Thermoscreens HX Series, HX2000AR, HX1000WR, HX1500WR, HX1500AR Installation, Operation And Maintenance Instructions

...

HX Series.

Recessed Range

9901098-2-1

INSTALLATION, OPERATION AND

MAINTENANCE INSTRUCTIONS

English

Page | 1

1 CONTENTS

CONTENTS ...................................................................................................................................... 2

1

2 ELECTRICAL SAFETY ..................................................................................................................... 3

3 SPECIFICATIONS ............................................................................................................................ 3

4. INTRODUCTION .............................................................................................................................. 4

5. DELIVERY CONTENTS ................................................................................................................... 5

6. TOOLS REQUIRED .......................................................................................................................... 5

7. INSTALLATION ................................................................................................................................ 6

8. REMOTE CONTROL INSTALLATION ............................................................................................. 9

9. REMOTE CONTROL SETTINGS ..................................................................................................... 9

10. EXTERNAL CONTROLS ................................................................................................................ 10

11. SYSTEM CONFIGURATION .......................................................................................................... 11

12. MULTIPLE AIR CURTAINS ............................................................................................................ 12

13. FAN SPEED SELECTION .............................................................................................................. 13

14. REMOTE CONTROL OPERATION ................................................................................................ 14

15. COMMISSIONING THE SYSTEM .................................................................................................. 15

16. SIGN OFF ....................................................................................................................................... 15

17. FAULT CONDITIONS ..................................................................................................................... 16

18. SERVICE & MAINTENANCE ......................................................................................................... 17

19. WARRANTY ................................................................................................................................... 18

APPENDIX 1 — DIMENSIONS OF HX RECESSED AIR CURTAIN ....................................................... 19

APPENDIX 2A — WIRING DIAGRAM -HX1000ER ................................................................................. 20

APPENDIX 2B — WIRING DIAGRAM HX1500ER .................................................................................. 21

APPENDIX 2C — WIRING DIAGRAM HX2000ER .................................................................................. 22

APPENDIX 2D — WIRING DIAGRAM HX1000WR, HX1500WR and HX2000WR ................................. 23

APPENDIX 2E — WIRING DIAGRAM HX1000AR, HX1500AR and HX2000AR .................................... 24

20. DECLARATION OF CONFORMITY ............................................................................................... 25

9901098-2-1 Page | 2

2 ELECTRICAL SAFETY

Electrical Supply and Wiring to the Air Curtain

All electrical wiring and connections MUST be carried out by a competent qualified electrici an in

accordance with the latest edition of the IEE wiring regulations and/or local statutory regulations.

A single phase or 3 phase local isolator having a contact separation of at least 3mm on all

poles must be fitted in the electrical supply to the air curtain and located in an accessible

position adjacent to the unit.

The appliance must be connected by cables having an appropriate heat resistant

temperature rating.

All supply cables, circuit breakers and other electrical installation equipment must be

correctly sized for the air curtain model being installed; see section 3: Specifications.

Models operating on 3 phase electrical supply - see section 3: Specifications - require a

neutral connection (3N~).

A 25mm size cable gland or conduit connector should be use d for the Electrical Supply

into the air curtain.

The air curtain must be earthed.

3 SPECIFICATIONS

Air Curtain

HX1000AR 230/1/50 0.2 0.8 – 1.10 45

HX1500AR 230/1/50 0.3 1.2 – 1.63 66

HX2000AR 230/1/50 0.35 1.4 – 2.15 80

HX1000WR 230/1/50 0.2 0.8 6/12 1.10 52

HX1500WR 230/1/50 0.3 1.2 9/18 1.63 75

HX2000WR 230/1/50 0.35 1.4 12/24 2.15 93

HX1000ER 400/3/50 12.2 18.2 6/12 1.10 46

HX1500ER 400/3/50 18.3 27.3 12/18 1.63 67

HX2000ER 400/3/50 24.35 36.2 12/24 2.15 84

Electrical

Supply

(V/ph/Hz)

Rated

Electrical

Power Input

(kW)

Rated

Current

per phase

(A)

Heat

Output

[Low/High]

(kW)

Effective

Width of

Airstream

(m)

Weight

(kg)

9901098-2-1 Page | 3

4. INTRODUCTION

Established in the 1960s, Thermoscreens is a leading air curtain manufacturer that exports to over 60

countries worldwide.

As with all our products, the HX range of air curtains is designed with energy efficiency in mind.

HX models suffixed ER, WR or AR are designed to be recess mounted inside a building and located

horizontally over a doorway.

They must not be installed on the outside of a building.

Please complete the following details for your reference:

Date of Purchase

Place of Purchase

Serial Number

Proof of purchase is required to make a claim under warranty.

Thermoscreens Ltd

St. Mary’s Road

Nuneaton

Warwickshire

England

CV11 5AU

Email: sales@thermoscreens.com — www.thermoscreens.com

Tel: +44 (0) 24 7638 4646 — Fax: +44 (0) 24 7638 8578

9901098-2-1 Page | 4

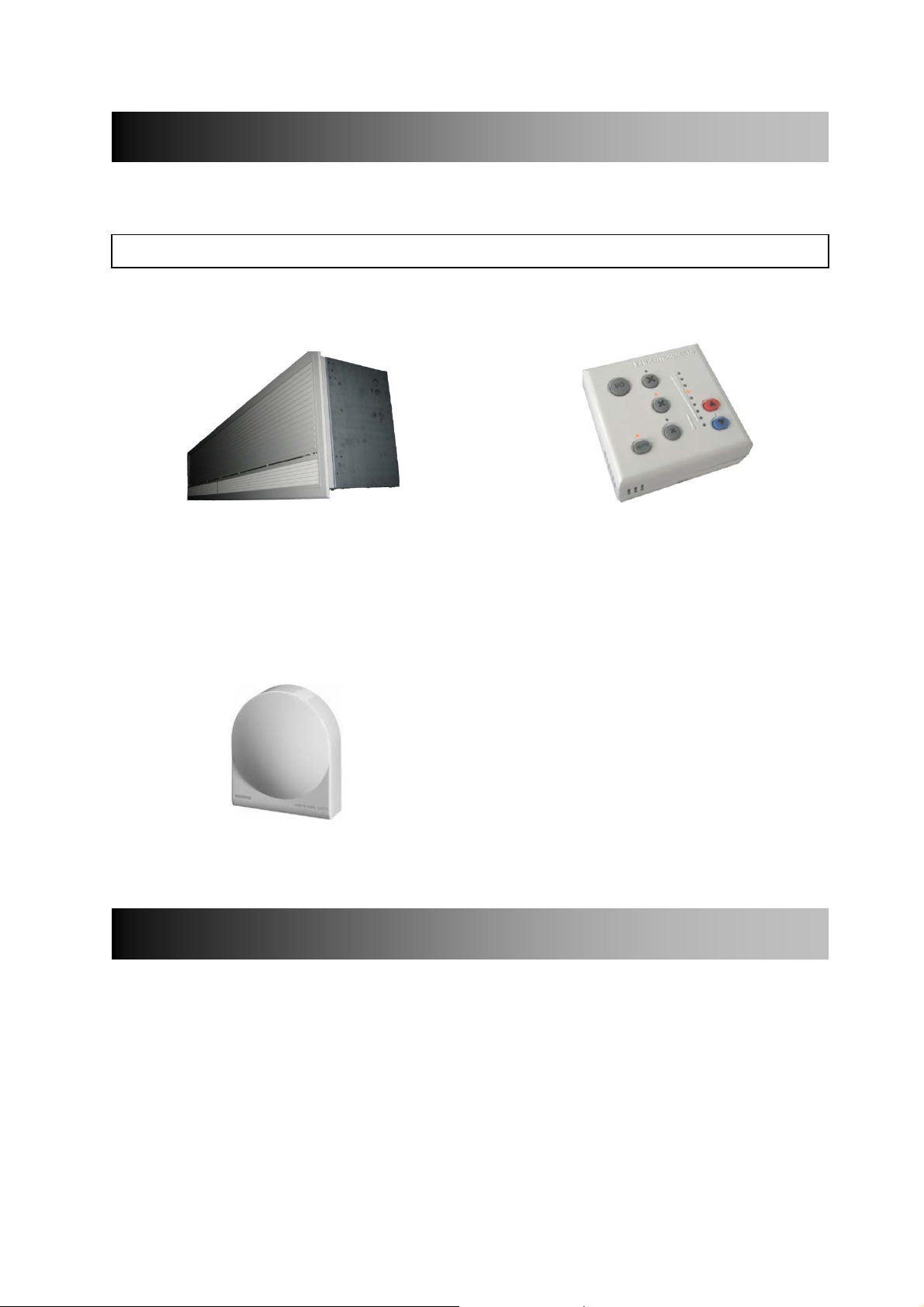

5. DELIVERY CONTENTS

The following items are supplied in the box at delivery.

NOTE: If any parts are missing or damaged contact your place of purchase.

HX Recessed Air Curtain Ecopower Remote Control

Note: The recessed grille is Supplied with 6m control cable

packed separately.

Outdoor Air Sensor (Optional)

Available for weather compensation

control

6. TOOLS REQUIRED

The following tools are required for installation:

Flat blade screwdrivers

Pozi head screwdrivers

10mm spanner

Adjustable spanner

9901098-2-1 Page | 5

Electric drill

Ladders

Appropriate lifting equipment

Appropriate tools for cutting ceiling

aperture

7. INSTALLATION

The air curtain is designed to be recessed within ceiling voids or bulkheads with in a building and

located horizontally over a doorway. It must not be installed outside of the building.

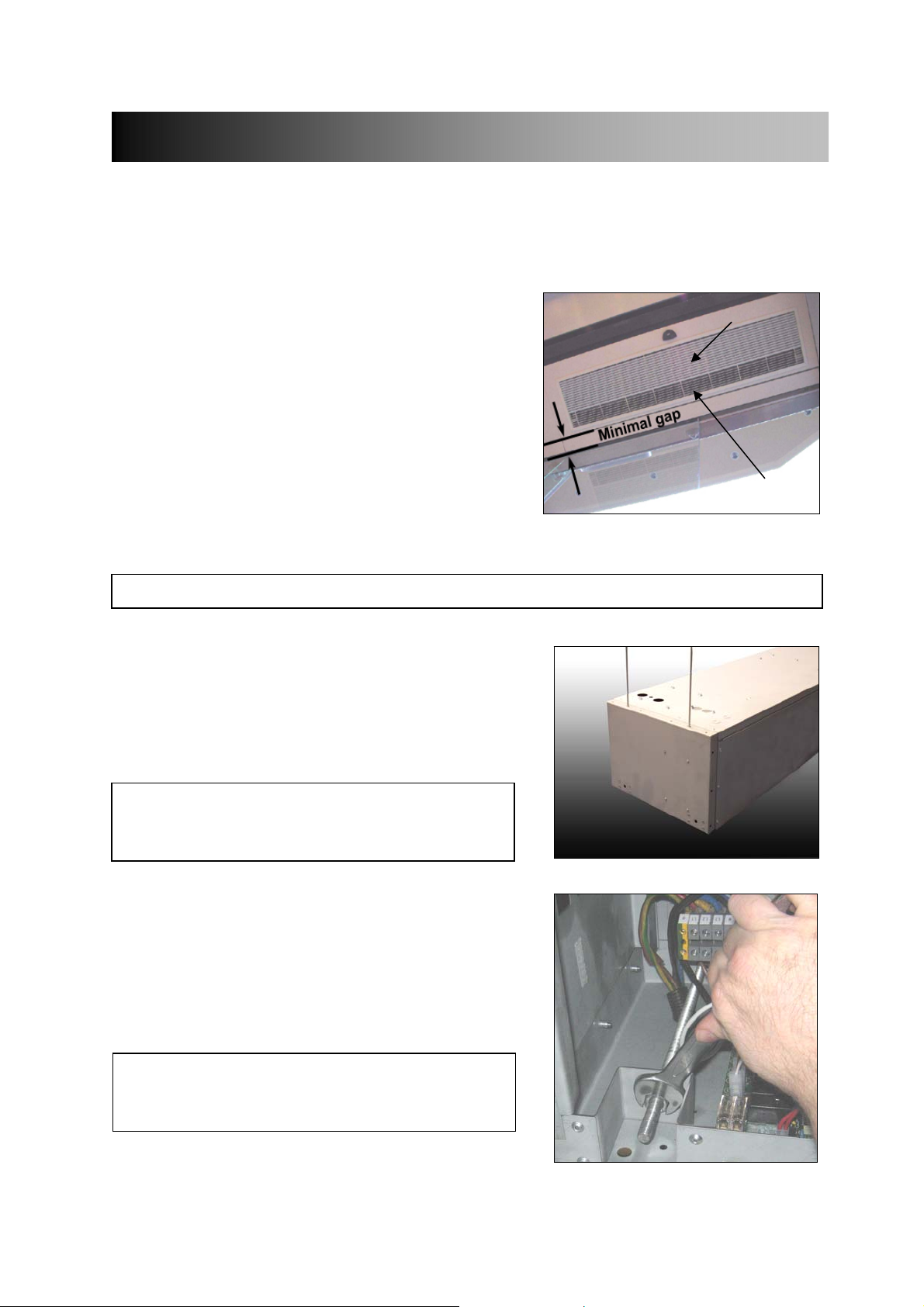

7.1 Location

Mount the air curtain above and as close to the doorway as

possible, with:

the recessed grille not more than 3.5m above floor

level

the air discharge (see 1, Fig 1) section of the

recessed grille nearest the doorway and the air inlet

section (see 2, Fig 1) furthest from the doorway

Beware of doorway top edges, structural beams, door

opening/closure devices, etc., which may interfere with

the air stream and affect the location of the unit.

Fig 1

2

1

NOTE: For the air curtain to work well the doorway should be less than the width of the airstream.

7.2 Ceiling Suspension

Step 1 Cut an aperture in the ceiling to the dimensions

in Appendix 1. Cut notches, if necessary, to clear

screws in the air curtain casing.

NOTE: For LPHW models, pipework will need to be

installed above the curtain. Allow sufficient access and

height clearance within the ceiling void to do this.

Step 2 Fix M10 threaded rods (not supplied) through

the 2 holes at each end in the top casing

(see Fig 2). Feed the rods through the casing and

attach to fixing brackets near the bottom of the

unit (see Fig 3, looking up into the air curtain). Use

M10 lock-nuts either side of the fixing bracket to

secure the hanging rod.

Fig 2

NOTE: Do not let these four hanging rods come below

the bottom of the unit casing or they may prevent the

recessed grille fitting properly.

9901098-2-1 Page | 6

Fig 3

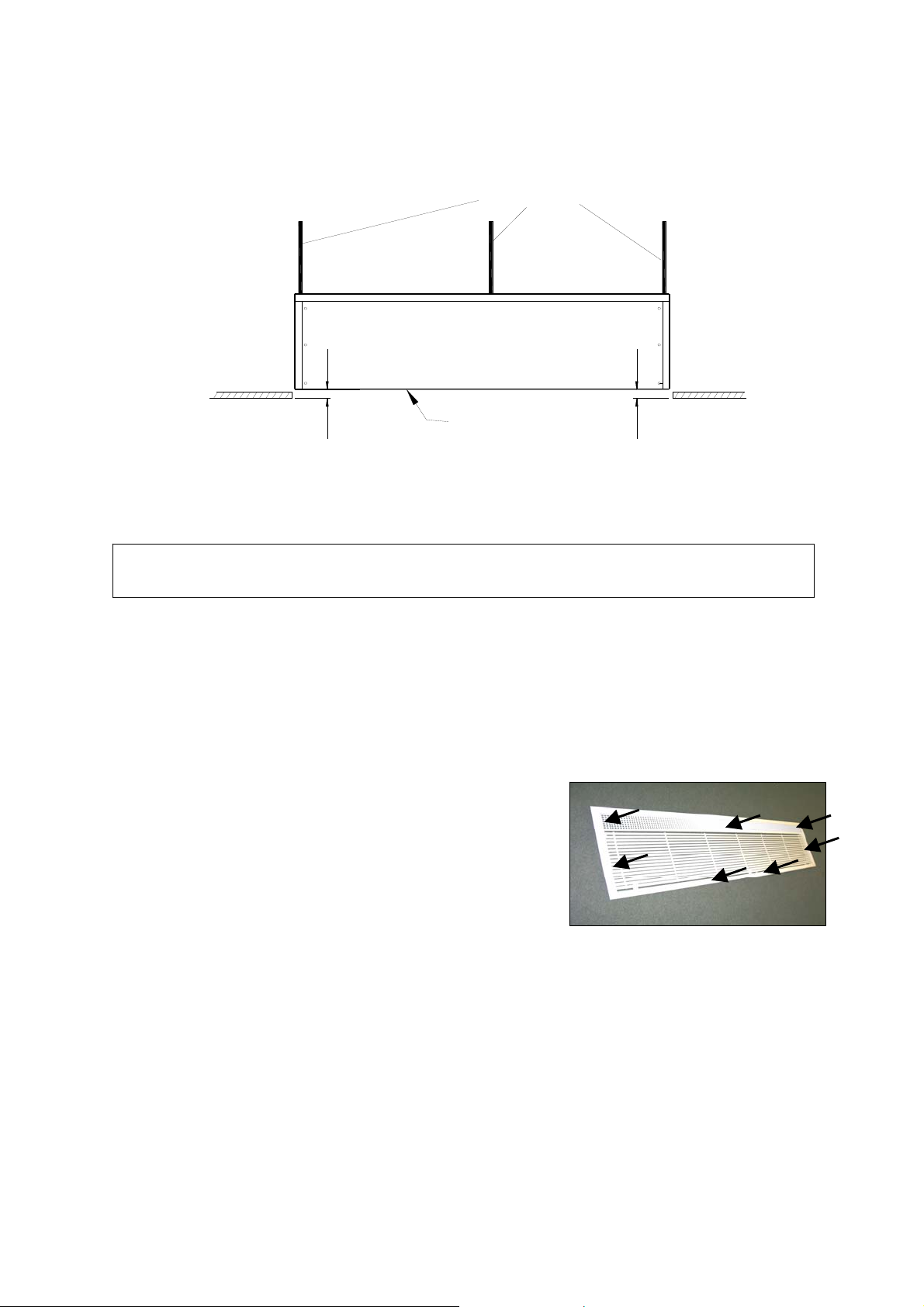

Step 3 If you are installing model HX1500R or HX2000R, fit a 5th M10 threaded rod into the

hanging point in the middle of the unit. Refer to Appendix 1 and Fig 4.

M10 hanging rods

Fig 4

RECESSED AIR CURTAIN

CEILING LEVEL CEILING LEVEL

38

Bottom surface of recessed

air curtain casing

38

Step 4 Secure each rod to a suitable structure that can support the weight of the unit (see

section 3: Specifications for weights).

WARNING: It is the sole responsibility of the installer to ensure that the fixing locations and

suspension system used are suitable for the air curtain being installed.

Step 5 Adjust the height of the unit on its hanging rods so the bottom surface of the casing goes

38mm up into the ceiling as shown in Fig 4. Ensure the unit is level.

7.3 Attaching the recessed grille to the air curtain

The recessed grille consists of:

Metal frame

Cellular discharge grille

Hinged inlet grille

There are 4 fixing points on the HX1000R, 6 on the HX1500R

and 7 on the HX2000R (see Fig 5).

Fig 5 (HX2000R shown)

9901098-2-1 Page | 7

Fix the grille as follows:

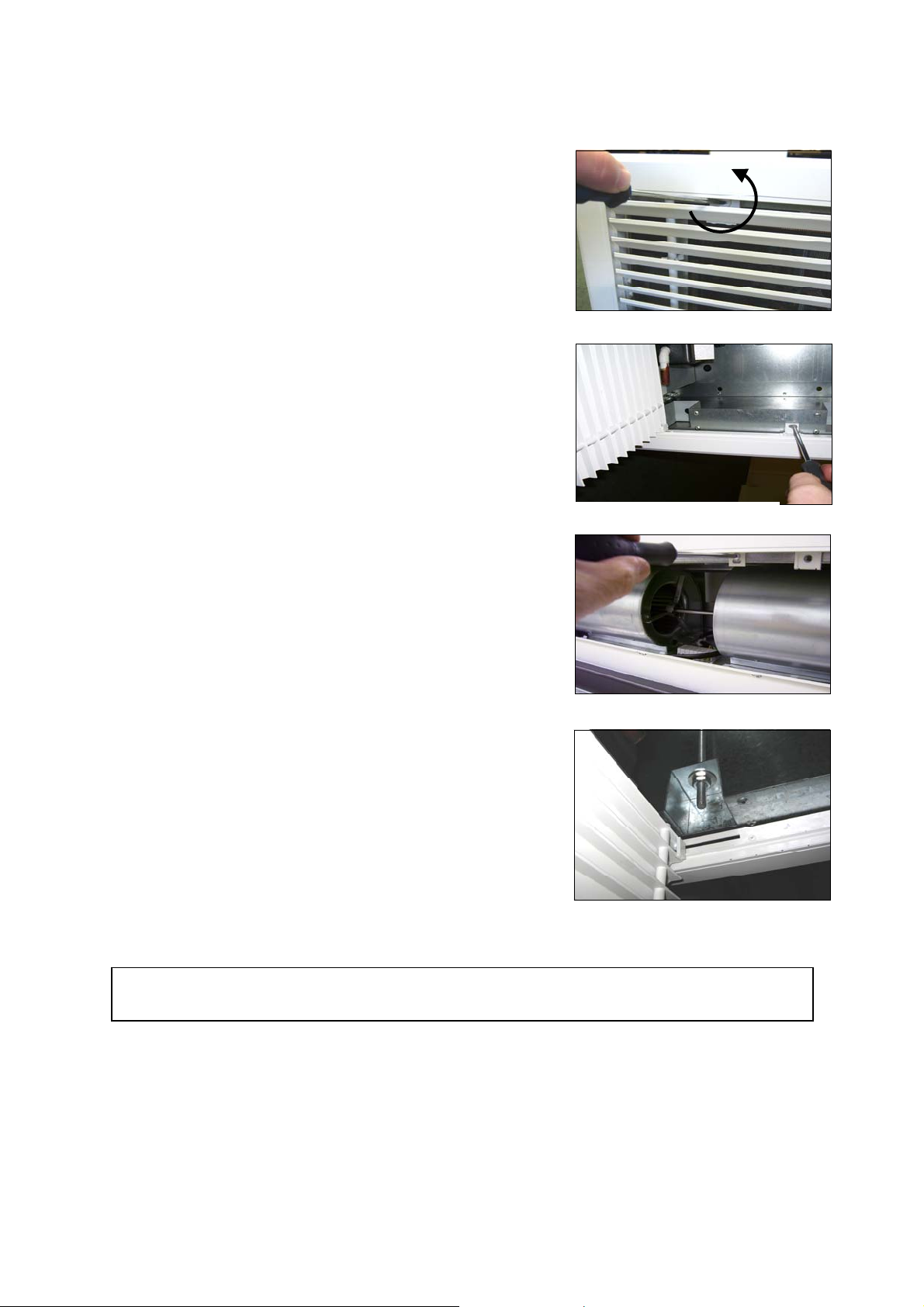

Step 1 Open the hinged inlet grille using a flat bladed

screwdriver to release the quarter turn fasteners (see

Fig 6). There are two fasteners on the HX1000R unit

and three fasteners on HX1500R and HX2000R units.

Step 2 Make sure the grille will go the correct way around

(cellular discharge nearest to doorway). Offer the

recessed grille up through the cut-out in the ceiling

and attach it to the bottom of the air curtain casing

using M4 pozi head screws supplied. Start with

the screws shown in Fig 7 and then fit the two

at each end of the discharge grille.

Step 3 If fitting model HX1500R or HX2000R units insert 1 or

2 screws towards the middle of the unit as shown in

Fig 8.

Step 4 On model HX1500R or HX2000R units fit 1 screw in

the middle of the discharge grille. This screw is easier

to access if the hinged inlet grille is temporarily shut.

Step 5 With the hinged inlet grille open again adjust the

hanging rods (see Fig 9) so the grille frame fits neatly

against the ceiling. Ensure the grille frame is a snug fit

against the ceiling with no gaps all the way around.

Fig 6

Fig 7

Fig 8

Fig 9

NOTE: Open the hinged grille core to gain access to electrical connections, and for se rvicing and

maintenance.

9901098-2-1 Page | 8

Loading...

Loading...