Page 1

BIOMASS-SOLID FUEL RETORT BOILER

BIOPLEX MCL-BIO

INSTALLATION AND SERVICE MANUAL

VERSI ON:

2.1

UPDATE:

10.10.2013

Page 2

Contents

1. GENERAL INFORMATION ................................................................................................. 3

1.1. Proper use of the appliance .............................................................................................. 3

1.2. Safety warnings .............................................................................................................. 3

1.3. Data label ...................................................................................................................... 3

1.4. Document information ..................................................................................................... 3

2. TECHNICAL FEATURES AND DIMENSIONS ....................................................................... 4

2.1. Technical features ........................................................................................................... 4

2.2. Function principle ............................................................................................................ 5

2.2.1. Boiler ...................................................................................................................... 5

2.2.2. Furnace ................................................................................................................... 5

2.3. Dimensions .................................................................................................................... 6

2.4. Fuel ............................................................................................................................... 8

3. BOILER MOUNTING ......................................................................................................... 9

3.1. Transportation and delivery .............................................................................................. 9

3.2. Boiler room .................................................................................................................. 10

3.2.1. General requirements ............................................................................................. 10

3.2.2. Boiler room dimensions ........................................................................................... 10

3.3. Chimney ...................................................................................................................... 11

4. INSTALLATION .............................................................................................................. 13

4.1. Hydraulic connections .................................................................................................... 13

4.2. Safety features ............................................................................................................. 13

4.3. Overheating serpentine .................................................................................................. 14

4.4. Return temperature protection ........................................................................................ 14

4.5. Filling the system .......................................................................................................... 15

4.6. Automatic ignition system .............................................................................................. 15

4.7. Connection diagrams ..................................................................................................... 16

4.7.1. Open expansion vessel connection ............................................................................ 16

4.7.2. Closed expansion vessel connection .......................................................................... 17

5. ELECTRICAL CONNECTIONS ........................................................................................... 18

5.1. General instructions ...................................................................................................... 18

5.2. Control panel functions .................................................................................................. 18

5.3. Wiring diagram ............................................................................................................. 19

6. BOILER START-UP ......................................................................................................... 20

6.1. Initial lighting checks ..................................................................................................... 20

6.2. Start-up ....................................................................................................................... 20

6.3. Checks to carry after initial start-up ................................................................................ 20

6.4. Fuel loading .................................................................................................................. 21

6.5. Combustion regulation ................................................................................................... 21

6.6. Chimney damper adjustment .......................................................................................... 22

7. SERVICE AND MAINTENANCE ........................................................................................ 23

7.1. Cleaning ...................................................................................................................... 23

7.1.1. Cleaning the boiler ................................................................................................. 23

7.1.2. Cleaning the chimney box ....................................................................................... 24

7.1.3. Cleaning the furnace ............................................................................................... 24

7.2. Maintenance intervals .................................................................................................... 24

7.2.1. Daily maintenance .................................................................................................. 24

7.2.2. Weekly maintenance ............................................................................................... 24

7.2.3. Monthly maintenance .............................................................................................. 24

7.3. Basic service procedures ................................................................................................ 25

7.3.1. Service after overheating ........................................................................................ 25

7.3.2. Service after feeder blockage ................................................................................... 25

7.3.3. Service after motor bolt breakage ............................................................................ 27

7.3.4. Service after power blackout .................................................................................... 27

7.3.5. Replacement of the ignition element ......................................................................... 27

7.4. Maintenance after long stop ........................................................................................... 28

7.4.1. Maintenance of the boiler ........................................................................................ 28

7.4.2. Maintenance of the furnace ...................................................................................... 29

8. TROUBLESHOOTING ...................................................................................................... 30

9. WARRANTY .................................................................................................................... 31

Page 3

GENERAL INFORMATION

3

1. GENERAL INFORMATION

1.1. Proper use of the appliance

Before you make use of this appliance make sure you have read and fully understood the

instructions included in this manual.

The installation and use of the appliance must be performed according to the instructions

indicated in this manual in combination with the current national safety regulations.

The appliance is designed for use in pumped hot water central heating systems. Any other use

is considered improper and is prohibited. THERMOSTAHL declines any responsibility for

damages or injuries caused by improper use; in this case the risk is completely at the user’s

responsibility.

To ensure an efficient and flawless function of the appliance, it is strongly recommended that

you have performed an annual service by a qualified technician.

1.2. Safety warnings

All installation and maintenance procedures must be carried out by professional and authorized

personnel, in compliance with the indications in the present manual and national regulations.

Any failure to correctly install this appliance could cause damage or injuries!

Do not make modifications to parts of the appliance, unless you have contacted the company

and an authorized service contractor.

Only original accessories and spare parts must be used to ensure correct and safe function.

Make sure you respect the cleaning and maintenance procedures on the corresponding

intervals. Failure to do so can cause malfunction to the appliance and possible damages.

The boiler is design to function on the fuels indicated in the corresponding paragraph. Any

other fuel is prohibited. Do not use explosive or flammable substances! Do not store such

substances inside the boiler room.

The working pressure varies according to the model. Make sure you use the appropriate water

pressure. Working in a pressure higher than the one indicated in this manual is

strictly prohibited and dangerous!

1.3. Data label

The data label of the appliance is placed on the boiler’s side cover, on the external part. Make

sure that it is properly placed and readable.

On the label it is indicated the serial number and the manufacturing year of the appliance.

1.4. Document information

This document is an integral and indispensable part of the product and must be retained in

good condition by the user. Keep it in a safe place for future reference.

If the appliance is sold or transferred to another person, this manual has to always follow the

appliance and handed to the new user or installer.

Page 4

TECHNICAL FEATURES AND DIMENSIONS

4

2. TECHNICAL FEATURES AND DIMENSIONS

2.1. Technical features

BIOPLEX boiler is a steel solid fuel boiler, with cylindrical heat exchanger consisted of fire

tubes. The furnace system BIOFIRE made of steel plates. The furnace plate and grates that

come in contact with fire are made of special refractory cast iron.

The boiler body is made of cold rolled steel St 37.2 STAS 500/2-80~S235 JR SR EN 10025/90

according to DIN 17100. The boiler is designed so that all the parts in contact with exhaust

gases are water cooled. The boiler body parts are assembled by welding. Weldings are

performed according to standards 288-1 and 288-3 according to DIN 50120, 50121-50145, SR

EN 1011.1/2001, by means of electric arc welding (MIG-MAG).

DESCIPTION OF BOILER COMPONENTS

Steel boiler body with cylindrical heat exchanger

Removable rear smoke box with inspection cleaning door

Upper door for cleaning the heat exchanger

Middle door for ignition and fuel loading, equipped with an inspection flange, which can also

be used for a burner mounting

Lower door for ash removal

Ash box positioned on the lower part of the fire chamber

Cast iron catalyst positioned above the furnace

Rockwool body insulation of 50 mm thickness

Electrostatically painted external covers

Control panel for electromechanical operation

Safety heat exchanger (optional)

DESCIPTION OF FURNACE COMPONENTS

Steel furnace body

Feeding auger welded to solid axis

Combustion air fan

Feeding motoreducer

Transmission system with chain wheels

Transmission system protection cover

Cast iron combustion plate

Cast iron grates for manual wood feeding

Ignition element (optional)

Fuel silo with protection frame and shuttering lid

Page 5

TECHNICAL FEATURES AND DIMENSIONS

5

2.2. Function principle

2.2.1. Boiler

The function of the BIOPLEX boiler is

based on natural gas evacuation through

the chimney. The fuel is positioned on the

grate. The combustion takes place in the

fire chamber. During the combustion the

flame comes in contact with the side

walls of the fire chamber, which are

surrounded by water. The fire chamber is

of big volume in order to receive big

dimension logs and to ensure a long

autonomy.

The combustion air is supplied by the fan

and distributed through an air distributor,

positioned below the fuel grate. The

combustion is regulated through the fan,

controlled by the control panel.

Fig 1. Boiler function

The exhaust gases are guided through the heat exchanger to the smoke box, and afterwards

evacuated to the chimney. The smoke box is equipped with an inspection and cleaning door,

which also actions as an explosion relief.

The doors have an insulation cord to ensure air-tight closing. Each door is equipped with a

screwed handle, which must always be well tightened during the combustion. The flange on

the middle door has a rotating clamp, for secondary air adjustment and flame inspection. If

necessary, this flange can be removed, and a burner can be placed in its position.

2.2.2. Furnace

The BIOPLEX boiler is equipped with the innovative biomass furnace BIOFIRE. The system is

consisted of two axes (BI-AX): The lower axis is the main one, feeding fuel to the furnace,

while the upper is the secondary, transporting the fuel from the silo to the main axis. Between

the two axes there is a safety DROPBOX device. This device has a metal flap that automatically

closes with a spring when the feeding stops. This way the danger of blockage and backfire is

eliminated. The motoreducer is mounted on the lower axis, and the transmission is realized

through chain wheels. A metal protection cover is places around the transmission system.

The combustion air is supplied by the fan mounted on the furnace. In case the optional ignition

system is installed, there is a 500W ignition element

mounted in the air pipe, close to the furnace plate.

Legend

1

Silo flange

2

Fuel box

3

Upper feeding axis

4

Transmission chain

5

Motor

6

Reducer

7

Support leg

8

Fan

9

Boiler flange

10

Lowe feeding axis

11

Mixing chamber

12

Fuel DROPBOX

13

Cast iron plate

14

Lower feeding axis

Page 6

TECHNICAL FEATURES AND DIMENSIONS

6

2.3. Dimensions

DIMENSIONS

Type

Feeding

door

A

A1

A2 B H

H1 E C

T3

T1-

T2

T5

T6

mm

mm

mm

inch

MCL-BIO 20

350x480

630

670

1470

560

1280

1380

960

860

195

1½”

1”

¾”

MCL-BIO 28

350x480

630

670

1470

660

1280

1380

960

960

195

1½”

1”

¾”

MCL-BIO 36

350x480

630

670

1470

760

1280

1380

960

1060

195

1½”

1”

¾”

MCL-BIO 45

350x480

630

670

1470

860

1280

1380

960

1160

195

1½”

1”

¾”

MCL-BIO 53

350x480

630

670

1470

960

1280

1380

960

1260

245

2”

1”

¾”

MCL-BIO 60

350x480

630

670

1470

1060

1280

1380

960

1360

245

2”

1”

¾”

MCL-BIO 70

600x360

910

810

1700

860

1600

1720

1240

1280

245

2”

1 ¼”

¾”

MCL-BIO 80

600x360

910

810

1700

980

1600

1720

1240

1380

245

2”

1 ¼”

¾”

MCL-BIO 90

600x360

910

810

1700

1100

1600

1720

1240

1480

245

2”

1 ¼”

¾”

MCL-BIO 100

600x360

910

810

1700

1200

1600

1720

1240

1580

295

2 ½”

1 ¼”

¾”

MCL-BIO 120

600x360

910

810

1700

1330

1600

1720

1240

1680

295

2 ½”

1 ½”

¾”

MCL-BIO 140

600x360

910

810

1700

1580

1600

1720

1240

1750

295

2 ½”

1 ½”

¾”

MCL-BIO 160

600x360

910

810

1700

1830

1600

1720

1240

2000

295

2 ½”

1 ½”

¾”

MCL-BIO 180

600x360

910

810

1700

1830

1600

1720

1240

2300

295

2 ½”

1 ½”

¾”

MCL-BIO 200

500x810

1100

1000

2050

1350

2000

2160

1500

1950

345

3”

2”

2x¾”

MCL-BIO 250

500x810

1100

1000

2050

1600

2000

2160

1500

2200

345

3”

2”

2x¾”

MCL-BIO 300

500x810

1100

1000

2050

1850

2000

2160

1500

2450

395

4”

2”

2x¾”

MCL-BIO 350

500x810

1100

1000

2050

1850

2000

2160

1500

2450

395

4”

2 ½”

2x¾”

MCL-BIO 400

500x810

1100

1000

2050

2100

2000

2160

1500

2650

395

4”

2 ½”

2x¾”

MCL-BIO 450

500x810

1100

1000

2050

2100

2000

2160

1500

2650

395

4”

2 ½”

2x¾”

MCL-BIO 500

1230x520

1540

1440

2400

1600

2400

2650

1750

2300

445

5”

2 ½”

2x¾”

MCL-BIO 550

1230x520

1540

1440

2400

1600

2400

2650

1750

2300

445

5”

2 ½”

2x¾”

MCL-BIO 600

1230x520

1540

1440

2400

1800

2400

2650

1750

25700

445

5”

2 ½”

2x¾”

MCL-BIO 650

1230x520

1540

1440

2400

1800

2400

2650

1750

25700

445

5”

2 ½”

2x¾”

MCL-BIO 700

1230x520

1540

1440

2400

2150

2400

2650

1750

2820

495

6”

2 ½”

2x¾”

MCL-BIO 800

1230x520

1540

1440

2400

2400

2400

2650

1750

3070

495

6”

3”

2x¾”

MCL-BIO 900

1230x520

1640

1540

2400

2600

2870

2650

1750

3350

495

6”

3”

2x¾”

Page 7

TECHNICAL FEATURES AND DIMENSIONS

7

*Nominal output is obtained with good quality wood pellet.

**Pellet consumption is calculated as average, based on pellet with calorific power 4.800

kcal/kg and external temperature 0oC.

FURNACE TECHNICAL DATA

Furnace type

BIOFIRE I

BIOFIRE II

BIOFIRE III

BIOFIRE IV

Boiler range

MCL-BIO 20-60

MCL-BIO 70-90

MCL-BIO 100-200

MCL-BIO 250-500

MCL-BIO 550-900

Fan

Type RV-12RK

RV-06

RV-05

RV-25 RK

RV-21 RK

Power W 80

80

85

230

250

Air debit

m3/h

240

350

400

580

900

Pressure

Pa

310

300

300

520

550

Voltage

V/Hz

230/50

230/50

230/50

230/50

Noise level

dB

<60

<60

<60

<60

Protection

IP 20

IP 20

IP 20

IP 20

Motor

Type

EWM 30-50/300

EWM 30-50/300

MAF 071 AR2-0

MAF 071 AR2-0

Power W 180

180

370

370

Voltage

V/Hz

230/50

230/50

380/50

380/50

Protection

IP 54

IP 54

IP 54

IP 54

Silo volume

lit

370

600

950

1.500

Weight

kg

200

250

320

450

BOILER TECHNICAL DATA

Boiler type

Nominal Output*

P

max

Fire

chamber

length

Pellet

consumption**

Max.

wood

length

Silo

volume

Weight

kcal/h

kW

bar

mm

kg/h

mm

lit

kg

MCL-BIO 20

20.000

23 3 450

2,0-3,0

400

370

380

MCL-BIO 28

28.000

32 3 550

3,0-4,0

500

370

420

MCL-BIO 36

36.000

41 3 650

4,0-5,0

600

370

460

MCL-BIO 45

45.000

52 3 750

5,0-6,5

700

370

500

MCL-BIO 53

53.000

61 3 850

6,0-7,0

800

370

550

MCL-BIO 60

60.000

69 3 950

7,0-8,5

900

370

600

MCL-BIO 70

70.000

81 3 700

7,5-9,5

650

600

750

MCL-BIO 80

80.000

93 3 820

7,5-9,5

750

600

880

MCL-BIO 90

90.000

104 3 920

8,5-10,0

850

600

930

MCL-BIO 100

100.000

116 3 1080

10,0-11,8

950

600

1000

MCL-BIO 120

120.000

139 3 1200

11,5-14,0

1100

600

1070

MCL-BIO 140

140.000

162 3 1450

12,5-16,0

1350

600

1220

MCL-BIO 160

160.000

186 3 1650

14,0-19,0

1550

600

1470

MCL-BIO 180

180.000

209 3 1650

14,0-19,0

1550

600

1680

MCL-BIO 200

200.000

232 3 1200

20,0-28,0

1100

950

1790

MCL-BIO 250

250.000

291 3 1450

24,0-33,0

1350

950

2010

MCL-BIO 300

300.000

348 3 1700

28,0-39,0

1600

950

2230

MCL-BIO 350

350.000

406 3 1700

33,0-45,0

1600

950

2230

MCL-BIO 400

400.000

464 3 1950

38,0-50,0

1850

950

2750

MCL-BIO 450

450.000

522 3 1950

43,0-55,0

1850

950

2980

MCL-BIO 500

500.000

580 3 1450

85,0-110,0

1350

2000

3500

MCL-BIO 550

550.000

638 3 1450

85,0-110,0

1350

2000

3800

MCL-BIO 600

600.000

696 3 1700

110,0-140,0

1600

2000

4200

MCL-BIO 650

650.000

754 3 1700

110,0-140,0

1600

2000

4700

MCL-BIO 700

700.000

812 3 1935

130,0-165,0

1800

3000

5200

MCL-BIO 800

800.000

928 3 2000

145,0-180,0

1900

3000

5650

MCL-BIO 900

900.000

1.044 3 2300

160,0-210,0

2200

3000

6150

Page 8

TECHNICAL FEATURES AND DIMENSIONS

8

2.4. Fuel

The BIOPLEX series is designed for automatic function with solid fuel of biogenic or fossil

nature, with granulation up to 30 mm and humidity up to 20%. The boiler is also able to be

used on wood or other solid fuels with manual feeding, without any modification.

This means different types of biomass fuels, such as pellet, agropellet, olive husks, fruit

kernels, cereals, granulated carbon. When the fuel used has characteristics that significantly

vary from nominal (i.e. carbon, cereals, agricultural residues), it is recommended that they are

used in combination with pellet or agropellet at a 50:50 ratio. If you want to use solely carbon

as fuel, please contact the manufacturer.

The fuel with the best quality, concidering calorific power, ash content, humidity and

standartization, is wood pellet. The less quality of the fuel, the more fuel supply must be

provided to achieve the nominal power and of course the most the consumption and the ash

remains.

The nominal characteristics of the boiler are calculated for use on wood pellet!

Fuel type

Calorific

power

Max

diameter

Max

humidity

Ash

content

kWh/kg

mm

%

%

Pellet

4,8

6 – 8

<10

<1

Agropellet

4 – 4,2

6 – 10

<10

<5

Coal

5,3 – 6,5

3 – 25

<15

4 – 8

Lignite

1,6 – 3,8

3 – 25

<20

<10

Cereals (oat)

4,2

3 – 6

10 – 13

0,6

Wood chips

4,3

5 – 25

<20

4 - 6

Barks

2,6

5 – 25

<20

8 - 10

Wood

4 – 4,3

-

<20

4 - 8

Wood briquette

5,2

-

<10

<4

Table 1. Characteristics of different types of fuels

Every type of biomass fuel contains a significant amount of humidity, which highly affects its

combustion behaviour and calorific value. Boiler output, efficiency and autonomy will

significantly diminish as the humidity increases. The nominal data presented in this manual are

calculated for humidity content 10%. Maximum allowable humidity content is 20%. If the fuel

has bigger humidity, the combustion will be highly imperfect, causing problems to the furnace

and the feeder.

For proper and efficient function and a long lifespan, it is strictly recommended that only dry

wood is used, with a humidity content of 20%. Practically, this means at least one year dry

wood.

In order for the feeding and combustion system to function properly the

maximum allowed humidity of the fuel is 20%!

It is prohibited the use of explosive, inflammable materials, plastic, domestic

residues, etc.

The boiler is provided with a flange for mounting a burner for use with oil or gas as an

alternative fuel. However, this option is an emergency alternative, and it is not recommended

that boiler is on stable function on oil or gas. The efficiency will be very low on such fuels.

If a burner is mounted, remove it before you use solid fuel again.

It is prohibited to manually feed solid fuel in the boiler simultaneously with the

burner function!

Page 9

BOILER MOUNTING

9

3. BOILER MOUNTING

3.1. Transportation and delivery

The boiler is delivered on wood pallet, well positioned with metal plates. Remove them

carefully by unscrewinf the screws holding them in place.

The loading and unloading of the boiler must be performed with a forklift or a crane. A special

hook is provided on the upper part of the boiler for lifting.

The boiler is very heavy. Do not try to lift by hands or other unsuitable

equipment. Danger of injury! Perform all moves with extreme attention and care.

Remove the boiler packaging with attention. Keep the packaging material away from

chidren since it can be dangerous. After having unpacked everything, make sure that the

appliacne is intact and undamaged. In case of doubt do not use the appliance and inform the

supplier.

The BIOPLEX boiler is delivered with the following equipment already fitted and mounted:

Boiler steel body

Rockwool insulation mounted on the boiler body and tightened with plastic tapes

Metal covers mounted on the boiler body

Turbinators positioned inside the fire tubes

Cast iron catalyst for the biomass combustion

Cast iron grates for wood combustion

Control panel and electrical connections

The furnace system BIOFIRE is already preassembled and mounted on the boiler side flange. It

consists of:

BIOFIRE furnace steel body

Fuel silo with lid, shutter, inspection window

Feeder with screw

Fan

Motoreducer

Transmission system with chain wheels

Protection cover of the mechanism

Cast iron combustion plate

The following accessories are positioned inside the boiler body. Remove them carefully by

opening the middle door.

Cleaning tools

Safety kit

Drainage valve

In the documentation folder you will find:

Technical manual

Warranty leaflet

Declaration of conformity

Page 10

BOILER MOUNTING

10

3.2. Boiler room

3.2.1. General requirements

The boiler must be installed in a special and separate room. This room must be chosen so that

it offers easy access for fuel transport, air supply and exhaust gas evacuation. The doors of the

boiler room must be metallic, open outwards, and have at least 0,9 m width.

The boiler installation is prohibited in rooms with extensive dust, dangerous

gases, and moist spaces.

For the correct boiler function it is necessary that the boiler room has openings for natural

ventilation and combustion air supply. It is recommended that two different openings are used

for this purpose, positioned on opposite walls and diagonally to ensure good air circulation. The

total surface of the openings must be at least 1/12 of the boiler room surface. Forced

ventilation is prohibited in the boiler room.

The boiler room must be provided with a drainage channel. All safety devices must be

connected to this channel.

The boiler room must have an appropriate fire extinguishing system, according to the

regulations in force. In case that the building is designed with a fire alarm system, a smoke

detector must be positioned on top of every boiler.

The fuel storage is prohibited in the boiler room. If so, the storage must be separated from the

boiler with a non-flammable wall, and proper distanced from the boiler.

3.2.2. Boiler room dimensions

The boiler must be placed on a horizontal plane, with

adequate mechanical resistance to support the boiler’s

weight. The boiler must be positioned in the room in such

a way so that it is easily accessible from all the sides. The

following dimensions are recommended (see Fig 2)

Distance from the front wall (N):

For boilers up to 100 kW – minimum 1,5 m

For boilers bigger than 100 kW – minimum 2 m

Distance from the rear wall (L):

Appropriate distance for maintenance access. Minimum

0,6 m.

Distance from side walls (M):

For boiler up to 300 KW – minimum 0,6 m

For boilers bigger than 300 kW – minimum 1 m

Boiler room height (H):

For boilers up to 70 kW – minimum 2 m

For boilers 70 to 230 kW – minimum 2,4 m

For boiler 230 to 400 kW – minimum 3 m

For boiler bigger than 400 kW – minimum 3,5 m

Distance between two boilers (P) must be at least 1m.

Fig 2. Boiler room dimensions

Page 11

BOILER MOUNTING

11

3.3. Chimney

The chimney installation must supply sufficient draught, air tightness and protection against

condensation.

The appropriate chimney installation is very important for the boiler’s efficient

and safe function!

The chimney must be positioned if possible in the interior of the building. It must be vertical,

with no changes in the direction. The cross-section of the chimney can be round or

rectangular. If the chimney is installed in the exterior, it must be insulated.

The horizontal part connecting the boiler’s chimney pipe with the vertical chimney must have

maximum length 2 m. If this distance is bigger, it is recommended to have a 15-30o inclination

upwards. The connection with the boiler’s chimney pipe must be air-tight.

The chimney must be equipped with a cleaning door at its base. Also cleaning doors are

recommended where there are changes in direction and ash can be accumulated. Tactical

cleaning is recommended (every 3 months) for efficient boiler function.

A chimney terminal must be installed at the end of the chimney for protection against weather

effects and foreign objects entrance. In areas with strong winds a special anti-downdraught

terminal is recommended.

The chimney height must exceed the roofline by at least 1 m. If there are other obstacles

positioned on the roof, the chimney height must exceed them by at least 1 m. If there are

multiple chimneys, minimum distance between them is 0,3m.

Each boiler should be connected to an independent chimney. Connection of multiple boilers to

the same chimney is not recommended.

Fig 3. Chimney distances

Page 12

BOILER MOUNTING

12

Fig 4. Chimney connection

Page 13

INSTALLATION

13

4. INSTALLATION

4.1. Hydraulic connections

The boiler is intended for connection with an open expansion vessel network. The boiler can be

connected also with closed expansion vessel, if it is equipped with an overheating serpentine

(optional).

The boiler is intended for maximum working temperature 90oC and maximum pressure 3 bar

for boilers up to 500 kW, and 4 bar for bigger boilers.

When connected with a closed expansion vessel, its volume must be chosen double to a similar

installation on liquid or gas fuel.

If a connection pipe is not used, it must be sealed before water fill!

Legend

T1

Outlet

T2

Return

T3

Chimney pipe

T4

Discharge valve connection

T5

Safety kit connection

T6

Additional safety connection

4.2. Safety features

The boiler equipment includes a safety kit, which shall be connected to the corresponding

connection pipe T5. The kit consists of a safety valve, an air relief valve and a

thermomanometer. Bigger boilers are equipped with two or more safety valves.

Additional safety equipment can be mounted at the

connection pipe T6. This can be a dual safety valve

(pressure and temperature) or a cooling valve.

Alternatively this pipe can be used for connection

with the expansion vessel.

Fig 5. Boiler safety kit

Page 14

INSTALLATION

14

4.3. Overheating serpentine

As an optional, the boiler can be equipped with an overheating protection serpentine. This is

incorporated in the boiler body, surrounding the fire chamber.

For the function of the safety serpentine, a discharge valve must be installed. The

bulb of the valve must be mounted on the boiler’s hot water delivery, at maximum distance

1m from the boiler.

Fig 6. Overheating serpentine connection

The valve can be connected on either side of the serpentine. Attention should be given to the

flow direction of the valve. The valve can be fitted on the cold water inlet or hot water outlet.

However, we recommend that the valve is fitted on the cold water inlet.

For the protection of the valve, a filter is recommended to be installed on the water line before

the valve.

On the opposite side of the serpentine, drainage must be connected.

The correct function of the discharge valve is crucial for the boiler’s safety.

Verify its function often and replace if defect.

4.4. Return temperature protection

For the correct function of the boiler and for protection against corrosion it is very important to

ensure steady temperature at the return of the boiler of at least 55oC.

This can be ensured by installing a recirculation pump between the boiler outlet and return

(see connection diagrams).

An alternative variation is by installing at the return of the boiler a three-way thermostatic

valve.

Page 15

INSTALLATION

15

4.5. Filling the system

After completing all the hydraulic connections, the circuit may be filled with water. After filling

the system, open the radiators air valves to get rid of the air in the installation.

Verify that the installation pressure is according to the technical feature of the boiler. The

pressure must be verified through the boiler’s manometer. An additional manometer should be

installed on the cold water inlet to verify the cold pressure, at the lowest point of the

installation, at a point close to the boiler.

The whole installation must remain under nominal pressure for at least 10 minutes. During this

period, check that all the connections are tight and there are no water leakages. Make sure

that during this period no pressure drop appears.

After firing the boiler, make sure the network functions properly at working temperature and

pressure.

The hardness of the mains water supply affects the boiler’s life span. It is

recommended to use a water softener if water hardness exceeds 15of.

Do not fill the system at the working pressure! When the boiler will be heated,

the water pressure will raise. Filling pressure must be at least 1 bar lower than

working pressure!

4.6. Automatic ignition system

As an optional, the furnace can be provided with an automatic ignition system. This consists of

the following:

Ignition element 500W (2 pieces in bigger boilers)

Control panel Ecomax 800P (technical manual given with the control panel)

Exhaust temperature sensor

The ignition element is installed in a special inox tube casing, positioned under the furnace cast

iron plate. The cables are protected with a silicon layer, resistant to temperature up to 300oC.

All the electrical connections are prewired.

The controller is equipped with an exhaust temperature sensor. This must be installed on the

chimney, at a distance maximum 1m from the boiler.

If the boiler comes with the automatic ignition system, refer to the controller’s

manual for electrical connections and settings.

Page 16

INSTALLATION

16

4.7. Connection diagrams

4.7.1. Open expansion vessel connection

Legend

1-9.

Separation valves

10,11.

Radiator valves

12.

Radiators

13-15.

Safety valves

16.

Filling valve

17.

Drainage valve

18.

Cold water valve

19-24.

One-way valves

B

Hot water boiler

VED

Open expansion vessel

PCI

Central heating pump

PRC

Recirculation pump

RP

Pressure reducer

F

Filter

A

Air relief valve

FD

Water softener

Page 17

INSTALLATION

17

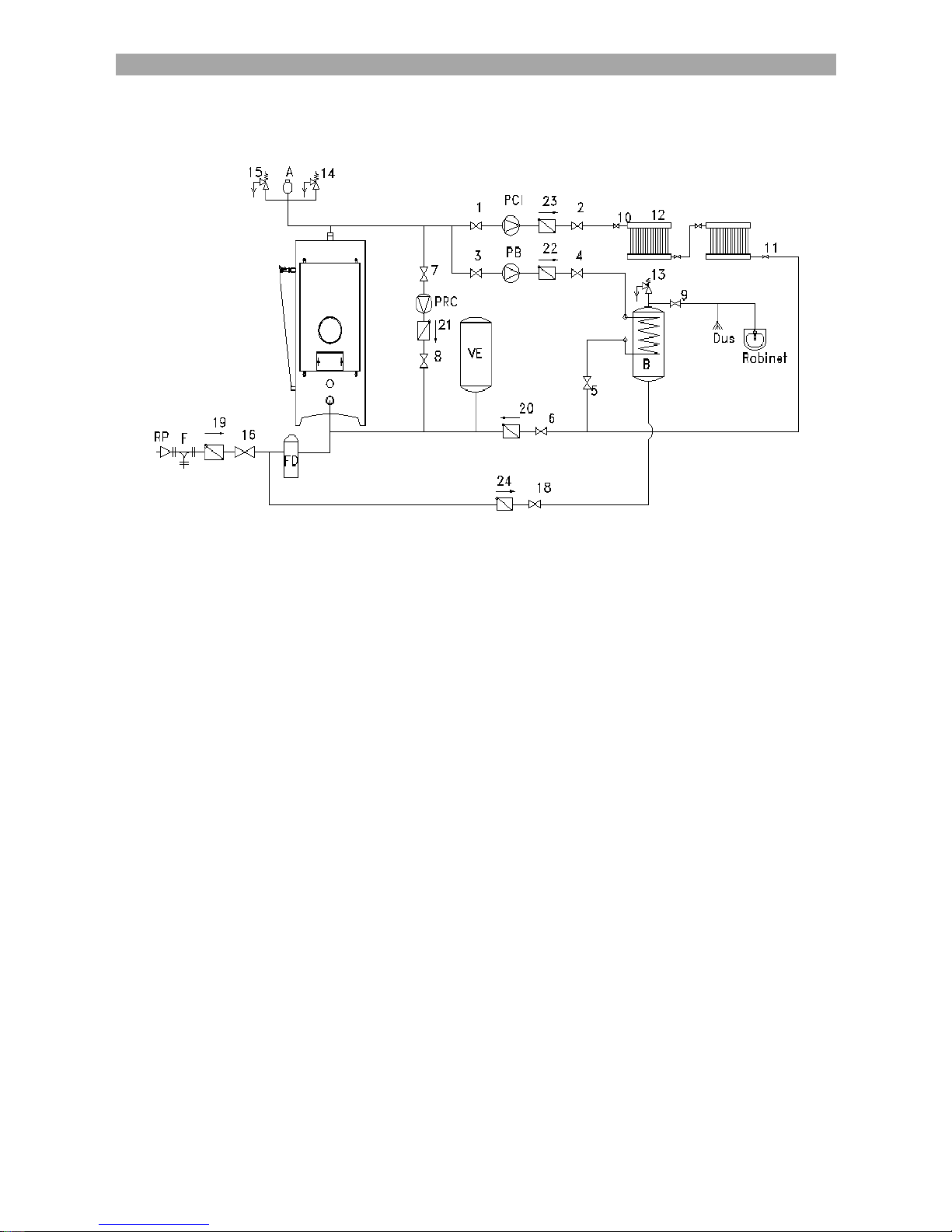

4.7.2. Closed expansion vessel connection

Legenda

1-9.

Separation valves

10,11.

Radiator valves

12.

Radiators

13-15.

Safety valves

16.

Filling valve

17.

Drainage valve

18.

Cold water valve

19-24.

One-way valves

B

Hot water boiler

VE

Closed expansion vessel

PCI

Central heating pump

PRC

Recirculation pump

RP

Pressure reducer

F

Filter

A

Air relief valve

FD

Water softener

Page 18

BOILER START-UP

18

5. ELECTRICAL CONNECTIONS

5.1. General instructions

All electrical connection must be performed by an authorized professional, in conformity with

the local regulations and the indications of this manual. Connections must be done according

to norms EN 60529 and EN 60335-1, and protection norms IP 40 and IP 44.

All wiring must be waterproof insulated. Exposed cables should be protected within plastic

channel. The main electrical supply of the boiler must be connected to an independent safety

of max 16A. The boiler room lighting must be on a separate circuit.

THERMOSTAHL is not responsible for accidents or malfunctions caused by

wrong or bad electrical connections.

5.2. Control panel functions

Fig 7. Control panel

The general switch ON/OFF interrupts the electrical supply to all the devices.

The furnace thermostat interrupts the fan and motor function when the preset boiler

temperature has been reached. It is recommended that this temperature is set between 7090oC. This temperature should never be set below 60oC.

The fan speed regulator regulates the fan rotating speed by means of a dimmer rheostat.

The pump thermostat starts the circulation pump function at the preset temperature. It is

recommended that this temperature is set around 45-55oC. The pump indication lamp follows

the function of pump.

The safety thermostat will interrupt the fan function if the boiler temperature reaches above

95oC. If so, it needs to be reset manually by unscrewing the plastic cover.

The ventilator and motor switches are used to activate or deactivate the corresponding

devices. The switch has an incorporated indication lamp that follows the function of the

devices.

The motor timer controls the motor function by means of ON/OFF time intervals. The first

timer T1 controls the TIME OFF interval, while the T2 the TIME ON interval.

If a burner is connected to the control panel, it can be connected in the place of the fan and

regulated by the fan thermostat.

Legend:

1.

Thermometer

2.

Furnace thermostat

3.

Safety thermostat

4.

Pump thermostat

5.

General ON/OFF switch

6.

Motor timer

7.

Fan speed regulator

8.

Pump indication lamp

9.

Motor switch

10.

Fan switch

Page 19

BOILER START-UP

19

The control panel offers the possibility to connect with a room thermostat. When the room

thermostat contact opens, the furnace function stops.

5.3. Wiring diagram

Fig 8. Control panel wiring diagram

Legend:

GS

General ON/OFF switch

TS

Safety thermostat

TM

Furnace thermostat

TP

Pump thermostat

VT

Fan speed regulator

LP

Pump indication lamp

SM

Motor switch

SV

Fan switch

TR

Room thermostat

PE

Grounding

Unscrew the control panel back plate to have access to the connection terminals in the interior.

Connect the main electrical supply to the terminals 1,2,3 as indicated. The fan is connected to

the terminals 10,11,12 and the pump to the terminals 4,5,6.

The motor phase is connected to the terminal 9, while neutral and grounding together with the

fan’s at terminals 12 and 11 respectively.

Between the terminals 7,8 there is a jumper. If you want to connect a room thermostat,

remove the jumper and connect it to these two terminals.

Attention: The room thermostat must be a simple contact interruptor. It is not

allowed to connect a digital thermostat with an electrical signal output!

Page 20

BOILER START-UP

20

6. BOILER START-UP

6.1. Initial lighting checks

Before you start the boiler, make the following checks:

Check that all the hydraulic connections and make sure they are tight. Make sure there is

no leakage or moisture on the pipes or other equipment.

Make sure that the connection with the chimney is air-tight and the chimney installation is

properly made.

Check that the controller bulbs are well inserted and secured in the boiler’s case.

Make sure that the pressure in the network is correct.

Check that the boiler pump and the central heating pumps function properly.

Make sure that the connection with the expansion vessel is correct and the expansion

volume is sufficient for the boiler. No valves should be installed between the boiler and the

expansion vessel.

Make sure the boiler’s separation valves are open.

Make sure that there is sufficient air supply and natural ventilation in the boiler room.

Do not store inflammable materials or fuel close to the boiler! Before you light

the boiler make sure the boiler room is clear and safe.

6.2. Start-up

To correctly start up the BIOPLEX boiler follow the next steps:

Make sure the silo is full with fuel.

Make sure the chimney damper is positioned in horizontal position (completely open).

Open the middle door (feeding door) to have visual supervision of the feeding procedure.

Turn the control panel on from the general switch and activate only the motor from the

corresponding switch. Keep the fan deactivated during this step.

Set the first timer T1 to maximum and the second T2 to zero, in order to fill the furnace

with fuel. Fill it until the fuel level reaches the cast iron plate and covers a small part of it.

Stop the motor function from the motor switch.

Using sheets of thin paper or other ignition material, light the fuel placed in the furnace.

Wait several minutes until the flame stabilizes and covers the entire plate surface.

Close the middle door of the boiler. Turn on the fan by the corresponding switch. During this

step the motor must remain deactivated.

When the flame is fully developed, activate both the motor and the fan. Set the furnace

thermostat to the required temperature.

Follow the instructions given in the chapter Combustion Regulation to correctly regulate the

combustion.

It is prohibited to light the boiler with inflammable or explosive liquids.

6.3. Checks to carry after initial start-up

During the first start-up you need to carefully check the air-tightness of all the connections,

especially the doors and the connection with the chimney.

Check that the thermostats function properly and devices operate accordingly. Wait for the

boiler to reach the preset temperature and make sure the fan stops properly and the flame

falls down.

Check the temperature and pressure rise in the network. Make sure it is according to the

indications. Check if there is any water leakage in the network.

After burning of the fuel is completed, check the situation inside the boiler. If the walls are too

black, it means that there is insufficient air supply. If there is condensation forming on the

Page 21

BOILER START-UP

21

boiler walls, it means that the pump operation starts at a low temperature or the fuel has too

big humidity content. Make sure you set the pump according to the indications and you install

a return temperature protection system as indicated.

6.4. Fuel loading

In order to correct add fuel to the boiler follow the next steps:

Stop the fan function by turning the fan thermostat to zero. Wait 30 seconds for the fume to

exit the boiler.

Open the middle door slowly to avoid leakage of smoke. Load a sufficient amount of fuel.

Each loading should be regulated according to the boiler output and the heat demand.

Never load too much to fuel to fill all the fire chamber volume! Maximum fuel should be 7080% of the fire chamber volume.

Close the door and secure with the handle.

Start again the fan function by putting the thermostat to the preset temperature.

When loading fuel in the boiler do not throw them but position them carefully.

6.5. Combustion regulation

After completing the start-up procedure and closing the door, set the required temperature to

the furnace thermostat (noted “Motor Regul”). After the fan and motor are activated, have a

look at the quantity of fuel fed to the furnace and the shape of it on the cast iron plate.

The timer must be set in such a way, so that the quantity of fuel fed is stable to a level where

it makes a small hill over the plate, covering almost half of its surface (middle picture). If the

fuel accumulates covering all the plate surface (left picture), it means the feeding is too big

and must be reduced. If the level of the fuel is below the plate (right picture), it means the

feeding is too small and must be increased.

Fig 9. Fuel feeding regulation

The feeding depends on two parameters: the feeding time (timer T1) and the stop time (time

T2). When you want to increase the feeding, increase the feeding time and reduce the stop

time. When you want to reduce the feeding, reduce the feeding time and increase the stop

time. These two timers must be set together, and with not too big difference (the ratio

between TIME ON/TIME OFF must be between 0,5-0,9). This way you achieve a stable feeding

and fire in the furnace.

After regulating the feeding, observe the flame shape and color through the flange provided on

the middle door. The flame will have to occupy about two thirds of the fire chamber and quietly

lick the cylindrical heat exchanger. Its shape must be fully developed and with not too many

detachments at the flame end. Its color must be vivid orange-yellow, not too transparent.

The combustion quality is regulated through the air delivery. By positioning the fan damper

you regulate the air pressure and by the control panel speed regulator you regulate the fan

Page 22

BOILER START-UP

22

speed. The combination of these two will result to the optimum air delivery in order to

accomplish perfect combustion.

GENERAL SUGGESTIONS

The flame needs to have reasonable dimensions and fill up the fire chamber as told.

The flame must not be too red (too low air supply).

The flame must not have big detachments and sparkles (too high air supply).

The flame must not be too small. If it is slow, easily influenced by air currents and the

chimney draught, it means that the air supply is too low.

The smoke at the chimney must be clear-grey. Black smoke means lack of air supply.

If too much ash and big coal pieces fall down to the ash box reduce the air supply.

The flame is too fast, dry, and might make a noise.

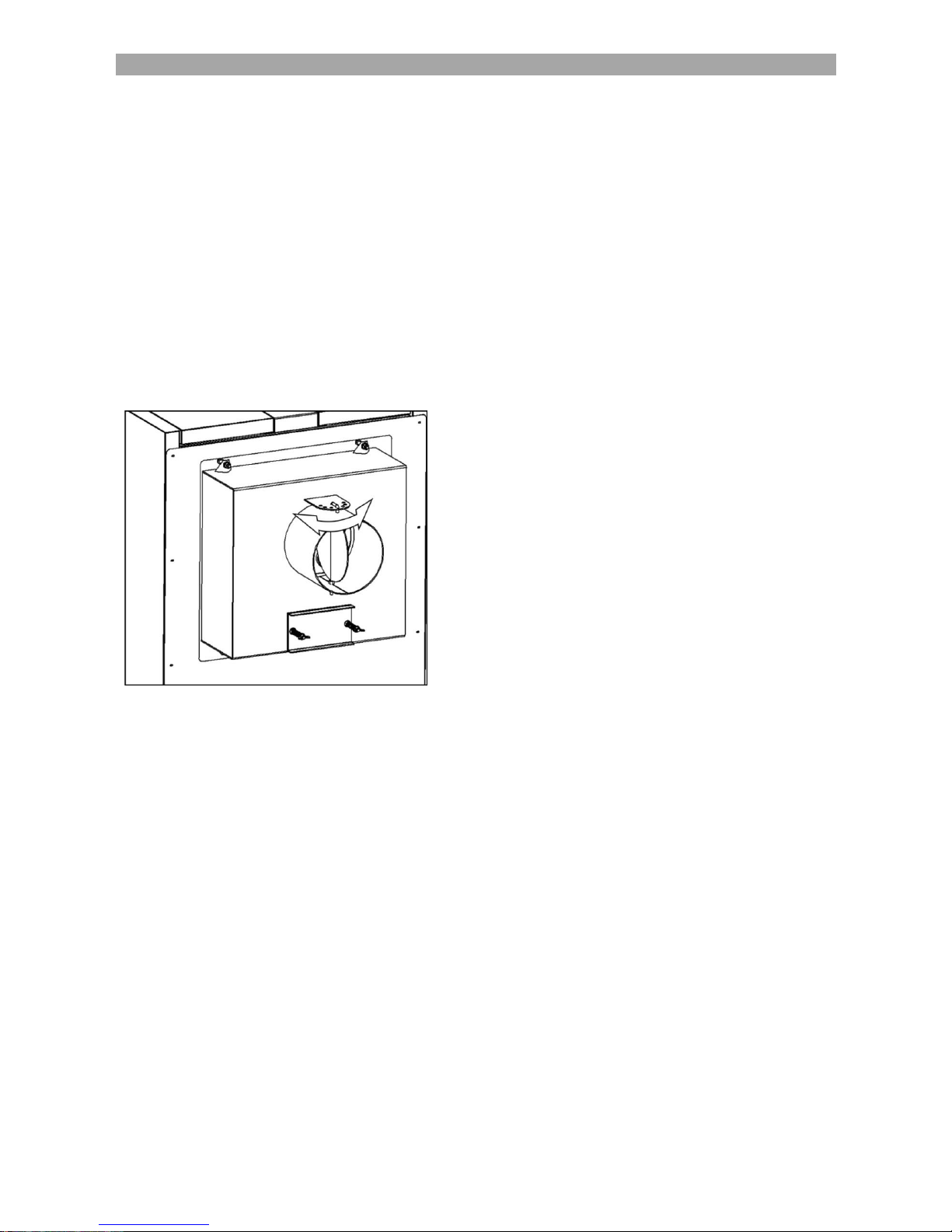

6.6. Chimney damper adjustment

The boiler chimney pipe is equipped with a damper.

This can be set in various positions to throttle the

exhaust gases.

At nominal function of the boiler this damper should

be normally open. Also it should always be at open

position at boiler start-up.

If the chimney draught is too big and the gases are

evacuated too fast, set this damper at a side

position by inserting the positioner at a different

hole.

If a burner is installed, it is recommended that the

damper is in completely closed position.

Fig 10. Chimney damper

Page 23

SERVICE AND MAINTENANCE

23

7. SERVICE AND MAINTENANCE

7.1. Cleaning

7.1.1. Cleaning the boiler

Solid fuel boiler require regular cleaning in order to function properly and efficient. Cleaning

must be effected at least once a week. The boiler is equipped with three cleaning tools

appropriate for the cleaning procedure of the boiler, as shown in Fig 11.

Fig 11. Boiler cleaning tools

The boiler function must be stopped before cleaning! Make sure all the devices

are stopped, and the boiler has cooled down. It is strictly prohibited to clean the

boiler while in function!

Open the upper door to have access to the heat exchanger. Remove the turbinators from the

tubes, and clean the tubes with the appropriate tool. Afterwards clean the exterior surface of

the cylindrical heat exchanger with the exchanger cleaning tool, as shown in Fig 12. With the

same tool, scrape the ash and any other remains from the side walls of the boiler.

Fig 12. Cleaning of the heat exchanger

Open the lower door of the boiler and remove

the ash box. Empty all the containing ash.

With the ash cleaning tool you can scrape the

lower surface of the boiler for any residues of

ash.

The ash must be disposed in an

appropriate container! Do not throw the

ash together with the domestic garbage.

Be careful since ash might contain hot

particles, even long time after stop.

Fig 13. Removing the ash

Legend:

1.

Tubes cleaning tool

2.

Heat exchanger cleaning tool

3.

Ash cleaning tool

Page 24

SERVICE AND MAINTENANCE

24

7.1.2. Cleaning the chimney box

To ensure efficient and safe function of the boiler, you must

clean the chimney box from ash residues at least every 3

months.

The ash box is equipped with a cleaning door for this

purpose, as shown in Fig 14. In order to open the door,

unscrew the wing nuts, remove the washers and springs that

keep it in place.

Clean the interior of the chimney box and remove all the ash

and residues.

Put back the door the same way as removed.

The springs must not be omitted! They act as

safety in order of explosion of exhaust gases in the

chimney box.

Fig 14. Cleaning the chimney box

7.1.3. Cleaning the furnace

The furnace should be regularly cleaned according to the ash deposits, but not less than once a

week. To clean the furnace follow the next steps:

Stop the furnace function by the control panel and leave it to cool down completely.

Clean the surface of the cast iron plate from ashes and other deposits. Make sure the air

holes are clean and free from obstacles.

Clean the ashes and deposits at the perimeter around the plate.

After you turn on again the furnace, ensure the fuel feeding is performed freely and the fuel

is evenly distributed at the plate surface.

Check the function of the motoreducer and the fan. Clean from dust if needed.

7.2. Maintenance intervals

7.2.1. Daily maintenance

The pressure of the network must be daily verified to be within the allowed limits. Make sure

that all the safety devices and pumps function properly.

7.2.2. Weekly maintenance

The boiler must be cleaned every 3-4 days or at least once a week, depending on the ash

quantity accumulated on the boiler walls and in the heat exchanger. Cleaning procedure must

be performed according to the instruction given in the corresponding paragraph.

Check the quantity of ash accumulated in the ash box. The ash disposal can be performed

every 1-2 weeks, depending on the ash quantity formed.

7.2.3. Monthly maintenance

Check the doors and the sealing cord. Make sure the contact with the boiler is air-tight. If ash

has accumulated on the sealing cord, clean it.

Check the fan and make sure it functions properly. Clean from dust and check that the air

passage is clear of obstacles and dust.

Remove the turbinators from the heat exchanger and check their condition.

It is recommended that you clean the chimney box of the boiler and the chimney pipes at least

every 3-4 months, in order to assure efficient and safe function of the boiler.

Page 25

SERVICE AND MAINTENANCE

25

7.3. Basic service procedures

7.3.1. Service after overheating

If overheating occurs, the safety valves of the boiler must open. If the boiler is equipped with

an overheating protection coil, cold water will enter the coil to protect the boiler.

Make sure the boiler pump is working. In case of blackout open all the valves of the system to

let hot water out of the boiler. In any case a blackout protection UPS is recommended to be

installed on the boiler pump.

If the chimney damper is not fully opened, put it in fully open position.

All safety devices must lead to drainage! After overheating, make sure that all the water from

the safety devices has drained, and the system has filled with cold water. Check the pressure

and the temperature of the boiler.

At overheating, the safety thermostat will activate, and cut electrical supply to the fan. In that

case, you need to manually reset the safety thermostat and put the system back in function.

Unscrew the plastic cover of the safety thermostat and press the switch. Put the plastic cover

back.

Verify the causes of the overheating! If it happens again, check the installation

and function of the pumps and safety devices!

7.3.2. Service after feeder blockage

If a blockage occurs to one of the feeders, you will have to remove the axes in order to clean

the feeding tubes. The same procedure is applicable at the annual maintenance procedure.

Before proceeding to any of the following steps, make sure the boiler function is

stopped, the boiler is cool, and it is disconnected from the electricity. Do not try to do

any works while the motor is working and the control panel is activated! Risk of

injury!

REMOVING THE UPPER AXIS

Remove the protection cover of the transmission system.

Remove the two gears from the axes by unscrewing the headless inserted screws keeping

them in place. You do not need to unmake the chain! Remove them all together with

the chain.

Unscrew the four nuts from the back side of the flange (see Fig 15)

Fig 15. Removing the upper axis flange

Page 26

SERVICE AND MAINTENANCE

26

Remove the whole feeder together with the bearings and supporting disk (see Fig 16).

Fig 16. Removing the upper axis

When putting back together, it is absolutely necessary to put the rubber gasket at

its position!

REMOVING THE LOWER AXIS

Remove the protection cover of the transmission system.

Remove the two gears from the axes by unscrewing the headless inserted screws keeping

them in place. You do not need to unmake the chain! Remove them all together with

the chain.

Unscrew the four nuts keeping the motor in place and remove it (see Fig 17).

Fig 17. Removing the lower axis

Remove the support disk and the feeder.

When putting back together, it is absolutely necessary to put the rubber gasket at

its position!

Page 27

SERVICE AND MAINTENANCE

27

7.3.3. Service after motor bolt breakage

The connection between the motoreducer and the

lower axis is realized through a protection bolt. This is

designed in such a way so that it breaks in case of

feeder blockage, to protect the motor from burning.

If this bolt breaks, follow these steps to replace it:

Remove the two gears from the axes by

unscrewing the headless inserted screws keeping

them in place. You do not need to unmake the

chain! Remove them all together with the chain.

Unscrew the nut and remove the broken bolt.

Introduce a new bolt M6x50 and tighten with the

nut from the other side.

Verify the causes of the breakage. If there is an

obstacle in the feeding pipe remove it.

Fig 18. Motor protection bolt replacement

7.3.4. Service after power blackout

In case there is a power blackout, it is absolutely necessary to perform some checks and take

some safety measures to avoid overheating. The solid fuel has all the time a certain amount of

fuel in the fire chamber, which will not stop burning immediately.

For safety reasons it is recommended you have installed a UPS with a battery,

which assures function of the boiler pump at least for 30 minutes.

Remove the amount of fuel that is still burning in the furnace. Due to power blackout, there

is risk of backfire to the silo.

Turn the control panel to OFF.

When the power is restored, turn on the control panel and make sure all the devices

function properly.

7.3.5. Replacement of the ignition element

In case you need to replace the ignition element follow the instructions:

Turn OFF the control panel and disconnect from electricity.

Disconnect the connection wires of the ignition element and loosen the plastic tap holding

them in place.

Remove the fan by unscrewing the four screws keeping it in place.

Remove the furnace plate. The ignition element is positioned inside the INOX tube casing.

Remove the ignition element from the tube and insert in position the new one.

When you position back the furnace plate, be careful to fix it correctly with the fixing tooth,

as shown on Fig 19.

Page 28

SERVICE AND MAINTENANCE

28

Fig 19. Removing the ignition element

7.4. Maintenance after long stop

7.4.1. Maintenance of the boiler

It is necessary to perform a general maintenance and cleaning of the boiler after the heating

season. Clean thoroughly all the surfaces of the boiler as described in the corresponding

paragraph. Also clean the chimney box, and all the chimney parts where ash might be

deposited. After cleaning all the ash, empty the ash box and leave the boiler clean for the next

winter season.

After long stop of the boiler, before you put in function you need to perform the following

checks:

Check the condition of the electric cables and the sensors. Make sure they are not

damaged. Check that the thermometer indicates the correct temperature and all the

thermostats function properly. Make sure the bulbs are properly positioned in the case.

Make a general check of the chimney and make sure it is clean and free of obstacles.

Verify the pressure in the heating network and the boiler.

Do not empty the water of the boiler and the heating installation after the

heating season! It will corrupt all the installation and especially the boiler.

Check that all the valves are working properly. Replace them if necessary. Pay special

attention so that all the safety equipment of the boiler functions properly!

Make sure all the ball valves of the boiler and other relative equipment are open.

Check the function of the pumps. They might be blocked after long stop.

Check that there have been no modifications to the installation and the boiler room

(ventilation openings, chimney, doors).

Check the fan and clean from dust. Turn it manually to ensure it is not blocked.

Page 29

SERVICE AND MAINTENANCE

29

7.4.2. Maintenance of the furnace

It is necessary to perform a general maintenance and cleaning of the furnace after the heating

season. The maintenance of the furnace should only be done when the boiler is stopped, cool

and the power deactivated. For easier maintenance it is recommended to leave all the fuel in

the silo be consumed before you proceed to works. The maintenance procedure includes the

following steps:

Do not attempt to do any maintenance or service to the furnace while working!

There is serious danger of burning! Wait until the boiler is cool and deactivate from

the electricity.

Make sure the silo is empty. If not, empty manually the silo before proceeding to any

works. Open the silo cleaning door if necessary to remove any remaining fuel.

Remove the silo from the furnace body by unscrewing the bolts.

Remove the motoreducer which is mounted on the lower axis. See instruction in chapter

7.3.2.

Check the motoreducer. Check the oil level in the reducer and add oil if necessary.

Remove the two feeders. Check them and make sure they are in good shape and not

deformed.

Clean the tubes where the feeders are inserted. Remove any fuel or ash remains.

Remove the cast iron plate of the furnace.

Clean thoroughly the elbow underneath the plate, form where the fuel is provided. It is very

important to be clean of any obstacles that could block the feeding.

Clean very well all the holes on the plate surface. If they are blocked use a sharp tool to

clean them.

Put together all the pieces in the reverse order. Check all the sealing material between the

connections. Make sure they are in good shape and provide an air-tight sealing. Tighten well

the screws to ensure an air-tight connection.

After putting together the axes and the chain wheels, make the chain has a good grip on

the wheels and the rotation is performed freely. Grease carefully the chain and the wheels.

Attention: All the connections (boiler-furnace, furnace-silo, inspection doors,

etc.) must be air tight! If not there is high danger of backfire to the silo!

Page 30

WARRANTY

30

8. TROUBLESHOOTING

Problem

Cause

Solution

The lamps of the

control panel do not

light

- no electrical supply to the lamp

- the control panel is not connected

to electricity

- lamp defect

- electric cable defect

- check/replace the lamp

- connect to electricity

- check/replace the cables

The boiler does not

reach set

temperature

- fan blocked

- air passages are blocked

- boiler is not cleaned

- incorrect boiler start-up

- insufficient water in the system

- too big pump debit

- boiler under dimensioned

- bad quality fuel used

- insufficient chimney draught

- check/replace the fan, check the

function of the fan regulator and

thermostat

- clean the air passages

- clean the boiler

- start the boiler correctly

- fill the system

- regulate the pump speed

- change the fuel used

- check/clean the chimney

High temperature in

the boiler, but low

temperature at the

radiators

- too high hydraulic resistance in the

heating network

- thermostatic mixing valve is

connected wrong

- increase the pump speed

- check/replace the mixing valve

Condensation

formation in the fire

chamber

- too big boiler power

- too low return temperature in the

boiler

- fuel with excessive humidity

- load less fuel in the chamber

- install a return protection

system/thermostatic valve

- change the fuel used

Smoke coming out of

the doors

- boiler doors not regulated

- defect sealing cord of the door

- insufficient chimney draught

- too high air supply by the fan

- regulate the doors so that the

sealing cord stays tight

- check/replace the sealing cord

- check/clean the chimney

- reduce the air speed

Smoke coming back

to the silo

- chimney not cleaned/blocked

- fire tubes blocked, boiler not

cleaned

- furnace air holes blocked

- insufficient air supply and

ventilation of the boiler room

- too low flame and fuel level

- bad air regulation

- wrong fuel ignition

- bad chimney connection/

insufficient chimney draught

- damaged sealing

- check the chimney, clean it

- clean the boiler and the tubes

- clean the furnace and the air

holes

- check the air supply and

ventilation

- regulate correctly the fuel feeding

- check the ignition procedure

- check the chimney connection

and draught

- check all the connections sealing,

do not leave the silo lid open

while in function

The fan does not

function or it makes

a lot of noise

- set temperature reached

- disconnected by safety thermostat

- capacitor/motor defect

- bad electrical connection of the fan

- correct boiler function

- reset manually

- check/replace the fan

- check the electrical connection of

the fan

The feeder does not

function/fuel not fed

to the furnace

- feeder blocked from obstacle

- feeder is burnt or damaged

- no electricity to motor

- damaged motor/reducer

- connection pin broken

- remove the axes and the

obstacle

- bad combustion regulation/bad

chimney draught

- replace feeder

- check the electrical connections

-replace the motoreducer

- replace the connection pin

Page 31

WARRANTY

31

9. WARRANTY

1. Warranty duration is 3 years for all boiler parts under pressure, 1 year for other

electro-mechanical equipment. The warranty period starts from the date of installation,

but no longer than 120 days from the day of purchase.

2. The warranty covers costs of replacing parts that have been proved to be defect, and any

work that is connected with replacing these parts. Costs related to removing defect parts or

products, transportation, etc. are not covered by the producer’s warranty.

3. The producer will not accept to cover warranty terms in case of the following:

Maltreating the product and bad conditions of transportation and loading-unloading.

Wrong installation, failing to apply the directions given in the manual.

Improper use of the product.

Damages that have been cause by using improper fuels, with dimensions or

characteristics different from those described in the manual.

Damages from freezing if not necessary measures are taken against anti-freezing.

Incident of explosion due to use of impropriate chemical substances.

Electrical shocks that may harm electrical parts of the appliance.

4. Warranty is only valid if the installation is performed by a professional installer, authorized

by the producer, according to the local legislation and the instructions of this manual.

5. Warranty does not cover function problems or damages that are caused by bad chimney

installation, failing to respect the instruction of this manual and local legislation.

6. Warranty is not valid if the boiler cleaning, maintenance and service intervals are not

respected and the directions given are not followed.

7. Warranty is not valid if the maintenance is not performed by an authorized professional

according the instructions given and at the time intervals given.

8. Warranty does not cover costs related to emergency incidents like: earthquake, fire,

electrical blackout, robbery.

9. Warranty is not valid if the hardness of the water is over the allowed limits and no water

softening protection is installed.

10. The warranty is not transferable in case of reselling or replacing the product. A new

warranty should be accorded to the new user.

Page 32

THERMOSTAHL ROMANIA

SISTEME TERMICE S.R.L.

DRUMUL OSIEI 57-59, sector 6

Bucharest 062395, Romania

www.thermostahl.ro

Loading...

Loading...