Page 1

Thermo Fisher Scientific Niton

Analyzers

XL3 Analyzer

Version 8.0

User’s Guide (Abridged)

Refer to NITON XL3 Resource Guide for complete information

Revision A October 2011

Page 2

Page 3

© 2010 Thermo Fisher Scientific Inc. All rights reserved.

Page 4

Thermo Fisher Scientific Inc. provides this document to its customers with a product purchase to use in the

product operation. This document is copyright protected and any reproduction of the whole or any part of this

document is strictly prohibited, except with the written authorization of Thermo Fisher Scientific Inc.

The contents of this document are subject to change without notice. All technical information in this

document is for reference purposes only. System configurations and specifications in this document supersede

all previous information received by the purchaser.

Thermo Fisher Scientific Inc. makes no representations that this document is complete, accurate or errorfree and assumes no responsibility and will not be liable for any errors, omissions, damage or loss that might

result from any use of this document, even if the information in the document is followed properly.

This document is not part of any sales contract between Thermo Fisher Scientific Inc. and a purchaser. This

document shall in no way govern or modify any Terms and Conditions of Sale, which Terms and Conditions of

Sale shall govern all conflicting information between the two documents.

Release history:

For Research Use Only. Not for use in diagnostic procedures.

Page 5

Contents

Chapter 0 Contact Us. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Chapter 1 Manual Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Warnings, Cautions, and Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Physical Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Other Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Chapter 2 Using Your Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Safely and Effectively Using Your Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Monitoring your radiation exposure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Safe Handling of Samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Niton XL3t Radiation Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Niton XL3t GOLDD Plus Radiation Profile. . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Niton XL3p Radiation Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Primary Radiation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Secondary Radiation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Deep and Shallow Dose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Proper and Improper Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Emergency Response Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Startup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Battery Installation and Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

The Control Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Startup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Performing a System Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

The Data Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Power Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Using the Navigation (NAV) Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Using the Tools Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Setting the Date and Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Data Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

The Results Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Chapter 3 How to Analyze . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

General Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Chapter 4 Basic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Taking a Sample Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

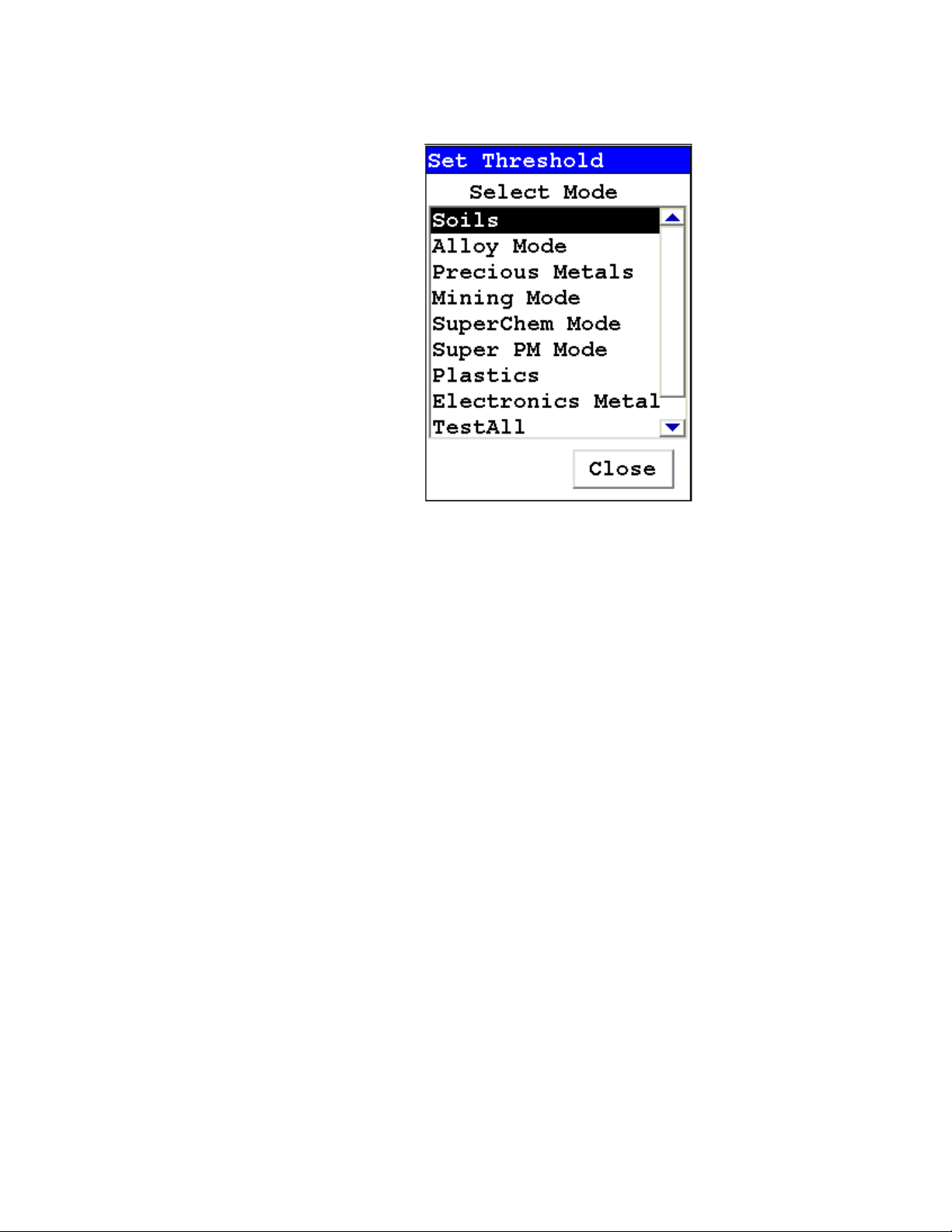

Analysis Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Chapter 5 Common Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Metal Sample Prep . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Soil Sample Prep . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Preparing Mining Samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Setting Up Beep Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Thermo Scientific manual-name 1

Page 6

Contents

Sorting the Custom Element Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Max Measure Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Minumum Test Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Virtual Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Setting Display Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Adjusting the Element Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Setting the Date and Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Calibrating the Touch Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Chapter 6 Data Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

Viewing Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Viewing Fingerprints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Erasing Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Managing Libraries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Chapter 7 Connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .145

Using Your Analyzer With Your PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Connecting From Your Analyzer to Your PC . . . . . . . . . . . . . . . . . . . . . . . . . 153

Using a USB Cable to Connect Your Analyzer . . . . . . . . . . . . . . . . . . . . . . . . 157

Downloading Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Chapter 7 Controlling Your Analyzer From Your PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Chapter 8 Learning More, Service, and Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .173

Replacing the Measurement Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Registration and Licensing FAQ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Storing and Transporting Your Niton XL3 Analyzer . . . . . . . . . . . . . . . . . . . . 183

Chapter 8 Advanced Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .185

Tools Menu Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

NDF Files: User Data Structuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Safety Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Camera and Small Spot Video. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Chapter 9 Helium Purged Analysis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .243

Chapter 9 Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

2 manual-name Thermo Scientific

Page 7

Contact Us

Americas Europe Asia

niton.eur@thermofisher.com

niton@thermofisher.com

tonEurope.support@thermofisher.com

Ni

niton.asia@thermofisher.com

NitonAsia.Support@thermofisher.com

1

Page 8

0

Contact Us

2 Niton XL3 Analyzer User’s Guide Thermo Scientific

Page 9

Manual Overview

Warnings, Cautions, and Notes

Warnings

Warnings are extremely important recommendations, violating which may result in either

njury to yourself or others, or damage to your analyzer and/or data. Warnings will always be

i

identified as Warnings in the text, and will always be visually presented as follows:

WARNING This is a Warning.

Example Warning:

WARNING Tampering with the 5,500 ppm (Lead high) lead-in-soil standard may cause

exposure to lead dust. Keep all standards out of reach of children.

1

Manual Overview

Warnings, Cautions, and Notes

Cautions

Example Caution:

Notes

Example Note:

Cautions are important recommendations. Cautions will always be identified as Cautions in

the text, and will always be visually presented as follows:

CAUTION This is a Caution.

CAUTION N

completely intact

Notes are informational asides which may help you with your analyses. Notes will always be

identified as Notes in the text, and will always be visually presented as follows:

Note This is a Note.

Note For defensible Quality Control, keep a record of the time and precision of every

calibration

ever tamper with Test Standards. They should not be used unless they are

Figures

Figures are illustrations used to show what something looks like. Figures will always be

labelled and identified as Figures directly below the Figure itself, and will always be visually

presented as follows:

Thermo Scientific Niton XL3 Analyzer User’s Guide 1

Page 10

1

Manual Overview

Physical Buttons

Figure 1. This is a Figure

Physical Buttons

Physical Buttons are actual buttons on the analyzer which must be pushed to activate their

unction. Physical Buttons will always be identified as Buttons in the text, and will always be

f

visually presented as follows:

This is a Physical Button.

Example Physical Buttons:

On/Off/Escape Button, Clear/Enter Button, Interlock Button, and Trigger Button.

Other Hardware

Other Hardware refers to any physical part of the analyzer which performs a necessary

unction. Other Hardware will always be visually presented as follows:

f

This is an example of Other Hardware.

Example Other Hardware:

Battery, Touch Screen Display, Measurement Window, and USB Cable

2 Niton XL3 Analyzer User’s Guide Thermo Scientific

Page 11

Using Your Analyzer

This section discusses the basics of using your analyzer, no matter the specific type of analysis

you wish to perform. First we go over analyzer safety, particularly radiation safety. Using an

X-ray based analyzer safely is very important, and not difficult, provided you read,

understand, and follow these guidelines. Secondly, we outline the startup procedure we

recommend for daily use to ensure that your analyzer is performing properly and at its most

efficient level.

Safely and Effectively Using Your Analyzer

CAUTION N

procedures should be followed in areas of concern.

Radiation and General Safety

WARNING Always treat radiation with respect. Do not hold your analyzer near the

measurement window during testing. Never point your analyzer at yourself or anyone else

when the shutter is open.

iton analyzers are not intrinsically safe analyzers. All pertinent Hot Work

2

Using Your Analyzer

Safely and Effectively Using Your Analyzer

Radiation and General Safety

This section covers topics related to radiation safety and general safety when using a Thermo

cientific Niton XL3 analyzer. At a minimum all operators of the analyzer should be familiar

S

with the instructions provided in this chapter in order to handle the analyzer in a safe manner.

In addition to reading the information presented on the following pages, Thermo Fisher

Scientific recommends that instrument users participate in a radiation safety and operational

training class.

Radiation Protection Basics

The Niton Model XL3t analyzer contains an x-ray tube which emits radiation only when the

user turns the x-ray tube on. When the x-ray tube is on and the shutter is open, as during a

measurement, the analyzer emits a directed radiation beam - see Figures 1 and 2. Reasonable

effort should be made to maintain exposures to radiation as far below dose limits as is

practical. This is known as the ALARA (As Low as Reasonably Achievable) principle. For any

given source of radiation, three factors will help minimize your radiation exposure: Time,

Distance, and Shielding.

The Niton Model XL3p analyzer contains a radioactive sealed source. Radiation from this

source is fully contained within the device when not in use and allowed to escape through the

measurement window only while the user is analyzing a sample. Radiation emission is

controlled by a shutter. The analyzer emits a directed radiation beam (See Figure 1 and Figure

Thermo Scientific Niton XL3 Analyzer User’s Guide 3

Page 12

2

Using Your Analyzer

Safely and Effectively Using Your Analyzer

2) when the shutter is open during a measurement. Reasonable effort should be made to

maintain exposures to radiation as far below dose limits as is practical. This is known as the

ALARA (As Low as Reasonably Achievable) principle. For any given source of radiation, three

factors will help minimize your radiation exposure: Time, Distance, and Shielding.

Time

The longer you are exposed to a source of radiation the longer the radiation is able to interact

n your body and the greater the dose you receive. Dose increases in direct proportion to

i

length of exposure.

Distance

The closer you are to a source of radiation, the more radiation strikes you. Based on geometry

alone, dose increases and decreases with an inverse-squared relation to your distance from the

source of radiation (additional dose rate reduction comes from air attenuation). For example,

the radiation dose one foot from a source is nine times greater than the dose three feet from

the source. Remember to keep your hands and all body parts away from the front end of the

analyzer when the shutter is open to minimize your exposure.

Shielding

Shielding is any material that is placed between you and the radiation source. The more

material between you and the source, or the denser the material, the less you will be exposed

to that radiation. Supplied or optional test stands are an additional source of shielding for

analysis. A backscatter shield accessory is also available and may be appropriate in some

applications.

Exposure to Radiation

Human dose to radiation is typically measured in rem, or in one-thousandths of a rem, called

illirem (mrem), 1 rem = 1000 mrem. Another unit of dose is the Sievert (Sv), 1 Sv = 100

m

rem. The allowable limit for occupational exposure in the U.S (and many other countries) is

5,000 mrem/year (50 mSv/year) for deep (penetrating) dose and 50,000 mrem/year (500

mSv/year) for shallow (i.e., skin) dose or dose to extremities. Deep, shallow, and extremity

exposure from a properly used Niton XL3t analyzer should be less than 200 mrem per year,

(2.0 mSv per year) even if the analyzer is used as much as 2,000 hours per year, with the

shutter open continuously. The only anticipated exceptions to the 200 mrem maximum

annual dose are: 1) routine and frequent analysis of plastic samples without use of a test stand,

backscatter shield, or similar additional protective measures, or 2) improper use where a part

of the body is in the primary beam path.

Note NEVER OPERATE THE DEVICE WITH A PART OF YOUR BODY IN THE

PRIMARY BEAM PATH OR WITH THE PRIMARY BEAM PATH DIRECTED AT

ANYONE ELSE.

4 Niton XL3 Analyzer User’s Guide Thermo Scientific

Page 13

2

Using Your Analyzer

Safely and Effectively Using Your Analyzer

Also, consider the use of protective accessories such as a shielded test stand or backscatter

shield (or equivalent) when performing routine and/or frequent analysis of any of the

following:

• plastic (or similarly low density) samples,

• thin samples (such as foils, circuit boards, and wires)

• samples that are smaller than the analysis window.

Shown in Table 1are the typical background radiation doses received by the average member

of the public. The radiation dose limits for radiation workers in the US are also shown in

Table 2.

Table 1. Typical Radiation Doses Received (Source: NCRP 1987)

Category

Dose in

mrem

Dose in mSv

Average total dose in US (annual) 360 3.6

Average worker exposure (annual) 210 2.1

Average exposure for an underground

miner

Exposure for airline crew (1,000 hours

at 35,000 ft)

Additional from living in Denver at

5300’ (annual)

400 4.0

500 5.0

25 .25

Additional from 4 pCi/l radon in home 1,000 10.0

Typical Chest X-Ray 6 0.06

Typical Head or Neck X-Ray 20 0.2

Typical pelvis/hip x-ray 65 0.65

Typical lumbar spine x-ray 30 0.3

Typical Upper G.I. x-ray 245 2.45

Typical Barium enema x-ray 405 4.05

Typical CAT scan 110 1.10

Thermo Scientific Niton XL3 Analyzer User’s Guide 5

Page 14

2

Using Your Analyzer

Monitoring your radiation exposure

Table 2. Annual Occupational Dose Limits for Radiation Workers

(Source: Code of Federal Regulations Title 10, Part 20)

Category

Whole Body 5000 50

Pregnant Worker (during gestation

period)

Eye Dose Equivalent 15,000 150

Shallow dose equivalent to the skin or

any extremity or organ

Maximum allowable dose for the

general public (annual)

For a Minor 500 5.0

Monitoring your radiation exposure

Individuals can be monitored for the radiation dose they receive by use of radiation dosimetry

evices (dosimeters). Monitoring dose using a dosimeter can be a way of identifying improper

d

use and at the same time demonstrating proper use. In some locations, dosimetry is required

by regulations and in others it is optional. It is normally required when the user could

reasonably be expected to receive in excess of 10% of the annual dose limit. Thermo Fisher

Scientific recommends that you determine and obey the local regulatory requirements

concerning radiation monitoring of occupational workers.

Dose in

mrem

Dose in mSv

500 5

50,000 500

100 1.0

Two common types of dosimeters are whole-body badges and ring badges. Whole body

badges are often attached to the user’s torso (e.g., clipped to the collar, shirt pocket, or waist as

appropriate). A ring badge is worn on the finger as a measure of maximum extremity dose.

When worn, the specific location of the dosimeter should be that part of the body that is

expected to receive the highest dose. This location will depend on how the analyzer is used

and so it may not be the same for all users. Dosimetry services are offered by many companies.

Two companies offering dosimetry services in the USA and much of the world are:

6 Niton XL3 Analyzer User’s Guide Thermo Scientific

Page 15

Monitoring your radiation exposure

Table 3. Dosimeters

Company Global Dosimetry Solutions Landauer, Inc.

Address 2652 McGaw Avenue 2 Science Road

City and State Irvine, CA 92614 Glenwood, IL 60425-9979

Website www.dosimetry.com www.landauerinc.com

Phone Number (800) 251-3331 (800) 323-8830

2

Using Your Analyzer

Note W

dosimeter badge only measures your exposure (at the dosimeter location).

earing a dosimeter badge does not protect you against radiation exposure. A

Pregnancy and Radiation Exposure

International guidance documents (e.g., ICRP Publication 60 and NCRP Publication 116*)

recommend that the radiation dose to the embryo/fetus of a pregnant woman should not

exceed a total of 500 mrem (10% of normal radiation worker limit) during the gestation

period. While this dose limit exceeds the dose limit to a trained operator, pregnant workers

may want to take special precautions to reduce their exposure to radiation. For more

information see the U.S. NRC Regulatory Guide 8.13 "Instruction Concerning Prenatal

Radiation Exposure" which can be found on the resource CD.

* The International Commission on Radiological Protection, ICRP, is an independent

Registered Charity, established to advance for the public benefit the science of radiological

protection, in particular by providing recommendations and guidance on all aspects of

protection against ionizing radiation.

* The National Council on Radiation Protection and Measurements (NCRP) was chartered

by the U.S. Congress in 1964 as the National Council on Radiation Protection and

Measurements.

How to Use the Niton XL3t Analyzer Safely

The Niton XL3t analyzer is designed to be safe to operate provided that it is used in

ccordance with manufacturer's instructions. Under conditions of normal use, monitored

a

operators seldom receive a measurable dose and have not been known to receive in excess of

10% of the annual occupational dose limits (a criteria that would require monitoring under

regulation in the U.S.). In addition to proper use of the XL3t, it is recommended that you

follow these precautions to ensure your safety and the safety of those around you.

Know where the beam is

The primary beam is a directed beam out of the front of the analyzer that can have high dose

ates. The secondary beam, or scattered beam, has much lower dose rates.

r

Thermo Scientific Niton XL3 Analyzer User’s Guide 7

Page 16

2

Using Your Analyzer

Monitoring your radiation exposure

Figure 2. Primary Beam

8 Niton XL3 Analyzer User’s Guide Thermo Scientific

Page 17

2

Using Your Analyzer

Monitoring your radiation exposure

Figure 3. Secondary (Scattered) Beam

Thermo Scientific Niton XL3 Analyzer User’s Guide 9

Page 18

2

Using Your Analyzer

Monitoring your radiation exposure

The Shutter-Open Indicator Lights

When the lights are flashing, the primary beam is on, and radiation is being emitted from the

front of the analyzer.

Figure 4. The X-ray Beam Indicator Lights

Handle and Use with Respect

Avoid holding the front of the analyzer when the x-ray tube is energized and the shutter is

pen. Never point the instrument at yourself or anyone else when the shutter is open and the

o

x-ray tube is energized. Never look into the path of the primary beam.

Follow a Radiation Protection Program

Your organization should establish, document, and follow a Radiation Protection Program.

An example of such a program can be found on the resource CD (provided with the

instrument).

Take Proper Care of your Niton XL3

Keeping your analyzer maintained in good condition will help minimize the risk of accidental

exposure. Mechanical malfunction of the shutter can be avoided by maintaining the

measurement window, as described in the User Guide. This prevents foreign objects from

entering your analyzer

10 Niton XL3 Analyzer User’s Guide Thermo Scientific

Page 19

Avoid Over-Exposures

Direct contact with the window could result in overexposures in the times indicated inTable 4

below.

Table 4. Potential Exposure Limit Times

Location of Dose Limit Time to Reach Limit

2

Using Your Analyzer

Safe Handling of Samples

Deep Dose /

Whole Body

Shallow Dose /

Extremities

Member of

Public (i.e.

untrained

operator)

Extremity is defined by the NRC as the hand, elbow, arm below the elbow, foot, knee, or

g below the knee. Whole Body is defined by the NRC as the head, trunk (including

le

male gonads), arms above the elbow, or legs above the knee.

*Based on maximum deep dose rate and US exposure limit.

Safe Handling of Samples

As mentioned many times in this chapter, never place any part of your body in the path of the

-ray beam. There is always a safe way to handle samples whether they are small, irregularly

x

shaped, or of low density. Never look into the path of the primary beam.

5 rem (50 mSv) 2.1 minutes

50 rem (500 mSv) 0.95 minutes

0.1 rem (1 mSv) 2.5 seconds*

Small Samples

A small sample would be any sample that is smaller than the measurement window. Small

samples present a unique risk because they don’t block the entire beam path. The difficulty

with placing small samples down on a work surface to analyze them is that you may get

readings from the work surface that interfere with analytical results. A test stand is an effective

way of analyzing small samples accurately and safely. Never hold samples during analysis or

look into the path of the primary beam.

Thermo Scientific Niton XL3 Analyzer User’s Guide 11

Page 20

2

Using Your Analyzer

Safe Handling of Samples

Irregularly Shaped Samples

Irregularly shaped samples may not allow the proximity button to be depressed, or they may

not entirely cover the primary beam and cause additional scattering. A back scatter shield is a

safe way of reducing your radiation exposure while effectively analyzing an irregularly shaped

sample.

Low Density Materials (such as plastics).

X-rays are attenuated more through denser materials and less through low density materials

uch as plastic. This causes higher dose rates in the scattered radiation. If you are frequently

s

handling low density samples, you should consider the use of test stands, backscatter shields,

or the equivalent.

12 Niton XL3 Analyzer User’s Guide Thermo Scientific

Page 21

Niton XL3t Radiation Profile

Radiation Meter Information

Model: Bicron MicroRem

SN: 2057

Cal Due: 10/10/2009

Background Radiation Level

<0.01 mr/hr

Table 1-4 - Niton XL3t Radiation Profile - Scatter Measurements - mRem/hr

2

Using Your Analyzer

Niton XL3t Radiation Profile

kV uA Range Substrate

EM, GM, S, T, IP, PM, DA, M, E, P (Main

50 40

50 40

20 100 S, P, T, M, E (Low Filter) Aluminum 0.015 0.01 0.01

20 100 S, P, T, M, E (Low Filter) Stainless 0.015 0.01 0.01

20 100 S, P, T, M, E (Low Filter) Plastic 0.13 0.015 0.015

20 100 S, P, T, M, E (Low Filter) Soil 0.015 0.015 0.015

15 100 IP, EM (Low Filter) Aluminum 0.015 0.015 0.015

15 100 IP, EM (Low Filter) Stainless 0.015 0.015 0.015

Filter)

S, T, M, E (High Filter)

EM, GM, S, T, IP, PM, DA, M, E, P (Main

Filter)

S, T, M, E (High Filter)

* GM = General Metals, EM = Electronics Metals, DA = Dental Alloy, PM = Precious

etals, M = Mining, S = Soil, E = Exploration, IP = Industrial Paint, T = Thin Sample,

M

P = Plastic

Scatter Measurements off various substrates - Dose Rates in mRem/hr

Plastic 40 3.5 2

Soil 8 0.4 0.07

Max @

5cm

Max @

30 cm

Max @

Trigger

Thermo Scientific Niton XL3 Analyzer User’s Guide 13

Page 22

2

Using Your Analyzer

Niton XL3t Radiation Profile

Table 1-5 - Niton XL3t Radiation Profile - Scatter Measurements - µS

kV uA Range Substrate

M, GM, S, T, IP, PM, DA, M, E (P (Main

E

50 40

50 40

20 100 S, P, T, M, E (Low Filter) Aluminum 0.15 0.1 0.1

20 100 S, P, T, M, E (Low Filter) Stainless 0.15 0.1 0.1

20 100 S, P, T, M, E (Low Filter) Plastic 1.3 0.15 0.15

20 100 S, P, T, M, E (Low Filter) Soil 0.15 0.15 0.15

15 100 IP, EM (Low Filter) Aluminum 0.15 0.15 0.15

15 100 IP, EM (Low Filter) Stainless 0.15 0.15 0.15

Filter)

S, T, M, E (High Filter)

EM, GM, S, T, IP, PM, DA, M, E (P (Main

Filter)

S, T, M, E (High Filter)

Notes:

catter measurements were taken at a radius of 5 or 30 cm around the nose of the analyzer

S

with the highest scatter dose rate being recorded.

Scatter Measurements off various substrates - Dose Rates in µSv/hr

* GM = General Metals, EM = Electronics Metals, DA = Dental Alloy, PM = Precious

Metals, M = Mining, S = Soil, E = Exploration, IP = Industrial Paint, T = Thin Sample,

P = Plastic

Plastic 400 35 20

Soil 80 4 0.7

v/hr

Max @

5cm

Max @

30 cm

Max @

Trigger

14 Niton XL3 Analyzer User’s Guide Thermo Scientific

Page 23

Table 1-6 Niton XL3t Radiation Profile - In Beam Measurements - Rem/hr

2

Using Your Analyzer

Niton XL3t Radiation Profile

kV uA Range

M, GM, S, T, IP, PM, DA, M, E, P (Main

E

50 40

20 100 S, P, T, M, E (Low Filter) 150 3200 0.52 0.05

15 100 IP, EM (Low Filter) 14.0 1100 0.43 0.042

Filter)

S, T, M, E (High Filter)

In Beam Measurements - Dose Rates in Rem/hr

GM = General Metals, EM = Electronics Metals, DA = Dental Alloy, PM = Precious

*

Metals, M = Mining, S = Soil,

E = Exploration, IP = Industrial Paint, T = Thin Sample, P = Plastic

Reported results are based on measurement results that have been reduced to 2 significant

digits by rounding up. For example, a measurement result of 1441 would be reported

as 1500.

Contact

Deep

110 410 8.4 1.3

Contact

Shallow

5cm

Deep

Shallow

Table 1-7 Niton XL3t Radiation Profile - In Beam Measurements - mSv/hr

kV uA Range

M, GM, S, T, IP, PM, DA, M, E, P (Main

E

50 40

Filter)

S, T, M, E (High Filter)

Contact

Deep

1100 4,100 84.0 13

Contact

Shallow

5cm

Deep

30 cm

30cm

Shallow

20 100 S, P, T, M, E (Low Filter) 1500 32000 5.2 0.50

15 100 IP, EM (Low Filter) 140 11000 4.3 0.42

Notes:

In beam dose rates were measured using thermoluminescent dosimeters (TLDs) or Opti-

cally Stimulated Luminescent Dosimeters (OSL).

In Beam Measurements - Dose Rates in mSv/hr

* GM = General Metals, EM = Electronics Metals, DA = Dental Alloy, PM = Precious

Metals, M = Mining, S = Soil,

E = Exploration, IP = Industrial Paint, T = Thin Sample, P = Plastic

Reported results are based on measurement results that have been reduced to 2 significant

digits by rounding up. For example, a measurement result of 1441 would be reported

as 1500.

Thermo Scientific Niton XL3 Analyzer User’s Guide 15

Page 24

2

Using Your Analyzer

Niton XL3t GOLDD Plus Radiation Profile

Niton XL3t GOLDD Plus Radiation Profile

Table 1-8 - Niton XL3t GOLDD Plus Radiation Profile - In Beam Measurements - mSv/hr

kV uA Range

M, MC, P, TA, PP (Main) M, S, T

50 40

50 40 GM, PM, M, S, IP (Main)

20 100

15 133.3

8 200

E

(High)

EM, P, TA, M, S, T (Low) 690 19000 190 9.2

GM (Low) 240 13000 50 2.3

GM, P, M (Light) 0.30 17000 0.10 <0.003

Notes:

SAMPLE TYPES (MODES)

*

GM=General Metals, M=Mining, EM=Electronics Metals, S=Soils, PM=Precious Metals,

IP=Industrial Paint (Action lead Paint & Quantify lead Paint), MC=Metal Coatings,

PP=Painted Products, P=Plastics, TG=Test All Geo (soil and mining), TA=Test All

(consumer products), T=Thin

Reported results are based on measurement results that have been reduced to 2 significant

digits by rounding up. For example, a measurement result of 1441 would be reported

as 1500.

Contact

Deep

440 1300 74 5.3

1500 3800 360 22

Contact

Shallow

5cm

Deep

Table 1-9 - Niton XL3t GOLDD Plus Radiation Profile - In Beam Measurements - Rem/hr

kV uA Range

Contact

Deep

Contact

Shallow

5cm

Deep

30cm

Deep

30cm

Deep

50 40

50 40 GM, PM, M, S, IP (Main)

20 100

15 133.3

8 200

16 Niton XL3 Analyzer User’s Guide Thermo Scientific

EM, MC, P, TA, PP (Main) M, S, T

(High)

44 130 7.4 0.53

150 380 36 2.2

EM, P, TA, M, S, T (Low) 69 1900 19 0.92

GM (Low) 24 1300 5.0 0.23

GM, P, M (Light) 0.030 1700 0.010 <0.0003

Notes:

*SAMPLE TYPES (MODES)

GM=General Metals, M=Mining, EM=Electronics Metals, S=Soils, PM=Precious Metals,

IP=Industrial Paint (Action lead Paint & Quantify lead Paint), MC=Metal Coatings,

PP=Painted Products, P=Plastics, TG=Test All Geo (soil and mining), TA=Test All

(consumer products), T=Thin

Reported results are based on measurement results that have been reduced to 2 significant

digits by rounding up. For example, a measurement result of 1441 would be reported

as 1500.

Page 25

2

Using Your Analyzer

Niton XL3t GOLDD Plus Radiation Profile

Table 1-10 - Niton XL3t GOLDD Plus Radiation Profile - Scatter Measurements - mRem/hr

kV uA Range Substrate Max @ 5cm

EM, MC, P, TA, PP

50 40

(Main) M, S, T

Steel 0.14 <0.01 <0.01

(High)

EM, MC, P, TA, PP

50 40

(Main) M, S, T

Aluminum 2 <0.01 <0.01

(High)

EM, MC, P, TA, PP

50 40

(Main) M, S, T

Soil 2 0.04 <0.01

(High)

EM, MC, P, TA, PP

50 40

(Main) M, S, T

Plastic 10 0.45 6

(High)

50 40

50 40

GM, PM, M, S, IP

(Main)

GM, PM, M, S, IP

(Main)

Steel 0.3 <0.01 <0.01

Aluminum 4 0.01 0.01

Max @ 30

cm

Max @

Trigger

50 40

20 100

20 100

GM, PM, M, S, IP

(Main)

EM, P, TA, M, S, T

(Low)

EM, P, TA, M, S, T

(Low)

Soil 4 0.09 <0.01

Soil <0.01 <0.01 <0.01

Plastic 0.07 <0.01 <0.01

15 133.3 GM (Low) Steel <0.01 <0.01 <0.01

Thermo Scientific Niton XL3 Analyzer User’s Guide 17

Page 26

2

Using Your Analyzer

Niton XL3t GOLDD Plus Radiation Profile

Table 1-10 - Niton XL3t GOLDD Plus Radiation Profile - Scatter Measurements - mRem/hr

15 133.3 GM (Low) Aluminum <0.01 <0.01 <0.01

<0.01 (no

detectable

scatter

radiation) at

8

200 GM, P, M (Light)

any location

for steel,

aluminum,

soil, or plastic

sample types

Notes:

SAMPLE TYPES (MODES)

*

GM=General Metals, M=Mining, EM=Electronics Metals, S=Soils, PM=Precious Metals,

IP=Industrial Paint (Action lead Paint & Quantify lead Paint), MC=Metal Coatings,

PP=Painted Products, P=Plastics, TG=Test All Geo (soil and mining), TA=Test All

(consumer products), T=Thin

Table 1-11 - Niton XL3t GOLDD Plus Radiation Profile - Scatter Measurements - µSv/hr

kV uA Range Substrate Max @ 5cm

Max @ 30

cm

Max @

Trigger

EM, MC, P, TA, PP

50 40

(Main) M, S, T

Steel 1.4 <0.1 <0.1

(High)

EM, MC, P, TA, PP

50 40

(Main) M, S, T

Aluminum 20 <0.1 <0.1

(High)

EM, MC, P, TA, PP

50 40

(Main) M, S, T

Soil 20 0.4 <0.1

(High)

EM, MC, P, TA, PP

50 40

(Main) M, S, T

Plastic 100 4.5 60

(High)

50 40

GM, PM, M, S, IP

(Main)

Steel 3 <0.1 <0.1

50 40

18 Niton XL3 Analyzer User’s Guide Thermo Scientific

GM, PM, M, S, IP

(Main)

Aluminum 40 0.1 0.1

Page 27

2

Niton XL3t GOLDD Plus Radiation Profile

Table 1-11 - Niton XL3t GOLDD Plus Radiation Profile - Scatter Measurements - µSv/hr

G

50 40

M, PM, M, S, IP

(Main)

Soil 40 0.9 <0.1

Using Your Analyzer

20 100

20 100

EM, P, TA, M, S, T

(Low)

EM, P, TA, M, S, T

(Low)

Soil <0.1 <0.1 <0.1

Plastic 0.7 <0.1 <0.1

15 133.3 GM (Low) Steel <0.1 <0.1 <0.1

15 133.3 GM (Low) Aluminum <0.1 <0.1 <0.1

<0.1 (no

detectable

scatter

radiation) at

8 200 GM, P, M (Light)

any location

for steel,

aluminum,

soil, or plastic

sample types

Note *

SAMPLE TYPES (MODES)

GM=General Metals, M=Mining, EM=Electronics Metals, S=Soils, PM=Precious Metals,

P=Industrial Paint (Action lead Paint & Quantify lead Paint), MC=Metal Coatings,

I

PP=Painted Products, P=Plastics, TG=Test All Geo (soil and mining), TA=Test All

(consumer products), T=Thin

Thermo Scientific Niton XL3 Analyzer User’s Guide 19

Page 28

2

Using Your Analyzer

Niton XL3p Radiation Profile

Niton XL3p Radiation Profile

Table 1-12 - Niton XL3p Radiation Profile - In Beam Measurements

Distance From Window Dose Rate (mSv/hr) Dose Rate (mrem/hr)

5 cm 0.45 45

30 cm 0.03 3.0

100 cm 0.003 0.3

Table 1-13 - Niton XL3p Radiation Profile - Scatter Measurements - mSv/hr

Location

Max Scatter @ 5cm from

Snout (A’)

Plastic

Substrate

0.06 0.03 0.018 0.01 0.0042

Wood

Substrate

Soil

Substrate

Aluminum

Substrate

Steel

Substrate

Max Scatter @ Trigger (B) 0.0038 0.002 0.0015 0.0048 0.0003

Table 1-14 - Niton XL3p Radiation Profile - Scatter Measurements - mRem/hr

Location

Max Scatter @ 5cm from

Snout (A’)

Plastic

Substrate

6.0 3.0 1.8 1.0 0.42

Wood

Substrate

Soil

Substrate

Aluminum

Substrate

Steel

Substrate

Max Scatter @ Trigger (B) 0.38 0.2 0.15 0.48 0.03

20 Niton XL3 Analyzer User’s Guide Thermo Scientific

Page 29

2

Using Your Analyzer

Niton XL3p Radiation Profile

Figure 5. Primary and Secondary Dose Locations (Not to Scale)

Thermo Scientific Niton XL3 Analyzer User’s Guide 21

Page 30

2

Using Your Analyzer

Primary Radiation

Primary Radiation

Niton XL3t and XL3t GOLDD

Primary radiation is radiation that is produced by the analyzer and emitted out through the

measurement window. Individuals should never place any part of their body in the primary

beam path when the x-ray tube is on. There should always be a sample in contact with the

measurement window when the x-ray tube is on. The sample will absorb most of the

primary-beam radiation unless it is smaller than the instrument's measurement window or of

low density and/or thickness. Caution should be taken when analyzing samples that are small,

thin, and/or low in density as they may allow much more of the primary beam to escape.

In-beam primary radiation dose rates are listed in Table 1-6, 1-7, 1-8, 1-9, and their location

identified relative to the analyzer in Figure 4 as Dose Point C.

Niton XL3p

Primary radiation is radiation that is produced by the analyzer and emitted out through the

easurement window. Individuals should never place any part of their body in the primary

m

beam path when the shutter is open. There should always be a sample in contact with the

measurement window when the shutter is open. The sample will absorb most of the

primary-beam radiation unless it is smaller than the instrument's measurement window or of

low density and/or thickness. Caution should be taken when analyzing samples that are small,

thin, and/or low in density as they may allow much more of the primary beam to escape.

In-beam primary radiation dose rates are listed in Table 1-6, 1-7, 1-8, 1-9, and their location

identified relative to the analyzer inFigure 4 as Dose Point C.

Secondary Radiation

Under conditions of normal and proper use, individuals can be exposed to secondary (or

scattered") radiation. Secondary radiation is low-level radiation that emanates from the

"

sample being analyzed as a result of primary beam radiation scattering in the sample or

primary beam radiation inducing fluorescent x-rays in the sample. Dose points A, A’ and B in

Figure 4 are examples of where you can encounter secondary radiation. The magnitude of this

secondary radiation is sample dependent. Higher density samples such as steel will emit the

lowest levels as they absorb most primary and secondary radiations. Lower density samples

such as aluminum, wood, and especially plastic, will produce higher levels of secondary

radiation.

Niton XL3t and XL3t GOLDD

Secondary radiation dose rates are listed in Tables 1-4, 1-5, 1-10, and 1-11, for a few common

sample types over a wide range of densities.

22 Niton XL3 Analyzer User’s Guide Thermo Scientific

Page 31

Niton XL3p

Secondary radiation dose rates are listed in Tables 1-13 and 1-14 for a few common sample

types over a wide range of densities.

Holding Samples

The operator is reminded that one should never hold samples during analysis, doing so will

esult in higher than necessary exposure to secondary radiation and could expose the operator

r

directly to the much higher primary-beam dose rates.

Deep and Shallow Dose

You will find in the tables that shallow dose rates are listed for some dose points. All dose rates

listed in the In-Beam Primary Radiation Tables are deep dose unless they are specifically

identified as shallow dose. Deep dose is dose from penetrating radiation that is delivered to

both skin and underlying tissues and organs and is the type most commonly referred to when

describing external radiation hazards. Occupational deep dose is limited to a maximum of 5

rem (50 mSv) per year in the United States and most countries internationally. Deep dose is

measured at 1.0 cm below the skin surface.

2

Using Your Analyzer

Deep and Shallow Dose

Shallow dose is often referred to as "skin dose" because it is a result of low penetrating

radiation that only interacts with the skin. Shallow dose is limited to a maximum of 50 rem

(500 mSv) per year in the United States and most countries internationally. Shallow dose is

listed for primary in-beam dose points only because the low penetrating radiation that causes

shallow dose is nearly all absorbed by a sample and does not produce any significant secondary

radiation. Shallow dose is measured at a point 0.007 cm below the surface.

Proper and Improper Operation

Storage and Transportation

Storage

Regulations in nearly all locations will require that you store your analyzer locked in a secured

rea to prevent access, use, and/or removal by unauthorized individuals. Storage requirements

a

will vary by location, particularly with regard to storage at temporary job sites or away from

your primary storage location such as hotels and motels and in vehicles. You should contact

your local Radiation Control Authority to identify the specific storage requirements in your

jurisdiction.

Thermo Scientific Niton XL3 Analyzer User’s Guide 23

Page 32

2

Using Your Analyzer

Proper and Improper Operation

Transportation

Niton XL3t and XL3t GOLDD

There are no X-ray tube specific US Department of Transportation (DOT) or International

Air Transport Association (IATA) radiation regulations regarding shipping the Niton XL3t

analyzer. It is recommended that you ship the analyzert in its carrying case and an over-pack

to protect the sensitive measuring equipment inside the analyzer. Do NOT ship the analyzer

with the battery pack connected to the analyzer.

Niton XL3p

For Thermo Fisher Scientific, Niton Analyzers (Niton Analyzers), in the United States, the

overnment agency that has primary authority and regulations which apply to transportation

g

is the Department of Transportation (DOT) (Code of Federal Regulations 49 Parts 100 to

185).

In addition, the EPA, OSHA, and the NRC also have regulations that touch on the

transportation of hazardous substances.

The International Air Transport Association (IATA) has recommendations that every major

air carrier has incorporated into their policies for the air transport of hazardous substances.

The enforcement of DOTregulations is carried out by the Department of Transportation, the

Federal Aviation Administration, the Federal Highway Administration, the Federal Railroad

Administration, the Coast Guard, and Customs and Border Protection. State agencies may

also enforce state DOT regulations.

The major aspects of the regulations include:

• "training to recognize hazards and how to safely deal with hazardous substances,

• "classification and identification of packages to inform of hazards,

• "protective packaging to safely transport hazardous materials,

• "hazard communication to inform personnel of hazards in a package,

and

• "incident reporting to inform regulators of incidents.

As part of shipping hazardous substances, you should be trained in:

• "a general awareness and a familiarity with the general provisions of the DOT and hazardous

materials regulations,

• "training that is function specific and be applicable to the daily work performed,

• "the recognition and identification of hazardous substances,

24 Niton XL3 Analyzer User’s Guide Thermo Scientific

Page 33

2

Using Your Analyzer

Proper and Improper Operation

• "the specific requirements for functions performed,

• "security measures to keep a package secure.

• "safety issues as related to safe handling and hazard communication.

• "knowledge of emergency response information, self-protective procedures, and accident

prevention procedures.

Employers are responsible for providing the proper training (every three years for DOT) to

employees, testing employee knowledge, and record keeping.

The DOT Hazardous Material Regulations set the criteria for determining the hazard class

and the proper shipping name for hazardous materials. The Hazard Classes as follows:

Class

1. Explosives

2. Gases

3. Flammable and Combustible Liquids

4. Flammable solids, combustible materials, and dangerous when wet materials

5. Oxidizers and organic peroxides

6. Toxic materials and infectious substances

7. Radioactive Materials

8. Corrosive Materials

9. Miscellaneous dangerous goods

Niton analyzers with radioisotopes are Hazard Class 7. The Hazard Class of the material being

transported tells you which Parts of the regulations are required.

A UN number is assigned to each type of hazardous material. It is the letters "UN" followed

by a four digit numerical code, which allows emergency responders to identify the chemical

being shipped. The UN number for Niton analyzers is "UN 2911".

There is also an official name designation for Niton Analyzers called the Proper Shipping

Name. The proper Shipping Name for the Niton Analyzers is "Radioactive material, excepted

package-instruments and articles".

A reportable quantity (RQ) is listed in DOT regulations for each hazardous material (e.g.,

each radioactive isotope). If you are shipping more than the reportable quantity in a package,

that package must be marked clear and legibly with the letters "RQ". The Niton XL3p

analyzer contains a 30 mCi (1.11 GBq) Am-241 source and is therefore considered a

reportable quantity requiring the RQ marking when being transported.

Thermo Scientific Niton XL3 Analyzer User’s Guide 25

Page 34

2

Using Your Analyzer

Proper and Improper Operation

Also, the quantity of Am-241 that is used in a Model XL3p Analyzer requires a special form

certification for transport as an excepted package. This Special Form certificate must

accompany the instrument during shipment. Thermo Fisher Scientific will provide the

Special Form certificate for any analyzer with Am-241.”

The type of protective packaging used is dependent on the nature of the material to be

packaged. All packaging must be designed to prevent a release of hazardous material during

normal transportation or storage of the material. The classification of package used for Niton

Analyzers is designated as an "Excepted Package". Always ship the analyzer in its original

plastic case to ensure that the packaging used meets the regulatory requirements for an

Excepted Package.

Shipments of radioactive materials must have proper Labeling and Marking.

Niton analyzers have a Marking requirement (i.e., UN number and RQ if applicable), but not

a Labeling requirement (i.e., diamond shaped hazmat labels), and vehicles transporting these

analyzers are not required to have "Placards".

When reading the DOT regulations, you will find the following information useful.

Thermo Fisher Scientific, Niton Analyzers are shipped:

• "Under the proper shipping name "Radioactive material, excepted package-instruments or

articles" in accordance with 49 CFR 173.424,

• "with the radiation level at 10 cm from the unpacked instrument surface less than 10

mrem/hr (0.1 mSv/hr) “

Note A Niton Analyzer in proper condition will be less than 0.5 mrem/hr (0.005 mSv/hr) at

10 cm,

• "with the radiation level at the package surface less than 0.5 mrem/hr (0.005 mSv/hr)”

Note A Niton Analyzer in proper condition will be less than 0.05 mrem/hr (0.0005 mSv/hr)

at the surface of the case,

• "with all radioactive sources as "solid", "sealed sources"

• "Am-241 listed in A1 column of 173.435 (270 Ci) (Special Form capsule)

• "with the package design meeting the requirements of 173.410

• "package marked with "UN2911"

• "with the Am-241 source, the package is marked with "RQ"

• "meeting the 173.424 criteria for labeling and marking requirements

For any shipment: Include in the package a current copy of the instrument Leak Test.

Include a list of emergency numbers in the package.

For Am-241, include the Special Form Certificate in the package.

26 Niton XL3 Analyzer User’s Guide Thermo Scientific

Page 35

2

Using Your Analyzer

Proper and Improper Operation

Always ship in supplied plastic case, with the case secured against accidental opening. Always

ship with the battery disconnected.

When shipping by air: Ship with the proper IATA marking (See IATA Dangerous Goods

regulations Figure 10.7.8.A), UN 2911, and proper shipping name.

"RQ" marking and "dangerous goods declaration" are required.

When shipping by Ground: Ship under proper marking "UN2911"

"RQ" marking and shipping papers are required (Note: a dangerous goods declaration form

can be used to meet the shipping paper requirement).

A "Dangerous Goods Declaration" can be obtained by the air carrier that you will be using.

Instructions can also be obtained from the same source.

Carefully follow the directions given by the air carrier. Several typed copies will be required.

Shipping papers contain all of the same information as a Dangerous Goods Declaration, but

do not have a specified format for that information.

At a minimum, a properly prepared shipping paper clearly identifies the hazardous substance

by its proper shipping name, hazard class and division, UN identification number, packing

group (if applicable), and total quantity. It also has consigner information, consignee

information, and a shipper's declaration that the package is in compliance with the DOT

regulations.

The elements of hazard warning information are communicated through shipping

documents, packaging markings, and written emergency response information.

The DOT & FAA Hazardous Materials Regulations require the carrier to report all incidents

involving hazardous materials.

An "incident" involves the unintended release of hazardous materials (Am-241), suspected

radioactive contamination, if the general public is evacuated for an hour or more, or the flight

pattern or routine of an aircraft is altered.

For any "incident", contact the Company Radiation Safety Officer or Responsible Party and

the state radiation control program.

Any "incident" needs to reported to the:

Hazardous Materials Information Center

1-800-467-4922

Mon-Fri 9AM-5PM Eastern

Thermo Scientific Niton XL3 Analyzer User’s Guide 27

Page 36

2

Using Your Analyzer

Proper and Improper Operation

Leak Tests (Niton XL3p Only)

The Niton XL3p Series analyzer contains a radioactive source that must be periodically leak

tested. The purpose of leak testing is to verify the integrity of the source encapsulation. A leak

test sample is obtained by wiping exterior surfaces of the device with moderate pressure using

a cotton swab, filter paper, or whichever wiping media is supplied by the analysis laboratory.

Leak test samples are then typically analyzed at a laboratory, although some device users have

the equipment and licensed authority to perform this analysis

Unless specified otherwise by your local authority or radioactive material license, the gauge

must be leak tested at intervals not to exceed 6 months. In the US, leak test samples may be

acquired by any end-user, however the analysis of the sample must be performed by an

organization licensed to do so. If you are using a vendor to perform the laboratory analysis of

the leak test sample, they will send you a leak test kit which comes with complete instructions

for performing the test. These vendors will also typically send you a reminder when it is time

to perform the next leak test on your instrument. Please follow the test kit instructions

carefully, and promptly mail the test samples to the laboratory. They will send you a leak test

certificate soon after. Keep one copy of the leak test certificate with the device at all times (i.e.,

in the case) and another copy safely on file.

Figure 6. Wipe Test Locations

28 Niton XL3 Analyzer User’s Guide Thermo Scientific

Page 37

CAUTION REMOVE THE BATTERY WHILE PERFORMING A WIPE TEST TO BE

SURE THAT THE SHUTTERS ARE NOT OPEN DURING THIS PROCEDURE!

Lost or Stolen Instrument

THIS PAGE CONTAINS EMERGENCY CONTACT INFORMATION THAT

HOULD BE AVAILABLE TO THE OPERATOR AT ALL TIMES.

S

If the Niton XL3t analyzer is lost or stolen, notify your Radiation Safety Officer (RSO) or the

equivalent responsible individual at your company or institution immediately. Your

company's RSO, as well as other important emergency contacts, are listed below. Your

company RSO may need to notify the x-ray tube regulatory authority and the local police. It

is also recommended that a notification is made to Thermo Fisher Scientific.

Damaged Instrument

Minor Damage

2

Using Your Analyzer

Proper and Improper Operation

Major Damage

If the instrument is intact but there is indication of an unsafe condition such as a cracked case,

a shutter mechanism failure, or the lights remain flashing after a measurement is terminated,

follow these steps:

1. Stop using the instrument

2. Remove the battery. The x-ray tube can not produce radiation when the battery is

disconnected. The instrument is now safe to handle.

3. Place the instrument securely in the holster.

4. Place the instrument in the carrying case that came with the instrument.

5. Notify your Radiation Safety Officer (RSO) or the equivalent responsible individual at

your company or institution immediately.

6. You or your RSO should call Thermo Fisher Scientific at one of their contact numbers

listed below for additional instructions and guidance.

If the instrument is severely damaged:

. Perform the same steps as described above for minor damage. There will be no radiation

1

hazard as long as the battery is removed from the instrument.

2. Place all components in a plastic bag and contact Thermo Fisher Scientific.

Thermo Scientific Niton XL3 Analyzer User’s Guide 29

Page 38

2

Using Your Analyzer

Emergency Response Information

Emergency Response Information

Please Complete the Following Emergency Response Information and Keep with the Analyzer

at All Times

NITON ANALYZER EMERGENCY CONTACT INFORMATION

The Company RSO is:______________________________________

RSO Telephone Number:____________________________________

Regulatory Agency Emergency Number:________________________

Local Fire Department:______________________________________

Local or State Police Department:_____________________________

Thermo Fisher Scientific's Niton Analyzer Contact Numbers

Main Number (USA): (800) 875-1578

Europe

Asia

Additional Radiation Emergency #'s: (978) 790-8269 or (617) 901-3125

Outside the USA - Local Niton Service Center:___________________

Niton Analyzers Europe

unich, Germany

M

Phone: +49 89 3681 380

Fax: +49 89 3681 3830

Email: niton.eur@thermofisher.com

Niton Analyzers Asia

Hong Kong

Phone: +852 2869-6669

Fax: +852 2869-6665

Email: niton.asia@thermofisher.com

Registration and Licensing

30 Niton XL3 Analyzer User’s Guide Thermo Scientific

Page 39

As a user of a Niton XL3 analyzer, you may be required to register or obtain a license with

your local radiation control authority. In the US, if you intend to do work with your analyzer

in states other than your own, you may be required to register there as well. See the Safety and

Compliance Web Hub for much more information.

Regarding Safety Devices for the Open Beam Configuration:

In the US, you may be required to file for an exemption, "variance letter", with your state if

here is a requirement for a safety device that would prevent entry of an extremity into the

t

primary beam. If you need assistance with the exemption letter, you may contact the radiation

safety group.

Registration and Licensing FAQ

2

Using Your Analyzer

Emergency Response Information

Thermo Scientific Niton XL3 Analyzer User’s Guide 31

Page 40

2

Using Your Analyzer

Startup Procedure

Startup Procedure

Unpacking and Preparing Your Niton XRF Analyzer

WARNING The nose of the analyzer should not be touched during sample testing and

calibration. If an ESD event occurs during measurement, the instrument may terminate the

testing in progress and automatically reset to Log On screen. Any test data collected prior to

reset will be lost and the testing may have to be repeated.

Figure 7. Populated Analyzer Case

• Inspect the shipping carton for signs of damage such as crushed or water damaged

packaging. Immediately notify the shipping company and Thermo Fisher Scientific, in

the United States, toll free, at (800) 875-1578, or outside the United States, at

+1-978-670-7460, if there is any visible damage to the shipping container or any of its

contents.

• Open the packing carton. If your analyzer is not packed in its carrying case, please call

Thermo Fisher Scientific immediately, in the United States, toll free, at (800) 875-1578,

or outside the United States, at +1-978-670-7460.

• Verify the contents of the shipping container against the enclosed packing list. If there are

any discrepancies between the actual contents of the shipping container and the enclosed

packing list, please notify Thermo Fisher Scientific immediately, in the United States, toll

free, at (800) 875-1578, or outside the United States, at +1-978-670-7460.

• Open the carrying case and visually inspect the analyzer for damage before removing it

from the case. Contact the freight carrier and Thermo Fisher Scientific if you find any

damage to the case or its contents.

32 Niton XL3 Analyzer User’s Guide Thermo Scientific

Page 41

2

Using Your Analyzer

Battery Installation and Charging

• Save the shipping carton and all packing materials. Store them in a safe, dry area for reuse

the next time that you ship the analyzer.

Figure 8. The Thermo Scientific Niton XL3 Analyzer Overview

Battery Installation and Charging

Installing or Replacing The Battery Pack

1. Slide back the catch on the bottom of your analyzer’s pistol grip and drop the battery out

nto your hand.

i

2. Place the old battery aside and slide the new battery up into the cavity in the bottom of

the pistol grip. The battery is keyed, and will only insert fully one way.

Thermo Scientific Niton XL3 Analyzer User’s Guide 33

Page 42

2

Using Your Analyzer

Battery Installation and Charging

Figure 9. Rear and Side of Battery Pack Showing Key

AUTION Do not force the battery into the cavity!

C

3. Press in until the latch resets.

Recharging The Battery Pack

Fully recharging a battery pack takes approximately 2 hours.

1. Remove the battery pack from the analyzer.

2. Place the battery pack upside down into the charger. The battery pack is keyed, and will

only fit into the charger fully one way. If your battery pack is resting on the back of the

back of the charger rather than sliding all the way to the bottom, remove the battery pack,

turn it around, and re-insert it into the charger.

CAUTION Do not force the battery into the charger!

3. The red light is on when the charger is plugged in. This is the power indicator light.

34 Niton XL3 Analyzer User’s Guide Thermo Scientific

Page 43

Figure 10. Power On

2

Using Your Analyzer

Battery Installation and Charging

. The yellow light indicates that the battery pack is currently being charged.

4

Figure 11. Charging

5. The green light indicates that the battery pack has finished charging and is ready for use.

Thermo Scientific Niton XL3 Analyzer User’s Guide 35

Page 44

2

Using Your Analyzer

Battery Installation and Charging

Figure 12. Charge Completed

N

a fault with the battery pack or charger.

ote If there is a fully seated battery pack in the charger and only the red light is on, there is

36 Niton XL3 Analyzer User’s Guide Thermo Scientific

Page 45

2

Using Your Analyzer

Battery Installation and Charging

Figure 13. Battery Pack in the Charger

AUTION Do not store battery packs or charger in direct sunlight.

C

CAUTION Do not let the battery pack recharge for excessive periods of time.

Thermo Scientific Niton XL3 Analyzer User’s Guide 37

Page 46

2

Using Your Analyzer

The Control Panel

The Control Panel

The control panel is located on the analyzer’s top housing, directly below the Touch Screen.

The control panel consists of a 4 Way Touch Pad, an Interlock Button, and two Control

Buttons, one on each side. Using either the control panel or the touch screen you may

navigate through all of the analyzer’s screens and menus. You can control the movement of the

screen cursor by pressing the 4 Way Touch Pad in one of four directions to highlight each of

the menu options. The Clear/Enter button to the right of the 4 Way Touch Pad is used to

select highlighted menu options. The On/Off/Escape Button both controls the power to the

analyzer and serves as an "escape" button. When the On/Off/Escape Button is pushed and

immediately released, it functions as an "escape", and brings you back to the Main Menu

from the current screen in the menu system.

Figure 14. The Control Panel

To turn your analyzer on, push and hold the On/Off/Escape Button until the Touch Screen

comes on. To turn off your analyzer, push the On/Off/Escape Button and hold it down until

the Touch Screen shuts off.

CAUTION If for any reason your analyzer does not shut off normally, removing the battery

will shut it down safely.

You also have the option of operating the analyzer, including navigating the menu system, by

using the built in Touch Screen. To select a menu option, tap on the icon once. The touch

screen icons have the same functionality as the 4 Way Touch Pad, the On/Off/Escape Button,

and the Enter Button. This User's Guide will refer to the process of choosing a course of

action by selecting an icon from a menu, either using the Touch Screen or using the control

panel buttons, as “selecting.”

Selecting the Return Icon works everywhere throughout the User Interface to bring you back

to the previous menu from the current menu in the menu system. Use the On/off/escape

button to return to the Main Menu.

38 Niton XL3 Analyzer User’s Guide Thermo Scientific

Page 47

The LCD Touch Screen

The LCD Touch Screen on your Niton XL3 Analyzer is designed to swing up and down to

different angles for ease in viewing and interacting with your analyzer. The LCD Touch

Screen is connected to your analyzer along the base of the screen, right above the Control

panel. The screen is not designed to separate from the analyzer, but can be adjusted to any

arbitrary angle between zero degrees - that is, flush with the analyzer - and 85 degrees, which

is almost perpendicular. The LCD Touch Screen will stay at any given angle between these

extremes until moved to a different angle. When in closed position, the screen is secured by a

catch at the top center of the screen housing.

2

Using Your Analyzer

The Control Panel

Figure 15. Niton XL3 Analyzer Showing LCD Screen Tilted.

To raise the LCD Touch Screen, disengage the catch at the top-center of the LCD Touch

Screen housing and gently pull the screen towards you until it is at the best angle for your use.

Thermo Scientific Niton XL3 Analyzer User’s Guide 39

Page 48

2

Using Your Analyzer

Startup Procedure

To close the LCD Touch Screen, gently push away from you along the top edge of the screen

housing. The screen will swing down until the catch solidly engages with an audible click.

Note The LCD Touch Screen cannot be removed from your Niton XL3 analyzer. Removing

or attempting to remove the LCD Touch Screen will damage your analyzer and void your

warranty.

Note Always close your LCD Touch Screen before storing or transporting your Niton XL3

analyzer.

Startup Procedure

To turn on the analyzer, depress the On/off/escape button on the control panel until the

ouch Screen comes on.

T

On startup, the screen will show by a Start Screen which will automatically count down from

4 to 0 in increments of one second.

Figure 16. Logon Screen

When the startup is complete, the Start Screen will be replaced by the Logon Screen (see

Figure 15). Tap anywhere on this screen to continue.

The Logon Screen will be replaced by a Warning Screen, see Figure 16, advising you that this

analyzer produces radiation when the lights are flashing. You must acknowledge this warning

by selecting the Yes button before logging on. Selecting the No button will return you to the

Logon Screen.

40 Niton XL3 Analyzer User’s Guide Thermo Scientific

Page 49

2

Using Your Analyzer

Startup Procedure

Figure 17. Warning Screen

fter selecting the Yes button, the Virtual Numeric Keypad becomes available for you to log

A

onto the analyzer.

Figure 18. Virtual Numeric Keypad

Thermo Scientific Niton XL3 Analyzer User’s Guide 41

Page 50

2

Using Your Analyzer

Performing a System Check

Select your 4 digit security code, followed by the Enter button. The default password is

1-2-3-4, followed by the Enter button. If you enter an incorrect number, you can use the

Backspace button to backspace over it, or use the Clear button to clear the field. After you

have completed the log on procedure, the word "USER" will appear on the bottom of the

screen, then the Main Menu will appear. Note that security codes are editable. Please see

Passwords and User Privileges for instructions on creating user-definable passwords.

Check the date/time. The time should be set correctly for accurate and verifiable record

keeping (Setting the Date and Time).

te Your analyzer can be stored and operated safely in temperatures from minus 5º C (23º

No

F) to 50º C (122º F). You will not be able to take a measurement if the analyzer overheats. If

it is hot to the touch, you should allow it to cool before testing.

Performing a System Check

Figure 19. System Check Menu Path

elect the System Check Icon on the Main Menu to perform a system check. Thermo

S

Scientific recommends that you perform a system check once every working day, as part of

your normal startup procedure, after allowing a minute or so for the analyzer to warm up.

42 Niton XL3 Analyzer User’s Guide Thermo Scientific

Page 51

2

Using Your Analyzer

Performing a System Check

Figure 20. System Check in Progress

hile performing the system check, your screen will show a progress bar indicating the

W

progress of the check. When it is done, the screen will show a 100% completion as in Figure

20 below.

Figure 21. System Check Completed

Thermo Scientific Niton XL3 Analyzer User’s Guide 43

Page 52

2

Using Your Analyzer

Performing a System Check

If you see any result other than "System OK", perform another system check. If the result is

still not "System OK", please notify Thermo Scientific Service at 800-875-1578.

44 Niton XL3 Analyzer User’s Guide Thermo Scientific

Page 53

Calibrating the Touch Screen

2

Using Your Analyzer

Performing a System Check

Figure 22. Touch Screen Calibration Menu Path

Thermo Scientific Niton XL3 Analyzer User’s Guide 45

Page 54

2

Using Your Analyzer

Performing a System Check

Select the Calibrate Touch Screen icon to re-calibrate the analyzer's touch screen display. This

procedure establishes the display boundaries for the touch screen interface.

1. Select the Touch Screen icon.

2. The display will show a message asking you to confirm whether or not you want to

calibrate your Touch Screen. Select the Yes button.

3. The display will show the message: "Calibrate Touch Screen". There will be a small cross

in the upper left-hand corner of the display.

4. Tap on this cross with the stylus, and the cross will disappear and reappear in the upper

right-hand corner of the screen.

5. Tap on the cross again, and it will reappear in the lower right-hand corner of the screen.

6. Tap on the cross again and it will reappear in the lower left-hand corner of the screen.

7. Tap on the cross once more, and you will be presented with a Confirmation Screen.

8. Select the Yes Button to confirm that the parameters are good. Select the No Button to

start the process again.

9. Once you have confirmed the parameters, the System Menu will be displayed. The screen

is now calibrated.

Figure 23. The System Menu

46 Niton XL3 Analyzer User’s Guide Thermo Scientific

Page 55

Calibrating the Touch Screen Without Using the Touch Screen

If the touch screen becomes misaligned, you may need to use the buttons below the screen to

complete this process. There are 2 single buttons and a 4 way switch located to the rear of the

display screen. The button at the left is the On/Off/Escape button. The button to the right is

the Enter button and the center keypad is a 4 Way Touch Pad.

The 4 Way Touch Pad has 4 positions, Up, Down, Left and Right. The Interlock Button is

not used in this procedure.

2

Using Your Analyzer

Performing a System Check

Figure 24. The Control Buttons for the Niton XL3

1. Please, turn on your XRF analyzer using the On/Off button.

Note From this point please DO NOT touch the touch screen.

2. Press the Enter button. You are now at the Radiation Warning screen.

3. Using the 4 way touch pad on the on the cover of the instrument, move the cursor around

the screen by pressing the appropriate up, down, left, or right button. Please move the

cursor such that the "Yes" option is highlighted in green.

4. Press the Enter button. You are now at the Enter Password Screen.

5. Move the cursor on the Virtual Numeric Keypad using the 4-way Touch Pad to the

appropriate first number in your password. Press the Enter button on the right - it has the

arrow/enter key symbol on it. The first number of your password should appear in the

lower left of the screen.

6. Repeat step 5 until you have entered the entire password. Then move the cursor to the

Enter Key on the Virtual Numeric Keypad and press the Enter button to enter it.

Thermo Scientific Niton XL3 Analyzer User’s Guide 47

Page 56

2

Using Your Analyzer

Performing a System Check

7. You will now be at the Main Menu.

8. Again using the 4 Way Touch Pad, move the cursor to highlight the System icon, and

press the Enter button to select it.

9. You will now be at the System Menu.

10. From the System Menu screen, move the cursor to highlight the Touch Screen icon and

press the Enter button.

11. Now move the cursor to highlight the Yes Button and press the Enter button.

12. You are now at the Touch Screen Calibration screen.

Note You must now use the touch screen for the balance of this procedure

13. In the upper left hand corner you will see a crosshair - like this: “+”. Using the stylus or a

pen, tap the center of the “+”.

14. Repeat this for each “+” sign that appears, there should be one for each of the 4 corners.

15. Select the Yes Button to confirm that the parameters are good. Select the No Button to

start the process again.

16. Once you have confirmed the parameters, the System Menu will be displayed. The screen

is now calibrated.

Your touch screen should work properly after this and you may use normally it from this point

forward. If it does not, please repeat the process.