PELLET BOILER

VERSION:

1.1

UPDATE:

31.05.2019

COMPACT

INSTALLATION AND USER MANUAL

Contents

1. GENERAL INFORMATION ................................................................................... 3

1.1. Proper use of the appliance ................................................................................ 3

1.2. Safety warnings ................................................................................................ 3

1.3. Data label ........................................................................................................ 3

1.4. Document information ....................................................................................... 3

2. TECHNICAL FEATURES AND DIMENSIONS ......................................................... 4

2.1. Technical data .................................................................................................. 4

2.2. Pellet fuel ......................................................................................................... 4

3. BOILER MOUNTING ........................................................................................... 5

3.1. Transportation and delivery ................................................................................ 5

3.2. General requirements ........................................................................................ 5

3.3. Chimney .......................................................................................................... 6

3.4. Air intake ......................................................................................................... 7

4. INSTALLATION .................................................................................................. 8

4.1. Boiler connections ............................................................................................. 8

4.2. Return temperature protection ............................................................................ 9

4.3. Filling the system .............................................................................................. 9

4.4. Electrical connections......................................................................................... 9

5. CONTROLLER ................................................................................................... 10

5.1. General description ......................................................................................... 10

5.2. Operation functions ......................................................................................... 10

5.3. Menu functions ............................................................................................... 13

5.4. Error signals ................................................................................................... 16

6. BOILER START-UP ........................................................................................... 17

6.1. Initial lighting checks ....................................................................................... 17

6.2. Start-up of the boiler ....................................................................................... 17

7. BOILER STOP ................................................................................................... 18

8. SERVICE AND MAINTENANCE .......................................................................... 19

8.1. Cleaning the boiler .......................................................................................... 19

8.2. Maintenance intervals ...................................................................................... 19

GENERAL INFORMATION

1. GENERAL INFORMATION

1.1. Proper use of the appliance

Before you make use of this appliance make sure you have read and fully understood the

instructions included in this manual.

The installation and use of the appliance must be performed according to the instructions

indicated in this manual in combination with the current national safety regulations.

The appliance is designed for use in pumped hot water central heating systems. Any other use

is considered improper and is prohibited. THERMOSTAHL ROMANIA declines any responsibility

for damages or injuries caused by improper use; in this case the risk is completely at the user’s

responsibility.

To ensure an efficient and flawless function of the appliance, it is strongly recommended that

you have performed an annual service by a qualified technician.

1.2. Safety warnings

All installation and maintenance procedures must be carried out by professional and authorized

personnel, in compliance with the indications in the present manual and national regulations.

Any failure to correctly install this appliance could cause damage or injuries!

Do not make modifications to parts of the appliance, unless you have contacted the company

and an authorized service contractor.

Only original accessories and spare parts must be used to ensure correct and safe function.

Make sure you respect the cleaning and maintenance procedures on the corresponding intervals.

Failure to do so can cause malfunction to the appliance and possible damages.

The boiler is design to function on the fuels indicated in the corresponding paragraph. Any other

fuel is prohibited. Do not use explosive or flammable substances! Do not store such substances

inside the boiler room.

The working pressure varies according to the model. Make sure you use the appropriate water

pressure.

Working in a pressure higher than the one indicated in this manual is strictly

prohibited and dangerous!

1.3. Data label

The data label of the appliance is placed on the boiler’s back cover, on the external part. Make

sure that it is properly placed and readable.

On the label it is indicated the serial number and the manufacturing year of the appliance.

1.4. Document information

This document is an integral and indispensable part of the product and must be retained in good

condition by the user. Keep it in a safe place for future reference.

If the appliance is sold or transferred to another person, this manual has to always follow the

appliance and handed to the new user or installer.

3

TECHNICAL FEATURES AND DIMENSIONS

Boiler type

COMPACT 25

COMPACT 35

Nominal power1

kW

25

35

Global power (max-min)

kW

27,8-9,9

35,0-10,6

Pellet consumption (max-min)

kg/h

5,5-2,2

7,7-3,1

Efficiency (max-min)

%

94,5-93,0

94,5-93,0

Max working pressure

bar 3 3

Max working temperature

C

85

85

Exhaust gas temperature

C

160

160

Water contents

lit

28

40

Chimney diameter

mm

80

80

Air intake diameter

mm

60

60

Fuel tank

kg

55

70

Fuel autonomy

h

20

20

Weight (empty)

kg

175

200

Dimensions LxWxH

mm

860x590x1190

880x590x1355

Power consumption (max-min)

W

525-225

540-240

Electrical connections

V/Hz

230/50

230/50

Pellet fuel characteristics

Diameter

6-8 mm

Length

12-30,5 mm

Density

650-700 kg/m3

Ash content

<1%

Calorific power

>4,8 kWh/kg

Humidity content

<8%

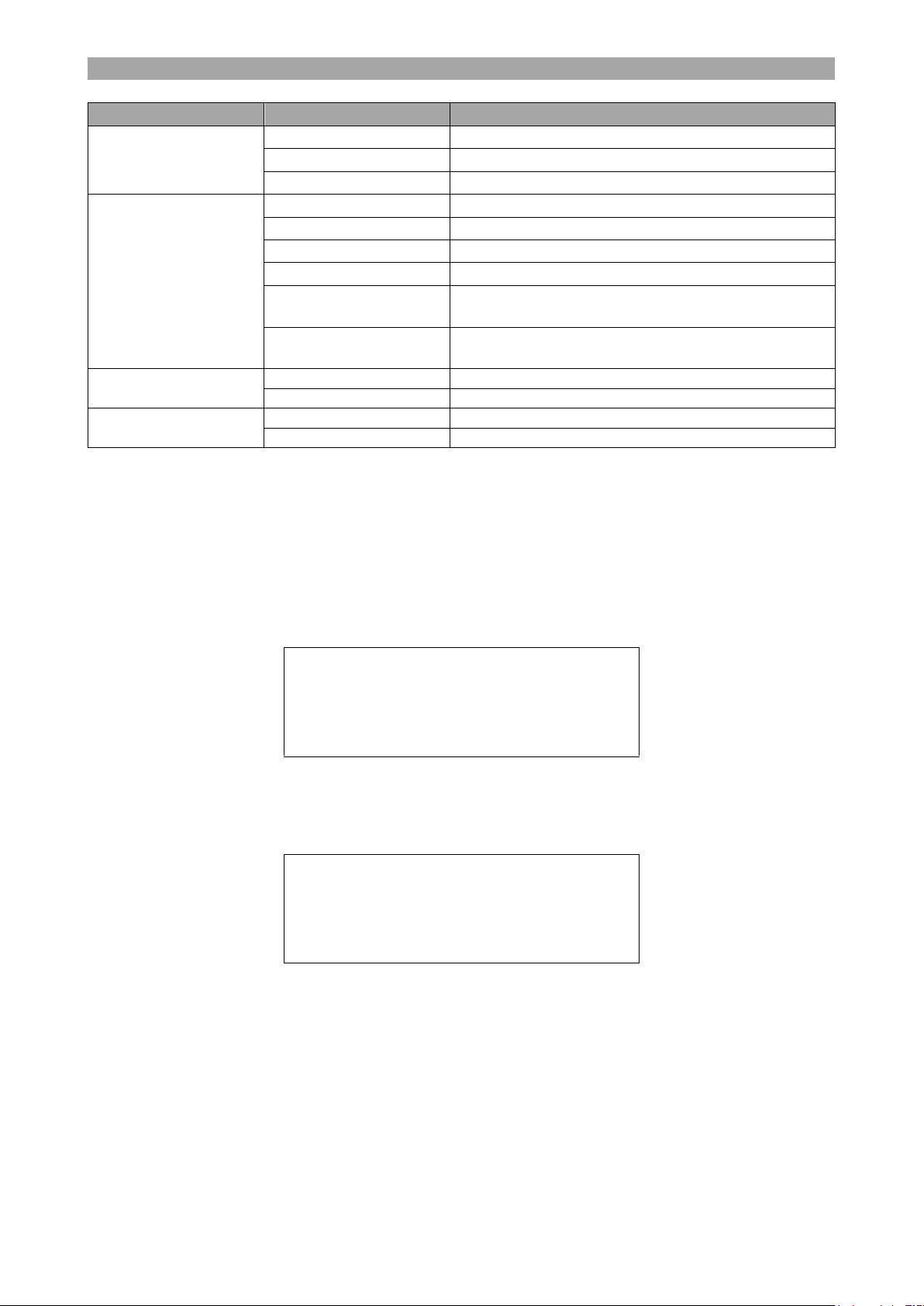

2. TECHNICAL FEATURES AND DIMENSIONS

2.1. Technical data

1. Nominal power output is obtained with fuel type C, calorific power 4,9 kWh/kg according to

standard EN 303-5:2012.

2.2. Pellet fuel

Pellet is used in an automatic way by means of an automatic pellet feeding mechanism. Only

wood pellets are to be used with this boiler. No other fuel is allowed to be used in the boiler. The

pellet is deposited in the fuel tank at the back of the boiler, and then automatically fed through

the feeder, which is controlled by the controller.

As fuel, it is recommended to use only premium quality wood pellet 6-8 mm diameter. Note that

if lower quality pellet is used, the ash produced can be signifantly bigger and the cleaning interval

more often. The pellet bags must be stored in a dry, not too cold environment.

Table 1. Pellet fuel characteristics

The quality of the pellets, calorific power, humidity and ash content is very

important for the boiler function and efficiency!

It is prohibited to manually feed pellets into the grate!

It is prohibited the use of processed wood pellets, or other chemical treatment.

It is prohibited the use of explosives, inflammable materials, plastic, domestic

residues, etc.

NEVER BURN ANY TYPE OF CORN, CHERRY PITS, STICKS OR OTHER TYPES OF FUEL

IN THE BURNER.

4

BOILER MOUNTING

3. BOILER MOUNTING

3.1. Transportation and delivery

The boiler is delivered on wood pallet. The loading and unloading of the boiler must be performed

with a forklift or a crane.

The boiler is very heavy. Do not try to lift by hands or other unsuitable

equipment. Danger of injury! Perform all moves with extreme caution.

Remove the boiler packaging with attention. Keep the packaging material away from

children since it can be dangerous. After having unpacked everything, make sure that the

appliance is intact and undamaged. In case of doubt do not use the appliance and inform the

supplier.

The COMPACT boiler is delivered with the following equipment:

Boiler steel body

Rockwool insulation mounted on the boiler body

Metal covers mounted on the boiler body

Incorporated pellet tank at the back of the boiler

Fuel feeder system

Pellet grate made of INOX steel

Ash box under the grate

Leveling supports

Electrical cable with plug

In the documentation folder you will find:

Technical manual

Warranty leaflet

3.2. General requirements

The boiler must be installed according to the applicable regulations as far as the chimney

installation and safety regulations are concerned. The installation should be performed only by

authorized personnel, and special care must be taken for the correct installation and draught of

the chimney.

The boiler must be placed on a horizontal plane, with adequate mechanical resistance to support

the boiler’s weight. The boiler can be installed in a special boiler room, or inside the house. The

installation must be performed in such a way so that it is easily accessible from all the sides.

The lack of draught from the chimney, or the obstruction of air intake can affect the correct

function of the product, cause error in the ignition, and even emit smoke.

The regular maintenance of the boiler must be performed at least once a year by an

authorized technician.

Special care must be taken for the air intake of the boiler, especially if the boiler is installed

in a narrow space.

Place a protective fireproof base (metal or ceramic) between the boiler and the floor,

especially if the floor is made of flammable material (wood, carpet).This board must be at

least 25-30 cm bigger in all directions than the dimensions of the boiler.

A safety distance is recommended between the sides of the boiler and walls, of at least 40

cm. This distance should be even bigger according to the objects close to the boiler (furniture,

curtains, decoration, etc.).

Make sure that the chimney remains clean and free of ash and obstacles at all times.

Pay attention so that the room temperature sensor positioned at the back of the boiler is not

close to the chimney.

Before every startup, or after an error or blackout, make sure that the grate is not full with

ash or pellet and the door is tightly closed.

After a fault startup, remove the unburnt pellet from the grate before you make a new startup.

5

BOILER MOUNTING

It is recommended to always keep clean the grate, in order to ensure long life and correct

ignition.

Do not ever use inflammable materials for manual ignition of the boiler!

Before any work of maintenance is effected, please turn off the boiler and disconnect from

electricity.

Do not open the boiler door during function!

Do not introduce any other materials for combustion in the pellet tank, or manually

in the grate, other than wood pellets!

3.3. Chimney

The chimney installation must supply sufficient draught, air tightness and protection against

condensation.

The appropriate chimney installation is very important for the boiler’s efficient

and safe function!

The chimney must be vertical, with no changes in the direction. The cross-section of the chimney

can be round or rectangular. If the chimney is installed in the exterior, it must be insulated. The

cross-section and total height of the chimney must be correctly calculated to ensure natural

draught.

The horizontal part connecting the boiler’s chimney pipe with the vertical chimney must have

maximum length 2 m. If this distance is bigger, it is recommended to have a 15-30o inclination

upwards. The connection with the boiler’s chimney pipe must be air-tight. If the total route of

the chimney pipe is more than 10 m, it is recommended to use a 100 mm chimney pipe.

It is prohibited to change the exhaust diameter by any means or reduction

between the boiler outlet and the vertical chimney pipe!

The chimney must be equipped with a cleaning door at its base. Also cleaning doors are

recommended where there are changes in direction and ash can be accumulated. Tactical

cleaning is recommended (every 3 months) for efficient boiler function.

A chimney terminal must be installed at the end of the chimney for protection against weather

effects and foreign objects entrance. In areas with strong winds a special anti-downdraught

terminal is recommended.

The chimney terminal must always be installed perpendicular to ground!

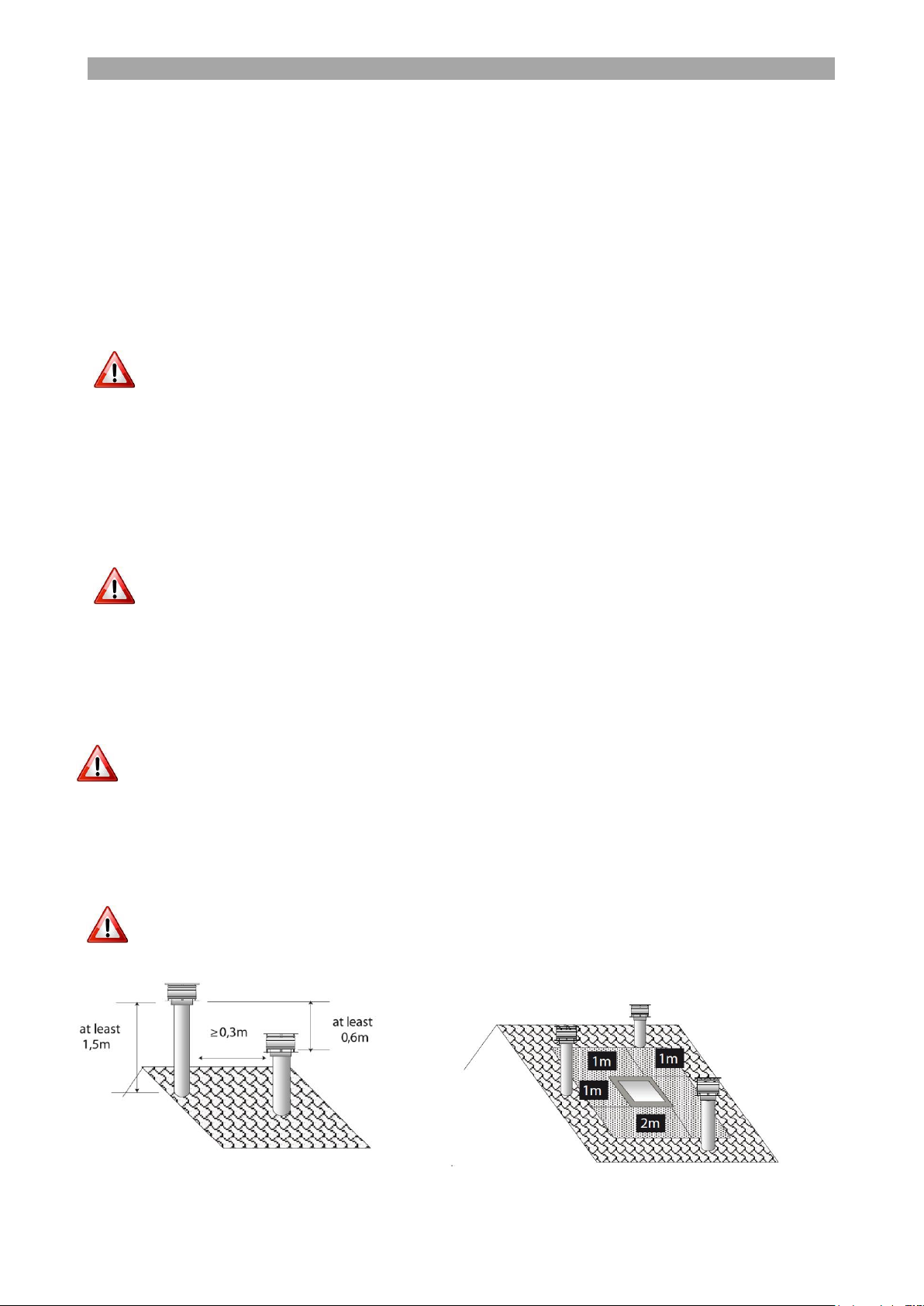

The chimney height must exceed the roofline by at least 1 m. If there are other obstacles

positioned on the roof, the chimney height must exceed them by at least 1 m. If there are

multiple chimneys, minimum distance between them is 0,3m.

Each boiler should be connected to an independent chimney. Connection of multiple

boilers to the same chimney is not recommended.

It is prohibited to use as a chimney flexible aluminum tube!

Fig 2. Chimney distances

6

BOILER MOUNTING

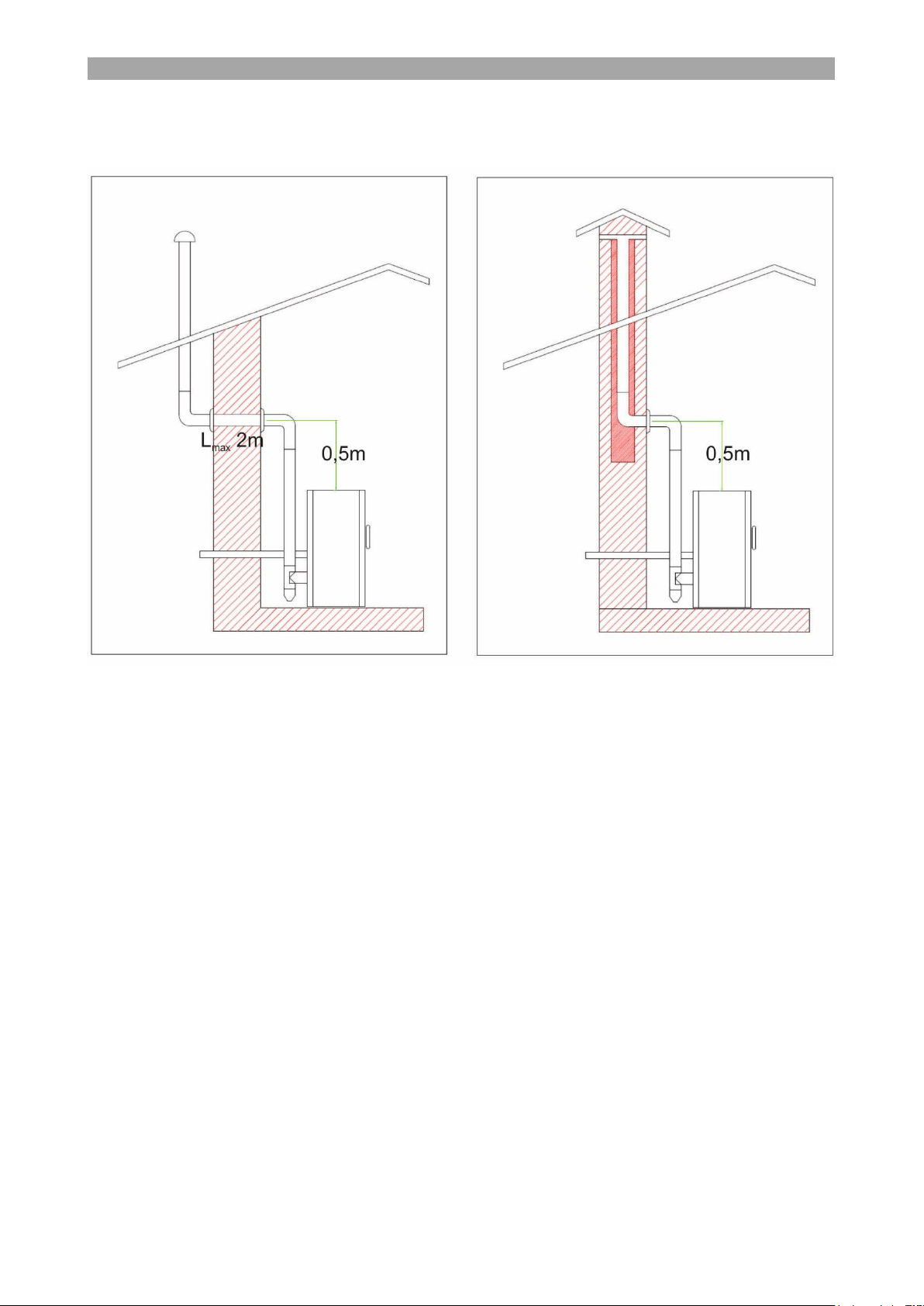

The vertical chimney pipe can be installed partially inside as in Fig 3, with a maximum of two

90o elbows. The vertical chimney pipe must have a height of minimum 2 m. All chimney

connections must be sealed with a temperature resistant silicon gasket.

Fig 3. Chimney connection

3.4. Air intake

The necessary for combustion air intake of the boiler is absorbed externally through an air intake

pipe that must be installed, as seen above. The air intake pipe must be protected with a grate,

according to UNI 10683.

The air intake can also be absorbed from the installation space. In this case, special care must

be taken so that sufficient air supply is given to the installation room by means of air intakes

surfaces, which must be protected with a grate, according to UNI 10683.

Periodically, the air intake pipes must be controlled against blocking.

7

INSTALLATION

Legend

1

Outlet

2

Return

3

Chimney pipe

4

Air intake pipe

5

Room temperature sensor

6

External thermostat connection (THERM)

7

Service programmer connection (JA)

8

General ON/OFF switch and electrical connection

9

STB overheating thermostat

4. INSTALLATION

4.1. Boiler connections

The boiler comes preassembled with all necessary for function hydraulic components (pump,

expansion vessel, safety valve, air-relief valve). All connections are performed at the back of the

boiler. There are two side doors for access inside the hydraulic of components of the boiler.

The boiler is intended for maximum working temperature 85oC and maximum pressure 3 bar.

Safety valve is not installed inside the boiler, it must be installed externally and

connected to the drainage!

External thermostat connection must be simple electrical switch (ON/OFF).

Voltage feed in these terminals can destroy the controller!

8

INSTALLATION

4.2. Return temperature protection

For the correct function of the boiler and for protection against corrosion it is very important to

ensure steady temperature at the return of the boiler of at least 55oC.

This can be ensured by installing a recirculation pump between the boiler outlet and return (see

connection diagrams).

An alternative variation is by installing at the return of the boiler a three-way thermostatic valve.

Having a return temperature less than 55oC is very dangerous for the boiler longlife and can cause warranty loss!

4.3. Filling the system

After completing all the hydraulic connections, the circuit may be filled with water. After filling

the system, open the radiators air valves to get rid of the air in the installation.

Verify that the installation pressure is according to the technical features of the boiler. A

manometer should be installed on the cold water inlet to verify the cold pressure, at the lowest

point of the installation, at a point close to the boiler.

The whole installation must remain under nominal pressure for at least 10 minutes. During this

period, check that all the connections are tight and there are no water leakages. Make sure that

during this period no pressure drop appears.

After firing the boiler, make sure the network functions properly at working temperature and

pressure.

The hardness of the mains water supply affects the boiler’s life span. It is

recommended to use a water softener if water hardness exceeds 15of.

Do not fill the system at the working pressure! When the boiler will be heated,

the water pressure will raise. Filling pressure must be at least 1 bar lower than

working pressure!

4.4. Electrical connections

The electrical connection is performed by the given cable. Plug the one end at the IEC plug at

the back of the boiler, and the other end to a 230V plug. The plug where the boiler will be

connected must have grounding, and must be ensured that has tension in nominal parameters.

The plug on the boiler is protected with an incorporated electrical fuse and has a general electrical

switch ON/OFF.

Make sure that the electric cable is not in contact with hot parts of the boiler or the chimney,

and is not crushed by heavy parts.

THERMOSTAHL ROMANIA SRL declines any liability for damage caused to

people, animals and goods, due to defects caused by faulty electrical

connections or lack of connecting the boiler to an efficient grounding system.

9

CONTROLLER

Button

Function

MODE / ESC

1

Mode selection (Manual, Auto) / Keep pressed to exit

-

2

Value decrease / menu navigation

MENU / OK

3

Menu enter / Setting confirmation

+

4

Value increase / menu navigation

5

Controller ON/OFF button / exit to main menu

IR

Remote control receiver

D

Display

2 2 .0

°C

1 1 1 4 6 5 .0

°C H 2 O

1 1 1 4

T H E R M O S T A H L

< T i p p r o d u s >

P r e s s M e n u 2 8 .0

°C H 2 O 1 1 1

4

F i r e : 5 T e r m : C O F F

5. CONTROLLER

5.1. General description

Description of buttons

5.2. Operation functions

After switching the boiler on from the main switch at back side, press the controller ON/OFF

button to activate the controller. The following messages will appear on the display on sequence:

10

CONTROLLER

FUNCTION

DISPLAY MESSAGE

DESCRIPTION

Function menu

Manu

Manual mode

Auto

Auto mode

Eco activated

Eco mode

Boiler status

IGNITION

Ingition mode

ON

Normal operation

SHUTDOWN

Fire off mode

OFF

Device stopped

STOP AFTER

BLACKOUT

Device stop after electric blackout

IGNITION AFTER

BLACKOUT

Ignition mode after electric blackout

Chronothermostat

Chrono programmer

Chronothermostat programming activated

Sleep 12:30

Slepp mode activated

Error

Error**

Automatic error recognition

ALARM

Alarm activated, boiler stopped

M o d e A U T O M e n u

T e m p 2 3

°C F a n A

e s c 2 3

°C O k

- T e m p e r . +

By pressing the MODE button the boiler can be changed to one of the available function modes:

manual mode (MANU), automatic (AUTO), economic (ECO).

5.2.1. AUTO mode

In mode AUTO, the boiler will automatically adjust the power level according to the temperature

settings chosen and the signal from the room temperature sensor (if activated). If the room

thermostat contact is open, the boiler will go to minimum power, but will not shut down.

In AUTO mode on the display will appear the following message:

By pressing the Button 2 (-) the room temperature can be adjusted from 5 to 35oC. By keeping

pressed the Button 2 (-), the following message will appear on the display and the same setting

can be adjusted here through the Buttons 2 (-) and 4 (+):

If the room temperature sensor is deactivated, the message Temp 0 will be shown instead, the

set point for mode AUTO will be the water temperature selected, and the room temperature

sensor will behave as an ON/OFF signal.

By pressing the Button 4 (+) the power level can be adjusted.

11

CONTROLLER

M o d e M A N U M e n u

F i r e 2 3

°C F a n A

e s c O k

- F i r e +

M o d e E C O M e n u

T e m p 2 3

°C F a n A

e s c 2 3

°C O k

- T e m p e r . +

5.2.2. MANUAL mode

In mode MANU, the power level of the boiler can be manually selected. The room thermostat

doe not function in this mode. In MANU mode on the display will appear the following

message:

By pressing the Button 2 (-) power level can be adjusted from Fire 1 to Fire 5. By keeping

pressed the Button 2 (-), the following message will appear on the display and the same setting

can be adjusted here through the Buttons 2 (-) and 4 (+):

The use of MANUAL mode is restricted for service settings and should not be

used in normal operation.

5.2.3. ECO mode (recommended)

In mode ECO, the power level of the boiler can be manually selected. If the room thermostat

contact is open, the boiler will go to minimum power, and will shut down after a preset

time. In ECO mode on the display will appear the following message:

By pressing the Button 2 (-) the room temperature can be adjusted from 5 to 35oC. By keeping

pressed the Button 2 (-), the following message will appear on the display and the same setting

can be adjusted here through the Buttons 2 (-) and 4 (+):

If the room temperature sensor is deactivated, the message Temp 0 will be shown instead, the

set point for mode ECO will be the water temperature selected, and the room temperature sensor

will behave as an ON/OFF signal.

By pressing the Button 4 (+) the power level can be adjusted.

12

CONTROLLER

MENU

PARAMETER

VALUE RANGE

RECOMMENDED

SETTING

Water temp.

Heating temp.

40-85oC

65-75oC

Sanitary temp.

30-65oC

45oC

MENU

PARAMETER

VALUE RANGE

Date & Time

Time

00–23

Minutes

0–59

Day

Mo-Tu-We-Th-Fr-Sa-Su

Day Number

1–31

Month

1–12

Year

2010-2109

e s c S e t

< W a t e r T e m p . >

e s c S e t

< D a t e & T i m e >

5.3. Menu functions

By pressing the Button 3 (MENU/OK) the different menu windows can be cyclically navigated.

There are 5 main menu windows, in order to access the parameters of a menu, press the Button

3 (MENU/OK).

In order to modify a parameter, press the Button 3 (MENU/OK) with indication Set. At this

point, the indication will change to OK, and the chosen parameter will blink. Change the value

through the Buttons 2 (-) and 4 (+). Confirm the value by pressing the Button 3 (MENU/OK).

After setting the value, use the Buttons 2 (-) and 4 (+) to navigate to the next parameter.

Press the Button 1 (MODE/ESC) at any point to go up a menu level. Press the Button 5

(ON/OFF) at any point to exit to the main window.

5.3.1. Water temperature

The water temperature for heating and sanitary mode can be set at this menu. On the display

the following message will appear:

5.3.2. Date and time

The date and time can be set at this menu. On the display the following message will appear:

5.3.3. Chronothermostat

In this menu, the user can set 6 different programs for each individual day of the week, this

meaning that there is a total available of 6*7=42 programs. On the display the following

message will appear:

13

CONTROLLER

MENU

PARAMETER

VALUE RANGE

RECOMMENDED

SETTING

Chrono

Enable

On / Off

Accordingly

Load Profile

1-10

1

Reset Chrono

Confirm?

Ok

Prog. 1-6

for each

individual

day

P1 Enable

On / Off

Accordingly

P1 Start

00.00-23.59 / Off

Accordingly

P1 Stop

00.00-23.59 / Off

Accordingly

P1 Air Temp.

5-35oC

18-25oC

P1 Heat Temp.

40-85oC

60-80oC

P1 Fire

1-5

Accordingly

P1 Days

Mo-Tu-We-Th-Fr-

Sa-Su

e s c S e t

< C h r o n o >

e s c o f f S e t

< S l e e p >

After activating the chronothermostat, the user can choose the individual settings for every

program and day of the week. The Reset parameter will null all the settings of the current

program.

For every program the start time and stop time of the boiler can be set from the corresponding

parameters P1 Start and P1 Stop, as well as the air temperature, water temperature, and power

level settings for this time interval.

Finally, with the P1 day parameter the day of the week when this program will be applicable can

be chosen.

After completing the P1 program, the same procedure is used to set P2-6 programs.

Pay attention during the weekly programming, so that different settings do not

interfere for same day and time intervals.

5.3.4. Sleep mode

This option is available only while the device is activated and is in ignition or function mode. In

this menu, the user can set the automatic stop of the boiler at a certain time. On the display the

following message will appear:

Use the Buttons 2 (-) and 4 (+) to set the stop time of the boiler and the Button 3

(MENU/OK) to save this option.

14

CONTROLLER

MENU

PARAMETER

VALUE RANGE

RECOMMENDED

SETTING

Settings

Language

En-It-Fr-Es-Gr

En

Eco

On / Off

On

Back Light

01-1000 s

Accordingly

Tones

On / Off

On

o

C / oF / Auto

o

C / oF

o

C

Recipe

Pellet Temp.

States

-5...+5

0

Pellet Power

States

-5...+5

0

Air Flow Temp.

States

-10...+10

0

Air Flow Power

States

-10...+10

0

Thermosat

Activation

On / Off

Accordingly

Charge

Pellets

Activation

Ok

Cleaning

Activation

Ok

Start

Pump

Activation

Ok

e s c S e t

< S e t t i n g s >

5.3.5. Settings

In this menu, the user can make general configuration settings of the device. On the display the

following message will appear:

The Eco parameter activates or deactivates the Eco mode.

The Back Light parameter sets the permanent lighting of the display (On) or for a certain amount

of time after pressing a button (01-1000 s).

The tones parameter will enable the keyboard sound when pressing a button.

Through the Recipe parameters, the pellet feeding and air supply can be adjusted individually

for the ignition mode (Temp. States) and the function mode (Power States). For every unit

interval, a 2,5% modification is performed to all the power levels.

Through the Thermostat parameter, the integrated room temperature sensor can be activated

(On) or deactivated (Off).

The last three parameters are used to manually activate the individual devices (feeder,

cleaning motor, pump), and must be used only during service by authorized technician.

15

CONTROLLER

CODE

MESSAGE

SOLUTION

A01

Failed ignition

Clean the grate from pellets and retry igntition

A02

No flame

Fill the tank with pellets

A03

Tank overheating

Check the fuel tank temperature sensor

A04

Exhaust temperature alarm

Check the exhaust temperature sensor and the

combustion settings

A05

Chimney block

Check the chimney condition, clean from ash and

possible obstacles

A06

Insufficient combustion air

Clean the grate, the air intake, the chimney

A07

Open door

Make sure the door is closed

A08

Exhaust fan damage

Call service

A09

Exhaust temperature damage

Call service

A10

Ignitor damage

Call service

A11

Pellet feed damage

Call service

A13

Controller damage

Call service

A15

Pellet level alarm

Check the fuel level in the tank

A16

Water pressure

Assure correct pressure of the installation

A18

Water temperature overheating

Investigate the causes of overheating

MESSAGE

DESCRIPTION

Service

Call the service for regular maintenance

Ex. temperature sensor error

The exhaust temperature sensor is damaged

Water temperature sensor error

The boiler water temperature sensor is damaged

Water pressure sensor error

The water pressure sensor is damaged

Water pressure out of limits

The water pressure in the heating installation is out of

limits

e s c S e t

< E r r o r >

i n f o A L A R M A 0 1

<

Alarm description

>

5.4. Error signals

The controller automatically recognizes the corresponding error, and will inform the user by

displaying the corresponding error code on the display. The errors are divided in two categories:

5.4.1. Errors

Errors are minor importance faults during operation. By pressing the Button 3 (MENU/OK),

the description of the error appears on the display. These minor errors do not stop the function

of the boiler. When an error incures, the following message will appear on the display:

5.4.2. Alarms

An alarm will be activated when a major safety issue will incure. When an alarm incures, the

ALARM message will blink on the display, and an alarm code and description will appear. The

following message will appear on the display:

By pressing the Button 1 (MODE/ESC), an indication of the alarm cause will appear, according

to the following table:

16

BOILER START-UP

2 2 .0

°C 1 1 1

4

I G N I T I O N

6. BOILER START-UP

6.1. Initial lighting checks

Before you start the boiler, make the following checks:

Check all the hydraulic connections and make sure they are tight. Make sure there is no

leakage or moisture on the pipes or other equipment.

Make sure that the connection with the chimney is air-tight and the chimney installation is

properly made.

Make sure that the pressure in the network is correct.

Check that the boiler pump functions properly.

Make sure the boiler’s separation valves are open.

Make sure that there is sufficient air supply and natural ventilation in the room.

Make sure there is pellet in the pellet tank.

Do not store inflammable materials or fuel close to the boiler! Before you light

the boiler make sure the room is clear and safe.

6.2. Start-up of the boiler

6.2.1. Manual start-up

Keep pressed the Button 5 (ON/OFF) for 2 seconds until the message IGNITION will appear

on the display.

6.2.2. Start-up by the room temperature sensor

The boiler will automatically start when the room temperature value is below the set limit. This

mode will be enabled only if the room temperature sensor is activated (see paragraph 5.3.5),

the AUTO or ECO mode is chosen, and the boiler is activated by the main electrical switch.

6.2.3. Start-up by the chronothermostat

The boiler will automatically start according to the chronothermostat settings (see paragraph 0),

given that the AUTO or ECO mode is chosen and the boiler is activated by the main electrical

switch.

6.2.4. Start-up by external room thermostat

The boiler will automatically start when signaled from an external room thermostat. This requires

an external room thermostat to be connected to the corresponding terminals setting s (see

paragraph 4.1), given that the AUTO or ECO mode is chosen and the boiler is activated by the

main electrical switch.

17

BOILER STOP

2 2 .0

°C 1 1 1

4

S T O P

7. BOILER STOP

7.1.1. Manual stop

Keep pressed the Button 5 (ON/OFF) for 2 seconds until the message STOP will appear on the

display.

7.1.2. Stop by the room temperature sensor

The boiler will automatically stop when the room temperature value has reached the set limit.

This mode will be enabled only if the room temperature sensor is activated (see paragraph

5.3.5), the AUTO or ECO mode is chosen, and the boiler is activated by the main electrical switch.

7.1.3. Stop by the chronothermostat

The boiler will automatically stop according to the chronothermostat settings (see paragraph 0),

given that the AUTO or ECO mode is chosen and the boiler is activated by the main electrical

switch.

7.1.4. Stop by SLEEP mode

The boiler will automatically stop according to the SLEEP mode settings (see paragraph 5.3.4).

The Sleep mode has priority over other settings made in the Chronothermostat menu.

7.1.5. Stop by external room thermostat

The boiler will automatically stop when signaled from an external room thermostat. This requires

an external room thermostat to be connected to the corresponding terminals settings (see

paragraph 4.1), given that the AUTO or ECO mode is chosen, and the boiler is activated by the

main electrical switch.

Do not stop the boiler by means of the main electrical switch ON/OFF! This can

cause damage to the boiler and may lead to alarm signals.

18

SERVICE AND MAINTENANCE

8. SERVICE AND MAINTENANCE

8.1. Cleaning the boiler

Solid fuel boilers require regular cleaning in order to function properly and efficient. Cleaning

must be effected at least once a week.

The boiler function must be stopped before cleaning! Make sure all the devices

are stopped, and the boiler has cooled down. It is strictly prohibited to clean the

boiler while in function!

8.2. Maintenance intervals

8.2.1. Daily maintenance

The pressure of the network must be daily verified to be within the allowed limits. Make sure

that all the safety devices and pumps function properly.

8.2.2. Weekly maintenance

The boiler and the burner must be cleaned every 3-4 days or at least once a week, depending

on the ash quantity accumulated. The ashes are collected to the ash box positioned under the

grate. Check regularly the quantity of ash accumulated in the ash box.

In order to clean the heat exchanger, open the external door cover and use the lever provided.

Push down firmly 3-5 times.

in order to clean the ash, open the external door cover

and the internal boiler door. Scrape the ashes from all

the surfaces. Empty the ashes from the grate and make

sure all the holes are clear of ashes and other obstacles.

The cleaning of the grate and the ash box can be made

also by means of a special vacuum cleaner.

All cleaning works should be done when

boiler is stopped and cooled!

8.2.3. Periodical maintenance

A periodical maintenance should be effected by an authorized technician. The frequency of this

maintenance depends on pellet quality, function time, chimney installation.

Call the service whenever the message Service appears on the display for periodical

maintenance, or there are difficulties on the boiler function.

8.2.4. Annual maintenance

It is obligatory that an annual maintenance is effected by an authorized technician. This includes

a general cleaning of the boiler and the heat exchanger, as well as a control of the electrical and

mechanical parts and all the safety equipment of the boiler.

Check the doors and the sealing cord. Make sure the contact with the boiler is air-tight. If ash

has accumulated on the sealing cord, clean it.

Empty the pellet tank to avoid moisture accumulation that can lead to wet pellets and feeder

blockage.

19

THERMOSTAHL ROMANIA

HEATING SYSTEMS S.R.L.

DRUMUL OSIEI 57-59, sector 6

Bucharest 062395, Romania

www.thermostahl.ro

20

Loading...

Loading...