Thermoscreens PHV1500A v, PHV2500W V, PHV1500W V, PHV2000W V, PHV3000W V Installation, Operation & Maintenance Instructions Manual

...Page 1

9901020-6 Page 1 of 25

PHV V NT VERTICAL AIR CURTAINS

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

PLEASE READ THESE INSTRUCTIONS CAREFULLY BEFORE ATTEMPTI NG INSTALLATION

Thermoscreens Ltd

St. Mary’s Road Nuneaton

Warwickshire England

CV11 5AU

Email: sales@thermoscreens.com

Tel: +44 (0) 24 7638 4646

Fax: +44 (0) 24 7638 8578

www.thermoscreens.com

Page 2

9901020-6 Page 2 of 25

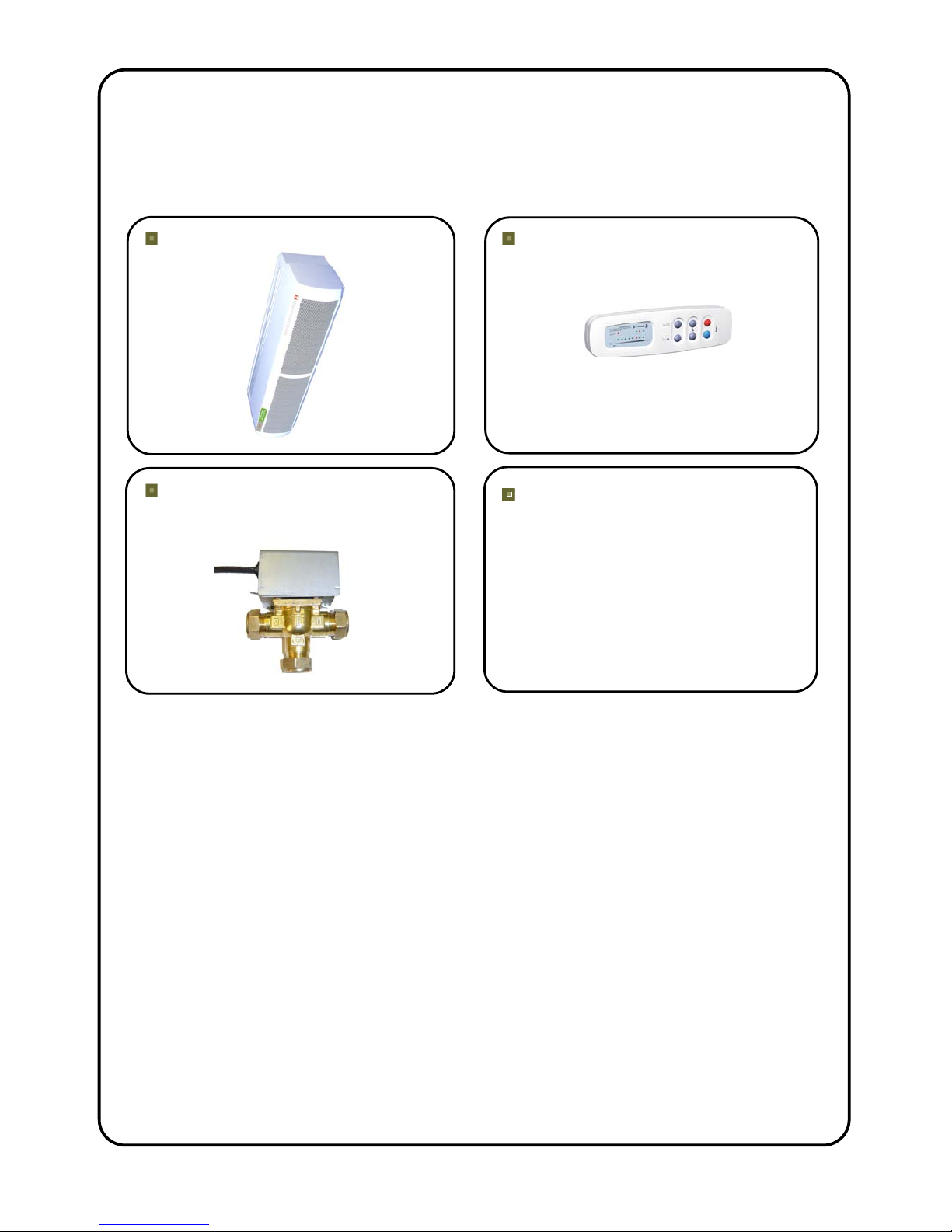

UN-PACKING YOUR PHV V NT VERTICAL AIR-CURTAIN

The following items are supplied and packaged within the boxes.

PHV V NT Vertical Air Curtain

Motorised Valve

(LPHW units only)

Remote Control

Accessories

M10 stainless steel dome nuts

Wall fixing kits

Stacking kit (spacer plate, M8 x 25 bolts

and M8 nyloc nuts) for stacked units

If anything is missing or damaged please contact your place of purchase immediately.

For your records

Date of Purchase……………………………..

Place of Purchase…………………………….

Serial Number…………………………………

For warranty purposes proof of purchase is necessary so please

keep a copy of your invoice.

(All documentation supplied with each unit should be stored and kept for future reference).

Page 3

9901020-6 Page 3 of 25

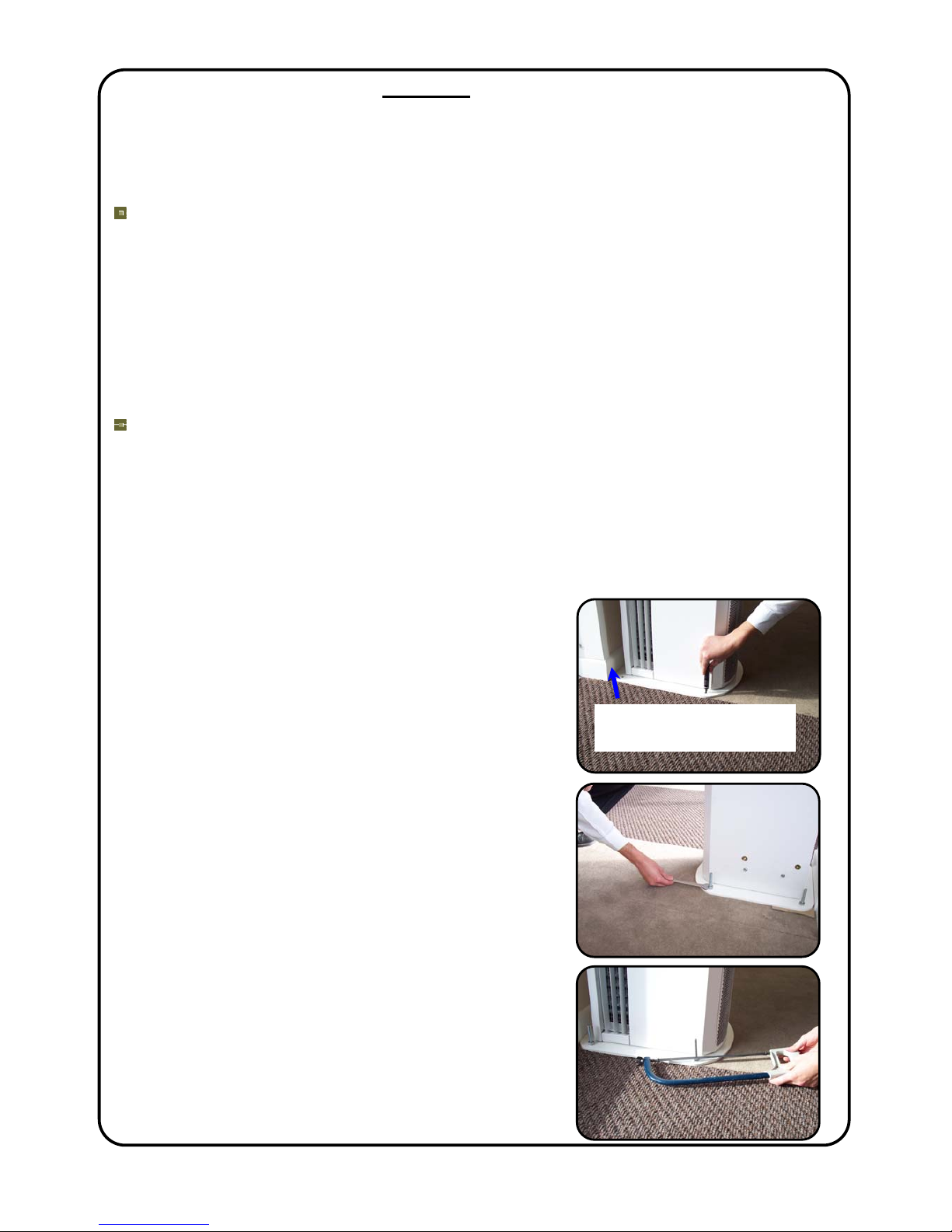

INSTALLATION OF YOUR VERTICAL APPLICATION PHV V NT AIR CURTAIN

The air curtain must be surface mounted within the building and not exposed to

the external environment or moist conditions. Do not install the air curtain in a

doorway situation where there is a likelihood, or there has been a history of, rain

ingress. The air curtain must not be built into a compartment or recessed.

Location

Prior to commencing any vertical installation it is essential to ensure the correct handing

has been selected, i.e. Left Hand (LH) or Right Hand (RH) - . see “Handing Guide” in

Figure 1. Maximum doorway width = 2m per air curtain.

The air curtain should be located close to the door opening with the air discharge grille

positioned nearest to the door. For maximum effectiveness it is essential to ensure the

top of the air curtain is slightly higher than the opening height of the door. Obstructions

such as door opening devices, structural beams etc will reduce the efficiency of the air

curtain.

Floor Fixing

Before installing the air curtain obtain four suitable M10 fixing bolts, taking into account

floor type and unit weight (See Table 1)*. Rawlplug ® M10 Projecting Rawlbolt ® 44356

type may be suitable. For dimensional details refer to the general assembly drawing,

Figure 1.

Determine and place the unit in position. A wall bracket is provided to secure the

vertical air curtain to the wall and this must be used. So that the wall bracket touches

the wall, ensure the back of the base plate touches against the wall, skirting board will

need to be cut away if necessary.

Using the base plate as a template, mark the location

of the four holes, as indicated in the adjacent picture.

Using a suitable masonry drill bit correctly drill the

four marked out holes. Place M10 fixing bolts into

each hole, ensuring all bolts are upright.

Reposition the air curtain base plate over the

projecting bolts. Tighten each M10 nut as indicated

in the adjacent picture. Ensure the vertical unit is

secure, level and square. It may be necessary to

pack under the base plate to ensure unit is vertical.

Using a hacksaw carefully cut the projecting bolt

flush with the nut, ensuring the base plate is not

damaged or marked in any way.

Base plate to touch wall

(cut away skirting board)

Page 4

9901020-6 Page 4 of 25

Remove only one M10 nut and refit and resecure bolt

with a stainless steel M10 dome nut supplied.

Repeat for each of the other three projecting bolts

one at a time.

Stacking of Units

PHV1500V and PHV2000V air curtains are delivered as single units. PHV2500V and

PHV3000V air curtains are delivered as separate 1.5m + 1m air curtains for a

PHV2500V unit and 2m + 1m air curtains for a PHV3000V unit. The 1m air curtain

must always be mounted as the top unit using the stacking kit supplied to secure it to

the bottom unit. The spacer plate, in the stacking kit must be bolted between the two

units using the 4 off M8 x 25 bolts and nyloc nuts. This will allow the removal of

access panels when required. All wall brackets must be used to properly secure both

the bottom and top air curtains in the stack to the wall (See Figure 1).

* It is the sole responsibility of the installer to ensure that all the fixing points and bolts

used are suitable for the air curtain.

Attention: The panels of the air curtain are coated in an easy to peel protective

film. Please ensure all the protective film is removed before the air curtain is put

into service.

Page 5

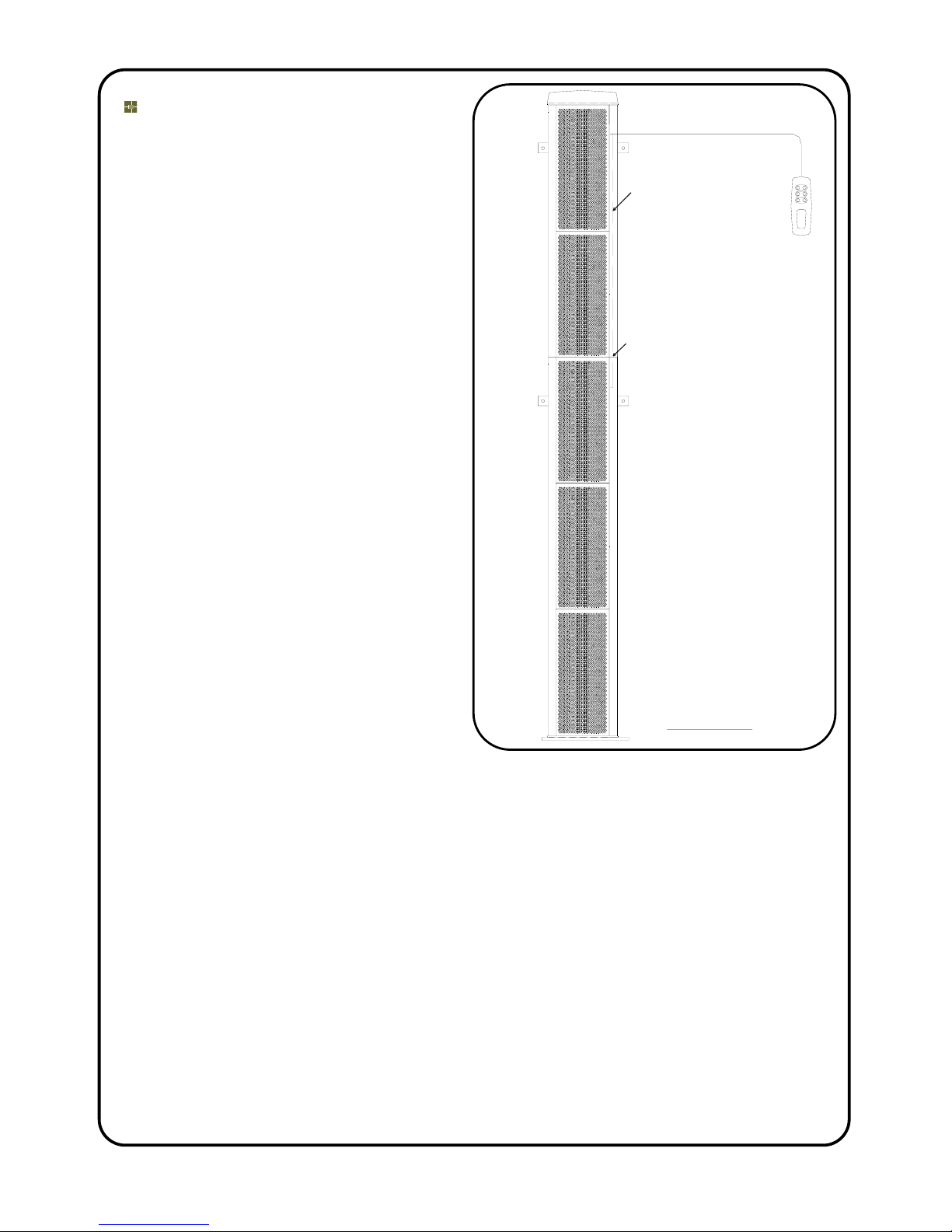

9901020-6 Page 5 of 25

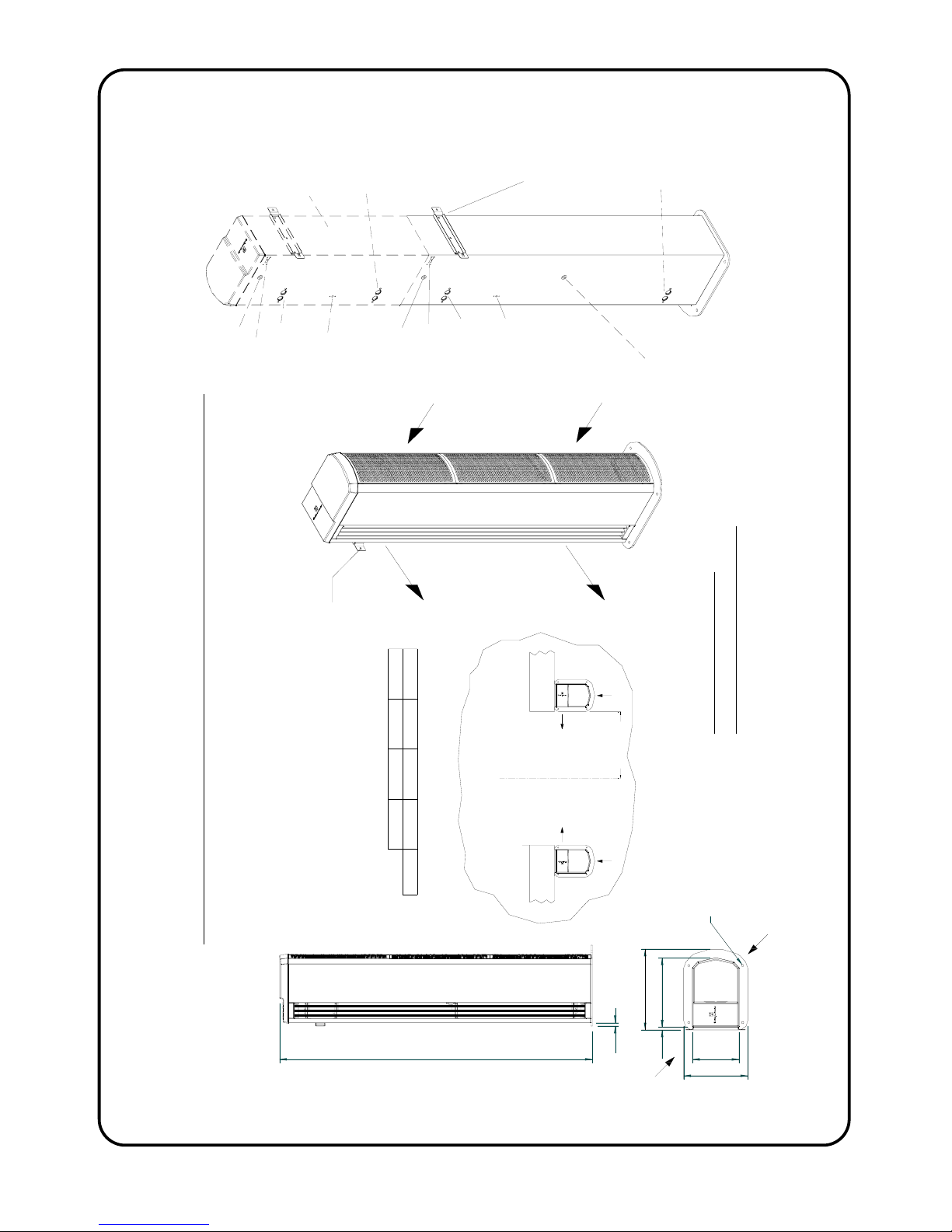

ENTERING AIR

DISCHARGE AIR

View 'A'

View 'B'

View 'A'

As drawn for R.H.

Opposite hand for L.H.

Bolt Holes for M10

Rawl bolts - 4 off

Figure 1 - VERTICAL PHV V NT AIR CURTAIN

PHV1500V

280922571707A(mm)

PHV2000V

PHV2500V PHV3000V

3359

DOORWAY

RHLH

OUTSIDE

INSIDE

"Handing Guide"

A

350

Foot Plate

439.6

Foot Plate

254.6

377.514.7

17

View 'B'

Electrical inlet

Wall Bracket:-

1 off for PHV1500V

& PHV2000V.

2 off for PHV2500V

& PHV3000V

Alternative

water connection

Electrical supply inlet

for PHV2000E V only

Controls

Water connection

Electrical inlet

Controls

(not used on

stacked units)

Water connection

1m Stack Unit

2 Holes for M8 fixing bolts

Distance between

hole centre s 295mm

Overheat reset

button for electric

heated unit

Overheat reset

button for electric

heated unit

2m Max.

Alternative

water connection

Page 6

9901020-6 Page 6 of 25

Safety and Electrical Connections

All electrical wiring and connections MUST be carried out by a competent qualified

electrician in accordance with the latest edition of the IEE wiring regulations and/or

local statutory regulations.

A single phase or 3 phase local isolator with a contact separation of at least 3mm in all

poles must be fitted to the supply wiring (the isolator must be fitted in an accessible

position).

The air curtain must be earthed.

The appliance must be connected using cables having an appropriate

temperature rating (heat resistant). For two air curtains in a stack, electrical power must

be connected separately to the bottom air curtain and to the top air curtain.

Ensure that the supply cables, circuit breakers and other electrical installation

equipment are correctly sized for the air curtain being installed; see Table 1 for Power

Ratings. See also data badge inside of unit adjacent to electrical inlet.

On a 3 phase electrical supply the unit requires a neutral connection (3N~).

Cable glands used for the Electrical Input must be rated IP21 or higher.

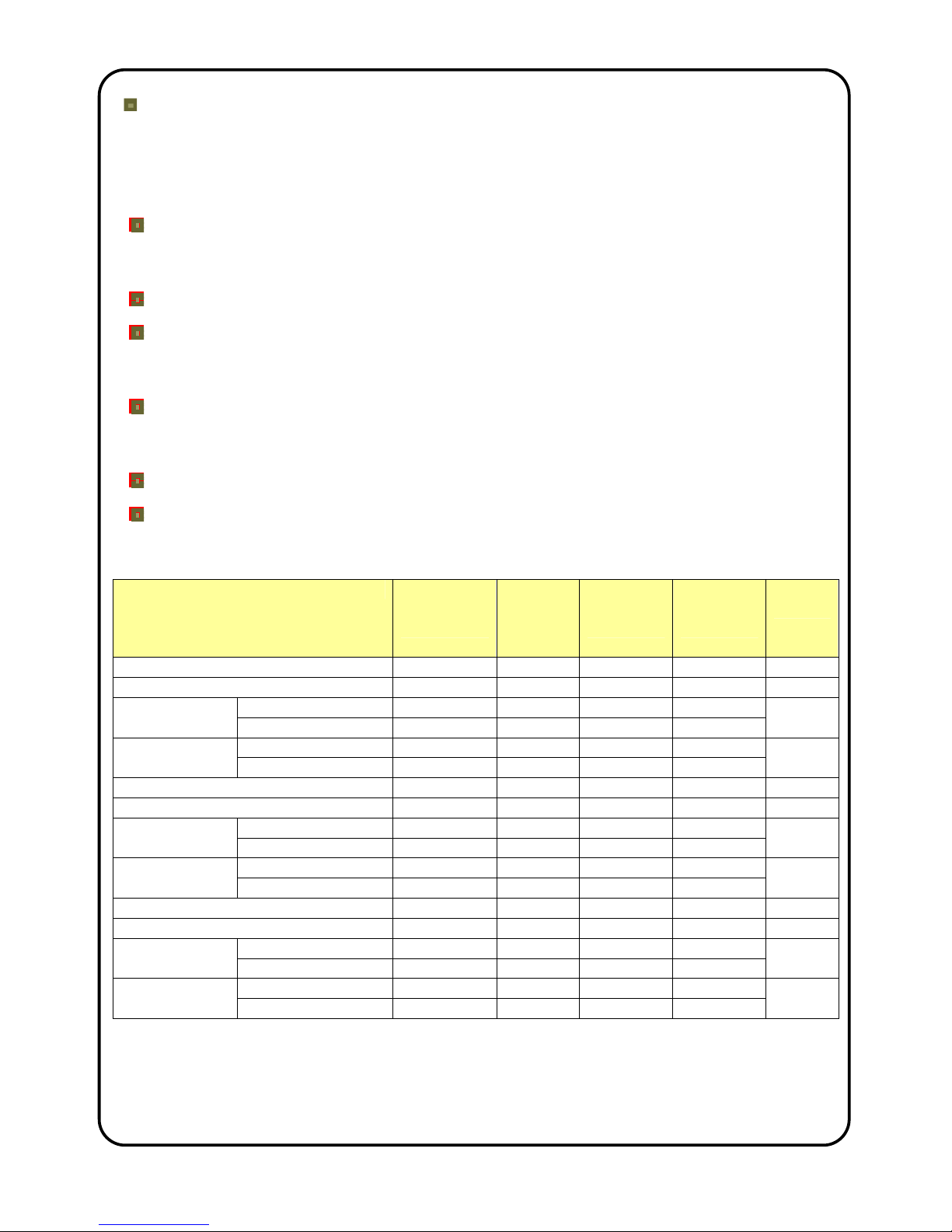

Table 1

Air Curtain Electrical

Supply

(V/ph/Hz)

Rated

Power

Input

(kW)

Current

per

phase (A)

Heat

Output

(kW)

Weight

(kg)

PHV1500A V 230/1/50 0.40 1.8 N/A 60

PHV2000A V 230/1/50 0.60 2.7 N/A 77

Top air curtain 230/1/50 0.30 1.3 N/A PHV2500A V

(Stacked Unit)

Bottom air curtain 230/1/50 0.40 1.8 N/A

99

Top air curtain 230/1/50 0.30 1.3 N/A PHV3000A V

(Stacked Unit)

Bottom air curtain 230/1/50 0.60 2.7 N/A

116

PHV1500W V 230/1/50 0.40 1.8 18.0 68

PHV2000W V 230/1/50 0.60 2.7 24.0 87

Top air curtain 230/1/50 0.30 1.3 12.0 PHV2500W V

(Stacked Unit)

Bottom air curtain 230/1/50 0.40 1.8 18.0

114

Top air curtain 230/1/50 0.30 1.3 12.0 PHV3000W V

(Stacked Unit)

Bottom air curtain 230/1/50 0.60 2.7 24.0

133

PHV1500E V 400/3/50 18.40 27.9 9.0/18.0 66

PHV2000E V 400/3/50 24.60 37.5 12.0/24.0 85

Top air curtain 400/3/50 12.30 18.7 6.0/12.0 PHV2500E V

(Stacked Unit)

Bottom air curtain 400/3/50 18.40 27.9 9.0/18.0

109

Top air curtain 400/3/50 12.30 18.7 6.0/12.0 PHV3000E V

(Stacked Unit)

Bottom air curtain 400/3/50 24.60 37.5 12.0/24.0

128

Page 7

9901020-6 Page 7 of 25

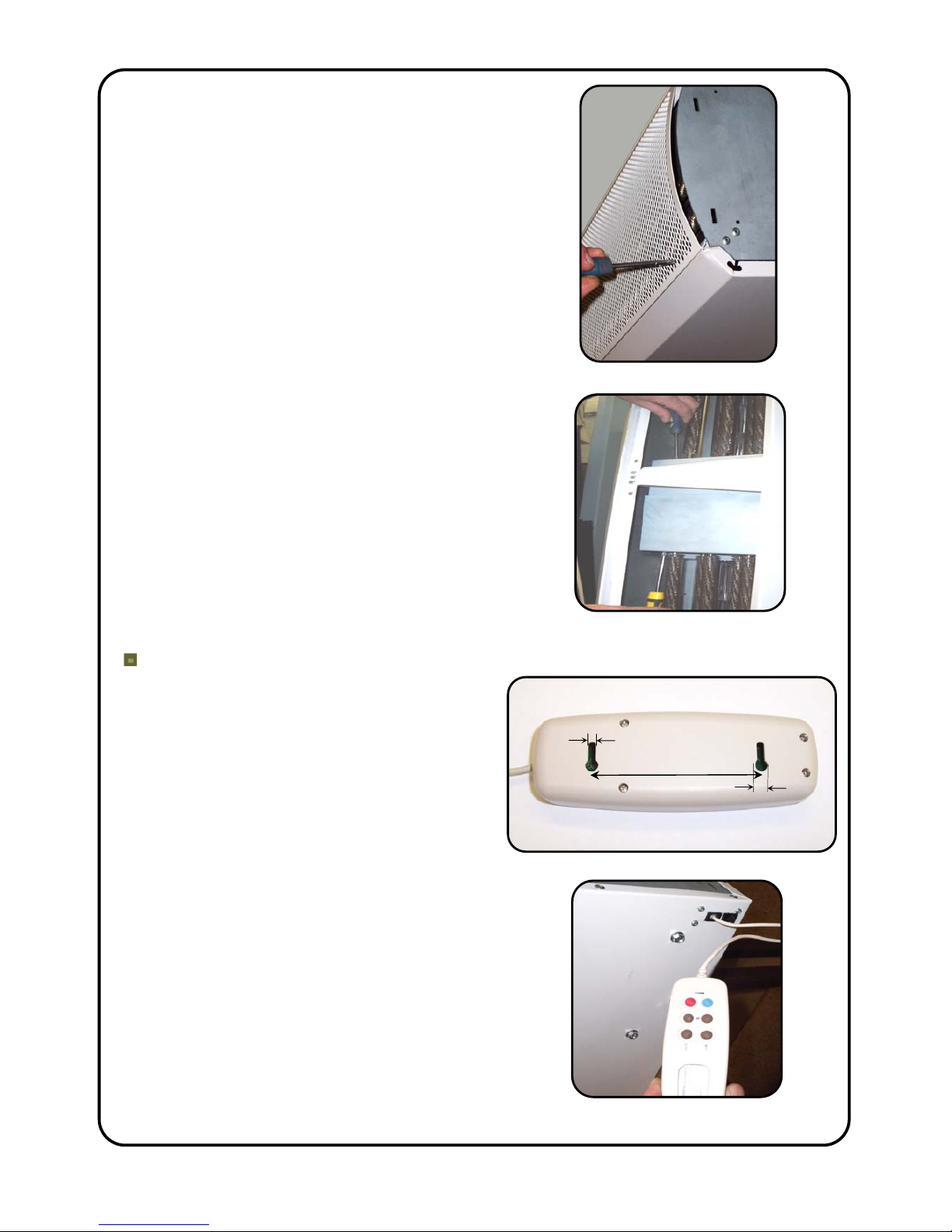

To gain access for making electrical and/or water

services the air intake grilles must be removed.

Remove intake grilles by unfastening two screws

on each grille; M4 x 10mm Pozi screws accessed

via larger hole in the side of the grille (See

Insert).

Access can now be gained to make the electrical

connections and assist with water connections.

When making electrical connections first remove

the safety cover plates over the electrical supply

terminals. On 2m electric air curtains the safety

cover plates are located towards the centre of

the air curtain (See Insert).

For two air curtains in a stack electrical and

water connections are made separately to the

bottom air curtain and to the top air curtain

(See Figure 1 View B).

Fitting/Connecting the Ecopower Remote Control

The remote control unit should be located in

a suitable place for easy access, it can be

fixed to the wall via two key-hole slots. Drill

and fix the screws into the wall leaving a

small gap between the head and the wall,

lower the unit onto the screws, for fixing

centres see adjacent figure. Ensure suitable

fixing screws are used.

The remote control is supplied with cable and

a pre-fitted RJ connecting plug.

Ensure the remote control cable is safely

secured and connected to the air curtain as

indicated. It can be plugged into either

socket.

80mm

3.5mm

6mm

Safety

cover

plates

Page 8

9901020-6 Page 8 of 25

RJ master/slave cable safely

routed internally between

circuit boards of top and

bottom air curtains

Figure 2

Route master/slave cable via

internal hole in stacking kit

Two Air Curtains in a Stack

When two air curtains are in a 2.5m or

3m stack the Ecopower control wiring

needs to be wired “master/slave”, so the

air curtain stack is controlled by a single

Ecopower remote control.

Plug the control cable from the remote

control into one of the RJ sockets at the

side of the top air curtain.

Inside the air curtain stack connect the

RJ master/slave cable that is already

plugged into the top unit circuit board,

into the Ecopower PCB of the bottom

unit. Route the RJ master/slave cable

safely via the hole in the stacking kit

(Refer to Figure 2).

Page 9

9901020-6 Page 9 of 25

A

B

A/B

22mm pipe

22mm pipe

22mm pipe

15mm

pipe

R

E

T

U

R

N

F

L

O

W

Upper water entry point shown

for Right Hand air curtain

Alternative water entry

points shown in dotted

A

B

A/B

22mm pipe

22mm pipe

22mm pipe

15mm

pipe

R

E

T

U

R

N

F

L

O

W

Optional 1m Stack Unit

Figure 3

LPHW Models

For LPHW models ensure suitable

water mains isolation valves are

fitted in the flow and return

pipework.

When fitting the 3-port valve ensure

that the pipe connections are fitted

as detailed and are in accordance

with the manufacturers leaflet

supplied with the valve.

For two air curtains in a stack each

air curtain requires a separate and

independent water flow and return

connection with its separate control

valve (See Figure 3). Each control

valve is wired to the terminal block

in each air curtain (see wiring

diagram for water heated units).

In order to obtain optimum heat

output, all air from the system and

the heating coil must be vented.

Refer to insert detailing the water

coil air bleed valve.

Air Curtain Water Flow Rate

(l/s) 82/72 °C

Coil Water Pressure

Drop (kPa)

PHV1500W V 0.43 2.60

PHV2000W V 0.57 4.72

Top air curtain 0.29 1.14 PHV2500W V

(Stacked Unit)

Bottom air curtain 0.43 2.60

Top air curtain 0.29 1.14 PHV3000W V

(Stacked Unit)

Bottom air curtain 0.57 4.72

Air vent

Page 10

9901020-6 Page 10 of 25

Ecopower Controller Motherboard (v8)

Function

Control

Comments

Standard

Fan Heat Interlock for Electric

Heated Air Curtains–

The heat output is dependent on the fan

speed. If low or medium fan speed is

selected the heat output can only go up to

first heat stage. Only if the unit is operating

on high fan speed can the second heat

stage be selected. This feature operates in

manual or auto mode.

DIP1

Maximum heat output achieved if

maximum fan speed selected.

Independently set-up DIP switch on

each mother board.

Used to avoid excessive temperatures

with electric heated air curtains.

As supplied, for electric

heated air curtains the

default setting for heat

output would be

dependent on fan speed

(DIP1 ON).

For Ambient and LPHW

heated air curtains

default setting for DIP1

OFF.

Disable Fan Run-on for LPHW and

Ambient Air Curtains –

Disable fan run-on.

DIP2

Must only be used for LPHW and

Ambient air curtains. Independently

set-up DIP switch on each mother

board.

As supplied, for Ambient

and LPHW heated air

curtains the default

setting would disable fan

run-on (DIP2 ON).

Thermostat Master –

Only the air sensor thermistor in the master

air curtain will be used for measuring the

reference air temperature for the whole

master/slave installation.

DIP3 Option

The air sensor thermistors in all the

slave air curtains will be ignored. This

will then avoid situations on larger

doorways with master/slave air

curtains where some units can blow

cold air whilst others can blow warm

air, because they currently all refer to

their own air sensor for control of the

heat output of each air curtain.

The master air curtain need not be the

one that the wall control is plugged

into.

This dip switch setting must also

be used for Global Switching

(Master/Slave) via the INHIBIT

terminal – see next page.

As supplied, the default

setting would be for the

air sensor thermistor on

all units to be measuring

(DIP3 OFF).

Overheat Fan Disable –

If DIP4 is on and thermal overheat trips,

heat and fan circuits are isolated and LED’s

on wall switch flash. If DIP4 is off and TOC

trips out, only the heat circuit is isolated and

the LED’s on the wall switch flash.

DIP4 Option

(Electric only)

Wall switch upgrade required.

The handset has to be powered on.

Independently set-up DIP switch on

each mother board.

To remove fault, isolate electrical

supply to air curtain, reset TOC and

reconnect supply.

As supplied, the default

setting would enable fan

if TOC trips (DIP4 OFF).

NB: If TOC operates with

an upgraded switch the

LED’s on switch flash,

regardless of DIP4

settings.

Retain User Settings (toggle) –

If electrical supply to the air curtain is

removed, upon restoring electrical supply

the customer’s settings on the remote

control will be retained, i.e. if unit were

operating beforehand, it would

automatically start up again and operate on

the exact same settings as before.

Optional

feature –via

secret key

press (Fandown)

Wall switch upgrade required.

To toggle – switch unit on from

handset. Hold Auto button till Auto

LED flashes. Press fan down button to

toggle selection.

As supplied, the default

setting would be for the

unit to start up again

automatically. Need to do

the secret key presses to

revert back to “nothing

happens” when power is

restored, as we have it

now.

Fan run-on time set two minutes. Built-in If “FAN ONLY” has been selected, at

switch off, no fan run-on.

Reduce time for fan speeds to turn on and

index up through Low, Medium and High

fan speed when turning on via the

BMS/Remote On/Off option.

Built-in

- white rectangle indicates the moveable head of each 4 way DIP switch

ON

OFF

1 2 3 4

ON

OFF

1 2 3 4

ON

OFF

1 2 3 4

ON

OFF

1 2 3 4

Page 11

9901020-6 Page 11 of 25

DIP switches fitted on the Ecopower board provide a selection of optional features as described above. Isolate and

switch electrical power off before configuring and/or changing any DIP switch settings.

• Easy plug-in arrangement for remote air sensor thermistor on a 1m lead. Plugging-in the remote air sensor to J3

disables the standard air sensor thermistor already fitted on the Ecopower board. As supplied, the board will not

have the remote air sensor fitted.

• An INHIBIT two screw terminal fitted on the Ecopower board for BMS remote On/Off feature.

If the terminal is linked, i.e. by 2 wires to a remote volt free contact, the unit will run. If it is open circuit across the

terminal the unit will switch off. This remote On/Off feature has global switching logic, i.e. if you master/slave several

units together you need connect the remote contact to only one of them to turn all units on and off in the master/slave

system. For global switching to work on the slave units, need to set DIP3 Option (see previous page) on the unit that

the remote contact is wired to and

have previously turned the unit on with the wall switch. As supplied, a wire link will

be fitted to the terminal block on every unit. For summer settings place a 3.3kΩ resistance across the INHIBIT

terminal, with these settings fans only will run even if controller is requesting for heat.

ECOPOWER BOARD

Customer Building Management System

• A HEALTHY two screw terminal is included on the board for a fault signal indication if the electric elements overheat

cut-out has operated. A healthy system provides a 24V DC signal at the terminals compared to an overheat fault

which provides OV DC.

Page 12

9901020-6 Page 12 of 25

Page 13

9901020-6 Page 13 of 25

Page 14

9901020-6 Page 14 of 25

Page 15

9901020-6 Page 15 of 25

Page 16

9901020-6 Page 16 of 25

Page 17

9901020-6 Page 17 of 25

Page 18

9901020-6 Page 18 of 25

Page 19

9901020-6 Page 19 of 25

Page 20

9901020-6 Page 20 of 25

Page 21

9901020-6 Page 21 of 25

Page 22

9901020-6 Page 22 of 25

Ecopower Remote Control Operation

Push On/Off switch to turn On, then operate as follows :-

Auto Switches between manual and automatic heat regulation.

The Auto on indicator LED is lit for "Auto Mode" and un-lit

for "Manual Mode".

On/Off Turns the air curtain On or Off (when turned off the settings for

heat and fan speed are retained). If the air curtain is heating

when it is turned off with this switch the fan will run-on for a time

(approx. 2 minute) to dissipate excess heat.

Selects the appropriate fan speed (Low, Medium or High) to suit the

air curtain height and outside wind conditions. Fan speed can be

changed when unit is in either Auto or Manual Modes. A fan speed

indicator LED shows which fan speed is selected.

In "Auto Mode” the air curtain measures the incoming air temperature

and automatically selects the necessary amount of heat to keep it at

the level selected. Heating level indicator LED's go from 0% to 100%

in 8 steps to show the level selected.

In "Manual Mode” heat output can be selected as Zero, Half Heat or Full

Heat. Heating level indicator LED's go 0%, 50% or 100% to show the

level selected.

Push On/Off switch again to turn Off

Note If the mains supply is isolated or cuts-out during operation the On/Off switch will need

to be pushed again to start the air curtain when the mains supply is restored. The

safety thermal cut-out in the air curtain may operate, if this happens it will need to be

reset by a competent technician.

Higher Heat

Lower Heat

Lower Fan speed

Higher Fan Speed

On / O

ff

Auto Mode

Auto on Indicator

Fan Speed Indicator

Heating Level Indicator

Page 23

9901020-6 Page 23 of 25

Commissioning

Set the discharge grille vanes so they point straight across the doorway. Once the air

curtain is functioning check that the fans operate at Low, Medium and High speeds, that

there is no excessive mechanical noise coming from the fans and that all fans are working.

If the unit is electric heated or water heated check that the air stream from the discharge

grille warms up across the whole height of the air curtain when heating is selected. If there

are two air curtains in a stack PHV2500V or PHV3000V ensure both units in the stack

operate correctly as master/slave. Check that heating increases as higher heat is selected

and feel to see that the warm air stream is reaching across the doorway with door open or

closed. If necessary the vanes of the discharge grille can be angled either inwards or

outwards if this gives better penetration/warming of any incoming draughts. For the

Ecopower controller check all functions operate correctly in Manual Mode. Then select

Auto Mode and increase the heating set point until the air stream warms up. Reduce the

heating set point until the air stream goes cold.

Once functional tests have been completed and

verified all electrical safety plates and intake grilles

must be correctly refitted. The plastic cap should be

clipped on the top of the air curtain (See Insert).

Before leaving site it is important that the air curtain

installation and these instructions are “Handed-Over”

to the end user or his representative and the

operation of it is fully explained and that they

understand how it operates. Explain also the service

intervals and that the unit must be regularly cleaned.

Fault Conditions

In the event of a fault with electrical heated air curtains the thermal cut out(s) may

operate. Note: If the mains supply is isolated during operation then the thermal cut

outs may operate. The thermal cut out(s) are located within the unit adjacent to the

electric elements (one on the 1m & 1.5m and two on the 2m model). There are two

fuses on the Ecopower circuit board which may blow in the event of a fault. The

Ecopower circuit board is located towards the top of each unit.

In the case of a fault condition (refer to flowchart) do not attempt to reset the thermal

cut outs or replace the fuses. Arrange for a Thermoscreens appointed technician or

certified electrician to attend the unit to investigate the reason why the thermal cut

outs/fuse(s) have operated. Once the cause has been determined and rectified, they

will reset/replace the thermal cut out/fuse and function test the unit.

PCB Status

Fitted on the PCB board inside of the air curtain is an LED shown as LED1 on wiring

diagrams that will indicate the Ecopower control status.

1. LED flashing green – operation normal.

2. LED flashing red – low supply voltage.

3. LED permanently red – thermal cut outs open circuit (electrically heated models

only).

Note to reset the thermal cut outs please refer to Fault Conditions section detailed

above.

Page 24

9901020-6 Page 24 of 25

User Fault Finding Flowchart (for Ecopower Control)

Yes

Unit is working

satisfactorily

Switch on Electrical

Power

Connect remote control

and push On/Off switch

to turn unit on

Select heat output

Contact Installer

Service Agent to

investigate why

thermal cut-out(s)

have operated

Service Agent to

reset thermal cut-

out(s)

Contact Installer

Yes

No

Yes

Yes

No

No

No

Yes

Yes

No

No

Is Electrical

Power

switched on

Are the fans

operating

correctly

Is the unit

discharging

warm air

Check if thermal

cut-out(s) have

tripped (Electric

Heated only)

Do the LED’s

light up on

the remote

control

Is the remote

control

plugged in

and turned

on

Page 25

9901020-6 Page 25 of 25

Service & Maintenance

Always disconnect and isolate the mains electricity supply before installing,

maintaining or repairing this equipment. With 2.5m or 3m vertical air curtains

there are two air curtains, one stacked on top of the other. Isolate the mains

supply to both top and bottom air curtains. Note: All maintenance/repairs

should only be carried out by a competent electrician or Thermoscreens

appointed technician.

Once the mains supply is isolated, remove the plastic cap from the top of the air

curtain. Remove each air intake grille by unfastening two screws on each grille –

M4 x 10mm Pozi screws accessed via the larger hole at one edge of each grille.

To ensure the air curtain operates at full efficiency the inlet/outlet grilles, fan impellers,

housings and motors must be kept free of dust and debris. Build up of dust on the fan

impellers can cause vibration, noise and excessive wear on the motor bearings.

Frequency of cleaning will depend on the environment, but we would recommend that

the unit be cleaned a minimum of every 3 months (failure to adequately maintain the

unit and provide a suitable cleaning schedule will result in performance degradation

and reduce the life expectancy of the air-curtain).

Vacuum and clean the build-up of dirt and debris within the air-curtain (please note

that the motor(s) are permanently lubricated and require no additional lubrication).

Once the air curtain has been cleaned, remove appropriate electrical safety cover

plates and check all electrical connections within the unit ensuring terminals are tight

and that crimped connections have not become loose. Always ensure all safety cover

plates are correctly refitted. Refit inlet grilles and plastic cap. Reconnect the electrical

supply and fully function test the air-curtain to ensure correct operation (See

Commissioning).

If the outer casing requires cleaning this should be done using a warm soft cloth. Do

not use solvents or abrasive materials.

Warranty

If any problems are encountered, please contact your installer/supplier. Failing this

please contact the Thermoscreens warranty department. All units are covered by a

two year warranty period.

Care has been taken in compiling these instructions to ensure they are correct, although

Thermoscreens disclaims all liability for damage resulting from any inaccuracies and/or

deficiencies in this documentation. Thermoscreens retain the right to change the

specifications stated in these instructions.

Thermoscreens Ltd

St. Mary’s Road Nuneaton

Warwickshire England

CV11 5AU

Email: sales@thermoscreens.com

Tel: + 44 (0) 24 7638 4646

Fax: + 44 (0) 24 7638 8578

www.thermoscreens.com

Loading...

Loading...