ThermoTex Nagel GmbH

Schutterstr. 14, 77746 Schutterwald, GERMANY

Phone +49 781 9616-0, fax +49 781 9616-50

info@thermo-tex.de, www.thermo-tex.de

Operating manual for

TT5-L

- Translated version of the original operating manual -

Table of contents

This document is the translated version of the original German

operating manual. For any translations into other languages, the

original German manual must be used as a basis. You can obtain the

original manual from ThermoTex.

6.3.1

6.3.2

6.3.3

6.10.1

6.10.2

6.10.3

6.10.4

7.2.1

7.2.2

CONTENTS

1 Product description ............................................................................................................... 4

1.1 Product Specifications ............................................................................................................................... 4

1.2 Conformity................................................................................................................................................. 4

1.3 Environment .............................................................................................................................................. 4

1.4 Content ..................................................................................................................................................... 5

2 Safety instructions ................................................................................................................. 6

2.1 Basic safety measures for normal operation.............................................................................................. 6

2.2 Basic safety measures for maintenance and servicing .............................................................................. 6

3 General informations ............................................................................................................. 6

3.1 Caution ..................................................................................................................................................... 6

4 Device Overview .................................................................................................................... 7

4.1 Front View ................................................................................................................................................. 7

4.2 Rear View ................................................................................................................................................. 7

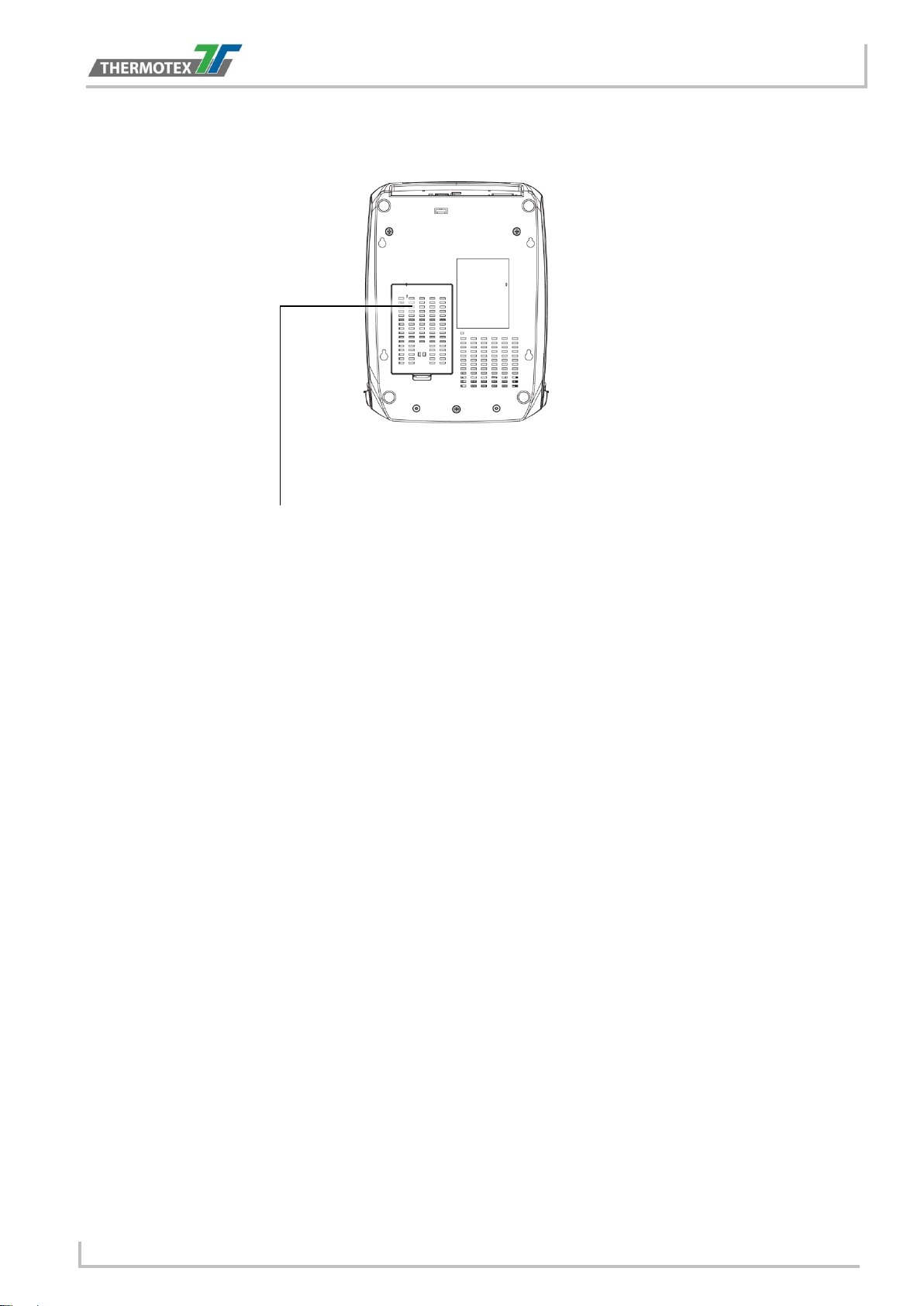

4.3 Bottom View .............................................................................................................................................. 8

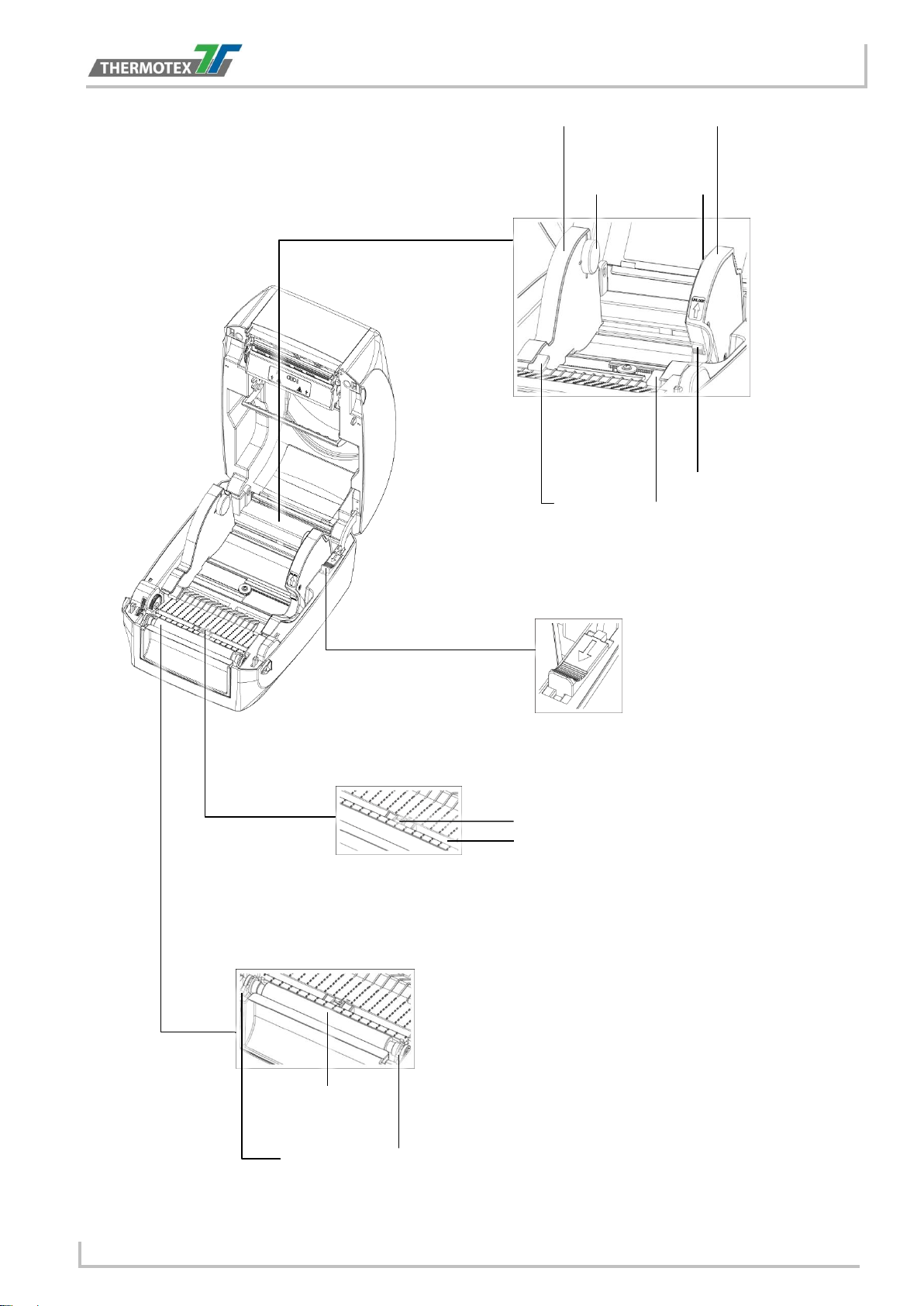

4.4 The Internal View of Printer ....................................................................................................................... 9

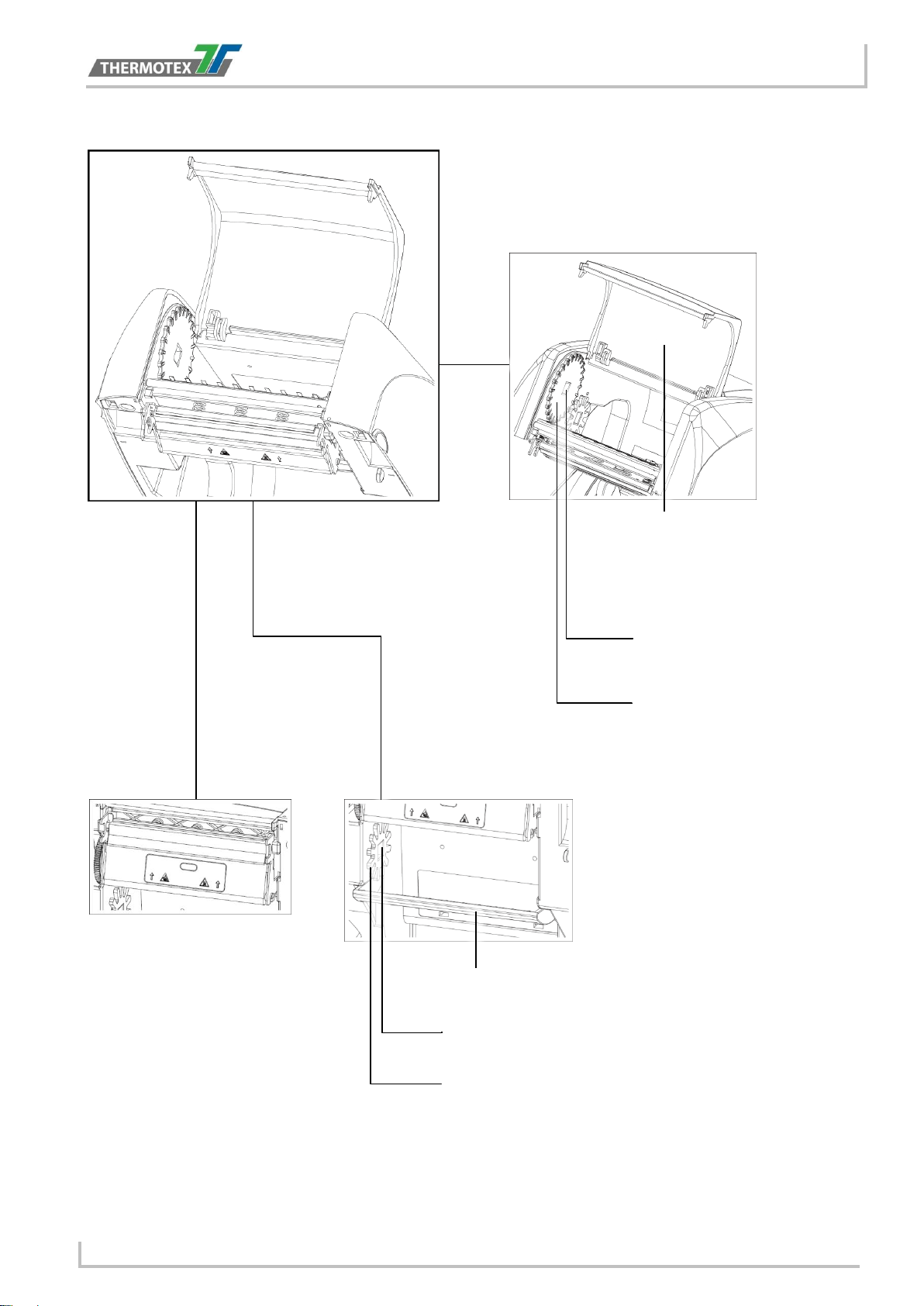

4.5 The Printing Mechanism.......................................................................................................................... 10

5 Printer Setup ........................................................................................................................ 11

5.1 Open the Printer ...................................................................................................................................... 11

5.2 Loading the Ribbon ................................................................................................................................. 12

5.3 Loading the Label Roll Module ................................................................................................................ 17

5.4 Connecting the Printer to the Host Computer .......................................................................................... 19

5.5 Printer Driver installation ......................................................................................................................... 21

6 Printer setting and control ................................................................................................... 23

6.1 Operation Panel ...................................................................................................................................... 23

6.2 LCD Interface Introduction ...................................................................................................................... 24

6.3 LCD Interface Function ........................................................................................................................... 25

Main Page ................................ ................................................................ ................................ 25

Device Page ............................................................................................................................. 25

Menu Structure ......................................................................................................................... 26

6.4 Keyboard Mode ....................................................................................................................................... 28

6.5 Label Calibration and Self Test ............................................................................................................... 29

6.6 Self Test .................................................................................................................................................. 29

6.7 Label Calibration Button .......................................................................................................................... 30

6.8 Error Alerts .............................................................................................................................................. 31

6.9 Operation Panel Status: ................................................................ ................................ .......................... 31

6.10 USB Host ............................................................................................................................................ 33

Usage of Extended Memory ..................................................................................................... 33

Usage of Firmware Update ....................................................................................................... 34

USB Keyboard.......................................................................................................................... 34

Scanner .................................................................................................................................... 34

6.11 Dump Mode Begin .............................................................................................................................. 34

7 Accessories.......................................................................................................................... 35

7.1 Preparation Steps ................................................................................................................................... 35

7.2 Installing the Cutter ................................ ................................................................ ................................ . 37

Installing the Cutter................................................................................................................... 37

Installing the Label Roll Module on the Printer .......................................................................... 40

BA_TT5-L_GB_V(0).DOCX page 2

Table of contents

8 Maintenance and adjustment............................................................................................... 41

8.1 Cleaning the Print Head ................................ ................................................................ .......................... 41

8.2 Troubleshooting ...................................................................................................................................... 42

8.3 Communication port specifications .......................................................................................................... 43

9 Bluetooth Setting ................................................................................................................. 44

9.1 Steps for setting Bluetooth keyboard ....................................................................................................... 44

9.2 Steps for setting Bluetooth connection on the LCD panel ........................................................................ 45

9.3 Introduction of the Bluetooth parameters ................................................................................................. 47

10 Spare parts list ..................................................................................................................... 47

BA_TT5-L_GB_V(0).DOCX page 3

Product description

WARNING

This is a Class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

Old appliances contain valuable recyclable materials that are to be recycled.

Dispose of separately from residual waste at suitable collection points.

The modular design of the printer makes it easy to break it down into its components.

Parts should be recycled.

The electronic board of the device is equipped with a lithium battery.

Disposal in used battery collection containers of the trade or with the public disposal

carriers.

1 Product description

1.1 Product Specifications

Print Method Thermal Transfer / Direct Thermal

Resolution 203 dpi (8 dots/mm)

Print Speed 7 IPS (177 mm/s)

Print Width 4.25” (108 mm)

Print Length Min. 0.16” (4 mm)

Max. 68” (1727 mm)

Length 11.0” (280 mm)

Dimension Height 7.7” (195 mm)

Width 8.3” (210 mm)

Weight 5.9 lbs (2.7 Kg) ,excluding consumables

Interfaces

USB 2.0 for PC Connection (B-Type), RS232C (D-Sub 9 pin),

IEEE 802.3 10/100 Base-Tx Ethernet port (RJ-45), USB Host (A-Type),

Parallel Port (Mini-Centronics)

Power Auto Switching 100-240V AC, 50-60Hz

Environment Operation Temperature 41°F to 104°F (5°C to 40°C)

Storage Temperature -4°F to 140°F (-20°C to 60°C)

Humidity Operation 25-85%, non-condensing.

Storage 10-90%, non-condensing

1.2 Conformity

EN 55032:2012 / AC:2013 Class A

EN 61000-3-2:2014

EN 61000-3-3:2013

EN 55024:2010

1.3 Environment

BA_TT5-L_GB_V(0).DOCX page 4

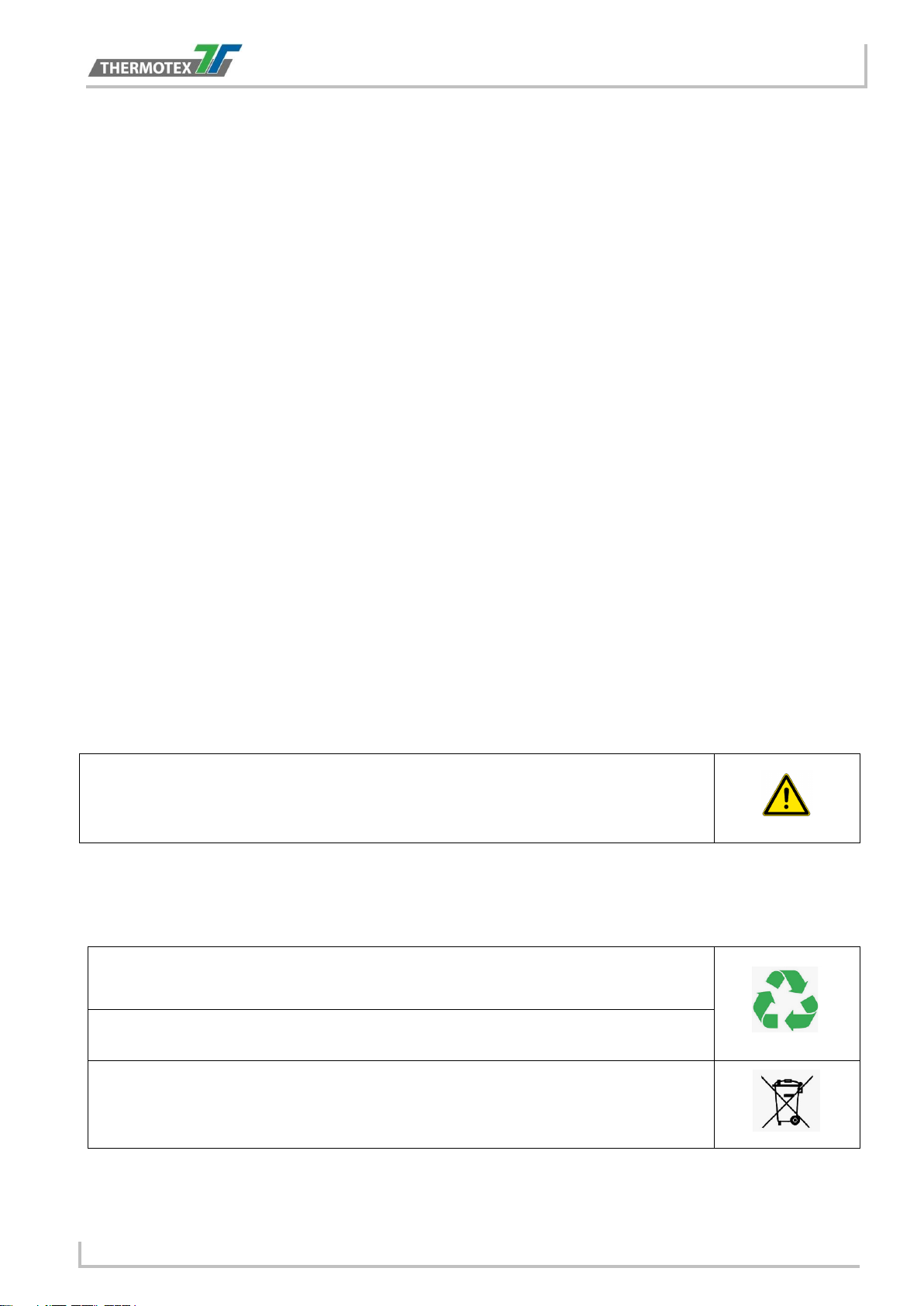

Product description

● Ribbon Hubs

Set of 2

● Ribbon Module

Empty Ribbon Core

● Quick Guide

● AC Adapter

● Power Adapter

Power Cord

● USB Cable

● CD

1.4 Content

Please check that all of the following items are included with your printer.

TT5-L Barcode Printer

BA_TT5-L_GB_V(0).DOCX page 5

Safety instructions

Keep the equipment away from humidity.

Before you connect the equipment to the power outlet, please check the voltage of the

power source.

Make sure the printer is off before plugging the power connector into the power jack.

It is recommended that you connect the printer to a surge protector to prevent possible

transient overvoltage damage.

Be careful not to get liquid on the equipment to avoid electrical shock.

For safety and warranty reasons, ONLY qualified service personnel should open the

equipment.

Do not repair or adjust energized equipment under any circumstances.

Danger of explosion if battery is incorrectly replaced. Replace only with the equivalent type

recommended by the manufacturer.

Dispose of used batteries according to the manufacturer’s instructions.

Only use with designated power supply adapter model.

Changes or modifications not expressly approved by the party responsible for compliance

could void the user's authority to operate the equipment.

2 Safety instructions

Please read the following instructions carefully.

2.1 Basic safety measures for normal operation

2.2 Basic safety measures for maintenance and servicing

3 General informations

3.1 Caution

Specifications are subject to change without notice.

BA_TT5-L_GB_V(0).DOCX page 6

Device overview

PRINTER COVER

POWER BUTTON

FEED BUTTON

TOUCH PANEL

FRONT COVER

COVER RELEASE CATCHES

Pull catches for opening the printer cover

FAN-FOLD LABEL INSERT

Feed slot for outside continuous labels

PARALLEL PORT

USB HOST

ETHERNET PORT

SERIAL PORT

USB PORT

POWER JACK

CALIBRATION

4 Device Overview

4.1 Front View

4.2 Rear View

BUTTON

BA_TT5-L_GB_V(0).DOCX page 7

4.3 Bottom View

COVER OF THE MODULE CONNECTION JACKS

Device overview

BA_TT5-L_GB_V(0).DOCX page 8

Device overview

LABEL

MODULE

LABEL GUIDE PLATE

LABEL SUPPLY HUB

LABEL GUIDE

RELEASE CATCH

supply hub

RELEASE CATCH

closing the printer cover

LABEL SENSOR

GUIDE TRACK

LABEL SENSOR

PLATEN MODULE

PLATEN

PLATEN LOCKERS

4.4 The Internal View of Printer

SUPPLY

Release catch for

opening the label

Release catch for

BA_TT5-L_GB_V(0).DOCX page 9

Device overview

RIBBON REWIND MECHANISM

COVER

NOTCH OF RIBBON

RIBBON REWIND WHEEL

PAPER PRESS BAR

NOTCH OF RIBBON SUPPLY WHEEL

RIBBON SUPPLY WHEEL

RIBBON

PRINT HEAD

4.5 The Printing Mechanism

The cover for Ribbon rewind

mechanism

REWIND WHEEL

SUPPLY

MECHANISM

BA_TT5-L_GB_V(0).DOCX page 10

Printer Setup

COVER RELEASE CATCHES

Pull the catches toward the direction

Pull the catches toward the direction

The printing mechanism is lifted up with the

5 Printer Setup

5.1 Open the Printer

Open the Printer Cover and the Printing Mechanism

Place the printer on a flat surface. Open the printer cover by pulling the cover release catches on both sides of

the printer and lift the printer cover.

Pull the catches for opening the printer cover

printer cover

BA_TT5-L_GB_V(0).DOCX page 11

Loading the Ribbon

A NEW RIBBON

EMPTY RIBBON CORE

RIBBON HUB

Stick on empty ribbon core

Insert the ribbon hub

Wind the ribbon around the core

RIBBON REWIND

RIBBON SUPPLY

A NEW RIBBON MODULE

5.2 Loading the Ribbon

A New Ribbon Module Installation

1. Attach the ribbon to the empty ribbon core with the adhesive strip at the end of the ribbon.

2. Insert the ribbon hub into empty ribbon core and new ribbon. Wind the ribbon around the empty ribbon

core for 2 to 3 circles.

3. A ribbon module is assembled as below.

BA_TT5-L_GB_V(0).DOCX page 12

Loading the Ribbon

RIBBON SUPPLY MECHANISM

NOTCH OF RIBBON SUPPLY WHEEL

RIBBON SUPPLY WHEEL

RIBBON SUPPLY

MODULE

HOLDER

NOTCH OF

WHEEL

HOLDER

NOTCH

Load the Ribbon on the Printer for Ribbon Supply Module

4. Place the ribbon supply module into the printing mechanism. Please the left-hand side of ribbon hub first.

Make sure the holder of ribbon hub is inserted into the notch. Then place the right-hand side of ribbon

hub.

RIBBON SUPPLY

BA_TT5-L_GB_V(0).DOCX page 13

Loading the Ribbon

RELEASE CATCH

COVER

mechanism

RIBBON REWIND MECHANISM

NOTCH OF RIBBON REWIND WHEEL

RIBBON REWIND WHEEL

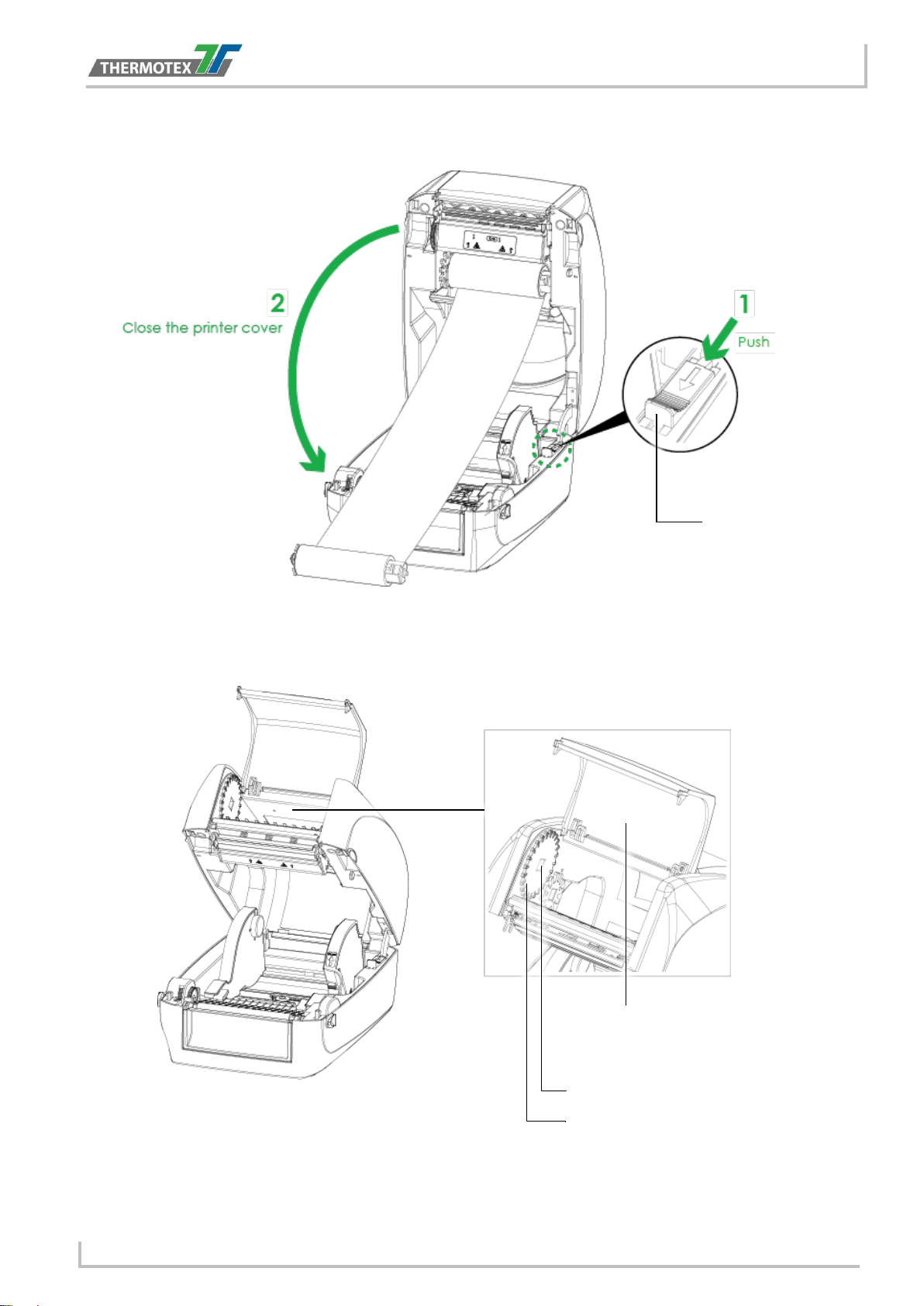

5. Unlock the release catch to close the printer cover. Push the release catch forward to unlock it. The

ribbon supply module loading is completed.

Release catch for closing

the printer cover

Load the Ribbon on the Printer for Ribbon Rewind Module

The cover for Ribbon rewind

BA_TT5-L_GB_V(0).DOCX page 14

Loading the Ribbon

RIBBON REWIND

NOTCH OF RIBBON

HOLDER

HOLDER

NOTCH

6. Open the cover of ribbon rewind mechanism.

7. Place the ribbon rewind module into the ribbon rewind mechanism. Please the left-hand side of ribbon

hub first. Make sure the holder of ribbon hub is inserted into the notch. Then place the right-hand side of

ribbon hub.

REWIND WHEEL

MODULE

BA_TT5-L_GB_V(0).DOCX page 15

Loading the Ribbon

RIBBON REWIND WHEEL

8. Turn the ribbon rewind wheel to tighten the ribbon until it has no wrinkles.

9. Close the cover of ribbon rewind mechanism. The ribbon loading is completed once the ribbon supply

module and ribbon rewind module are assembled correctly.

BA_TT5-L_GB_V(0).DOCX page 16

5.3 Loading the Label Roll Module

LABEL STOCK

LABEL

LABEL GUIDE PLATE

LABEL SUPPLY HUB

LABEL GUIDE

RELEASE CATCH

LABEL GUIDE

PLATE

RELEASE CATCH

Release catch for opening the label supply

hub

Loading the Label Stock on the Printer

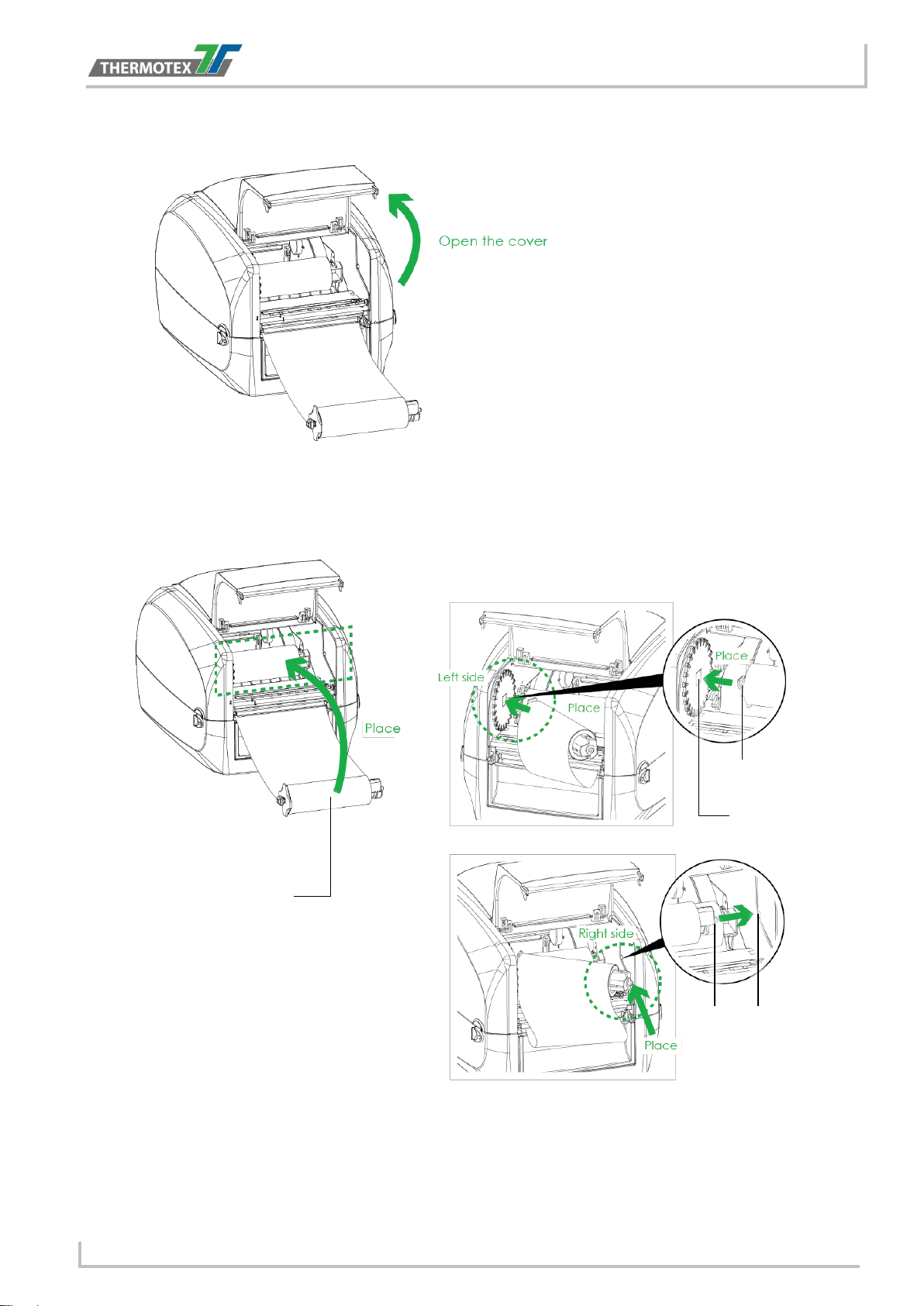

1. Unlock the ribbon catch and pull to open the label guide plate.

Place the label stock on label supply hubs. Make sure the label stock is aligned to both hubs. Adjust the label

guide plates to fix the label width. Remember to push the release catch when moving the label guide plates.

Loading the Label Roll

SUPPLY

MODULE

Release catch for

opening the label

supply hub

BA_TT5-L_GB_V(0).DOCX page 17

Loading the Label Roll

LABEL GUIDE

RELEASE CATCH

closing the printer cover

2. Feed the Label through the label guides. The label guides will help to prevent the label swaying.

3. Unlock the release catch to close the printer cover.

Release catch for

4. Press the FEED key and make sure the label is fed smoothly. The label loading is completed now.

NOTE: * Please keep the rack gear clean to ensure the smoothness of label holder.

BA_TT5-L_GB_V(0).DOCX page 18

Connecting to the Computer

POWER CORD

AC ADAPTER

POWER ADAPTER

TT5-L

JACK

SLOT

PLUG

SOCKET

THE WALL

5.4 Connecting the Printer to the Host Computer

1. Please make sure that the printer is switched off.

2. Connect the power cord to the AC adapter.

Connect the jack of the power adapter to the printer and connect the plug of the power

adapter to the socket of the wall.

BA_TT5-L_GB_V(0).DOCX page 19

Connecting to the Computer

USB CABLE

PLUG

PLUG

USB PORT

PC

SOCKET

TT5-L

TOUCH PANEL LCD

3. Connect the USB/serial cable to the printer and host computer.

4. Press the power button. The Touch Panel LCD will light up.

BA_TT5-L_GB_V(0).DOCX page 20

Printer Driver installation

5.5 Printer Driver installation

1. From the Driver CD launch the Application

2. Select “I accept the terms in the license agreement”, and click ”Next”,then click ”Finish” to next step

3. The Driver Wizard will guide you through the installation procedure. Select "Install printer drivers" and

click “Next”.

BA_TT5-L_GB_V(0).DOCX page 21

Printer Driver installation

4. With a USB connection, search models such as the right diagram printer device. Specify your printer

model and click ”Next”.

5. Enter the printer name (you can use default), then click "Next" to display as right diagram. Click "Finish"

button to start installation.

6. Driver installation completed

BA_TT5-L_GB_V(0).DOCX page 22

Printer setting and control

OPERATION TOUCH PANEL

POWER

FEED

TOUCH PANEL

6 Printer setting and control

6.1 Operation Panel

POWER Button

Press the POWER button to turn on the printer, and the START UP SCREEN appears. The printer is on “ready

to print” status, the LCD screen should display the message “READY“ on the screen. When printer is turned on,

hold and press down the POWER button for 3 second will turn the printer off.

FEED Button

When you press the FEED button, the printer will advance media until the FEED button is released. If you are

using continuous labels, pressing the FEED button will advance a length of media until the button is released. If

you are using media with gaps, pressing the FEED button once will advance only one label. If the label does not

stop at the correct position, you need to run the auto-detection function for your media, please see Section 3.4

Label Calibration and Self-Test.

PAUSE PRINTING_FEED Button

Pressing the FEED button during printing will interrupt printing, and the LCD display message “PAUSE...”. When

the FEED button is pressed again, the printer resumes printing. Example: While a 10-label print job is running,

you press the FEED button to pause the printer. Two of the labels have been printed. To resume printing and

print the remaining eight labels, you will need to press the FEED button again.

CANCEL PRINTING_FEED Button

Press and hold the FEED button for 3 seconds during printing, the current print job will be cancelled. Example:

While a 10-label print job is running, you press the FEED button. Two of the labels have been printed. The print

job is cancelled and the remaining eight labels will not be printed.

BUTTON

BUTTON

BA_TT5-L_GB_V(0).DOCX page 23

Printer setting and control

Power on

6.2 LCD Interface Introduction

Getting Started

Press the POWER button to turn on the printer, and the START UP SCREEN appears.

If the printer is on “ready to print” status, the LCD screen should display the message “Ready“ on the screen.

Use touch gestures to get around the main screen and other screen for setting.

Tap the screen with your finger when you want to select on screen items such as settings icons.

On the Ready Page, three functions mode for setting. You can make various setting functions in FUNCTIONAL

MODE.

Main Wizard Test

To finish setting tap to return to Ready screen.

If you don’t want to save any changes, tap system to return to

the Ready screen.

Unlock

Lock

If printer functions are locked, printer settings cannot be overwritten

by WinTexx or any devices.

BA_TT5-L_GB_V(0).DOCX page 24

LCD Interface Function

6.3.1

6.3.2

6.3 LCD Interface Function

Main Page

Setting items for printer, ex. Printing speed, darkness. Also

includes a Printing Wizard for your ease of printing.

10 languages for printer setting

It consists of a table of values that describes the character set for

a particular language

Setting items for printing label, ex. Rotation, Printing position

offset

Providing Buzzer, Option Setting, Smart Backfeed, Serial Part

Setting, LAN Setting, LCD Setting, Clock Setting, WiFi Setting,

and Bluetooth Setting

Self- Diagnose functions for printer, ex. Calibration, Self-Test

page and Clear Memory

Recall Label and preview label

Device Page

Setting off or on for buzzer

Setting items for options, ex. Cutter, Label Dispenser,

Applicator

Setting programing language

Setting items for Serial Port, ex. Baud Rate, Parity , Data Bits,

Stop Bits

Setting items for LAN, ex. DHCP, IP Address, Subnet Mask,

Gateway

Setting for LCD, ex. off or on for Password function, Correction

Setting items for Clock, ex. Year, Month, Day, Hour, Minute and

off or on for Visible function

BA_TT5-L_GB_V(0).DOCX page 25

6.3.3

Printer Settings

Darkness

0-19

Speed

2-7

Sensor Select

Auto Select

See-Through

Reflective

Media Type

Label with Gaps

Label with Marks

Continuous

Printing Mode

Direct Thermal

Thermal Transfer

Tear-off Position

0-40

Top of Form

OFF

FULL

Door Open Only

Back Up Only

LCD Language

English

Deutsch

Francais

Espanol

Italiano

簡體中文

繁體中文

Türkce

日本語

Pусский

Code Page

850

852

437

860

863

865

857

861

862

855

866

737

851

869

Windows 1252

Windows 1250

Windows 1251

Windows 1253

Windows 1254

Windows 1255

Windows 1257

Label Settings

Rotation

0°-90°- 180°- 270°

X-Offset

-864 ~+864

Y-Offset

-400 ~+400

Start Offset

-100 ~+100

BA_TT5-L_GB_V(0).DOCX page 26

LCD Interface Function

Menu Structure

Devices

Buzzer

OFF

ON

Options

None

Option Setting

Cutter

Label Dispenser

Applicator

Smart

Backfeed

OFF

ON

Baud Rate

4800

9600

19200

38400

57600

115200

Serial Port Setting

Parity

None

Odd

Even

Data Bits

7

8

Stop Bits

1

2

LAN Setting

DHCP

OFF/ON

IP Address

0.0.0.0

Subnet Mask

255.255.255.0

Gateway

192.168.0.254

Port N°

9100

LCD Setting

Password

OFF/ON

Correction

Clock Setting

Year

Month

Day

Hour

Minute

Visible

OFF/ON

Printer Control

Test

Configuration

Directory

TPH Testing

Dump Mode

Sample pattern

Self-Test page / Balance

Select Memory

Internal / External

Clear Memory

Label Formats

Graphics

Bitmap Fonts

True Type Fonts

Asian Fonts

Printer Info

Calibration

Reset

To default

Wizard

Darkness

0-19

Speed

2-7

Media Type

Label with Gaps

Label with Marks

Continuous

X-Offset

-864 ~+864

Y-Offset

-100 ~+100

BA_TT5-L_GB_V(0).DOCX page 27

LCD Interface Function

Keyboard Mode

6.4 Keyboard Mode

When plug-in an USB keyboard to the printer, LCD touch panel will display “Enter Standalone”, press the “Y” or

“ENTER” key on keyboard to entering to the dialog for “Keyboard Mode” operation.

Recall Label

From the “Ready” page, tap to Main page.

From the Main page tap Recall Label to

Recall Label page.

From the Recall Label Page the touch panel shown on all labels.

The Data processing time will be extend as long as the labels increase.

Tap up to choose labels.

Tap down to choose labels.

Select label and print out selected label

BA_TT5-L_GB_V(0).DOCX page 28

Label Calibration

6.5 Label Calibration and Self Test

Label Calibration

The printer can automatically detect and store label height.

That means the host computer does not need to transmit the label height to the printer.

6.6 Self Test

Self-test function lets you check whether the printer is functioning normally.

Here is how you run the label size calibration and self-test.

1. Check that the label stock is loaded correctly.

2. Turn off the printer and pressing the FEED button.

3. Turn the printer on again, keeping the FEED button pressed. When the LCD displays Ready Screen,

release the FEED button. The printer will now measure the label stock and store the label height.

4. Once the printer has successfully measured the label stock, it will print a self-test label.

The contents of a self-test printout are listed below.

BA_TT5-L_GB_V(0).DOCX page 29

Label Calibration

Press and hold about

1 ~ 2 seconds

CALIBRATION BUTTON

6.7 Label Calibration Button

A hardware button to make a Label Calibration while printer encountering ‘’Media Error’’ during the cases when

first-time printer start up or change label to another type, such as change using gap label to continuous or black

mark labels.

Press Calibration button for 1 ~ 2 seconds, it will make an auto-sensing to calibrate the label’s parameters.

NOTE: *Press Calibration button is equivalent to the auto-sensing command ‘’~S,SENSOR’’ that will cancel onprinting-job and make the Label Calibration immediately.

**It can also be launched through following Menu: Main => Printer Control => Calibration

BA_TT5-L_GB_V(0).DOCX page 30

Operation Panel Status

OPERATION TOUCH PANEL

POWER

FEED

TOUCH PANEL

Type

Beeps

Description

Solution

Door Open Only

2 x4 beeps

The printing mechanism is

not correctly closed.

Open the print

mechanism and close it

again.

TPH Over Heat

None

High temperature at the print

head.

Once the print head has

cooled down, the printer

switches to standby

mode.

6.8 Error Alerts

In the event of a problem that prevents normal functioning of the printer, you will see an error message on LCD

screen and hear some beep signals. Please refer to below table for the error alerts.

BUTTON

BUTTON

6.9 Operation Panel Status:

BA_TT5-L_GB_V(0).DOCX page 31

Operation Panel Status

Ribbon Error

2 x 3 beeps

No ribbon is installed and the

printer displays an error.

Make sure that the printer

is set to direct thermal

printing mode.

The ribbon is finished or the

label supply hub is not

moving.

Replace the ribbon roll.

Media Error

2 x 2 beeps

No paper is detected.

Make sure that the label

sensor is positioned

correctly.

If the sensor still does not

detect the paper, run the

auto- detection function

again

Paper is finished.

Replace the label roll.

Printer feed problem.

Possible reasons: the

printer medium has

become trapped around

the rubber roll; the sensor

cannot detect a gap or

black mark between the

labels; there is no paper.

Please reset the sensor.

File Error

2 x 2 beeps

The memory is full. The

printer prints the message

« File System full ».

Delete unnecessary data

or install additional

memory.

Unable to find file. The

printer prints the message

« File not found »

Use the « ~X4 »

command to print all files.

Then check whether the

files exist and whether the

names are correct.

BA_TT5-L_GB_V(0).DOCX page 32

Operation Panel Status

6.10.1

File Error

2 x 2 beeps

A file of the same name

already exists. The printer

prints the message

« Duplicated Name ».

Change the name of the

file and try storing it again.

6.10 USB Host

Definition: USB Host port supports either device: USB memory stick, USB keyboard or scanner.

Purpose

USB memory stick: It extends the user memory space for Graphic, Font, Label Format, DBF and

Command files downloading. The printer’s Firmware can also be updated by copying a new version of

Firmware into USB memory stick.

Connecting an USB keyboard to printer for ‘’Keyboard Mode’’ mode operation.

Plug-in an USB scanner to operate the printer in ‘’Keyboard Mode’’.

USB memory stick : It supports hot-plugging function; printer will create a Folder ‘’\LABELDIR’’ and switch

Usage of Extended Memory

‘’User Flash’’ to ‘’ Extended Memory‘’ automatically while user plugs an USB memory stick into the

printer.

BA_TT5-L_GB_V(0).DOCX page 33

Operation Panel Status

6.10.2

6.10.3

6.10.4

Remove USB memory stick from printer and plug-in it to a PC’s USB port.

Copy a new version of Firmware ‘’xxxx.bin’’ to the Folder ‘’\LABELDIR\FW’’

Remove USB from PC and plug-in back to the printer. The printer will update the Firmware automatically

The "\ LABELDIR \ FW" directory allows only one file exists, if there are multiple files, the files will be

Don’t remove the USB memory stick out while it’s under updating with ‘’Flash Writing...’’message that

When plug-in an USB keyboard to the printer, LCD touch panel will display “Enter Standalone”, press the

By connecting a USB keyboard to the printer, if you don’t want to enter the Standalone mode, press the

After leaving the keyboard mode, for re-entry, press the keyboard "F1" key or reboot to display “Enter

When plug-in an USB scanner to the printer, LCD touch panel will display “Enter Standalone”, tap the

Usage of Firmware Update

confused.

displays on LCD panel.

USB Keyboard

“Y” key on keyboard to entering “Keyboard Mode” operation. In this mode you can perform "Recall Label",

set "Country Code", "Code Page", "Clock Setting", "Database Setting" and "Label Edit".

"N" key to leave. To leave Standalone mode operation, press "ESC" key to exit.

Standalone”.

Scanner

“Feed” Key to entering “Keyboard Mode” operation.

Note

The USB Host port on printer does not support ‘’USB HUB’’ function.

The USB Memory Stick supports with ‘’FAT32’’Disk Format and up to 32GB only. The certified venders

are Transcend, Apacer, ADATA, Patriot, Corsair and Kingston.

The USB Memory Stick only supports download through the printer, On a PC, user may copy entire folder

“\LABELDIR” from USB memory stick to PC or vice-versa. You can’t copy the data to USB Memory Stick

via PC individually.

*External USB Host port is for power 500 mA, is not recommended as electronics charging use.

6.11 Dump Mode Begin

For make sure provide us correct information for check what commands sent from the PC or software, please

following below steps,

STEP 1: Let the printer enter Dump Mode

Here is how you switch to dump mode:

On the Ready Page, three function mode for setting. You can make various setting functions in FUNCTIONAL

MODE.

1. Tap ‘’Main‘’ on LCD menu

2. Tap ‘’Printer Control‘’

3. It will show Printer Control setting items such as Configuration--→Directory--→TPH Testing--→Dump

Mode

Please select to Dump Mode.

STEP 2: Make sure printer ready for print a label

STEP 3: Send a label or commands which met problem to the printer

STEP 4: Printer will print out a label with letters and numbers, please take a picture on them and send us by

email.

To cancel (get out of) the Dump Mode, please press the FEED key, and then the printer will

automatically print “OUT OF DUMP MODE.” This indicates that the printer is back to the standby mode.

BA_TT5-L_GB_V(0).DOCX page 34

Accessories

FRONT COVER

7 Accessories

7.1 Preparation Steps

Before installing the cutter, please make some preparations as follows.

1. Turn off the printer:

Remember to switch off the printer before installing any module.

And also remove the power supply.

2. Open the printer cover and the printing mechanism:

Open the printer cover by pulling the release catches on both sides of the printer and lift the cover.

3. Remove the front cover:

Please pull upward to remove the front cover.

BA_TT5-L_GB_V(0).DOCX page 35

Accessories

CLIP

PLATEN MODULE

4. Remove the platen :

Lift up the release clips on both sides of the platen to release and pull upward the platen.

5. Ribbon loading:

Please see the Section 5.2 for further information about Loading the Ribbon.

6. Label loading

Please see the Section 5.3 for further information about Loading the Label Roll Module.

BA_TT5-L_GB_V(0).DOCX page 36

Cutter Installation

7.2.1

CONNECTION CABLE OF CUTTER

FEED-OUT SLOT

COVER

SLOT

7.2 Installing the Cutter

Preparation Steps

Please see the Section 7.1 Preparation Steps to complete the preparation steps before installing the cutter.

The Overview of the Cutter

Installing the Cutter

1. Pass the connection cable through the slot of the printer.

NOTE:

* Remember to switch off the printer before installing the cutter.

** Do not use to cut adhesive labels! Glue residue will be left on the cutter blade and impair its functioning.

*** You can cut paper with a max. width of 100mm.

**** With the cutter installed, set the stop position in WinTexx to 33.

BA_TT5-L_GB_V(0).DOCX page 37

Cutter Installation

CLIP

RELEASE CATCH

2. Place the cutter to align both holes of screw and then tighten the screws.

(Screw holes on the front side of the bottom barcode Printer)

3. Place the platen back to the printer and lock the clips.

4. Close the printer cover and printing mechanism.

Then turn the printer upside down.

Release catch for

closing the printer

cover

BA_TT5-L_GB_V(0).DOCX page 38

Cutter Installation

COVER OF THE MODULE CONNECTION JACKS

JACK

CONNECTOR OF THE CONNECTION

COVER OF THE MODULE CONNECTION JACKS

CUTTER JACK

LABEL DISPENSER JACK

5. Open the cover on the bottom of printer.

6. Plug the connector for the cutter to the jack.

7. Close the cover of the module connection jacks.

NOTE:

* The printer must be switched off, or the motherboard may be destroyed!

** There are 5 jacks: the lower jack for the label dispenser, the upper jack for the cutter. And additionally Real

Time Clock, Bluetooth and Wi-Fi.

BA_TT5-L_GB_V(0).DOCX page 39

Cutter Installation

7.2.2

Installing the Label Roll Module on the Printer

1. Pass the labels through the guides and the cutter.

2. Close the top cover and printing mechanism. To finish, press the FEED button to set the label position.

NOTE:

* We advise against using inside wound label stock.

** Labels should be at least 30 mm high. When using the printer with the cutter, you should set the stop position

(^E) to 33.

BA_TT5-L_GB_V(0).DOCX page 40

Maintenance

8 Maintenance and adjustment

8.1 Cleaning the Print Head

Dirt on the print head or ribbon may result in inadequate print quality (there are only partial images on the label).

The printer cover should therefore be kept closed when possible. Keeping dirt and dust away from the paper or

labels ensures a good print quality and a longer lifespan of the print head.

Cleaning Steps

1. Switch off the printer.

2. Open the printer cover.

3. Remove the ribbon.

4. To remove any label residue or other dirt from the print head (see green arrow), please use a soft lint-free

cloth dipped in alcohol to wipe.

NOTE:

* We advise to clean the print head once per week. (Recommended)

** When cleaning the print head, please do not use any sharp or hard objects!

*** Do not touch the glass safeguard of the print head with your bare hands!

BA_TT5-L_GB_V(0).DOCX page 41

Troubleshooting

Problem

Solution

The printer is switched on but the LCD screen

does not light up.

Check the power supply. (Please see the Section 5.4)

The LCD screen displays error alert and

printing is interrupted.

Check the software settings (driver settings) or command

codes.

Look for the error alert in the table in Section 6.8. Error Alerts.

Check whether the print mechanism is closed correctly.

(Please see the Section 4.5)

The label stock passes through the printer but

not image is printed.

Please make sure that the label stock is loaded the right side

up and that it is the suitable material.

Choose the correct printer driver.

Choose the correct label stock and a suitable printing mode.

The label stock jams during printing.

Clear the paper jam. Remove any label material left on the

thermal print head and clean the print head using a soft lintfree cloth dipped in alcohol. (Please see the Section 8.1)

There is no printed image on some parts of

the label.

Check whether there is any label material or ribbon stuck to

the thermal print head.

Check for errors in the application software.

Check whether the starting position has been set correctly.

Check the ribbon for wrinkles.

Check the power supply is correct.

There is no printed image on part of the label

or the image is blurred.

Check the thermal print head for dust or other dirt.

Use the internal ‘~T‘ command to check whether the thermal

print head will carry out a complete print job.

Check the quality of the print medium.

The printed image is positioned incorrectly.

Check whether there is paper or dust covering the sensor.

Check whether the label stock is suitable. Contact your

supplier.

Check the paper guide settings.

Skipping labels during printing.

Check the label height setting.

Check whether there is dust covering the sensor.

Run the auto-detection function. (Please see the Section 6.7)

The printed image is blurred.

Check the darkness setting.

Check the thermal print head for dust or dirt. (Please see the

Section 8.1)

The cutter does not cut off the labels in a

straight line.

Check whether the label stock is positioned straight.

The cutter does not cut off the labels

completely.

Check whether the label is more than 0.2 mm thick.

When using the cutter, the labels are not fed

through or cut off incorrectly.

Check whether the cutter has been correctly installed.

Check whether the paper guides are functioning correctly.

The label dispenser is not functioning

normally.

Check whether there is dust on the label dispenser.

Check whether the label stock is positioned correctly.

8.2 Troubleshooting

Please address any questions to our technical hotline in Germany

Tel.: 00 49 781/9616-36, Fax: 00 49 781/9616-30, E-Mail: hotline@thermo-tex.de

For clients from Switzerland: Tel.: 00 41 61751/9100, Fax: 00 41 61751/9101,

E-Mail: info@thermo-tex.ch

BA_TT5-L_GB_V(0).DOCX page 42

Port Specifications

Connector Type:Type B

Pin NO. 1 2 3 4 NC

D-

D+

GND

RS232 Housing (9-pin to 9-pin)

Pin NO.

1

2 3 4 5 6 7 8 9 Type

+5V, max

500mA

TXD

RXD

N/C

GND

RTS

CTS

RTS

N/C

DB9

Plug

-

RXD

TXD

DTR

GND

DSR

RTS

CTS

RI

DB9

Socket

Type: RJ45

Pin NO. 1 2 3 4 5 6 7 8 TX+

TX-

RX+

NC

NC

RX-

NC

NC

Connector Type:Type A

Pin NO. 1 2 3 4

VBUS

D-

D+

GND

8.3 Communication port specifications

Pinout Description

USB Port

Serial Port

Default Settings: Baud rate 9600, no parity, 8 data bit, 1 stop bit, XON/XOFF, Protocal and RTS/CTS

Ethernet Port

USB Host

BA_TT5-L_GB_V(0).DOCX page 43

Bluetooth Setting

Type: Centronics Female

Pin NO. 1 2 3 4 5 6 7 8 9 10

11

12

BUZY

SELECT

ACK

FAULTN

LPT

PER

DATA0

DATA1

DATA2

DATA3

DATA4

DATA5

DATA6

Pin NO.

13

14

15

16

17

18

19

20

21

22

23

24

DATA7

LPT

INTN

STROB

SELIN

AUTO

NC

GND

GND

GND

GND

GND

GND

Pin NO.

25

26

27

28

29

30

31

32

33

34

35

36

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

5V

Parallel Port

NOTE:

* Serial port total output cannot exceed the maximum current of 500mA

9 Bluetooth Setting

9.1 Steps for setting Bluetooth keyboard

Step 1 Power off the printer

Step 2 Install the Bluetooth module

Note: Methods for installing Bluetooth module, please refer to Bluetooth module manual

Step 3 A grey Bluetooth icon will be displayed in the main page after switching on the printer

and it indicates that the printer has detected the Bluetooth module.

BA_TT5-L_GB_V(0).DOCX page 44

Bluetooth Setting

Activate the Bluetooth keyboard to be detectable.

Step 4 Switch on the keyboard on the left side

Step 5 Hold down F1 Button for 3 seconds => fast blinking light means the keyboard

enters pairing mode.

Step 6 Steady light for 5 seconds indicates successful pairing.

If light blinks slowly, repeat previous step.

9.2 Steps for setting Bluetooth connection on the LCD panel

Step 1 Turn on the printer and LCD panel will display home screen.

Step 2 Select “Main” Step 3 Select “Devices”

Step 4 Select “Bluetooth Settings” Step 5 Set “Profile” to “HID Mode”

and click “Search Devices”

BA_TT5-L_GB_V(0).DOCX page 45

Bluetooth Setting

Step 6 The LCD panel will display “Waiting” when the printer detects the Bluetooth keyboard.

When the Bluetooth keyboard is detected by the printer, the monitor will indicate the

information of Bluetooth keyboard.

Step 7 Press “ON” button on the LED panel to create a connection between the printer and the

Bluetooth keyboard, and then the LCD panel will display „Please enter PIN Code“

Enter the “PIN Code” into the printer via the Bluettoth keyboard.

Note: The “PIN Code” does not need to be entered if the “SPP” of the printer and the

Bluetooth keyboard is set “ON”.

Step 8 When the connection is successfully created, the current panel will be automatically

switched to the setting menu of Bluetooth, as the figure below indicates.

(The upper left corner LED of Blutooth keyboard will steady light for 5 seconds)

BA_TT5-L_GB_V(0).DOCX page 46

Bluetooth Setting

SSP

The Bluetooth code is not needed to be inputted when the

Secure Simple Pairing mode of the Bluetooth setting in the

printer and the PC/Keyboard is set “Activated”.

Note: To be allowed to change this setting, please select “Clear

Bind” in order to disconnect the paired device.

Profile

It can be switched to SPP mode or HID mode.

SPP mode : for creating the connection of PC or mobile phone

HID mode : for creating the connection of Bluetooth keyboard

and Bluetooth scanner.

Note: To be allowed to change this setting, please select “Clear

Bind” in order to disconnect the paired device.

PIN

Code

Code of printers and Bluetooth.

Note: To be allowed to change this setting, please select “Clear

Bind” in order to disconnect the paired device.

Clear

Bind

It deletes connections of Bluetooth devices.

Search

Devices

It scans Bluetooth devices when pressing the button.

It shows information of devices when the searching is completed

1. It only support HID

2. It only shows English and numbers

3. It shows maximum 16 pairs informatin of devices

4. *It disconnects current connection when functioning,

after creating a successful connection

Designation

ThermoTex Article No.

Printhead 203 dpi

22711

Printing Roller

22713

External roll holder

18064

Rotary cutting device

22687

Cleaning set

50393

USB cable type A/B

14224

Ethernet cable 3m RJ45

14405

Ink ribbon holder

22733

USB Mini-Keyboard UK

22782

Power supply

22716

British 3-pin blade plug

20667

9.3 Introduction of the Bluetooth parameters

10 Spare parts list

BA_TT5-L_GB_V(0).DOCX page 47

Loading...

Loading...