Thermsaver unvented water heater Installation Manual

unvented water heater

installation manual

3bar kit version

2

TECHNICAL DATA & INSTALLATION

INSTRUCTIONS FOR DIRECT &

INDIRECT UNVENTED WATER HEATERS

WITH EXTERNAL EXPANSION TANK

Your vessel is made by one of the worlds leading unvented water heater

manufacturers.

Your water heater is made from Duplex Stainless Steel,which is one

of the toughest and best grades of steel currently available.

Each unit has been individually tested and inspected to industry

standard.

Your water heater uses advances in technology and innovative

techniques to provide you with a high performance water heater at

the best price possible.

No other type of water heater can provide all of the benefits that

can be achieved from unvented units such as this model of

Unvented Water Heater.

IMPORTANT NOTICE FOR INSTALLATION

READ THESE INSTALLATION AND MAINTENANCE

INSTRUCTIONS BEFORE COMMENCING

UNVENTED CYLINDERS ARE DESIGNED TO BS STANDARD AND

INSTALLED TO RELEVANT BUILDING REGULATIONS

THE RELEVANT REGULATIONS ARE

ENGLAND & WALES – BUILDING REGULATION G3

SCOTLAND – TECHNICAL STANDARD P3

NORTHERN IRELAND – BUILDING REGULATION P5

AFTER INSTALLATION THE BENCHMARK LOG BOOK MUST BE

COMPLETED AND LEFT ALONG WITH THESE INSTRUCTIONS WITH

THE HOUSEHOLDER FOR FUTURE REFERENCE.

INSTALLATION INSTRUCTION MANUAL

TO BE LEFT WITH THE UNIT

CONTENTS

SPECIFIERS GUIDE

The law and unvented p3

The benefits of unvented systems p3

The benefits of unvented systems p3

Standard energy losses p4

What is supplied with your vessel?p4

INSTALLATION INSTRUCTIONS

Siting the unit

p4

Check water pressure & flow rates p4

Connecting the water supply p5

Cold water valve p5

Drain tap p5

Pipework to taps p5

Secondary circulation p5

Wiring p7

Fitting immersion heaters p7

Fitting the thermal cut out & primary connections p7

Tundish p8

Commissioning the unit p8

External expansion tank p8

Scale p8

Draining p8

Discharge pipework p8

G3 Requirement p9

Problem solving p10

Spares p10

Part component references p10

Guarantee p11

DIAGRAMS

Dimensional data for DH / IDH

range of water heaters p3

Typical installation of a DH tank p5

Typical installation of a IDH tank p5

Secondary circulation connection p6

2 x 2 port (S-plan) valve system p6

2 port valve + 3 port mid position valve (y-plan) p7

Immersion heater p7

Schematic discharge pipe arrangement p8

3

WATER HEATER SPECIFIERS GUIDE

THE BENEFITS OF UNVENTED

WATER HEATERS

● Expansion vessel supplied

● Annual inspection as per warranty

● Duplex Stainless Steel

● Operates at 3bar,which is higher than some other

unvented units

● High quality finish

● Has one of the lowest heat losses for maximum economy

● No sacrificial anode - low maintenance

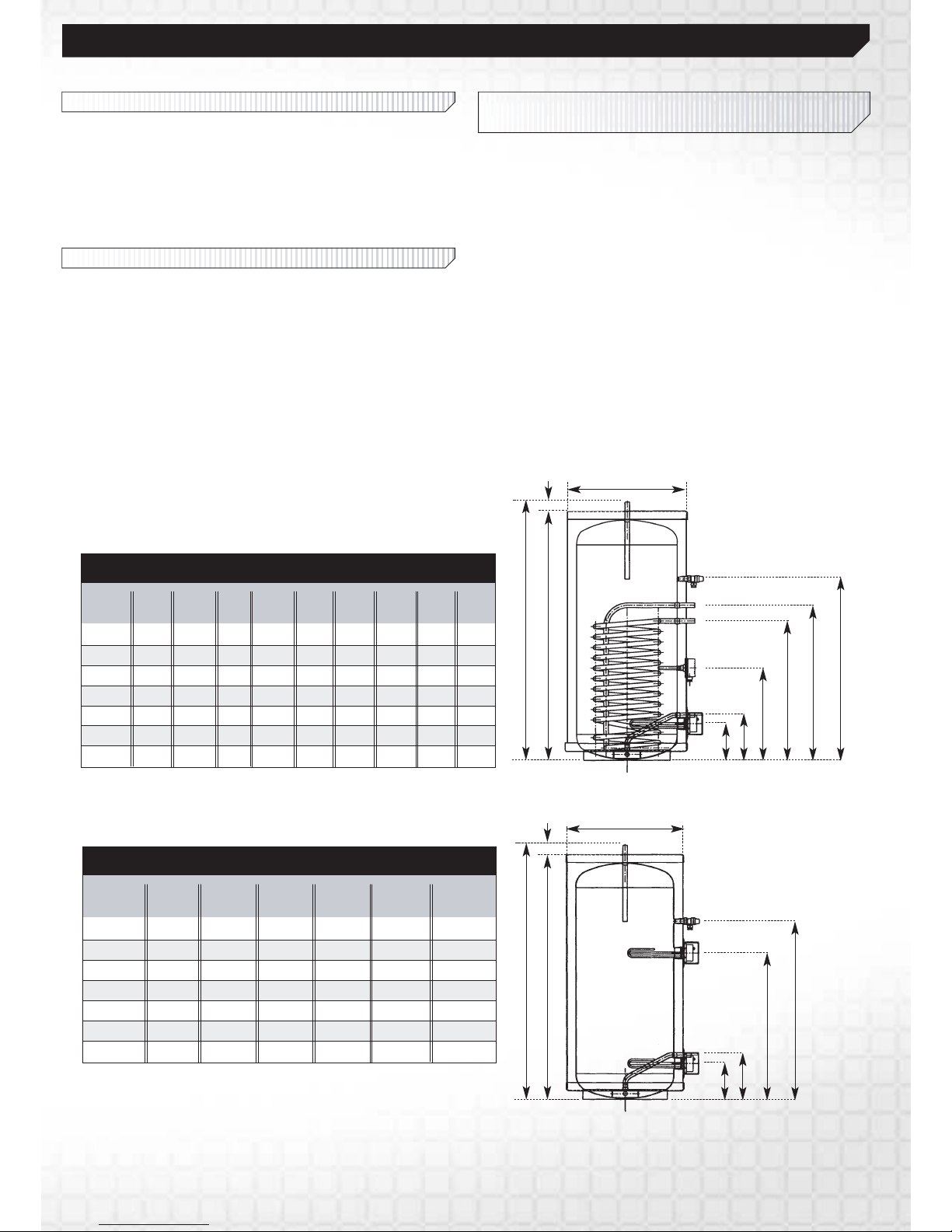

thgieH

lla

r

e

v

O

th

g

i

e

H k

n

aT

r

et

a

eH

mottoB

te

lnI

re

ta

W

ta

t

somreh

T

n

i

w

T

l

i

o

C m

ott

o

B

l

ioC poT

evlV T & P

54

574

Note:

All External Exposed

Pipework is 22mm Diameter

316L Stainless Steel

thgieH llarevO

t

h

g

i

e

H k

n

a

T

r

et

a

eH

m

ott

o

B

te

ln

I

re

t

a

W

re

ta

eH p

o

T

ev

lV T

&

P

5

4

574

Note:

All External Exposed

Pipework is 22mm Diameter

316L Stainless Steel

THE LAW AND UNVENTED

It is legal to fit an Unvented Unit into any property. UK water

byelaws were amended to allow this change.There is no

longer a requirement to have an old-fashioned

“Tank-in-the-Roof” system.

THE BENEFITS OF UNVENTED SYSTEMS

● A real Power Shower without a noisy pump

● No tanks in the roof – no ballcocks to jam or leak – no noise

from tank filling

● All your water – hot and cold – is direct from the mains

● Site the unvented water heater wherever convenient

● Your vessel fills your bath in minutes and will run two at the

same time (subject to good plumbing and flow rates)

● The unit works off electricity (economy 7) or any oil

or gas fired boiler (not suitable for solid fuel boilers)

Dimensional data for Indirect Heat/Direct Heat range of water heaters

Direct Heat Exterior Reference Dimensions

Reference Tank Overall P&T Top Bottom Water

Volumes Height Height Valve Heater Heater In

litres mm mm mm mm mm mm

80 636 694 347 N/A 250 230

130 928 986 618 521 188 230

150 1056 1114 737 640 188 230

175 1213 1271 883 786 188 230

215 1455 1513 1108 1011 188 230

255 1723 1781 1356 1259 188 230

305 1999 2057 1613 1516 188 230

Indirect Heat Exterior Reference Dimensions

Reference Tank Overall P&T Bottom Top Bottom Temp Water Top

Volumes Height Height Valve Heater Coil Coil Monitor In Heater

litres mm mm mm mm mm mm mm mm mm

80 636 681 347 188 N/A 283 233 230 N/A

130 928 973 618 188 558 483 357 230 521

150 1056 1101 737 188 558 483 357 230 640

175 1213 1258 883 188 758 683 458 230 786

215 1455 1500 1108 188 758 683 507 230 1011

255 1723 1768 1356 188 758 683 608 230 1259

305 1999 2044 1613 188 758 683 608 230 1516

4

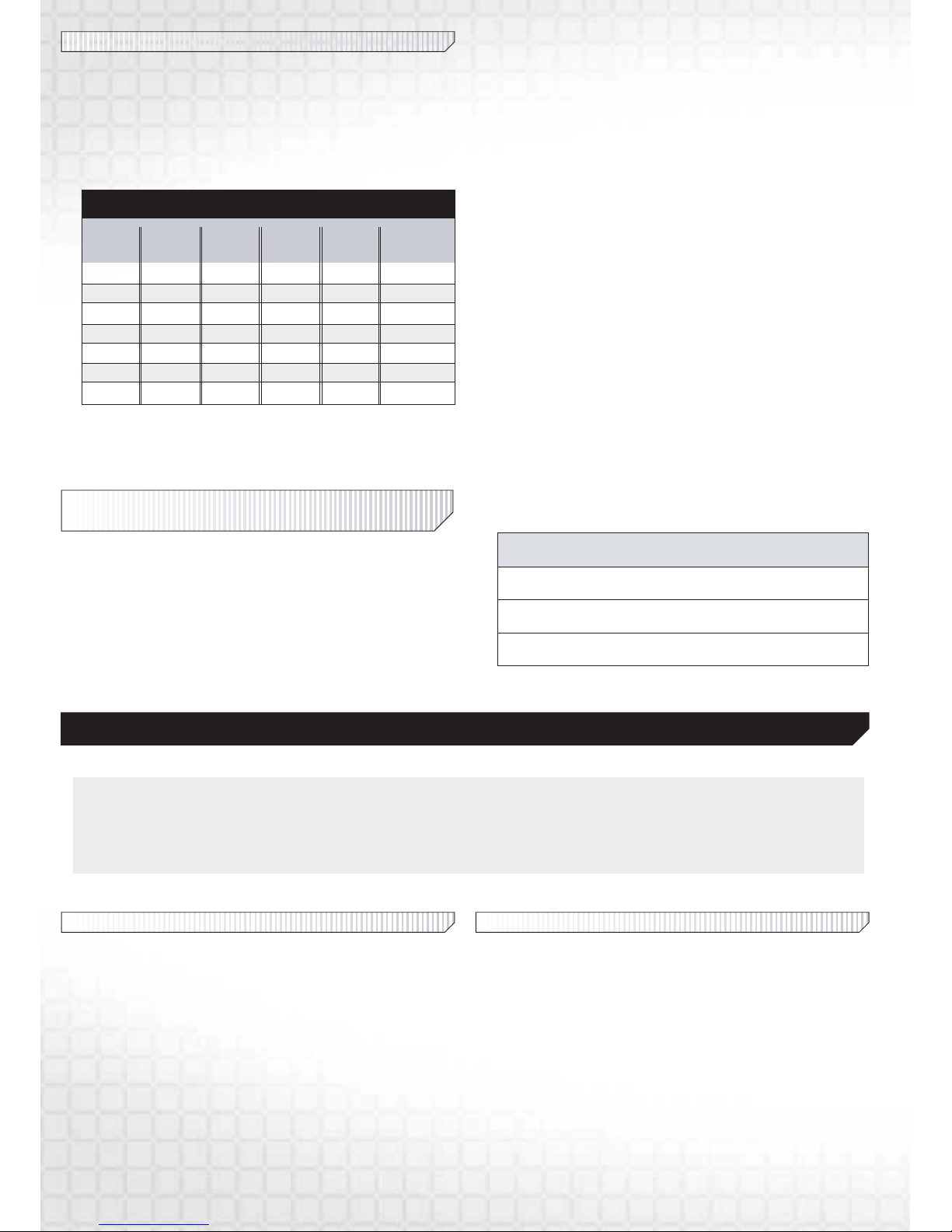

STANDARD ENERGY LOSSES

The heat loss of each Unvented Unit while

maintaining the temperature of the stored water at 65 degrees

Celsius. (See performance table below).

1) Tests carried out by BBA.Slight variations may occur with

changes to water mains supply pressure

Performance

Nominal Heat up Heat up Reheat Reheat Heat loss in

Capacity Model IDH Model DH Model IDH Model DH 24 hrs

Litres Mins Mins Mins Mins kw/hr

80 33 64 23 53 1.12

130 28 115 21 90 1.50

150 33 138 24 104 1.82

175 27 167 24 124 2.10

215 35 212 30 153 2.64

255 42 263 35 184 2.73

305 50 313 42 220 2.88

SITING THE UNIT

The unit can be placed anywhere convenient. Because it is

connected directly to the mains water supply it is equally efficient

on any floor – ground, first or second. Avoid areas that may be

subject to frost. Try to keep pipe runs as short as possible for

maximum economy,especially hot water discharge pipes running

down from the unit.

The unit can be fitted into a conventional airing cupboard and

does not require any additional insulation.

ALL UNVENTED VESSELS MUST BE STORED VERTICALLY

CHECK WATER PRESSURE & FLOW RATES

We suggest 1.5 bar pressure & 15 litres / minute flow rate to be the

minimum requirements for satisfactory operation. Less than this

the unit will still operate but you will not be able to run two, or

more, outlets at the same time. 85% of all U.K homes have more

than 2-bar pressure.

The mains supply must not exceed 16 bar.If it does a special

pressure-reducing valve will be required.

● 1 Element on IDH indirect models up to 305 litres and 80 litre

DH direct model

● 2 Elements on DH direct models from 130 up to 305 litres.

Additional elements from 215 to 305 litres are available on

request.

● Cold-water control valve comprising line strainer, check valve,

pressure reducing valve set to 3 bar

● Expansion relief valve with non return valve set at 6 bar

● Tundish 15mm x 22mm F x F

● Temperature / Pressure relief valve set at 90 degrees Celsius

and 7 bar pressure relief (factory fitted)

● Motorised valve (indirect units only)

● Cylinder thermostat-factory fitted to cylinder, maximum setting

85 degrees Celsius (indirect units only)

● Thermal cut out set to operate at 87 degrees Celsius plus or

minus 3 degrees (indirect units only)

● Expansion vessel capacity ranges as shown in the table below: -

Tank Size

80 to 130 Litres

150 to 215 Litres

255 to 305 Litres

Expansion Tank Required

12 Litres

18 Litres

25 Litres

2) These figures relate to a 45 degree differential between the

stored water and ambient temperature

WITH YOUR UNVENTED CYLINDER

THE FOLLOWING IS SUPPLIED AS STANDARD

Before commencing installation check that all the components of

your Unit are contained in the kit.

● 3KW Incoloy 825 heating element-incorporating thermostat to

70 degrees Celsius and resetable safety cut out set at 80

degrees Celsius

UNVENTED INSTALLATION INSTRUCTIONS

WARNING : Under no circumstances must the factory fitted temperature pressure relief valve be removed.This will totally invalidate any

guarantee or claim.The cold-water inlet valve assembly must be fitted or the unit will not perform satisfactorily.

DO NOT ATTEMPT TO VENT THE PRIMARY CIRCUIT THROUGH THE UNIT.

All boilers should be installed to manufacturers instructions and the primary circuit through the unit must be pumped.

Loading...

Loading...