Page 1

T9901018-1 Page 1 of 26

PHV2000NT CHILLED WATER HEAT PUMP,

SENSIBLE/DRY COOLING UNIT

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

For use with PUHZ-HW140VHA2 or YHA2 Outdoor Units

PLEASE READ THESE INSTRUCTIONS CAREFULLY BEFORE ATTEMPTI NG INSTALLATION

Thermoscreens Ltd

St. Mary’s Road Nuneaton

Warwickshire England

CV11 5AU

Email: sales@thermoscreens.com

Tel: +44 (0) 24 7638 4646

Fax: +44 (0) 24 7638 8578

www.thermoscreens.com

English

Page 2

T9901018-1 Page 2 of 26

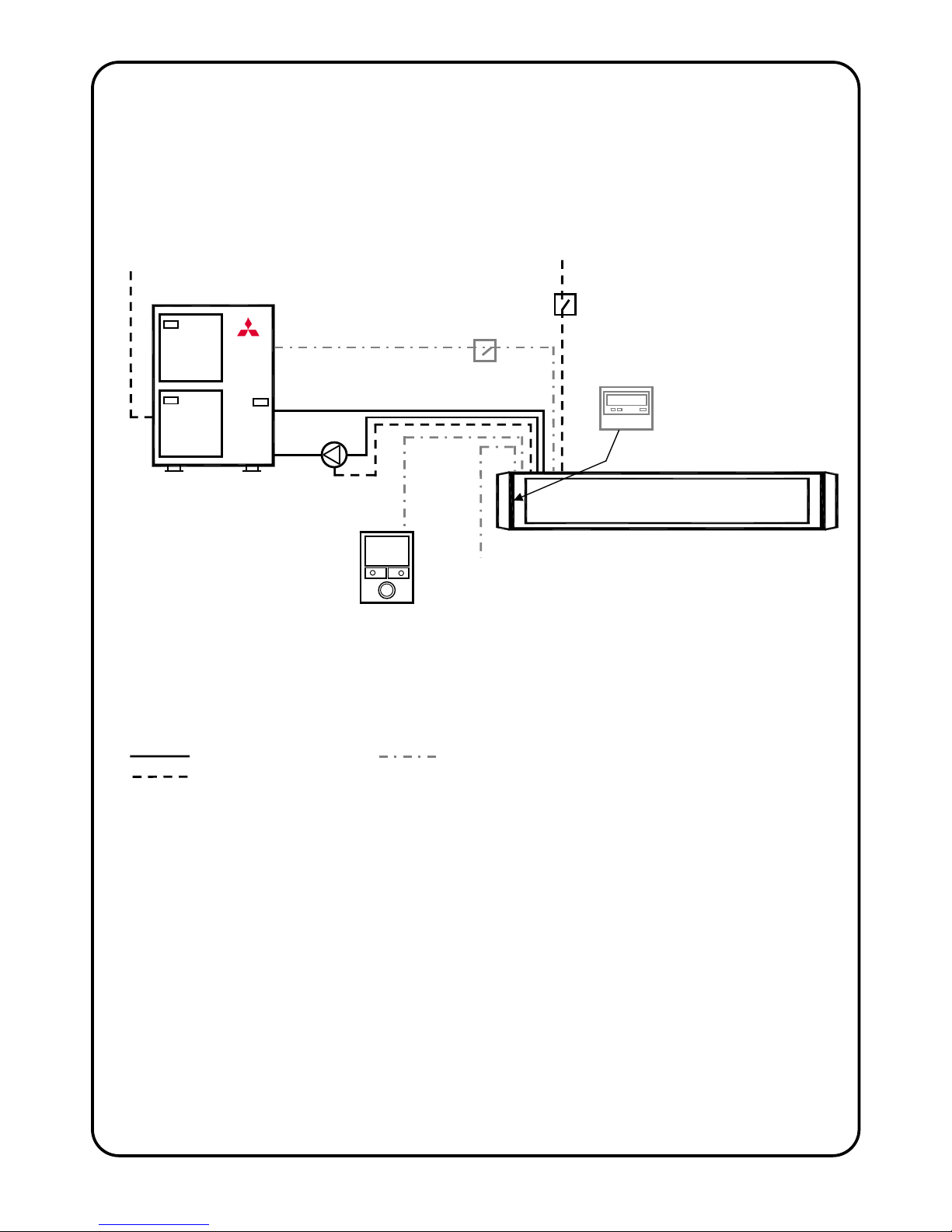

Thermoscreens / Mitsubishi Electric

PHV2000NT Chilled Water Heat Pump,

Dry Cooling Unit - Split System

The PHV2000NT Chilled Water Heat Pump System consists of :-

a Thermoscreens 'PHV2000NT Dry Cooling Unit' with Mitsubishi Electric PAC-IF010B-

E Interface PCB and PAR-W21MAA Controller and Siemens RDG400 Manual Room

Control for manual control by the end user *

a Mitsubishi Electric PUHZ-HW140VHA2/YHA2 Air to Water Outdoor Unit *

* - supplied by Mitsubishi Electric

Water Pipework Installation and Water Pump(s) ‡

Electrical installation ‡

a 2-pole On/Off Switch for the end user ‡

a 2-pole Isolator for the S1, S2, S3 link ‡

‡

- installation items supplied and fitted by installer

Thermoscreens PHV2000NT

Dry Cooling Unit

Mitsubishi Electric

PUHZ-HW140

Outdoor Unit

Permanent 1-phase mains electrical supply

Siemens RDG400

Manual Room Control

On/Off – Input

Cooling Temp Set Point – Input

Air Temp Sensor – Input

(alternative to return air temp sensor in unit)

S1, S2, S3 link

Permanent electrical supply

(from local switched isolator)

Pump

Flow and Return water pipework

Remote Signals

On/Off - Input

Mitsubishi Error - Output

Room over-temp alarm - Output

Chilled water pipework

Electrical cables

Control cables

Supplied and fitted inside plastic end

cap. Not used for control by the end

user, only needed so the outdoor

unit will run.

2-pole On/Off Switch for End User

(easily accessible next to unit)

[connect fire alarm circuit here]

Mitsubishi Electric

PAR-W21MAA

S1, S2

Isolator

Page 3

T9901018-1 Page 3 of 26

DESIGN INFORMATION

The Thermoscreens dry cooling unit is designed to provide up to 12kW * of dry/sensible

cooling (SHR/SHF = 1) (e.g. zero latent cooling with no condensate coming from the unit)

to areas where cooling is required but with no increase in moisture content of the air, i.e. IT

Server Rooms, laboratory areas, etc. It will do this if the room environmental conditions are

no higher than 24°C dry bulb with a relative humidity no greater than 40% and the chilled

water flow temperature entering the unit is no lower than 10°C **. The 10°C chilled water

flow temperature is set at commissioning and controlled by the Mitsubishi Electric PUHZHW140 Outdoor Unit. Under design conditions the return water temperature from the dry

cooling unit is 13°C with a flow water temperature of 10°C.

* - output may be reduced if antifreeze additives are used.

** - validated by tests carried out at independent test house BSRIA, UK.

Chilled water pipework and water pump(s) must be supplied and installed to supply the

chilled water from the PUHZ-HW140 Outdoor Unit to the Thermoscreens dry cooling unit.

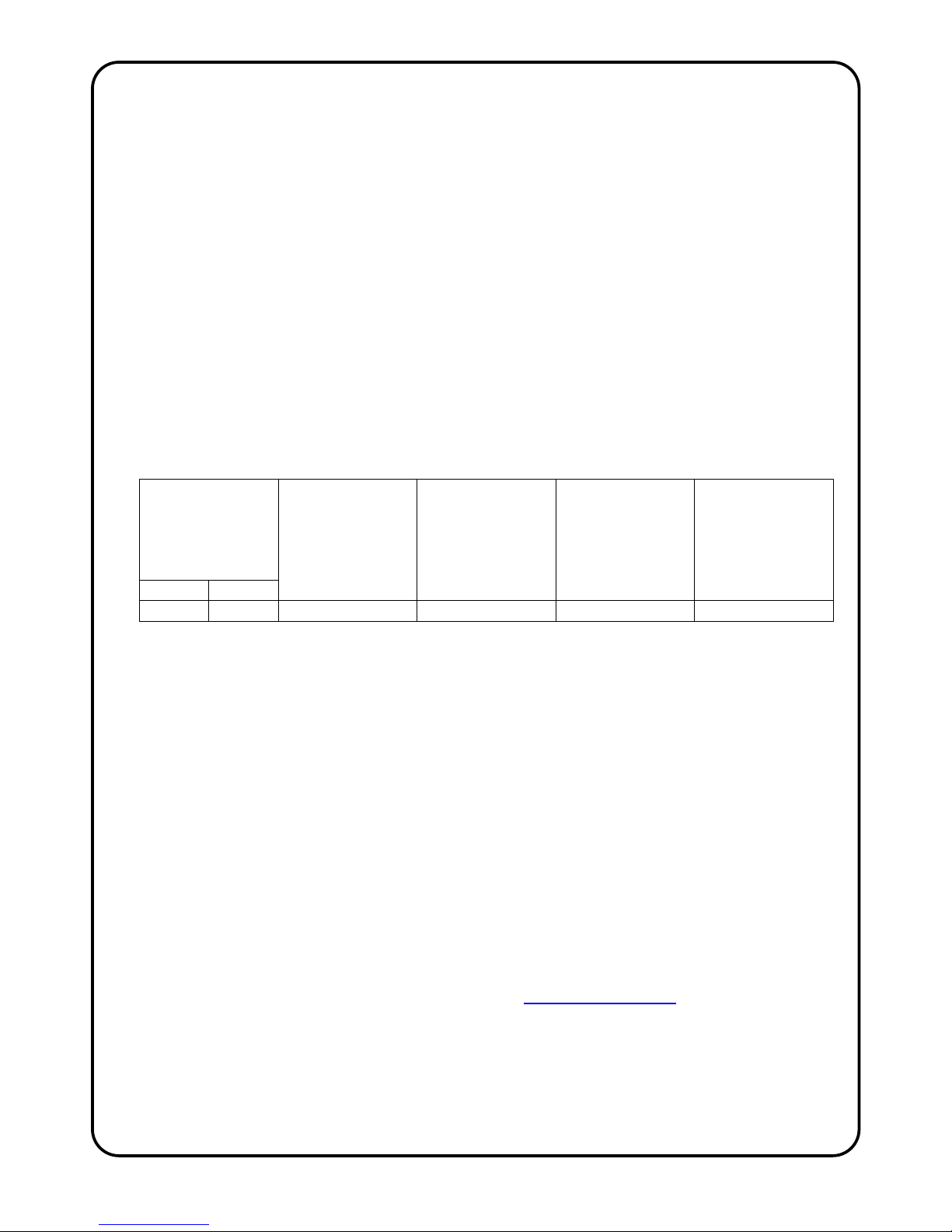

Hydraulic details for this installation are as follows:

Table 1

Water Volume

Flow Rate for

12kW maximum

output

Hydraulic

Resistance of

water coil in

Thermoscreens

Dry Cooling Unit at

3.2 m

3

/h

(kPa)

Hydraulic

Resistance of heat

exchanger in

Mitsubishi PUHZ

Outdoor Unit at

3.2 m3/h

(kPa)

Water Volume of

water coil in

Thermoscreens

Dry Cooling Unit

(litre)

Water Volume of

heat exchanger in

Mitsubishi PUHZ

Outdoor Unit

(litre)

m3/h l/min

3.2 53 36 15 5.1 2.5

A separate, self contained ‘closed/unvented’ water system must be used for the flow and

return water pipework between the Thermoscreens dry cooling unit and the Mitsubishi

Electric outdoor unit. This should incorporate water pump(s), expansion vessel, pressure

relief valve, filling loop, pressure gauge, automatic air vents, water dirt trap device, flow

setter valve (recommended), drain valve(s), isolating valves and union fittings for the

removal of components. The water system must be suitable for chilled water and installed

and commissioned by a qualified technician in accordance with CIBSE Commissioning

Code W, CIBSE KS9, BSRIA AG 2/89.3 and BSRIA AG 1.2001.1. For the Mitsubishi

Electric system to operate correctly the minimum water volume of the water system must

be 80 litres, so a buffer vessel may be necessary. A water dirt trap device should be

incorporated into the chilled water system to help protect the system from any

contamination and provide an ongoing indication of the system water condition. Please

note that the Fernox Boiler Buddy water dirt trap device has a hydraulic pressure drop of

12kPa (clean) at a water flow rate of 3.2m3/h**. If pressure drop in the system becomes an

issue it may be necessary to use a commercial type water strainer with a lower hydraulic

pressure drop. It is recommended that a flow setter valve is fitted in the water pipework

system to verify the water flow rate. We recommend the AV23 SETTER Bypass SD 20-70

l/min DN32 (Code No.223.2561.00) by Taconova www.taconova.com or equivalent.

For a self contained, close coupled 35mm pipework installation the following suggested

water pumps are given as a guide only :-

Wilo TOP-S 30/10 (230V/1ph/50Hz) or Grundfos UPS32-120F (230V/1ph/50Hz)

Pump selection must of course be checked by a Building Services Engineer for

each installation !

Page 4

T9901018-1 Page 4 of 26

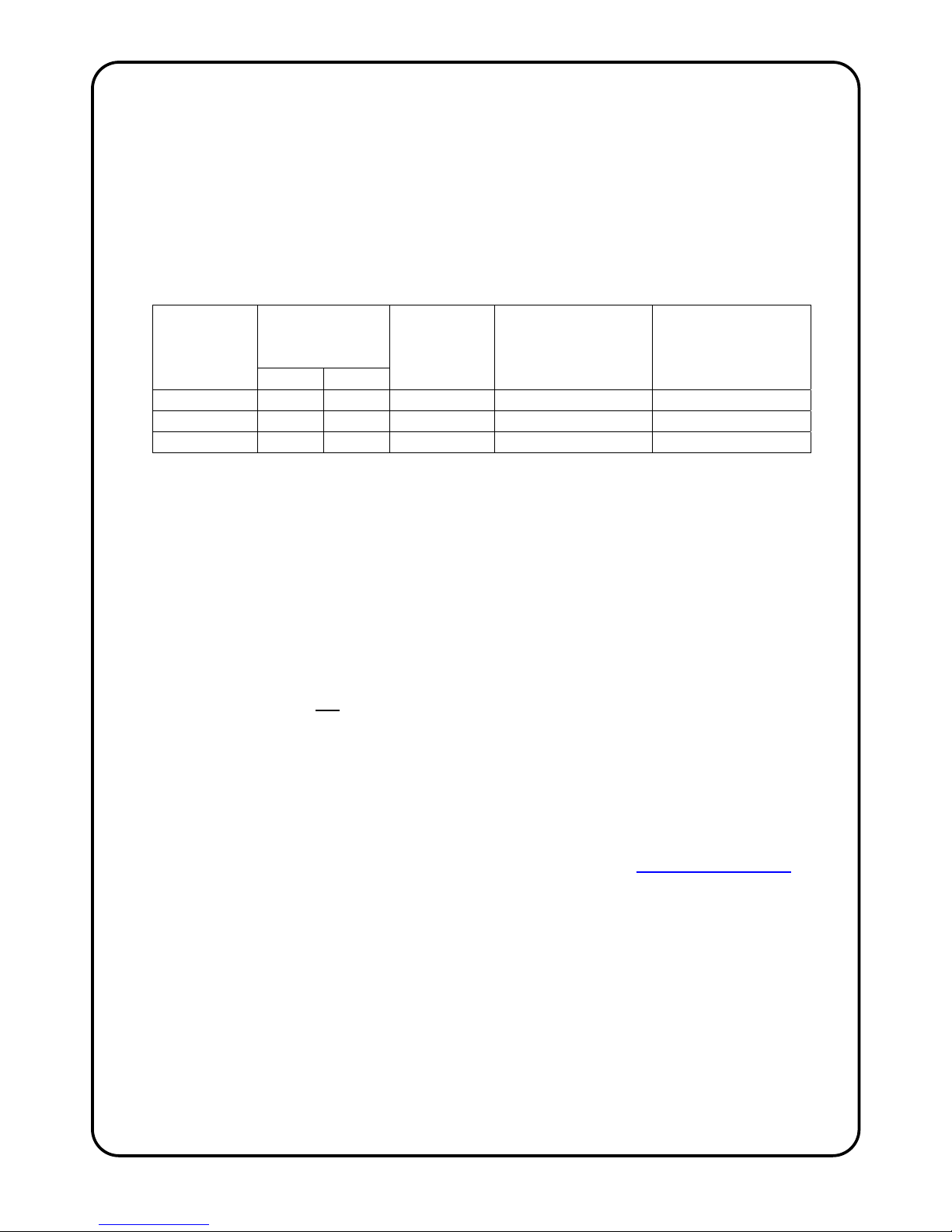

Because of the relatively high hydraulic pressure drops it may be cost effective to

incorporate two water pumps operating in series. Pump(s) need to be 230V/1ph/50Hz with

a total maximum current = 2A for all pumps combined. If the pump(s) total current is higher

than this an interface relay/contactor will need to be used.

If so required, the cooling duty can be reduced from 12kW and a smaller water pump

used. Dry cooling will still be achieved providing the room environmental conditions are no

higher than 24°C dry bulb with a relative humidity no greater than 40% and the chilled

water flow temperature entering the unit is no lower than 10°C. The following table gives

details for this:

Table 2

Cooling Duty

(kW)

Water Volume

Flow Rate

Water Return

Temperature

(

°C)

Hydraulic Resistance

of water coil in

Thermoscreens Dry

Cooling Unit

(kPa)

Hydraulic Resistance

of heat exchanger in

Mitsubishi PUHZ

Outdoor Unit

(kPa)

m3/h l/min

11.5 2.6 44 13.8 24 10

11.0 2.0 33 14.8 14 6

10.5 1.6 26 15.7 9 4

Calculated for Water Flow Temperature = 10°C

In case of emergency, condensate could form on the cooling coil if there was a failure in

the air conditioning on site or environmental conditions in the server room went above

24°C/40%Rh due to some other circumstance, e.g. doors left open, extreme weather

conditions. To allow for this the Thermoscreens dry cooling unit is supplied with an integral

condensate drain tray and outlet pipe to drain condensate away from the unit. A gravity

condensate drain system extending to a suitable drain outside of the room must be

supplied and fitted by the installer in case this emergency situation were to occur. This

should be connected to the 15mm copper drain pipe that protrudes from the right-hand

rear of the cooling unit behind the plastic end cap. Condensate pumps are not

recommended but if a gravity drain system is impossible and a condensate pump is the

only alternative it must not be fitted at the dry cooling unit because of reliability issues with

these devices. If the condensate needs to be pumped to a higher level with a condensate

pump this should be done in a separate room away from the server room. If there was a

spillage of condensate at the pump, therefore, it will not occur in the server room. Suitable

condensate pumps are Peristaltic or Rotary Diaphragm type with a suction head. The

condensate pump needs to have the facility so it only operates if water is detected in the

drain tray. It should also have a pump overrun to empty the drain tray as much as

possible. We recommend the Blue Diamond rotary diaphragm type with cooling signal

sensor (drainStik) manufactured by Charles Austen Pumps Ltd. (www.miniblue.co.uk).

The condensate drain tray inside of the Thermoscreens dry cooling unit has a metal fixing

bracket located at the right hand end so a condensate sensor can be fixed in the tray in

the appropriate position by the installer. There is a rubber grommet with 9.5mm hole fitted

in the fixing bracket which will accept a 10mm diameter condensate sensor. Different size

grommets can be fitted by the installer to suit other condensate sensors or if the grommet

is removed a larger condensate sensor can be located in the 13mm diameter hole in the

fixing bracket and held with silicon sealant. See also the manufacturer’s instructions that

come with the condensate pump for further information.

Valuable or delicate equipment should not be placed beneath the dry cooling unit or

directly in the path of the cool air discharge from the unit.

Page 5

T9901018-1 Page 5 of 26

The Thermoscreens dry cooling unit operates from its own separate 1 phase electrical

supply (1L+N+E) with a local switched isolator, see Page 12, and the fan within the unit

runs continuously when this electrical supply is connected. If the local switched isolator is

not easily accessible by the end user there should be a 2-pole On/Off switch fitted in an

easily accessible position next to the dry cooling unit. The Mitsubishi Electric interface pcb

fitted inside the dry cooling unit, however, is powered via the S1, S2, S3 wiring from the

outdoor unit and a 2-pole S1, S2 isolator is required for this electrical/communications link.

Room temperature control of the Thermoscreens dry cooling unit is done using a Siemens

RDG400 Manual Room Control that is supplied with the unit. This room control is used to

select the target temperature (set point) of the room air temperature and it then switches

the Mitsubishi Electric cooling system On and Off to achieve this temperature. The room

air temperature is measured using either a return air temperature sensor in the air intake

of the dry cooling unit or via an integral air temperature sensor within the RDG400 manual

room control. This is selectable at the time of commissioning. A volt free remote On/Off

control switch or BMS Dig/Output signal can be connected to the Thermoscreens dry

cooling unit to turn the cooling system On and Off as an alternative to manually switching it

On and Off at the RDG400 manual room control via the target temperature.

A separate thermostat with its air sensor positioned in the air intake is incorporated within

the Thermoscreens dry cooling unit. This is to provide warning of elevated room air

temperatures which could indicate a fault in the air conditioning system or some other

problem. This thermostat can be set during commissioning to between 15°C and 35°C and

terminals are provided within the unit for external monitoring of the contacts opening or

closing on rising temperature. Contacts are rated 16A(4A) at 230v AC.

The Thermoscreens dry cooling unit includes the facility to provide a global error signal

should an error occur in the Mitsubishi Electric heat pump system.

A Mitsubishi Electric PAR-W21MAA Remote Controller is supplied and pre-fitted inside the

left hand end cap of the Thermoscreens dry cooling unit. It is needed for the Mitsubishi

Electric heat pump system to operate and is also useful to diagnose error messages. It is

not used for control of the system by the end user, this is done via the Siemens RDG400

manual room control, see above.

The Thermoscreens dry cooling unit is designed only for use with a Mitsubishi Electric air

to water heat pump system for use on R410A. The complete Thermoscreens/Mitsubishi

Electric air to water heat pump system, including fridge pipework, water pipework system,

wiring, controls, etc. must be installed only by an approved Mitsubishi Electric refrigeration

contractor in accordance with the relevant installation instructions.

Persons using the dry cooling system must be given adequate instruction and supervision

concerning the use of the appliance by a person responsible for their safety. The cooling

system is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities.

These instructions must be read in conjunction with the separate Mitsubishi Electric

instructions that come with the PUHZ-HW140 Outdoor Unit. All instructions should be kept

by the building facilities manager for future reference.

Page 6

T9901018-1 Page 6 of 26

UNPACKING THE DRY COOLING UNIT

The following items are supplied and packaged within the dry cooling unit box :-

There will also be a PUHZ-HW140VHA2 or YHA2 Air to Water Outdoor Unit supplied by

Mitsubishi Electric.

The complete Thermoscreens/Mitsubishi Electric dry cooling system, to provide dry cooling to

a server room or other space, including chilled water pipework system and wiring is to be

installed only by an approved Mitsubishi Electric contractor.

For your records

Date of Purchase……………………………..

Supplier/Installer………………………..…….

Serial Number…………………………………

For warranty purposes proof of purchase is necessary so please keep a copy of your invoice.

IMPORTANT

This Dry Cooling Unit is intended only for use with a Mitsubishi Electric

PUHZ-HW140VHA2 or YHA2 Air to Water Outdoor Unit.

These instructions must be read in conjunction with the separate instructions that

come with the Mitsubishi Electric PUHZ-HW140VHA2 or YHA2 Air to Water Outdoor

Unit.

(All documentation supplied with the unit should be stored and kept for future reference.)

If anything is missing or

damaged please contact

your supplier immediately.

PHV2000NT Dry Cooling Unit

End caps are supplied loose to

be fitted during installation

Mitsubishi Electric PAR-W21MAA

fitted inside LH end cap

Siemens RDG400

M

anua

l Room Control

Wall Brackets and Fixing Bolts

for if Dry Cooling Unit is to be fixed to a wall

Page 7

T9901018-1 Page 7 of 26

150mm

minimum clearance

COOL AIR

White unit shown for picture clarity only

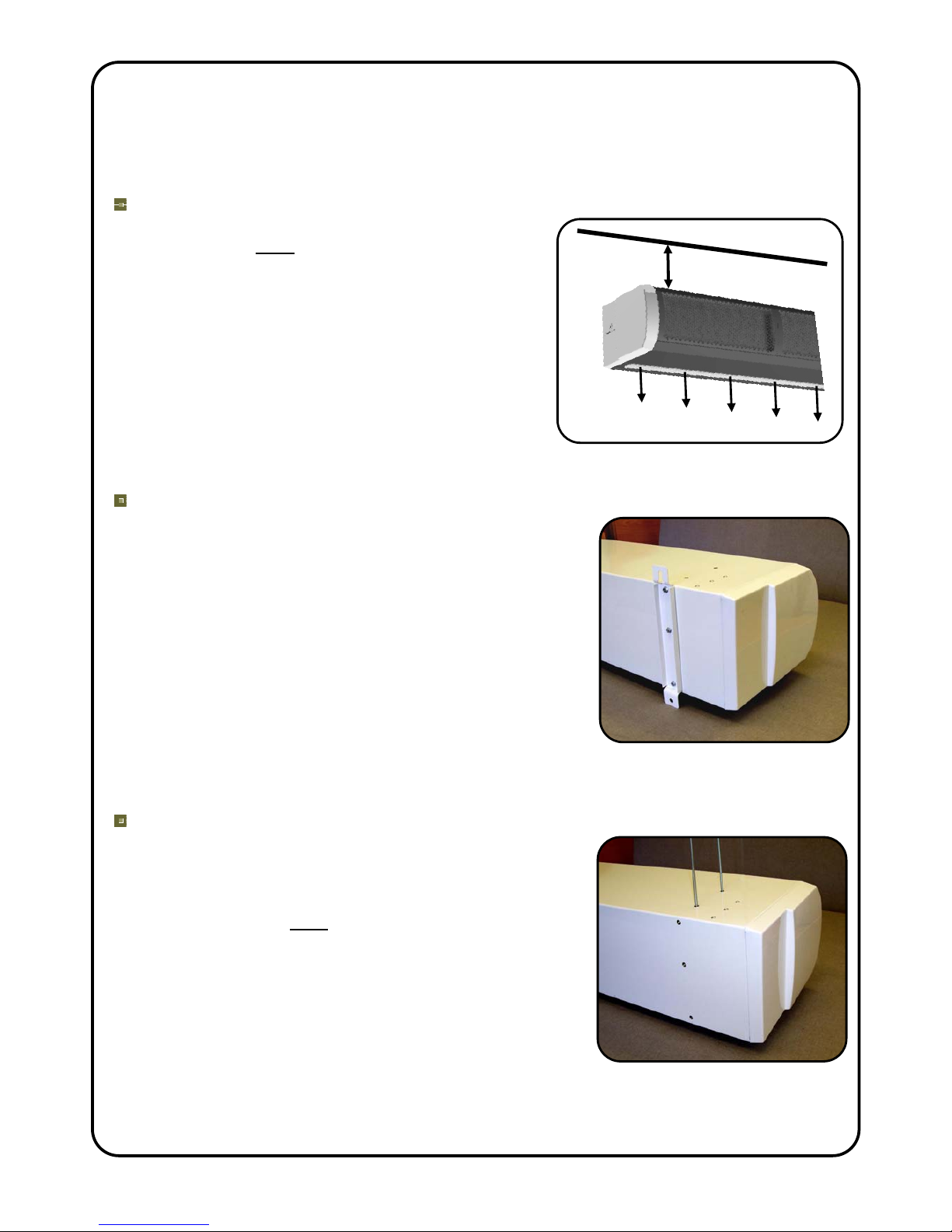

INSTALLING THE DRY COOLING UNIT

The dry cooling unit has been designed to be mounted on a wall or suspended from

above using M10 drop rods. It must not be installed on the outside of the building,

or built into a cabinet or recessed in anyway.

Location

The dry cooling unit must be mounted so the unit is

horizontal and level and the discharge grille faces

downwards. The discharge grille must be at least

2.4m above ground level and located so the

downwards flowing cool air will distribute throughout

the room or across equipment to be cooled. It

should not, however, be positioned directly above

valuable or delicate equipment in case of water

leaks or an emergency condensate situation, e.g.

doors left open, extreme weather conditions.

Beware of obstructions in the room that may

interfere with air distribution. Leave a gap of 150mm

minimum above the unit to allow for installing the water pipework.

Wall Fixing

There are three wall brackets supplied and these need to

be bolted to the rear face of the cooling unit as shown in

the adjacent picture using the M10 bolts supplied. A

suitable wall fixing system (not supplied) needs to be

used to fix the brackets to the wall, taking into account the

type of wall and the weight of the unit - 76kg.*

Step 1. Refer to Figure 1, Page 8 for mounting details

and drill the fixing points in the wall.

Step 2. Screw in the top wall bolts leaving a small gap

between the bolt head and the wall. Lower the cooling

unit onto the bolts via the key-hole slots in the top of the

wall brackets and then screw in the bottom wall bolts.

Step 3. Ensure all fixing bolts are tightened and the dry

cooling unit is safely secured to the wall.

Ceiling Suspension

There are six M10 threaded inserts provided in the top

face of the cooling unit (see Figure 1, Page 8 for

positions) so it can be suspended on M10 threaded

hanging rods with lock nuts (not provided). All six

suspension points must be used. Ensure each of the

hanging rods is secured onto a suitable structure that can

support the weight of the unit - 76kg.* Screw the M10

hanging rods into the threaded inserts by a minimum of

20mm and fit locking nuts to prevent the rod rotating and

coming away from the casing. Do not screw the hanging

rods too far in or they could interfere with internal

components.

* It is the sole responsibility of the installer to ensure that

the building fixing locations and suspension system used

are suitable for the dry cooling unit being installed.

White unit shown for picture clarity only

Page 8

T9901018-1 Page 8 of 26

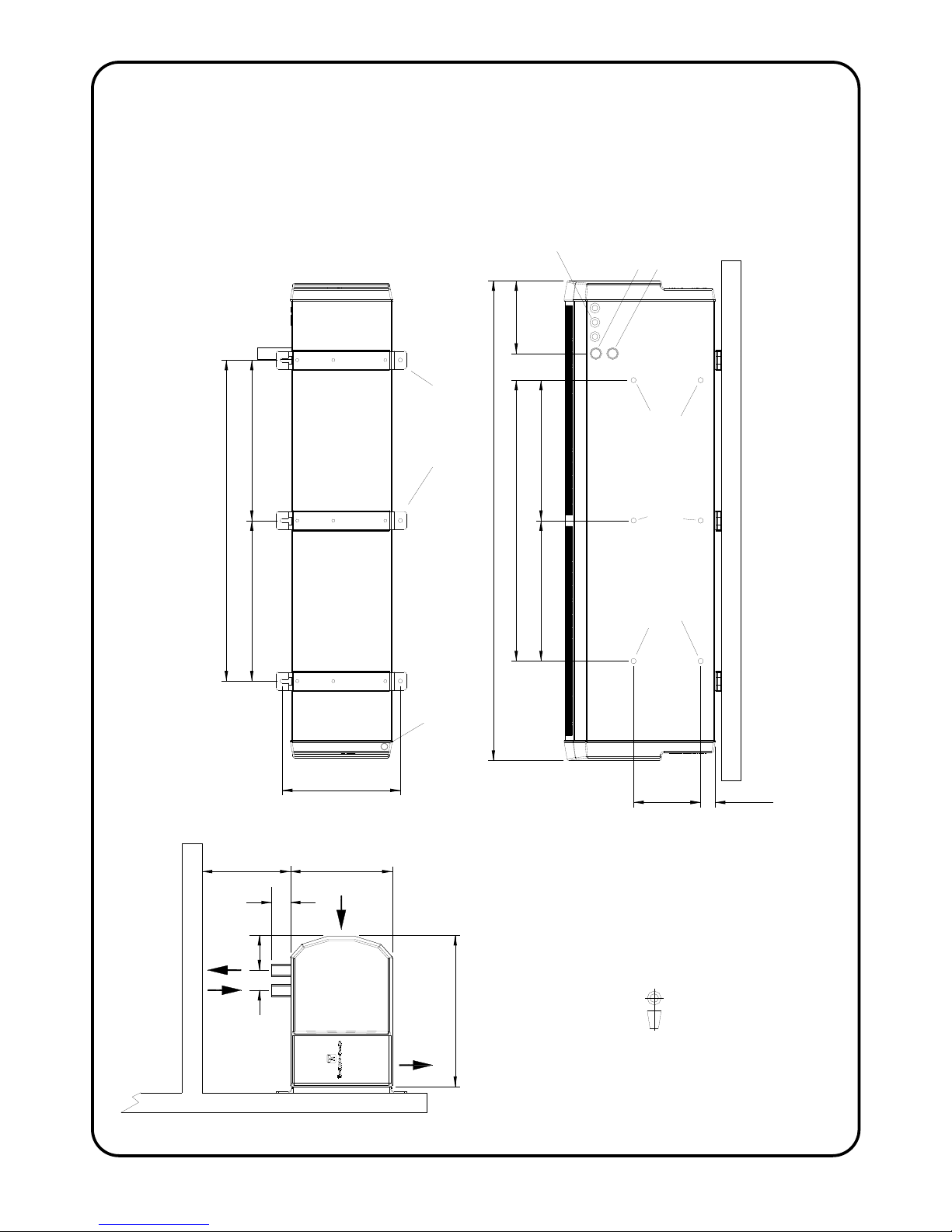

295

912

1824

798

1596

2296

168

36

255

377

Water Return Connection

60

Electrical Supply and

Control Wiring Inlets

for pipes

c. 150 min.

6 x M10 threaded holes for M10 drop rods

IMPORTANT - Use all 6 drop rod holes

3 Holes x 20mm

Water Connections, Rp1

56

70

(1in. BSP Internal.)

Emergency Condensate Connection

at rear of plastic end cap, 15mm copper

798

215

912

AIR

AIR

Wall Mounting Brackets

FLOW RETURN

Water Flow Connection

FIGURE 1 – DIMENSIONS OF THERMOSCREENS DRY COOLING UNIT

Page 9

T9901018-1 Page 9 of 26

FLOW

RETURN

access panel

screw

To gain access inside the Dry Cooling Unit

To gain access for connection of the chilled water pipework,

electrical supply, controls wiring and to work on the unit during

commissioning, remove the air inlet grilles and the bottom

access panel.

First remove the plastic end caps at each end of the unit, if

already fitted, by pulling off to the side (see picture).

Then remove each inlet grille in turn with its air filter by

unscrewing the M4 Pozi Head screws at the bottom corner of the

grille. Use a Pozi No.1 screwdriver to access each screw via the

elongated hole at the bottom corners of the grille (see picture).

To remove the bottom access panel unfasten the access panel

securing screws, one at each end (see picture) plus two in the

centre and pull the panel out forwards.

Chilled Water Pipework (Left hand side of unit)

This should ideally be carried out before connection of any electrical and controls

cables.

The water system must be suitable for chilled water and installed by a qualified

technician.

Install chilled water flow and return pipe connections to the dry

cooling unit using suitable pipework fittings. The flow and return

connections on the cooling unit are Rp1 (1in. BSP Internal). The

chilled water flow is the rear connection, the chilled water return is

the front connection – these are marked. It is important that the flow

and return is connected the right way around or the performance of

the unit will be compromised, see picture opposite.

Ensure that when tightening the pipe connections onto the dry

cooling unit that pipe grips are used to hold the 1 inch steel bush of

each pipe connection to avoid damaging the copper coil inside the

unit, see picture opposite.

Page 10

T9901018-1 Page 10 of 26

Install the expansion vessel, pressure relief valve, filling loop, pressure gauge, automatic

air vents, water dirt trap device, flow setter valve, drain valve(s), isolating valves and union

fittings for the removal of components. Installation pipework should be supported

independently from the cooling unit. The fitting of test points, e.g. binder, should be

considered for measuring pressures and temperatures. See Section ‘Design Information’

Page 3 and 4 for selection information on water pumps and flow setter valve.

The chilled water system needs to be cleaned using a suitable cleaning agent to ensure

that any flux residues/installation debris is removed (see BSRIA AG 1/2001.1). Fill the

chilled water system with water, vent air from the water system and thoroughly check the

whole system for water leaks. Once the system is ready add inhibitor to the correct

concentration. If necessary, the system should be protected against freezing and antifreeze should be added to the correct concentration.

NB. output may be reduced if antifreeze additives are used.

Fully insulate the chilled water system to prevent energy loss and to avoid condensation

dripping from chilled surfaces. External pipework, if used, must be weather-wrapped or

installed in suitable trunking.

Condensate Disposal System (Right hand side of unit)

As explained in Section ‘Design Information’ Page 3, the dry cooling unit is supplied with

an integral condensate drain tray and outlet pipe to drain condensate away from the unit in

an emergency condensate situation.

Remove the right hand plastic end cap by pulling off and connect a gravity condensate

drain pipe system to the 15mm copper drain pipe that protrudes from the right-hand rear of

the cooling unit. Extend this to a suitable drain or condensate pump (if required) outside of

the room that the dry cooling unit serves. Condensate pumps are not recommended but if

a gravity drain system is impossible and a condensate pump is the only alternative it must

not be fitted at the dry cooling unit because of reliability issues with these devices. If the

condensate needs to be pumped to a higher level with a condensate pump this should be

done in a separate room away from the server room. If there was a spillage of condensate

at the pump, therefore, it will not occur in the server room.

Make sure condensate pipework can be unclipped for when the drain tray needs to be

inspected and cleaned, see Page 22.

If using wall brackets use copper

elbow to extend drain pipe downwards

If using hanging rods and there is

space to the rear the drain pipe can

extend backwards

Page 11

T9901018-1 Page 11 of 26

If a condensate pump is being used the pump condensate sensor that starts/stops the

pump and indicates an alarm situation should be fitted in the metal fixing bracket at the

right hand end of the condensate drain tray within the unit. There is a rubber grommet with

9.5mm hole fitted in the fixing bracket which will accept a 10mm diameter condensate

sensor. Different size grommets can be fitted to suit other condensate sensors or if the

grommet is removed a larger condensate sensor can be located in the 13mm diameter

hole in the fixing bracket and held with silicon sealant. See also the manufacturer’s

instructions that come with the condensate pump for further information.

Condensate sensor fixing bracket at

RH end of drain tray with 9.5mm hole

grommet

Condensate sensor fixing bracket at

RH end of drain tray with grommet

removed to give 13mm hole

Page 12

T9901018-1 Page 12 of 26

Electrical Supply to the Dry Cooling Unit (Left Hand Side of the Unit)

All electrical wiring and connections MUST be carried out by a competent

qualified electrician in accordance with the latest edition of the IEE wiring

regulations and/or local statutory regulations. (see also Wiring Diagram on Page

13)

A 2-pole local isolator having a contact separation of at least 3mm on both live and

neutral poles must be fitted in the 230V electrical supply to the Thermoscreens dry

cooling unit and located in an accessible position within 1m of the unit. This local

isolator will also serve as the On/Off switch for the fans inside of the cooling unit.

The unit must be connected using cables having an appropriate temperature rating

(heat resistant).

Ensure that the supply cables, circuit breakers and other electrical installation

equipment are correctly sized for the cooling unit.

0.5kW for cooling unit

Rated Electrical Power Input = +

kW rating of water pump installed

2.7A for cooling unit

Rated Current = +

Amps of water pump installed (max. 2A)

IMPORTANT: Please note that the water pump is supplied and fitted by the

installer and the electrical power consumption of it (kW and Amps) is entirely

dependent on which pump the installer selects, see Section ‘Design Information’

Page 3 & 4 for water pump selection. The electrical feed to operate the water

pump is a 230V/1ph/50Hz switched feed that comes from the dry cooling unit

(terminal Pu L), so the sizing of the electrical supply to the dry cooling unit must

also include for the pump as well.

NB. If the rated current of the water pump(s) is more than 2A an interface

relay/contactor will need to be used, powered from terminal Pu L, and the pump

electrical feed may then be from a separate electrical supply.

A 20mm size cable gland or conduit connector should be used for the

230V/1ph/50Hz Electrical Supply into the unit. See Figure 1, Page 8 showing

where the electrical supply enters the unit.

This appliance must be Earthed.

Connect the 230V/1ph/50Hz Electrical Supply to terminals L, N and Earth in the

dry cooling unit.

Page 13

T9901018-1 Page 13 of 26

THERMOSCREENS PHV2000NT DRY COOLING UNIT

L3

Electrical Supply for

Outdoor Unit

230V/1ph/50Hz

or 400V/3ph/50Hz

Electrical Supply

230V/1ph/50Hz

24V AC

RELAY

24V

AC

240V

AC

Built In Thermostat

set to 30°C,

can be adjusted

between 10 - 35°C

Grey

Pink

Blue

Violet

Orange

Orange

Black

Red

Brown

Blue

Green/Yellow

Yellow

Yellow

Grey

T 8A

N

E

F2A

2

3

1

5

648

7

101112

S2

S3

PUHZ-HW140VHA2/YHA2

OUTDOOR UNIT

S1

S3 S2

WATER

PUMP

M

1

L

FUSE

FUSE

MITSUBISHI PAC-IF010B-E PCB

TB61

TB142

8

7

IN4

TB6

2-Core

Cable

CNX2 GRY

DIP SWITCH SETTINGS :-

SW1-1, 1-5, 1-6 ON Rest OFF

SW2- All OFF

SW3-1, 3-7 ON Rest OFF

SW6- Both OFF

TH1

RC

OPERATION

SIGNAL

Black

Remote ON/OFF

(Volt Free Input)

SITE WIRING

TB62

5

6

AB

Brown

Blue

PUHZ-HW140VHA2/YHA2 Unit

Error Signal (Volt Free Output)

FAN

MOTORS

SIEMENS RDG400

MANUAL ROOM

CONTROL

CN20

RED

Link Fitted

L2

L1 N E

CNS2

Mitsubishi sensor

fitted in pocket of flow

pipe on water coil

9

2-Pole Local

Isolator

ON/OFF Switch

Yellow

Black

White

SIEMENS QAH11.1

Return Air Sensor

FAN

HIGH

MED

LOW

M

1

Black

Blue

Red

White

Room Over Temperature Alarm [16(4)A at 230V]

10 to 11 contacts close on rising temperature

11 to 12 contacts open on rising temperature

TRANSFORMER

Pu L

Pu N

Pu E

White

S1

Brown

Brown

Brown

PAR-W21MAA

Not used for control

by the end user,

only needed so the

Outdoor Unit will run

.

(Supplied and fitted

inside LH end cap)

DIPs :-

SW1-3 ON

Rest OFF

L

N

E

230V/1ph/50Hz

2A maximum

2-Pole Local

Isolator

WARNING: 400V may exist between terminal S1 and other Live

terminals inside the Thermoscreens dry cooling unit

WIRING DIAGRAM – PHV2000NT DRY COOLING UNIT

Page 14

T9901018-1 Page 14 of 26

Controls Wiring to the Dry Cooli ng Unit (Left Hand Side of the Unit)

All electrical controls wiring and connections MUST be carried out by a

competent qualified electrician in accordance with the latest edition of the IEE

wiring regulations and/or local statutory regulations. (see also Wiring Diagram on

Page 13)

The following connections need to be made, except where stated as optional. Use 20mm

size cable glands or conduit connectors:

Terminal on Dry Cooling Unit

Terminal on SIEMENS RDG400

Manual Room Control

(use 0.5mm2 max. cable size - small terminals)

1 G

2 G0

3 Y1

4 – for return air sensor in air intake M (do not wire if using air sensor inside RDG400)

5 – for return air sensor in air intake B1 (do not wire if using air sensor inside RDG400)

6 - optional DG (volt free input, for remote On/Off or

Run/Standby or Fire Alarm Circuit)

7 - optional D1 (ditto as above)

Terminal on Dry Cooling Unit

Optional Error Signal Output Connection

8 Mitsubishi Electric heat pump system, Error Signal

(volt free contacts, rated 1A max, Error = Closed)

9

Terminal on Dry Cooling Unit

Optional Room Over Temperature Alarm

Volt Free contacts rated at 16(4)A at 230V

(use 1.0mm2 maximum cable size)

10 10 – 11 contacts close on rising temperature

11

12 11 – 12 contacts open on rising temperature

Terminal on Dry Cooling Unit

Terminal on 230V/1ph/50Hz

Water Pump – 2A maximum

(use 1.5mm2 maximum cable size)

Pu L L

Pu N N

Pu E E

Terminal on Dry Cooling Unit

(electrical supply and communications link

for interface pcb inside dry cooling unit)

Terminal on Mitsubishi Electric

PUHZ-HW140VHA/YHA2

(use 1.0mm2 maximum cable size)

S1 S1

S2 S2

S3 S3

A local isolator to switch S1 and S2 On/Off is required within 1m of the dry cooling unit.

NB. The interface PCB is already Earthed via the supply to the dry cooling unit.

WARNING: 400V may exist between terminal S1 and other Live terminals inside the

Thermoscreens dry cooling unit.

The Mitsubishi Electric PUHZ-HW140 Outdoor Unit needs to be installed in accordance

with the relevant sections of the Mitsubishi Electric instructions supplied with the unit.

Page 15

T9901018-1 Page 15 of 26

Once complete the electrical supply and controls wiring should appear as shown in the

picture:-

NB. For clarity the site wiring to terminals 6 to 12 for the optional items:

Remote ON/OFF

Mitsubishi Error Signal

Room Over Temperature Alarm

is not shown in this picture.

Please note: All the panels of the Thermoscreens dry cooling unit are covered in a

protective plastic film which should now be removed.

Page 16

T9901018-1 Page 16 of 26

COMMISSIONING THE DRY COOLING UNIT

Ensure that the electrical supply to the Mitsubishi Electric Outdoor Unit and the

local electrical supply switch to the Thermoscreens Dry Cooling Unit are

switched off.

Chilled Water System Checks

The chilled water system must be commissioned by a qualified technician in accordance

with CIBSE Commissioning Code W, CIBSE KS9, BSRIA AG 2/89.3 and BSRIA AG

1.2001.1.

Check that the chilled water system has been cleaned using a suitable cleaning agent to

ensure that any flux residues/installation debris is removed (see BSRIA AG 1/2001.1).

Check that the chilled water system has been filled and the correct concentration of

inhibitor has been added.

If necessary, check that the system has been protected against freezing and that the

correct concentration of anti-freeze has been added.

Check that all water valves are open.

Check that air has been vented from the water system and thoroughly check the whole

system for water leaks – repair as necessary.

Dry Cooling Unit Checks

Check that the components inside the dry cooling unit are as shown in the picture below

Siemens

QAH11.1

Return Air

Sensor

(Black)

Interface

PCB

Room Over Temperature

Alarm Sensor (Silver)

Room Over Temperature

Alarm Thermostat

(

underneath the unit

)

24v AC

Relay

Page 17

T9901018-1 Page 17 of 26

A Mitsubishi Electric Interface PCB is located within the left hand end of the

Thermoscreens Dry Cooling Unit to provide communication between the Outdoor Unit

and the Dry Cooling Unit. The Interface PCB on its mounting plate is held in place by a

fixing screw located in the left-hand end panel of the dry cooling unit under the left-hand

plastic end cap. Remove the screw and carefully slide the pcb partially out.

Check that the dip switches on the Interface PCB are set as follows:

SW1-1, 1-5, 1-6 ON; SW1-2, 1-3, 1-4, 1-7, 1-8 OFF

SW2 – All OFF

SW3-1, 3-7 ON; SW3-2, 3-3, 3-4, 3-5, 3-6, 3-8 OFF

SW6 – Both OFF

Room temperature control of the dry cooling unit is done via a Siemens RDG400 Manual

Room Control that is supplied with the unit. This room control is used to select the target

temperature (set point) of the room air temperature and to then switch the Mitsubishi

Electric cooling system On and Off to achieve this temperature.

If there is site wiring between terminals 4 & 5 in the dry cooling unit and terminals M & B1

in the Siemens RDG400 manual room control the room air temperature will be measured

using the black return air temperature sensor clipped onto the coil in the air intake of the

dry cooling unit. If there is no wiring from terminals 4 & 5 the room air temperature will be

measured in the RDG400 manual room control using its integral air temperature sensor.

Remove the RDG400 manual room control from its back-plate (2 screws at LH side of

control and pull at LH) and check that the dip switches in the control are set as follows:

SW1-3 ON

SW1-1, 1-2, 1-4, 1-5 OFF

Check that the wiring between the Thermoscreens dry cooling unit and the Siemens

RDG400 Manual Room Control, the water pump and, if used, the remote On/Off, error

signal and room over temperature alarm is in accordance with the Wiring Diagram on

Page 13.

Check that the S1, S2, S3 wiring between the Thermoscreens dry cooling unit and the

Mitsubishi Electric outdoor unit is in accordance with the Wiring Diagram on Page 13.

Fixing screw

(accessed from

end of dry

cooling unit)

DIP

SW1

SW2

SW3

LED 1

DIP SW6

LED 3

Page 18

T9901018-1 Page 18 of 26

Carefully slide the Interface PCB back into place if still withdrawn on its slide rails.

Ensure cables are not trapped inside and refit the fixing screw in the left hand end

panel.

Testing the Dry Cooling System

Ensure that the local electrical ON/OFF Switch/Isolator to the Thermoscreens dry

cooling unit is switched OFF !!

Switch on the S1, S2 local isolator adjacent to the Thermoscreens dry cooling unit.

Switch on electrical power to the Mitsubishi Electric Outdoor Unit.

WARNING! – Terminal S1 and the Mitsubishi Interface PCB inside the dry cooling unit

will now become Live with 230V electrical power from the outdoor unit !!

LED 1 on the Interface PCB should be lit to indicate power onto the PCB. Wait for the

PAR-W21MAA controller at the left hand end of the unit to initialize. The message

‘PLEASE WAIT’ will repeat on the screen of the PAR-W21MAA controller until

communication is set-up and the heat pump system is ready to operate. The PARW21MAA controller will not respond to push button commands because of the dip

switch settings on the Mitsubishi Interface PCB. The outdoor unit must now be left

energised for 12 hours before carrying out any further operations.

Now switch on the local electrical ON/OFF Switch/Isolator to the Thermoscreens dry

cooling unit.

WARNING! – The fans inside of the dry cooling unit will now operate, beware of fast

spinning fans.

WARNING! – 400V may exist between terminal S1 and other Live terminals inside the

Thermoscreens dry cooling unit.

Check there is no mechanical noise coming from the fans and that both fans work.

If there is a Remote On/Off wired into terminals 6 & 7 on the dry cooling unit, switch this

On. Check that the LCD display screen on the Siemens RDG400 Manual Room Control

is working and lit-up. The display screen will be indicating the room temperature in large

numerals. Rotate the knob on the room control anti-clockwise and the numerals will

change to indicate the target (set-point) temperature. Set this target temperature at least

5°C below the room temperature. The numerals will then flash this target temperature 5

times and go back to showing the air temperature. At this point the water pump(s) will

start to operate and the outdoor unit will also start to work. The display on the PARW21MAA controller will change to show that the outdoor unit is working and LED 3 on

the interface PCB should be lit to indicate the compressor in the outdoor unit is working.

Stop and start the water pump(s) by adjusting the target temperature up and down on

the manual room control to help bleed air out of the chilled water system. Ensure air is

bled out of the pump(s). If a flow setter valve is fitted check that the water flow rate of

the chilled water system is in accordance with Table 1, Page 3 or Table 2, Page 4.

After the system has been operating for a few minutes check that the chilled water

pipework is cooling down and the pipe temperature indicator on the PAR-W21MAA

controller (small numerals) shows a falling temperature. If the system is operating

correctly the pipe temperature should go down to 10°C. Check that cold air is being

discharged from the dry cooling unit across the whole length of the unit and that there is

Page 19

T9901018-1 Page 19 of 26

no moisture forming on the surface of the cooling coil after at least 15 minutes of

operation at 10°C water flow temperature.

NB. If the outdoor unit has just been switched off via the controls it will require a few

minutes to start cooling again after the controls switch it back on.

If necessary adjust the angle of the outlet grille louvres in the air discharge of the dry

cooling unit to suit the air stream required in the room. Take care not to push objects

into the outlet grille.

Using the Siemens RDG400 manual room control take a mental note of the room air

temperature displayed on the screen and rotate the knob on the manual room control

clockwise and set the target temperature to above the room temperature. Check that

the water pump(s) and outdoor unit switches off. The fans in the dry cooling unit will

stay on.

Set the knob of the Room Over Temperature Alarm very high and using a multimeter

check that contacts 10 to 11 go open contact. Set the knob very low and check that

contacts 10 to 11 then go closed contact. Then set the knob to the setting that is

required by the operator to indicate there is a room over temperature alarm situation.

If a condensate disposal system has been installed check that it

operates correctly by filling the drain tray with some water and that

the water completely drains away from the unit. If a condensate

pump is being used ensure this is operating correctly and if possible

simulate a pump alarm fault condition to check that the alarm will

function. Some condensate pumps may require distilled water to do

this working test.

Switch off electrical power to the Thermoscreens dry cooling unit and the Mitsubishi

Electric outdoor unit. Replace the bottom access panel, air inlet grilles (with air filters)

and plastic end caps (see ‘To gain access inside the Dry Cooling Unit’, page 9). Switch

electrical power back on to the dry cooling unit and the outdoor unit and fully test all

operating parameters as above using the Siemens RDG400 manual room control.

Hand-over to End-User

Before leaving site it is important that there is a 'Hand-Over Meeting' to hand-over the

dry cooling system to the end user or their representative. This should include a full and

clear explanation of how the system operates and a demonstration showing the dry

cooling system running. Be sure to explain that the air inlet grilles and the air filters

inside the grilles must be regularly vacuum cleaned and the unit serviced at regular

intervals.

Fully explain and demonstrate the operation of the Siemens RDG400 Manual Room

Control. Also the remote On/Off, room over temperature alarm & Mitsubishi error signal,

if used. Explain that the fans in the Thermoscreens dry cooling unit can be switched off

in an emergency at the local electrical On/Off Switch/Isolator to the dry cooling unit.

Ensure that all instructions and manuals are handed to the end user or their

representative.

Fill tray with water

Page 20

T9901018-1 Page 20 of 26

USER INSTRUCTIONS FOR THE DRY COOLING SYSTEM

For manual control using the Siemens RDG400 Manual Room Control

To Switch On and Off:

Make sure the On/Off Switch adjacent to the Thermoscreens dry cooling unit is

switched on. When it is switched on the fans in the dry cooling unit will operate

continuously.

The display screen on the manual room control will be indicating the air temperature in

large numerals.

Rotate the knob on the room control either clockwise or anti-clockwise and the numerals

will change and indicate the target (set-point) temperature as you rotate the knob.

Set this target temperature to the temperature required, say, 24°C.

The numerals will then flash this target temperature 5 times and go back to showing the

air temperature.

If the target temperature is lower than the air temperature the outdoor unit and the water

pump(s) will start to operate.

NB. If the outdoor unit has just been operating it will be necessary to wait several

minutes before it will restart again to provide chilled water.

Control of the room temperature will now be fully automatic and the dry cooling system

should be left to do its job. Fans will run continuously in the Thermoscreens dry cooling

unit and the outdoor unit and water pump(s) will automatically cut in and out to control

the room temperature.

If the On/Off Switch adjacent to the dry cooling unit is switched off the fans will turn off

and the outdoor unit and water pump(s) will not operate.

Siemens RDG400

Manual Room Control

Air Temperature

Knob

Target Temperature

(when flashing)

Page 21

T9901018-1 Page 21 of 26

access panel

screw

SERVICING THERMOSCREENS DRY COOLING UNIT

Vacuum Clean the Air Inlet Grilles / Air Filters

(Weekly, or when they show signs of getting dirty)

Switch the dry cooling unit OFF at the local On/Off switch so

the fans stop operating. A vacuum cleaner with an extension

tube and brush attachment at its end should then be used to

clean the face of the air inlet grilles. This is important to

minimise the build-up of dust and lint on the air filters which are

just inside the inlet grilles as this will affect the performance of

the dry cooling unit. This is a simple service task that can be

carried out by the Cleaner or Janitor on a regular basis from

floor level without having to access the dry cooling unit at high

level. This should be done weekly as a regular service task or

when the inlet grilles show signs of getting dirty.

Servicing the Dry Cooling Unit

(suggest ever y 3 Months or when conditions merit it )

Always disconnect and isolate the mains electricity supply both at the local

electrical supply to the Thermoscreens Dry Cooling Unit and at the Mitsubishi

Electric Outdoor Unit before servicing, maintaining or repairing the Unit.

Note: All servicing, maintenance and repairs to the dry cooling unit must be carried out

by an approved Service Agent. Keep any loose fixings for re-assembly.

Remove the plastic end caps by pulling

off to the side as shown.

Then remove each inlet grille in turn with

its air filter by unscrewing the M4 Pozi

Head screw at the bottom corner of the

grille. Use a Pozi No.1 screwdriver to

access each screw via the elongated

hole at the bottom corners of the grille

(see picture).

Remove the air filters from the air inlet grilles by gently prizing

them free as shown. Gently vacuum clean and refit the filters into

the curved air inlet grilles. The filters are durable but may need to

be replaced after a number of service intervals.

Remove the bottom access panel by unfastening the panel fixing

screws, one at each end (see picture) plus two in the centre and

pull the panel out forwards.

White unit shown for picture clarit

y

onl

y

Page 22

T9901018-1 Page 22 of 26

Vacuum clean and remove any build-up of dust, dirt and debris within the dry cooling unit,

especially on the cooling coil.

Note: Fan motors are permanently lubricated and require no additional lubrication.

If the Dry Cooling Unit has been condensing during the last service interval :-

(e.g. has experienced an emergency situation)

Unclip the condensate pipe at the right hand rear of the dry cooling unit.

The drain tray now angles down along its front edge and the

inside surface of the tray can be easily cleaned. Remove all

debris from the drain tray, outlet spout and condensate hose.

BEWARE of sharp metal fins on the cooling coil !

Check there are no kinks in condensate hoses. If the

condensate pump is a peristaltic type change the rubber

pump head tube.

If the dry cooling unit has been condensing it is important to find out why this has been

happening and correct the situation. It may be that there has been a failure in the air

conditioning on site or environmental conditions in the server room have gone above

24°C/40%Rh due to some other circumstance, e.g. doors left open, extreme weather

conditions.

Once the dry cooling unit has been cleaned, visually inspect the cooling unit

components. Ensure the two temperature sensors are located correctly on the front face

of the cooling coil (see Section – Commissioning, Page 16). Check all electrical

connections and terminals within the unit are tight and that crimp connections have not

become loose.

Refit the drain tray (if released), bottom access panel and air inlet grilles with air filters.

Switch on the electrical supplies and fully function test the dry cooling unit to ensure

correct operation (see Section – Commissioning, Page 16). Check the condensate

pump operates, if fitted.

Loosen by 3 turns, the rear row of

drain tray fixing screws along the

whole length of the tray. Do not

remove these screws completely.

Remove the front row of drain tray

fixing screws along the whole

length of the drain tray. Keep the

screws.

Page 23

T9901018-1 Page 23 of 26

Annual Service of the Dry Cooling System

Always disconnect and isolate the mains electricity supply both at the local

electrical supply to the Thermoscreens Dry Cooling Unit and at the Mitsubishi

Electric Outdoor Unit before servicing, maintaining or repairing the Unit.

In addition to the 3 monthly checks as described above carry out the following service

procedures:-

Clean the casing of the Thermoscreens dry cooling unit using a damp cloth. Do not use

scouring cream products.

Visually inspect the pipe work system for water leaks and repair as necessary.

Check the condition of the pipework insulation and repair as necessary.

Check for loose electrical connections in the Thermoscreens dry cooling unit and in the

Mitsubishi Electric outdoor unit and tighten connections if necessary.

Clean the water dirt trap device in the chilled water pipework.

Check the concentration of anti-freeze/inhibitor in the chilled water system and replenish

if necessary.

Test the operation of the dry cooling system as described from Page 18 onwards.

Page 24

T9901018-1 Page 24 of 26

Fault Conditions

If the Dry Cooling System does not operate as expected see fault finding table below:

Symptom Possible Cause Action Required

Fans in Dry

Cooling Unit

do not

operate

Electrical power is not switched on at

the local electrical isolator next to the

Thermoscreens dry cooling unit

Switch on power to the

Thermoscreens dry cooling

unit

Wire link missing between FAN terminal

and HIGH or MED or LOW terminals

Fit wire link to required speed

(HIGH for specified cooling output)

T8A fuse in dry cooling unit has blown

Replace T8A fuse and

investigate why it has blown

Problem with dry cooling unit motor(s),

or internal wiring, or controls

Use wiring diagram to

investigate possible cause of

fault

Dry Cooling

Unit does not

cool well or

does not cool

at all

Outdoor unit not switched on and/or

(S1, S2 isolator) not switched on

Switch on power to outdoor

unit and (S1, S2 isolator)

Dry cooling heat pump system has

been running for less than 10 minutes

and is still cooling down

Give system sufficient time to

reach operating condition

Remote ON/OFF Control: Dry cooling

unit is set to 'Off'.

Switch Remote ON/OFF to ON

Siemens Manual Room Control: Target

temperature is set too high for cooling

If necessary adjust the Manual

Room Control target

temperature down.

NB. Dry cooling unit will only

cool if room air temperature is

above the target temperature

Room temperature is low - Air Inlet

Sensor is measuring low air

temperature so target temperature has

been exceeded

Water dirt trap device is blocked Clean water dirt trap device

F2A fuse in dry cooling unit has blown

Replace F2A fuse and

investigate why it has blown

Water pump has failed in water circuit Repair water pump

Airflow is low

coming from

the discharge

grille

Dry cooling unit air filters and/or cooling

coil is dirty.

Service dry cooling unit as

described in Section –

Servicing on pages 21 to 23

Mitsubishi

Electric

system is

indicating an

error code

A variety of error codes can occur

because of a fault within the heat pump

system. These will display on the

Mitsubishi Electric PAR-W21MAA.

Refer to Mitsubishi Electric

Service Manual to understand

fault, then inspect, adjust

and/or repair as appropriate

Condensate

forming on

the chilled

water coil in

the dry

cooling unit

Failure in the site air conditioning

system

Repair site air conditioning

system

Environmental conditions in the server

room are above 24°C/40%Rh due to

some other circumstance, e.g. doors left

open, extreme weather conditions

Reduce environmental

conditions if possible

Chilled water flow temperature below

10°C

Investigate why water flow

temperature is too low

If the Heat Pump Dry Cooling System is still not operating correctly call for a Mitsubishi

Electric Service Agent.

Page 25

T9901018-1 Page 25 of 26

Warranty

If any problems are encountered with the heat pump dry cooling system please contact

your Mitsubishi Electric Service Agent.

Care has been taken in compiling these instructions to ensure they are correct, although

Thermoscreens Ltd. disclaims all liability for damage resulting from any inaccuracies

and/or deficiencies in this documentation. Thermoscreens Ltd. retain the right to change

the specifications stated in these instructions.

Thermoscreens Ltd

St. Mary’s Road Nuneaton

Warwickshire England

CV11 5AU

Email: sales@thermoscreens.com

Tel: + 44 (0) 24 7638 4646

Fax: + 44 (0) 24 7638 8578

www.thermoscreens.com

Page 26

T9901018-1 Page 26 of 26

EC DECLARATION OF CONFORMITY

as defined by the EC Council Directive on Machinery 2006/42/EC, the Low Voltage Directive 73/23/EEC,

the Electromagnetic Compatibility Directive 89/336/EEC and the Pressure Equipment Directive 97/23/EC

Herewith we declare that the air movement equipment designated below, on the basis of its design and

construction in the form brought onto the market by us in accordance with the relevant safety, health and

performance requirements of the Machinery.

If alterations are made to the machinery without prior written permission from us this declaration becomes invalid.

Designation of Equipment : THERMOSCREENS DRY COOLING UNIT

Series Type : PHV2000 NT used with Mitsubishi Electric PUHZ-HW140VHA/YHA

VRF PHV2000 NT used with Mitsubishi Electric PWFY-P200VM-E-AU

Relevant EC Council the Machinery Directive (2006/42/EC)

the Low Voltage Directive (73/23/EEC)

the Electromagnetic Compatibility Directive (89/336/EEC) as amended by

Directive 92/31/EEC

Applied Harmonised Machinery - EN 294, EN 414, EN ISO 14121-1

Standards : LVD - EN 60335-1, EN 60335-2-30, EN 60335-2-40

EMC - EN55011, EN 61000-3-2, EN 61000-3-3, EN 61000-4-2,

EN 61000-4-4, EN61000-4-5, EN61000-4-11, EN61000-6-4

Basis of Self Attestation : Quality Assurance to BS EN ISO 9001 : 2000

B.S.I. Registered Firm Certificate Number FM 85224

Responsible Person : Mr. M. Francis, Managing Director, Thermoscreens Limited

Date : 15th April 2011

Signed :

Thermoscreens Ltd

St. Mary’s Road

Nuneaton

Warwickshire

CV11 5AU

United Kingdom

Telephone: +44 (0)24 7638 4646

Fax: +44 (0)24 7638 8578

Loading...

Loading...