Page 1

Valid: 01.2009 / 50118069

Operating Instructions

Safety Cabinets

Safe 2020

Maxisafe 2020

Page 2

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

2

© 2009 Thermo Fisher Scientific Inc. All rights reserved.

These operating instructions are protected by copyright. Rights resulting thereof, particularly reprint, photomechanical or digital postprocessing or reproduction,

even in part, are only allowed with the written consent of Thermo Electron LED GmbH.

This regulation does not apply to reproductions for in-plant use.

Trademarks

All trademarks mentioned in the operating instructions are the exclusive property

of the respective manufacturers.

Thermo Electron LED GmbH

Robert-Bosch-Straße 1

D - 63505 Langenselbold

Germany

Page 3

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

3

Contents

1. General notes ......................................................................................... 6

1.1 General safety instructions ............................................................. 6

1.2 Warranty ......................................................................................... 7

1.3 Explanation of symbols................................................................... 7

1.3.1 Symbols used in the operating instructions ............................. 7

1.3.2 Symbols on the device ............................................................. 8

1.4 Use of the device ............................................................................ 8

1.4.1 Correct use ............................................................................... 8

1.4.2 Incorrect use: ............................................................................ 9

1.5 Standards and safety regulations ................................................... 9

2. Delivery ................................................................................................. 10

2.1 Standard components................................................................... 10

2.2 Acceptance inspection.................................................................. 10

2.3 Transport lock and device packaging ........................................... 10

3. Installation ............................................................................................ 11

3.1 Ambient conditions ....................................................................... 11

3.2 Room ventilation ........................................................................... 11

3.3 Correct location ............................................................................. 12

3.4 Installation in line .......................................................................... 12

3.5 Transport ....................................................................................... 13

4. Unit description .................................................................................... 14

4.1 Overall view .................................................................................. 14

4.2 Safety system ............................................................................... 17

4.3 Filter system ................................................................................. 18

4.4 Controls and display ..................................................................... 20

4.5 Sample chamber access .............................................................. 21

4.6 Device interfaces .......................................................................... 22

4.7 Sample chamber illumination ....................................................... 23

4.8 UV lamp unit ................................................................................. 24

4.9 Working area ................................................................................. 24

5. Start-up.................................................................................................. 25

5.1 Initial operation ............................................................................. 25

5.2 Installing unit and accessories ..................................................... 25

5.3 Levelling the cabinet ..................................................................... 27

5.4 Power supply connection ............................................................. 28

5.5 RS 232 interface connection ........................................................ 30

5.6 UV connection .............................................................................. 30

5.7 Installation test .............................................................................. 31

6. Handling and control ........................................................................... 32

6.1 Display .......................................................................................... 32

6.1.1 Functions of the display components ..................................... 32

6.1.2 Display during the calibration routine ..................................... 33

6.1.3 Display in OFF mode .............................................................. 33

6.1.4 Display in work mode ............................................................. 33

6.1.5 Power interruption .................................................................. 33

6.1.6 Display and functions after a power failure ............................ 34

6.1.7 Failure messages ................................................................... 34

6.2 Description of the operating modes ............................................. 35

6.3 Operation system ......................................................................... 37

6.3.1 Basic functions ....................................................................... 37

6.3.2 Moving the front window to the working position ................... 39

6.3.3 Silencing the audible alarm signal ......................................... 39

6.3.4 Switching the illumination on and off ...................................... 40

Page 4

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

4

Contents

6.3.5 Activating and deactivating the internal power supply ........... 40

6.3.6 Displaying the UV disinfection time ........................................ 40

6.3.7 Activating and deactivating the potential-free contact

(optional) ................................................................................. 40

6.3.8 Switching the cabinet to OFF mode ....................................... 41

6.3.9 Setting the time ....................................................................... 41

6.3.10 Displaying the downflow velocity ........................................... 42

6.3.11 Displaying the operating hours of the HEPA filters ................ 43

6.3.12 Displaying the Performance Factor ........................................ 43

6.3.13 Setting and activating the timer .............................................. 44

6.3.14 Deactivating the timer ............................................................. 45

6.3.15 Setting the UV disinfection time ............................................. 46

6.3.16 Starting the UV disinfection .................................................... 46

6.3.17 Cancelling the UV disinfection ............................................... 47

6.3.18 Activating the stop watch ....................................................... 47

6.4 Pilot switch .................................................................................... 48

6.4.1 Moving the front window ......................................................... 48

6.4.2 Switching the device to OFF mode ........................................ 49

7. Operation .............................................................................................. 50

7.1 Hygiene preparations for the sample chamber ............................ 50

7.2 Preparing the sample chamber .................................................... 50

7.3 Response to failure messages ..................................................... 50

7.4 Work rules ..................................................................................... 51

8. Shut-down............................................................................................. 52

8.1 Interrupting an operation .............................................................. 52

8.2 Shutting the unit down .................................................................. 52

9. Cleaning and decontamination .......................................................... 53

9.1 Decontamination procedure ......................................................... 53

9.2 Wipe/spray disinfection................................................................. 53

9.3 UV disinfection after a wipe/spray disinfection ............................ 54

9.3.1 UV disinfection using the integral UV lamps .......................... 54

9.3.2 UV disinfection using a mobile UV device ............................. 55

9.3.3 Changing the UV disinfection time ............................................ 55

9.4 Sterilization with formaldehyde..................................................... 56

9.5 Cleaning the exterior surfaces...................................................... 56

9.6 Cleaning the floorpan ................................................................... 56

10. Maintenance ......................................................................................... 57

10.1 Inspection...................................................................................... 57

10.2 Service .......................................................................................... 57

10.2.1 UV lamps ................................................................................ 57

10.2.2 Sample chamber illumination ................................................. 58

10.2.3 Replacing the front window seal ............................................ 58

10.3 Retrofitting and repairs ................................................................ 59

11. Disposal ................................................................................................ 60

11.1 Disposal procedure ...................................................................... 60

12. Technical data ...................................................................................... 62

13. Device log ............................................................................................. 69

14. Certificate of decontamination ........................................................... 70

Page 5

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

5

Figures

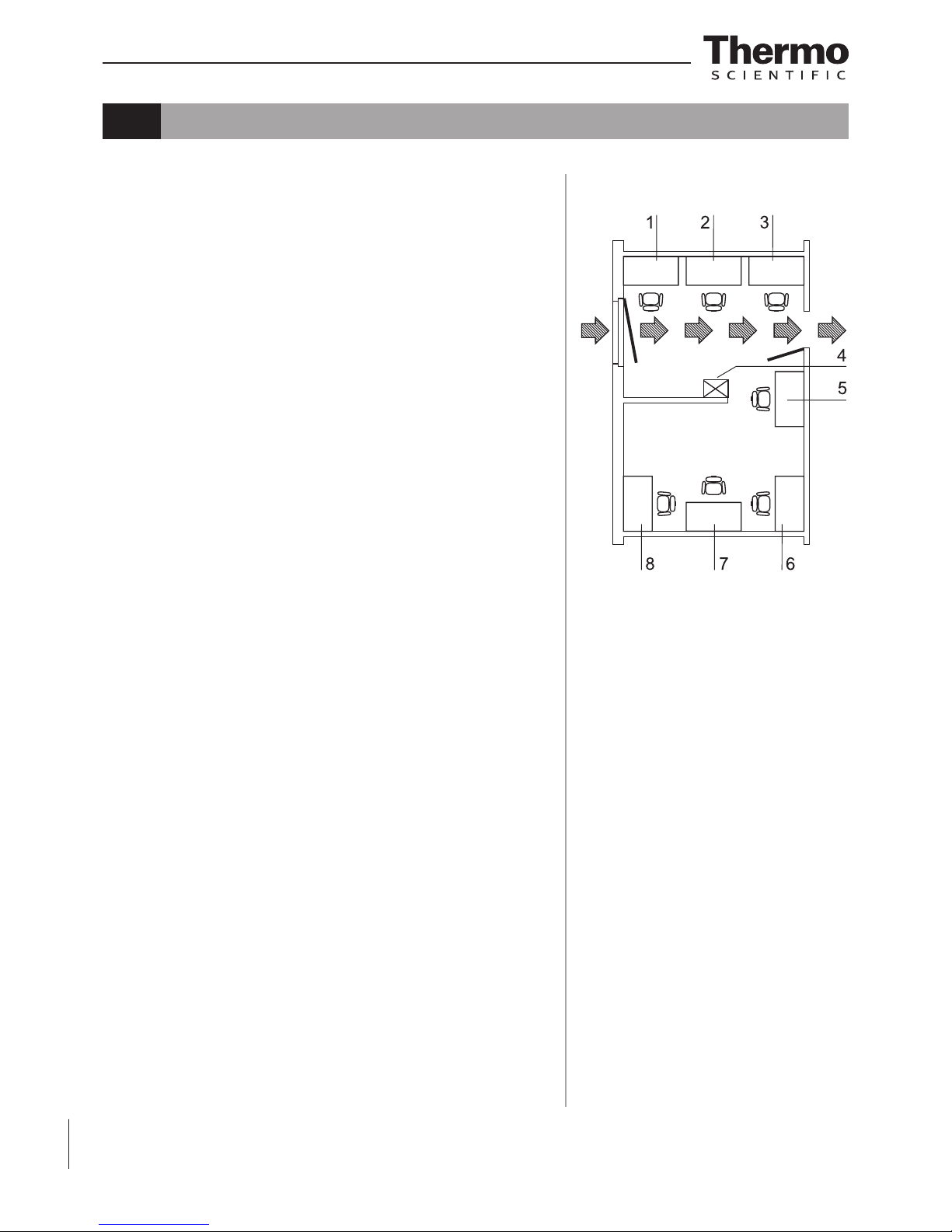

Fig. 1 Device locations in a room ........................................................... 12

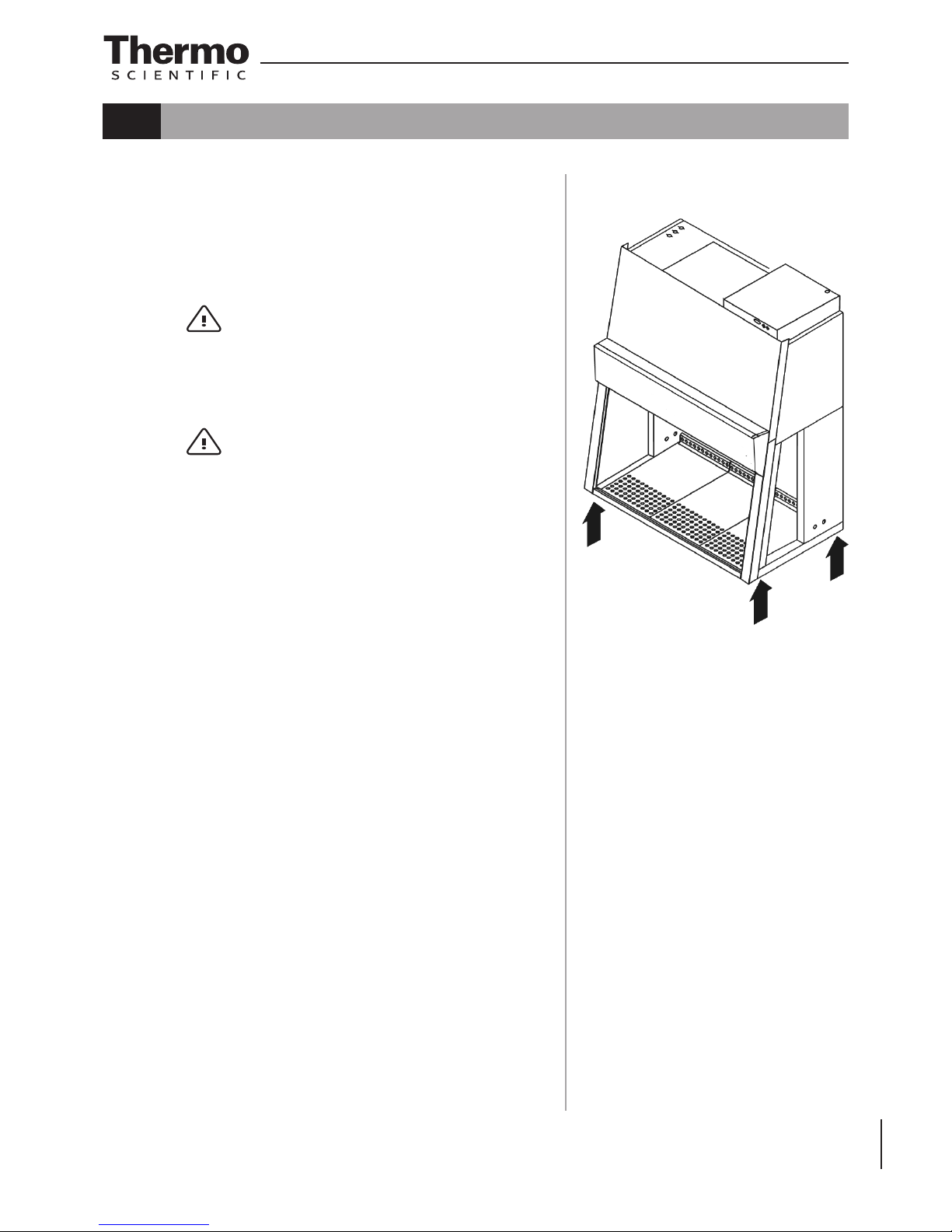

Fig. 2 Lift points ...................................................................................... 13

Fig. 3-a Overall view / model Safe 2020 ................................................... 15

Fig. 3-b Overall view / model Maxisafe 2020 ............................................16

Fig. 4-a Filter system with downflow filter and exhaust

air filter / model Safe 2020 ...........................................................18

Fig. 4-b Filter system with primary filter, downflow filter and exhaust

air filter / model Maxisafe 2020 ....................................................19

Fig. 5 Controls and indicators ................................................................ 20

Fig. 6-a Access through front cover ..........................................................21

Fig. 6-b Access through front window .......................................................21

Fig. 7-a Supply interfaces .......................................................................... 22

Fig. 7-b Sample chamber illumination ....................................................... 23

Fig. 8 UV lamp unit .................................................................................24

Fig. 9 Working area on the workplate, armrests .................................... 24

Fig. 10-a Stand installation / model Safe 2020 ........................................... 25

Fig. 10-b Stand installation / model Maxisafe 2020 .................................... 26

Fig. 10-c Drain valve installation ................................................................. 27

Fig. 11 RS 232 interface connection ........................................................ 30

Fig. 12 UV connection .............................................................................. 30

Fig. 13 Indicator and operating panel ...................................................... 33

Fig. 14 Indicator and operating panel ...................................................... 37

Fig. 15 Basic functions of the pilot switch ................................................48

Fig. 16 Sitting posture .............................................................................. 52

Fig. 17 Front window seal replacement ...................................................58

Page 6

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

6

1. General notes

The following are the addresses of the international Thermo

Sales Organisations.

1.1 General safety instructions

These safety instructions describe the safety features of the Safe 2020 and

Maxisafe 2020 series.

The safety cabinet has been manufactured in keeping with the latest

technological developments and has been tested before delivery for its correct

function. It may, however, present potential hazards if it is not used according

to the intended purpose or outside of operating parameters. Therefore, the

following procedures must always be observed:

• The safety cabinet must be operated only by trained and authorized personnel.

• For any operation of this unit, the operator must prepare clear and concise

written instructions in the language of the operating and cleaning personnel

based on these operating instructions, applicable safety data sheets, plant

hygiene guidelines, and technical regulations, in particular:

• which decontamination measures are to be applied for the cabinet and

accessories,

• which protective measures apply while specific agents are used,

• which measures are to be taken in the case of an accident.

• Repairs to the device must be carried out only by trained and authorized expert

personnel.

• The contents of the operating instructions are subject to change without

further notice.

• Concerning translations into foreign languages, the German version of these

operating instructions is binding lease.

• Keep these operating instructions close to the unit so that safety instructions

and important information are always accessible.

• Should you encounter problems that are not detailed adequately in these

operating instructions, please contact Thermo Electron LED GmbH

immediately for your own safety.

Postal address Germany

Thermo Electron LED GmbH

Robert-Bosch-Straße 1

D - 63505 Langenselbold

Enquiries from Germany:

Phone

Sales 0800 1 536376

Service 0800 1 112110

Fax

Sales/Service 0800 1 112114

E-Mail

info.labequipment.de@thermofisher.com

International enquiries

Tel. + 49 (0) 6184 / 90-6940

Fax + 49 (0) 6184 / 90-6772

E-Mail

info.labequipment@thermofisher.com

Page 7

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

7

1. General notes

1.2 Warranty

Thermo Electron LED GmbH warrant the operational safety and functions of the

safety cabinet only under the condition that:

• the device is operated and serviced exclusively in accordance with its intended

purpose and as described in these operating instructions,

• the device is not modified,

• only original spare parts and accessories that have been approved by Thermo

Electron LED GmbH are used,

• inspections and maintenance are performed at the specified intervals,

• an installation test is performed prior to the initial operation of the device and

that a repeat test is performed on the occasion of all inspections and repairs.

The warranty is valid from the date of delivery of the device to the operator.

1.3 Explanation of symbols

1.3.1 Symbols used in the operating instructions

WARNING!

is used if non-observance may cause serious

or even lethal injuries.

CAUTION!

is used if non-observance may cause medium

to minor injuries or damage.

NOTE

is used for hints and useful information.

RECYCLING!

Valuable raw materials can be reused.

Page 8

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

8

1. General notes

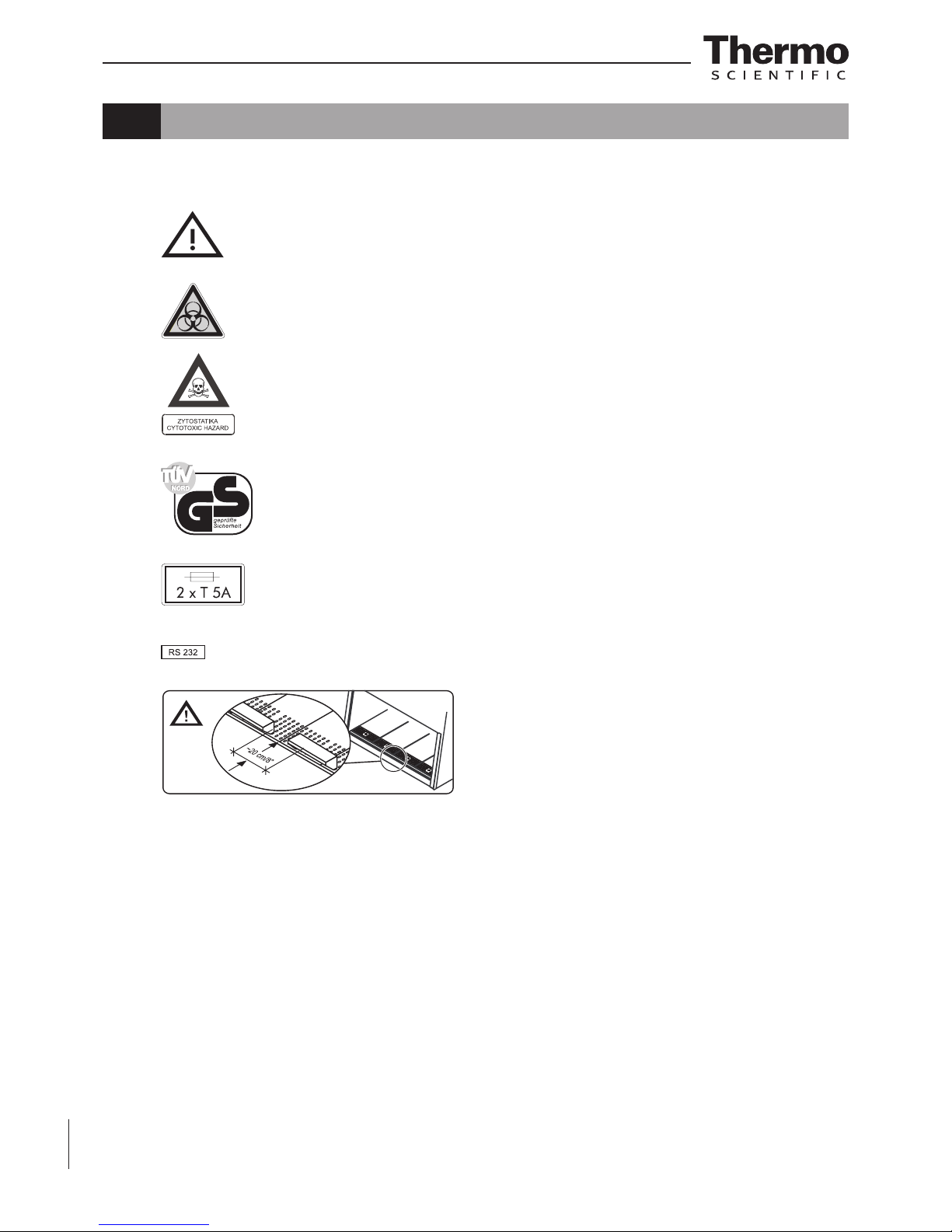

1.3.2 Symbols on the device

Observe operating instructions (switchbox ceiling)

Biohazard (left device front)

Cytostatic agents (left device front)

Checked safety (right side of device)

T5A note (sample chamber fusing)

RS 232 interface (connection label)

Armrest installation

(right side of light dome)

1.4 Use of the device

1.4.1 Correct use

Model Safe 2020:

The safety cabinet is a laboratory device for installation and operation in

microbiological and biotechnical laboratories of safety levels 1, 2, and 3. It has

been designed as a Class II microbiological safety cabinet, in accordance with

EN 12469 / 2000.

Depending on the hazard level of the agents involved, the operator must

prepare in writing appropriate decontamination procedures for the device and

the accessories used in the sample chamber.

Page 9

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

9

1. General notes

Model Maxisafe 2020:

The safety cabinet also meets the requirements from DIN 12980 / 2005-06 and

can be used for the production of cytostatic agents.

For cytostatic agent applications, use the lowered one-piece working plate only.

Prior to the initial operation of the cabinet, the operator must perform an

installation test. The test result must be documented by a test report. The

cabinet must only be released for operation if it is in compliance with the

operating parameters specified by Thermo Electron LED GmbH.

After any changes to the installation conditions or after any modification to the

technical system, a repeat test must be performed and the test result must be

documented by a test report that shows that all operating parameters are in

compliance with those specified by Thermo Electron LED GmbH.

1.4.2 Incorrect use:

The safety cabinet must not be used in laboratories that do not comply with the

requirements of safety levels 1, 2, or 3.

The unit must not be operated as a Class II safety cabinet, if:

• no repeat test is performed after changes to the installation conditions or after

modifications to the technical system,

• the alarm system of the device has issued a failure message and the

cause for the failure has not been repaired.

The alarm system must not be tampered with or disabled. If alarm system

components heve been removed or disabled for service or repairs, the unit must

only be released for operation if all alarm system components are functioning

again properly.

The filters installed in the device are not capable of separating gaseous

substances. Therefore, do not work with or store substances in the device:

• which in quantity or concentration are toxic,

• if a reaction with other substances may result in hazardous toxic concentrations

or formation of toxic gases,

• that may form combustible or explosive mixtures in combination with air.

1.5 Standards and safety regulations

The device complies with the safety requirements of the following standards and

guidelines:

• IEC 61010-1 / EN 61010-1

• EN 12469 / 2000

• DIN 12980 / 2005-06 (model Maxisafe 2020 only)

• Low Voltage Directive

• EMC Directive

Page 10

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

10

2. Delivery

2.1 Standard components

Delivery for the safety cabinet includes the following:

Model Safe 2020:

• safety cabinet,

• drain valve.

Model Maxisafe 2020:

• safety cabinet

• armrests

• stand

All models:

• Device documentation:

— operating instructions,

— factory test report.

Optional components and accessories are listed as separate items in the

delivery document.

2.2 Acceptance inspection

After the device has been delivered, immediately check the device:

• for completeness,

• for possible damage.

If the delivery is incomplete or if you detect any transport damage to the

device, contact the forwarding agency and Thermo Electron LED GmbH

immediately.

2.3 Transport lock and device packaging

Do not transport the device over large distances without transport lock and original

device packaging.

Page 11

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

11

3. Installation

3.1 Ambient conditions

The operational safety and correct function of the unit depend on the location

where it is to be operated. The safety cabinet must be operated only at

locations that meet the ambient conditions listed below.

Location requirements:

• The electrical system of the device has been designed for an operating height

of up to 2000 m above sea level.

• The mains power supply outlets should be out of normal reach to prevent

accidental shut-off. Ideally, the outlets should be installed above the safety

cabinet.

• The flooring of the location must be adequately strong and not flammable.

• The room in which the device is installed must be of adequately height. For

units not connected to an exhaust system, the distance between the exhaust

air opening and the room ceiling must be at least 200 mm (8 in).

• The location must be equipped with an appropriate ventilation system

(see Section 3.2.).

• The temperature within the room must be between 15 °C and 40 °C

(49 °F and 104 °F).

• The relative humidity in the vicinity of the device must not exceed 90 %.

NOTE - Ambient conditions

If ambient conditions vary from those described above, please contact Thermo Electron

LED GmbH for assistance in installing the device.

NOTE - Temporary storage

If the device is stored only temporarily (up to

four weeks), the ambient temperature may be

between -20 °C and +60 °C (-4 °F and +140 °F)

at a relative air humidity of up to 90 %. For longer storage periods, the location requirements

apply.

3.2 Room ventilation

The room ventilation should preferably be a ventilation system that complies with

the national requirements for the application.

• The inlet air and exhaust air openings of the room ventilation must be located

so that drafts are prevented from impairing the function of the safety

cabinet air system.

Page 12

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

12

Fig. 1

Locations in a room

3. Installation

3.3 Correct location

Choose a draft-free location where the safety cabinet does not

interfere with the room traffic.

Fig. 1: This figure shows preferred locations for safety

cabinets and unsuiable locations, not in accordance with the

safety requirements.

Unsuitable locations: The locations [1], [2], and [3] are not

suitable because they are exposed to drafts from windows and

doors.

Location [5] is undesirable because it is in range of plant traffic

and within the exhaust air range of a ventilation system [4].

Preferred locations [6], [7], and [8] are correct because they

are in a draft-free section of the room and not exposed to plant

traffic.

3.4 Installation in line

When several devices are to be installed in line, please observe

the following:

• Make sure that vibrations cannot be transferred between

adjacent units.

• Exterior surfaces of the cabinets must always be accessible

for cleaning and disinfection.

Page 13

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

13

3. Installation

3.5 Transport

Model Safe 2020:

Fig. 2: To prevent tilting, always transport the device using

a suitable carrier, even for a transport within a building, and

separate it from the stand.

CAUTION – Danger of tipping over!

For transport, lift the device only using the lift

points shown in the illustration. Do not load the

floorpan with the weight of the device frame!

CAUTION – Contusion hazard!

When lifting the safety cabinet, never place

fingers or hands under the base of the device!

Model Maxisafe 2020:

If required, the device stand must be removed from the stand

to be reinstalled onto the stand for the initial start-up after the

transport (see Section 5.2).

Fig. 2

Lift points

Page 14

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

14

4. Unit description

4.1 Overall view

Model Safe 2020:

• Fig. 3a: Plenum assembly [5] with plenum for downflow blower [24] and

plenum for exhaust air blower [2]. The downflow filter and the exhaust air filter

are installed directly to the relevant blower. The exhaust air is released into

the environment around the device through the opening [1].

• At the side of the plenum, the optional media supply lines [25] are routed into

the sample chamber [20].

• Electrical box [4] with power supply cable [3]. An RS 232 connection to a PC

and two fuse holders are installed at the front of the electrical box.

• Front cover [6] with integral, electrically movable front window [7], operated by:

• the pilot switch [26].

The gas struts [22] secure the front cover in the open state.

• The light dome [23] with two tubes is part of the front cover assy.

• Side panels [9] with two sealed access openings [19]. These can be

equipped with media valves [13].

• Internal outlets [10] for power supply of accessories and adapter [11] for mobile

UV device.

• Optional UV lamp unit [8] consisting of two UV lamps per side.

• Optional stands [12], adjustable in height and with fixed height

• Workplate segments [15] with optional arm rests [16]. A one-piece workplate

and special workplates are available options.

• Lockable drain valve [17] for installation into floorpan.

• Display [21] with alarm system indicators.

• Test hoses for the supply unit [18] at the left side of the sample chamber and

for the exhaust unit [14] at the right side of the sample chamber.

NOTE – Test hoses

Do not remove the two test hoses for checking

downflow and exhaust air.

Page 15

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

15

4. Unit description

Fig. 3a

Overall view / Model Safe 2020

Page 16

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

16

4. Unit description

Model Maxisafe 2020:

• Fig. 3b: Stand [5] with integral prefilter housing [6].

• Filter inserts [2] for the prefilter housing. The number of supplied filter

inserts depends on the width of the device. To protect from liquid residues,

the filter inserts are oriented slightly sloping from the device backpanel to

form a drain duct to the floorpan [3].

The filter plates [4] have tongues and grooves and are inserted in an

overlapping pattern from right to left.

• Membrane sleeve or opening for filling with aerosol for testing the filter of the

downflow unit [1] at the left side of the sample chamber and of the exhaust

air unit [7] at the right side of the sample chamber.

Fig. 3b

Overall view / Model Maxisafe 2020

Page 17

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

17

4. Unit description

4.2 Safety system

The safety system comprises a combination of protective and alarm systems

that ensure maximum personal and material protection.

Safety systems:

• Vacuum-sealed air system

A vacuum-sealed air system in combination with HEPA filters for downflow

and exhaust air forms the basis of the safety system for personal and

material protection.

• Personal protection

Air aspired from the exterior along the entire working opening at a constant

high velocity prevents that:

• agents may leak through the working opening of the chamber.

As the exterior air pressure around the unit exceeds the pressure of the

internal air system (vacuum sealing), it is ensured that:

• agents cannot be released to the exterior in the case of a leak in the

cabinet housing.

• Material protection

A steady airflow within the air system ensures that:

• a constant downflow allows the HEPA filters to remove contaminants

so that the samples are always surrounded by ultrapure air,

• harmful particles are not carried over through the sample chamber

(protection from cross-contamination).

• HEPA filters

The downflow (i.e. the air circulating within the device) and the exhaust air

(air that is released to the exterior) are cleaned by HEPA filters (HEPA = High

Efficiency Particulate Air Filter).

For version Maxisafe 2020, a prefiltering system is used to increase the filter efficiency and to protect the exhaust air and downflow systems.

• Safety lockout

To protect from UV radiation, the optional UV disinfection routine can be run

only if the front opening is closed. During UV disinfection, the front opening

safety lockout is activated and prevents harmful UV radiation from being

emitted from the sample chamber.

Warning system:

• Airflow monitoring

Airflow monitoring determines the velocity of the airflow in the sample chamber

as well as the inflow velocity of the air aspired from the exterior through the

working opening. As soon as airflow velocities move above or below a

specified safety value, a signal is transmitted to the alarm system.

• Visual and audible alarm system

The warning system constantly monitors the safety-relevant device functions:

• Inflow velocity of the air aspired from the exterior,

• downflow velocity,

• working position of the front window.

If the warning system detects changes to one of these device functions, it

issues:

• an audible and a visual alarm signal.

Page 18

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

18

4. Unit description

• Position monitoring

The position sensors monitor the position of the front

cover as well as the movement of the front window; it will

indicate when the front window is in the working position.

• Performance Factor

The Performance Factor (PER) is a value that indicates the

safety state of the safety cabinet. This value is calculated

from data determined by the safety system and from

values captured empirically by service personnel during

safety checks. This data is entered into a parameter list of

the control software and interconnected. The result can be

indicated by the display.

4.3 Filter system

Model Safe 2020:

Fig. 4a: The filter system consists of two HEPA filters [2] and

[5] for the circulating air and for the exhaust air and of a coarse

filter for the aspired air.

HEPA filters: Room air [10] is drawn into the sample

chamber through the working opening. In the air duct, room

air and the downflow within the chamber [7] are then blended

to make up the blend air [9]. The blend air is then:

• filtered proportionally by the downflow filter [5] and

supplied as ultrapure air [6] evenly into the sample chamber

of the device,

• filtered by the exhaust air filter [2] and released as

ultrapure air [1] to the exterior of the device.

Inlet air protection: The air duct between the sample chamber

and the device plenum has an inlet air protection [8] below the

working surface to prevent coarse particles from entering the

plenum where they may impair blower [3] und [4] and filter

functions.

Fig. 4a

Filter system with downflow

filter and exhaust air filter /

model Safe 2020

Page 19

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

19

4. Unit description

Model Maxisafe 2020:

Fig. 4b: The filter system consists of a set of HEPA primary

filter [10] (the number of filters depends on the sample chamber

width) and two HEPA filters [2] and [5] for downflow air and

exhaust air.

HEPA primary filter:

The compact size of the filter inserts allows filter replacement

with minimal contamination hazard. The use of the primary filter

protects the downflow and exhaust air filters considerably.

The filter inserts used are HEPA filters of Class H14

(according to DIN EN 1822). Alternatively, activated carbon

filters can be inserted into the housing to protect from smells.

Room air [11] is drawn into the sample chamber through the

working opening. In the air duct above the prefilter, room air

and the downflow within the chamber [7] are then blended to

make up the blend air [8]. The blend air is then:

• aspirated into the prefilter [10], filtered and fed into the air

duct [9].

HEPA filters: From the air duct, the primary filtered air is:

• filtered proportionally by the downflow filter [5] and

supplied as ultrapure air [6] evenly into the sample chamber

of the device,

• filtered by the exhaust air filter [2] and released as ultrapure

air [1] to the exterior of the device.

Fig. 4b

Filter system with primary

filter, downflow filter and

exhaust air filter / model

Maxisafe 2020

Page 20

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

20

4. Unit description

4.4 Controls and display

Fig. 5: The safety cabinet is equipped with two separate control

elements that operate independently of each other:

• pilot switch [1].

• operating panel [2],

The status indicators of the display [2] indicate control

operations initiated with the control elements.

Pilot switch: Use to control all basic functions required for the

operation.

Operating panel: The operating panel [2] has a display

panel for text or number value output as well as 12 LEDs for

visual indication of the current operating state of the device.

All device functions can be controlled via the keys on the

operator panel.

Fig. 5

Controls and indicators

Page 21

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

21

4. Unit description

4.5 Sample chamber access

The sample chamber of the device is accessible via two

modes:

Front cover:

Fig. 6a: Manual opening of the front cover [2] allows access

to the complete sample chamber width with an opening height

C. It is generally needed for decontamination and introduction

of larger accessories.

NOTE – Front cover lockout

The front cover is equipped with a safety

lockout and can only be opened when the front

window is completely closed.

Front window:

Fig. 6b: The electrically operated front window [1] is made of

multi-layer safety glass and integral to the front cover frame.

It can be raised to a maximum opening height B (480 mm). To

access the sample chamber during the work process, the front

window must stay in the work position with opening height A

(200 mm).

CAUTION – Front window movement!

Do not attempt to move the front window

manually as otherwise the motor drive may be

damaged.

Lowering the front window when the device is deenergized:

The safety feature (optional) is backed up by a battery. Should

a power failure occur, the pilot switch (see Section 6.4) can be

used to lower the front window completely.

Fig. 6a

Access through front cover

Fig. 6b

Access through front window

Page 22

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

22

4. Unit description

4.6 Device interfaces

Fig. 7a: The standard equipment includes the outlets [10] for internal power supply

as well as the openings [8] on both sides for routing of cables and hoses. All other

supply connections are available as options.

Power supply connection: The connection to the power supply system is

achieved through a cable with grounding plug [2] at the rear of the electrical box.

Contact connection: The front of the box has an RS 232 interface [3] for the

connection to a PC as well as two fuse holders for 5A miniature fuses:

[4] for (L),

[5] for (N).

Internal power supply: There are two electrical outlets (5A) [10] and one UV

disinfection adapter (optional) [9] located in the side walls.

Media valves: There are two sealed feed throughs [8] on each side. These may

be used for installation of media valves [7].

Media supply lines: Additionally, media can be supplied into the sample chamber

through three pipes. The inlets [1] are located on top of the housing, the

outlets [6] are placed at the sample chamber backpanel.

Fig. 7a

Supply interfaces

Page 23

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

23

4. Unit description

Disinfection adapter (optional), Fig. 7a: The disinfection

adapter [9] is used to connect a mobile UV radiation device.

The adapter is connected to the device control, the UV

disinfection routine with a mobile UV device may be controlled

with the remote control.

Media connections (optional): The media supply unit

consists of three pipes that are routed into the sample chamber

through the top of the unit. The inlet connections [1] and

outlet connections [6] with thread (R 3/8"), e.g. for media valves

[7], are preinstalled and equipped with a sealing plug.

The media connections are universal-type connections. Two

equipotential bonding connections are installed at the top of

the unit and at the stand.

Caution – Combustible gas!

If a gas burner is to be operated in the sample

chamber, an appropriate shut-off device for the

gas supply system (shut-off valve, solenoid

valve) must be installed.

Use only laboratory safety burners in the

sample chamber.

External systems: A failure detection systems or gas supply

solenoid valves may be connected to the safety cabinet control.

The unit may also be connected to an external ventilation

system.

4.7 Sample chamber illumination

Fig. 7b: The work space illumination [4] is equipped with two

fluorescent tubes [3] that are installed behind the light dome

[2].

Fig. 7b

Sample chamber illumination

Page 24

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

24

4. Unit description

4.8 UV lamp unit

Fig. 8: The UV lamp unit consists of two lamp housings [2]

with two UV lamps each [1] that are integral to the side walls.

Both lamp housings are protected by a stainless steel cover

[3].

By cross-radiation of the UV units, all surfaces will be

disinfected as the shadow zone is reduced.

The operating time of the UV lamps is preset.

NOTE – Protection from UV radiation

As a protection from harmful UV radiation, the

UV lamps can only be activated if the front

window is completely closed.

4.9 Working area

The standard equipment comprises the segmented workplate for

the models Safe 2020 and Maxisafe 2020. Special workplates are available as optional accessories.

The workplates or workplate segments are placed onto the

frame above the sample chamber floorpan using two

submerging wire straps as handles.

Fig. 9: The working area A for perfect material protection

extends over the entire width B and depth C of the workplate.

The two arm rests [3] are positioned at a distance

D (20 cm) to each other centrically on the workplate [1] or on

the workplate segments. The armrests are installed to the

second perforation line [2] of the workplate.

NOTE – Spilling liquid

(model Maxisafe 2020 only)

If larger quantities of liquid are spilled accidentally while working with the model Maxisafe

2020, the segmented filters installed below the

working surface must be checked, and, if required, the safe functioning of the device has

to be inspected by qualified service personnel.

Fig. 8

UV lamp unit

Fig. 9

Working area on the workplate, armrests

Page 25

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

25

5. Start-up

5.1 Initial operation

Prior to initial operation, the safety cabinet must be subjected

to an installation test. Correct assembly and installation

performed by the operator are essential for good start-up.

Model Maxisafe 2020:

Upon the initial connection to the power supply system, the

device control of version Maxisafe 2020 starts an automatic calibration routine to determine the parameters for the safety system of the device.

NOTE – Calibration routine

The calibration routine is no substitite for the

installation check performed by the service

personnel.

5.2 Installing unit and accessories

Model Safe 2020:

Device without stand:

• Place the device without stand onto a sufficiently stable

substructure so that the weight of the device frame does

not rest upon the floorpan.

Device with stand:

To assemble the (optional) stand and to install the device frame

to the stand:

1. Fig. 10a: Slide the two crossmembers [2] onto the retaining

angles [3] of the sidemembers [1]. Secure the crossmembers

to the two sidemembers using the screws [4].

2. To attach the device frame [5] to the stand [7], install four

Allen screws [6] loosely into the corresponding threaded

holes at the underside of the device.

3. Place the safety cabinet [1] onto the stand so that the

Allen screws [6] pass through the corresponding holes [8]

of the retaining tabs [10].

4. Push the device frame [5] in the grooves [9] of the retaining

tabs [10] all the way to the stop.

5. Tighten the four Allen screws [6].

Fig. 10a

Stand installation model

Safe 2020

Page 26

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

26

5. Start-up

Model Maxisafe 2020:

Fig. 10b: The stand [3] and the prefilter housing form an

assembly. To facilitate the installation of the device frame [1],

the stand is equipped with a lifting mechanism.

The four columns [7] of the stand have threaded rods [6] onto

which the device frame can be placed and lowered.

1. Fig. 10b: Unscrew the threaded rods from their hex disks

[5] by approx. 10 cm and make sure their height is identical on all four columns.

2. Place the safety cabinet onto the threaded rods. Check to

see whether each guide pin [4] is seated perfectly in its

receptacle at the lower device frame.

3. Screw in each threaded rod at its column in short, even

intervals all the way to the stop of the hex disk.

NOTE – Leveling the device

To level the device, do not use the lifting

mechanism but only the adjustable stands of

the device.

4. Align the working area of the safety cabinet:

Place a bubble level onto the workplate and rotate the stands

[2] of the stand using a 24-mm wrench until the workplate is

exactly horizontal in all directions. For the vertical alignment

of the device stands, proceed from left to right and from rear

to front.

Fig. 10b

Stand installation model

Maxisafe 2020

Page 27

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

27

5. Start-up

Drain valve (optional)

Fig. 10c: The drain valve [2] is installed into the floorpan

opening [1] at the floor at the left front area of the sample

chamber.

NOTE – Installation

The optional drain valve must be installed only

by authorized service personnel.

WARNING – Drain valve lock!

To prevent contaminated liquid from being

accidentally drained from the floorpan, the

drain valve must be secured using a

conventional padlock.

5.3 Levelling the cabinet

The cabinet should be levelled only after it has been

positioned.

1. Remove transport protection (foil) from the workplate or from

the workplate segments.

2. Lift the workplate or the workplate segments by the wire

hooks and place it/them onto the front and rear rails in the

sample chamber with the wide line of holes facing forward.

3. Device without stand: Place a bubble level onto the

workplate and align the substructure until the bubble level

indicates an exactly horizontal position in all directions.

4. Device with stand: Place a bubble level onto the

workplate and use the four levellers of the stand to effect

a level state in all planes.

When adjusting the device stand height, proceed from right

to left and from rear to front.

Fig. 10c

Drain valve installation

Page 28

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

28

5. Start-up

5.4 Power supply connection

WARNING – High voltage!

Contact with current-carrying components may

cause a lethal electric shock.

Before connecting the device to the power

supply system, check plug and power supply

cable for possible damage.

Do not use damaged components to connect

the device to the power supply system!

Establishing the power supply connection:

1. Before connecting the device to the power supply system, check to see if the

voltage of the outlet corresponds with the specifications on the nameplate

of the device. If the ratings given for voltage (V) and maximum current (A)

are not correct, the device must not be connected to the power supply

system.

2. Connect the grounding plug of the device to a properly grounded and fused

outlet.

• The outlet must be fused separately using a fusible link T 16 A or using

a circuit breaker B 16.

3. Make sure that the power supply line is not subjected to tensile or compressive

force.

Installation of the power supply connection:

To protect against accidental switch-off, the outlets for the connection to the power

supply must be located outside the normal hand reaching range and must be

accessible only to auhorized personnel. Ideally, the outlets should be installed

above the safety cabinet.

Connecting the equipotential bonding:

If the sample chamber is supplied with media (gas, water, etc.), the on-site

equipotential bonding must be connected to one of the premounted threaded

bushings either at the top of the housing or at the stand.

Initialization routine:

After the unit has been connected to the power supply system, the device control

runs through a start-up initialization routine and switches the functions to the OFF

mode. The safety cabinet is now operational and can be operated using the

operating panel or the pilot switch

Presetting the alarm limits upon initial operation, Maxisafe 2020:

NOTE – Presetting the alarm linits

The alarm limits must be set only upon the

initial operation of the device.

Page 29

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

29

5. Start-up

After the initialization routine has been completed, the calibration routine is run

(only Maxisafe 2020):

• The display shows "CAL".

• The routine starts automatically when the device control is in the work mode

(sees Section 6.2) and runs for approx 30 minutes. If the airflow is disturbed

during the run time, the routine is cancelled and restarted automatically.

• At the end of the routine, the determined parameters for the alarm limits are

saved.

NOTE – Initial operation

According to applicable national standards

and regulations, the calibration routine is no

substitute for a start-up performed by an

authorized service technician.

Setting the clock:

After the initialization routine has been run, the clock should be set to the

appropriate time zone (see Section 6, Operation).

NOTE – Power supply connection

The safety cabinet should remain connected

to the power supply system at all times to

ensure that settings for the individual unit

configuration remain active in the memory. If

the power supply is interrupted for more than

5 minutes, the time must be reset correctly.

After the power supply connection has been

reestablished, the system switches to the

operating mode that had been active last.

Page 30

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

30

5. Start-up

5.5 RS 232 interface connection

The RS 232 interface has been designed for a cable connection

with 9-pin connectors and a contact assignment of 1:1.

Connection of the device:

1. Turn PC off.

2. Fig. 11: Connect the connector of the serial interface

cable (not comprised in the scope of delivery) to the

socket [1] at the supply interface at the front of the

electrical box.

3. Connect the serial interface cable to an unassigned

slot COM 1/COM 2 etc. at the PC.

4. Turn PC on.

Transfer protocol:

The interface must be configured as follows:

Baud: 9600

Data bits: 8

Parity: none

Stop bit: 1

Protocol: none

FIFO–puffer(extended modulation): enabled

Occupancy of conductors:

Type of connector [X] : 9-Pin SUB-D

Pin 2: TxD

Pin 3: RxD

Pin 5: GND

5.6 UV connection

Fig. 12: UV disinfection adapter (optional) for an external UV

disinfection unit.

Voltage: 230 V

Current: max. 1,1 A

Connectors: [1], [2], [3] and PE-sign

Fig. 11

RS 232 interface connection

Fig. 12

UV connection

Page 31

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

31

5. Start-up

5.7 Installation test

Do not operate the device before the installation test has been completed.

• The installation inspection of the device must be conducted in accordance

with EN 12469 and additionally according to DIN 12980 for Maxisafe 2020.

The cabinet may be operated as a Class II microbiological safety cabinet,

in accordance with EN 12469 / 2000, if the device functions or function patterns

listed below were checked and if the test results are within the safety value

tolerances specified in Annex F:

• Electrical safety test

• Inflow velocity test

• Downflow velocity test

• Leakage test of HEPA filters

• Airflow control test

• A repeat test must also be performed after repairs to the device or after

major changes (more than 5 cm) to the location of the device.

• The operator must prepare a test report or request a written test report from

the authorized test service.

NOTE – Safety warranty

The operational safety of the device,

particularly the personal and material

protection, are guaranteed only if all safety

functions of the device have been tested and

approved.

Thermo Electron LED GmbH will not warrant

the operational safety if the device is operated

without performance of the required

installation test or if the installation test and

repeat test are not performed by adequately

trained and authorized personnel!

NOTE – Device hygiene

The initial start-up with subsequent installation

test does not include any decontamination

measures. For operation in the work process,

the sample chamber of the device and the

accessories required for the work process

must be disinfected and cleaned in accordance

with the hygiene guidelines set forth for the

application.

Page 32

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

32

6. Handling and control

6.1 Display

Fig. 13: The display in the light dome is used as indicator and output instrument

for:

• status messages,

• parameter input and output.

6.1.1 Functions of the display components

[1] Display segment for numbers and text

Value displays

The LEDs 2-5 illuminate when the corresponding value is called up:

[2] Display time (yellow LED), usually the active standard display

[3] Display downflow velocity (yellow LED)

[4] Operating hours after last filter replacement (yellow LED)

[5] Display Performance Factor (yellow LED)

Keys

[6] Potential-free contact for solenoid

[7] Set time

[8] Move window up

[9] Switch internal outlet on/off (the LED [17] indicates that voltage is applied)

[10] Move window down

[11] Switch UV disinfection on/off (the yellow LED indicates that the UV

disinfection routine has been activated; if the optional UV lamp is not installed,

the function of this key is disabled).

[12] Switch device on/off (switch-off only in stand-by mode, see Chapter 6.3)

[13] Toggle display: Time, downflow velocity, operating hours, performance factor

[14] Switch work space illumination on/off

Function displays

The LEDs 15 - 18 illuminate only when the corresponding value is called up:

[15] Ventilation reduced (yellow LED)

[16] Potential-free contact activated (yellow LED)

[17] Internal power supply activated (yellow LED)

[18] UV disinfection routine activated (yellow LED)

Status displays

The LEDs 19/20 and 21/22 show the operating condition of the device as

either/or conditions:

[19] Front window is not in working position (red LED)

[20] Front window is in working position (green LED)

[21] Airflow is not steady (red LED)

[22] Airflow is steady (green LED)

Page 33

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

33

6. Handling and control

Fig. 13

Indicator and operating panel

6. Handling and control

6.1.2 Display during the calibration routine

The routine runs for approx 30 minutes. During this time, the display shows

alternatingly cal and the descending time value. If the calibration routine

cannot be started due to faults, the display shows cal permanently.

6.1.3 Display in OFF mode

In the OFF mode, the display shows the current time.

For the initial start-up of the device, the clock must be set to the correct time zone

and to the corresponding time output (CET mode or AM/PM mode)

(see Section 6.3.9).

6.1.4 Display in work mode

In the work mode, the display shows the values of the device data that had been

shown last (see Section 6.3.9.ff):

• Time (hours and minutes)

• Downflow velocity

• Operating hours after last filter replacement

• Performance Factor

6.1.5 Power interruption

If the master PCB of the device detects a power failure or a failure of the

power supply, a warning is issued.

Note – Power failure warning

In case of a power failure, the display goes off

after 10 seconds, then an audible alarm signal

sounds for about 30 seconds.

After this warning, the device is no longer

operative.

Page 34

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

34

6. Handling and control

The battery operation safety feature (optional) allows the complete lowering of

the front window after a power failure by pressing the pilot switch.

6.1.6 Display and functions after a power failure

After the power supply has been reestablished after a power failure, the display

shows the values and functions that were last shown prior to the failure.

The functions that had been selected last will be continued where they had been

interrupted.

6.1.7 Failure messages

Failure messages are shown on the display as text/number combinations with

the codes ER 1 to ER 5. If one of these codes appears on the display, contact

Technical Service immediately.

Error code Fault cause

ER 1 Pressure sens or 1 / supply

ER 2 Pressure sens or 2 / exhaust

ER 4 BUS error

ER 5 RAM error

Page 35

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

35

6. Handling and control

6.2 Description of the operating modes

The following operating modes exist for the device:

• Calibration mode (after initial start-up,

version Maxisafe 2020)

• OFF mode

• Work mode

• Window open mode

• Standby mode

• UV mode

OFF mode: The device is at "idle". Utilized for charging the sample chamber

or for cleaning and disinfection, the front cover can be opened when the front

window is completely closed.

• The air system blowers are switched off.

• The sample chamber illumination is available.

• The internal power supply within the sample chamber is available:

• If the internal power supply is activated, the yellow status indicator

INTERNAL POWER SUPPLY ACTIVATED is illuminated.

• The display shows the time. If the timer has been activated, the display

alternately shows the current time and the preset switching time for the

timer.

• The contact for the external device connection is not available.

Work mode: Ensures personal and material protection. In this operating mode,

the work process is run within the sample chamber. The device is in the work

mode when the front window has been moved into the working position and the

airflow is steady.

• The front window is in the working position:

• The green status indicator FRONT WINDOW IS IN WORKING POSITION is

illuminated.

• No audible alarm signal.

• The air system blowers are switched on to ensure steady airflow:

• The green status indicator AIRFLOW STEADY is illuminated.

• The sample chamber illumination is available.

• The power supply for the sample chamber outlets is available:

• If the internal power supply is ON, the yellow status indicator INTERNAL

POWER SUPPLY ACTIVATED is illuminated.

• The monitor-contact for the external device connection is available:

• If the contact is activated, the yellow status indicator POTENTIAL-FREE

CONTACT ACTIVATED is illuminated.

• The display can show values for: Operating hours, downflow velocity, and

exhaust airflow velocity.

Window open mode: Designates the condition when the window is open and

located outside the working position. To install and remove accessories, the front

window can be opened or moved upwards.

• The airflow system blowers are switched on:

• The red status indicator AIRFLOW NOT STEADY Is illuminated.

• The front window is not in the working position:

• The red status indicator FRONT WINDOW NOT IN WORKING POSITION is

illuminated.

• The work space illumination is operational.

Page 36

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

36

6. Handling and control

• The internal power supply is operational:

• If the internal power supply is switched on, the status indicator

INTERNAL POWER SUPPLY ACTIVATED illuminates.

Standby mode: For an interruption of the work process, the front window can

be lowered and the sample chamber sealed aerosol-tight. The air system

output has been reduced to match the lower air requirement.

• The front window is closed:

• The air system operates at reduced output.

• The red status indicator FRONT WINDOW IS NOT IN WORKING POSITION is

illuminated.

• The yellow status indicator AIRFLOW REDUCED is illuminated.

• The sample chamber illumination is available.

• The internal power supply in the sample chamber is available:

• If the internal power supply is ON, the yellow status indicator INTERNAL

POWER SUPPLY ACTIVATED is illuminated.

UV mode: For running the UV disinfection routine, the front window is completely

lowered to protect against UV radiation. The routine cannot be run until the front

window is in the "closed" position.

• The UV disinfection routine is activated:

• The yellow status indicator UV DISINFECTION ROUTINE ACTIVATED is

illuminated until the preset time for the routine has elapsed. Then, the

UV lamps are switched off automatically, and the status indicator is

switched off.

• The sample chamber illumination is available.

• The internal power supply in the sample chamber is not available.

• The integral UV lamp (optional) is available.

• The power supply for the UV disinfection adapter (optional) is available.

Page 37

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

37

6. Handling and control

6.3 Operation system

The device control software automatically determines the temporary operating

state of the safety cabinet and automatically disables those functions of the

operating panel that are in contradiction to the safety requirements of the switching

state.

6.3.1 Basic functions

Fig.14: The easy operator guidance ensures that all basic functions can be

controlled with only a few operating steps and that the sfety cabinet can be shifted

into the working mode.

Switching the device into work mode:

• Keep the key depressed until the ready signal sounds

Moving the front window up:

• Press the key for approx. 1 second

When the front window reaches the working position, the movement

stops automatically. When the movement starts above the working

position, the front window stops at the maximal opening position.

Stopping the upward movement:

• Press, then release the key

This function can be selected with any key except

the key.

Fig14

Indicator and operating panel

Page 38

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

38

6. Handling and control

Lowering the front window:

• Keep the key depressed

Stopping the downward movement:

• Release the key

Switching the device to OFF mode:

• Keep the key depressed until the ready signal sounds

Availability of functions in the different operating modes: x = available

Key

OFF mode Work mode

Standby

mode

UV mode

XXXX

XX

XX

XXX

XXXX

XX X

XXXX

XX

X

Mode

Page 39

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

39

6. Handling and control

6.3.2 Moving the front window to the working position

1. Raising or lowering the front window:

• Press, then release the key for approx. 1 second

• The red status indicator on the display is illuminated

• The audible alarm signal is on.

2. When the front window reaches the working position, the movement is

automatically stopped.

• The green status indicator on the display is illuminated

• The audible alarm signal is off if the airflow is steady.

3. If the movement starts above the working position, the front window must first

be lowered below the working position and then be raised again. To lower

the front window:

• Keep the key depressed

4. To stop the downward movement:

• Release the key

6.3.3 Silencing the audible alarm signal

When the front window is moved out of the working position or when the

pressure sensors detect a safety-relevant change of the airflow velocities, the

corresponding visual and audible alarm signals are issued. The alarm remains

active until the front window has been moved to the correct working position or

until the airflow velocity corresponds with the preset values.

CAUTION – Unsafe working!

When the alarm signals are activated, safe

working is no longer ensured.

NOTE – Switching the alarm signals off

If the alarm signals fail to be switched off

automatically, move the front window to the

uppermost or lowest position and contact the

Technical Service.

Page 40

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

40

6. Handling and control

6.3.4 Switching the illumination on and off

In each operating mode, the sample chamber illumination can be switched on

or off.

• To switch the illumination on or off:

Press, then release the key

6.3.5 Activating and deactivating the internal power supply

All outlets in the sample chamber can be activated (power supply on) or

deactivated (power supply off) simultaneously.

1. To activate the power supply:

Press, then release the key

The yellow status indicator is illuminated.

2. To deactivate the power supply:

Press, then release the key

The yellow status indicator goes off.

6.3.6 Displaying the UV disinfection time

This value refers to the operating hours of the set run time of the UV

disinfection or of the power supply for the UV disinfection adapter (optional).

This display function is only available when the front window is not closed.

The device must be switched to work mode.

1. To display the value:

• Press, then release the key

The time value is output in segments of 30 minutes.

2. To deactivate the value display:

The value display is deactivated automatically after 2-3 seconds.

6.3.7 Activating and deactivating the potential-free contact (optional)

An external solenoid valve or alarm system that is connected to the safety

cabinet control system can generally be enabled only if the device is operated

in the secure work mode. Enable or disable an external system:

1. To activate the contact:

Press, then release the key

The yellow status display is illuminated.

Page 41

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

41

6. Handling and control

2. To deactivate the contact:

Press, then release the key

The yellow status display goes off.

NOTE – LED for potential-free contact

If this button is pressed on the operating panel,

the LED also illuminates if no external alarm

system is connected to the device.

6.3.8 Switching the cabinet to OFF mode

The unit can be switched to OFF mode from any other operating mode:

• Keep the key depressed until the ready signal sounds

6.3.9 Setting the time

The current time of the time zone in which the unit operates must be set at the

start-up of the safety cabinet. Two different display modes can be selected:

• CET mode (24:00 hours)

• AM/PM mode (12:00 hours)

When the time is to be set, the device must be in the OFF mode.

1. Set the time:

Keep the key depressed until the two-digit hour disply flashes.

The minute display shows either A, P or no value (CET time display).

The time zone is set at the same time as the hour value: First, set

the time zone (sequence: CET, A, P), then set the exact hour value.

2. While increasing or decreasing the hour value in increments, set the

time zone:

Press, then release the or the key

3. Scroll through values:

Keep the or the key depressed

If the keys are depressed for approx. 2 or 3 seconds, a higher scroll

speed is selected.

4. Store the hour and time zone setting:

Press the key

The function switches to minute display (flashing).

Page 42

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

42

6. Handling and control

5. Set the minutes:

Press, then release the or the key

6. Scroll through values:

Keep the or the key depressed

If the keys are depressed for approx. 2 or 3 seconds, a higher scroll

speed is selected.

7. Store the minute value:

Press, then release the key

The display shows the time.

NOTE – Calling up device data

The following data can be called up in

succession:

• Time (hours/minutes)

• Downflow velocity

• Operating hours after last filter

replacement

• Performance Faktor

To call up values in succession:

• Press, then release the

key for each

value

The following three sections contain detailed

information about displaying values.

6.3.10 Displaying the downflow velocity

The sensor system of the device continuously monitors the downflow velocity

of the airstream in the sample chamber. The currently determined value (m/s)

can only be called up in the work mode.

• To display the velocity value:

Press the key repeatedly until the yellow E LED illuminates.

Page 43

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

43

6. Handling and control

6.3.11 Displaying the operating hours of the HEPA filters

The filter total operating hours after the last filter replacement can be

displayed. Upon each filter replacement, the hours are reset to zero.

1. To display the total operating hours:

Press the key repeatedly, until the yellow status indicator

on the display is illuminated.

2. The value indicates the full hours.

6.3.12 Displaying the Performance Factor

The Performance Factor (PER) is a value that indicates the safety state of the

safety cabinet.

This value is calculated from data determined by the cabinet safety system and

from values captured empirically by service personnel during safety checks. This

data is entered into a parameter list of the control software and interconnected.

The result can be indicated by the display.

1. To call up the PER:

Press the key repeatedly until the yellow status indicator

on the display is illuminated.

The PER is displayed as an integer.

2. To evaluate the PER:

Number in the 100 to 60 range: The safety cabinet is operationally

safe. Personal and material protection is ensured.

Number in the 59 to 30 range: The safety cabinet is still operationally

safe. Personal and material protection is ensured.The safety system

should be checked.

Number in the 29 to 0 range: The safety of the device may be

impaired. The failure causes must only be repaired by authorized

service personnel. Contact Technical Service.

NOTE – Calling up value

The value should only be called up, when the

airflows have stabilized itself after a lead time

of approx. 20 min.

Page 44

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

44

6. Handling and control

6.3.13 Setting and activating the timer

The timer function allows you to switch the safety cabinet from the OFF mode

to the work mode at a predetermined time. The timer can only be set when the

device is in the OFF mode.

1. To set the switching time:

Keep the key depressed until the ready signal sounds

The display flashes the two-digit hour display.

2. Increase or decrease the hour value in increments:

Press, then release the or the key

3. Scroll through the value display:

Keep the or the depressed

If the keys are depressed for approx. 2 or 3 seconds, the higher

scroll speed is selected.

4. Store the hour setting:

Press, then release the key

The function switches to minute display (flashing).

5. Set the minute value:

Press, then release the or the key

6. Scroll through the value display:

Keep the or the depressed

If the keys are depressed for approx. 2 or 3 seconds, the higher

scroll speed is selected.

7. Store the minute value and activate the timer:

Press, then release the key

The status display flashes. After a moment, the display shows

the current time again. When the value is stored, the timer is

automatically activated.

If the setting is not stored, the switching time will be reset to the original value

after approx. 15 seconds.

Page 45

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

45

6. Handling and control

NOTE – Activating the timer

If the timer is to be activated without a prior

change of the time values, the procedure

above is performed and the existing time

values are confirmed:

Press, then release the

key for each

value.

After the minute value has been confirmed, the

timer has been activated.

NOTE – Timer function

The timer can not be used as a start routine

that calls up its function automatically.

It must be reactivated separately for each

deferred device start.

6.3.14 Deactivating the timer

If the device was started at a preset time, the timer function is also deactivated

automatically. The deferred start can therefore be cancelled only while the

device is still in the OFF mode.

• To deactivate the timer function for starting the device:

Keep the key depressed until the ready signal sounds

The safety cabinet changes to the work mode.

The status indicator illuminates continuously, and the display

shows the current time.

Page 46

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

46

6. Handling and control

6.3.15 Setting the UV disinfection time

Depending on the equipment option of the cabinet, this setting is used to:

• determine the disinfection time of the optional UV lamps in the side walls or

• set the time for the power supply of a mobile UV device at the UV adapter.

Factory setting is one hour. The time can be set within a range between 0 and

24 hours in increments of 30 minutes each. The unit must be in the work mode

(the front window must not be closed). For each following start of the UV

disinfection, the routine is run with this preset time value.

1. Select the function:

Keep the key depressed until the ready signal sounds

The display flashes the run time that had been selected last.

2. Set or change the disinfection time. To increase the value in

increments:

Press, then release the or the key

3. Scroll through the value display in increments of 30 minutes:

Keep the or the key depressed

4. Store the setting:

Press, then release the key

If the setting is not stored, the disinfection time will be reset to the original

value after approx. 15 seconds.

6.3.16 Starting the UV disinfection

The UV disinfection can only be started if the front window is completely lowered

(standby mode). Depending on the equipment of the unit version, this function

is used to:

• switch on the optional UV lamps in the side walls or

• activate the power supply for the outlets of the mobile UV device.

• Start the routine:

Keep the key depressed until the ready signal sounds

The display alternately shows the Text UV and the remaining

disinfection time in hours and minutes.

The yellow status indicator is illuminated.

After the disinfection time has elapsed, the current time is displayed.

Page 47

Operating Instructions Safety Cabinet Safe 2020 / Maxisafe 2020

47

6. Handling and control

6.3.17 Cancelling the UV disinfection

While the UV disinfection routine is run, it can be interrupted at any time.

1. Cancelling the routine:

• Press, then release the key

The status indicator goes off.

2. The display shows the current time.

6.3.18 Activating the stop watch