ThermoTex TT4-S Operating Manual

ThermoTex Nagel GmbH

Schutterstraße 14, D-77746 Schutterwald

Tel.: +49 (0)781/9616-0, Fax: +49 (0)781/9616-50

info@thermo-tex.de, www.thermo-tex.de

GBTT4SBA.002

Operating manual for

TT4-S

- Translated version of the original operating manual -

GBTT4SBA

Page - 2

Contents

1 Product description ......................................................................................................... 3

1.1 General description, intended purpose ......................................................................................................... 3

1.2 Scope of supply............................................................................................................................................. 3

1.3 Technical data ............................................................................................................................................... 4

1.4 Parts of the printer ........................................................................................................................................ 4

1.5 Properties of the thermo print head .............................................................................................................. 5

1.6 Instructions for the lithium battery ................................................................................................................. 5

1.7 Declaration of conformity .............................................................................................................................. 6

2 Safety instructions ........................................................................................................... 7

3 Initial commissioning ...................................................................................................... 8

3.1 Power connection ......................................................................................................................................... 8

3.2 Connecting to the computer .......................................................................................................................... 8

3.3 General information for inserting labels and ink ribbons ............................................................................... 8

3.4 Inserting labels .............................................................................................................................................. 9

3.5 Inserting the ink ribbon ................................................................................................................................ 10

3.6 Mounting the cutting device ........................................................................................................................ 12

4 Operation ........................................................................................................................ 13

4.1 Control panel ............................................................................................................................................... 13

4.2 Symbols ...................................................................................................................................................... 13

4.3 Energy saving mode ................................................................................................................................... 13

4.4 Button functions .......................................................................................................................................... 14

4.5 Configuration menu ..................................................................................................................................... 15

5 Settings ........................................................................................................................... 16

6 Test functions ................................................................................................................ 18

7 External keyboard .......................................................................................................... 20

7.1 Keyboard configuration ............................................................................................................................... 20

8 Troubleshooting ............................................................................................................ 22

9 Cleaning .......................................................................................................................... 25

9.1 General cleaning ......................................................................................................................................... 25

9.2 Cleaning the printing roller .......................................................................................................................... 25

9.3 Cleaning the print head ............................................................................................................................... 25

9.4 Cleaning the label light barrier .................................................................................................................... 26

9.5 Cleaning the cutting device ......................................................................................................................... 27

10 Spare parts list ............................................................................................................ 27

Product description

GBTT4SBA

Page - 3

1 Product description

1.1 General description, intended purpose

The TT4-S is a label printer for both thermotransfer printing and also for thermo direct printing, and offers great

variability in the printing image design.

Thermotransfer printing requires a special ink ribbon together with the label material. The printing image is

produced by heating dots in the ink ribbon with corresponding transfer of the ink particles to the label.

Thermo direct printing is based on using label material with a thermoreactive coating. The printing image is

created by heating dots of the material at the thermo print head, causing corresponding changes in colour to the

coating.

The use of a high-speed 32 bit Coldfire processor with a clock speed of 266MHz and the main memory of 64 MB

produce printing results in a matter of seconds, even for very large labels (up to 2000 mm long). The TT4-S

offers the following interfaces for data transfer:

Interfaces TT4-S

Serial interface RS232 C, 8 bit, 1200-230400 baud

Serial interface RS422/485, 8 bit, 1200-230400 baud

Parallel interface, bi-directional, as per IEEE1284

USB 2.0 high-speed slave (for PC connection)

Ethernet 10/100 Base T, LPD, RawIP-Printing, DHCP, http,

FTP, SMTP, SNMP, NTP

WLAN card 802.11b/g

Twinax/coax converter

2x USB master for keyboard and scanner

= standard, = optional

The printer offers the possibility of using memory cards for permanent storage of graphics, fonts or label

descriptions. To this end, the data can be transferred via the above named interfaces. CompactFlash cards type

I with capacity of up to 1 GB are suitable memory cards.

The unit must only be used for printing labels, continuous paper and similar materials.

Safe operation of the machine cannot be guaranteed if the TT4-S is not used for its

intended purpose.

Compliance with all information in the operating manual is an integral part of proper use.

1.2 Scope of supply

The standard scope of supply includes

• thermotransfer printer TT4-S

• label trough

• operating manual

• driver CD

• empty foil core (mounted on ink ribbon winder)

• power lead

• serial connection lead

Product description

GBTT4SBA

Page - 4

1.3 Technical data

Electrical data

Operating voltage: 230 V / 50 Hz

Power: 200 W

Dimensions

Height: 274 mm

Width: 242 mm

Depth: 446 mm

Weight: 9 kg

Printing unit

Resolution: 300 dpi (standard)

Max. printing width: 105.6 mm

Printing speed: 75...250 mm/s (adjustable)

Ink ribbon

Ink ribbon width: up to 114 mm (the ink ribbon should be at least as wide as the label material,

to protect the print head from wear)

Core diameter: 25 mm

Max. roll diameter: 80 mm

Labels

Width: 4...116 mm

Height: 5-2000 mm

Max. thickness: 0.35 mm

Core diameter: 38...76 mm

Max. roll diameter: 210 mm

Label sensor (transparent light/reflection from below)

Distance to lay edge: 5...53 mm

Control panel (buttons illuminated depending on operating mode)

LCD graphic display WxH: 60x40 in mm

Text lines/digits: 4 / approx. 20

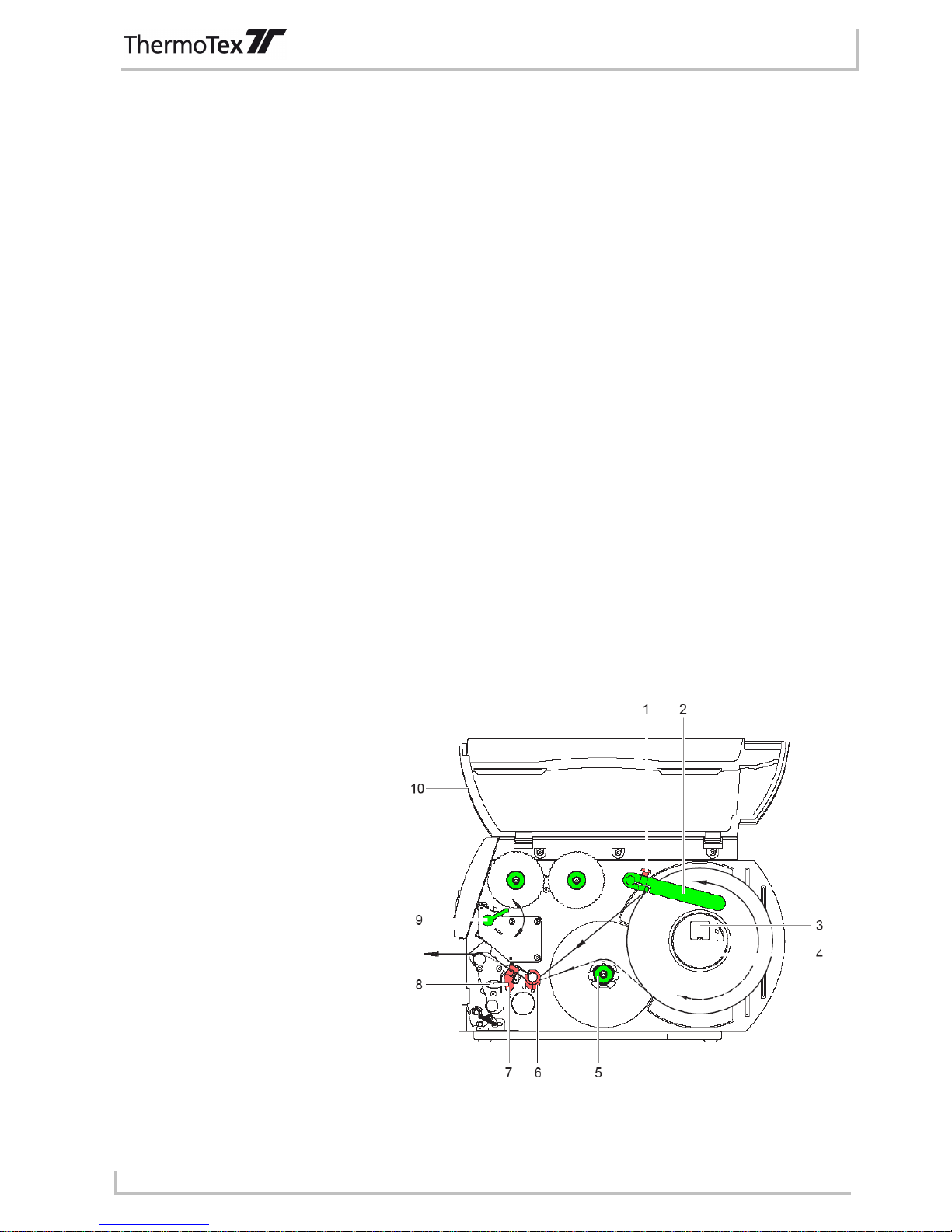

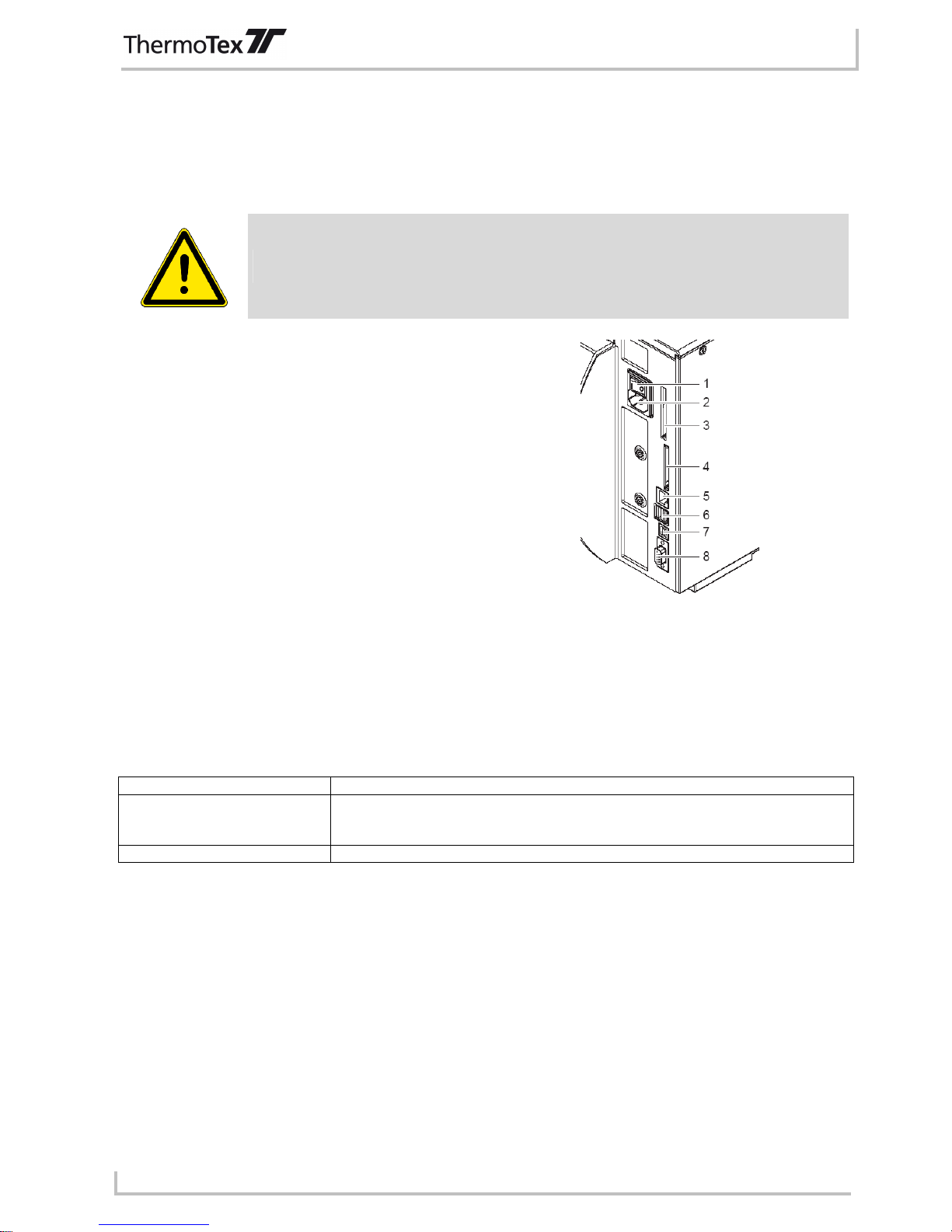

1.4 Parts of the printer

1 Retaining screw

2 Roll guide

3 Roll holder

4 Core adapter 76mm (option)

5 Internal winder (option)

6 Sliding guide ring

7 Label light barrier

8 Hex key

9 Lever for locking print head

10 Lid

Fig. 1-1 - Parts of the printer

Product description

GBTT4SBA

Page - 5

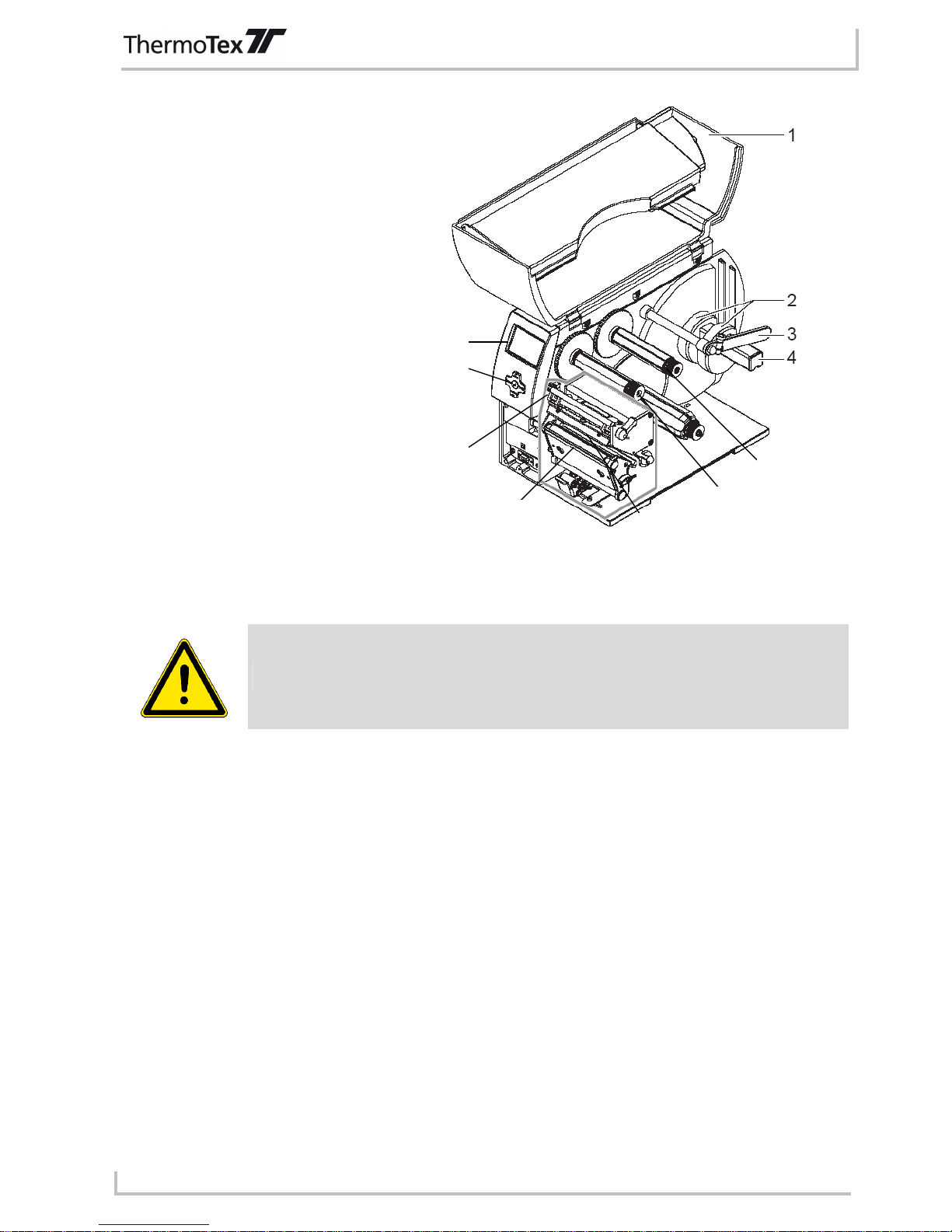

1 Lid

2 Core adapter 76mm (option)

3 Roll guide

4 Roll holder

5 Display

6 Navigator pad

7 Transfer film deflector

8 Printing roller

9 Print head

10 Film winder

11 Film unwinder

Fig. 1-2 - Parts of the printer

1.5 Properties of the thermo print head

The thermo print head is the most delicate part of your printer. Please always comply with

the following instructions.

1. Do not touch the glass safeguard on the print head with your hand. Do not use any sharp objects (knife,

screwdriver, etc.) to clean the print head.

2. During printing, make sure that there are no impurities on the label which could be pulled through under

the print head. These could damage the head.

3. Ensure the label has a good, smooth surface. Rough label surfaces act as sandpaper and reduce the

service life of the head.

4. Clean the head regularly with cotton buds soaked in alcohol.

5. Print at the lowest possible head temperature.

Incorrect handling can damage your print head very quickly.

1.6 Instructions for the lithium battery

The electronic board of your printer is equipped with a lithium battery. Discharged batteries must be disposed of

in corresponding old battery collections. If the batteries are not completely discharged, place adhesive tape over

the poles to prevent short circuits.

When decommissioning the printer, the battery must always be disposed of separately from the rest of the

printer.

5

6

7

8

9

10

11

Product description

GBTT4SBA

Page - 6

1.7 Declaration of conformity

CE Declaration of Conformity

Manufacturer:

ThermoTex Nagel GmbH

Schutterstraße 14

D-77746 Schutterwald

Device description:

Type: TT4-S

Production status: December 2009

The device fulfils the health and safety requirements of the following EC directives:

• Low voltage directive 2006/95/EC

Applied standard: EN 60950-1:2006

• Electromagnetic compatibility directive 2004/108/EC

Applied standards: EN 55022:2006

EN 55024:1998+A1:2001+A2:2003

EN 61000-3-2:2006

EN 61000-3-3:1995+A1:2001+A2:2005

Schutterwald, 17.12.2009

ThermoTex Nagel GmbH

Dietmar Nagel

(Managing Director)

Safety instructions

GBTT4SBA

Page - 7

2 Safety instructions

The following warning symbols are used on the machine and in this operating manual:

Hazard Warning

Warning, dangerous electrical voltage

Warning of cutting injuries

Disconnect from the power supply

Always comply with the following safety instructions to avoid personal injuries or damage to

the printer.

• The printer must only be operated by correspondingly trained and authorised staff who know the manual and

are capable of working accordingly,

• Only connect the unit to a power supply with suitable voltage. The unit is rated for AC voltage from 100 to

240 V. Only connect the printer to a grounded power socket.

• Only connect the printer to units with protective low voltage.

• Ensure that all units being connected (printer, computer etc.) are switched off when connecting together.

Also switch the units off before disconnecting them.

• Ensure that your printer is not exposed to damp or wet conditions.

• The printer can be operated with the lid opened. In this condition, the rotating parts are freely accessible.

Ensure that no hair, jewellery etc. can get caught up in these rotating parts.

• During operation, the print head component can get hot. Beware when touching the component.

• Disconnect the printer from the power supply before starting any cleaning or maintenance work.

• Only qualified maintenance technicians should repair the printer.

Do not open the rear wall! Mortal risk from power supply voltage!

Initial commisioning

GBTT4SBA

Page - 8

3 Initial commissioning

3.1 Power connection

The printer is equipped with a wide-range power unit (100...240V~) so that it can be operated from a power

supply of both 230V~/50Hz and 115V~/60Hz without having to interfere with the printer.

Before connecting your printer to the power supply, make sure that the power switch (1) is

in the "0" (OFF) setting.

1 Power switch

2 Power socket

3 Slot for card bus or PC card type II

4 Slot for CompactFlash memory card

5 Ethernet 10/100 Base-T

6 USB interface for keyboard and/or scanner

7 USB high-speed slave interface

8 Serial RS 232 C interface

Fig. 3-1 - Connecting the printer

Connect the power lead to the power socket (2) and plug the lead into an earthed socket.

3.2 Connecting to the computer

The standard printer has a serial RS-232 interface (8), a USB high-speed interface (7) and an Ethernet 10/100

Base-T interface (5). For a serial connection, the RS-232 interface of the printer must be configured according to

the settings on your computer.

Standard settings on delivery:

Interface Configuration

RS-232 Baud rate: 115200

Parity: none

Flow control: RTS/CTS

Data bits: 8

Stop bits: 1

Ethernet 10/100 Base-T DHCP: on Gateway: off

Connect the computer and printer with a suitable lead and use the screws or straps on the connectors to secure

the lead connection.

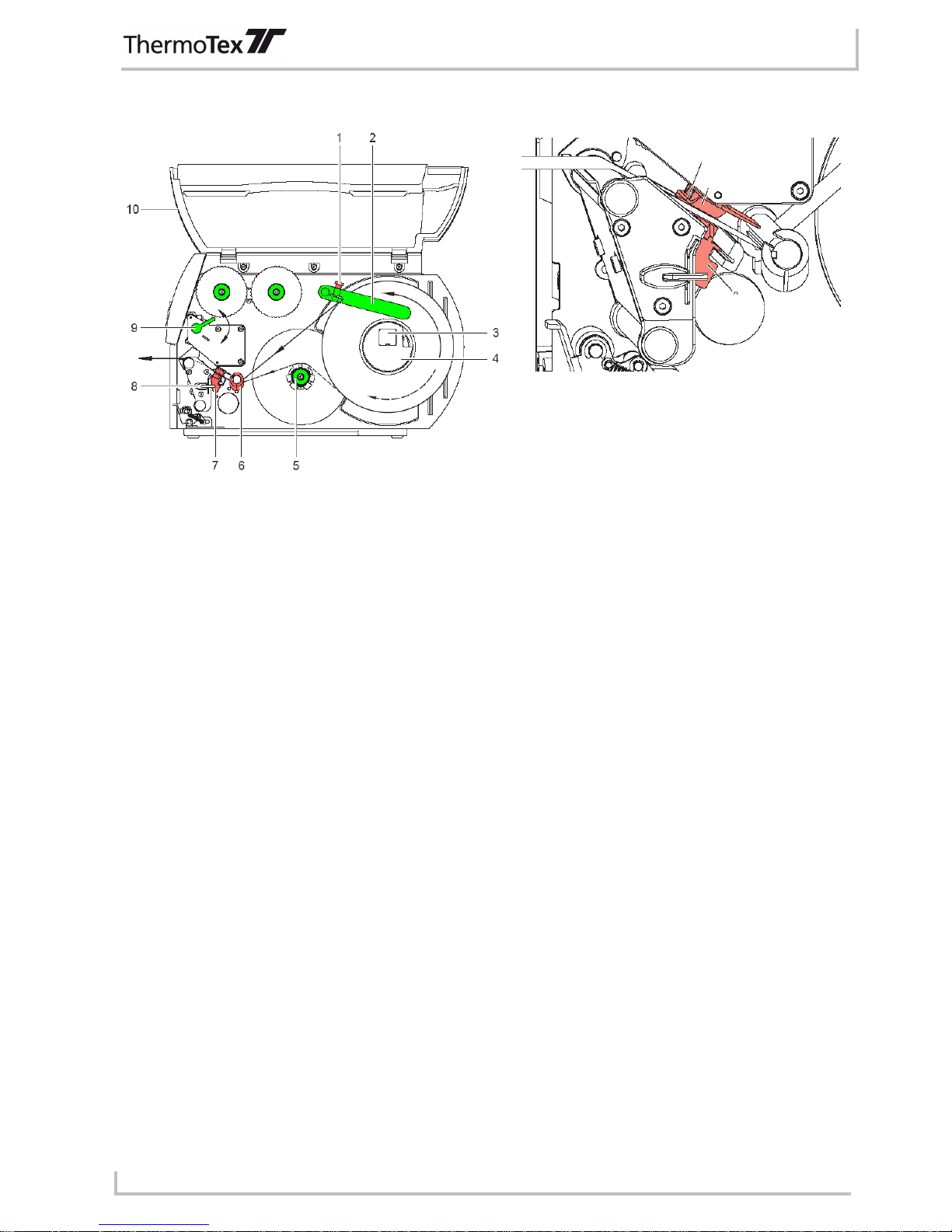

3.3 General information for inserting labels and ink ribbons

The various control and adjusting elements inside the printer are marked green or red.

Only the green control elements are required to change a label roll or ink ribbon roll of the same width.

It may be necessary to use the red control elements as well when inserting a label roll or ink ribbon roll of a

different width.

Initial commisioning

GBTT4SBA

Page - 9

3.4 Inserting labels

Fig. 3-2 - Inserting labels Fig. 3-3 - Adjusting the label light barrier

1. Loosen the knurled screw (1), swivel the guide (2) upwards and push it as far as possible to the outside.

2. Place the roll of labels on the roll holder (3) and unwind a longer strip of labels from the main roll. Push the

roll as far as it will go.

3. Swivel the guide (2) down to the roll holder (3). Push the guide against the main roll so that it is braked

slightly when unwinding. Tighten the knurled screw (3).

4. Swivel the lever (9) counter-clockwise as far as it will go, thus lifting the print head component.

5. Push the guide ring (6) outwards as far as it will go.

6. Guide the strip of labels through the printer as shown in Fig. 3-2. The run of paper for labels on the outside

is shown as a continuous line, the run of paper for labels on the inside as a dotted line.

ThermoTex rolls of labels are on the outside, i.e. the side being printed is on the outside. Exception:

ThermoTex fix plastic film: this is on the inside.

7. Adjust the label light barrier (12) so that the actual sensor (11) can register the gap between the labels or

the reflection or perforation marks. To adjust, push the label light barrier into the right position using the

handle (13).

8. Push the guide ring (6) against the outer edge of the strip of labels.

9. Swivel the lever (9) clockwise as far it will go. This locks the print head.

3.4.1 Adjusting the print head pressure

The print head is pressed in position by two tappets. The outer sliding tappet must be adjusted to the width of the

textile tape being used. The sliding tappet must be positioned to produce uniform printing quality. The tappets

can be adjusted to prevent any pleating.

11

12

13

Loading...

Loading...