Thermoscreens VRF PHV1000 DXE HO, VRF PHV1500 DXE HO, VRF PHV2000 DXE LO, VRF PHV1500 DXE LO, VRF PHV2000 DXE HO Installation, Operation & Maintenance Instructions Manual

9901035-1 Page 1 of 30

PHV SURFACE MOUNTED HEAT PUMP AIR CURTAINS

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

For use with CITY MULTI VRF units

PLEASE READ THESE INSTRUCTIONS CAREFULLY BEFORE ATTEMPTI NG INSTALLATION

Thermoscreens Ltd

St. Mary’s Road Nuneaton

Warwickshire England

CV11 5AU

Email: sales@thermoscreens.com

Tel: +44 (0) 24 7638 4646

Fax: +44 (0) 24 7638 8578

www.thermoscreens.com

English

9901035-1 Page 2 of 30

Thermoscreens / Mitsubishi Electric

Thermoscreens City Multi Heat Pump Air Curtains can be used with Mitsubishi Electric City

Multi Y/WY-Series (Heat Pump) or City Multi R2/WR2-Series (Heat Recovery) systems.

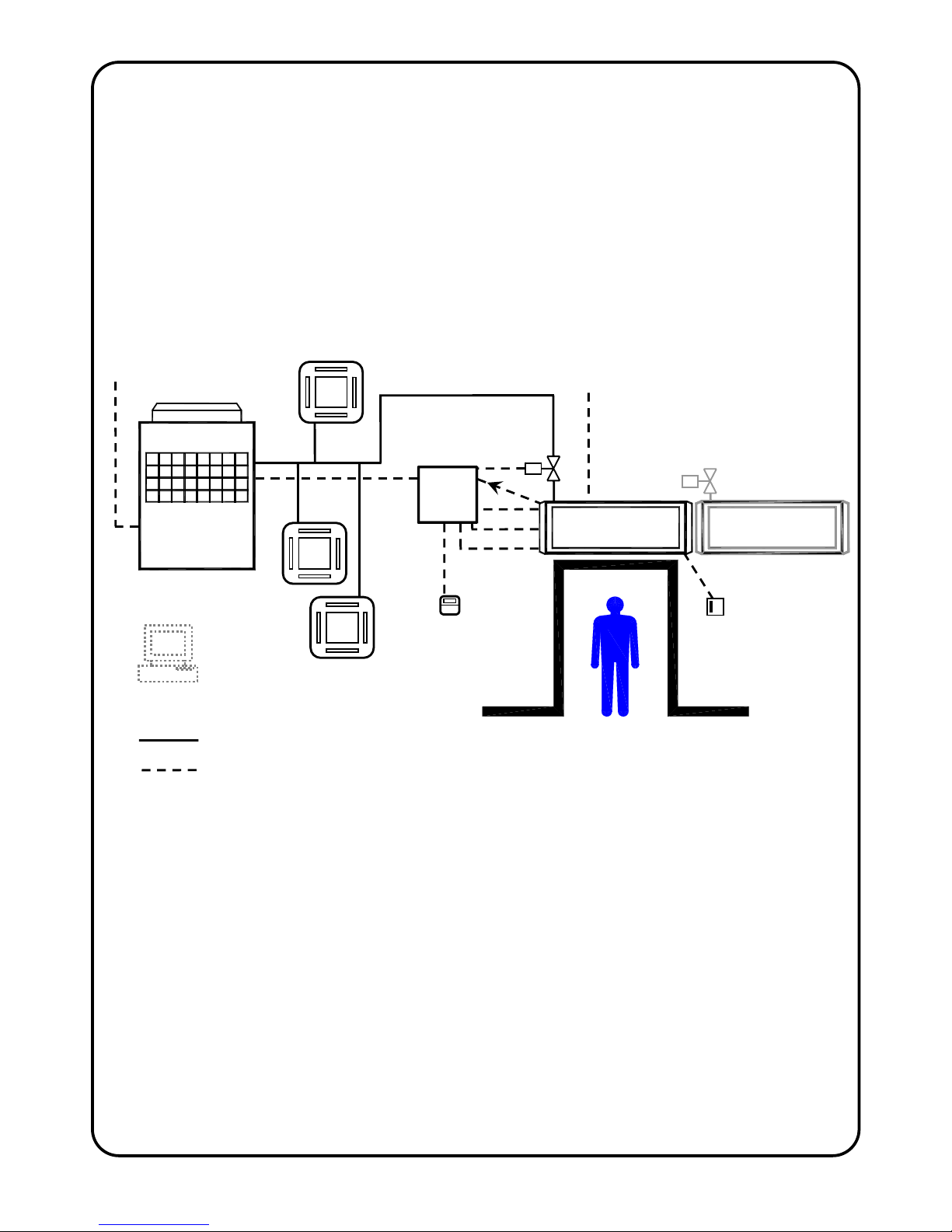

City Multi Y/WY-Series Heat Pump Air Curtain System

City Multi Y/WY-Series Heat Pump Air Curtain Schematic :-

City Multi Y-Series System: Indoor Units and Air Curtains(s) all operate on heating at the same time, or all operate on

cooling at the same time.

The City Multi Y Series Heat Pump Air Curtain system consists of :-

• One or more Thermoscreens VRF PHV Heat Pump (heating and cooling) Air Curtains *

• A Mitsubishi Electric PAC-AH…M-G AHU Controller or PAC-AH…M-H AHU Controller

(one for each air curtain) *

• A Mitsubishi Electric PAR-21MAA Remote Controller (one for each AHU Controller) +

• One or more Mitsubishi Electric City Multi Y/WY-Series Compressor Unit +

• Mitsubishi Electric Indoor Unit(s)

+

[NB. Can be used on a full air curtain basis if required

up to 100% diversity]

• Mitsubishi Electric BMS System or Centralised Controller, if required

+

* - supplied by Thermoscreens Ltd.;

+

- supplied by others

Heat Pump

Air Curtain

Mitsubishi Electric

Com

p

resso

r

Unit

LEV(s)

PAC-AH AHU

Controller

BMS Control

Fan

Sensors

Mitsubishi Electric

Indoor Units

Permanent electrical supply

(from local switched spur)

PAR-21MAA

remote

controlle

r

Defrost signal

Refrigeration pipework

Electrical/Controls cables

1 per air

curtain

Powe

r

Permanent mains electrical supply

(from local switched spur) for:

x Fans

x Defrost electric heaters (if used)

x PAC-AH…AHU Controller

Remote

3-Speed

Fan Switch

Cond. alarm

9901035-1 Page 3 of 30

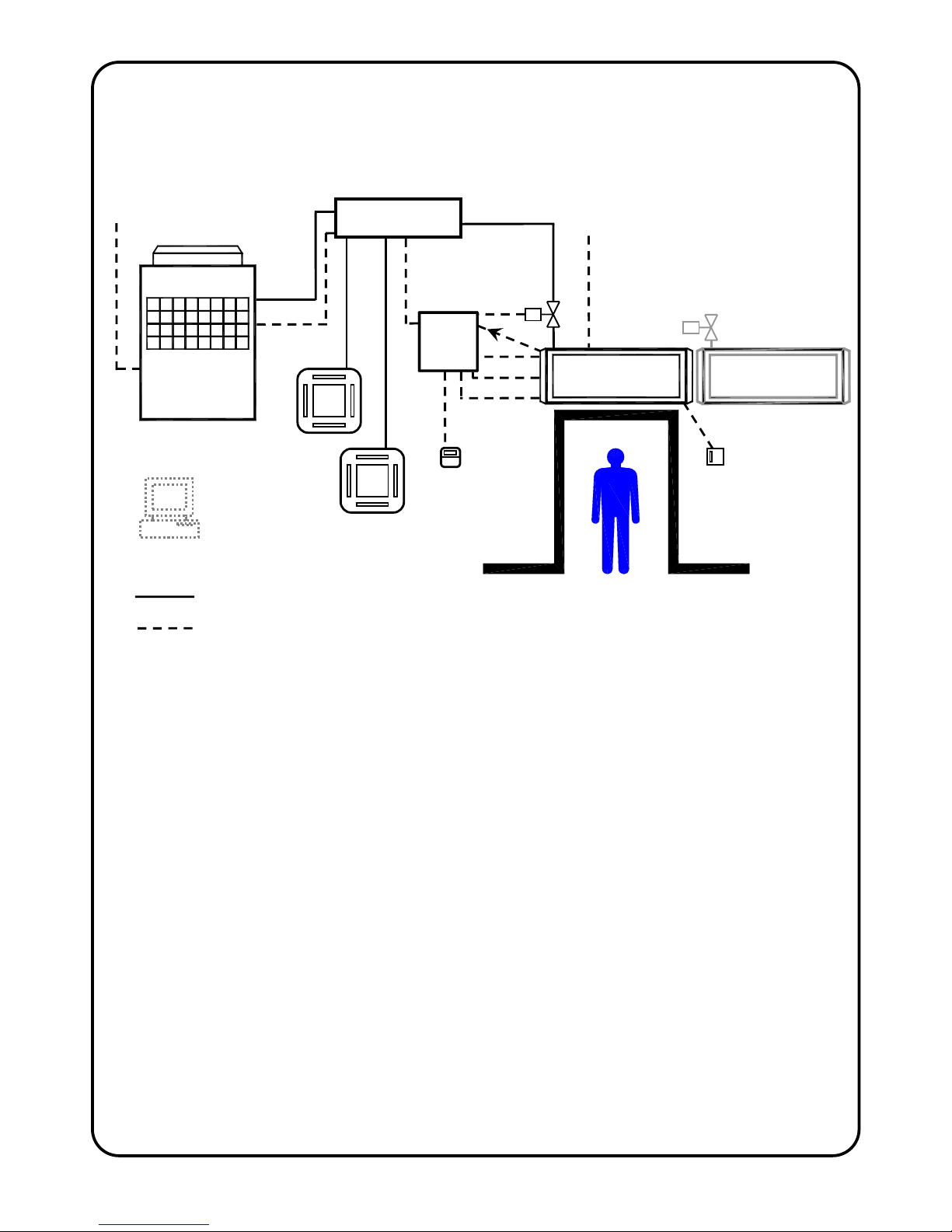

City Multi R2/WR2-Series Heat Pump Air Curtain System

City Multi R2/WR2-Series Heat Recovery Heat Pump Air Curtain Schematic :-

City Multi R2/WR2-Series System: Indoor Units and Air Curtains(s) can operate on heating or cooling simultaneously, e.g.

some indoor units are cooling whilst other indoor units and air curtain are heating at the

same time.

The City Multi R2/WR2-Series heat recovery system with Heat Pump Air Curtain(s) consists

of :-

• One or more Thermoscreens VRF PHV Heat Pump (heating and cooling) Air Curtains *

• A Mitsubishi Electric PAC-AH…M-G AHU Controller or PAC-AH…M-H AHU Controller

(one for each air curtain) *

• A Mitsubishi Electric PAR-21MAA Remote Controller (one for each AHU Controller)

+

• One or more Mitsubishi Electric City Multi R2/WR2-Series Compressor Unit

+

• Mitsubishi Electric BC Controller

+

• Mitsubishi Electric Indoor Unit(s)

+

[NB. Can be used on a full air curtain basis if required

up to 100% diversity]

• Mitsubishi Electric BMS System or Centralised Controller, if required +

* - supplied by Thermoscreens Ltd.; + - supplied by others

Heat Pump

Air Curtain

Mitsubishi Electric

Compressor Unit

Permanent mains electrical supply

(from local switched spur) for:

x Fans

x Defrost electric heaters (if used)

x PAC-AH…AHU Controller

PAC-AH AHU

Controller

BMS Control

Fan

Sensors

Mitsubishi Electric

Indoor Units

Permanent electrical supply

(from local switched spur)

PAR-21MAA

remote

controller

Defrost signal

BC Controller

Refrigeration pipework

Electrical/Controls cables

1 per air

curtain

LEV(s)

Remote

3-Speed

Fan Switch

Power

Cond. alarm

9901035-1 Page 4 of 30

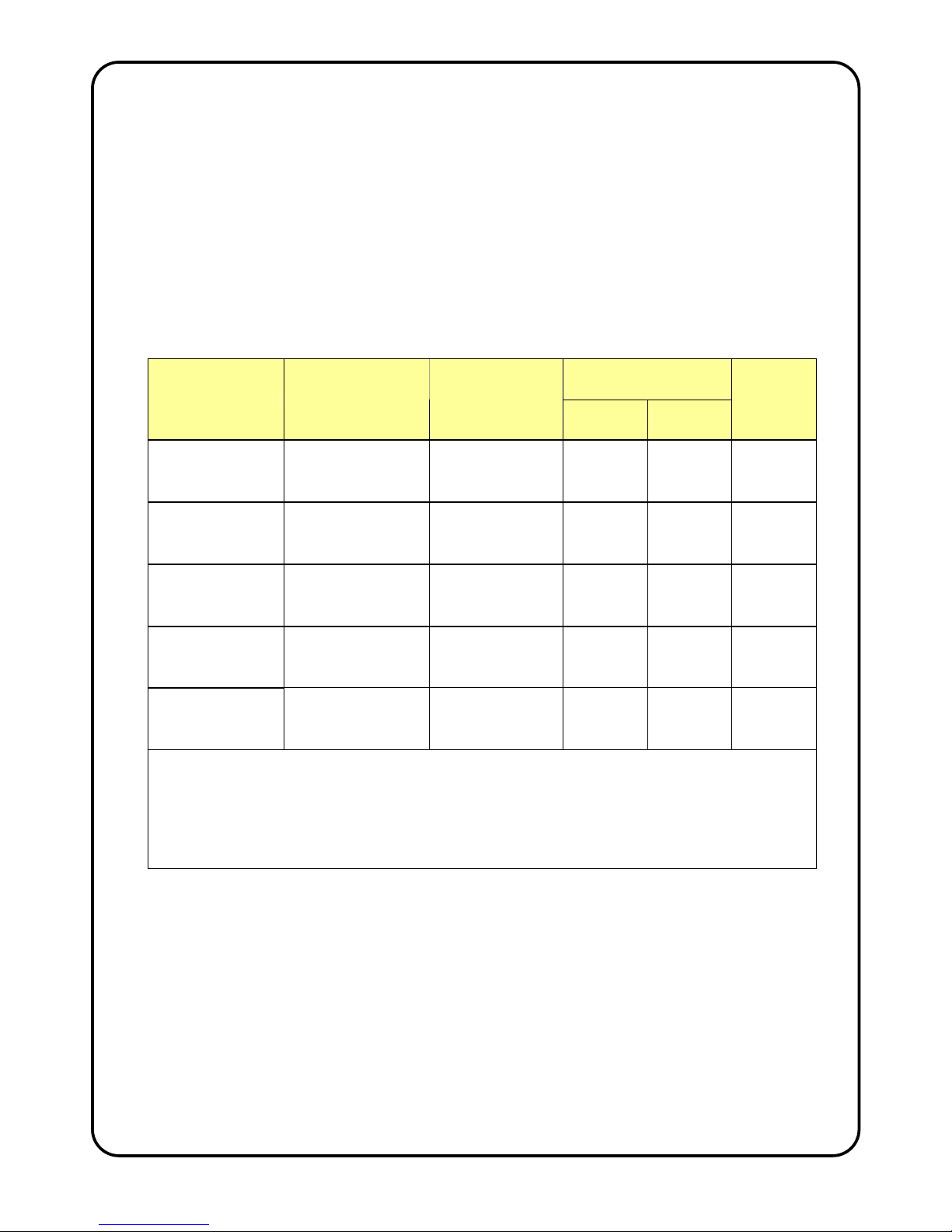

DESIGN INFORMATION

Each Thermoscreens Heat Pump Air Curtain needs to operate with a Mitsubishi Electric

PAC-AH…AHU Controller. There are two versions that can be used; PAC-AH…M-G and

PAC-AH…M-H the supply of which is dependent on the EU state where the installation is

being carried out.

The rated size of the PAC-AH…AHU Controller needs to be matched to the size of the

heat pump air curtain. Each size of AHU Controller comes with different size LEV(s) and

number of LEVs so they need to be matched to the air curtain. The table shows the AHU

Controller to be selected and maximum outputs and air volume flow rates of the heat

pump air curtain.

Maximum Heat

Pump Output (kW)

Air Curtain

PAC-AH…AHU

Controller

LEV(s)

No.Off

Index Size

Heating Cooling

Air

Volume

Flow

(m3/h)

VRF PHV1000

DXE HO

PAC-AH125M-G

or

PAC-AH125M-H

Type P632411X01

1 off

P100

9.0 8.1 1400

VRF PHV1500

DXE LO

PAC-AH125M-G

or

PAC-AH125M-H

Type P632411X01

1 off

P125

10.6 9.0 2500

VRF PHV1500

DXE HO

PAC-AH140M-G

or

PAC-AH140M-H

Type P632414X01

1 off

P140

15.1 13.6 2600

VRF PHV2000

DXE LO

PAC-AH140M-G

or

PAC-AH140M-H

Type P632414X01

1 off

P140

16.4 14.8 3300

VRF PHV2000

DXE HO

PAC-AH250M-G

or

PAC-AH250M-H

Type P632411X01

2 off

P200

21.4 19.3 3130

Maximum heat pump output refers to the heating or cooling output from the air curtain air stream.

Figures are derived from laboratory testing with reference to test standard EN14511. They are with

the air curtain operating at high fan speed, outdoor air temperature 7/6°C db/wb indoor air

temperature 20°C db for heating; outdoor air temperature 35/27°C db/wb indoor air temperature 27°C

db for cooling. Contact Mitsubishi Electric for performance at other outdoor and indoor conditions.

The air curtain normally operates under automatic temperature control set on the PAR-21MAA remote

controller and can also run at part load.

The following City Multi compressor units can be connected:

For Y/WY-Series systems:

PUHY-(E)P200 …. 1250Y(S)HM-A

PQHY-P200 …. 600Y(S)HM-A

PUMY-P100 …. 140V(Y)HMB

PUHY-HP200 …. 500Y(S)HM-A

For R2/WR2-Series systems:

PURY-(E)P200 …. 800Y(S)HM-A

PQRY-P200 …. 600Y(S)HM-A

9901035-1 Page 5 of 30

The Thermoscreens Air Curtain requires a permanent mains electrical supply from a local

switched isolator. Electrical power to the PAC-AH…AHU controller is then fed from the air

curtain. Electrical power to the Mitsubishi Electric compressor unit(s) and BC Controller is

fed separately in the normal way (see separate Mitsubishi Electric instructions). If the

defrost cycle electric heaters inside the air curtain are to be used during the heating mode

defrost cycle the electrical supply to the air curtain needs to be 3-phase (3L+N+E). If the

defrost cycle electric heaters are not required they can be permanently disconnected at

installation and a single phase electrical supply (1L+N+E) fed to the air curtain instead,

see 'Installation - Electrical Supply'.

Warning: Air curtain fans continue to operate during heating mode system defrost to

maintain an air stream across the doorway. With the defrost cycle electric heaters

operating the discharge air temperature from the air curtain is kept to a few degrees below

that of the indoor ambient air temperature during the duration of system defrost. If the

electric heaters are disconnected, discharge air temperatures could be very cold,

approximately 6ºC during the defrost and defrost times will also be extended, particularly

with the R2-Series System. Defrost does not occur with WY and WR2 systems so the

defrost cycle electric heaters should be disconnected on these systems.

There are various control cables that are wired on site to the PAC-AH…AHU Controller

and the Thermoscreens Air Curtain that provide control for the operation of the unit. These

are:-

• Start/Stop of air curtain fans

• Operation of LEV(s) for control of heating or cooling output

• Thermistor sensors

• PAR-21MAA Remote Controller for end user manual control, if used

• On/Off of electric heaters inside the air curtain during system defrost (if used)

• Condensate alarm derived from condensate pump alarm sensor (if used)

• M-Net communications link to the Mitsubishi Electric Compressor Unit.

(see also wiring diagrams)

The Thermoscreens Air Curtain is supplied with an integral condensate drain tray to

enable the air curtain to be used in cooling mode during warm weather, if so desired. If it is

intended to use the air curtain in cooling mode a suitable condensate pump (not supplied

by Thermoscreens) must be supplied by the installer. The condensate pump must be of

sufficient capacity, self priming and capable of providing the appropriate suction head so

the pump will lift condensate out from the top of the air curtain but can be hidden in a

remote location if necessary. Suitable condensate pumps are Peristaltic or Rotary

Diaphragm type. We recommend the Blue Diamond rotary diaphragm type with cooling

signal sensor (drainStik) manufactured by Charles Austen Pumps Ltd.

(www.miniblue.co.uk).

It is recommended that the condensate pump has the facility so it only operates when the

air curtain is in cooling mode by detection of water in the drain tray or by detecting a

cooling differential in the airflow. It should also have a pump overrun to empty the drain

tray as much as possible when the air curtain is switched off. It should have an alarm

system with appropriate sensor that will give a volt-free signal (open circuit = alarm). This

will stop the air curtain cooling if the condensate drain tray is in danger of flooding, air

curtain fans will continue to operate. Other City Multi indoor units are unaffected if the air

curtain condensate alarm occurs. There is a plastic fixing bracket with 8mm diameter hole

9901035-1 Page 6 of 30

attached to the drain tray inside the air curtain so a condensate sensor can be fixed in the

tray by the installer. The hole can be enlarged, if necessary, to suit the type of sensor used

so it is located in the tray at the appropriate position, see the manufacturer’s instructions

that come with the condensate pump for further information. The 230v AC, single phase

electrical supply to operate the condensate pump will come from the air curtain.

Warning: The air curtain condensate collection system is designed to remove condensate

with the air curtain operating in cooling mode during normal summer weather conditions in

countries with a temperate climate. In case of extreme weather conditions or condensate

pump failure, which can occur, it is vital that the design of the floor beneath the air curtain

and its surface is such that it will not become slippery or damaged if it became wet. This is

similar to the conditions that might be experienced with heavy rainfall or wet pedestrian

foot traffic at an open doorway, so careful consideration must be paid to the design of the

floor and its finish.

If it is intended that the air curtain should not be operated in cooling mode and a

condensate pump is not fitted, the BMS System, Centralised Controller or PAR-21MAA

manual Remote Controller must be configured at commissioning so that COOL or AUTO

mode can never be selected (see Section – Commissioning). It is still recommended,

however, that the floor design and surface be as described above in case cooling mode is

used in the future and to cope with heavy rainfall or wet pedestrian foot traffic.

Note: It could still be possible for an end user to unlock a PAR-21MAA Remote Controller

if they found out how to and switch it into cooling, not realising that condensate would then

flood out of the drain tray. It may therefore be considered prudent to install a condensate

pump and drain system even if it is intended that the unit should only be used in HEAT or

FAN mode.

If a Building Management System (BMS) or Centralised Controller is to be used for control

of the air curtain please contact Mitsubishi Electric for more details.

The air curtain is designed only for use with a Mitsubishi Electric City Multi VRF system for

use on R410A. The complete Thermoscreens/Mitsubishi Electric heat pump system,

including fridge pipework, wiring, controls, etc. must be installed only by an approved

Mitsubishi Electric refrigeration contractor.

The air curtain is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless they

have been given supervision or instruction concerning the use of the appliance by a

person responsible for their safety.

High Output (HO) and Low Output (LO) in this document refers to the heat pump heating

or cooling capacity of the Air Curtain, not to any electrical rating. HO air curtains have a 3row coil, LO air curtains have a 2-row coil.

These instructions must be read in conjunction with the Mitsubishi Electric instructions that

come with other components of the heat pump system, e.g. Compressor Unit, BC

Controller, PAR-21MAA Remote Controller, BMS System, Centralised Controller, etc.

They should be kept by the building facilities manager for future reference.

9901035-1 Page 7 of 30

UNPACKING THE HEAT PUMP AIR CURTAIN

The following items are supplied and packaged within the Thermoscreens air curtain box.

The Mitsubishi Electric PAC-AH…M-G AHU Controller or PAC-AH…M-H AHU Controller

comes in its original Mitsubishi Electric box. It is delivered with the larger Thermoscreens air

curtain box. It is factory pre-wired as much as possible to reduce installation time on site.

Check with the cross-reference labels on the Thermoscreens air curtain box and the

Mitsubishi Electric AHU Controller box that the correct AHU Controller is matched with the

correct air curtain.

Other components for the heat pump system are as described above on the System

Schematics on pages 2 and 3.

Wall Brackets and Fixing Bolts

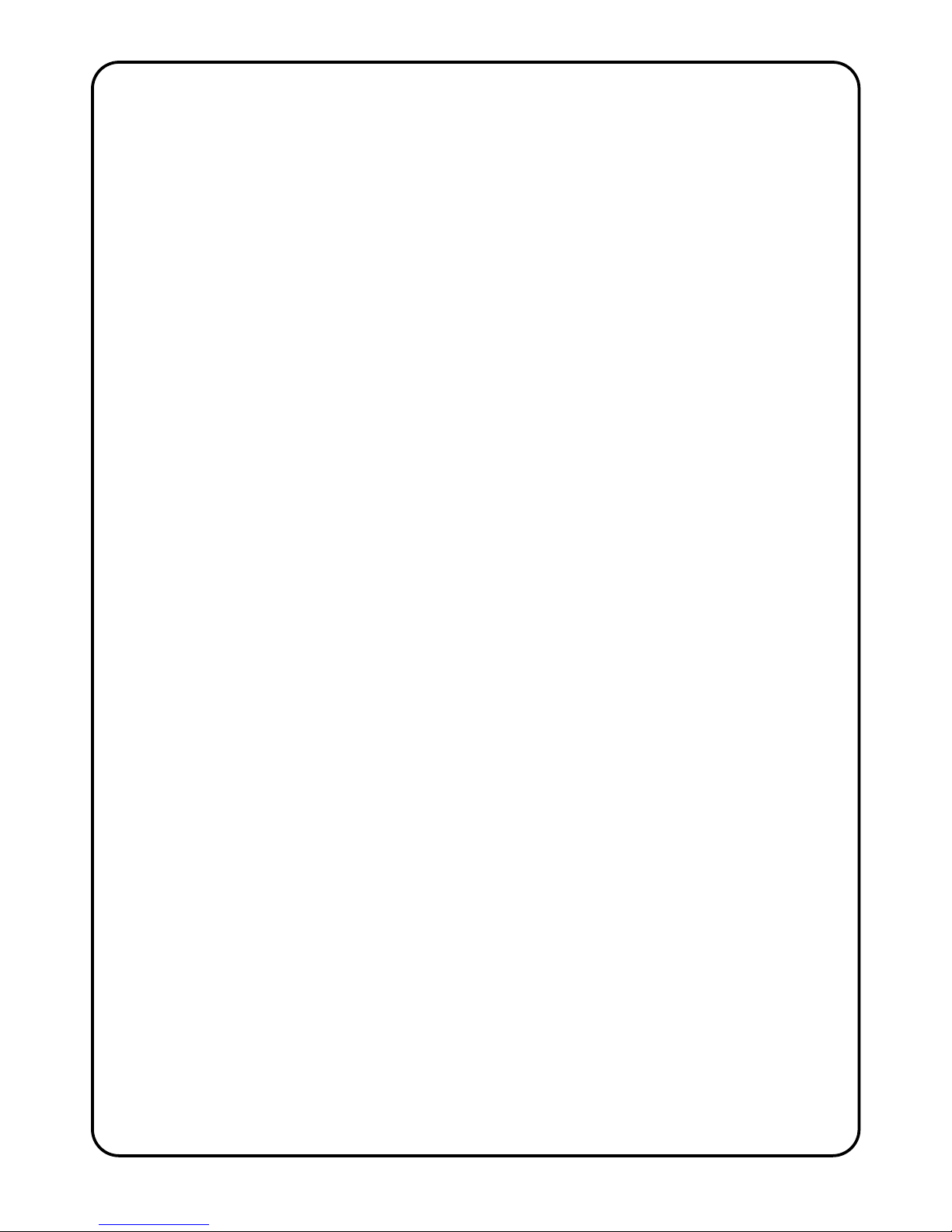

City Multi Heat Pump Air Curtain

Please note, end caps are supplied loose

to be fitted during installation

Remote 3-Speed Fan Switch

PAC-AH..M-G or M-H..AHU Controller

9901035-1 Page 8 of 30

The Installer will also need to supply and install the following:-

The following optional equipment is also available for the air curtain:-

For your records:

Date of Purchase……………………………..

Place of Purchase…………………………….

Serial Number…………………………………

For warranty purposes proof of purchase is necessary so please keep a copy of your invoice.

Sheet metal covers to hide services Fan Speed Controller for low speeds

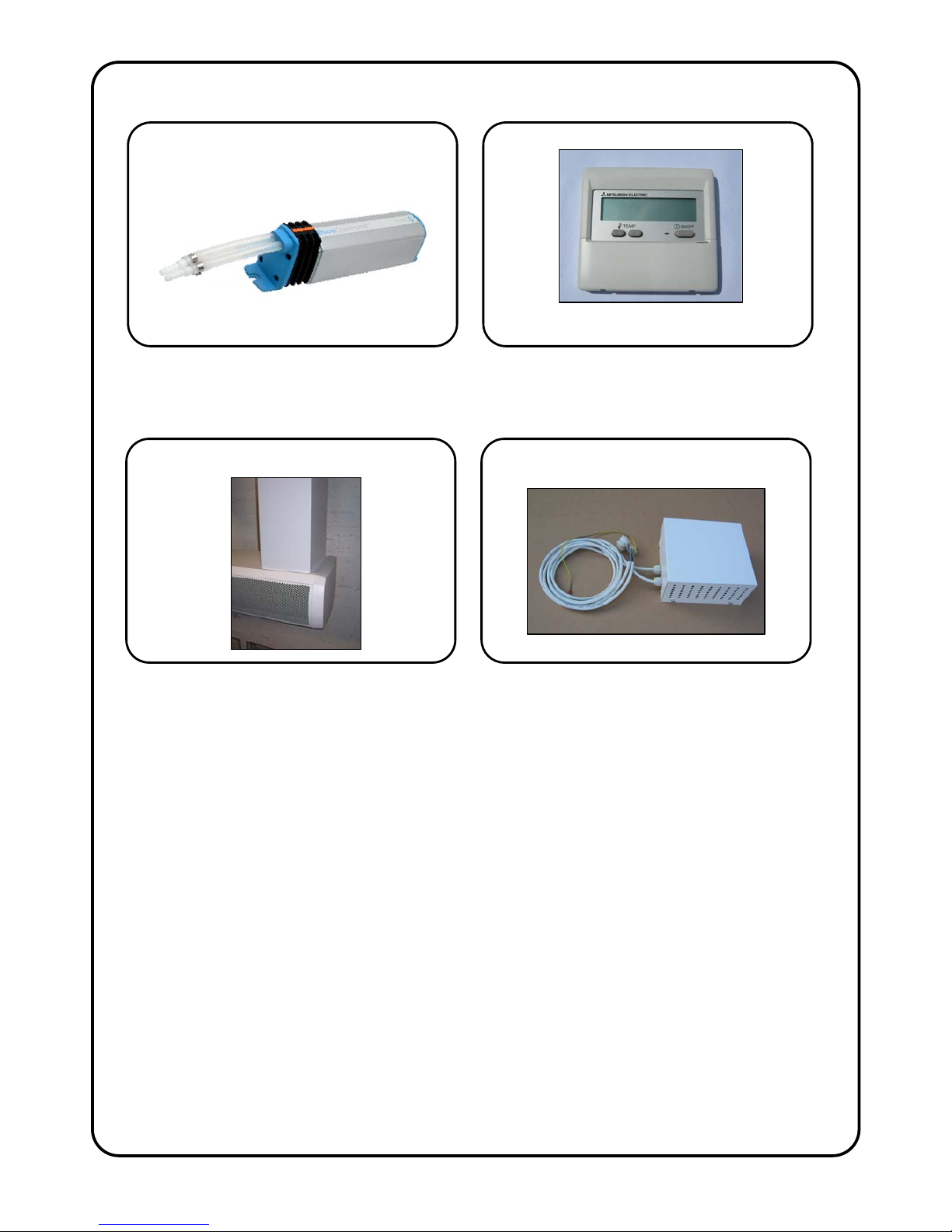

Condensate Pump – self priming with

cooling mode detection, alarm

system and pump overrun

PAR-21 MAA Remote Controller

If Air Curtain is to be manually controlled,

also needed for commissioning

If Air Curtain is to be operated in COOL or

AUTO mode – see text for more information

9901035-1 Page 9 of 30

INSTALLATION OF THE HEAT PUMP AIR CURTAIN

The air curtain is designed to be surface mounted inside of the building and located

over a doorway. It must not be installed outside of the building, or built into a

cabinet or recessed in any way.

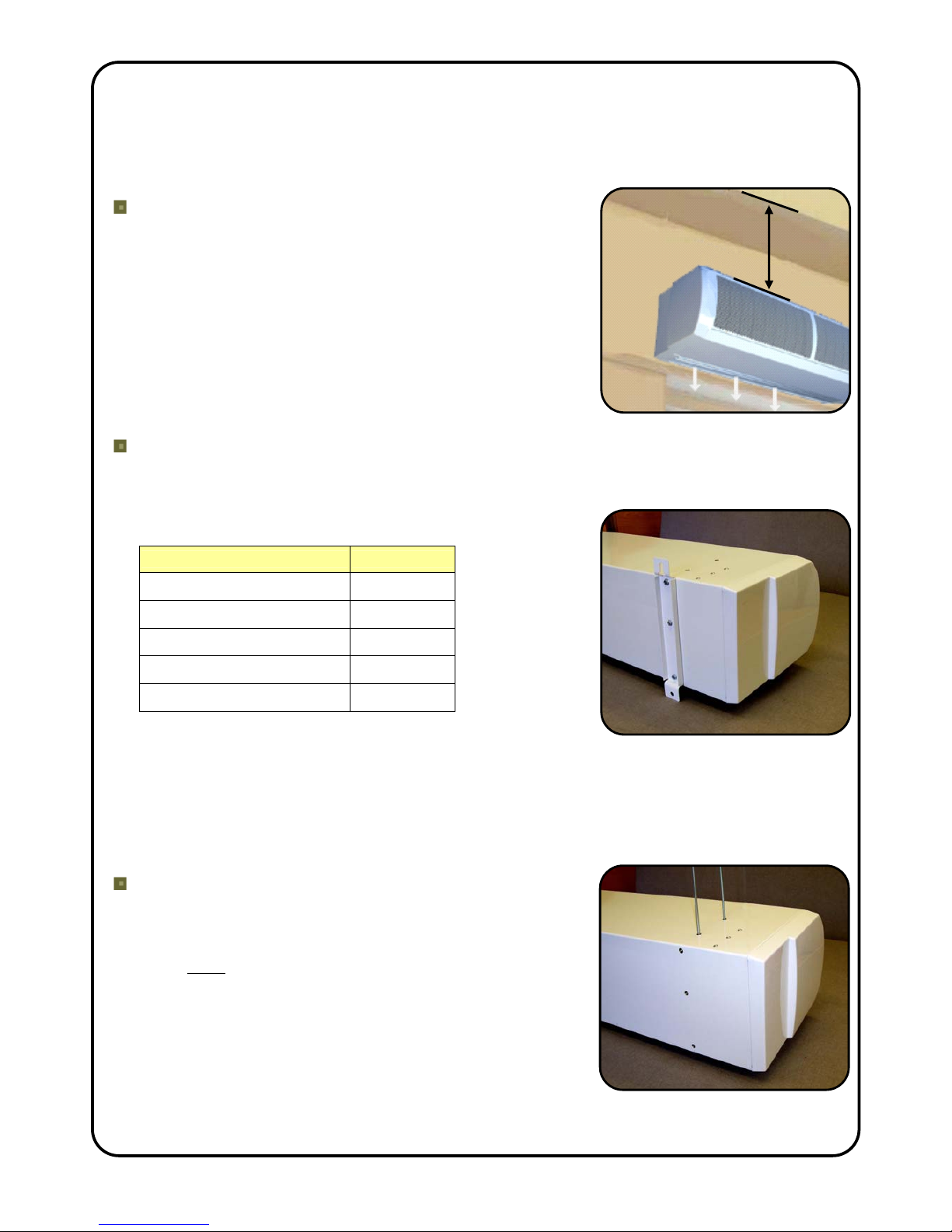

Location

The air curtain must be mounted so the discharge grille is

between 1.8m minimum and 3.75m maximum above floor

level and situated as close to the doorway as possible.

Beware of doorway top edges, structural beams, door

opening devices, etc. which may interfere with the air

stream and affect the location of the unit. The air curtain

must be installed level or condensate may leak out,

particularly if it tilts down at the left hand side (looking out

of the doorway from inside). It is better to tilt down slightly

at the right hand side as the drain tray spout is this side.

Wall Fixing

Bolt all of the wall brackets supplied to the rear face of the unit as shown in the adjacent

picture using the M6 bolts supplied. Suitable wall fixing bolts (not supplied) need to be

used to fix the brackets to the wall, taking into account the

type of wall and the weight of the unit*, see table:

Air Curtain Weight (kg)

VRF PHV1000 DXE HO 39

VRF PHV1500 DXE LO 59

VRF PHV1500 DXE HO 60

VRF PHV2000 DXE LO 78

VRF PHV2000 DXE HO 80

Step 1. Refer to Figure 1 for mounting details and drill the

fixing points in the wall.

Step 2. Screw in the top wall bolts leaving a small gap between the head and the wall.

Lower the unit onto the bolts via key-hole slots in the top of the wall brackets and then

screw in the bottom wall bolts.

Step 3. Ensure all fixing bolts are tightened and the air curtain is safely secured to the

wall.

Ceiling Suspension

M10 threaded inserts are provided in the top face of the

unit (see Figure 1 for positions) so it can be suspended on

M10 threaded hanging rods (not provided). All suspension

points must be used. Ensure each of the hanging rods is

secured onto a suitable structure that can support the

weight of the unit (see table above)*. Screw the hanging

rods into the inserts by a minimum of 20mm and fit

locking nuts (not supplied) to prevent the rod rotating and

coming away from the casing. Do not screw the hanging

rod too far in or it will interfere with internal components.

* It is the sole responsibility of the installer to ensure that the building fixing locations and

suspension system used are suitable for the air curtain being installed.

250mm min

Loading...

Loading...