Page 1

MaxQ 4000 Incubated and

User Manual

Refrigerated Shakers

Models SHKE4000 and SHKA4000

Operating Manual and Parts List 057-287-00 (7004342) Rev. 16

Visit us online to register your warranty

www.thermoscientific.com/labwarranty

Page 2

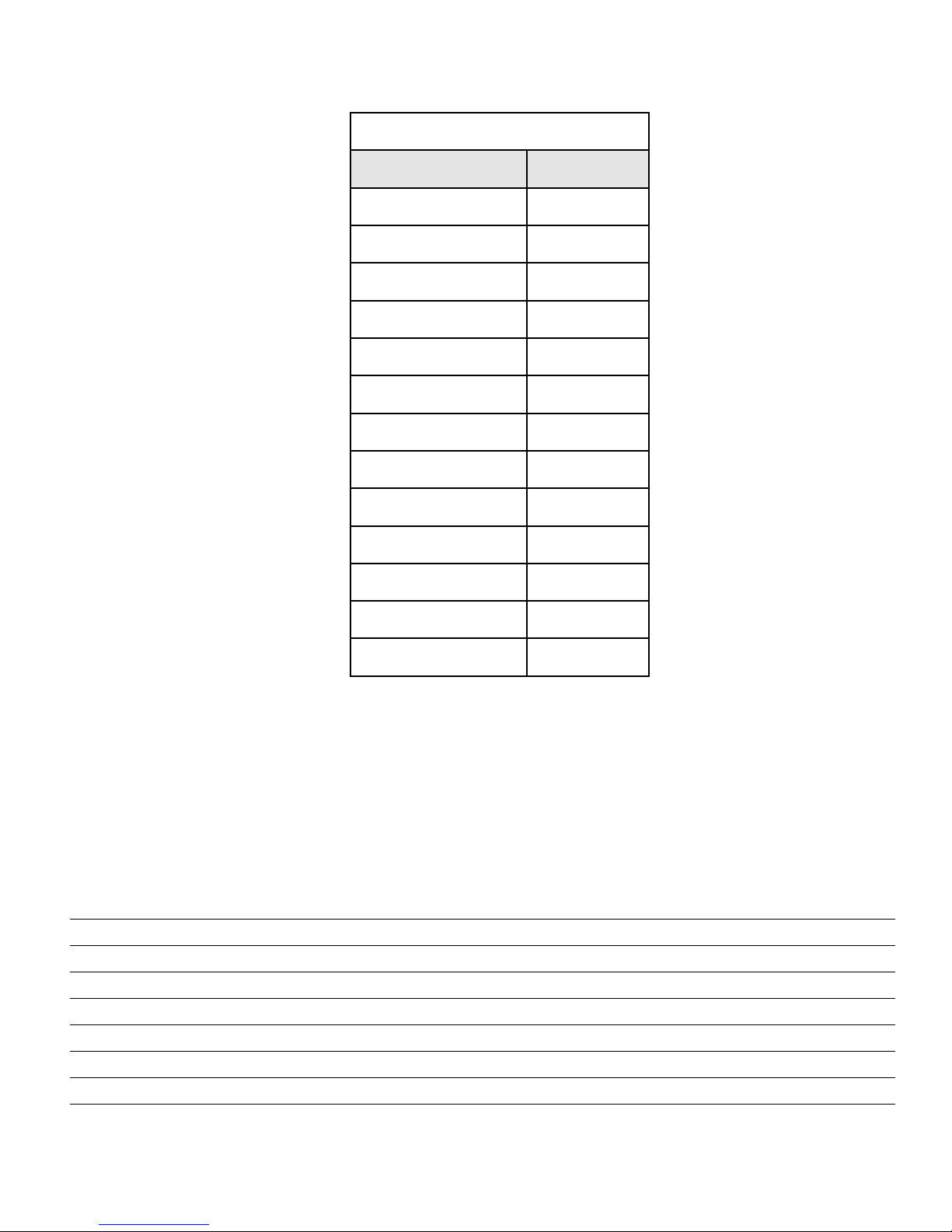

odels covered in this manual

M

Model number Voltage

SHKA4000 (4320) 120V

SHKA4000-1CE (4321) 220-240V

SHKA4000-5 (4322) 120V

SHKA4000-6CE (4323) 220-240V

SHKA4000-7 (4338) 120V

SHKA4000-8CE (4339) 220-240V

SHKE4000 (4328) 120V

SHKE4000-1CE (4329) 220-240V

SHKE4000-5 (4330) 120V

Preface

SHKE4000-6CE (4331) 220-240V

SHKE4000-7 (4342) 120V

SHKE4000-7JPN (4343) 100V

SHKE4000-8CE (4344) 220-240V

MANUAL NUMBER 057-287-00 (7004342)

16 40722 7/10/17 Added gas springs section to Maitinence bpg

15 41343 5/02/17 Added F-Gas statement, removed declaration of certification bpg

14 40673 4/20/17 Updated voltage information bpg

13 40453 9/13/16 Circuit breaker P/N in Replacement Parts from 330-250 & 330-399 to 330-138-00 ccs

12 40139 4/15/15 Updated warranty information ccs

11 31361 7/18/14 Removed CE reference from pg 2-5 ccs

10 31164/OS-775 7/9/14 Added care and cleaning of acrylic lid to Section 3 ccs

9 30954 4/10/14 Updated Setting TImer for Continuous Shaking Step 3 - pg 5-6 ccs

Thermo Scientific

Incubated and Refrigerated Shakers i

Page 3

Preface

Contains Parts and Assemblies

Susceptible to Damage by

E

lectrostatic Discharge (ESD)

CAUTION

Preface

Important Read this instruction manual. Failure to read, understand and follow the instructions in this manual

may result in damage to the unit, injury to operating personnel, and poor equipment performance.

s

Caution All internal adjustments and maintenance must be performed by qualified service personnel. s

Material in this manual is for information purposes only. The contents and the product it describes are subject

to change without notice. Thermo Fisher Scientific makes no representations or warranties with respect to this

manual. In no event shall Thermo be held liable for any damages, direct or incidental, arising out of or related to

the use of this manual.

©2010 Thermo Fisher Scientific. All rights reserved.

Thermo Scientificii Incubated and Refrigerated Shakers

Page 4

Preface

Important operating and/or maintenance instructions. Read the accompanying text carefully.

Potential electrical hazards. Only qualified persons should perform procedures associated with this

symbol.

Equipment being maintained or serviced must be turned off and locked off to prevent possible injury.

Hot surface(s) present which may cause burns to unprotected skin, or to materials which may be

damaged by elevated temperatures.

WEEE Compliance: Thermo Fisher Scientific has contracted with companies for recycling/disposal in

each EU Member State. For further information, send an email to weee.recycle@thermofisher.com.

4 Always use the proper protective equipment (clothing, gloves, goggles, etc.)

4 Always dissipate extreme cold or heat and wear protective clothing.

4 Always follow good hygiene practices.

4 Each individual is responsible for his or her own safety.

Thermo Scientific

Incubated and Refrigerated Shakers iii

Page 5

Preface

Do You Need Information or Assistance on

Thermo Scientific Products?

If you do, please contact us 8:00 a.m. to 6:00 p.m. (Eastern Time) at:

1-740-373-4763 Direct

1-800-438-4851 Toll Free, U.S. and Canada

1-877-213-8051 FAX

http://www.thermofisher.com Internet Worldwide Web Home Page

service.led.marietta@thermofisher.com Tech Support Email Address

Certified Service Web Pagewww.unitylabservices.com

Our staff can provide information on pricing and give you quotations. We canSales Support

take your order and provide delivery information on major equipment items or make

arrangements to have your local sales representative contact you. Our products are listed on the

Internet and we can be contacted through our Internet home page.

Our staff can supply technical information about proper setup, operation orService Support

troubleshooting of your equipment. We can fill your needs for spare or replacement parts or

provide you with on-site service. We can also provide you with a quotation on our Extended

Warranty for your Thermo Scientific products.

Whatever Thermo Scientific products you need or use, we will be happy to discuss your

applications. If you are experiencing technical problems, working together, we will help you

locate the problem and, chances are, correct it yourself...over the telephone without a service

call.

When more extensive service is necessary, we will assist you with direct factory trained

technicians or a qualified service organization for on-the-spot repair. If your service need is

covered by the warranty, we will arrange for the unit to be repaired at our expense and to your

satisfaction.

Regardless of your needs, our professional telephone technicians are available to assist you

Monday through Friday from 8:00 a.m. to 6:00 p.m. Eastern Time. Please contact us by

telephone or fax. If you wish to write, our mailing address is:

Thermo Fisher Scientific (Asheville) LLC

401 Millcreek Road, Box 649

Marietta, OH 45750

International customers, please contact your local Thermo Scientific distributor.

Thermo Scientificiv Incubated and Refrigerated Shakers

Page 6

Table of Contents

Section 1

Section 2

Section 3

Section 4

Section 5

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Control Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

A-Class Control Panel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

E-Class Control Panel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Unpacking and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Platform Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Test Tube Rack Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Flask Clamp Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

A-Class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Temp Controller -Setting Temperature . . . . . . . . . . . . . . . . . . . . . . . 5-2

Temperature Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

E-Class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Temperature Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

AC Power Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Setting Operating Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Setting Timer for Continuous Shaking . . . . . . . . . . . . . . . . . . . . . . . 5-6

Setting Timer for Timed Shaking . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

RS232 Communication Configuration . . . . . . . . . . . . . . . . . . . . . . . 5-7

RS232 Interface Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Setting High-Limit Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Optional Refrigeration System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Setting Low-Limit Control (Refrigerated) . . . . . . . . . . . . . . . . . . . . . 5-9

Optional Refrigeration System . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Defrost Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Incubated and Refrigerated Shakers vThermo Scientific

Page 7

Table of Contents

Section 6

Section 7

Section 8

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Gas Springs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Platform Mounting Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Platform Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

For A-Class Series Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Care and Cleaning of Acrylic Lid . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Ordering Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

vi Incubated and Refrigerated Shakers Thermo Scientific

Page 8

Section 1 Safety Information

This manual contains important operating and safety information. The

user must carefully read and understand the contents of this manual prior

to the use of this equipment.

Your Thermo Scientific MaxQ 4000 Shaker has been designed with

function, reliability, and safety in mind. It is your responsibility to install

it in conformance with local electrical codes. For safe operation, pay

attention to Notes, Cautions, Warnings throughout the manual.

Warnings

To avoid electrical shock, always:

1. Use a properly grounded electrical outlet of correct voltage and current

handling capacity.

2. Disconnect from the power supply prior to maintenance and servicing.

To avoid personal injury:

1. Do not use in the presence of flammable or combustible materials; fire

or explosion may result. This device contains components which may

ignite such materials. Not rated for use in hazardous atmospheres.

2. Wear appropriate eye and hand protection when handling hazardous

chemicals.

3. Refer servicing to qualified personnel.

4. Do not modify construction and/or assembly of equipment.

5. Do not remove tags, labels, decals, or other information from the unit.

6. Stand clear of equipment when it is operating.

7. If shaking action will result in the evolution of gases or fumes, carry

out the operation in a well-ventilated laboratory hood.

Incubated and Refrigerated Shakers 1-1Thermo Scientific

Page 9

Section 1

Safety Information

To avoid personal injury (continued):

8. Use equipment only for its intended purpose. Use only the accessories

and attachments that are shipped with the equipment or are specified

for it. Substituting other attachments or accessories can produce

hazards or make the unit inoperative.

9. Perform regular maintenance service as specified in this manual and

keep unit in good repair. Do not operate with known defects.

10. Do not use the shaker to mix flammable materials or where the

transfer of mechanical energy to glass could cause glass breakage.

1-2 Incubated and Refrigerated Shakers Thermo Scientific

Page 10

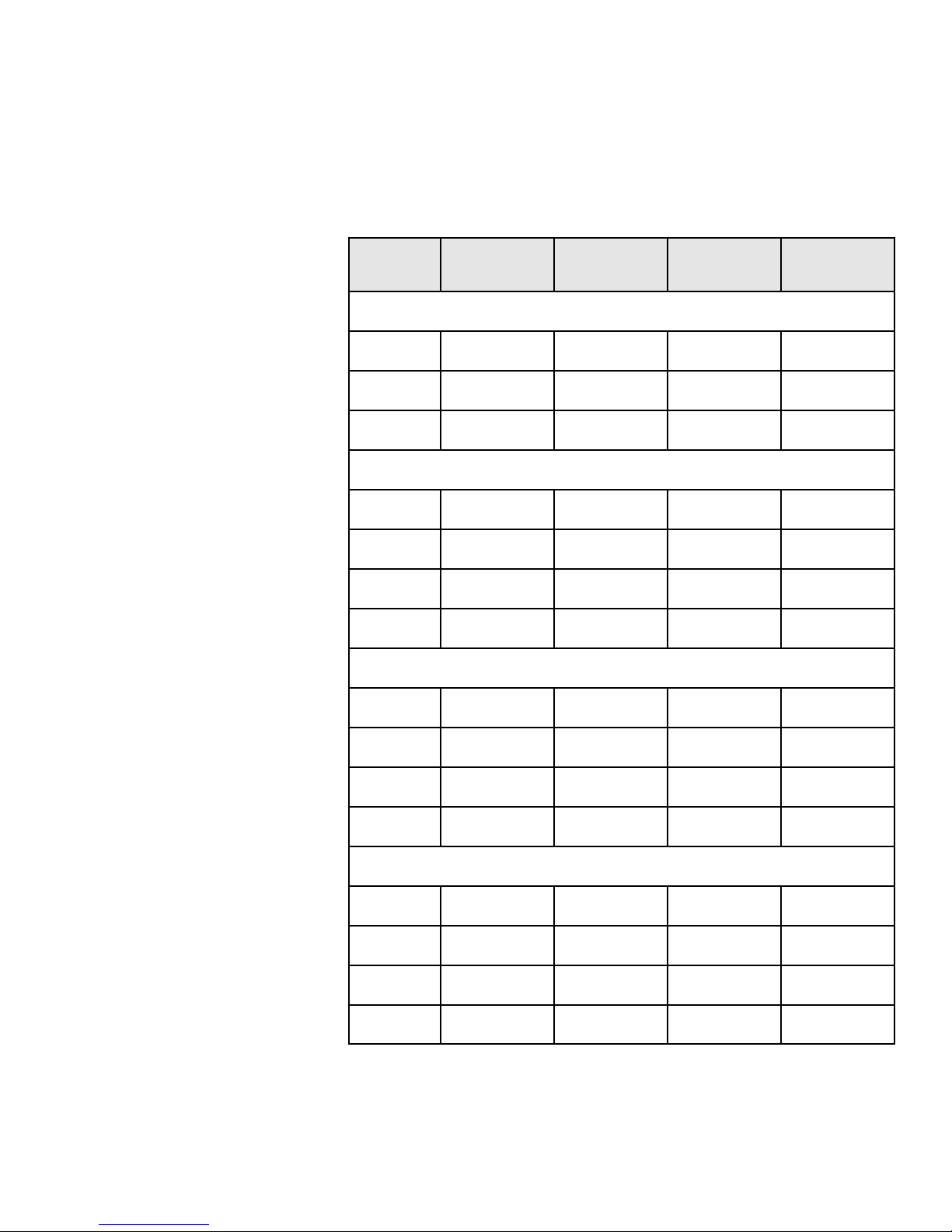

Section 2 General Specifications

Model

number

Exterior Unit Dimensions

Length 32” (81.3 cm) 32” (81.3 cm) 32” (81.3 cm) 32” (81.3 cm)

Width 22.5” (57.2 cm) 22.5” (57.2 cm) 22.5” (57.2 cm) 22.5” (57.2 cm)

Height 22” (55.9 cm) 22” (55.9 cm) 22” (55.9 cm) 22” (55.9 cm)

Electrical - Standard Temperature

Voltage AC 120 220-240 120 220-240

Amperage 5.0 3.0 5.0 2.5

Wattage 625 725 625 625

Frequency 60 50/60 60 50/60

High Temperature

All Analog

“A” Series units

All Analog

“A” Series units

All Digital

“E” Series units

All Digital

“E” Series units

Voltage AC 120 220-240 120 220-240

Amperage 9.0 5.0 9.0 4.5

Wattage 1100 1200 1100 1100

Frequency 50/60 50/60 50/60 50/60

Refrigerated

Voltage AC 120 220-240 120 220-240

Amperage 14.0 7.0 14.0 7.0

Wattage 1500 1500 1500 1500

Frequency 60 50 60 50

Incubated and Refrigerated Shakers 2-1Thermo Scientific

Page 11

Section 2

General Specifications

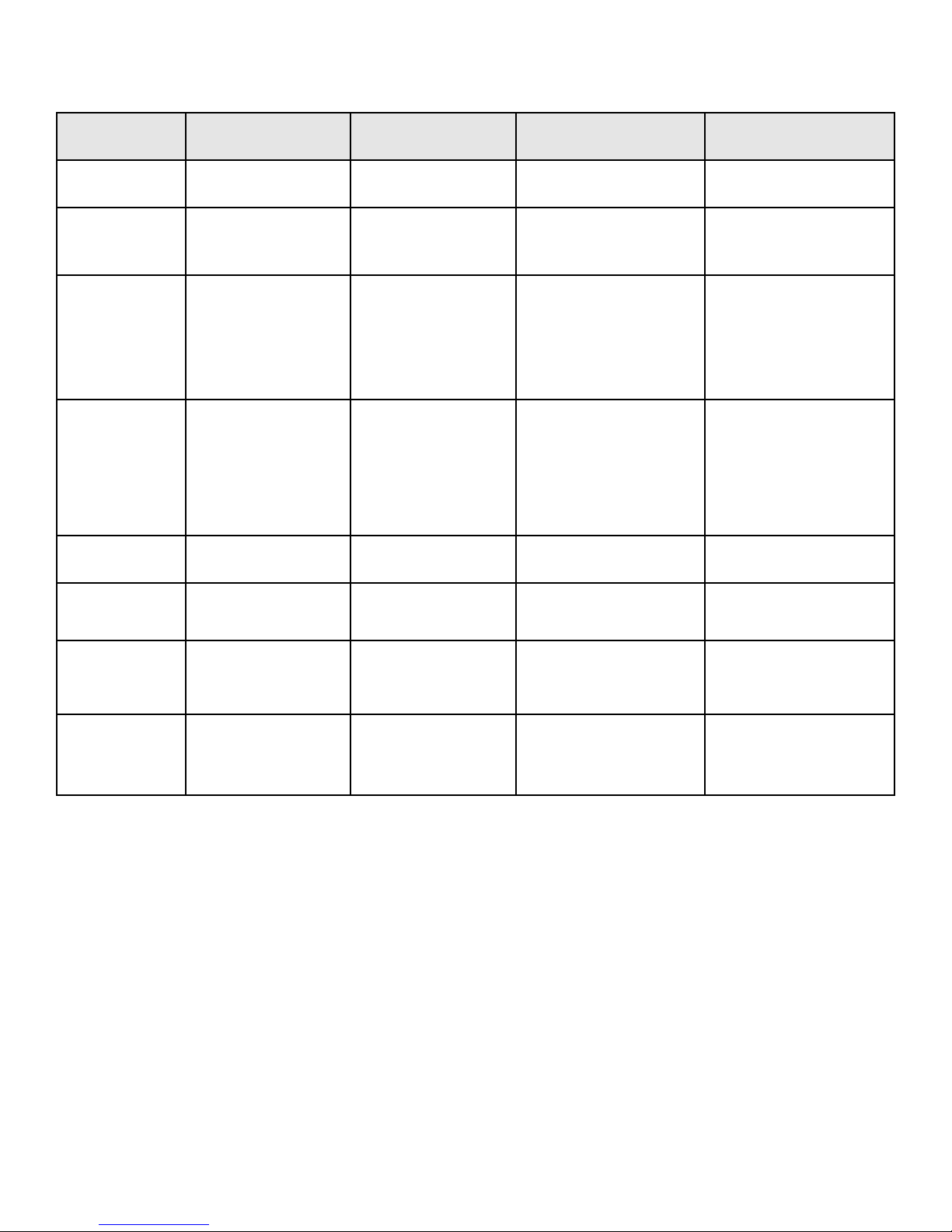

Model number

peed Accuracy

S

Timer

Display

Mutable Alarms None None

Motor Permanent Magnet DC Permanent Magnet DC Solid State Brushless DC Solid State Brushless DC

All Analog

A” Series units

“

0 to 400 rpm, ±10 rpm

4

Continuous or timed opera-

tion from 1-60 min.

3 individual LED displays

indicate temperature in 1°C

increments. Analog

tachometer displays speed

in rpm.

All Analog

A” Series units

“

0 to 400 rpm, ±10 rpm

4

Continuous or timed opera-

tion from 1-60 min.

3 individual LED displays

indicate temperature in 1°C

increments. Analog

tachometer displays speed

in rpm.

All Digital

E” Series units

“

5 to 500 rpm, ±1 rpm

1

Continuous or timed operation

0.1-999 hours or 0.1-999 mins.

3 individual LED displays indicate temperature, time and

speed simultaneously. 3 characters height 1/2 inch (1.27 cm)

Audible portion of the alarm

can be silenced for a period of

1 hour without deactivating the

actual alarm condition by

depressing any key.

All Digital

E” Series units

“

5 to 500 rpm, ±1 rpm

1

Continuous or timed operation

0.1-999 hours or 0.1-999 mins.

3 individual LED displays indicate temperature, time and

speed simultaneously. 3 characters height 1/2 inch (1.27 cm)

Audible portion of the alarm can

be silenced for a period of 1

hour without deactivating the

actual alarm condition by

depressing any key.

Soft Start Feature None None

RS232 Interface * None None

Recorder Output * None None

Intended Use

Orbital shakers are designed to provide increased aeration in a stable

temperature environment.

Unintended Use

1) Not intended for use in Class I or II applications as defined in 21 CFR

2) Not intended for mixtures of flammable materials

Software algorithms prevent

sudden start/stops.

Monitor speed, temperature in

°C and time with a computer.

10 mv/°C output monitors temperature with external chart

recorder.

Software algorithms prevent

sudden start/stops.

Monitor speed, temperature in

°C and time with a computer.

10 mv/°C output monitors temperature with external chart

recorder

2-2 Incubated and Refrigerated Shakers Thermo Scientific

Page 12

Section 2

General Specifications

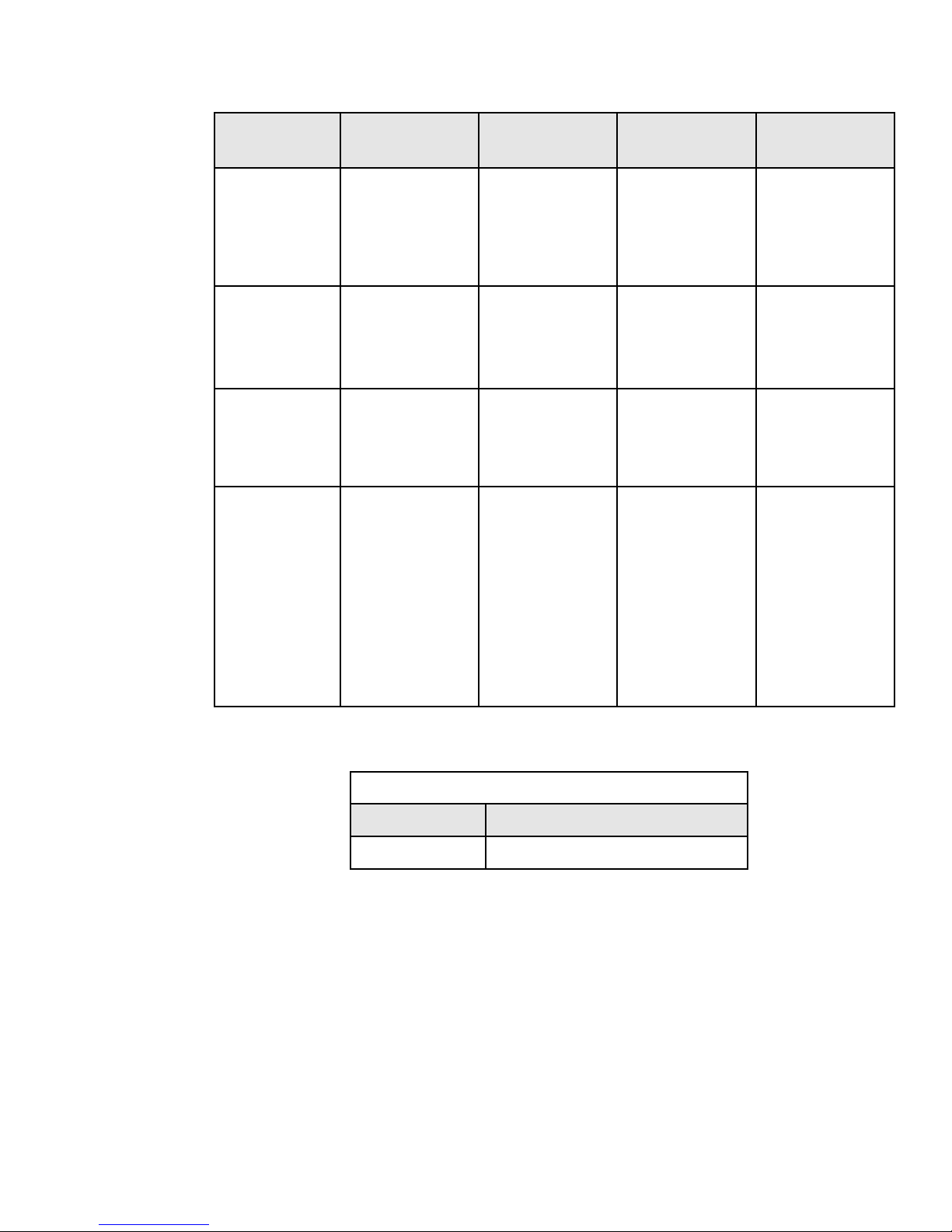

Model number

peed

S

All Analog

A” Series units

“

one

N

All Analog

A” Series units

“

one

N

Speed Shut off None None

Timer None None

Unbalanced Load None None

All Digital

E” Series units

“

Audible with flashing

LED indicate when

speed deviates more

than 10% of set point.

When speed deviates

10% of set point, unit

will shut down immediately.

Beeps twice when

time has expired.

Shaking motion stops.

If the unit is running

in an unbalanced condition, an alarm will

sound and the shaker

will stop until the end

user corrects the condition. The speed display

will flash “bAL” on

speed panel LED.

All Digital

E” Series units

“

Audible with flashing

LED indicate when

speed deviates more

than 10% of set point

When speed deviates

10% of set point, unit

will shut down immediately.

Beeps twice when

time has expired.

Shaking motion stops.

If the unit is running

in an unbalanced condition, an alarm will

sound and the shaker

will stop until the end

user corrects the condition. The speed display

will flash “bAL” on

speed panel LED.

Optional Platform Dimensions - in. (cm)

Catalog Number L xW

30110 Universal 18” x 18” (45.7 x 45.7 cm)

Incubated and Refrigerated Shakers 2-3Thermo Scientific

Page 13

Section 2

General Specifications

The MaxQ 4000 series of bench top, incubated and refrigerated shakers

are available in either analog or digital control configurations:

• A-Class shakers: SHKA4000, SHKA4000-1CE, SHKA4000-5,

SHKA4000-6CE, SHKA4000-7, SHKA4000-8CE: control

temperature by a Proportional/Integral/Derivative (PID)

microprocessor-based controller. Solid-state control maintains time and

speed and is adjustable with rotary dials. Analog tachometer displays

speed in RPM, verifying accuracy of speed setting. Refrigerated units

feature environmentally safe CFC free insulation and coolant.

• E-Class shakers: SHKE4000, SHKE4000-1CE, SHKE4000-5,

SHKE4000-6CE, SHKE4000-7, SHKE4000-8CE: control

temperature, time and speed by a Proportional/Integral/Derivative

(PID) microprocessor-based controller that is adjustable with switches

on a keypad in 1 rpm increments. Refrigerated units feature

environmentally safe CFC free insulation and coolant. Flashing display

indicates power interruption. Pressing any key will clear display. Nonvolatile memory maintains speed and time set points in the event of a

power interruption. Speed and time set points are automatically

reactivated after power is restored.

• Temperature range and accuracy follow. All units have a uniformity of

±0.5°C at 37°C in flask:

Standard Temperature: SHKA4000, SHKA4000-1CE, SHKE4000,

SHKE4000-1CE,

10°C above ambient to 60°C, ±0.1°C at 37°C in flask.

High Temperature: SHKA4000-5, SHKA4000-6CE, SHKE4000-5,

SHKE4000-6CE,

10°C above ambient to 80°C, ±0.1°C at 37°C in flask.

Refrigerated: SHKA4000-7, SHKA4000-8CE, SHKE4000-7,

SHKE4000-8CE,

15°C below ambient to 60°C, ±0.1°C at 37°C in flask. Refrigeration

system needs to be turned off whenever the set point is at or above

32°C.

2-4 Incubated and Refrigerated Shakers Thermo Scientific

Page 14

Section 2

General Specifications

In addition, all versions offer:

• Space efficient tubular heaters.

• Drive interrupt halts shaking action when lid is opened.

• All set points are retained by non-volatile memory that automatically

reactivates after power is restored.

• Visual, user adjustable over-temperature safety signal with independent

thermostat controls the heat if main controller fails.

• 3/4 inch (1.9 cm) triple eccentric orbital drive.

• 6 permanently lubricated ball bearings.

• 50 lb (22.7 kg) platform load capacity at safe speeds less than 400 rpm

for A-Class shakers and less than 500 rpm for E-Class shakers.

Environmental Operating Conditions

Pollution Degree 2**

Installation Category II**

Altitude . . . . . . 2000 meters MSL (Mean Sea Level)

Relative Humidity . . .20% to 80% maximum, non-condensing

Electrical Supply . . . . . . . . . . 120 VAC or 240 VAC

Voltage Tolerance . . . . . . +10% of normal rated line

Temperature . . . . . . . . . . . . . . . . . . . . 15°C to 32°C

Product Usage . . . . . . . . . . . . . . . . . Indoor use only

**Refer to IEC 664-1

Caution Operation of the shaker in a CO2 enriched atmosphere is not

recommended. The formation of carbonic acid could cause electrical

failures.

s

Incubated and Refrigerated Shakers 2-5Thermo Scientific

Page 15

Section 2

General Specifications

Fluorinated Greenhouse Gases

Compliant with REGULATION (EU) No 517/2014 OF THE EUROPEAN

PARLIAMENT AND OF THE COUNCIL on fluorinated greenhouse gases.

This product contains fluorinated greenhouse gases in a hermetically sealed

system. If a leak in the sealed system is detected, the operator shall repair

without undue delay.

The following model is designed for use with the following amounts of fluorinated greenhouse gases:

Model Refrigerant Amount (kg) GWP

SHKE4000-8CE R-134a 0.227 1430

Declaration of Conformity

Copies of the Declaration of Conformity are available upon request.

2-6 Incubated and Refrigerated Shakers Thermo Scientific

Page 16

Section 3 Control Panels

Figure 3-1. A-Class Control Panel

A-Class Control Panel

Features

1. Temperature Controller: Maintains chamber temperature.

2. Temperature Switch: Activates heater-allowing controller to maintain

temperature.

3. Temperature High-Limit Light: Illuminates when high limit

thermostat is controlling chamber temperature.

4. Speed Control: Sets platform rotation speed.

5. Power Switch: Turns power on and off to shaker.

6. Speed Tachometer: Analog display of platform rotation speed.

7. Time(r): Allows user to choose either continuous or timed operation.

Incubated and Refrigerated Shakers 3-1Thermo Scientific

Page 17

Section 3

Control Panel Operation

l

e

n

a

P

l

o

r

t

n

Co

s

s

a

Cl

-

E

.

2

-

3

e

gur

i

F

E-Class Control Panel

Features

1. Speed Display: 3 digit LED indicates actual or set point speed

2. Up Arrow Key: Increases platform rotation speed

3. Down Arrow Key: Decreases platform rotation speed

4. Speed Light: Red light Illuminates when a locked rotor or over-speed

condition exists

5. RPM Light: Illuminates to indicate actual speed

6. Set RPM Light: Illuminates when speed is being set

7. Stop Switch: Stops platform rotation

8. Start Switch: Starts platform rotation

9. Power Switch: Turns power on and off to shaker

10. Up Arrow key: Increases shaking time

3-2 Incubated and Refrigerated Shakers Thermo Scientific

11. Down Arrow key: Decreases shaking time

12. Time(r) Display: 3 digit LED indicates time remaining or elapsed time

13. Set Time: Illuminates when time is being set

14. Timer/Elapsed: Allows the user to choose elapsed time operation,

elapsed, or timed operation, timer.

15. Hours/Minutes Switch: Allows user to choose timing operation in

either hours or minutes

Page 18

Section 3

Section title

E-Class Control Panel

Features (continued)

16. Minutes: Timer indicates minutes

17. Hours: Timer indicates hours

18. Elapsed Timer Light: Indicates accumulated time

19. Temperature Display: 3 digit LED indicates chamber temperature

20. Up Arrow Key: Increases temperature

21. Down Arrow Key: Decreases temperature

22. High-Limit Light: Indicates high-limit control has been activated

23. Water Light: This display has no function on this unit

24. Heat On Light: Indicates heaters are energized

25. Set Temp Light: Indicates temperature can be set

26. Heat On Switch: Turns on heat

27. Heat Off Switch: Turns off heat

Incubated and Refrigerated Shakers 3-3Thermo Scientific

Page 19

Section 4 Unpacking and Installation

The shipping carton should be inspected upon delivery. When received,

carefully examine for any shipping damage before unpacking. If damage is

discovered, the delivering carrier should specify and sign for the damage on

your copy of the delivery receipt.

Open the carton carefully making certain that all parts are accounted for

before packaging materials are discarded. After unpacking, if damage is

found, promptly report it to the carrier and request a damage inspection

properly.

Important Failure to request an inspection of damage within a few days

after receipt of shipment absolves the carrier from any liability for damage.

Call for a damage inspection promptly.

Unpacking

Location

Use the packing list below when unpacking to verify that the complete

unit has been received. Do not discard packing materials until all is

accounted for.

The following items are included in the shipment:

Inspection Tag- 528-028-00

Mounting Plate Mat- 790-316-13

Thumbscrew Knob (4) - 562-184-10

Male Connector (E-class only)- 420-359-00

If any items are missing, contact Technical Services.

Put the shaker on a level table or bench capable of supporting the weight

of the shaker with any accessories while in operation. Place shaker near an

electrical outlet that matches the unit nameplate requirements. Allow

approximately 2” (5 cm) of clearance around the unit for free air

convection, accessory attachments and user convenience. Shakers with

refrigeration should be placed near an accessible drain. Route the drainage

tube on the back of the unit to this drain.

Incubated and Refrigerated Shakers 4-1Thermo Scientific

Page 20

Section 4

Unpacking and Installation

Electrical

Requirements

SHKA4000 and SHKE4000 Series shakers require a 120VAC, 60 Hz

power source. They are supplied with a 3-wire line cord and should be

plugged into an outlet designed for 3-prong plugs. If an extension cord is

used, it also should be the 3-wire grounded type. For an outlet designed to

accept 2-prong plugs (ungrounded), it is required that a qualified

electrician replaces the outlet with a new, grounded type.

SHKA4000-1CE and SHKE4000-1CE Series shakers require a 220240VAC, 50/60 Hz power source. Power cords are supplied.

If a plug must be installed, use only the 3-prong grounded type, rated for

the unit load requirements and matching the power outlet. Make sure the

green ground wire is secured to the plug ground terminal.

To eliminate hazard of electrical shock, make sure floor around shaker is

dry. In the event of accidental spilling or splashing of liquids, clean up

and/or neutralize the spilled liquids before continuing.

Disconnect the shaker from the power source when not in use.

Warning Do not operate shaker with a damaged electrical cord.

s

Platform Installation

1. Select the appropriate platform for the vessels to be shaken. A wide

variety of platforms and accessories are available:

• Dedicated platforms have the maximum number of flask clamps

attached for safe operation.

• Combination platforms allow the user to shake a wide variety of

different sized vessels on the same platform.

2. Carefully position the platform horizontally over the shaker’s mounting

plate, aligning the 4 mounting holes.

3. Position one of the thumbscrews provided through each of the 4platform mounting holes and tighten securely.

Caution Do not operate shaker with an unbalanced load. Platforms should

be loaded for optimum stability and operation. Do not lift shaker by the

platform.

s

4-2 Incubated and Refrigerated Shakers Thermo Scientific

Page 21

Section 4

Unpacking and Installation

Flask Clamp

Installation

Each flask clamp contains a support spring located at the narrow top of

the clamp.

Depending on the size of the clamp, the clamp base may contain one or

several screws necessary to secure the clamp to the platform. All screws

provided with the clamp must be properly attached to the platform.

1. Carefully place the desired vessel in the clamp by first pulling the

clamp spring far enough apart to enable the flask base to be positioned

inside the clamp. Gently slide the flask into its proper position

securing it to the wider bottom of the clamp. The spring will hold the

neck of the flask securely in place and provide security during shaking.

2. Make sure all vessels are securely clamped before turning on unit.

Wherever possible, vessels should contain a stopper to prevent hazardous

substances being thrown out during the mixing action.

Warning Do not operate the shaker at speeds that will cause the contents

of vessels to be thrown out.

s

Test Tube Rack

Installation

1. Position the test tube rack on the combination platform so that the

cutouts on the rack’s outside bottom are aligned with corresponding

mounting holes on the platform. There are two cutouts on each side of

the rack.

2. Secure the rack to the platform with mounting screws provided with

the rack.

Incubated and Refrigerated Shakers 4-3Thermo Scientific

Page 22

Section 5 Operation

A-Class

Refer to Section 3 for control panel reference.

Power Switch

1. Depress top portion of power switch to turn on shaker.

2. Depress bottom portion of power switch to turn off shaker.

Caution It is recommended that shaking action be started at a low speed in

order to check that all vessels are secure and that no spilling of contents

will occur.

Speed Control and Display

1. Slowly rotate the knob on the solid-state speed control clockwise to

increase speed and counterclockwise to decrease speed. The markings

on the outside of the dial are for reference purposes only.

2. The speed control tachometer provides an analog readout of the actual

platform rotation speed up to a maximum of 400 rpm.

s

Time(r)

1. From the 12 o’clock off position, rotate timer knob counterclockwise

to the ON position to initiate continuous operation.

2. For timed operation, rotate timer knob clockwise from 1 minute to 60

minutes. The markings on the side of the dial are in 5-minute

increments.

Note Shaker will not operate if the timer is in the Off position.

Incubated and Refrigerated Shakers 5-1Thermo Scientific

Page 23

Section 5

Operation

Temp Controller -

Setting Temperature

Refer to Figure 5-1 for control panel reference.

Figure 5-1. Temperature Controller

1. CONTROLLER SELF-TEST: When the shaker is powered up, the

controller will display 8888 along with the three decimal points and

the HEAT ON indicator lamp. The display will then blank out for 2

seconds before showing the chamber temperature.

2. HEAT ON INDICATOR: The HEAT ON indicator lamp is lit when

the chamber heaters are receiving power. The lamp will normally flash

when the chamber temperature is at set point.

3. SET POINT ADJUSTMENTS: The temperature controller normally

displays the chamber temperature.

Press Controller

*

* s

* t

View set point

Decrease set point

Increase set point

To view or change the temperature set point, proceed as follows:

a. Press and hold the “star” (*) key and use either the up or down

arrow key to adjust the set point to the desired temperature.

Release the “star” (*) key.

b. Allow sufficient time for chamber temperature to stabilize.

5-2 Incubated and Refrigerated Shakers Thermo Scientific

Page 24

Section 5

Operation

Temperature

Calibration

1. Fill a 250-ml Erlenmeyer flask with approximately 100ml of water and

position it at the approximate geometric center of the shaking

platform.

2. Install a thermocouple inside the flask with the thermocouple junction

in direct contact with the water.

3. Press and hold the “star” (*) key and using the up or down arrow key,

adjust the set point to the desired temperature.

4. Allow the shaker to run until chamber temperature has stabilized.

5. The controller display should now be indicating the set point

temperature. Make note of the thermometer reading.

6. Press and hold both arrow keys until the controller display indicates

“tunE”. Release the arrow keys. Press and release the down arrow key,

the display should now alternate between “LEUL” and “1”. Press and

hold the “star” (*) key and using the up arrow key adjust the display to

read “3”. Release the “star” (*) key. The display should now alternate

between “LEUL” and “3”. Press and release the up arrow key until the

display indicates “Zero”. The display should now alternate between

“Zero” and a numerical value.

Thermometer = 60°C

7. Using the examples shown in the table

at right and the thermometer value

obtained in Step 5 above, enter the

correct “Zero” value into the controller

by pressing the “star” (*) key and using

the up or down arrow key. If there is

already a “Zero” value present, then add

the new value to the one already

present.

Controller Reading = 65°C

Subtract = -5°C

Enter Zero value of -5°C

Thermometer = 70°C

Controller Reading = 65°C

Subtract = +5°C

Enter Zero value of +5°C

8. When the correct “Zero” value has been entered, press and hold the

two arrow keys together until the display again indicates the chamber

temperature. If the procedure was done correctly, the controller display

should now agree with the thermometer reading to within ±0.5°C.

9. Allow the unit to run for at least an additional 30 minutes.

10. Re-check the thermometer reading. The controller display and the

thermometer should agree to within ±0.5°C. If not, repeat Steps 6, 7

and 8.

Incubated and Refrigerated Shakers 5-3Thermo Scientific

Page 25

Section 5

Operation

E-Class

Refer to Section 3 for control panel reference.

Turning Shaker On

Begin with the shaker power off.

1. Press power switch once (I) to turn on shaker.

2. Press power switch a second time (O) to turn off shaker.

Note There will be a 3 second delay from the time power is turned On to

the time the shaker is activated. Control panel will illuminate when shaker

power is activated. An audible tone will sound before the display lights.

Setting Shaking Speed

1. Hold down appropriate arrow key in the speed module of the control

panel, up or down, until desired speed is set up to 500 rpm. SET RPM

light will illuminate.

2. Press START switch to begin shaking. RPM light will illuminate.

3. Press STOP switch to end shaking. SET RPM light will illuminate.

Note Speed can be changed without pressing the start or stop switches.

Simply press the appropriate up or down key until desired rpm is reached.

An audible tone will sound before the display lights.

Calibrating Shaking Speed

1. Choose a speed for which calibration is desired by using the shaker’s

up or down arrow keys.

2. Measure current shaker speed by using a digital hand-held tachometer.

3. If the tachometer reading matches the shaker display, no calibration is

necessary. If the tachometer reading is different from the shaker’s

display, then calibration is required.

4. To get into Calibration mode, hold down the START key, press and

release the STOP key, then release the START key.

5. The decimal point on the SPEED display will flash, indicating

Calibration mode.

6. Use the up or down arrow keys to set the shaker speed to match the

tachometer’s readout.

5-4 Incubated and Refrigerated Shakers Thermo Scientific

7. Press STOP key to enter the new speed value.

8. Press START key to exit Calibration mode.

Page 26

Section 5

Operation

Setting Operating

Temperature

AC Power Loss

1. Press and hold up arrow key to increase temperature, release key when

desired set point is obtained.

2. Press and hold down arrow key to decrease temperature, release key

when desired set point is obtained.

3. Once set, temperature control is initiated by pressing the heat on

button; the heater will react and start increasing the temperature to

reach the set point.

4. During operation, both the up and down arrow keys can be used to

adjust the temperature to a new set point.

The operating microprocessor possesses a non-volatile memory. Upon

resumption or recovery from an AC power loss, the following will be

noted:

• All readouts will flash until any key is pressed.

• If unit was shaking at the time of power failure, it will resume

operation at the speed and timer settings that were entered at the time

that AC power failed.

Temperature

Calibration

1. Fill a 250-ml Erlenmeyer flask with approximately 100 ml of water

and position it at the approximate geometric center of the shaking

platform.

2. Install a thermocouple inside the flask with the thermocouple junction

in direct contact with the water.

3. Adjust the safety thermostat to its maximum clockwise position.

4. Using the up and down keys, adjust the set point temperature to read

37ºC or any other desired set point.

5. Allow sufficient time for chamber temperature to stabilize.

6. Press HEAT ON button and, while continuing to hold, press and

release the HEAT OFF button. Now, release the HEAT ON button.

7. The decimal point should now be flashing indicating Calibration

mode.

Incubated and Refrigerated Shakers 5-5Thermo Scientific

Page 27

Section 5

Operation

Temperature

Calibration (cont.)

Setting Timer for

Timed Shaking

8. Use the up and down arrow keys to adjust the temperature on LED

readout to match the temperature reading on the thermocouple meter.

9. Press the HEAT OFF button. The beeper will sound indicating that

the new calibration value just added is now stored in the nonvolatile

memory of the temperature controller.

10. Press HEAT ON button twice to complete return to normal operating

mode.

Note It is important to press the HEAT OFF button to exit Calibration

mode.

1. Press TIMER/ELAPSED switch until TIMER and SET TIME lights

are illuminated. The HOURS or MINUTES light will also light up at

this point, depending on which option was previously chosen.

2. Press HOURS/MINUTES switch for desired timing mode.

Setting Timer for

Continuous Shaking

3. Hold down appropriate arrow switch in the TIME module of the

control panel, up or down, until desired timing cycle is set from 0.1

hour up to 999 hours, or from 0.1 minute to 999 minutes depending

on which timing mode is chosen. SET TIME light will illuminate.

4. Press START to begin timed shaking; countdown will begin from time

set. TIMER and MINUTES or HOURS lights will illuminate and

timer will count down from time selected. An audible alarm will sound

at the end of the timing cycle and platform rotation will cease.

1. Press TIMER/ELAPSED membrane switch until ELAPSED light is

illuminated. The HOURS or MINUTES light will also light up at this

point depending on which option was previously chosen.

2. Press HOURS/MINUTES membrane switch for desired timing mode.

3. TIME display should show 000. Press START to begin timed shaking.

Timer will begin to count up and will display accumulated time in

display window. Platform rotation will continue until operator presses

the Stop button. The TIME display will flash when ELAPSED time

reaches 999 minutes or 999 hours.

5-6 Incubated and Refrigerated Shakers Thermo Scientific

Page 28

Section 5

Operation

RS232 Interface Port

RS232 Communication

Configuration

The RS232 interface port is located on the left side rear of the shaker

cabinet and requires the use of a laptop or desk top computer running

Microsoft Windows 98 or newer operating system.

Figure 5-2. RS232 Interface Port

Note The following paragraphs detail the step-by-step procedures for

configuring Microsoft® Hyperterminal running on a host computer using

Windows® XP. These instructions may need to be modified to be used

with a different terminal emulator program and/or operating system.

Contact Technical Services if further assistance is required.

1. Power up the host computer and close any running applications.

2. Open the HyperTerminal application by clicking on “Start” \

“Programs” \ “Accessories” \ “Communications” \ “HyperTerminal.”

3. In the “Connection Description” box, enter the name “Max Q Shaker”

and choose an icon and click “OK.”

4. In the “Connect To” box, verify that “COM1” is selected under

“Connect Using.” Click “OK.”

5. In the “COM1 Properties” box \ “Port Settings” folder select the

following options:

Bits per second: . . . . . . . . . . . . . . . . . . . . 19200

Data bits: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Parity: . . . . . . . . . . . . . . . . . . . . . . . . . . . . None

Stop bits: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Flow control . . . . . . . . . . . . . . . . . . . . . . . None

After verifying the above settings, click “OK.”

6. In the main dialog box click on “File” \ “Save.”

7. Exit the program by clicking on “File” \ “Exit” \ “Yes”.

8. Verify the program was saved by going to “Start” \ “Programs” \

“Accessories” \ “Communications” \ “HyperTerminal” \ “Max Q

Shaker.”

9. This completes the configuration of HyperTerminal. Go to Step 10.

Incubated and Refrigerated Shakers 5-7Thermo Scientific

Page 29

Section 5

Operation

RS232 Communication

Configuration (cont.)

Setting High-Limit

Control

10. Turn shaker off and connect computer (COM 1) to shaker (COM

PORT) with DB-9 serial printer cable.

11. Start HyperTerminal by clicking on “Max Q Shaker.”

12. Power up shaker. Shaker will screen print speed, time and temperature

at one-minute intervals.

Note RS232 Interface Port is for output only. Interface cables must not

exceed 9.8’ (3m) in length.

The high and low-limit controls are located on the right front side panel of

the shaker cabinet (Figure 5-3). The high-limit light is located on the

control panel (see Section 3).

High limit control (adjustment screw)

Low limit light

Low limit control (adjustment screw)

Figure 5-3. Control Limit Locations (Refrigerated Unit Shown)

Note Shakers without optional refrigeration system only have high-limit

control on side panel.

1. Make appropriate power connection.

2. Turn power switch ON.

3. Rotate high-limit control fully clockwise.

4. Set chamber temperature.

5. Allow sufficient time for chamber temperature to stabilize before

setting the high-limit control.

6. Rotate high-limit control slowly counterclockwise until set point is

reached.

• For A-Class shakers high-limit light will illuminate when set point is

reached. Rotate high limit control clockwise until status lamp goes out.

Make an additional 1/8 turn clockwise beyond this point.

5-8 Incubated and Refrigerated Shakers Thermo Scientific

Page 30

Section 5

Operation

Setting High-Limit

Control (continued)

Setting Low-Limit

Control (Refrigerated)

• For E-Class shakers, when set point is reached, high-limit status lamp

will flash and the audible alarm will beep once. Rotate the high-limit

control slowly clockwise approximately 1/8 turn beyond this point.

7. When desired temperature is achieved, load the shaker.

Warning Do not operate the unit if any of the temperature controls

become inoperative. A hazardous condition will develop which can result

in injury or death and property damage.

The high and low limit controls are located on the right front side panel of

the shaker cabinet. The high-limit light is located on the control panel.

Refer to Figure 5-3. The low-limit control and low limit light are available

only on units supplied with optional refrigeration system.

1. Turn ON refrigeration switch located to the left of the defrost timer

on the right rear of the shaker cabinet.

2. Rotate low-limit control fully counterclockwise.

s

3. Set chamber temperature.

4. Allow sufficient time for chamber temperature to stabilize before

setting the low-limit control.

5. Rotate low-limit control slowly clockwise. When the set point is

reached, low-limit status lamp will illuminate. Rotate the low-limit

control slowly counterclockwise until the low-limit status lamp goes

out.

6. Continue rotating the low-limit control about 5° of rotation to set it

about 1°C to 3°C below the set point, the low-limit status lamp will

extinguish and the temperature control status lamp stays lit.

7. When desired temperature is achieved, load the shaker.

Incubated and Refrigerated Shakers 5-9Thermo Scientific

Page 31

Section 5

Operation

Optional

Refrigeration System

This section applies only to units supplied with this option. The

refrigeration system on the A and E series shakers are identical in

operation. Refer to Replacement Parts for refrigeration replacement parts.

When the unit power is on, refrigeration can be initiated by turning ON

the refrigeration switch which is located to the left of the defrost timer on

the lower right side panel of the shaker cabinet. This should be initiated

(turned on) only when a temperature set point of approximately 32°C or

less is required (based on your ambient temperatures). Both the main

power switch and the refrigeration switch need to be ON for the

refrigeration system to work. When the refrigeration switch is activated,

the compressor system will run continuously and the system will go

through the following routine:

Upon every activation

of the refrigeration switch to the ON position, there

is an approximate 2-minute delay until the compressor becomes activated.

This is a safety feature, to prevent damage to the compressor in the case of

quickly switching the refrigeration switch off and on again. Because the

compressor does not turn on immediately after switching the refrigeration

switch to on, please note, THIS IS NORMAL. The defrost timer will

begin initiation. This may turn the fans off for several minutes until it

completes a normal defrost cycle.

During operation, the defrost timer will automatically “engage” every 4

hours, switching cold gas through the evaporator (inside) coils to hot gas in

order to defrost the coils. There is a dedicated sensor inside the coils which

will terminate the defrost when the temperature reaches a point where it is

assured that there is no ice or frost on the coil. At low set point

temperatures (i.e. 5°C), this defrost time will be longer than higher set

point temperatures (i.e. 25°C), which may initiate and terminate

immediately because the coils will be much warmer at higher set point

temperatures.

5-10 Incubated and Refrigerated Shakers Thermo Scientific

Page 32

Section 5

Operation

Defrost Timer

The defrost timer is located on the lower right side panel of the shaker

cabinet to the right of refrigeration power switch and is engaged whenever

the refrigeration system is turned on.

Figure 5-4. Defrost Timer

1. Refrigeration Power Switch - Activates refrigeration system, I is ON,

O is OFF.

2. Defrost Time Power Status Lamp (Power) - Timer is powered along

with refrigeration system whenever green power status lamp is lit.

3. Defrost Status Lamp (Defrost) - Cooling coil is being defrosted

whenever yellow defrost status lamp is ON. Hot gas is being bypassed

through the iced coil. When ice on the coil has melted, defrost cycle

ends automatically.

4. Fan Delay Status Lamp (Fans) - During defrost timer power-up and

after defrost cycle, the circulating fan is locked off for a 1½ minute

delay. Green fan status lamp flashes during this fan delay period.

Incubated and Refrigerated Shakers 5-11Thermo Scientific

Page 33

Section 6 Maintenance

Note The shaking mechanism is equipped with sealed ball bearings which

do not require further lubrication or adjustment.

Note Make no attempt to service or repair a Thermo Scientific product

under warranty before consulting your distributor. After the warranty

period, such consultation is still advised, especially when the repair may be

technically sophisticated or difficult.

If assistance is needed beyond what the distributor can provide, call the

Technical Services department. No merchandise, however, should be

returned without prior approval.

Wash the exterior of the unit with a soft cloth using a solution of mild

soap and water, rinse off with clean water and dry thoroughly.

Gas Springs

Replacing Platform

Mounting Plate

Warning Disconnect plug from electrical outlet before attempting any

maintenance or repair of the unit.

The gas springs should be checked periodically, and ideally every six

months. The opening force, as measured from the front lip from a closed

position, should be below 100 N (22.5 lbf) maximum. If the force is

above this value, the gas springs should be replaced. If a force

measurement is not possible, the gas springs should be replaced every two

years.

1. Remove the platform by loosening the 4 thumbscrews, remove ribbed

mat, remove the 9 smaller screws on the platform mounting plate,

there are 3 Phillips screws at each of the 3 bearing mounts. Refer to

Figure 6-1.

2. Position the platform mounting plate atop the shaker body and install

all 9 screws by hand until they are finger-tight

control fully counterclockwise (OFF) and plug the unit into an outlet.

Rotate the speed control knob slowly in the clockwise direction to

allow the shaker to orbit at its slowest speed.

s

only. Rotate the speed

Incubated and Refrigerated Shakers 6-1Thermo Scientific

Page 34

Section 6

)&!04&1 %), 1"!1

(,# %*"/

"/&+$*,2+10

-)1#,/**,2+1&+$

-)1"

%

&

$

&

%

%

&

$

$

Maintenance

Replacing Platform

Mounting Plate

(cont.)

Note While adjusting the platform retaining screws, make certain lid

switch, located at back of chamber, is activated (pressed in).

3. While it is slowly orbiting, slightly tighten each of the A screws in

Figure 1. Repeat this procedure by slightly tightening all the B screws,

then complete procedure by tightening the C screws.

Caution All screws must first be slightly tightened

to seat plate properly. s

4. Repeat the screw-tightening procedure at 50-100 RPM until all 9

screws are securely tightened.

Figure 6-1. Platform Mounting Plate

Platform

Maintenance

Suggested with every 3 months of constant use.

Caution Any internal adjustments or repairs must be performed by a

qualified service representative.

s

Remove the platform by loosening 4, thumbscrews in the platform center.

Remove the sheet metal panel (9 screws) under the platform to expose the

belt and interior parts. Inspect the drive belt for wear. Order a replacement

if necessary.

6-2 Incubated and Refrigerated Shakers Thermo Scientific

Page 35

Section 6

Maintenance

For A-Class Series

Only

Care and Cleaning of

Acrylic Lid

1. Take out the 2 motor mount screws and lift the motor out.

2. Two brushes are located under plastic caps on opposite sides of the

lower part of the motor. Unscrew the plastic caps and slide the brushes

out. Replace brushes when they are worn down to 3/16" (0.48 cm) in

length.

3. Belt tension is automatically set by the location of the motor and is

not adjustable.

4. To align a pulley, loosen the motor pulley set screws, slide the pulley

up or down into alignment then securely tighten the motor pulley set

screws.

Washing: Clean with a solution of mild soap or detergent and lukewarm

water. Use a clean soft cloth, applying only light pressure. Rinse with clean

water and blot dry with a damp cloth or chamois.

Grease, oil, or tar may be removed with a good grade of hexane, aliphatic

naphtha, or kerosene. These solvents may be obtained at a paint or

hardware store and should be used in accordance with manufacturer’s

recommendations.

Caution Do not use

or solvents such as acetone, gasoline, benzene, alcohol, carbon

tetrachloride, or lacquer thinner. These can scratch the sheet’s surface

and/or weaken the sheet causing small surface cracks called “crazing.”

Dusting: Remove dust with a soft, damp cloth or chamois. Avoid dry or

gritty cloths as they may cause surface scratches and create a static electric

charge on the surface causing dust to cling to the lid.

Polishing: Protect the lid and maintain its surface gloss by occasional

polishing with a good plastic cleaner and polish. Apply a thin, even coat

with a soft clean cloth and polish slightly with cotton flannel. Then wipe

with a damp cloth to help eliminate electrostatic charges that can attract

dust particles.

Use of proper cleaning agents: When selecting a cleaning or

decontamination agent, use the following table as a guideline.

window cleaning sprays, kitchen scouring compounds

s

Incubated and Refrigerated Shakers 6-3Thermo Scientific

Page 36

Section 6

Maintenance

Care and Cleaning of

Acrylic Lid (cont.)

Table 3-1 . Cleaning Agents

Chemical Code Chemical Code

Acetic Acid (5%) LR Hydrogen Peroxide (3%) R

Acetic Acid (Glacial) N Hydrogen Peroxide (28%) LR

Acetone N Isopropyl Alcohol (30%) LR

Ammonium Chloride R Kerosene R

Ammonium Hydroxide (10%) R Lacquer Thinner N

Ammonium Hydroxide (Conc.) R Metlhyl Alcohol (30%) LR

Aniline N Methyl Alcohol (100%) N

Battery Acid R Methyl Ethyl Ketone (MEK) N

Benzene N Methylene Chloride N

Butyl Acetate N Mineral Oil R

Calcium Chloride (Sat.) R Nitric Acid (10%) R

Calcium Hypochlorite R Nitric Acid (40%) LR

Carbon Tetrachloride LR Nitric Acid (Conc.) N

Chloroform N Oleic Acid R

Chromic Acid LR Olive Oil R

Citric Acid (10%) R Phenol Solution (5%) N

Cottonseed Oil (Edible) R Soap Solution (Mild dish soap) R

Detergent Solution (Heavy Duty) R Sodium Carbonate (2%) R

Diesel Oil R Sodium Carbonate (20%) R

Diethyl Ether N Sodium Chloride (10%) R

Dimethyl Formamide N Sodium Hydroxide (1%) R

Dioctyl Phthalate N Sodium Hydroxide (10%) R

Ethyl Acetate N Sodium Hydroxide (60%) R

Ethyl Alcohol (30%) LR Sodium Hypochlorite (5%) R

Ethyl Alcohol (95%) N Sulfuric Acid (3%) R

Ethylene Dichloride N Sulfuric Acid (30%) R

Ethylene Glycol R Sulfuric Acid (Conc.) N

Gasoline LR Toluene N

Glycerine R Transformer Oil R

Heptane R Trichloroethylene N

Hexane R Turpentine R

Hydrochloric Acid R Water R

Hydrofluoric Acid (25%) N Xylene N

6-4 Incubated and Refrigerated Shakers Thermo Scientific

R = Resistant LR = Limited Resistance N = Not Resistant

Page 37

Section 7 Troubleshooting

Problem Possible Causes Solutions

Shaker doesn’t operate Check if power cord is plugged in. Plug in.

Platform doesn’t rotate or

has erratic speed

Check if power supply matches requirements on

data label.

E-Class, check circuit breaker. Reset circuit breaker.

E-Class, check for flashing lights on control panel. Press any switch on control panel.

E-Class, check if elapsed timer is flashing. Reset timer.

A-Class, check if timer is in off position.

A-Class, check if power switch is functioning. Replace if defective.

Check for power to motor. Replace motor if defective.

Check drive belt.

Locate power supply that matches

unit requirements.

Set timer for continuous or timed

operation.

Replace if worn, broken or slipped

off pulley.

Shaker won’t heat E-Class make sure “HEAT ON” lamp is lit. Push “HEAT ON” button.

A-Class, check for power to speed control. Replace if defective.

Incubated and Refrigerated Shakers 7-1Thermo Scientific

Page 38

Section 8 Replacement Parts

Catalog Number Description Part Number

SHKA4000-5, SHKE4000-5, SHKA4000-6CE, SHKE4000-6CE Cover H-Temp Assembly CV1412X2

SHKA4000, SHKA4000-1CE, SHKE4000, SHKE4000-1CE Cover Assembly CV1412X1

SHKA4000, SHKE4000, SHKA4000-5, SHKE4000-5 Fan (120V) FAX29

SHKA4000-5, SHKE4000-6, SHKA4000-5, SHKE4000-5 Fan, 240V Hi-Temp FAX7

SHKA4000, SHKA4000-1CE, SHKE4000, SHKE4000-1CE Fan, 240V FAX7

SHKA4000-1CE, SHKA4000-6CE Capacitor 310-191-00

ALL SHKA4000 UNITS Circuit Breaker, 0.5 Amp 330-138-00

ALL SHKA4000 UNITS Circuit Breaker, 10 Amp, 120V 330-119-00

SHKA4000-1CE, SHKE4000-1CE, SHKE4000-6CE Circuit Breaker, 5 Amp, 240V 330-118-00

ALL SHKA4000 UNITS Disc Thermostat 330-397-00

SHKE4000, SHKE4000-1CE, SHKE4000-5, SHKE4000-6CE Display/time/speed/temp bd 019-536-00

ALL SHKE4000 UNITS Drive belt 150-288-00

ALL SHKA4000 UNITS Drive belt 150-318-00

ALL UNITS Drive Crank 803-632-00

ALL UNITS Gas Spring 850-117-00

SHKA4000-5, SHKE4000-5 Heater, 120V Hi-Temp 340-398-01

ALL UNITS Heater, 120V 340-394-00

SHKE4000-5, SHKE4000-6CE Heater, 240V Hi-Temp 340-398-01

ALL UNITS Idler 803-633-00

ALL UNITS Immersible RTD Temp sensor 410-632-00

ALL SHKA4000 UNITS Knob 560-275-00

ALL SHKA4000 UNITS Knob, Locking Tab 600-125-00

Incubated and Refrigerated Shakers 8-1Thermo Scientific

Page 39

Section 8

Replacement Parts

Catalog Number Description Part Number

ALL SHAKER UNITS Lamp Base 360-233-01

ALL UNITS (120V) Line Cord, 120V 319349

ALL UNITS (240V) Line Cord, CE, 240V 470-305-00

ALL UNITS Line Cord, UK, 240V CRX108

ALL UNITS Line Cord, China, 240V CRX115

ALL SHKA4000 UNITS Mini Rocker Switch 440-397-00

ALL SHKE4000 UNITS Motor 370-390-00

ALL SHKA4000 UNITS Motor 370-388-00

Motor replacement brushes for 370-388-00 370-272-01

ALL UNITS Platform Mat 790-316-13

ALL SHKE4000 UNITS Power Supply 460-315-00

SHKE4000, SHKE4000-1CE Program Micro Bd 019-533-04

SHKE4000-5, SHKE4000-6CE Program Micro Bd 019-533-05

ALL SHKE4000 UNITS Prwr/Mtr Drive PC BD 019-534-00

ALL SHKA4000 UNITS Red Lens 360-234-00

ALL SHKA4000 UNITS Round Power Switch 440-396-00

ALL UNITS Rubber Foot 790-423-00

ALL UNITS Shaker Mechanism 019-445-00

ALL UNITS Solid State Relay 400-233-00

ALL SHKA4000 UNITS 240 VOLT Speed Control, 240V 229-419-00

ALL SHKA4000 UNITS Speed Control, 120V 227-598-00

ALL UNITS SPST Switch 440-080-00

ALL SHKA4000 UNITS Tach PCB 228-612-00

ALL SHKA4000 UNITS Tachometer 660-111-00

SHKA4000 RPO Configured Temp Controller, 120V CN71X125P

SKKA4000-5 RPO Configured Temp Controller, 120V CN71X126P

SHKA4000-7 RPO Configured Temp Controller, 120V CN71X125P

SHKA4000-1CE RPO Configured Temp Controller, 240V CN71X129P

SHKA4000-6CE RPO Configured Temp Controller, 240V CN71X130P

SHKA4000-8CE RPO Configured Temp Controller, 240V CN71X131P

ALL UNITS Thermostat 920-301-00

ALL UNITS Thumb Screw 562-184-10

ALL SHKA4000 UNITS Timer 270-135-00

ALL UNITS Defrost Timer 270-108-00

8-2 Incubated and Refrigerated Shakers

Thermo Scientific

Page 40

Section 8

Section title

Ordering Procedures

Refer to the Specification Plate for the complete model number, serial

number, and series number when requesting service, replacement parts or

in any correspondence concerning this unit.

All parts listed herein may be ordered from the Thermo Scientific dealer

from whom you purchased this unit or can be obtained promptly from the

factory.When service or replacement parts are needed, check first with

your dealer. If the dealer cannot handle your request, then contact our

Technical Services Department.

Prior to returning any materials, contact our Technical Services

Department for a “Return Materials Authorization” number (RMA).

Material returned without an RMA number will be refused.

Incubated and Refrigerated Shakers 8-3Thermo Scientific

Page 41

THERMO FISHER SCIENTIFIC ANALOG SHAKER WARRANTY USA

The Warranty Period starts two weeks from the date your equipment is shipped from our facility. This allows shipping time

so the warranty will go into effect at approximately the same time your equipment is delivered. The warranty protection extends

to any subsequent owner during the warranty period.

During the first year, component parts proven to be non-conforming in materials or workmanship will be repaired or replaced

at Thermo’s expense, labor included. For an additional 4 years, component parts proven to be non-conforming in materials or

workmanship will be repaired or replaced at Thermo’s expense, labor excluded. In addition, the Orbital Shaker mechanism is

warranted for 10 years, parts only, F.O.B. factory. The mechanism is defined as the bearing assemblies. The warranty will be

void if the equipment is altered without written authorization from Thermo. Installation and calibration is not covered by this

warranty agreement. The Technical Services Department must be contacted for warranty determination and direction prior to

performance of any repairs. Expendable items, i.e., glass, filters, light bulbs and lid gaskets are excluded from this warranty.

Extended warranties are dependent on the units being maintained regularly as stated in the operation and service manuals.

Replacement or repair of components parts or equipment under this warranty shall not exceed the warranty to either the equip-

ment or to the component part beyond the original warranty period. The Technical Services Department must give prior

approval for return of any components or equipment.

THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, WHETHER WRITTEN, ORAL, OR

IMPLIED. NO WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE SHALL APPLY.

Thermo shall not be liable for any indirect or consequential damages including, without limitation, damages relating to lost prof-

its or loss of products.

Your local Thermo Sales Office is ready to help with comprehensive site preparation information before your equipment arrives.

Printed instruction manuals carefully detail equipment installation, operation, and preventive maintenance.

If equipment service is required, please call your Technical Services Department at 1-800-438-4851 (USA and Canada) or 1-

740-373-4763. We’re ready to answer any questions on equipment warranty, operation, maintenance, service and special

applications. Outside the USA, contact your local distributor for warranty information.

Rev. 2 6/2015

ISO

9001

REGISTERED

Incubated and Refrigerated Shakers 9-1Thermo Scientific

Page 42

Section 9

THERMO FISHER SCIENTIFIC DIGITAL SHAKER WARRANTY USA

The Warranty Period starts two weeks from the date your equipment is shipped from our facility. This allows shipping time

so the warranty will go into effect at approximately the same time your equipment is delivered. The warranty protection extends

to any subsequent owner during the warranty period.

During the first 24 months, component parts proven to be non-conforming in materials or workmanship will be repaired or

replaced at Thermo’s expense, labor included. For an additional 3 years, component parts proven to be non-conforming in

materials or workmanship will be repaired or replaced at Thermo’s expense, labor excluded. In addition, the Orbital Shaker

mechanism is warranted for 10 years, parts only, F.O.B. factory. The mechanism is defined as the bearing assemblies. The

warranty will be void if the equipment is altered without written authorization from Thermo. Installation and calibration is not

covered by this warranty agreement. The Technical Services Department must be contacted for warranty determination and

direction prior to performance of any repairs. Expendable items, i.e., glass, filters, light bulbs and lid gaskets are excluded

from this warranty. Extended warranties are dependent on the units being maintained regularly as stated in the operation and

service manuals.

Replacement or repair of components parts or equipment under this warranty shall not exceed the warranty to either the equip-

ment or to the component part beyond the original warranty period. The Technical Services Department must give prior

approval for return of any components or equipment.

THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, WHETHER WRITTEN, ORAL, OR

IMPLIED. NO WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE SHALL APPLY.

Thermo shall not be liable for any indirect or consequential damages including, without limitation, damages relating to lost prof-

its or loss of products.

Your local Thermo Sales Office is ready to help with comprehensive site preparation information before your equipment arrives.

Printed instruction manuals carefully detail equipment installation, operation, and preventive maintenance.

If equipment service is required, please call your Technical Services Department at 1-800-438-4851 (USA and Canada) or

1-740-373-4763. We’re ready to answer any questions on equipment warranty, operation, maintenance, service and special

applications. Outside the USA, contact your local distributor for warranty information.

Rev. 2 6/2015

ISO

9001

REGISTERED

Warranty Information

9-2 Incubated and Refrigerated Shakers Thermo Scientific

Page 43

THERMO FISHER SCIENTIFIC INTERNATIONAL ANALOG SHAKER WARRANTY

The Warranty Period starts two months from the date your equipment is shipped from our facility. This allows shipping time so the

warranty will go into effect at approximately the same time your equipment is delivered. The warranty protection extends to any sub-

sequent owner during the warranty period.

During the first year, component parts proven to be non-conforming in materials or workmanship will be repaired or replaced at

Thermo’s expense, including labor. For an additional 4 years, component parts proven to be non-conforming in materials or work-

manship will be repaired or replaced at Thermo’s expense, excluding labor. In addition, the Orbital Shaker drive mechanism is war-

ranted for 10 years, parts only, F.O.B. factory. The mechanism is defined as the bearing assemblies. The warranty will be void if the

equipment is altered without the written authorization from Thermo. Installation and calibration is not covered by this warranty agree-

ment. The local Thermo Fisher Scientific office must be contacted for warranty determination and direction prior to performance of

any repairs. Expendable items, i.e., glass, filters, light bulbs and lid gaskets are excluded from this warranty. Extended warranties

are dependent on the units being maintained regularly as stated in the operation and service manuals.

Replacement or repair of component parts or equipment under this warranty shall not exceed the warranty to either the equipment

or to the component part beyond the original warranty period. The local Thermo Fisher Scientific office must give prior approval for

return of any components or equipment.

THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, WHETHER WRITTEN, ORAL, OR IMPLIED.

NO WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE SHALL APPLY. Thermo shall not be

liable for any indirect or consequential damages including, without limitation, damages relating to lost profits or loss of products.

Thermo International Sales Office is ready to help with comprehensive site preparation information before your equipment arrives.

Printed instruction manuals carefully detail equipment installation, operation, and preventative maintenance.

If equipment service is required, please call your local Thermo Fisher Scientific office. We’re ready to answer your questions on

equipment warranty, operation, maintenance, service and special applications.

ISO

9001

REGISTERED

Rev. 2 6/2015

Section 9

Warranty Information

Incubated and Refrigerated Shakers 9-3Thermo Scientific

Page 44

Section 9

THERMO FISHER SCIENTIFIC INTERNATIONAL DIGITAL SHAKER WARRANTY

The Warranty Period starts two months from the date your equipment is shipped from our facility. This allows shipping time so the

warranty will go into effect at approximately the same time your equipment is delivered. The warranty protection extends to any sub-

sequent owner during the warranty period.

During the first 24 months, component parts proven to be non-conforming in materials or workmanship will be repaired or replaced

at Thermo’s expense, including labor. For an additional 3 years, component parts proven to be non-conforming in materials or work-

manship will be repaired or replaced at Thermo’s expense, excluding labor. In addition, the Orbital Shaker drive mechanism is war-

ranted for 10 years, parts only, F.O.B. factory. The mechanism is defined as the bearing assemblies. The warranty will be void if the

equipment is altered without the written authorization from Thermo. Installation and calibration is not covered by this warranty agree-

ment. The local Thermo Fisher Scientific office must be contacted for warranty determination and direction prior to performance of

any repairs. Expendable items, i.e., glass, filters, light bulbs and lid gaskets are excluded from this warranty. Extended warranties

are dependent on the units being maintained regularly as stated in the operation and service manuals.

Replacement or repair of component parts or equipment under this warranty shall not exceed the warranty to either the equipment

or to the component part beyond the original warranty period. The local Thermo Fisher Scientific office must give prior approval for

return of any components or equipment.

THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, WHETHER WRITTEN, ORAL, OR IMPLIED.

NO WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE SHALL APPLY. Thermo shall not be

liable for any indirect or consequential damages including, without limitation, damages relating to lost profits or loss of products.

Thermo International Sales Office is ready to help with comprehensive site preparation information before your equipment arrives.

Printed instruction manuals carefully detail equipment installation, operation, and preventative maintenance.

If equipment service is required, please call your local Thermo Fisher Scientific office. We’re ready to answer your questions on

equipment warranty, operation, maintenance, service and special applications.

ISO

9001

REGISTERED

Rev. 2 6/2015

Warranty Information

9-4 Incubated and Refrigerated Shakers Thermo Scientific

Page 45

thermoscientific.com

© 2014 Thermo Fisher Scientific Inc. All rights reserved. All trademarks are the property of Thermo Fisher Scientific and its

subsidiaries. Specifications, terms

and pricing are subject to change. Not all products are available in all countries. Please consult your local sales representative

for details.

Thermo Fisher Scientific (Asheville) LLC

401 Millcreek Road

Marietta, Ohio 45750

United States

A Thermo Fisher Scientific Brand

Loading...

Loading...