The Swan Corporation BS-2515, BS-1515 User Manual

TOOLS REQUIRED

• Ruler

• Drill

• Caulk

• Saber Saw

(if counter top

cutout is required)

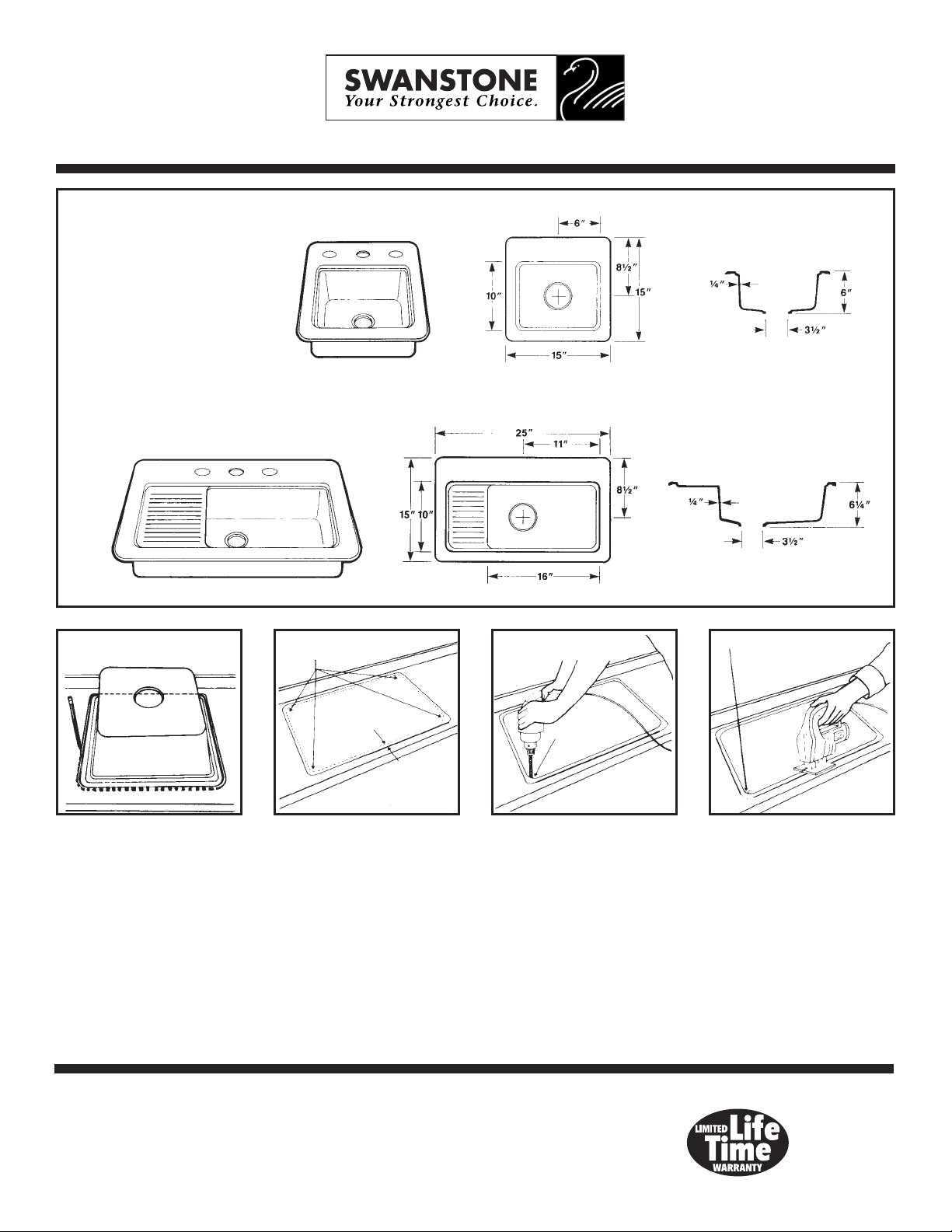

BS-2515

BAR SINKS

BS-1515

TRACE COMPLETELY

AROUND EDGE OF SINK

1. If it is necessary to cut out

the counter top, invert sink

and position onto the counter

top. Locate sink front to rear

and so that the bowl will not

interfere with the cabinets

below. Trace a pencil line

around the outside edge of

the sink and remove the sink

from the counter top.

DRAW A 1-1/2ⴖ RADIUS

AT EACH CORNER

5/16⬙

2. Measure in 5/16⬙ from the

initial sink outline and draw a

second line inside the first.

Draw a 1-1/2⬙ radius at each

corner. This second interior

line will be your cutout line.

Check Cutout

Line Measurements

Model Width Depth

BS-1515 14-3/8⬙ 14-3/8⬙

BS-2515 24-3/8⬙ 14-3/8⬙

Measure the cutout or the

pre-cut opening to be sure it

conforms to the sizes listed.

DRILL STARTER HOLE

INSIDE OF CUTOUT LINE

CUTOUT LINE

3. Drill starter hole inside of

cutout line.

CUT INSIDE OF LINE

4. Using a saber saw, cut

inside of cutout line. Trial fit

sink to check proper fit.

OWNER’S MANUAL

MODEL NOS.

BS-1515

BS-2515

Installation

Care and

Cleaning

CAUTION:

Read ALL instructions carefully

BEFORE starting your installation.

Save this manual for future reference.

BAR SINKS

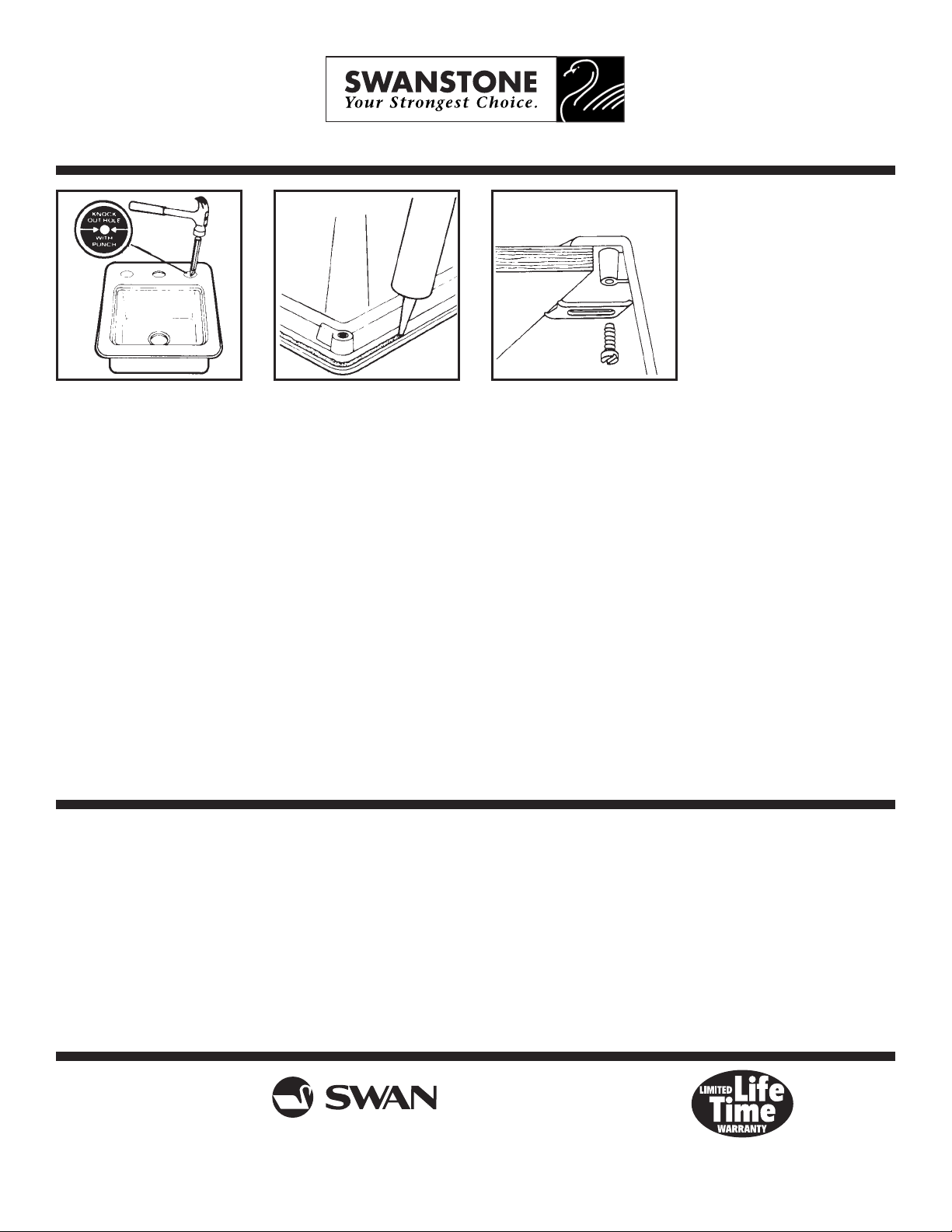

5. Fixture hole locations are

identified with a gray label

indicating the most desired

placement. Position a chisel on

the desired dot and strike with

a hammer to break out the

hole. Clean out fixture hole

with a knife.

If hole is not used, peel off the

label.

Attach faucet, drain, and

accessories according to manufacturer’s instructions.

APPLY CAULK

6. Apply a bead of caulk (not

included) to the underside of

the sink flange and position

sink into counter top opening.

8. Connect all faucet supply

lines, disposal (if available),

and drain trap fittings per

manufacturer instructions.

CHECK FOR LEAKS

• Supply user tubes to faucet

• Supply riser tubes to shut off

valves or lower connections

• Fill sink with water and check

for leaks around drain

• Release water from sink and

check for possible leaks

• Tighten as needed

7. Attach four (4) sink clips to

underside of sink. Sink clips

provided will accommodate a

counter top up to 1-1/2⬙ thick.

Tighten screws in front then

rear first. Work from side to

side. Do not overtighten. Clean

up excess caulk.

CLEANING

Clean your Swanstone sink as

you would any other fine bath

fixture, using normal household detergents and cleansers.

Just wiping the wall surfaces

quickly removes watermarks

and residues. Occasional

scrubbing with household

abrasive cleansers ensures

that the original luster is

maintained.

REPAIRING

SOLID COLORS

Use 400 grit sandpaper to

remove scratches and gouges

in the surface. A “scotchbright

pad” can be used to blend in

the area.

AGGREGATE & GALAXY

COLORS

Use 400 grit sandpaper to

remove scratches and gouges

in the surface. To blend in the

area use a fine grade, white,

automotive polishing compound or paste wax.

The Swan Corporation

One City Centre

St. Louis, MO 63101

(314) 231-8148

Patent Pending

Form #256-11-91-10M

Loading...

Loading...