ThermoTex Thermo-Ident 1, Thermo-Ident 2 Operating Manual

ThermoTex Nagel GmbH

Schutterstr. 14, 77746 Schutterwald, GERMANY

Phone +49 781 9616-0, fax +49 781 9616-50

info@thermo-tex.de, www.thermo-tex.de

GBTHIDBA_V(2).DOC

Operating manual for

Thermo-Ident 1 and

Thermo-Ident 2

- Translated version of the original operating manual -

Contents

GBTHIDBA_V(2).DOC Page - 2

Contents

1! Product description .......................................................................................................... 3!

1.1! General description and intended use ......................................................................................................... 3!

1.2! Machine versions ......................................................................................................................................... 4!

1.3! Layout .......................................................................................................................................................... 4!

1.4! Technical data ............................................................................................................................................. 4!

1.5! Declaration of Conformity ............................................................................................................................ 5!

2! Safety advice ..................................................................................................................... 5!

2.1! Warning symbols ......................................................................................................................................... 5!

2.2! Dangerous spots on the machine ................................................................................................................ 6!

2.3! Safety devices ............................................................................................................................................. 6!

2.4! Due diligence by the operator ...................................................................................................................... 6!

2.5! Basic safety measures in standard operation .............................................................................................. 6!

2.6! Basic safety measures for maintenance and servicing ............................................................................... 7!

3! General advice .................................................................................................................. 8!

3.1! Transport ..................................................................................................................................................... 8!

3.2! Unpacking the machine ............................................................................................................................... 8!

3.3! Installation advice ........................................................................................................................................ 8!

3.4! Start-up ........................................................................................................................................................ 8!

3.5! Properties of the thermal print head ............................................................................................................ 9!

3.6! Materials and parameters .......................................................................................................................... 10!

4! General operation ........................................................................................................... 11!

4.1! Principal work sequence ............................................................................................................................ 11!

4.2! Inserting the ink ribbon roll ........................................................................................................................ 11!

4.3! Inserting the marking tape ......................................................................................................................... 11!

4.4! Changing between temporary and permanent marking ............................................................................ 12!

5! Operation of the control unit .......................................................................................... 13!

5.1! Operating display ....................................................................................................................................... 13!

5.2! Menus ........................................................................................................................................................ 14!

5.3! Quick access buttons ................................................................................................................................ 15!

5.4! Operating modes ....................................................................................................................................... 15!

5.5! Entering text .............................................................................................................................................. 15!

5.6! Saving the settings .................................................................................................................................... 16!

6! Description of menu points ............................................................................................ 17!

6.1! Numbering ................................................................................................................................................. 17!

6.2! Automatic printing ...................................................................................................................................... 17!

6.3! Delete text after print ................................................................................................................................. 17!

6.4! Logo print ................................................................................................................................................... 17!

6.5! Label type .................................................................................................................................................. 18!

6.6! Barcode type ............................................................................................................................................. 18!

6.7! Check digit ................................................................................................................................................. 18!

6.8! Label alignment ......................................................................................................................................... 18!

6.9! Print position .............................................................................................................................................. 18!

6.10! Label length ........................................................................................................................................... 18!

6.11! Single label length .................................................................................................................................. 18!

6.12! Double label length ................................................................................................................................ 18!

6.13! Immediate heat-seal .............................................................................................................................. 18!

6.14! Font size ................................................................................................................................................ 19!

6.15! Heat-seal temperature for temporary marking ....................................................................................... 19!

6.16! Heat-seal temperature of the permanent marking ................................................................................. 19!

6.17! Heat-seal temperature for the "heat-seal removal" operating mode ...................................................... 19!

6.18! Short temporary marking heat-seal time ................................................................................................ 19!

6.19! Long temporary marking heat-seal time ................................................................................................ 19!

6.20! Permanent marking heat-seal time ........................................................................................................ 19!

6.21! Operating mode ..................................................................................................................................... 19!

6.22! Baud rate ............................................................................................................................................... 19!

6.23! Language ............................................................................................................................................... 19!

Contents

GBTHIDBA_V(2).DOC Page - 3

6.24! Keyboard allocation ............................................................................................................................... 20!

6.25! Daily counter .......................................................................................................................................... 20!

6.26! Total counter .......................................................................................................................................... 20!

6.27! Operating hours counter ........................................................................................................................ 20!

6.28! Heating energy ....................................................................................................................................... 20!

6.29! Copy logos ............................................................................................................................................. 20!

6.30! Gluing Teflon .......................................................................................................................................... 21!

6.31! Heat-seal removal .................................................................................................................................. 21!

7! Label layout ..................................................................................................................... 22!

7.1! Examples for Thermo-Ident 1 .................................................................................................................... 22!

7.2! Examples for Thermo-Ident 2 .................................................................................................................... 23!

8! Remote control ................................................................................................................ 24!

8.1! Serial interface ........................................................................................................................................... 24!

8.2! Ethernet connection ................................................................................................................................... 24!

8.3! Communication sequence ......................................................................................................................... 24!

8.4! PC data transfer → Thermo-Ident ............................................................................................................. 25!

8.5! Data transfer Thermo-Ident → PC ............................................................................................................. 25!

9! Error Messages ............................................................................................................... 26!

10! Assistance with faults ................................................................................................. 27!

11! Servicing (maintenance) .............................................................................................. 28!

11.1! Basic safety measures for maintenance and servicing .......................................................................... 28!

11.2! Cleaning the print head .......................................................................................................................... 28!

11.3! Teflon film .............................................................................................................................................. 28!

11.4! Heat-seal rubber .................................................................................................................................... 28!

11.5! Air filter ................................................................................................................................................... 29!

11.6! Maintenance message ........................................................................................................................... 29!

12! List of spare parts ........................................................................................................ 29!

13! Circuit diagram ............................................................................................................. 30!

This document is the translated version of the original German

operating manual. For any translations into other languages, the

original German manual must be used as a basis. You can obtain the

original manual from ThermoTex.

1 Product description

1.1 General description and intended use

The Thermo-Ident marking machine may exclusively be used for temporary or permanent textile marking. The

machine prints labels, cuts them off and applies them to textiles.

Depending on the type of marking tape and the set parameters, temporary marking or permanent marking is

possible.

The labels are resistant to most industrial washing and dry-cleaning processes. Temporary labels can be

removed from the textile without residues after the washing or dry-cleaning process.

Safe operation of the machine is not guarantee if the marking machine is not used

for this purpose.

The following improper uses are to be excluded:

• Do not leave any highly flammable objects or any processing materials in or on the

machine; do not use any highly flammable objects and no flammable liquids and do not

Product description

GBTHIDBA_V(2).DOC Page - 4

use them or place them near the machine. This also applies to liquids or solids that can

disintegrate thermally into dangerous substances.

• Do not use the machine to dry or remove stains, especially with flammable liquids.

Observation of all information in the manual is part of proper use.

1.2 Machine versions

1.2.1 Thermo-Ident 1

The width of the marking tape is 10 mm.

Single line and double line labels can be printed.

1.2.2 Thermo-Ident 2

The width of the marking tape is 15 mm.

Labels with up to four lines can be printed.

1.3 Layout

Figure 1-1

1.4 Technical data

Type name: Thermo-Ident 1 / Thermo-Ident 2

Electrical connection values: 230 V, 50 Hz, 500 W

Nominal current: 2.2 A

Fuse: 4.0 A (time-lag)

Noise emissions: Workplace-related emission value < 70 dB (A)

Keyboard: Mini keyboard with USB connection

Serial interface: 9-pole Sub-D plug (connection to a PC using a null modem cable)

Network interface: RJ45 socket

Compressed air connection: 4 bar working pressure, maximum authorised pressure 6 bar

Dimensions:

Width: 540 mm

Height: 310 mm

Depth: 460 mm

Weight: 32 kg

Hand lever with

heat-seal rubber

Heating element

with Teflon film

Control unit

Roll holder

Keyboard

Declaration of conformity

GBTHIDBA_V(2).DOC Page - 5

1.5 Declaration of Conformity

"CE" Declaration of Conformity

Manufacturer:

ThermoTex Nagel GmbH

Schutterstraße 14

77746 Schutterwald

Device description:

Type: Marking machine Thermo-Ident 1 / Thermo-Ident 2

Production status: April 2012

The device fulfils the health and safety requirements of the following EC directives:

• Machinery directive 2006/42/EC

Applied standards: EN 13857:2008

EN 13732-1:2008

EN ISO 12100:2010

EN 60204-1:2006/A1:2009

• Electromagnetic compatibility directive 2004/108/EC

Applied standards: EN 61000-6-2:2005

EN 61000-6-3:2007

Schutterwald, 24.04.2012

ThermoTex Nagel GmbH

Dietmar Nagel

(Managing Director)

2 Safety advice

2.1 Warning symbols

The following warning symbols are found on the machine and in this manual:

Safety advice

GBTHIDBA_V(2).DOC Page - 6

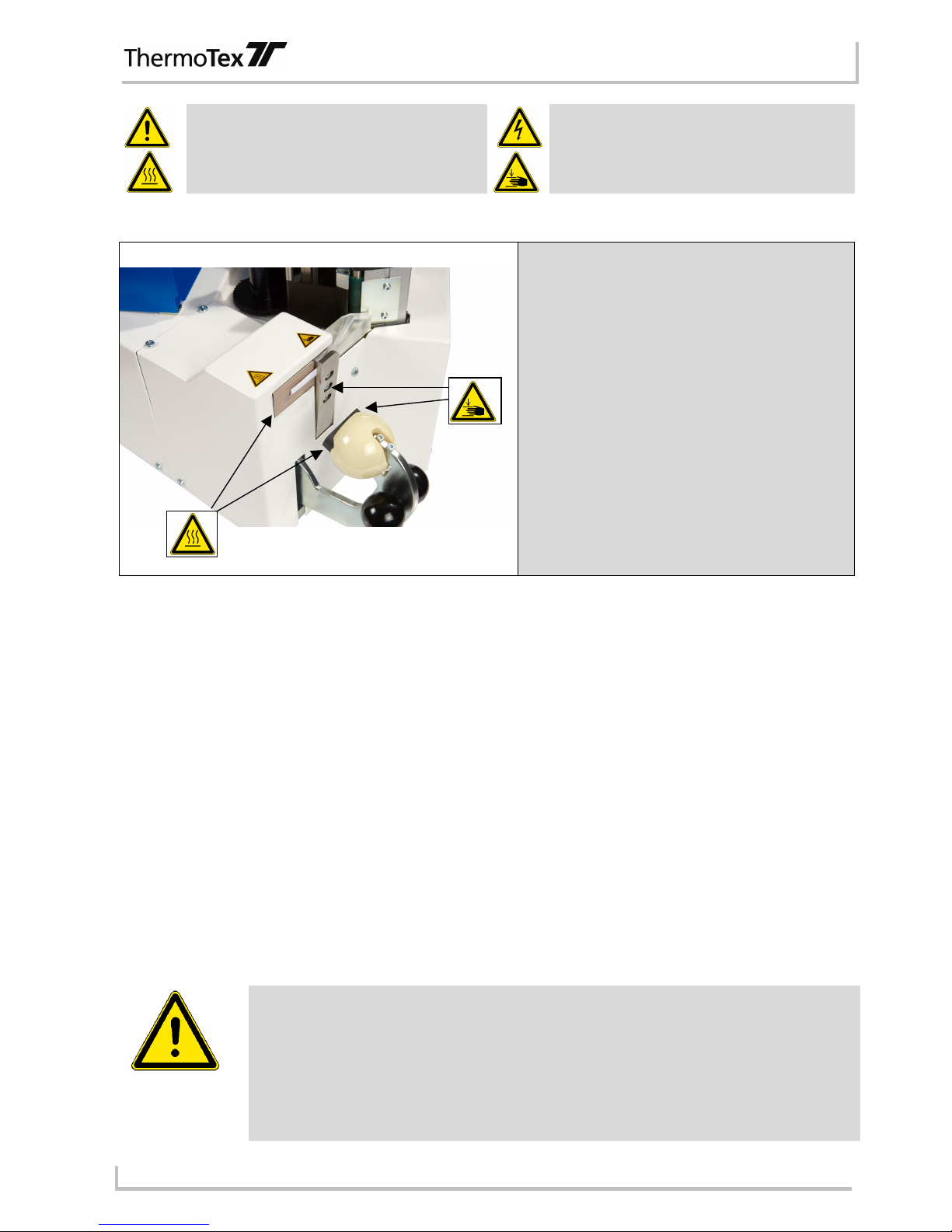

"Warning of dangerous spots"

"Warning of dangerous electrical voltages".

"Warning of hot surfaces"

"Warning of hand injuries"

2.2 Dangerous spots on the machine

Caution, hot surfaces!

• The heating element can reach temperatures

above 200°C.

• The heat-seal rubber on the hand lever can

become hot.

• The processed material can become hot.

Caution, risk of hand injuries!

• There is the risk of cuts and crushing in the

area of the cutting device.

• There is the risk of crushing in the area of the

hand lever. Do not reach into the space

between the hand lever and heating element!

2.3 Safety devices

The machine is protected with a 4.0 A (time-lag) microfuse.

The heating element is protected with a thermal fuse.

2.4 Due diligence by the operator

The operator must particularly ensure the following:

• The machine is only used for the intended purpose

• No unauthorised conversions and changes are made to the machine

• The machine is only operated in a perfect, fully functional condition and that the safety equipment is

particularly checked regularly for functionality

• The full operating manual is always kept in a legible condition at the place of use of the machine

• Only sufficiently qualified and authorised personnel operate, maintain and repair the machine

• These members of personnel are regularly inducted in all relevant issues of work safety and environmental

protection and are aware of the manual and especially the safety advice contained in it

• All safety and warning device personally attached to the machine may not be removed and must remain

legible.

2.5 Basic safety measures in standard operation

• The machine may only be operated by trained and authorised persons who are aware of

the manual and can work following the manual!

• Check and make sure that only authorised persons are within the working range of the

machine when switching the machine on.

• Check the machine for any visible damages before beginning production and ensure

that it is only operated in perfect condition! Report any defects immediately to the

superior!

• Check and make sure that all safety devices are in perfect working order before

Safety advice

GBTHIDBA_V(2).DOC Page - 7

beginning production!

• The materials to be processed must be checked with respect to possible risks before

processing (temperature resistance, gases or toxicity).

• The Teflon film on the heating plate must be immediately replaced if damaged.

• The machine must always be switched off after finishing work (mains switch).

2.6 Basic safety measures for maintenance and servicing

• Comply with the specified inspection and maintenance intervals in the manual!

• Switch the machine off before beginning maintenance and repair work, disconnect the

power connector and release the air connection!

• Before carrying out maintenance and repair work, make sure that any parts of the

machine that it is possible to touch have cooled down to room temperature!

• Repair work on the electrical equipment on the machine may only be carried out by

trained electricians!

General advice

GBTHIDBA_V(2).DOC Page - 8

3 General advice

3.1 Transport

Before transport, make sure that any parts of the machine that it is possible to touch have cooled down to room

temperature! The mains cable, compressed air hose and data cable to the PC system must be removed for

transport.

3.2 Unpacking the machine

When unpacking the marking machine, make sure that all of the parts listed as follows are definitely included in

the delivery and are not damaged:

• Thermo-Ident 1 or Thermo-Ident 2 marking machine

• Compressed air hose

• Keyboard

• Power cable

• Manual

• 1 set of tape rests

3.3 Installation advice

Please give some thought to where the machine should be installed before taking the machine into operation.

• The machine must be positioned on a strong and level base.

• A specific table height does not need to be maintained. It should however be chosen to suit the person

working on the machine.

• The mains socket must be close to the machine and easy to access.

• Make sure that no highly flammable objects are near to the heating plate.

• Installation in rooms at risk of explosion is prohibited.

• The machine may only be used in dry indoor areas.

• The air filter is equipped with an automatic water separator. This empties itself automatically if required so

that the installation area under the machine can be checked for moisture at regular intervals.

3.4 Start-up

• The machine must be switched off when connecting the connection cables.

• Insert the ink ribbon roll (see chapter 4.2).

• Connect the keyboard to the USB socket on the right side of the machine.

• The compressed air is connected using a euro coupling on the back of the machine.

• The connection cable to a computer system (9-pole Sub-D plug) can be connected on the serial interface.

• You can connect the machine to a network with the RJ45 socket.

• Insert the supplied power cable into the back of the machine. Insert the power cable plug into a protective

contact socket.

The voltages stated on the type label must match the mains voltages in the place of

installation.

• Switch the machine on with the main switch on the back.

• Insert a marking tape (see chapter 4.3).

General advice

GBTHIDBA_V(2).DOC Page - 9

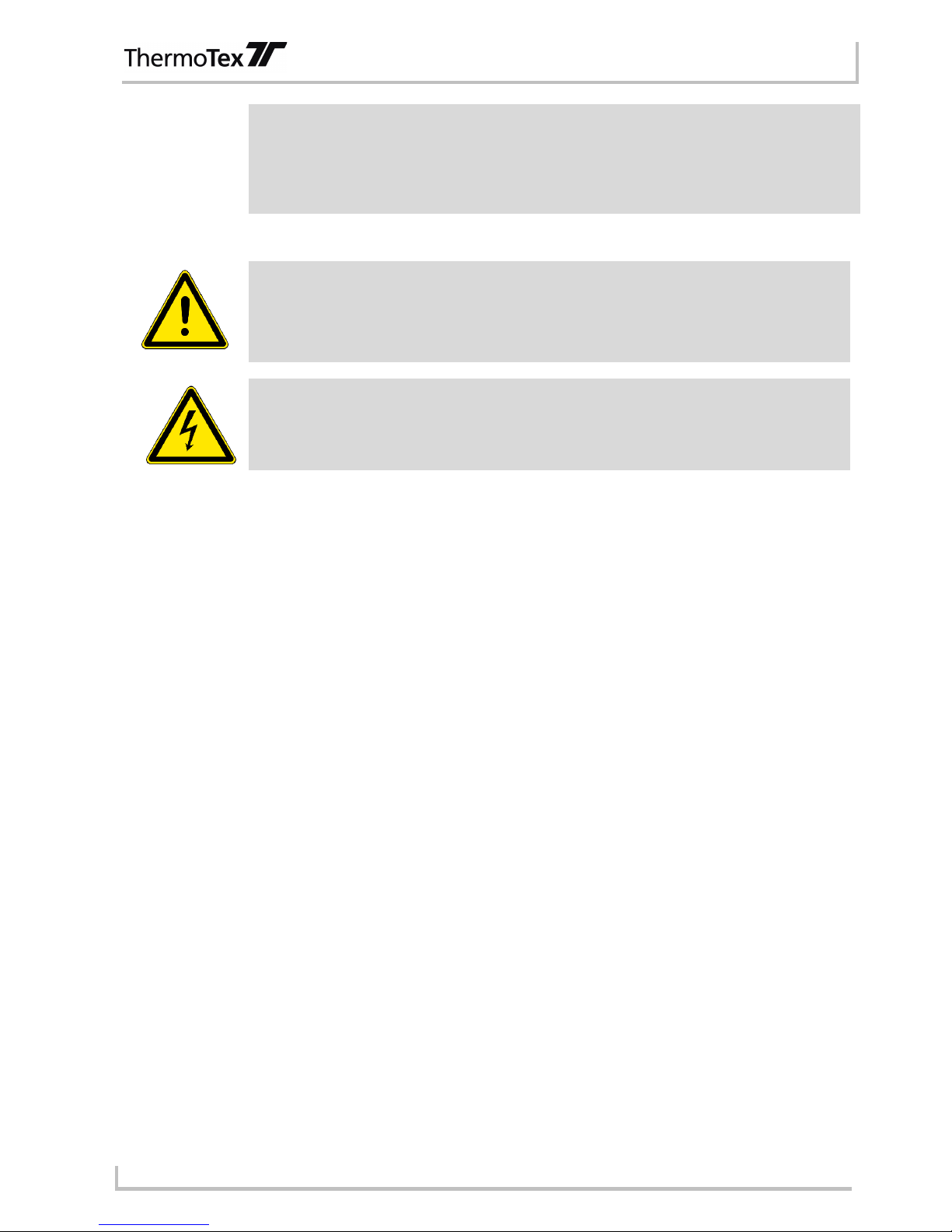

Figure 3-1

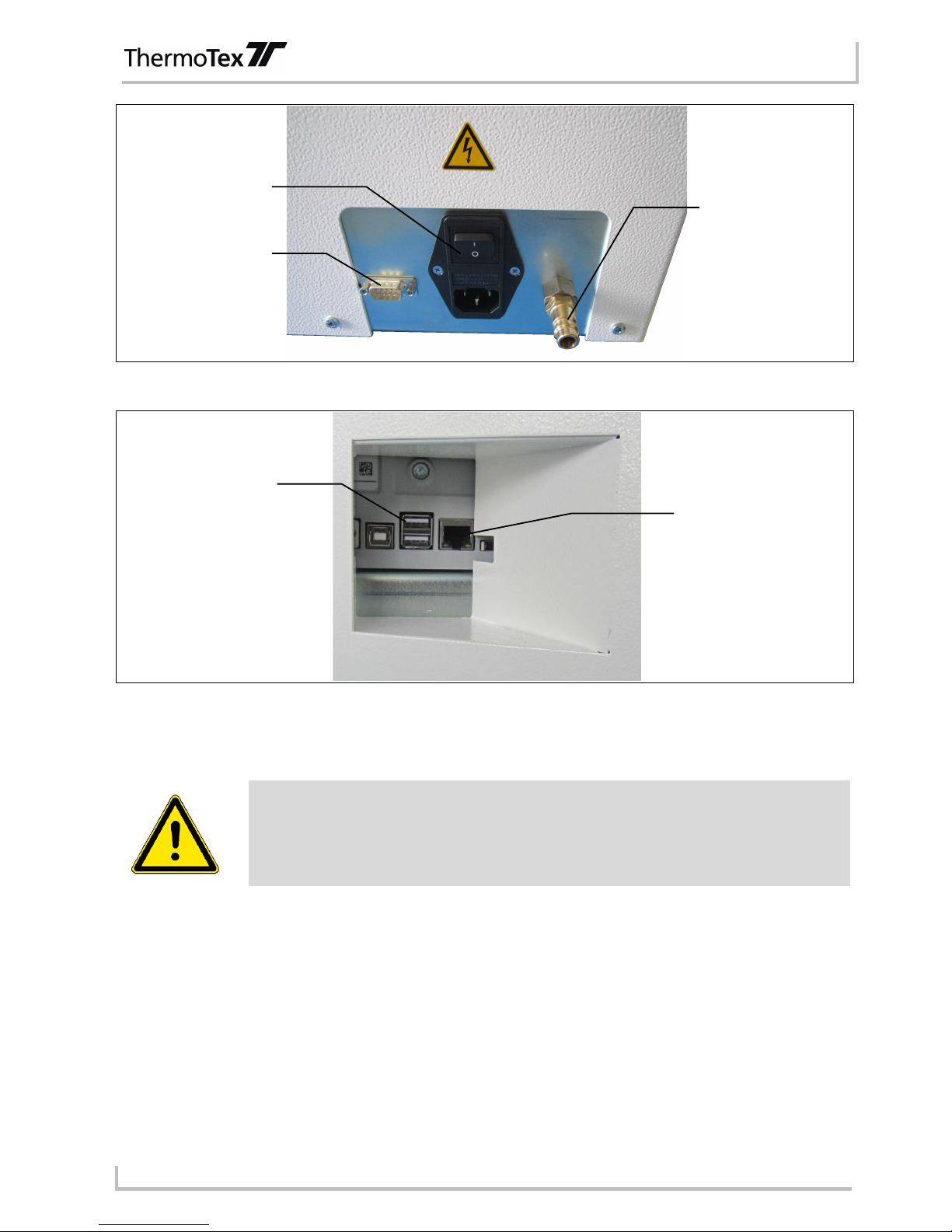

Figure 3-2

3.5 Properties of the thermal print head

The thermal print head is the most sensitive part of your machine. It is compulsory to pay

attention to the following advice.

• The glass protection layer on the print head may not be touched by hand. Never use any sharp objects

(knife, screwdriver or similar) to clean the print head.

• Make sure when printing that no dirt is on the labels that could be pulled through under the print head. This

could damage the print head.

• Pay attention to a good, smooth label surface. Rough label surfaces are like sandpaper and reduce the life

span of the print head.

• Clean the print head at regular intervals with a cotton bud soaked in alcohol.

• Print with the lowest possible heating energy.

Your print head can be damaged very quickly if handled incorrectly.

Power connector

and main switch

Serial interface

Compressed air

connection

USB connection

Ethernet connection

Loading...

Loading...