Page 1

Installation Manual

For 1200XX models: 12.0 cu.ft., 2-way, 4-door, R.V. refrigerator.

For 120X-IMXX models: 12.0 cu.ft., 2 way , 4-door, R.V. refrigerator with ice maker.

The letter “X”, in the model numbers above, stands for a letter or numeral which means a

refrigerator option.

WARNING: Improper installation, adjustment, alteration, service or maintenance

can cause injury or property damage. Refer to this manual. For assistance or additional information, contact a qualified installer, service

agency, or the gas supplier.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquid in

the vicinity of this or any other appliance.

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. Don’t touch electrical switches.

3. Extinguish any open flame.

4. Immediately call your gas supplier.

WARNING: DO NOT install this refrigerator in below deck marine

applications. Do not install this refrigerator in a fixed indoor cabin or

other dwelling applications. This refrigerator must use only

NORCOLD designed and approved outside air intake and exhaust

ventilation for correct and safe operation. Any other ventilation could

cause lethal combustion exhaust fumes and/or explosive propane

gas fumes to be in the living area and/or to be below deck.

English

French

NORCOLD, Inc.

P.O. Box 4248

Sidney, OH 45365-4248

Part No. 628936A (2-06)

Page 2

Table of Contents

Safety Awareness ....................................................................... 2

Safety Instructions ...................................................................... 2

Certification and Code Requirements ....................................... 2

Ventilation Requirements ........................................................... 3

Key Refrigerator Dimensions .................................................... 3

Assemble the Enclosure for the Refrigerator ............................ 4

Install the Lower and Upper Vents ............................................. 4

Install Decorative Door Panels (non-metal door models) ........ 6

Install the Refrigerator................................................................ 6

Optional Installation ................................................................... 7

Connect the Ice Maker (optional) ............................................... 7

Connect the water supply line ............................................. 7

Connect the Electrical Components .......................................... 7

Connect the 120 volts AC supply ........................................ 8

Connect the 12 volts DC supply.......................................... 8

Connect the Propane Gas Components ................................... 8

Connect the propane gas supply system ........................... 8

Examine the propane gas supply system for leaks ........... 8

Ignition and Start Up ................................................................... 9

Set the controls to automatic mode operation ................... 9

Set the controls to manual mode operation ....................... 9

Do a test of the gas safety valve........................................ 10

Shut down ......................................................................... 10

Fault Codes ...............................................................................11

Safety Awareness

- Incorrect installation, adjustment, alteration, or maintenance of this refrigerator can cause personal injury,

property damage, or both.

- Obey the instructions in this manual to install intake and

exhaust vents.

- Do not install the refrigerator directly on carpet. Put the

refrigerator on a metal or wood panel that extends the full

width and depth of the refrigerator.

- Do not allow anything to touch the refrigerator cooling

system.

- Propane gas can ignite and cause an explosion that can

result in property damage, personal injury, or death. Do

not smoke or create sparks. Do not use an open flame

to examine the propane gas supply line for leaks. Always

use two wrenches to tighten or loosen the propane gas

supply line connections.

- Make sure the electrical installation obeys all applicable

codes. See “Certification and Code Requirements”

section.

- Do not bypass or change the refrigerator’s electrical

components or features.

- Do not spray liquids near electrical outlets, connections,

or the refrigerator components. Many liquids are electrically conductive and can cause a shock hazard, electrical

shorts, and in some cases fire.

Read this manual carefully and understand the contents before

you install the refrigerator.

Be aware of possible safety hazards when you see the safety

alert symbol on the refrigerator and in this manual. A signal

word follows the safety alert symbol and identifies the danger of

the hazard. Carefully read the descriptions of these signal

words to fully know their meanings. They are for your safety.

WARNING: This signal word means a hazard, which if

ignored, can cause dangerous personal injury, death, or

much property damage.

CAUTION: This signal word means a hazard, which if

ignored, can cause small personal injury or much

property damage.

Safety Instructions

WARNING:

- This refrigerator is not approved for use as a free

standing refrigerator. It is equipped for the use of

propane gas only and can not be changed to use any

other fuels (natural gas, butane, etc.).

- The refrigerator cooling system is under pressure. Do

not try to repair or to recharge a defective cooling system.

- The cooling system contains sodium chromate. The

breathing of certain chromium compounds can cause

cancer. The cooling system contents can cause severe

skin and eye burns, and can ignite and burn with an

intense flame. Do not bend, drop, weld, move, drill,

puncture, or hit the cooling system.

CAUTION:

- The rear of the refrigerator has sharp edges and corners.

To prevent cuts or abrasions when working on the

refrigerator, use caution and wear cut resistant gloves.

Certification and Code Requirements

Installation Manual 2

Page 3

This refrigerator is certified by CSA International as meeting the

latest edition of ANSI Z21.19 / CAN 1.4 standards for installation

in mobile homes or recreational vehicles.

The installation must obey these standards and this

“Installation Manual” for the NORCOLD limited warranty to be in

effect. Installation must conform with the following as

applicable:

In the United States and Canada:

The bottom of the opening for the lower intake vent, which is

also the service access door, must be even with or immediately

below the floor level. This allows any leaking propane gas to

escape to the outside and not to collect at floor level.

CSA International certification allows the refrigerator to have

zero (0) inch minimum clearance at the sides, rear, top, and

bottom. While there are no maximum clearances specified for

certification, the following maximum clearances are necessary

for correct refrigerator performance:

- Local codes, or in the absence of local codes, the National

Fuel Gas Code, ANSI Z223.1/NFPA 54, the Natural Gas and

Propane installation Code, CSA B149.1, ANSI A119.2

Recreational Vehicles Code, and CSA Z240 RV Series,

Recreational Vehicles.

- A manufactured home (mobile home) installation must

conform with the Manufactured Home Construction and

Safety Standard, Title 24 CFR, Part 3280 [formerly the

Federal Standard for Mobile Home Construction and Safety,

Title 24 (part 280), and the current CSA Z240.4, Gasequipped Recreational Vehicles and Mobile Housing.

- If an external power source is utilized, the appliance, when

installed, must be electrically grounded in accordance with

local codes or, in the absence of local codes, the National

Electrical code, and ANSI/NFPA 70, or the Canadian

Electrical Code, CSA C22.2. Parts 1 and 2.

All propane gas supply piping and fittings must obey local,

state, and national codes about type and size. These

components must also obey the current NFPA 501C section 24, and in Canada with the current CAN 1-6.10 Standard.

Ventilation Requirements

WARNING: The completed installation must:

- Make sure there is sufficient intake of fresh air for

combustion.

- Make sure the living space is completely isolated from

the combustion system of the refrigerator.

- Make sure there is complete and unrestricted ventilation of the flue exhaust which, in gas mode, can

produce carbon monoxide. The breathing of carbon

monoxide fumes can cause dizziness, nausea, or in

extreme cases, death.

- Make sure the refrigerator is completely isolated from

its heat generating components through the correct use

of baffles and panel construction.

Bottom 0 inch min. 0 inch max.

Each Side 0 inch min. 1/2 inch max.

To p 0 inch min. 1/4 inch max.

Rear 0 inch min. 1 inch max.

These clearances plus the lower and upper vents allow the

natural air draft that is necessary for good refrigeration. Cooler

air comes in through the lower vent, goes up around the

refrigerator coils where it removes the excess heat from the

refrigerator components, and goes out through the upper vent.

The refrigerator also has two thermostat controlled fans to

move air across the cooling system. These fans turn on when

the condenser fin temperature at the thermostat is about 130° F

or higher and only when the refrigerator controls are on. These

fans turn off when the condenser fin temperature at the thermostat is about 115° F or less. Even with these fans, if the air flow

is blocked or decreased, the refrigerator will not cool correctly.

Each NORCOLD model is certified by CSA International for

correct ventilation. Install only the certified vents that are listed

in this manual.

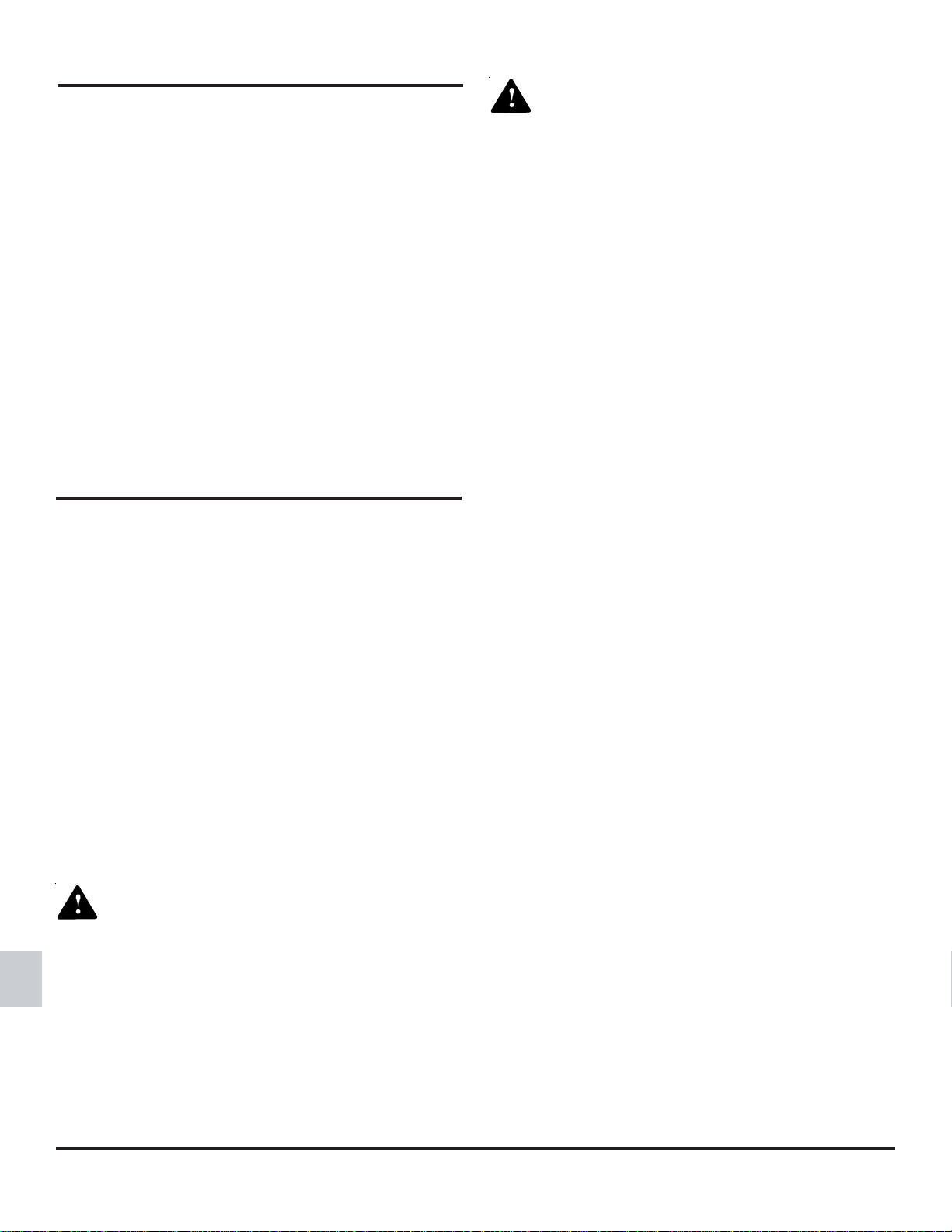

Key Refrigerator Dimensions

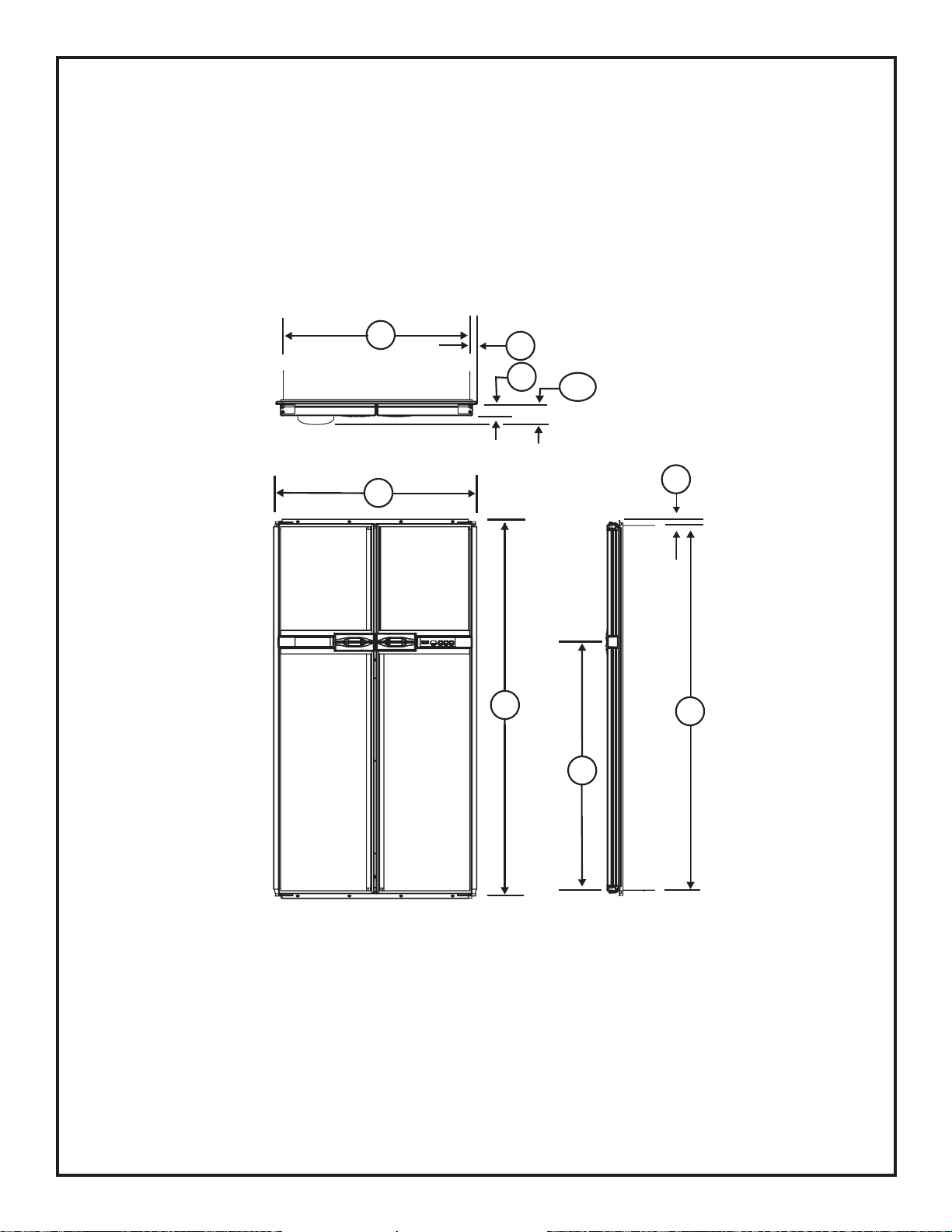

These key refrigerator dimensions are for your reference as

necessary (See Art01734).

Refrigerator cabinet width w/o trim - 32.4 in. ............................. 1

Refrigerator width overall w/ trim - 35.0 in.................................. 2

Refrigerator cabinet to side trim - 1.30 in. ................................. 3

Refrigerator cabinet height w/o trim - 63.2 in............................. 4

Refrigerator height overall w/ trim - 65.1 in. ............................... 5

Refrigerator cabinet to top/bottom trim - 0.90 in. ....................... 6

Enclosure wall to hinges - 3.10 in. ............................................. 7

Refrigerator cabinet to center of handles - 40.5 in. ................... 8

Enclosure wall to door (w/dispenser) - 3.90 in...................... 123

Certified installation needs one lower intake vent and one upper

exhaust vent. Install the vents exactly as written in this manual.

Any other installation method voids both the certification and the

factory warranty of the refrigerator.

Installation Manual 3

Page 4

Assemble the Enclosure for the Refrigerator

1. Make sure the enclosure is 63.25 - 63.38 inches high x 32.69

- 32.82 inches wide x 24 inches deep.

2. Make sure the enclosure shelf is solid and level. The

enclosure shelf must be:

- a metal or a wood panel and extend the full width and depth

of the enclosure.

- able to support the weight of the refrigerator and its con-

tents.

- level to maintain door alignment.

3. Install the upper exhaust vent:

CAUTION: Make sure that no sawdust, insulation, or

other construction debris is on the refrigerator or in the

enclosure. Debris can cause a combustion hazard and

prevent the refrigerator from operating correctly.

NOTE: Tighten the screws of the upper roof exhaust cap to 10

inch-pounds max. Also make sure that the air flow

around the upper roof exhaust cap is not blocked or

decreased by other roof mounted features such as a

luggage carrier, an air conditioner, a solar panel, etc.

- If the design of the vehicle allows, install the roof exhaust

vent [12] directly above the refrigerator cooling system (See

Art01597 and Art01596).

3. Make sure there are no adjacent heat sources such as a

furnace vent, a hot water heater vent, etc.

4. The enclosure face must be perpendicular to the enclosure

shelf to provide a combustion seal.

5. The cutout opening must be square and perpendicular to the

enclosure shelf to maintain door alignment.

Install the Lower and Upper Vents

1. Using the following chart, decide which vents and rough

opening (RO) sizes to use:

Certified Vent P/ N RO Height RO Width

Upper Roof 622293 N/A N/A

Exhaust Cap

Upper Roof 616319 24 in. 5 1/4 in.

Exhaust Vent

Lower Square 616010 9 3/4 in. 19 3/8 in.

Corner Intake

Upper Exhaust 62115 6 13 3/4 in. 21 1/2 in.

& Lower Intake

Plastic

2. Install the lower intake vent:

NOTE: The lower intake vent is also the service access

opening for the components on the rear of the refrigerator.

- Align the roof exhaust vent above the lower intake vent.

- Install a baffle [13] to prevent stagnant hot air in the

area [14] above the refrigerator.

- Make sure there is less than 1/4 inch clearance

[15] between the baffle and the top of the refrigerator.

- Make sure the baffle is the full width of the inside of

the enclosure.

- If the design of the vehicle does not allow you to install the

roof exhaust vent directly above the refrigerator cooling

system:

- Align the roof exhaust vent [12] above the lower intake

vent and move it inboard as necessary (See Art01597

and Art01595).

- Install two baffles [13] to prevent stagnant hot air in the

area [14] above the refrigerator.

- Make sure the baffles are the full width of the inside of

the enclosure.

- Make sure that the baffles are no more than 45°

from vertical [20].

- Put one baffle between the top rear edge of the

refrigerator and the inside edge of the roof exhaust

vent opening.

- Put the other baffle between the outside edge of

the roof exhaust vent opening and the side wall of

the vehicle.

WARNING: Make sure the bottom of the opening of the

lower intake vent is even with or immediately below the

floor level. This allows any leaking propane gas to

escape to the outside and not to collect at floor level.

- Make sure the bottom of the opening of the lower intake vent

[9] is even with or immediately below the floor level (See

Art01597).

- Make sure that the opening for the lower intake vent is

between 1/2 inch and 1 inch from the burner side of the

refrigerator enclosure.

Installation Manual 4

- If the depth of the enclosure is 24 inches or more and is

less than 25 inches, no baffles are necessary at the rear of

the enclosure.

- If the depth of the enclosure is 25 inches or more and is

less than 26 inches, add two baffles [16] to the rear of the

enclosure (See Art01595 and Art01596).

Page 5

- Put one baffle 18 inches to 18 1/2 inches above the

bottom of the enclosure [17] (4 1/4 inches to 4 3/4

inches above the top of the lower intake vent opening

REF) [18] .

- To prevent stagnant hot air in the area above the

refrigerator, install an aluminum or galvanized

steel sheet baffle [13] between the top of the

refrigerator and the top of the upper exhaust vent,

- Put the other baffle at the lowest edge of the condenser

[11] of the refrigerator.

- Make sure that the baffles are 1 inch or less [19]

from the coils [10] and condenser of the refrigerator.

- Make sure that the baffles are the full width of the

inside of the enclosure.

- If the depth of the enclosure is more than 26 inches, install

a wood or an aluminum or galvanized sheet solid box baffle

[21] in the rear of the enclosure (See Art01644 and

Art01645).

- Make sure that the bottom of the solid box baffle is 18

inches to 18 1/2 inches above the bottom of the

enclosure [17] (4 1/4 inches to 4 3/4 inches above the

top of the lower intake vent opening REF) [18] .

- Make sure that the back of the solid box baffle is

perpendicular to the bottom of the enclosure.

- Make sure that the back of the solid box baffle is either

against the top of the enclosure or against the angled

baffle [13] (depending on the vehicle design).

- Make sure that the solid box baffle is one inch or

less [19] from the coils [10] and condenser of the

refrigerator.

- Make sure there is 1/4 inch or less of clearance between the baffle and the top of the

refrigerator and that the baffle overlaps the

refrigerator 1 inch or less [19].

- Make sure that the baffle is against the wall of

the vehicle at the top of the upper exhaust vent

and 1/4 inch or less from the top of the

opening for the upper exhaust vent [124].

- Make sure the baffle is the full width of the

inside of the enclosure.

- Make sure the clearance at the sides of the refrigerator is

correct:

- If there is more than 1/2 inch of clearance between

either side of the refrigerator and the wall, fill the space

with fiberglass insulation or add a baffle to eliminate

the excess clearance.

- When using an upper side-wall exhaust vent:

- If the depth of the enclosure is more than 24 inches

and less than 26 inches [27], install a bent aluminum

or galvanized steel sheet baffle [26] to the rear of the

enclosure (See Art01588).

- Make sure that the bend of the baffle is the full

width of the inside of the enclosure.

- Make sure that the solid box baffle is the full width

of the inside of the enclosure.

- If there is more than 1/2 inch of clearance between either

side of the refrigerator and the wall, fill the space with

fiberglass insulation or add a baffle to eliminate the excess

clearance.

- If the design of the vehicle does not allow you to install a

roof exhaust vent, install an upper side-wall exhaust vent.

NOTE: The refrigerator is 23.7 in. min. to 24.0 in. max. from

the rear of the breaker to the rear of the condenser

[22] and is 59.0 in. min. to 59.3 in. max. from the

bottom of the refrigerator to the bottom of the

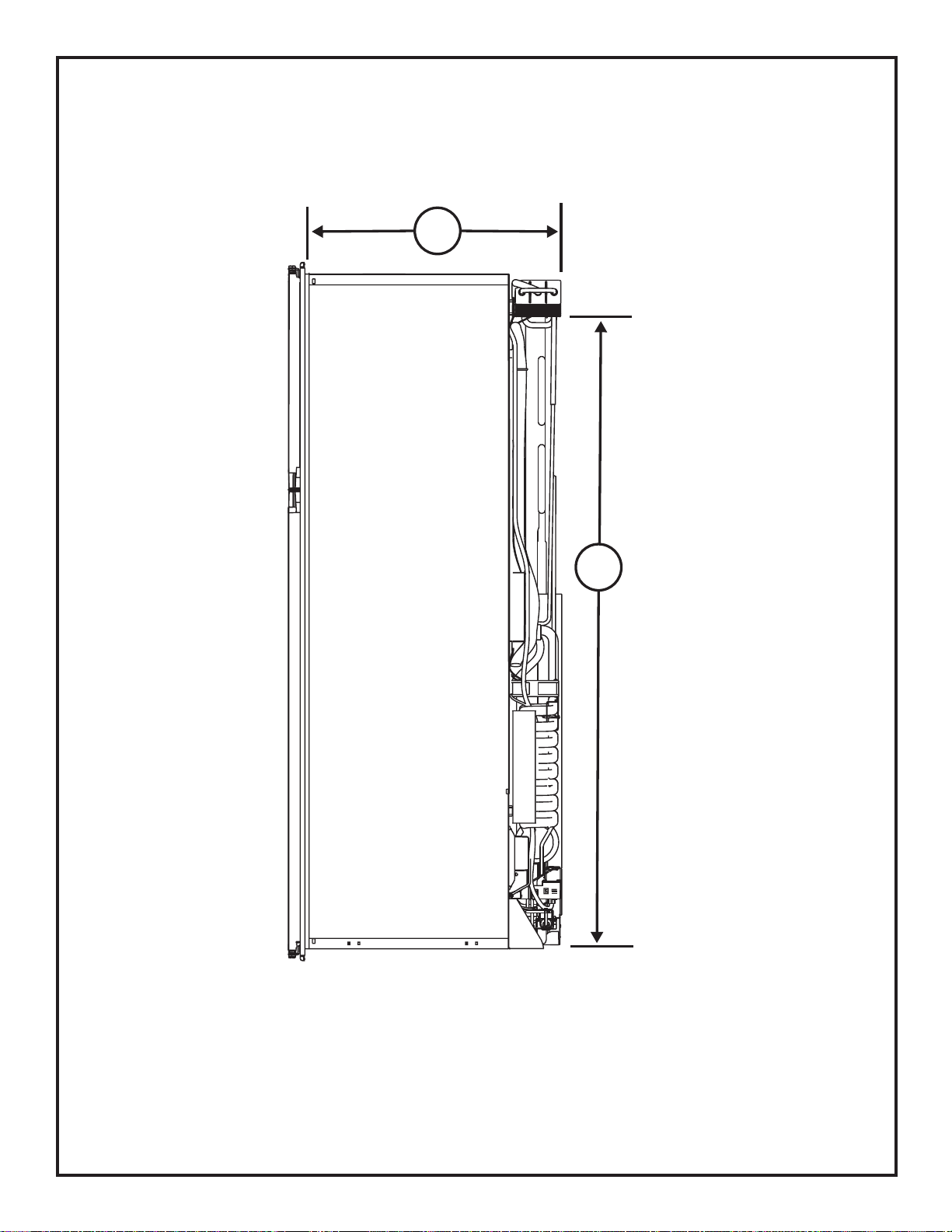

refrigerator condenser [23] (See Art01600).

- Install the upper side-wall exhaust vent [24] so that the

distance [25] from the bottom of the enclosure to the

top of the rough opening for the upper exhaust vent is

at least 63 inches (see Art01588 and Art01589).

- Align the upper exhaust vent horizontally above the

lower intake vent [9].

- Make sure that the bend of the baffle is flush with

the bottom edge of the upper intake vent door

frame.

- Make sure that the top edge of the baffle is 1/4

inch or less [124] below the condenser [11] and

that there is 1/4 inch or less clearance [124]

between the lower rear corner of the condenser

and the baffle.

- If the depth of the enclosure is more than 26 inches

[27], install a wood or an aluminum or galvanized steel

sheet solid box baffle [21] between the lower intake

vent and the upper exhaust vent (See Art01589).

- Make sure that the solid box baffle is the full width

of the inside of the enclosure.

- Make sure that the bottom of the solid box baffle is

18 inches to 18 1/2 inches above the bottom of the

enclosure [17] (4 1/4 inches to 4 3/4 inches above

the top of the lower intake vent opening REF) [18].

Installation Manual 5

Page 6

- Make sure that the back of the solid box baffle is

perpendicular to the bottom of the enclosure.

Install the Refrigerator

- Make sure that the horizontal top of the solid box

baffle is even with the bottom edge of the upper

exhaust vent [24].

- Make sure that the vertical top edge of the baffle is

1/4 inch or less [124] below the lower rear corner

of the condenser [11].

- Make sure that there is 1/4 inch or less clearance

[124] between the rear of the condenser and the

baffle.

Install Decorative Door Panels (non-metal

door models)

NOTE: The doors are made to accept decorative panels. The

decorative panels must be 3/16 inch or less in

thickness. Install the decorative door panels in the

refrigerator doors before installing the refrigerator in

the vehicle.

1. Make two upper door panels that are 16 13/64 inches wide x

18 3/8 inches high:

- Raised panels must be centered on each door and no

larger than 15 11/32 inchs wide x 17 17/32 inches high.

2. Make two lower door panels that are 16 13/64 inches wide x

41 13/64 inches high:

- Raised panels must be centered on each door and no

larger than 15 11/32 inchs wide x 40 11/32 inches high.

3. Install the decorative door panels:

- Pull the panel retainer [37] off of each door [39] (See

Art00965).

1. Put the refrigerator in position:

WARNING: Make sure the combustion seal is not

broken, is completely around the refrigerator mounting

flanges, and is between the mounting flanges and the

wall of the enclosure If the seal is not complete, exhaust

fumes can be present in the living area of the vehicle.

The breathing of exhaust fumes can cause dizziness,

nausea, or in extreme cases, death.

NOTE: Be careful when you put the refrigerator into position.

The refrigerator has vacuum insulating panels on the

top and sides. If punctured, these panels lose

insulation value which decreases the cooling performance of the refrigerator. It is not necessary to remove

the protective packaging from the doors of metal door

models to install or operate the refrigerator.

- Make sure that the flue cap is not pushed down against the

top of the flue tube.

- Push the refrigerator into the enclosure so the side trim is

approximately one inch from the wall.

2. Make sure that the side trim pieces [127] are in the correct

position (See Art01649 and Art01650):

- Slide both side trim pieces up or down as necessary so

that the ends of the side trim pieces are fully covered by the

upper and lower trim pieces [40 and 128].

- Pull the left hand side trim piece toward the left as far as it

will go so that there is no gap between the edge of the side

trim piece and the upper and lower trim pieces.

- Pull the right hand side trim piece toward the right as far as

it will go so that there is no gap between the edge of the

side trim piece and the upper and lower trim pieces.

- Push the refrigerator completely into the enclosure.

- Push a decorative door panel [38] into the slots of each

door.

- Make sure that each panel retainer is correctly positioned

and push the curved snap [125] of the panel retainer [37]

inside of the curved snap [126] of the door (See Art01648).

Installation Manual 6

3. Install the mounting screws and trim:

- Put the upper trim piece [40] onto the front of the refrigerator

(See Art01649).

- Put the four screws [41] through the mounting flange on the

front of the refrigerator and into the enclosure wall.

- Put a cap plug [129] on each of the screw holes in the upper

trim piece on the front of the refrigerator.

WARNING: Do not omit the lower trim piece. This

piece is part of the combustion seal.

Page 7

Push the lower trim piece [128] onto the front of the refrigera-

tor (See Art01650).

- Put the four screws [41] through the mounting flange on the

front of the refrigerator and into the enclosure wall.

- 1/4 in. OD copper tubing for the water supply line.

OR

- 1/4 in. OD plastic tubing for the water supply line.

- Put a cap plug [129] on each of the screw holes in the lower

trim piece on the front of the refrigerator.

- Put two or more screws through the mounting flange on the

rear of the refrigerator and into the floor.

4. On metal door models only, you may wish to remove the

protective packaging from the doors.

NOTE: Be careful to not scratch or dent the metal doors. Do

not use any abrasive cleaners, chemicals, or scouring

pads because they can damage the fininish of the

doors.

Optional Installation

You can change enclosures that were made for Norcold model

N8XX refrigerators so that you can put Norcold model 120X

refrigerators into them.

To change the Norcold model N8XX refrigerator enclosure [130]

into the Norcold model 120X refrigerator enclosure [131] (See

Art01597):

- Increase the height of the enclosure by 3 3/8 inches [132].

- Increase the width of the enclosure by 8 13/16 inches [133].

- Make sure to add the additional width to the left side of the

enclosure (as looking at the rear of the refrigerator).

Install the necessary baffles only as written in the “Install the

Upper and Lower Vents” section of this manual.

The locations of the 12 VDC supply, the 120 VAC supply, and the

propane gas supply line do not change.

- 1/4 in. shut off valve in the water supply line. This should be

easily accessible through the lower intake vent.

Connect the water supply line:

Install a 1/4 in. OD water supply line [43] from the water shut off

valve of the vehicle to the solenoid water valve [44] at the rear of

the refrigerator (See Art01014):

NOTE: A brass compression nut [45], a brass sleeve, a plastic

sleeve [46] , and a brass insert [47] are supplied and

attached to the rear of the refrigerator (See Art01604).

- Put the compression nut and then the sleeve onto the water

supply line [43].

- For copper tubing, use the brass sleeve.

- For plastic tubing, use the plastic sleeve [46].

- For plastic tubing with .040 in. wall thickness, also use

the brass insert [47].

- Flush the water supply line until the water is clear.

- Put the tubing into the adapter [48] until it is against the stop

of the adapter.

- Tighten the compression nut by hand (hard finger tight).

- Using two wrenches, tighten the compression nut 1 ½ to 2

turns.

- Open the water shut off valve of the vehicle.

- Examine the connections for leaks.

Connect the Ice Maker (optional)

The ice maker is assembled to the refrigerators at the factory as

optional equipment. If the refrigerator does not have a factory

installed ice maker, one can not be added to the refrigerator at a

later time.

The refrigerator installer must connect a cold water supply line

to the solenoid valve at the rear of the refrigerator. The following

are necessary to connect the icemaker:

Connect the Electrical Components

AC Operation 120 volts AC voltage

(132 volts max. - 108 volts min.)

12 volts DC control voltage

(15.4 volts max. - 10.5 volts min.)

This refrigerator operates on these electrical sources. Operation out of these limits may damage the refrigerator’s electrical

circuit parts and will void the warranty.

Installation Manual 7

Page 8

WARNING: The rear of the refrigerator cooling system

has hot surfaces and sharp surfaces that can damage

electrical wiring. Make sure that there is a good clearance between all electrical wiring and the cooling system

of the refrigerator. Position any electrical wiring within the

refrigerator enclosure opposite the burner side of the

refrigerator. Do not put any electrical wiring through the

roof exhaust vent. Failure to correctly position electrical

wiring can result in electrical shock or fire.

- Push the DC ground wire [51] onto the terminal of the power

board [49] that is marked GND.

- Make sure each DC power supply wire is on the correct

polarity terminal.

Connect the Propane Gas Components

Connect the 120 volts AC supply:

WARNING: Connect the AC power cord(s) only to a

grounded three-prong receptacle. Do not remove the

round ground prong from the AC power cord of the

refrigerator or the ice maker (optional). Do not use a two

prong adapter or an extension cord with either AC power

cord. Operation of the refrigerator without correct ground

can cause dangerous electrical shock or death if you are

touching the metal parts of the refrigerator.

Put the AC power cord(s) into a grounded three-prong receptacle:

- Make sure the receptacle is positioned within easy reach of

the lower intake vent.

- Make sure the power cord(s) does not touch the burner

cover, the flue pipe, or any hot component that could

damage the insulation of the power cord.

Connect the 12 volts DC supply:

The refrigerator controls operate on 12 VDC power. As the

distance from the vehicle battery to the refrigerator increases,

the correct AWG wire size and fuse size also increases. If the

wire size is too small for the distance, a voltage drop occurs.

Use a minimum of 18 AWG wire and a maximum 6 Amp fuse. If

the wire size is larger than the min. size, use the correct fuse

per RVIA A119.2 standard or local codes.

Propane Gas Operation

Propane gas

(11 inches water column pressure)

12 volts DC control voltage

(10.5 volts min. - 15.4 volts max.).

This refrigerator operates on these energy sources. Operation

out of these limits can damage the refrigerator electrical circuit

parts and will void the warranty

Connect the propane gas supply system:

WARNING: Be very careful when working on or near

the propane gas system.

- Do not smoke, or use an open flame near the propane

gas system.

- Do not use an open flame to examine for leaks.

- Do not connect the refrigerator to the propane gas tank

without a pressure regulator between them.

- To avoid a propane gas leak, always use two

wrenches to tighten or loosen the propane gas supply

line connections.

- Leaking propane gas can ignite or explode and result

in dangerous personal injury or death.

1. Install a fuse in DC power supply wires between the battery

and the refrigerator:

- Put fuse as close to the battery as possible.

2. Connect the DC power supply wires (See Art01748):

- Attach a 1/4 inch Quick Connect terminal to each DC power

supply wire.

NOTE: Do not use the chassis of the refrigerator or the

vehicle frame as one of the conductors.

- Connect the positive DC power wire [50] to the teminal on

the power board [49] that is marked 12VDC.

Installation Manual 8

Connect the gas supply line to the refrigerator:

- Make sure that all tubing and fittings obey all local, state,

and national codes about size and type.

- Make sure that all flexible metal connectors obey the current

CAN1-6.10 Standard.

- Make sure that the materials used for the gas supply line

obey both the current ANSI A 119.2 (NFPA 1192) and CSA

Z240 Standards on Recreational Vehicles. Norcold

recommends the use of 3/8 inch copper tubing as the gas

supply line and requires a 3/8 inch SAE (UNF 5/8-18) male

flare fitting as the connection to the refrigerator.

- Put the propane gas supply line up through the floor of the

enclosure.

Page 9

- Make sure the hole through the floor is large enough allow

clearance for the gas supply line.

- Put a weather resistant seal (grommet, sealant, etc.)

around the gas supply line where it goes through the floor

to prevent vibration and abrasion.

Set the controls to automatic mode operation:

- Push the ON / OFF button to turn the refrigerator on.

- Push and hold the MODE button until the letters “AU” show

in the center display and then release.

- To prevent vibration and abrasion, make sure that the gas

supply line is not against anything in the enclosure.

- Attach the gas supply line to the bulkhead fitting of the

refrigerator.

Examine the propane gas supply line for leaks:

WARNING: Do not allow the leak detecting solution to

touch the electrical components. Many liquids are

electrically conductive and can cause electrical shorts

and in some cases, fire.

Use a leak detecting solution to examine the gas supply line

and all propane gas connections for leaks.

If you use compressed air for the test:

- The pressure of the compressed air at the manual shut off

valve of the refrigerator must not be more than 1/2 psig (14

inches Water Column).

- If the pressure of the compressed air is more than 1/2 psig

(14 inches Water Column), remove the gas supply line

from the bulkhead fitting of the refrigerator before the test.

- If the pressure of the compressed air is equal to or less

than 1/2 psig (14 inches Water Column), close the manual

shut off valve of the refrigerator before the test.

- If 120 volts AC is available to the refrigerator:

- The letters “AU” and then “AC” show in the center

display.

- After ten seconds, the “AU” and then “AC” go off and

only a green power ON light remains.

- This means that the refrigerator is operating on AC

electric.

- If 120 volts AC is not available to the refrigerator:

- The letters “AU” and then “AC” show in the center

display.

- After five seconds, the “AU” and then “LP” show in the

center display.

- After ten seconds, the “AU” and the “LP” go off and only

a green power ON light remains.

- This means that the refrigerator is operating on

propane gas.

- If neither 120 volts AC nor propane gas is available to the

refrigerator:

- The fault codes “no” “AC” and then “no” “FL” show in

the center display and an audible alarm sounds.

Ignition and Start Up

Before ignition or start up of the refrigerator:

- Make sure the air flow in the lower intake vent, through the

refrigerator coils and condenser, and out the upper exhaust

vent is not blocked or decreased.

- Make sure there are no combustible materials in or around

the refrigerator.

NOTE: If the gas does not ignite in 30 seconds, the gas safety

valve of the refrigerator automatically closes. The

controls either select a different energy source or “no”

“FL” appears in the center display and you will hear an

alarm sound. This means that the gas did not ignite.

If the gas does not ignite after several attempts, refer to the

“Fault Codes” section of this manual.

If an energy source is available to the refrigerator, but is not

operating correctly:

- A fault code shows in the center display.

- The refrigerator controls try to change to a less efficient

energy source.

- If a less efficient energy source is not available:

- An audible alarm starts.

- A fault code shows in the center display.

- Refer to the “Fault Codes” section of this manual.

Set the controls to manual mode operation:

- Push the ON / OFF button to turn the refrigerator on.

- Push and hold the MODE button until the letters “ AC” show

in the center display and then release.

Installation Manual 9

Page 10

- After ten seconds, the “AC” goes off and only a green

power ON light remains.

- Push and hold the MODE button until the letters “LP” show

in the center display and then release.

- After ten seconds, the “LP” goes off and only a green

power ON light remain

Do a test of the gas safety valve:

1. Start up the refrigerator in the manual mode operation.

2. Open the lower intake vent.

3. Remove one wire from the solenoid of the gas safety valve at

the rear of the refrigerator.

4. Within 30 seconds, the flame should extinguish. This

means that the gas safety valve is operating correctly.

5. Put the wire back on the solenoid of the gas safety valve.

6. Close the lower intake vent.

Shut down - all models:

To shut down the refrigerator, push and hold the ON/OFF button

for one second.

Installation Manual 10

Page 11

Fault Codes

sedoCtluaFgninaeMedoCtluaFsnoitcAevitcerroC

siegatlovCD

oN

.yalpsid

"rd"

.oslamralaelbiduA

"LF""on"

.oslamralaelbiduA

"CA""on"

.oslamralaelbiduA

"OL""cd"

"Po""IL"

ehtotelbaliavanu

lortnocrotaregirfer

ehtrolenap

.FFOsirotaregirfer

rofneposawroodehT

.setunim2nahterom

tondidrenrubehT

.etingi-erroetingi

siegatlovCA

ehtotelbaliavanu

.lortnocrotaregirfer

ehtotegatlovCD

lortnocrotaregirfer

.wolootsilenap

erutarepmethgihehT

.neposihctiwstimil

:kcehC

.NOsirotaregirferehttahT-

.lanoitareposielcihevehtfotnempiuqegnigrahcyrettabehttahT-

.)elbacilppafi(lanoitareposiretrevnocCD/CAehttahT-

.retnececivresdezirohtuadlocroNarorelaedruoyeeS-

.roodehtesolC

:kcehC

.neposi)s(knatsagenaporpehtfoevlavehttahT-

.erusserptcerrocehttasisagenaporpehttahT-

.neposirotaregirferehtfoevlavffotuhslaunamehttahT-

riagnivomeR"eeS.enilylppussagenaporpehtniriaonsierehttahT-

.launamsihtfonoitces"senilylppussagenaporpehtmorf

.retneCecivreSdlocroNdezirohtuarorelaedruoyeeS-

:kcehC

.teltuoelbaecivresaotnideggulprotaregirferehttahT.tcatnisielcihevehtforekaerbtiucricroesufehttahT-

.)elbacilppafi(lanoitareposirotarenegelcihevehttahT-

.retneCecivreSdlocroNdezirohtuarorelaedruoyeeS-

:kcehC

.lanoitareposielcihevehtfotnempiuqegnigrahcyrettabehttahT-

.)elbacilppafi(lanoitareposiretrevnocCD/CAehttahT-

.retneCecivreSdlocroNdezirohtuarorelaedruoyeeS-

ecivreSdlocroNdezirohtuarorelaedruoyeeS.elbaecivresrenwotonsisihT

.retneC

rebmunerutarepmeT

TESnehwsehsalf

.dehsupsinottubPMET

"Er""CA"

.oslamralaelbiduA

"EH""CA"

.oslamralaelbiduA

"rS"

.oslamralaelbiduA

sirotaregirferehT

kcaB"ehtnognitarepo

."metsySgnitarepOpU

ehtnihtiwtluafasisihT

.slortnocrotaregirfer

ehtnihtiwtluafasisihT

.slortnocrotaregirfer

ehtnihtiwtluafasisihT

.slortnocrotaregirfer

.retneC

.retneC

.retneC

.retneC

ecivreSdlocroNdezirohtuarorelaedruoyeeS.elbaecivresrenwotonsisihT

ecivreSdlocroNdezirohtuarorelaedruoyeeS.elbaecivresrenwotonsisihT

ecivreSdlocroNdezirohtuarorelaedruoyeeS.elbaecivresrenwotonsisihT

ecivreSdlocroNdezirohtuarorelaedruoyeeS.elbaecivresrenwotonsisihT

97710trA

Installation Manual 11

Page 12

Installation Manual 12

Page 13

132

133

12

12

11

130

N8XX

131

120X

9

Art01597

Page 14

15

13

12

12

13

14

19

11

16

19

14

20

4

16

19

19

Art01596

16

18

10

16

17

17

18

10

9

Art01595

9

Page 15

15

13

12

12

13

14

19

21

14

20

19

21

Art01644

18

10

18

17

17

10

9

Art01645

9

Page 16

22

23

Art01600

Page 17

19

13

124

11

124

124

24

26

27

25

9

Art01588

Page 18

19

13

124

124

11

124

24

21

27

25

18

9

17

Art01589

Page 19

37

38

127

39

Art00965

129

126

37

125

Art01648

127

4041

Art01649

128

4127

129

127

Art01650

Page 20

49

50

Art01014

Art01748

45

51

43

44

48

48

47

46

45

Art01604

43

33

on

1 COLD-9 COLDEST

SET TEMP MODE ON / OFF

32

31

30

Art01333

Page 21

1

3

7

123

2

5

8

6

4

Art01734

Loading...

Loading...