2 Wire Motor Leads, yellow to yellow and green to green.

7. Position Blade Seal over Mechanism Plate.

8. Insert Mechanism into Toilet, tucking wires behind Mechanism. Line up and secure 4 Mechanism Screws (Fig. B).

9.

High Profile:

a. Lubricate sealing surface of Extension Tube Seal with silicone grease.

b. Install Extension Tube Seal on Extension Tube.

c. Install Extension Tube and seal assembly on Mechanism.

Make sure that seal is seated at least 1/2 inch below Mechanism tube lip.

d. Ensure Hose Clamp on Mounting Flange Seal is tight.

e. Lubricate Mounting Flange Seal sealing surface with Sili-

To install Extension Tube (Refer to Fig. G):

Shown

separate

Mounting

Flange Seal

for clarity

– these

items

Clamp

normally

remain

as-

sembled

Extension

Tube

Extension

Tube Seal

Mechanism

Tube Lip

HIGH

PROFILE

ONLY

Mechanism

To Replace Toilet To Floor

1. Secure new Closet Flange Seal, lip side up, to Toilet.

2. Position Toilet over flange.

3. Reconnect Water Supply Line.

4. Reconnect 12-volt power supply to Toilet.

5. Reconnect RV’s power supply to the Toilet.

6. Secure to floor with Lag Screws. Tighten.

7. Turn on RV’s water supply. Press Toilet flush button to close

blade and to flush test.

8. Resecure Bolt Caps.

Loading...

Loading...