Page 1

RV Toilet Service Parts

for

Aria Deluxe II

Tools needed

• Flat-blade screwdriver • Pliers

• Adjustable Wrench

• DAP Dynaex Caulk or equivalent (available at most hardware

stores)

Note:

• Read all instructions before beginning work.

•

You may not need to replace all the Seals in this package.

• All replacements will require removing toilet from oor.

• Use gloves when handling parts that may have come in contact

with waste.

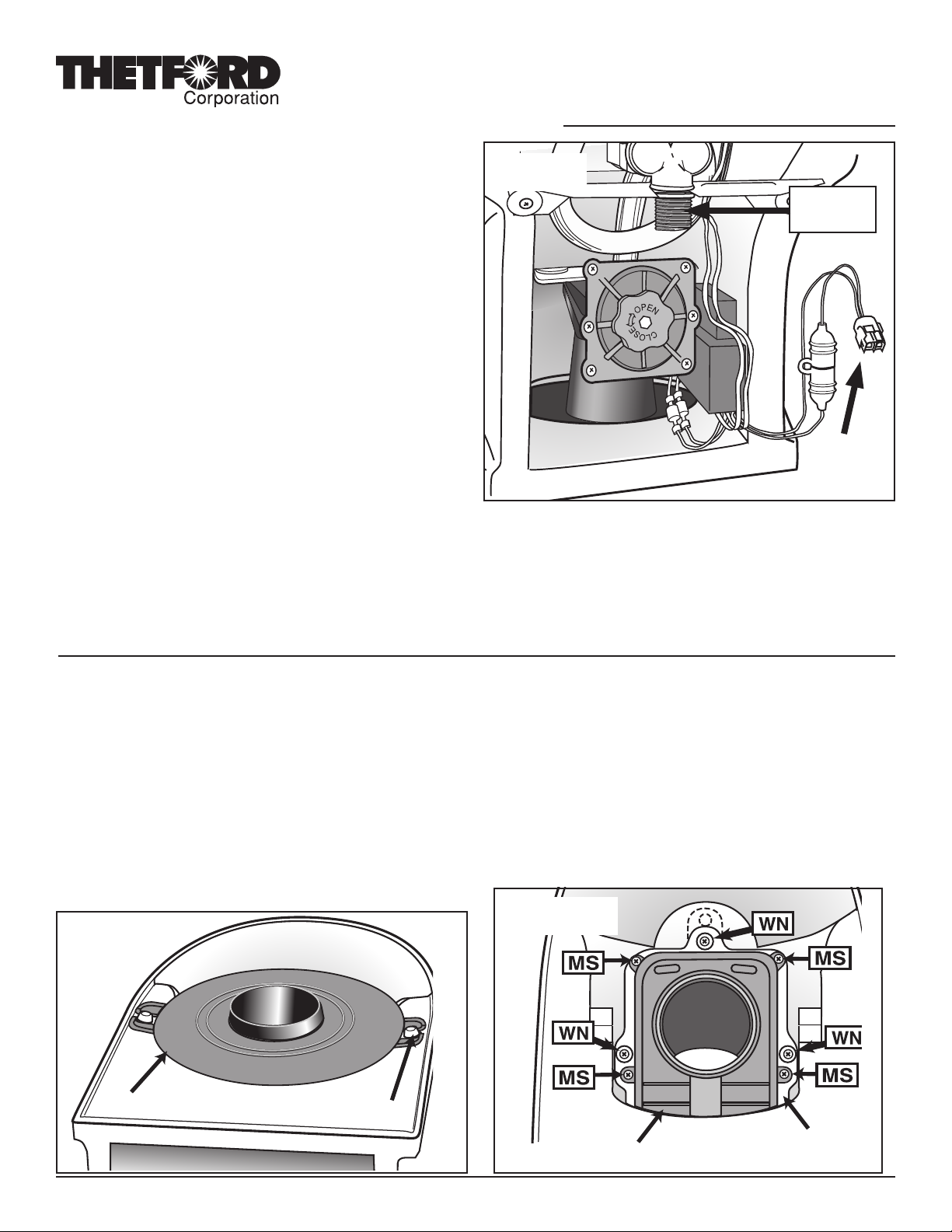

To Remove Toilet From Floor

1. Turn off RV water supply per RV Owner’s Manual.

2. Press both keypad buttons at the same time, twice, to open blade

and drain bowl of water.

3. Pry off Bolt Caps with Flat-blade screwdriver. Use wrench to

remove 1/2-inch Lag Screws.

4. Swivel Toilet to gain access to back.

5. Turn off RV’s power supply to the Toilet.

6. Disconnect Water Supply Line with Adjustable Wrench (Fig. A).

7. Disconnect Toilet’s 12-volt power hookup to RV.

Seal Replacement Package

Part #19621

Fig. A

Water supply

hookup

Power supply

connector

8.

Place an old towel or soft cloth on work surface. Remove Toilet from oor

and place upside down on work surface.

9. Remove old Closet Flange Seal (may be found in toilet or in oor

at Closet Flange). Discard.

10. Cover Holding Tank opening to contain odor.

Replacement of Blade Seal, O Ring Seal and Hopper Seal

To Remove Parts

1. Tap out 2 Mounting Bushings (Fig. B).

2. Remove Mounting Flange and Flange Seal.

3. High Prole models only: Remove Extension Tube. It may

be found connected to Mounting Flange or to the Mechanism.

Remove Tube Seal.

4.

if you need to replace the Blade Seal, remove 4 Mechanism Screws

without Washers (MS, Fig. C). If not, remove the three screws shown

with washers (no arrows).

Fig. B

Mounting Flange

Mounting Bushing

5. Lift Mechanism Assembly off Seal. Pull out carefully through back

of toilet, just far enough to gain access to the seal(s) to be replaced.

(No need to disconnect/remove motor wiring, Overow Tube or

Sound Deadening Insulation – if present – from Mechanism.)

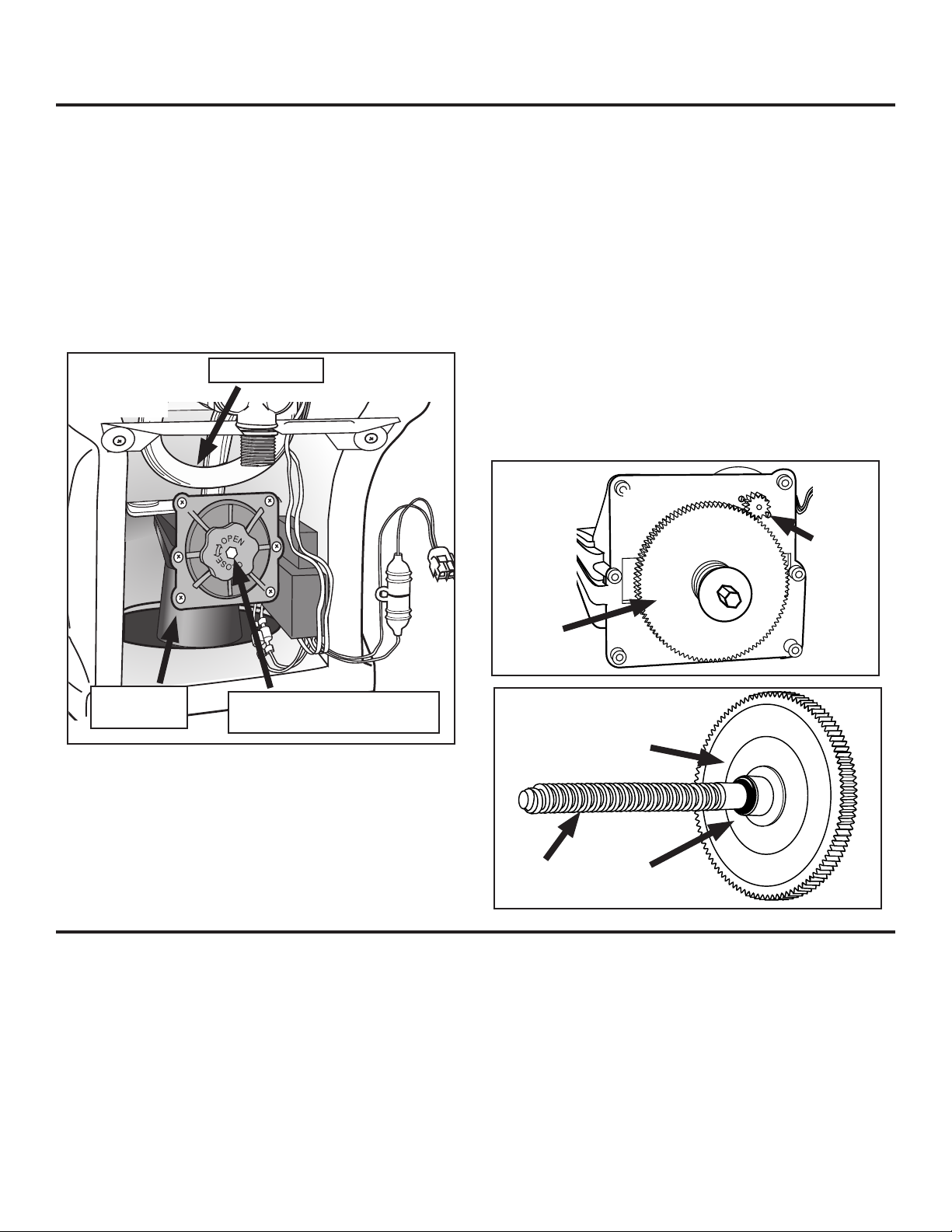

To Replace Blade Seal

1. Remove Blade Seal (may be attached to white Mechanism Plate).

Discard. Fit new seal in its place.

Fig. C

Form #19639B

Mechanism

White Mechanism Plate

Rev. 01/22/08

Page 2

Part #19621

Seal Replacement Package Page 2

To Replace O-Ring Seal

If you do not need to replace this seal, skip down to Re-install Mechanism sec-

tion below.

It is not necessary to remove Mechanism from toilet to install this seal. If you decide

to remove it, disconnect the Overow tube from top of Mechanism by twisting it off.

Then disconnect the yellow and green Motor Lead, using pliers if necessary.

1. Remove the Sound Deadening Kit insulation (if present) from Mechanism by

unwrapping the VelcroTM strap.

2. R

emove 6 End Cap Bolts from Mechanism. Remove End Cap (Fig. D).

3.

Grasp Gear/Clutch Assembly (Fig. E) and pull it out of the housing. This retracts

Fig. D

Overow Tube

Lead Screw into the Valve Blade. Release the Valve Blade. (Caution: wear

gloves when handling Valve Blade or anything that may have

come in contact with waste.)

7. Re-engage the large gear with the small pinion gear (Fig .E) and slide the Gear/

Clutch/Lead Screw Assembly fully into the housing.

8. Make sure curved washer is in place on the Lead Screw, concave side facing

toilet. Reinstall End Cap and secure 6 Screws.

9. Replace the Sound Deadening Kit insulation (if present) onto Mechanism, securing

it with the VelcroTM strap.

If you have removed Mechanism from toilet, do these steps now:

1. Reattach Overow Tube to Mechanism.

2.

Reattach 2 Wire Motor Leads, yellow to yellow and green to green.

Fig. E

Pinion

Gear

Mechanism

End Cap

the Valve Blade fully. The Lead Screw (Fig. F) is engaged in the Lead Screw

Boss on the Valve Blade (not shown).

4.

Turn Lead Screw counterclockwise until it releases from the Valve Blade.

Withdraw the entire Gear/Clutch/Lead Screw Assembly.

5. On the back side of the Gear/Clutch subassembly (Fig. F) you will nd a small

black “O” Ring. Slide it off and replace it with the new one.

6. Slide the Gear/Clutch/Lead Screw Assembly back into the housing. Holding

the Valve Blade, turn Lead Screw clockwise enough turns to fully engage the

Mechanism Lead Screw (knob

shown not on all units)

To Replace Hopper (Bowl Opening) Seal

If you do not need to replace this seal, skip down to Re-install Mechanism

section below.

1. Unscrew 3 Well Nut Screws with Washers (shown without arrows in Fig. C, page

1) to free white Mechanism Plate.

2. Scrape off old Seal on china with sharp tool. Use mineral spirits to remove

residue.

3. Apply a generous ring of caulk sealant around Bowl Drain opening (Fig. G, next

page).

4. Apply Flat Foam Seal to caulk sealant. Press down in place, center the seal, and

Gear/clutch assembly

Fig. F

Gear/clutch assembly

Lead

Screw

wipe away any excess sealant squeezed into opening.

To Replace Mechanism

1. Wet blade seal with clean water.

2. Fully seat new blade seal, lip up, onto Mechanism Plate (Fig. G).

3. To avoid damaging blade seal, make sure blade in new mechanism is fully closed.

Turn mechanism lead screw counter-clockwise to close valve (Fig. D).

4. Connect 2 Motor Leads, yellow-yellow, green-green (Fig. A).

5. Working from the back, position Mechanism in Toilet. NOTE: on

“O” Ring

Seal

Page 3

Part #19621

Seal Replacement Package Page 3

some low-prole units, it may be a tight squeeze. Align mechanism over Mecha-

nism Plate, press down and secure with four screws (MS, Fig. D).

6. Turn toilet over to check centering. Loosen well-nuts to re-center if needed.

Do the permanent tightening down of the well-nut screws at this

time by hand. Tighten in a diagonal pattern to get an even seal. Be

careful not to overtighten and cause deection of the plate at the

edges. Wipe off excess sealant when done.

7. Cut approximately 1” off Overow Tube. Forming a full loop, reattach to

Mechanism. Tuck in and away from lead screw.

8. If you removed the Controller Assembly and/or the Switch Box, re-install

now, using the adhesive foam pads provided. If you removed Metal

Bracket, reinstall.

9. High Prole: To install Extension Tube (Refer to Fig. H):

a. Lubricate sealing surface of Extension Tube Seal with silicone

grease.

b. Install Extension Tube Seal on Extension Tube.

Fig. H

Shown

separate for

Mounting

Flange Seal

Mounting

Flange

clarity – these

items nor-

mally remain

Clamp

assembled

Extension

Tube

HIGH

PROFILE

ONLY

Extension

Tube Seal

Mechanism

Tube Lip

Fig. G

Blade

Seal

Mechanism

Lead Screw

Mechanism

Plate

Well-nut

ass’y

Flat Foam

Seal

Sealant

c. Install Extension Tube and seal assembly on Mechanism. Make sure

that seal is seated at least 1/2 inch below Mechanism tube lip.

d. Ensure Hose Clamp on Mounting Flange Seal is tight.

e. Lubricate Mounting Flange Seal sealing surface with Silicone

Grease.

f. Install Mounting Flange and Seal assembly on Extension Tube. Make

sure there is at least a 1/2” overlap between the Extension Tube

and Mounting Flange Seal.

Low Prole: Replace the Mounting Flange Seal onto the lip of the

Mounting Flange. Install Mounting Flange to Mechanism. (No extension

tube is used.)

10. Replace 2 Mounting Bushings with at surface out.

Mechanism

Replacing Flush Nozzle Seals

This does not require removing the Mechanism.

To Remove Old Parts

1. Disconnect 2 upper Tubes from outside Nozzle Connectors (Fig.

I).

2. Cut Tie Strap securing Solenoid Valve to Metal Bracket (Fig. J).

3. Being careful not to bend Metal Bracket, slide Solenoid Valve out

of slot in Bracket. Swing entire Valve/Hose Assembly down and to

right out of the way. Support it to avoid putting stress on the Wire

Harness.

4. Pop up Seat/Lid Bolt Covers (hinged from rear).

Fig. I

Hinge Post Bolts

Locking

Nut

Outside Nozzle Connectors

Page 4

Part #19621

Seal Replacement Package Page 4

5. Holding Hinge Post Nuts from inside (Fig. J), turn screwdriver

counterclockwise to unscrew Hinge Posts. Remove Nuts and Bolts

(but not Seat/Lid).

6. Take note of Overow Tube position for future reference. Pull

Overow Tube off center Nozzle Connector.

7. To remove 2 outside Nozzle Connectors (Fig. I), push them in,

twist counterclockwise and pull back. (They may be caulked tight

and difcult to remove. Use pliers if necessary.)

8. Remove Locking Nut from center Nozzle by turning counterclock-

wise until it releases. Save Locking Nut.

9. Scrape away 3 Seals and Sealant with a sharp-edged tool. Use

mineral spirits to remove all residue from china.

To Replace Parts (Fig. K)

1. Push small Foam Seal over Flush Cover barb. Position new Flush

Cover/Nozzle Assembly in bowl. (Be sure Foam Seal is stuffed

completely/ush into opening.)

2. Place Locking Nut on center Nozzle. Holding Nozzle Assembly

rmly in position from inside Toilet Bowl, Turn Locking Nut clock-

wise to lock. (Note: all 4 prongs must mate with locking ears to

achieve proper lock.)

3. Adhere Nozzles to Connectors. Again Holding Nozzle Assembly

rmly, push in hard and rotate clockwise (you will feel it lock).

4. Reattach center Overow Tube. Tuck in Tube. To form a water

trap, it must be curved at approximately same position as when

removed.

5. Align/adjust Flush Cover/Nozzle Assembly level to Toilet inside

bowl.

6. Align Seat/Cover Assembly. Replace Hinge Posts and reattach

Nuts. Tighten rmly (Fig. J).

7. Swing entire Valve/Hose Assembly upright. Holding Metal Bracket

rmly to avoid bending it, slide Solenoid Valve back into slot in

Bracket. Rearrange Wire Harness.

8. Reconnect Hoses to outside Flush Nozzles. Push on rmly (Fig.

J).

9. Attach new Tie Strap holding Solenoid Valve to Metal Bracket (Fig.

K).

Fig. J

Overow Tube

Fig. K

Nozzle As-

sembly

Back wall of

china bowl

Hinge

Post

Bolts

Nozzle

Gasket

Nozzle Connector

Water Solenoid Valve

Tie Strap

Metal Bracket

Foam

Nozzle

Seal

Nozzle Con-

nector

Locking Nut

To Replace Toilet To Floor

1. Secure new Closet Flange Seal, lip side up, to Toilet.

2. Position Toilet over ange.

3. Reconnect Water Supply Line.

4. Reconnect 12-volt power supply to Toilet.

5. Reconnect RV’s power supply to the Toilet.

6. Turn on RV’s water supply. Press Toilet ush button to close blade

and to ush test.

7. Secure to oor with Lag Screws. Tighten.

8. Resecure Bolt Caps.

Loading...

Loading...