Page 1

Sarasota 200

Ultrasonic Multipath Flowmeter

User Guide

P/N HB-S200

Revision A

Part of Thermo Fisher Scientific

Page 2

Page 3

Sarasota 200

Ultrasonic Multipath Flowmeter

User Guide

P/N HB-S200

Revision A

Page 4

Page 5

©2007 Thermo Fisher Scientific Inc. All rights reserved.

All trademarks are the property of Thermo Fisher Scientific Inc. and its subsidiaries.

Thermo Fisher Scientific (Thermo Fisher) makes every effort to ensure the accuracy and completeness of

this manual. However, we cannot be responsible for errors, omissions, or any loss of data as the result of

errors or omissions. Thermo Fisher reserves the right to make changes to the manual or improvements to

the product at any time without notice.

The material in this manual is proprietary and cannot be reproduced in any form without expressed

written consent from Thermo Fisher.

Thermo Fisher Scientific

1410 Gillingham Lane

Sugar Land, TX 77478

USA

Phone: 713-272-0404

Fax: 713-272-2272

Web: www.thermofisher.com

Thermo Fisher Scientific

14 Gormley Industrial Avenue

Gormley, Ontario L0H 1G0

Canada

Phone: 905-888-8808

Fax: 905-888-8828

Page 6

This page intentionally left blank.

Page 7

Sarasota 200 Ultrasonic Multipath Flowmeter

SECTION 1

INTRODUCTION

1.2.1 The Standard

1.3 Implementation of principles in Sarasota 200

1.1 Applications

1.2 Principle of operation

1.2.2 Velocity x area method

1.2.3 Water level

1.2.4 Water velocity

1.2.5 Flow determination

1.2.5.1 Mid section method

1.2.5.2 Mean section method

1.2.6 Path configurations

1.2.7 Transducer frequency

1.2.8 Minimum depth of water

1.2.9 Performance estimates

INDEX

SECTION 2

SYSTEM COMPONENTS

2.1 Flowmeter system overview

2.2 Family tree

2.3 Flowmeter contents and options

2.3.1 Flowmeter layout

2.3.2 Internal components

2.3.2.1 Mother board

2.3.2.1.1 Power supply & internal battery

2.3.2.1.2 Transducer connections

2.3.2.1.3 Depth input signals

2.3.2.1.4 Output signal connections

2.3.2.1.5 Relay connections

2.3.2.1.6 Digital signal connections

2.3.2.1.7 Serial communications

2.3.2.2 Central processor (CPU)

2.3.2.3 LCD display

2.3.2.4 Transducer interface card (TIF)

2.3.2.5 AC power adapter

2.4 Ultrasonic transducers

2.4.1 1 MHz transducers

2.4.2 1 MHz I.S. transducers

2.4.3 500 kHz transducers

2.4.4 Lower frequency transducers

2.4.5 Maximum cable lengths

2.5 Controls and displays

2.6 Software & firmware

2.6.1 Operating firmware

2.6.2 “GAFA” PC software

2.7 Documentation

INDEX Page 1

Thermo Fisher Scientific

Page 8

Sarasota 200 Ultrasonic Multipath Flowmeter

SECTION 3

PERIPHERAL EQUIPMENT

SECTION 4

INSTALLATION

4.1 Safety

SECTION 5

COMMISSIONING

5.1 Site dimensions

SECTION 6

CALIBRATION/

VERIFICATION

3.1 Additional items

3.2 Transducer mounting hardware

4.2 General

4.3 Unpacking and laying out

4.4 Installing transducer assemblies

4.5 Connecting transducers to flowmeter

4.6 Transducer alignment

4.7 Output connections

4.8 Power connection

5.2 Powering up

5.3 Programming

5.4 Setting up

5.5 Outputs

6 Calibration/verification

INDEX

SECTION 7

MAINTENANCE

7.1 Channel maintenance

7.1.1 Weed

7.1.2 Profile

7.1.3 Debris

7.2 Flowmeter maintenance

7.3 Routine checks

7.3.1 Remote

7.3.2 On site

APPENDIX 1

GAFA PC SOFTWARE

A2 GAFA PC software

INDEX Page 2

Thermo Fisher Scientific

Page 9

Sarasota 200 Ultrasonic Multipath Flowmeter

APPENDIX 2

SPECIFICATION

A2.1 Enclosure

A2.2.1 DC supply

A2.3 Electronics

A2.4.1 1 MHz

A2.5 GAFA software

A2.2 Power supply

A2.2.2 AC power adap ter modu le

A2.3.3 Internal battery option

A2.4 Transducers

A2.4.2 500 kHz

A2.4.3 Other frequencies

A2.4.4 Transducer ca ble

INDEX

APPENDIX 3

REFERENC ES

A3 References

APPENDIX 4

SITE DATA BOOK

A4.1 Model and serial number

A4.2 Site and customer

A4.3 General description

A4.4 Software issue

A4.5 Card layout in rack

A4.6 Programmed data

A4.7 Schedule of drawings

A4.8 Test certificates

APPENDIX 5

I.S. INTERFACE AND

TRANSDUCER

A5.1 Introduction

A5.2 Installation Guidelines

A5.3 Marking

A5.4 Maintenance

INDEX Page 3

Thermo Fisher Scientific

Page 10

Sarasota 200 Ultrasonic Multipath Flowmeter

This page is blank

INDEX

INDEX Page 4

Thermo Fisher Scientific

Page 11

Sarasota 200 Ultrasonic Multipath

Flowmeter

INTRODUCTION

1 INTRODUCTION

1.1 Applications

The Thermo Scientific Sarasota 200 is a velocity x area open channel flowmeter which uses

the ultrason ic “ tim e of fli ght ”, also kno wn as th e “tr ans it t ime” m et hod. It is sim ilar to the l arge r

Sarasota 2000 but with fewer ultrasonic velocity paths (up to 4) and just one water channel.

Unlike traditional methods of open channel flow measurement which use weirs or flumes, the

transit time method creates no obstruction and assumes no relation between level and flow. It

will correctly determine flow throughout its designed range by measuring water velocity and

cross section area (see Section 1.2).

The method is tolerant of backwater effects caused by tides, downstream confluence or

blockages. Unlike a weir or flume it does not drown out at high flow conditions.

The method employs the transmission of ultrasonic “beams” which can be affected by factors

which impede or deflect them. For this reason the method should not be used in situations of:

• Aerated water

• Weed growth between the transducers (unless it is regularly cut)

• High levels of suspended solids (greater than 2000 mg/l) *

• Gradients

• Gradients

* In relatively small channels (up to 5 metres) the method is more tolerant of

** Provided the velocity of sound in water (VOS) remains within the range 1350 to 1650

Though described as an open channel method, the flowmeter may be used in closed

conduits, including those which run full. In the latter case, the cross section area is defined by

the conduit geometry without the need to measure water level.

Suitable applications include water flow measurement of:

• Rivers

• Canals

• Aqueducts

• Irrigation conduits

• Sewage discharges

• Sewage works

• Industrial discharges

• Power generation

Note that although the flowmeter is most often used for open channels or part filled conduits,

it is often used for conduits which always run full. Under these circumstances it is not

necessary to have a depth input but steps need to be taken to ensure that the flowmeter

always takes the conduit as full. This is done via the fixed level input PC screen. The conduit

shape must sti ll be ent e red.

of salinity (the actual value of salinity is, however, unimportant**)

of temperature (the actual temperature is, however, unimportant**)

suspended solids and therefore is often used in sewage applications.

m/s

Section 1 INTRODUCTION Page 1-1

Thermo Fisher Scientific

Page 12

Sarasota 200 Ultrasonic Multipath

Flowmeter

1.2 Principle of operation

1.2.1 The Standard

The Thermo Scie ntific Sarasota 200 is an ultrasonic “tra nsit time” flowmet er which complies

with the International Standard ISO 6416. The UK standard BS 3680 part 3E is identical. The

transit time method belongs to the general category of velocity x area methods. A full

description of the method and its applications is to be found in the Standard. A brief summary

is given below.

1.2.2 Velocity x area method

Velocity x area methods require a means of determining the water velocity and the cross

section area. The product of the two determines the flow rate in a manner which is not

dependent on factors influencing the level, for example downstream constrictions, tidally

affected water level etc.

Assuming the shape of the channel cross section is stable, determination of the area

becomes a matter of measuring water level. This may be done by a variety of methods.

1.2.3 Water level

Water level is required in order to determine the cross section area in an open channel.

Though a single level measurement may be used, it is common to use more than one and to

average them. This has the advantage of a more representative level, particularly if the

measurements are made at different positions, for example on either side of the channel.

Another advantage is that flow may still be computed even if a level sensor fails.

Level may be determined by using one or more ultrasonic transducers in the water facing

upwards. The time taken for a pulse of sound to return to the transducer after being reflected

from the surface is converted into level using the velocity of sound in water as measured by

the water velocity paths (see Section 1.2.4). There is a minimum depth of water required

above the transducer for it to carry out a measurement. This is given in Appendix 2:

Specification.

Water level may also be provided by external auxiliary depth gauges via 4-20 mA signals, for

example pressure transmitters, downward facing ultrasonic devices and float systems with

shaft encoders.

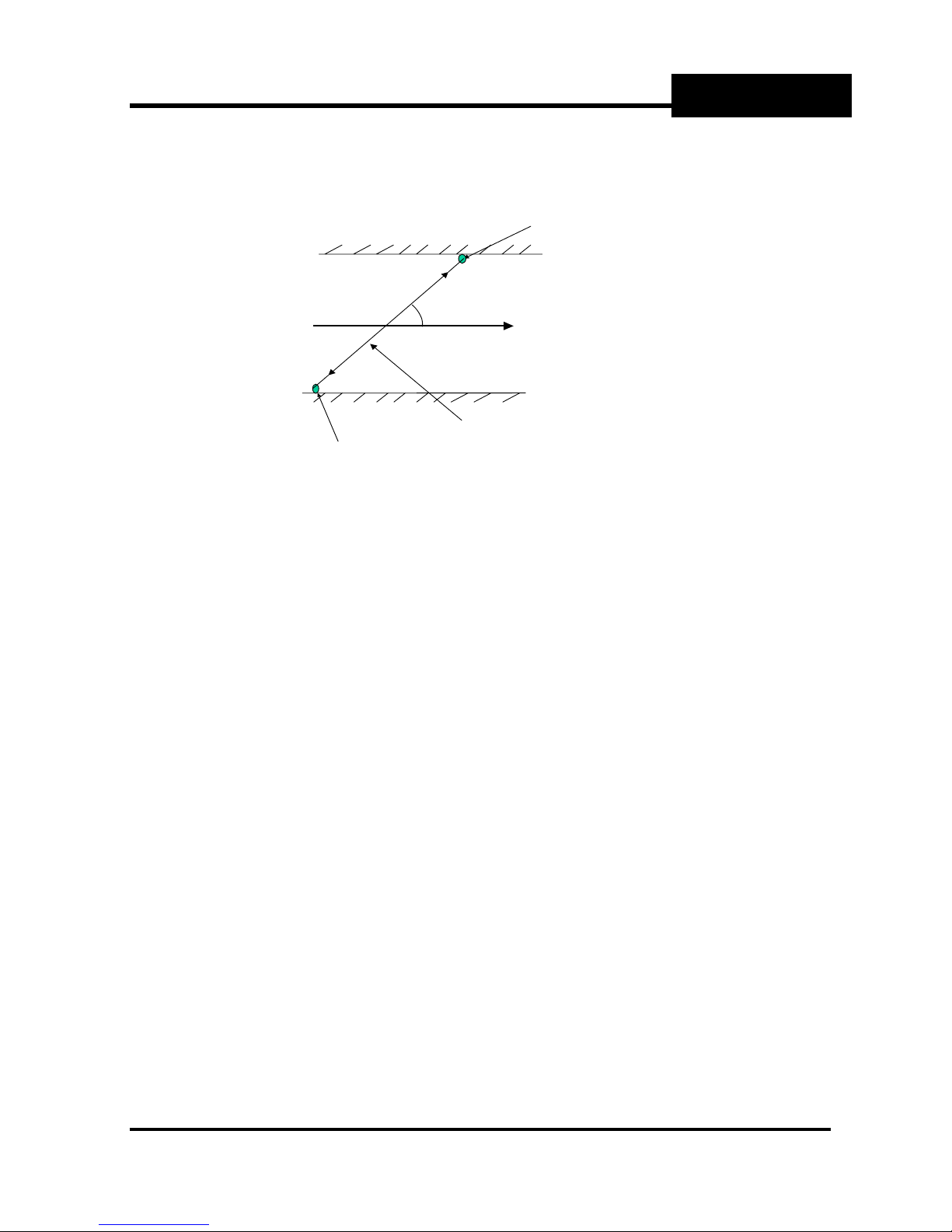

1.2.4 Water velocity

In the transit time method, water velocity is determined at a number of heights within the body

of water by measurement of time taken for pulses of ultrasound to travel across the channel

at an angle to the flow direction.

Transducers are mounted in the water at or near the sides of the channel with each pair

usually at the same height and aligned so that each one can transmit a “beam” of ultrasound

towards its partner. The ultrasonic “path” between the transducer pairs must be at an angle

(usually about 45

Each transducer acts as a transmitter and receiver and is connected to a processing unit,

which measures the transit time and the time difference.

o

) to the flow direction.

INTRODUCTION

Section 1 INTRODUCTION Page 1-2

Thermo Fisher Scientific

Page 13

Sarasota 200 Ultrasonic Multipath

θ

Flowmeter

The mean water velocity at the height of each path is determined from these timing

measurements, based on pre-determined geometrical measurements (length of the path and

the angle to the flow direction).

V

It may be shown that the water velocity at the height of the path AB is:

v = L x (T

– TBA) / (TAB x TBA x 2 cosθ)

AB

Where

T

T

= Transit time from transducer A to B

AB

= Transit time from transducer B to A

BA

L = Path length (distance between transducer A and transducer B)

θ = the angle between the “path” and the direction of flow.

1.2.5 Flow determination

The flow is determined by combining the water velocity measurements at the height of each

path with the cross section area defined by the water level and the shape of the channel. The

channel shape need not be the same as the projected width between the transducers. For

example if the transducers are mounted on piles inset from the channel sides. For the

purposes of flow determination the cross section area is divided into horizontal slices

determined by the channel bed, the heights of the paths themselves and the water surface

level.

The channel flow is the sum of the flows in each slice determined by the path velocity or

velocities and the area of the slice. The bottom slice is defined by the bed (which is assumed

not to move) and the top slice by the water surface (the level of which is me asured by the

flowmeter). The slice widths may be determined by the projected width between the

transducers or by a separate table defining the cross section shape. The latter method is

used by the Sarasota 200.

There are 2 methods, mid section and mean section.

Transducer A

Direction of the Flow

Ultrasonic Path

Transducer B

INTRODUCTION

Section 1 INTRODUCTION Page 1-3

Thermo Fisher Scientific

Page 14

Sarasota 200 Ultrasonic Multipath

Flowmeter

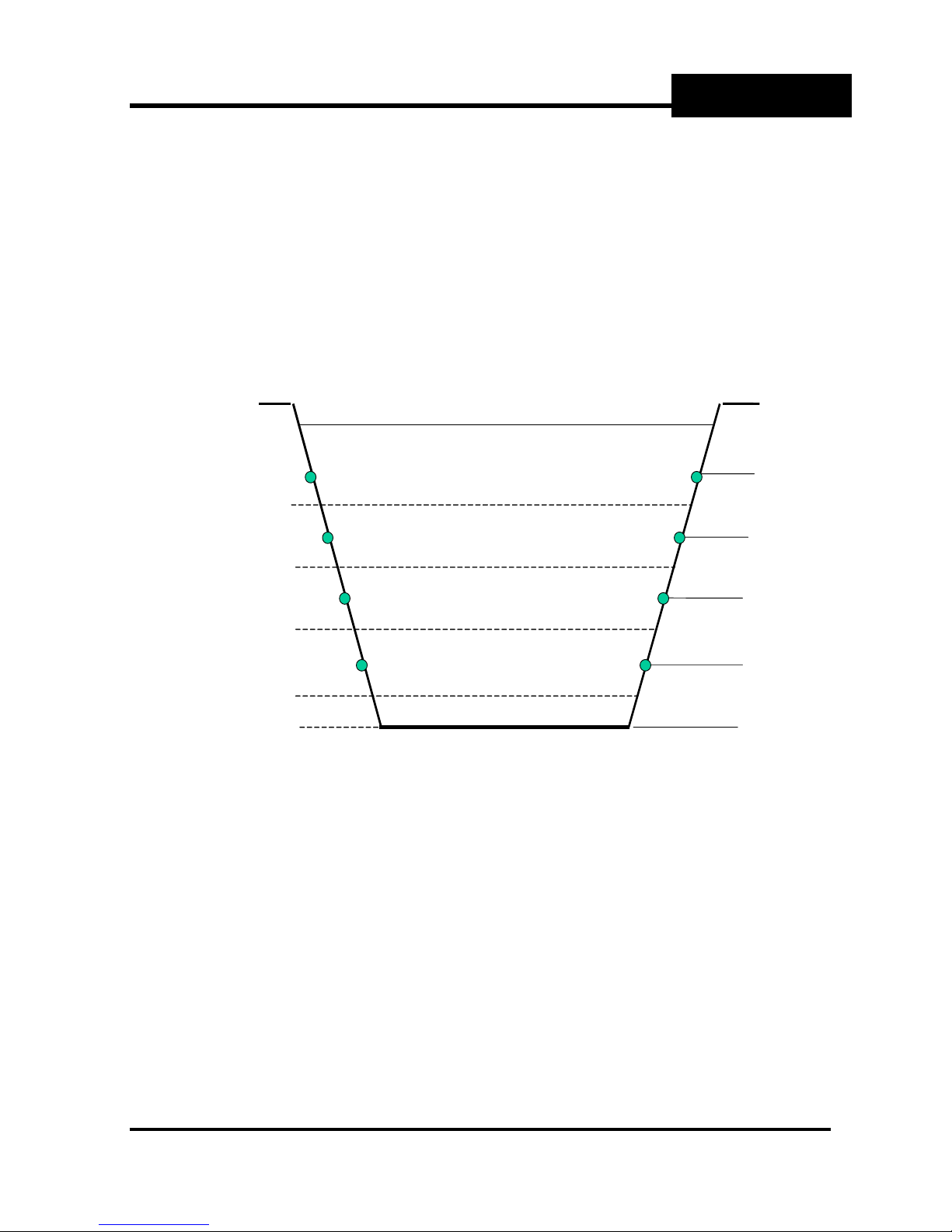

1.2.5.1 Mid section method

In the mid section method, the slice boundaries are defined by lines mid way between the

paths. The slice velocity is taken as that determined by the ultrasonic path within the slice and

the slice area as the product of the slice height and the (average) width. The upper boundary

of the top slice is the water surface. At the bottom, an additional slice is defined between the

bed and a line half way between the bed and the bottom path. This bottom slice has a

weighting factor, K, normally between 0.4 and 0.8 to allow for the slow moving water near the

bed. To reduce the uncertainty of this factor, the bottom path should be positioned as close to

the bed as practical.

INTRODUCTION

Height H

Top panel

½(H

+ H3)

4

S

Water S u rf ac e

QS = V4 {HS − ½(H4 + H3)}W

QS = ½V3 (H4 – H2)W

3

4

½(H3 + H2)

+ H1)

½(H

2

+ H0)

½(H

1

Height H

0

Bottom panel

QS = ½V2 (H3 – H1)W

QS = ½V1 (H2 – H0)W

QS = ½kV1 (H1 – H0)W

2

1

Width W

Bed

Width W

Illustration of the mid section method for 4 paths

Width W

Width W

Width W

1

Bed

4

3

2

Path 4 H e ight H

Path 3 Height H

Path 2 Height H

Path 1 Height H

Bed Height H

4

3

2

1

0

Section 1 INTRODUCTION Page 1-4

Thermo Fisher Scientific

Page 15

Sarasota 200 Ultrasonic Multipath

4

Flowmeter

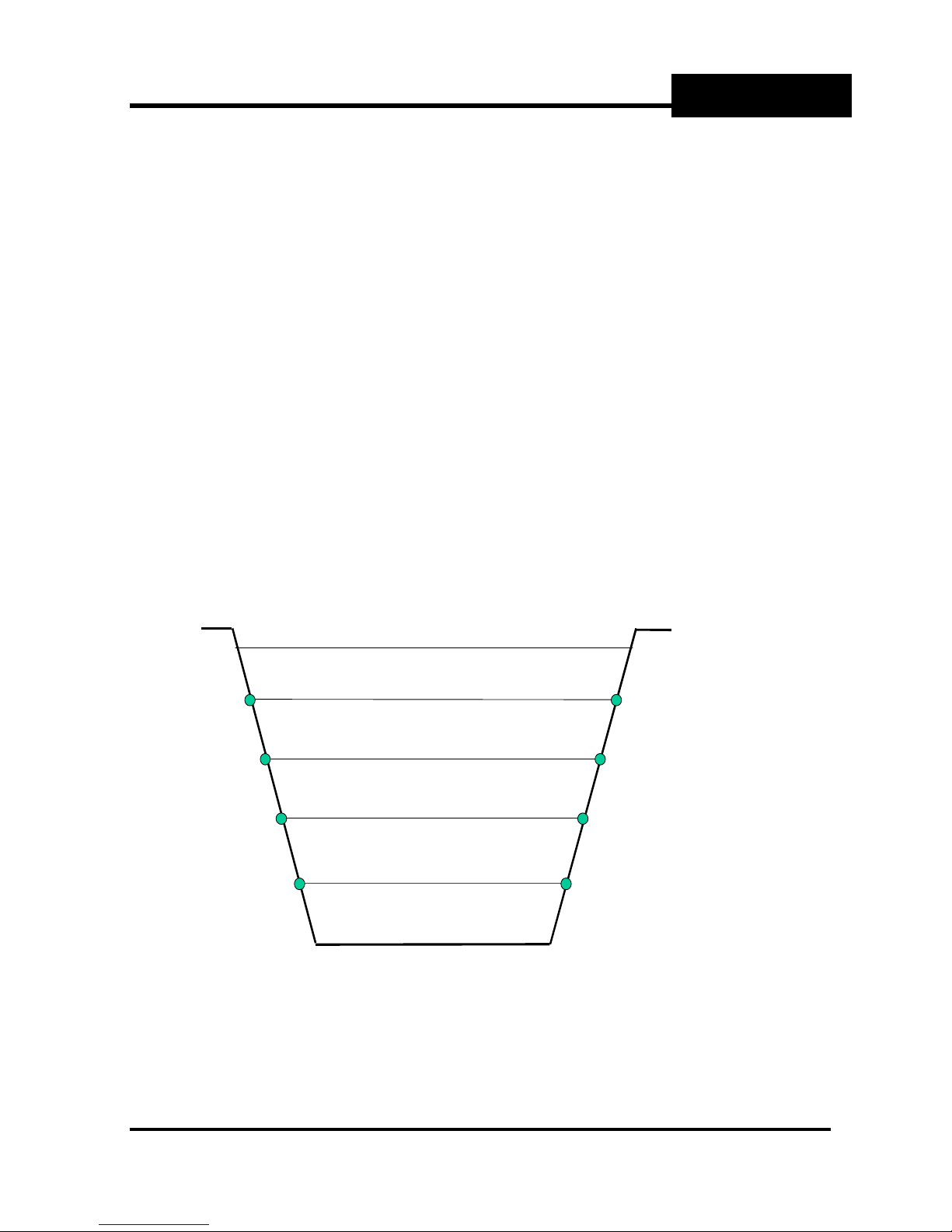

1.2.5.2 Mean section method

In the mean section method, the slice boundaries are defined by the path heights themselves.

The slice velocity is taken as the mean of the upper and lower paths which define the slice

boundaries. The upper boundary of the top slice is the water surface.

The velocit y of the water surface, Vs, is given by:-

Vs = V

Where Ks is a multiplying factor normally between 0 and 1 to allow for the projection

of velocity to the water surface

Vs is limited to a value of V

The lower boundary of the bottom slice is the bed. This bottom slice has a weighting factor,

, normally between 0.4 and 0.8 to allow for the slow moving water near the bed.

K

B

The mean section method is superior in cases where the paths are not near the slice centres,

but the mid section method handles the top slice better. The more paths that are deployed,

the less the differences matter.

The mean section method is illustrated in the following diagram:

+ (V4-V3) x Ks(Hs-H4)/(H4-H3)

4

+ (V4-V3) in the event of (Hs-H4) being greater than (H4-H3)

4

INTRODUCTION

Water Surface

Qs = ½(VS + V4) x (HS – H4) x ½(WS+ W4)

Q

= ½ (V4+ V3) x (H4 – H3) x ½(W4 + W3)

s

= ½ (V3 + V2) x (H3 – H2) x ½(W3 + W2)

Q

s

= ½ (V2 + V1) x (H2 – H1) x ½(W2 + W1)

Q

s

Q

= ½V1(1 + kB) x (H1 – H0) x ½(W1 + W

s

W

W

W

W

Wbed

Width W

4

3

2

1

)

Bed

S

Illustration of the mean section method for 4 paths

Surface Heigh t H

Path 4. Height H

Path 3. H eight H

Path 2. He i ght H

Path 1 Height H

Bed, Height H

S

3

2

1

0

Section 1 INTRODUCTION Page 1-5

Thermo Fisher Scientific

Page 16

Sarasota 200 Ultrasonic Multipath

Flowmeter

1.2.6 Path configurations

The simplest arrangement is to have a number of paths “in line” above each other. This

would be suitable for a channel of regular cross section shape, which is straight for a long

distance compared with its width (5 to 10 times).

Other configurations are often used in other circumstances. For example:

• Crossed paths where there is uncertainty about the flow direction

• Sloping paths where the depth is greater on one side compared with the other

• Transducers inset from the banks

• Reflected paths where transducers are on one side only and reflectors “bounce” the

sound pulses back from the far side. This method saves cable but increases path lengths

and is very sensitive to misalignment.

The Sarasota 200 f l o wm e t e r is capable of being con f i gured for these and ot her situation s .

For more complex configurations requiring more than 4 paths or compound channels, the

Sarasota 2000 offers more flexibility. Examples are:

• Multiple sets of paths for compound channel shapes

• V configuration used to divide the width because of size or uneven profile

• Multiple channels

Please consult Thermo Fisher Scientific for examples and advice.

1.2.7 Transducer frequency

Transducers are manufactured with characteristic frequencies. These are in the range 1 MHz

to 250 kHz. For propagation reasons, the greater the path lengths the lower the frequency

and the larger the transducer. As a guide, path lengths below 10 metres would use 1MHz

transducers, 5 to 80 metres 500 kHz, 50 to 200 metres 250 kHz. These figures are for

guidance and the selection may be influenced by other factors relating to the application.

Where there is overlap, lower frequency transducers may be used to improve pen etration in

conditions of high suspended solids provided there is sufficient depth and velocity.

Please consult Thermo Fisher Scientific for advice.

1.2.8 Minimum depth of water

In order to avoid reflections from the bed or surface causing distortion of the ultrasonic

signals, a minimum height of water is necessary above each path. This depends on the

transducer frequency and the path length.

INTRODUCTION

H

= 27 √ ( L / ƒ )

min

Where:

is the minimum height of water above the path, in metres

H

min

L is the path length, in metres

ƒ is the transducer freque ncy, in Hertz

A similar restriction applies to the channel bed, particularly if it is smooth and reflects rather

than absorbs an acoustic signal. The minimum depth of water is therefore usually 2 x H

Section 1 INTRODUCTION Page 1-6

min

Thermo Fisher Scientific

Page 17

Sarasota 200 Ultrasonic Multipath

Flowmeter

1.2.9 Performance estimates

ISO 6416 describes how to estimate the uncertainty of measurement in any particular

installation. Please consult Thermo Fisher Scientific for advice on this.

1.3 Implementation of the principles of operation in the Sarasota 200

The principles described in Section 1.2 are used by the Sarasota 200 subject to certain rules

as listed below. See also Appendix 1: GAFA Screens that describe in detail how the

flowmeter is programmed via a PC.

Flow

• There is a choice of mean or mid section method of flow calculation.

• The channel cross section shape is entered as a height/width table independent from the

path lengths and angles. (For rectangular or trapezoidal channels it is only necessary to

enter 2 points to define the channel.) The separate table allows the path velocities to be

applied to more accurate slice areas since the defined shape is used rather than a fixed

width for each slice as specified in the Standard.

• Where no path velocity is available, for example at low water height, flow may be inferred

from water level. This is done via a flow estimation table, which may be derived

empiricall y o r by calculation.

Velocity

• The upstream velocity transducers are connected as shown in section 2.

• Path numbering is from the bottom.

• Paths are automatically brought into operation according to the water level and the

programmed minimum water cover.

• Paths entered as being at the same height are taken as crossed, otherwise they are

separate.

• Separate paths may be “normal” with transducers on each side or “reflected” with

transducers on one side only. The latter method saves cable but is not recommended

because of the increased path lengths and sensitivity to alignment.

• The velocities calculated by a pair of paths comprising a crossed path are averaged and

the average velocity used for the slice. The velocity calculated by a separate path is used

alone for the slice.

• When a velocity path fails, the slice boundaries automatically adjust to use only the

working paths.

• A failed path will show on the status indicated. The path status is a percentage of the

“instantaneous” transducer firings which result in successful reception. If this figure drops

below 12% the path is considered to have failed during the corresponding instantaneous

cycle time and is discarded for that cycle. This could be the result of a fault, misalignment

or obstruction.

• Only valid velocity paths which are in the water and covered by sufficient water to be

operating are used for the status indication.

• Each path may have a multiplying factor (“X Factor”) assigned to it. This will normally be 1

but may be different in exceptional circumstances for calibration purposes. An example of

when this might be is when the transduce rs are not exactly at the channel edges.

• Transducers in each velocity path may be set to operate simultaneously (the norm) or

sequentially. Simultaneous operation allows more measurements in a given time but

there is a small possibility of confusing a signal reflected back to the firing transducer with

one received from the opposite transducer.

INTRODUCTION

Section 1 INTRODUCTION Page 1-7

Thermo Fisher Scientific

Page 18

Sarasota 200 Ultrasonic Multipath

Flowmeter

Water level

• Levels are combined in the following algorithm:

Only non-faulty measurements are used.

Highest and/or lowest are discarded until 3 remain.

The one furthest from the others is discarded leaving 2.

The remaining 2 measurements are averaged for arbitrated level if within an

acceptable band defined via the PC GAFA software.

If they are not within the acceptable band, level determination fails and flow cannot

be calculated.

If only 1 level measurement is installed or only 1 remains after arbitration, it is used

as the arbitrated level.

If not OK, level fails and flow cannot be calculated.

• Levels defined as valid but rejected by the algorithm will be indicated on the level status.

• Where the flowmeter is installed in a cl osed conduit which always runs full, th e channel

shape is entered in the usual way but there is no need for a level measurement. The

flowmeter is programmed with a fixed level input corresponding to the top of the conduit.

Transducer and bed levels

All heights may be set to a fixed datum (local or national) or relative to mean bed level. The

former requires a height for the bed and avoids re-entering all path and level transducer

heights in the event of a change to the bed.

General

• “Instantaneous” means the average over the cycle time scale. This defaults to 10

seconds for fast response suitable for small channels. It may be set to 1 minute for

smoother averaging where the rate of change of flow conditions is slower.

• The average period is the time over which measurements are averaged for the purpose

of output or logged data. The average period cannot be shorter than the cycle time.

• At the data logging intervals, the averaged values of the selected data are stored.

• Analogue inputs will normally be linear. However, non linear characteristics may be

entered via the PC, see Appendix 1

• When operating on a 12 volt source, for example from a solar panel, power saving is

possible by using intermittent operation. Power consumption in normal and intermittent

modes is quoted in the Appendix 2: Specification.

INTRODUCTION

Section 1 INTRODUCTION Page 1-8

Thermo Fisher Scientific

Page 19

Sarasota 200 Ultrasonic Multipath

Flowmeter

SYSTEM COMPONENTS

2 SYSTEM COMPONENTS

2.1 Flowmeter system overview

• The Thermo Scientific Sarasota 200 is an ultrasonic multi-path flowmeter, which complies

with ISO6416.

• It employs state of the art technology to achieve excellent performance in conditions

which have previously be en outside th e scope of this type of instrument.

• Smart transducer technology incorporating drive and receiver circuits optimises signal to

noise ratio and minimises losses. The smart circuits are located inside the transducer

housings except for the 1 MHz transducers. In that case they are in sealed in-line

housings known as Tboxes.

• Automatic adjustment of receiver gain and transducer drive voltage (HT).

• Low power consumption and intermittent modes make mains free operation feasible.

• Multi-path operation, (up to 4) with multi-drop facility made possible by smart transducer

addressing to save cable.

• Multiple water level inputs, subject to a maximum of 4 overall:

- up to 4 ultrasonic level transducers

- up to 2 auxiliary level gauges (via 4-20 mA inputs.)

• Up to 2 analogue 4-20 mA outputs

• System fault relay (volt free contacts)

• 2 programmable relays, 1 volt free contact, 1 high speed solid state. Programmable, f or

example for alarms, status, totaliser pulses.

• Two serial ports. RS232 for PC, RS232 for modem.

• Internal data logger, 1 Mbyte capacity, programmable.

• Water temper ature measurem e nt at each smart transducer (except 1 MHz transduc er s )

Section 2, SYSTEM COMPONENTS, Page 2-1

Thermo Fisher Scientific

Page 20

Sarasota 200 Ultrasonic Multipath

Flowmeter

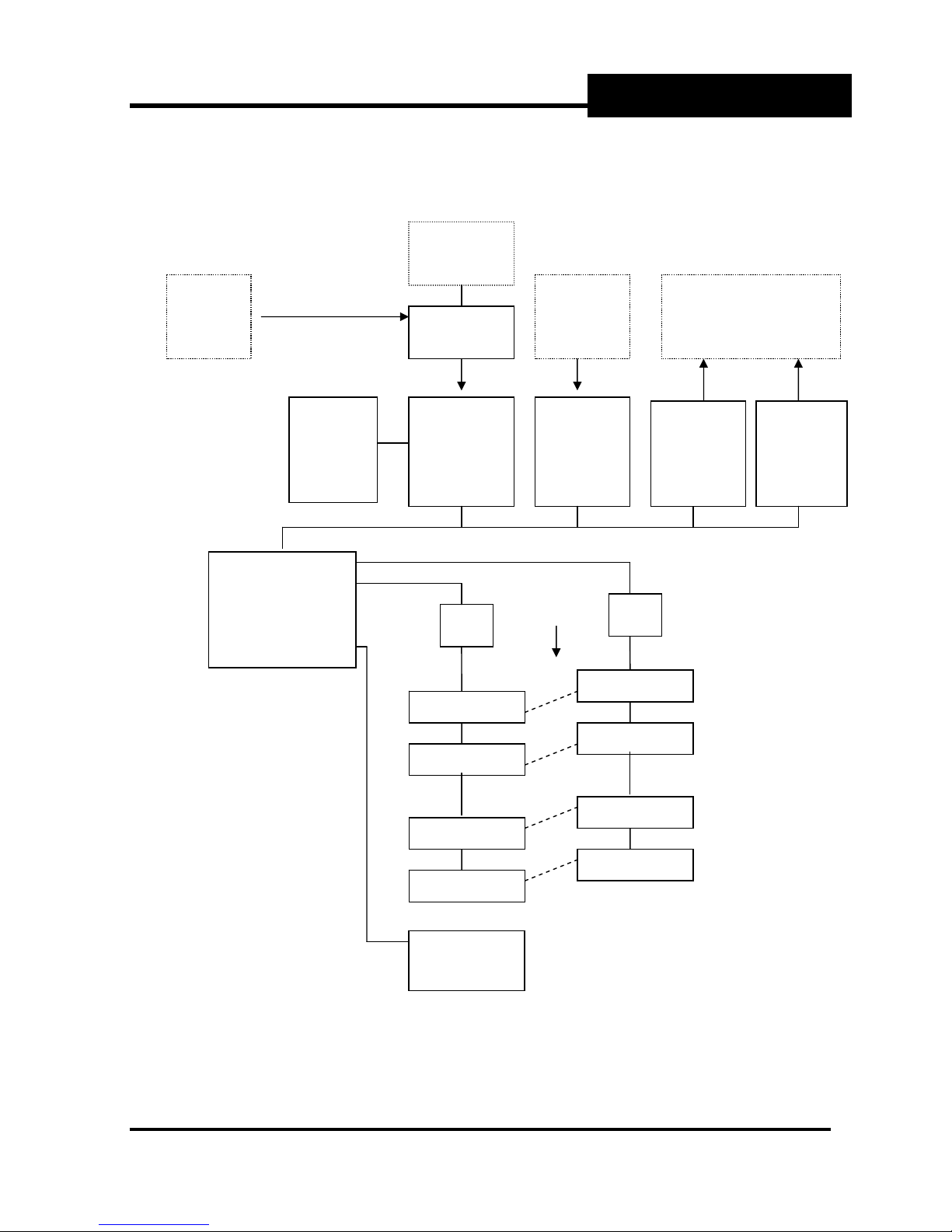

2.2 Family tree

The schematic diagram below is an illustration of a four path system.

Internal

Battery

option

External

power

source

11 to 30 V DC

Auxiliary

depths

Power

control

SYSTEM COMPONENTS

External equipment

Display

Transducer u/s

interface d/s

Level

Central

Processor

inc.

2 x serial I/O

Star

J box

Trans. 1 d/s

Trans. 2 d/s

Trans. 3 d/s

Trans. 4 d/s

Inputs

2 x

4-20 mA,

Flow

Star

J box

Trans. 1 u/s

Trans. 2 u/s

Trans. 3 u/s

Trans. 4 u/s

Outputs

2 x

4-20 mA,

Relays

2 x VFC

Section 2, SYSTEM COMPONENTS, Page 2-2

Level

Transducer

Option

Thermo Fisher Scientific

Page 21

Sarasota 200 Ultrasonic Multipath

Flowmeter

2.3 Flowmeter contents and options

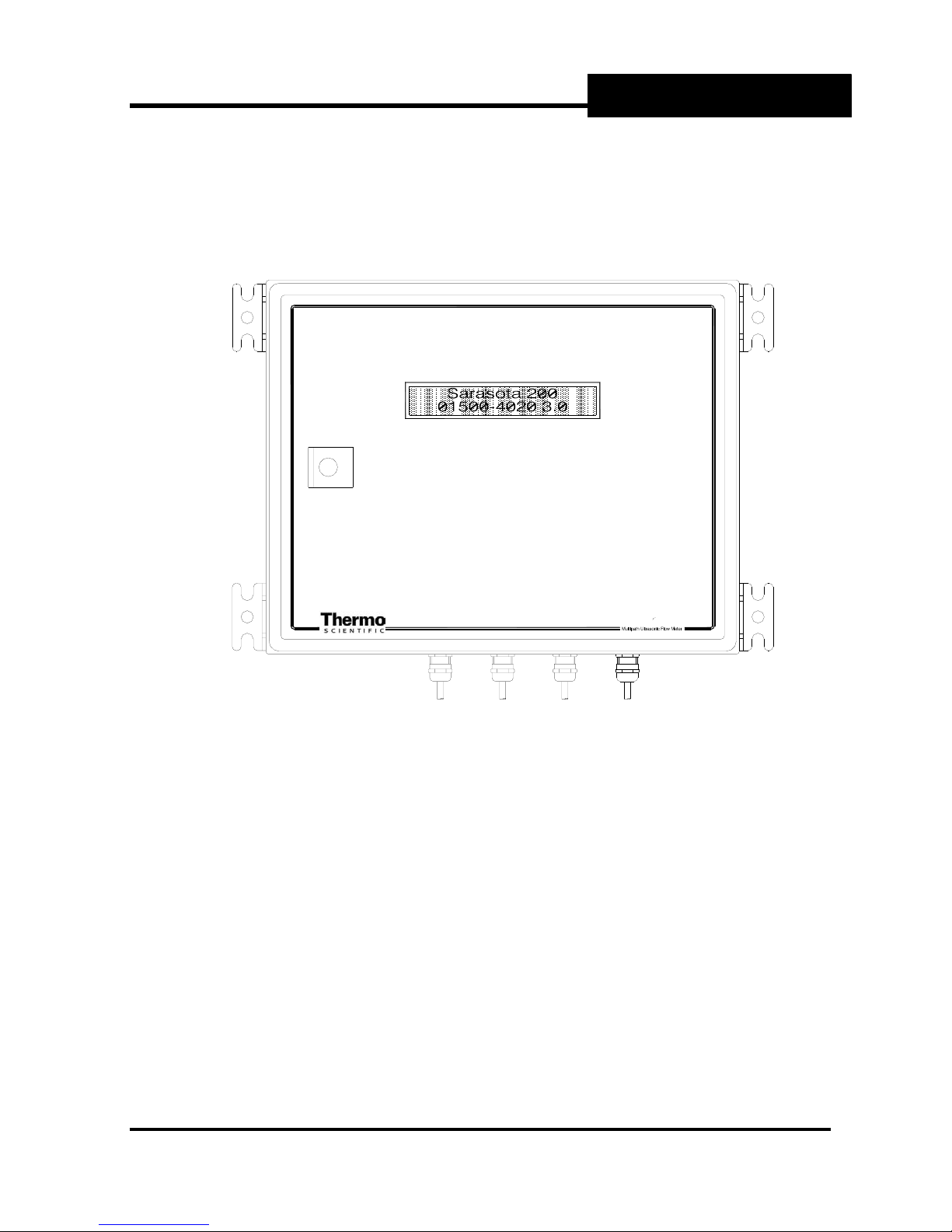

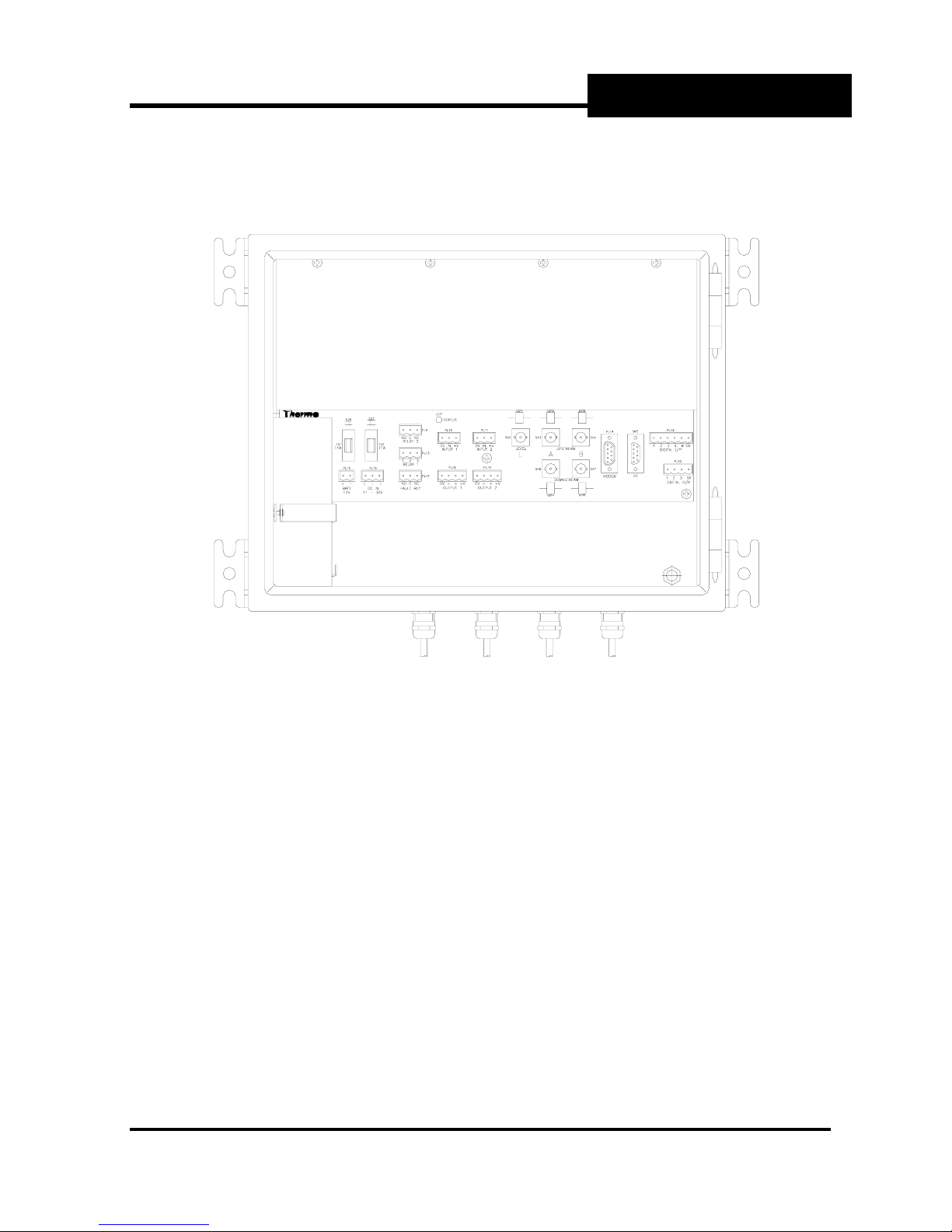

2.3.1 Flowmeter layout

SYSTEM COMPONENTS

s„˜„™•š„@RPP

Fig 1 Sarasota 200 Flowmeter. Front panel view

This view of the Sarasota 200 shows:

• the LCD display (see section 2.3.2.3)

• the cable entry glands at the bottom

• the wall mounting brackets (see Appendix 2 for mounting dimensions)

Section 2, SYSTEM COMPONENTS, Page 2-3

Thermo Fisher Scientific

Page 22

Sarasota 200 Ultrasonic Multipath

Flowmeter

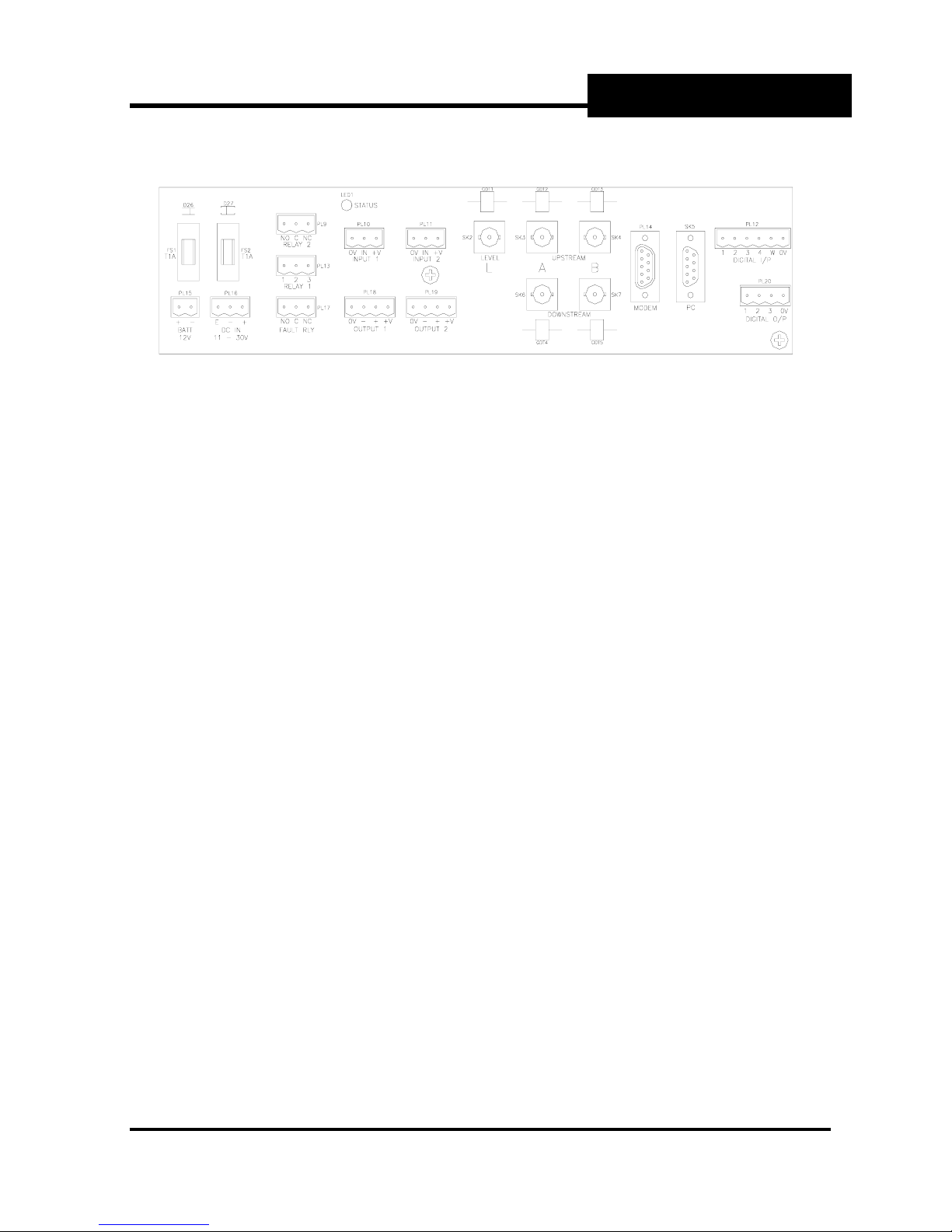

SYSTEM COMPONENTS

Fig 2 Sarasota 200 with lid open showing internal components

This view shows the connection panel protruding from the protective cover and the internal

battery in the bottom left corner.

The connection panel is part of the mother board which contains the input, output and power

management functions. It supports the main processor (CPU) card and the transducer

interface (TIF) card which plug in beneath the protective cover. The connection panel is

shown on a larger scale in Fig 3.

The internal battery allows operation to continue when the external power source has failed.

This is an optional facility which may only be fitted for certain external power sources. See

section 2.3.2.1.1

Section 2, SYSTEM COMPONENTS, Page 2-4

Thermo Fisher Scientific

Page 23

Sarasota 200 Ultrasonic Multipath

Flowmeter

Fig 3. Connection panel - enlarged view.

This panel is where all the connections are made and where the power fuses are located.

Before making any connections the external power source and the internal battery (if fitted)

should be unplugged. The connections are in groups from left to right:

Power connections. See section 2.3.2.1.1

• PL15 – BATT. 2 pin plug for connection to the internal 12volt battery if one is to be fitted.

• PL16 – DC IN. 3 pin plug for connection to the external dc supply.

• Fuses FS1 and FS2

Relay connections. See Specification, Appendix 2

• PL9 – RELAY 2 - VFC, 3 pins, NC, Common and NO

• PL13 – RELAY 1 - SOLID STATE, 3 pins. See Appendix 2

• PL17 – FAULT RLY, 3 pins, NC, Common and NO

Status LED

Inputs See section 2.3.2.1.3

• PL10 – INP 1. 3 pin plug, 4-20 mA

• PL11- INP 2. 3 pin plug, 4-20 mA

Outputs See section 2.3.2.1.4

• PL18 – OUT 1. 4 pin plug, 4-20 mA

• PL19 – OUT2. 4 pin plug, 4-20 mA

Ultrasonic transducer connections. See section 2.3.2.1.2

• SK2 – LEVEL (L). BNC coaxial socket for ultrasonic water level transducer(s) if fitted.

• SK3 – UPSTREAM (A). BNC coaxial socket for upstream velocity transducer(s)

• SK6 – DOWNSTREAM (A). BNC coaxial socket for downstream velocity transducer(s)

• SK4 – UPSTREAM (B). BNC coaxial socket for upstream crossed path velocity

transducer(s) if fitted.

• SK7 – DOWNSTREAM (B). BNC coaxial socket for downstream crossed path velocity

transducer(s) if fitted.

Communications See section 2.3.2.1.7

SK5 – PC. 9 way D socket for RS232 serial link to PC

PL14 – MODEM. 9 way D plug for RS232 serial link to modem.

Digital See section 2.3.2.1.6

PL12, External connection W to 0V to wake up if in intermittent (external control) mode.

PL12 1 to 4 and PL20 – not used.

SYSTEM COMPONENTS

Section 2, SYSTEM COMPONENTS, Page 2-5

Thermo Fisher Scientific

Page 24

Sarasota 200 Ultrasonic Multipath

Flowmeter

2.3.2 Internal components

The enclosure houses the following components

• Mother board with power connections, connectors for transducers and peripheral devices.

• Internal battery option.

• Transducer interface card

• Central processor card, with data storage, input/output and communications circuits

• LCD display

2.3.2.1 Mother board

2.3.2.1.1 Power supply and internal battery option

The power supply input is 11 to 30 Volts DC (see specification in Appendix 2)

For operation from an AC source, an external adapter is required.

If the DC input is 15 Volts or more, the internal battery option may be fitted to allow operation

to continue in the event of power failure. The internal battery is automatically charged by the

power supply when external power is being supplied.

Power consumption and the period of operation from the internal battery option depend on the

mode of operation and are given in the specification.

The fuse values are both T1A.

2.3.2.1.2. Transducer connections

For an in-line configuration of velocity paths there will be 2 star junction boxes, 1 for each

transducer array. The coaxial cable from the upstream star box terminates at SK3. The

coaxial cable from the downstream star box terminates at SK6.

For a crossed configuration of velocity paths there will be 4 star junction boxes, 1 for each

transducer array. The coaxial cable from the upstream left star box terminates at SK3 and the

downstream right at SK6. The coaxial cable from the upstream right star box terminates at

SK4 and the downstream left at SK7.

If an upward facing depth transducer is being used, the coaxial cable from it terminates at

SK2.

SYSTEM COMPONENTS

Section 2, SYSTEM COMPONENTS, Page 2-6

Thermo Fisher Scientific

Page 25

Sarasota 200 Ultrasonic Multipath

Flowmeter

2.3.2.1.3. Depth input signals

These will normally be from auxiliary depth gauges via 4-20 mA. Common examples are

pressure transmitters and downward facing ultrasonic devices. The Sarasota 200 can accept

up to 2 inputs of this type via PL10 and PL11. The power for the 4-20 mA loop can come from

the Sarasota 200 or from the external device.

Pin Signal

name

1 0V N/C 4-20mA 2 IN 4-20mA - 4-20mA +

3 +V 4-20mA + N/C

2.3.2.1.4. Output signal connections (Analogue)

There are 2 analogue output connectors, OUT1 PL18 and OUT2 PL19. The functions to be

output and their ranges are programmable. The power for the 4-20 mA loop can be internal,

from the Sarasota 200 in which case the outputs are not isolated, or from the external device

in which case they are isolated.

Pin Signal

name

1 0V 4-20mA -

2 - 4-20mA + 4-20mA 3 + 4-20mA +

4 +V

2.3.2.1.5. Relay connections

There are 3 relay connections

PL17 System fault relay. This relay has Normally Open (NO), Normally Closed

(NC) and Common (C) contacts. It operates when there is a fault which prevents flow

being calculated. This will occur when no velocity path is functioning or when no

depth is functioning.

PL13 Relay 1. Solid state relay, see Appendix 1, Screens. Although relay 1 may be

programmed for any of the available functions, its faster switching rate makes it

particularly suited for a pulsed output to an external totaliser. See appendix 2

Specification.

PL9 Relay 2. Programmable, see Appendix 1, Screens. This relay has Normally

Open (NO), Normally Closed (NC) and Common (C) contacts.

For example, relay 2 coul d be programmed as a high flow a larm to switch on at a high flow

and off again at a lower value (hysteresis).

Connect for internal

loop power

Connect for internal

loop power

Link 3 – 4

Connect for external

loop power

Connect for external

loop power

SYSTEM COMPONENTS

Comment

Applies to

INP 1 on PL10 and

INP2 on PL11

Comment

Applies to

OUT1 PL18 and

OUT2 PL19

Section 2, SYSTEM COMPONENTS, Page 2-7

Thermo Fisher Scientific

Page 26

Sarasota 200 Ultrasonic Multipath

Flowmeter

2.3.2.1.6. Digital signal connections

When in intermittent mode under external control (see Appendix 1, screens), the external

controlling device must apply a connection between W and OV of PL12 to switch the

Sarasota 200 on.

PL12 - 1 to 4 and PL20 – not used at present.

2.3.2.1.7 Serial communications connectio ns

Serial communications are controlled by the CPU (see 2.3.2.2). It has 2 ports and

connections are made via SK5 and PL14 on the mother board as follows:

• SK5 - RS232 via 9 way D c onnec tor (fe male ). S ee Fi g 3. This po rt is used for c onn ect ion

to a PC for setting up, diagnostics and downloading logged data.

• PL14 - RS232 via 9 way D connector (male). See Fig 3. This port is used for connection

to a modem for remote access for programme alterations, diagnostics and downloading

logged data.

Pin (F) Signal Comment

2 TxD

3 RxD

5 0V

SK5 – RS232, PC connection

9 way female D connector

Pin (M) Signal Comment

1 CD

2 RxD

3 TxD

4 DTR

5 0V

7 RTS

8 CTS

9 RI

PL14 RS232, Modem connection

9 way male D connector

2.3.2.2 Central processor (CPU)

The central processor carries out the control and timing functions, stores and runs the

operating program and stores the data logs.

It controls the two serial i/o ports, see 2.3.2.1.7.

The CPU card plugs into the mother board by removing the cover.

There are no operator settable links on the CPU.

2.3.2.3 LCD display

The LCD has 2 lines of 20 characters to display measurements, computed results and

diagnostic information. (see Section 2.5).

The LCD card is located on the opening l id of the enclos ure.

SYSTEM COMPONENTS

Section 2, SYSTEM COMPONENTS, Page 2-8

Thermo Fisher Scientific

Page 27

Sarasota 200 Ultrasonic Multipath

Flowmeter

2.3.2.4 Transducer interface card (TIF)

The flowmeter has a single TIF which plugs into the mother board by removing the cover. The

transducer connections are made via internal cables to the mother board.

The jumper links on the card should not be altered. When a TIF is changed during s ervice,

the replacement must have the same links set.

2.3.2.5 AC Power adapter module

The adapter is an external module. It allows the Sarasota 200 to be operated from AC mains

electricity between 90 and 264 Volts and between 47 and 63 Hz.

SYSTEM COMPONENTS

Section 2, SYSTEM COMPONENTS, Page 2-9

Thermo Fisher Scientific

Page 28

Sarasota 200 Ultrasonic Multipath

Flowmeter

2.4 Ultrasonic transducers

Each velocity path requi res two transducers and each ultrasonic depth requires one.

The transducers are available in a number of frequencies. See Section 1.2.7 for frequency

selection. The frequency of the ultrasonic depth transducer, if used, is not normally critical.

1 MHz is usually used if the velocity transducer frequency is 1 MHz or 500 kHz otherwise.

The diameter of the transducer is different for different frequencies. This is to maintain the

angular spread of the beam, which is a function of frequency and diameter.

The transducers for the Sarasota 200 are “smart”, with local circuits for the drive voltage (HT)

generation and the receiver amplifier built in to minimise losses and optimise signal-to-noise

ratio. In t he case of the 1 MHz transduc ers the siz e of the tr ansducer is limit ed and the l ocal

circuit is separated from the transducer in a potted in-line housing called a “Tbox”,

Transducers are wired to the flowmeter using the multi-drop method, via “star” junction boxes

in each transducer array. Up to 4 transducers may be joined together in this way.

The maximum c apacity with mul ti-drop is 4 paths and 4 ultrasonic depths. (Auxili ary depths

may also be used via 4-20 mA inputs).

The transducers connected to each star box must be pre-programmed with different

addresses from 1 to 4 to enable each one to be operated separately by the flowmeter.

Specialist equipment is necessary to programme the transducers and it is usual for them to

be supplied with specified addresses.

2.4.3 1 MHz transducers

For use with path lengths up to 10 metres. In cases where serious attenuation is anticipated

(for example, sewage) it is recommended that the use be restricted to 5 metres and a lower

frequency be used above that. Of course the lower frequency requires a greater depth of

water in which to operate and this must be taken into account (see Section 1).

An in-line Tbox is fitted in line with each transducer.

The co-axial cable from the T box must be connected t o a star b ox or exten ded to run d irectly

to the flowmeter. Coaxial cables to the flowmeter enclosure are usually made up on site.

Cables may be supplied to length with made up ends if specified with the order. However this

often makes the installation more difficult where there is the need to pull cables through ducts.

2.4.3 1 MHz intrinsically safe (IS) transducers

1 MHz transducers are available for use in hazardous areas which have atmospheres with a

risk of explosion. The IS specification is given in Appendix 2, specification. The transducer is

internally different from the standard one and a special barrier is wired between it and its

Tbox. The transducer and connecting cable can be used in the hazardous area but the barrier

and all other electronic parts must be located in safe areas.

SYSTEM COMPONENTS

Section 2, SYSTEM COMPONENTS, Page 2-10

Thermo Fisher Scientific

Page 29

Sarasota 200 Ultrasonic Multipath

Flowmeter

SYSTEM COMPONENTS

2.4.3 500 kHz transducers

For use with path lengths above 10 metres. In cases where serious attenuation is anticipated

(for example, sewage) it is recommended that 500 kHz transducer be used above 5 metres.

At the upper end, they may normally be used up to 80 metres. For cases where serious

attenuation is anticipated, lower frequency transducers should be used for paths above 50

metres.

The 500 kHz transducers have the HT and signal amplifiers built in. They are connected

directly to the flowmeter or via star boxes. If ultrasonic depth transducer(s) are being used, it

is usual to use 500 kHz frequency when that frequency is being used for water velocity

measurement.

The transducers are supplied with 5 metres of cable which is connected to a star box or

extended to run directly to the flowmeter. Coaxial cables to the flowmeter enclosure are

usually made up on site. Cables may be supplied to length if so ordered with made-up ends.

However, this often makes the installation more difficult where there is the ne ed to pull ca bles

through ducts.

The 500 kHz transducer also has a temperature sensor built in allowing water temperature at

each transducer to be recorded by the Sarasota 200.

2.4.4 Lower frequency transducers

Consult Thermo Fisher Scientific about low frequency transducers for path lengths above 80

metres or where conditions might attenuate higher frequency signals.

If ultrasonic depth transducer(s) are being used, it is usual to use 500 kHz frequency when

lower frequency transducers are being used for water velocity measurement.

2.4.5 Maximum cable lengths

Item From To Max

length

1 500 kHz transducer

(velocity or depth)

2 1 MHz TBox

(velocity or depth)

3 Star box Flowmeter 300 m Multi-drop

4 500 kHz transducer Star box 5 m Multi-drop

5 1 MHz Tbox 1.5 m std. Longer separations may be supplied.

6 Tbox Star box 5 m Multi-drop

7 500 kHz depth transducer Star box 50 m Multi-drop depth option

8 1 MHz depth TBox Star box 50 m Multi-drop depth option

9 1 MHz IS Barrier Consult factory

10 Barrier Tbox 1 m

Flowmeter 300 m Direct connection

Flowmeter 300 m Direct connection

Comment

(but see depth options items 6 & 7)

(but see depth option item 6)

Consult factory.

(but see depth option item 7)

(star box max 5 m from flowmeter)

(star box max 5 m from flowmeter)

Section 2, SYSTEM COMPONENTS, Page 2-11

Thermo Fisher Scientific

Page 30

Sarasota 200 Ultrasonic Multipath

Flowmeter

2.5 Controls and displays

Fig 1 shows the layout of the front panel. It contains the liquid crystal display (LCD).

Electronic access to the flowmeter is by means of a (laptop) PC via the serial connector

locally or remotely via a modem. This allows the operator to:-

• programme the flowmeter with site data. For example. path lengths, angles, heights

• set up the inputs and outputs (including simulation for test purposes)

• set up the relay functions and values on which they switch

• set up the information to be displayed cyclically on the flowmeter LCD

• display ultrasonic waveforms

• display measurements and results

• display diagnostic data

• download stored data

The information being displayed cycles through items selected from a menu on a PC screen.

2.6 Software & firmware

There are 2 types of software:

• The internal pre-loaded operating software, normally called “firmware”

• The PC software for communicating with the flowmeter, called “GAFA”

2.6.1 Operating firmware

The flowmeter is supplied with the operating firmware already loaded. It would not normally

be necessary to re-load the firmware. In the event that new firmware is to be loaded, Thermo

Fisher Scientific will provide the procedure or carry out the operation. Alternatively upgrades

may be loaded remotely by Thermo Fisher Scientific via a modem.

2.6.2 “GAFA” PC software

GAFA software runs on a PC under Windows. This allows communication with the flowmeter:-

• Via the RS232 PC port on the mother board

• Remotely via a modem connected to the RS232 MODEM port on the mother board

See Appendix 1: GAFA Screens.

2.7 Documentation

In addition to the hardware described above, and possible peripheral equipment, the following

documentation may also be supplied:

• A copy of this manual (additional paper or electronic copies may be supplied)

• Site specific data (Appendix A4: Site Data). Configuration and program data completed

by installation and commissioning engineers.

• Site specific drawings – transducer mounts, site layout, civil details (if part of contract)

• Certificate of conformity (specific test sheets available on request)

• Certificate of approval for Quality Ma nagement System

• On site calibration certificate (if included in the installation contract)

SYSTEM COMPONENTS

Section 2, SYSTEM COMPONENTS, Page 2-12

Thermo Fisher Scientific

Page 31

Sarasota 200 Ultrasonic Multipath

Flowmeter

PERIPHERAL EQUIPMENT

3 PERIPHERAL EQUIPMENT

3.1 Additional items

A number of additional items will be required to complete a flowmeter system. These may

include:-

• Hardware to be installed in the channel on which to mount the transducers.

• Auxiliary depth gauge(s)

• Kiosk to house the flowmeter

• Communications equipment – for example modems, telemetry outstations, GSM

modems.

• Power supplies, for example solar power systems.

plus, often, some civil work for cable ducts, supporting piles etc.

The additional items are often supplied and installed by Thermo Fisher Scientific as part of

the contract, in which case details will be included in Appendix 4: Site Data Book.

3.2 Transducer mounting hardware

Thermo Fisher Scientific has extensive experience of transducer mounting system design and

maintains a comprehensive computerised library. Please consult Thermo Fisher Scientific for

a quotation to design and supply a suitable system.

Section 3, PERIPHERAL EQUIPMENT, Page 3-1

Thermo Fisher Scientific

Page 32

Sarasota 200 Ultrasonic Multipath

Flowmeter

This page is blank

PERIPHERAL EQUIPMENT

Section 3, PERIPHERAL EQUIPMENT, Page 3-2

Thermo Fisher Scientific

Page 33

Sarasota 200 Ultrasonic Multipath

Flowmeter

4 INSTALLATION

4.1 Safety

SAFETY NOTICE

The installation of the Thermo Scientific Sarasota 200

flowmeter may involve a number of steps which require

special skills, training and special equipment. Examples

include:

• Electrical installation

• Working on construction sites

• Working near water (may be deep or fast flowing)

• Lifting equipment

• Working at height

• Working from boats

• Confined space working

It is recommended that prior to the installation the installer

should write a method statement detailing:

• The scope and purpose of the work,

• The steps in the operation,

• Interaction with others,

• The personnel to be involved,

• Their qualifications for the work,

• Protective clothing and equipment,

• Machinery, tools etc.

• Emergency contacts and procedures.

A risk assessment should be carried out and both the

method statement and risk assessment should be

approved by the person responsible for Health and Safety

on the site.

Thermo Fisher Scientific accepts no responsibility for the

safety of personnel other than its own employees in the

installation and commissioning of the Thermo Scientific

Sarasota 200 flowmeter and accessories supplied.

INSTALLATION

Section 4 INSTALLATION Page 4-1

Thermo Fisher Scientific

Page 34

Sarasota 200 Ultrasonic Multipath

Flowmeter

4.2 General

It is usually necessary for some preparatory work to be carried out prior to installation of the

flowmeter system. This work is often performed under a separate contract and typically

includes:-

• Installation of supporting structures for transducer mounts, for example, piles in a river,

brackets on concrete channel walls.

• Installation of ducts o r cable tray f or the interconnecting c ables.

• Installation of a suitable housing for the flowmeter and peripheral equipment. This could

be an existing building or a kiosk.

• Provision of a power supply.

• Provision of a PSTN connection.

The installation of the equipment on site follows the above. It is normal practice to carry out a

risk assessment and to write a method statement to be agreed by the client before startin g

work. The installation work is often restricted to times when suitable site conditions apply.

It is recommended that the installer of the flowmeter should inspect the preparatory work prio r

to mobilising resources for the installation.

4.3 Unpacking and laying out

If site and general assembly drawings were specified as part of the supply contract they will

normally have been supplied and accepted prior to delivery of the equipment. The drawings

will be a useful guide to checking the inventory of equipment delivered.

The equipment supplied should be carefully unpacked and checked for content and damage.

The transducers may have been supplied in rack assemblies ready to be fixed to the

supporting structure. There will normally be two or four racks (for in-line or crossed paths). In

large channels or those with complex shapes, there may be more than two racks, for

example, in a stepped channel with a low level channel and a wider high one.

If the racks have not been assembled, this may be carried out on site according to the

assembly drawings.

It is important to check that sufficient cable has been supplied for connecting transducers and

that suitable fixings for all the items have been supplied or separately procured.

4.4 Installing transducer assemblies

WARNING – Installing transducer racks may involve working near deep or

contaminated water and/or in confined spaces. Appropriate precautions and suitably

qualified personnel should be used.

The transducer rack assemblies should be installed in their prepared positions according to

the drawin gs and method s tatements.

Care must be taken not to damage the coaxial cables during this operation.

See Section 2.4 for transducer and junction box configuration.

Depth gauge transducers or transmitters may be fitted to one or more of the transducer racks

or have a separate fitting.

INSTALLATION

Section 4 INSTALLATION Page 4-2

Thermo Fisher Scientific

Page 35

Sarasota 200 Ultrasonic Multipath

Flowmeter

4.5 Connecting transducers to flowmeter

Cables for the ultrasonic transducers should be labelled for identification, cut and pulled

through the ducts or attached to trays and run back to the flowm eter. Connectors should be

fitted to each end according to the instructions supplied with the connectors.

Where 1 MHz transducers are being installed, the connections are via the transducer boxes

(see Section 2.4.1) which are fitted at the rack assemblies.

Cables for depth gauges other than Sarasota ultrasonic transducers should also be pulled

back to the flowmeter. Generally, if the depth gauge is a pressure transmitter, the attached

cable will be supplied long enough for this purpose without joining. Care must be taken to

ensure that the transducer vent, which is part of the cable, is open to the atmosphere and in

no danger of becoming blocked or submerged in water.

The transducer cables are to be terminated at the flowmeter end and plugged in to the

flowmeter connection panel as shown in Section 2.3.1.

Ultrasonic path numbers are as shown, numbered from the lowest path. If 2 paths are at the

same height the firmware will take them as crossed for the purposes of slice allocation and

flow calculation (see 1. 2.5).

4.6 Transducer alignment

At this stage it is usual practice to align the transducers. Each transducer should point at its

partner to within ±1

• Pre-set alignment derived from construction drawings.

• Visual methods involving pointers and sighting arrangements.

• Low power laser methods.

If the transducers are in the water, only the first of these may be possible and final adjustment

should then be carried out by adjustments to maximise signals during commissioning.

4.7 Output connections

Output signals should be wired to the peripheral devices according to the connection tables

given in section 2.3. In some cases standard cables will have been provided, eg RS232, or

pre-made cables will have been ordered as part of the contract.

Note For compliance with EMC emissions control, I/O cables should be screened and the

screen connected to a 0V pin. Where the connector is a ‘D’ t ype connector, the screen may

alternatively be connected to the connector body if metal.

4.8 Power Connection

Connection should be made to the external power source according to local or national

regulations. The flowmeter is supplied with a standard 11 to 30 volt DC input with an optional

external mains convertor for connection to an AC source in the range 90 to 264 volt AC, 47 to

63 Hertz. This may be connected to the power outlet via a plug or, more usually via a

switched spur. This work should be carried out by a per son with the appropriate qualificatio ns.

o

. The method used will vary according to the conditions.

INSTALLATION

Section 4 INSTALLATION Page 4-3

Thermo Fisher Scientific

Page 36

Sarasota 200 Ultrasonic Multipath

Flowmeter

This page is blank

INSTALLATION

Section 4 INSTALLATION Page 4-4

Thermo Fisher Scientific

Page 37

Sarasota 200 Ultrasonic Multipath

Flowmeter

COMMISSIONING

5 COMMISSIONING

5.1 Site dimensions

If this information is not already available, it will be necessary to carry out a dimensional

survey of the installed transducers and the channel in order to programme the flowmeter. It

will be necessary to determine the following:-

• length, angle and the heights of each path,

• average cross section profile, if different from that defined by the paths,

• mean bed level (MBL),

• height offset of the level transducers and,

• relationship between the local heights and a fixed datum if not

MBL.

This manual does not cover surveying techniques. However, for small sites physical

measurements are easily carried out by means of a tape measure. Angles may be

determined by triangulation.

5.2 Powering up

Check that the flowmeter has been connected up correctly and the cards are plugged in

securely.

Load the GAFA software into a PC and plug in to the PC serial port.

Switch on the power source.

The LCD will be activated though the display may be meaningless at this stage.

5.3 Programming

The flowmeter should be programmed via the PC as described in Appendix 1: GAFA

Screens. The programme details should be recorded to become part of Appendix 4: Site

Data.

Appendix 4: Site Data is a useful checklist covering all programmed data, some of which may

not be required for any particular site.

5.4 Setting up

5.4.1 Velocity paths

Select “Manual” and set the gain and voltage for each path to obtain a clean waveform and

detection point.

5.4.2 Ultrasonic levels

Select “Manual” and set the gain and voltage for each level to obtain a clean waveform and

detection point.

working with respect to

Section 5, COMMI SS I O NIN G Page 5-1

Thermo Fisher Scientific

Page 38

Sarasota 200 Ultrasonic Multipath

Flowmeter

5.4.3 Auxiliary levels – analogue input

Set the input range. This allows the input to be linearised, but most level devices will be

sufficiently linear and only need 2 points to define the input. On the table, define 4 mA as the

minimum, 20 mA as the maximum and enter the depth offset (level above datum).

5.5 Outputs

The outputs are selected from analogue and relays.

Analogue outputs may be forced to a value of mA which may be entered via the PC. See

“Loop Test”, Appendix 1, A1.4.1.2. This is a valuable tool for setting up the link to peripheral

equipment. The forced values may be confirmed by a calibrated multi-meter.

Correspondence between the displayed selected parameter value and the output should be

checked. It is possible to force the outputs by temporarily changing the set-up, for example

changing the level datum will affect not only the apparent level measurement but also the

flow.

Alarm thresholds may be altered to check relay operation.

Alarm outputs may be checked by a calibrated multi-meter and verified as being received by

the destination device.

COMMISSIONING

Section 5, COMMI SS I O NIN G Page 5-2

Thermo Fisher Scientific

Page 39

Sarasota 200 Ultrasonic Multipath

Flowmeter

CALIBRATION/

VERIFICATION

6 CALIBRATION/VERIFICATION

Flowmeters of this type do not normally require calibration. Exceptions are where there are

significant unmeasured areas, for example, behind transducers, or where local conditions

might create atypical velocity profiles and a small number of velocity paths are deployed. See

Section 1: Introduction and Appendix 3: References.

However, it is normal to carry out periodic checks to verify the overall performance of the flow

determination.

Whether for calibration or verification purposes, the comparison method to be used will be the

same and will depend on the site.

Reference is made to ISO 748 for details of methods. See Appendix 3: References.

The most common method used is by current metering using a calibrated rotating element or

electromagnetic current meter. Recently the use of an acoustic Doppler profiler (ADP) has

become more common for this purpose. This has enabled the checking process to become

much quicker and, where high flows in rivers are concerned, safer too.

Care should be taken to use repeated checks and to minimise the experimental uncertainties

which could otherwise be greater than the uncertainty of the ultrasonic flowmeter.

Section 6 CALIBRATION/VERIFICATION Page 6-1

Thermo Fisher Scientific

Page 40

Sarasota 200 Ultrasonic Multipath

Flowmeter

This page is blank

CALIBRATION/

VERIFICATION

Section 6 CALIBRATION/VERIFICATION Page 6-2

Thermo Fisher Scientific

Page 41

Sarasota 200 Ultrasonic Multipath

Flowmeter

MAINTENANCE

7 MAINTENANCE

There is little maintenance as such relating to the flowmeter itself. However, the river or

channel must be kept free of weed, silt and other obstructions to avoid interruption of the

ultrasonic paths or changing the cross section area which would affect the accuracy of flow

determination.

Periodic checks on the functioning of the flowmeter and verification of the flow as calculated

are recommended.

7.1 Channel maintenance

7.1.1 Weed

• If weed tends to grow in the channel, it must be kept cut.

• Weed must be kept clear from between the transducer arrays where it may stop the

passage of sound between the transducers.

• Weed should also be controlled on the approach to the gauged section and immediately

downstream of it where its presence c ould distort the velocity profile.

The user must decide on the season al cu t t i n g re gi m e t o suit the channel.

7.1.2 Profile

Periodically the channel shape should be checked to determine whether it has changed since

the flowmeter was programmed. It is particularly important to check the bed where silt might

have been deposited or scouring could have occurred.

Changes may be required to the programmed channel shape or mean bed level.

In serious cases, it may be necessary to dredge the channel, taking care not to damage the

transducers.

The user must decide on the checking regime to suit the channel.

7.1.3 Debris

Under high flow conditions it is not uncommon for debris to be washed along the channel.

Whilst the design of the transducer supports should be such as to minimise the risk of

snagging this debris, separate deflectors or devices intended to capture it may be employed.

If the channel is prone to this phenomenon, the user must instigate an appropriate debrisclearing regime.

7.2 Flowmeter maintenance

There are no parts requiring maintenance except that the transducers should be checked

occasionally for a build-up of surface coating, for example by grease, and for misalignment

caused by physical shocks. These checks may be carried out along with the channel

maintenance.

Normally it is possible to obtain advance warning of problems by checking the signal quality.

This may be done on site or remotely via GAFA (Appendix 1: GAFA Screens).

Section 7, MAI N T E NANCE Page 7-1

Thermo Fisher Scientific

Page 42

Sarasota 200 Ultrasonic Multipath

Flowmeter

7.3 Routine checks

7.3.1 Remote

Remote checks of operation of all velocity paths and depths are easily carried out via GAFA.

It is recommended that a monthly routine should be set up to handle this.

If the flowmeter is fitted with the relay option, one of the relays may be programmed to initiate

an early warning call via a telemetry outstation.

7.3.2 On site

It is recommended that regular checks be made on site. These should include:

• A visual observation of the equipment in the channel and the flowmeter.

• A functional check of the operation of the paths, levels and outputs.

• A c h ec k on t he operation of the i nternal battery .

• A verification of calculated flow by a comparison method, see Section 6: Calibration

Any corrective work should be taken at the time if possible or reported for subsequent action.

MAINTENANCE

Section 7, MAI N T E NANCE Page 7-2

Thermo Fisher Scientific

Page 43

Sarasota 200 Ultrasonic Multipath

g

Flowmeter

APPENDIX 1 GAFA PC SOFTWARE

APPENDIX 1 “GAFA” PC SOFTWARE

A1.1 Screen organisation chart

A1.2 Main Screen

File A1.3 View A1.4 Config A1.5 Log A1.6 Waveform A1.7 Password Help

A1.3.1

Flow & Level

A1.3.2

Velocity Paths

A1.3.3

Flow Meter Status

A1.4.1

Station Config

A1.4.1.1

System

A1.4.1.2

I/O Allocation

A1.4.1.3

Relays

A1.4.1.4

Comms

A1.4.2

Channel Config

A1.4.2.1

Channel

A1.4.2.2

Velocity Path

A1.5.1

Logging

A1.5.1.1

Log Confi

A1.6.1

Waveform

Capture

Enter Password

Appendix 1 GAFA PC Software Page A1-1

A1.4.2.3

Level

A1.4.2.4

Profile

A1.4.2.5

Flow Est

A1.4.3

Read Gauge Config

A1.4.4

Write Gauge Config

Thermo Fisher Scientific

Page 44

Sarasota 200 Ultrasonic Multipath

Flowmeter

A1.2 Main Screen

APPENDIX 1 GAFA PC SOFTWARE

Notes

• This is the main screen showing current measurements and status.

• Measurements displayed on this screen are subject to averaging as set up on the

“Station Configuration - System” screen A1.4.1.1.

• Cumulative volume is the total volume passed since last reset via the “Station

Configuration – System” screen A1.4.1.1.

• If more than 1 level input is used, the Leve l dis play ed on this screen is the combination

subject to the arbitration rules given in section 1 of this manual.

• Average temperature is taken from all sensors with transducers that are in the water.

Transducers above the water are not included. Temperature is measured by sensors in

the transducer smart electronic circuits. For 1 MHz transducers this will often not

water temperature since the circuits are in Tbox es which may b e out of the wat er.

Individual temperatures may be viewed on the “Velocity Paths” screen A1.3.2.

• Data presented on the screen is automatically refreshed every 30 seconds.

• Click on “Refresh” to update immediately.

• Click on menu bar across the top of the screen to obtain drop down menus for other

screens.

• Pressing Escape on the PC keyboard when in other scree ns causes a return to the

previous screen.

be

Appendix 1 GAFA PC Software Page A1-2

Thermo Fisher Scientific

Page 45

Sarasota 200 Ultrasonic Multipath

Flowmeter

A1.3 “View” Screens

A1.3.1 (View) Flow and Level

APPENDIX 1 GAFA PC SOFTWARE

Notes

• “Instantaneous” data is based on the measurement cycle of 10 seconds or 1 minute as

set on the “Station Configuration – System” screen A1.4.1.1.

• “Average” is based on the period set on the “Station Configuration – System” screen

A1.4.1.1.

• “Daily Mean” is the flow for the previous 24 hour period to the DMD time as set on the

“Station Configuration – System” screen A1.4.1.1. The Daily Mean value will only change

at the set time.

• “Cumul ative Total” volume is from the date indicat ed as set via th e “Station Configuration

– System” screen A1.4.1.1.

• “Cumulative, Today” is from the DMD time to the present time.

• “Level Inputs” are the instantaneous separate inputs used to calculate the average level.

• Click on “Refresh” to update the display.

• Click on X or Cancel or press the escape key to return to the Main screen.

Appendix 1 GAFA PC Software Page A1-3

Thermo Fisher Scientific

Page 46

Sarasota 200 Ultrasonic Multipath

Flowmeter

A1.3.2 (View) Velocity Paths

APPENDIX 1 GAFA PC SOFTWARE

Notes

• “Success” indicates the proportion of “flights” of sound pulses resulting in acceptable

signals received.

• “VOS” is the velocity of sound measured by each path. It is the path length divided by

the transit time.

• “Velocity” is the water velocity calculated for each path. (see Section 1 of the manual)

• “TOF” is the ultrasonic time of flight or transit time

• “Diff” is the difference in transit times between the upstream and downstream

directions.

• “Temp” is the temperature measured by sensors in the transducer smart electronics.

This will be water temperature for transducers other than 1 MHz immersed in water.

• Click on “Refresh” to update the displayed data.

• Click on X or Cancel or press the escape key to return to the Main screen.

Appendix 1 GAFA PC Software Page A1-4

Thermo Fisher Scientific

Page 47

Sarasota 200 Ultrasonic Multipath

Flowmeter

A1.3.3 (View) Flow Meter Status

APPENDIX 1 GAFA PC SOFTWARE

Notes

• “Software IDs” are the issue numbers of the software loaded on the system cards

• “CPU Power Rails” show the values of the internal supply voltages.

• “Status” conditions are red for a fault and green for OK.

• For “Channel” status, “Level” is red if all the levels are faulty and “Path” if all the paths

are faulty. These are “fatal” conditions that could prevent flow being calculated. Under

these conditions, a flow figure could still be estimated using the flow estimation table,

See A1.4.2.5

• “Relay Status” indications depend on conditions as set on the “Station Configuration –

Relay” screen.

• Click on “Refresh” to update displayed data.

• Relays may be reset on this screen or alternatively on the “Station Configuration -

Relays” screen A1.4.1.3.

• Click on X or Cancel or press the escape key to return to the Main screen.

Appendix 1 GAFA PC Software Page A1-5

Thermo Fisher Scientific

Page 48

Sarasota 200 Ultrasonic Multipath

Flowmeter

A1.4 Configuration screens

A1.4.1 Station Configuration

A1.4.1.1 System

APPENDIX 1 GAFA PC SOFTWARE

Notes

This screen is us e d t o

• Set the site name or number if used (ID)

• Select the flow calculation method (See section 1 of th e manual.)

• Select the measuring cycle time (default 10 seconds)

• Set the averaging period. This is a rolling average, updated at each measuring cycle.

• Set the time of day for the Daily Mean Discharge (daily mean flow) calculation.

• Set the date and time

• Select the power source ( used by the power supply alarm threshold circuits).

• Select low power control (if required) via external interrupt or internal timer.

• Select the units of measurement.

• Select the items to be displayed

on the LCD by clicking on “Edit

Display List” (see picture, right)

• “Reset Totals” clears the

cumulative flow total.

• Write selection to Sarasota 200

by clicking “Write to Gauge”.

• Additional data is for changing

the password (See A1.7) and

altering the date format.

• Click on X or press the escape

key to return to the Main screen.

Appendix 1 GAFA PC Software Page A1-6

Thermo Fisher Scientific

Page 49

Sarasota 200 Ultrasonic Multipath

Flowmeter

A1.4.1.2 (Station configuration) I/O Allocation

APPENDIX 1 GAFA PC SOFTWARE

Notes - Level Inputs

• Click on “Allocate” to get pop up sc reen (right)

• Up to 4 levels in total may be selected

• For each one, select a type :

Not Used if none allocated to that level input

USL for an ultrasonic upward facing

transducer. For this selection, a multi-drop

address between 1 and 4 must be specified

via the Input drop down. If there is only 1 USL,

use Input 1 on the drop down.

Analogue for 4-20 mA auxiliary depth inputs.

For this selection, input 1 or 2 must be

selected on the drop down.

Fixed for a channel where the depth does not

change, e.g a full pipe.

• Click on “Write” to confirm selected levels to the Sarasota 200.

• Click on “Exit” to abandon selection.

• See “Channel Configuration – Level” A1.4.2.3 to set up the selected levels.

Appendix 1 GAFA PC Software Page A1-7

Thermo Fisher Scientific

Page 50

Sarasota 200 Ultrasonic Multipath

Flowmeter

Notes – U/S Path Inputs

• Click on “Allocate” to get pop up sc reens (right)

• Up to 4 velocity paths in total may be selected

• If the “2 00 Cross Path Application” is not

the paths will be allocated to an in-l ine

configuration using connectors A only.

• Paths, numbering from the bottom, shall be

allocated to A connectors (upstream and

downstream) via addresses 1 to 4

• If the “2 00 Cross Path Application” is checked

(right), the allowabl e configurations are:

- up to 2 paths allocated to A and 2 to B

- up to 3 paths allocated to A and 1 to B

• A relay may be selected for any path or paths.

The relay will then operate in the event of a fault

on any

of the paths for which the relay is selected

• Click on “Write” to confirm selected levels to the

Sarasota 200.

• Click on “Exit” to abandon selection.

• See “Channel Configuration – Velocity Paths”

(A1.4.2.2) to set up the selected paths.

Notes – Analogue Outputs

• There are 2 analogue (4-20 mA) outputs.

• Click on each one to get the drop down and allocate to functions:

Flow

Level

Velocity

DMD

• Ranges are set up on this screen for the

functions selected by entering numbers for

“Zero” and “Full Scale”

• Click on “Write” to confirm selected analogue

outputs to the Sarasota 200.

• Click on “Loop Test” to obtain pop up (right).

• Select output 1 or 2 and the value of mA to be

applied to the output for test purposes. Before

using loop test, the analogue output must be

set to “None” on the drop down menu.

APPENDIX 1 GAFA PC SOFTWARE

ticked,

Appendix 1 GAFA PC Software Page A1-8

Thermo Fisher Scientific

Page 51

Sarasota 200 Ultrasonic Multipath

Flowmeter

A1.4.1.3 (Station configuration) – Relays

APPENDIX 1 GAFA PC SOFTWARE

Notes

Relay 1 or 2.

• Select and allocate an “Action”. For each action, certain parts of the “Configuration” box

are enabled and should be set up.

Totaliser

totaliser pulses to be scaled. Note that relay 1 is a solid state relay and is more

suitable for this action than relay 2. See the Specification in Appendix 2 of the

manual.

Flow Estimate Alarm

being used in place of the normal transit time measurements.

Path Failed

been selected via the I/O Allocation screen A1.4.1.2.

Level Failed

Level Low Alarm

Level High Al arm

Flow Low Alarm

Flow High Alarm

Fault Relay.

• Set the condi tions, any o ne of which will cause the fault relay to operate.

• Click on “Reset Relays” to clear all the relays which h ave been set to “Latching”.

• Click on “Write To Gauge” to confirm selections to the Sarasota 200 or “Cancel” to

abandon.

. When this is selected, the “Totaliser Scaling” box is enabled to allow the

. If selected, this is actioned when the flow estimation table is

. If selected, this is actioned for failure of any of the paths which have

. If selected, this is actioned when all the levels fail.

. Define the low level threshold to operate the relay selected.

. Define the high level threshold to operate the relay selected.

. Define the low flow threshold to operate the relay selected.

. Define the high flow threshold to operate the relay selected.

Appendix 1 GAFA PC Software Page A1-9

Thermo Fisher Scientific

Page 52

Sarasota 200 Ultrasonic Multipath

Flowmeter

A1.4.1.4 (Station Configuration) - Comms

APPENDIX 1 GAFA PC SOFTWARE

Notes

• Use this screen to set up the serial ports.

• Click on “Write To Gauge” to confirm selections to the Sarasota 200 or “Cancel” to

abandon.

• When the modem comms configuration is changed, the dial-up connection will be lost and

it will be necessary to re-dial to re-establish comms.

Appendix 1 GAFA PC Software Page A1-10

Thermo Fisher Scientific

Page 53

Sarasota 200 Ultrasonic Multipath

Flowmeter

A1.4.2 Channel Configuration

A1.4.2.1 (Channel Configuration) Channel

APPENDIX 1 GAFA PC SOFTWARE

Notes

• If a “Fixed Datum” is used, the height of the bed of the channe l must be specified relative

to the fixed datum via this screen. Also all path heights and depth offsets must be

specified relative to the fixed datum via the “Channel Configuration – Velocity Path” and

“Channel Configuration – Level” screens A1.4.2.2 and A1.4.2.3.

• If the “Mean Bed Level” datum is used, the Sarasota 200 sets the “Bed Level” to zero. All

path heights and depth offsets must be specified relative to the Mean Bed Level via

“Channel Configuration – Velocity Path” and “Channel Configuration – Level” screens

A1.4.2.2 and A1.4.2.3.

• “Level Arbitration” is the allowable difference between individual level measurements.

• “Fire Sequence” is normally Simultaneous. “Alternate” should only be used if there is a

risk of reflections from a transducer being confused with signals being transmitted by its

partner. “Alternate” will slow the operation.