Thermo Scientific SP88857190, HP88857190, S88857190, HP88857195, S88857195 Operation Manual

...Page 1

Thermo

SCIENTIFIC

+

SUPER-NUOVA

Hot Plates, Stirrers and

Stirring Hotplates

OPERATION MANUAL

AND PARTS LIST

CIC0000810 • 03/09/15

1

Page 2

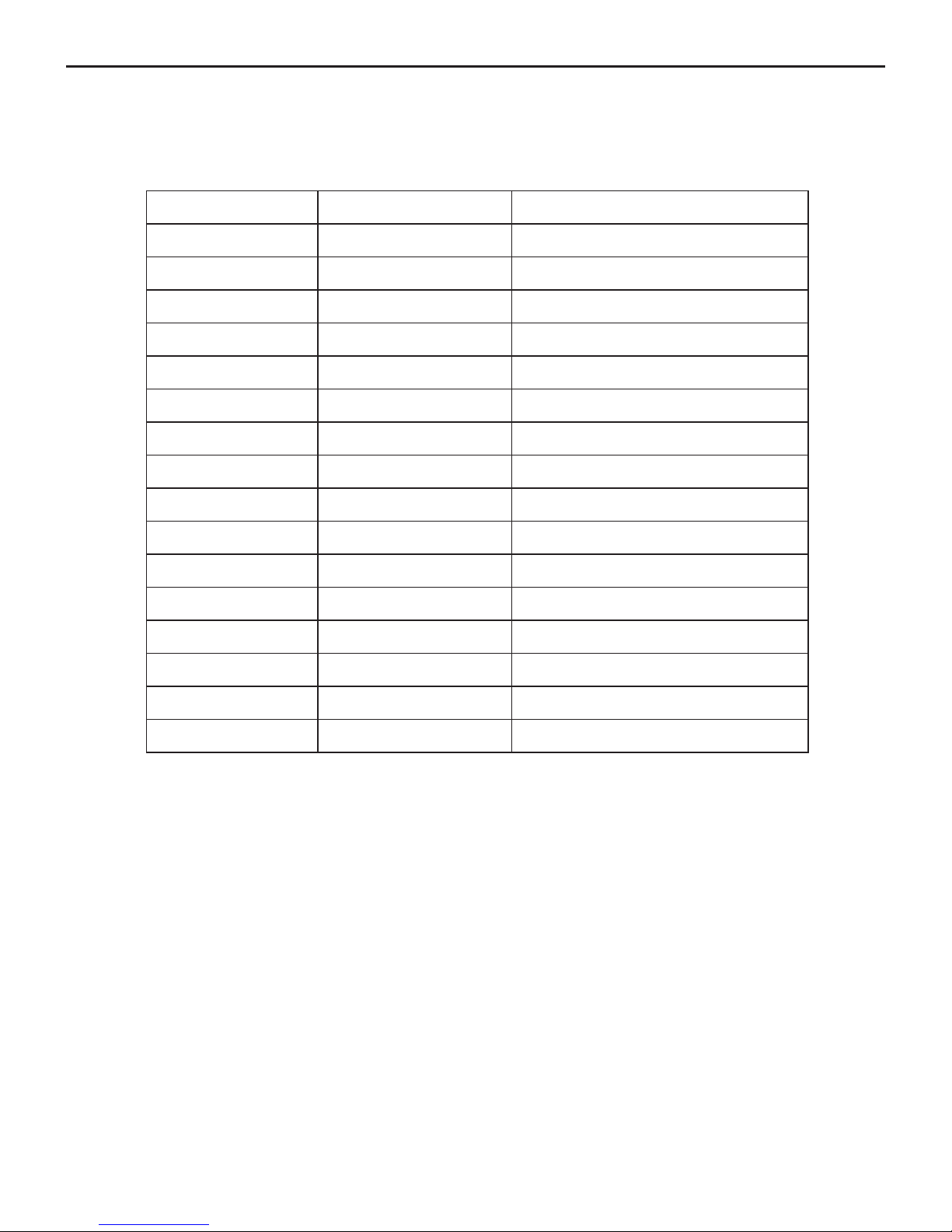

This manual covers the models shown below

Model Voltage Description

HP88857190 100-120V 7x7 Ceramic Hot Plate

HP88857195 220-240V 7x7 Ceramic Hot Plate

S88857190 100-120V 7x7 Ceramic Stirrer

S88857195 220-240V 7x7 Ceramic Stirrer

SP88857190 100-120V 7x7 Ceramic Stirring Hotplate

SP88857195 220-240V 7x7 Ceramic Stirring Hotplate

HP88857194 100-120V 7x7 Aluminum Hot Plate

HP88857198 220-240V 7x7 Aluminum Hot Plate

SP88857194 100-120V 7x7 Aluminum Stirring Hotplate

SP88857198 220-240V 7x7 Aluminum Stirring Hotplate

HP88850190 100-120V 10x10 Ceramic Hot Plate

HP88850195 220-240V 10x10 Ceramic Hot Plate

S88850190 100-120V 10x10 Ceramic Stirrer

S88850195 220-240V 10x10 Ceramic Stirrer

SP88850190 100-120V 10x10 Ceramic Stirring Hotplate

SP88850195 220-240V 10x10 Ceramic Stirring Hotplate

2

Page 3

Do You Need Information or Assistance on

Thermo Scientic Products?

If you do, please contact us 8:00 a.m. to 6:00 p.m. (Eastern Time) at:

1-740-373-4763 Direct

1-800-438-4851 Toll Free, U.S. and Canada

1-877-213-8051 FAX

http://www.thermoscientic.com Internet Worldwide Web Home Page

service.led.marietta@thermosher.com Tech Support Email Address

www.unitylabservices.com Certied Service Web Page

Our Sales Support staff can provide information on pricing and give you quotations. We can take

your order and provide delivery information on major equipment items or make arrangements to have

your local sales representative contact you. Our products are listed on the Internet and we can be

contacted through our Internet home page.

Our Service Support staff can supply technical information about proper setup, operation or

troubleshooting of your equipment. We can ll your needs for spare or replacement parts or provide

you with on-site service. We can also provide you with a quotation on our Extended Warranty for your

Thermo Scientic products.

Whatever Thermo Scientic products you need or use, we will be happy to discuss your applications.

If you are experiencing technical problems, working together, we will help you locate the problem and,

chances are, correct it yourself...over the telephone without a service call.

When more extensive service is necessary, we will assist you with direct factory trained technicians or

a qualied service organization for on-the-spot repair. If your service need is covered by the warranty,

we will arrange for the unit to be repaired at our expense and to your satisfaction.

Regardless of your needs, our professional telephone technicians are available to assist you Monday

through Friday from 8:00 a.m. to 6:00 p.m. Eastern Time. Please contact us by telephone or fax. If you

wish to write, our mailing address is:

Thermo Fisher Scientic

401 Millcreek Road, Box 649

Marietta, OH 45750

International customers, please contact your local Thermo Scientic distributor.

3

Page 4

Table of Contents

Safety Information .........................................................................................................................6

Alert Signals ................................................................................................................................6

Warnings ......................................................................................................................................6

Información de seguridad ............................................................................................................8

Señales de alerta .........................................................................................................................8

Advertencias ...............................................................................................................................8

Sicherheitshinweise ......................................................................................................................10

Gefahrensymbole ........................................................................................................................10

Warnungen ..................................................................................................................................10

Informations de sécurité ...............................................................................................................12

Signaux d'alerte ..........................................................................................................................12

Avertissements ...........................................................................................................................12

Informação de Segurança.............................................................................................................14

Sinais de Aviso ............................................................................................................................14

Avisos ..........................................................................................................................................14

Информация по безопасности ..................................................................................................16

Сигналы тревоги ......................................................................................................................16

Предупреждения .......................................................................................................................16

General Specication ....................................................................................................................18

Ceramic Hot Plate Specications ..............................................................................................18

Ceramic Stirrer Specications ...................................................................................................18

Ceramic Stirring Hotplate Specications .................................................................................19

Aluminum Hot Plate Specications ..........................................................................................19

Heating Specications ...............................................................................................................20

Stirring Speed Specications ....................................................................................................20

Environmental Conditions .........................................................................................................21

Declaration of Conformity ..........................................................................................................21

Introduction ....................................................................................................................................22

General Cleaning Instructions ...................................................................................................22

Unpacking and Installation ...........................................................................................................23

Unpacking ....................................................................................................................................23

Installation ...................................................................................................................................23

SUPER-NUOVA

SUPER-NUOVA

SUPER-NUOVA

Control Panel ...............................................................................................................................25

Principles of Operation .................................................................................................................26

+

Hot Plate Control Panel .................................................................................24

+

Stirrer Control Panel ......................................................................................24

+

Stirring Hot Plate Control Panel ....................................................................24

4

Page 5

Operation ........................................................................................................................................27

Hard Switch .................................................................................................................................27

Setting the Stirring Speed ..........................................................................................................27

Setting the Temperature .............................................................................................................28

Controlling Solution Temperature Using External Probe .......................................................29

Using Preset Programs .............................................................................................................29

Heating Metal Vessels and Sand Baths ....................................................................................30

Setting the Time ..........................................................................................................................30

Hardware Over-Temperature-Protection ...................................................................................30

System Conguration ...................................................................................................................31

Temp Unit .....................................................................................................................................32

Over-temperature Set Point –OTP .............................................................................................32

Preset Continue ..........................................................................................................................33

Temperature Probe Calibration .................................................................................................34

Troubleshooting ............................................................................................................................35

Error Codes .................................................................................................................................35

Exploded Views .............................................................................................................................36

Wiring Diagram ..............................................................................................................................40

Replacement Parts List .................................................................................................................41

Accessories ...................................................................................................................................42

THERMO FISHER SCIENTIFIC STANDARD PRODUCT WARRANTY ........................................43

5

Page 6

Safety Information

Your Thermo Scientic SUPER-NUOVA+ hot plate, stirrer

Alert Signals

or stirring hot plate has been designed with function,

reliability, and safety in mind. It is your responsibility to

install it in conformance with local electrical codes. For

safe operation, please pay attention to the alert signals

throughout the manual.

Warning

Warnings alert you to a possibility of

personal injury

.

Caution

Cautions alert you to a possibility of

damage to the equipment.

Note

Notes alert you to pertinent facts and

conditions.

Hot Surface

Hot surfaces alert you to a possibility of

personal injury if you come in contact with

a surface during use or for a period of time

after use.

Warning: These products should be used only under the

operating conditions specied in the Operating Manual.

Always use safe laboratory practices and do not leave

the unit in operation while unattended as product

functionality or laboratory practice failures could occur

that might lead to uncontrolled or excessive heating of

the top surface. Safety procedures (including, but not

limited to, unplugging when not in use) and response

plans should be put in place to address the worst case

possibility. If an over-temperature failure occurs, the

top surface temperature could rise to the maximum

temperature (300-450°C depending on your model’s

specication) and remain at that temperature indenitely.

Under these conditions, the material being heated on

the surface of the hotplate could reach levels in excess

of the maximum temperature.

This manual contains important operating and

safety information. The user must carefully read and

understand the contents of this manual prior to the use

of this equipment.

Note

The SUPER-NUOVA+ hot plates are not

explosion proof. If explosion proof models

are required, contact Customer Service at

1-800-553-0039 for more information.

Warning

Refer servicing to qualied personnel.

6

Warnings

To avoid electrical shock, always:

1.Use a properly grounded electrical outlet of correct

voltage and current handling capacity.

2.Disconnect from the power supply prior to maintenance

and servicing.

Page 7

AFETY INFORMATION

S

To avoid personal injury:

1.Do not use in the presence of ammable or combustible

materials — re or explosion may result. This device

contains components which may ignite such materials.

Not rated for use in hazardous atmospheres.

2. Use caution when heating volatile materials; top surface

and element can reach the “Flash Point Temperature”

of many chemicals. These hot plates are not explosion

proof. Fire or explosion may result. Unit contains

components which may ignite such materials.

3. Keep top surface clean. Use a non-abrasive cleaner.

Alkali spills, hydrouoric acid spills or phosphoric acid

spills may damage top and lead to thermal failure.

Unplug unit and remove spills promptly. Do not

immerse unit for cleaning.

4. Replace the top immediately if damaged by etching,

scratching or chipping. A damaged top can break in

use.

5. Do not use metal foil on hot plate which may block air

ow. Overheating will result.

6. Check and tighten the removable cord periodically

making sure it is secure. If loosened, the cord could

become hot and/or spark and be a potential re

hazard. If cord appears damaged, replace immediately.

If cord is repeatedly loosened it is recommended

to purchase the power entry module (part number

CIC0000793 or CIC0000469 depend on models)

listed in the Replacement Parts section of this manual.

7. Do not remove or modify grounded power plug. Use

only properly grounded outlets to avoid shock hazard.

8. Use appropriate hand and eye protection when

handling hazardous chemicals.

9. Gross weight of items placed on top of hot plates

should not exceed 35 lbs. (15.9 kg.) on the 10” x 10”

models and 25 lbs. (11.3 kg) on the 7” x 7” models.

10.“Caution: Hot Top. Avoid Contact.” The top plate of

the unit can remain hot for some time after use. A

“CAUTION-HOT TOP” light will remain on until top

plate temperature cools to below 50°C.

11.Do not leave an active probe out of the uid. This may

cause uncontrolled heating of the uid on the hot plate

and unintentional boiling or an explosion could occur.

12.Localized heater element temperature can be

signicantly higher than the temperature indicated on

the display. If ammable concentrations reach internal

element, a re could result.

13.Note that the exterior housing will be hot during and

for a period of time after use.

14.Refer servicing to qualied personnel.

7

Page 8

Información de seguridad

Su Plancha Caliente de Agitación Thermo Scientic

Cimarec fue diseñada con la función, la abilidad

y la seguridad en mente. Para su instalación es su

responsabilidad hacerlo en conformidad con los códigos

Señales de alerta

Advertencia

Las advertencias le alertan de la posibilidad

de lesiones personales.

Precaución

Precauciones le alerta de posibilidades de

daños en el equipo.

Nota

Las notas le alertan sobre información y

condiciones pertinentes.

Supercie caliente

Las superficies calientes le alertan de la

posibilidad de lesiones personales si tiene

contacto con la superficie durante su uso

o después de un determinado periodo de

tiempo.

eléctricos locales. Para su seguro funcionamiento,

por favor, preste atención a las señales de alerta

especicados en el manual.

Advertencia: Estos productos deben ser usados

siguiendo las condiciones de operación especicadas

en el Manual de Operación. Siempre use prácticas

seguras de laboratorio y no deje la plancha de

calentamiento en funcionamiento sin vigilancia ya que

puede haber cualquier falla en la funcionalidad del

producto o en la práctica de laboratorio que podría

conducir a un calentamiento incontrolado o excesivo

de la supercie superior. Se deben poner en marcha

los procedimientos de seguridad (incluyendo, pero no

limitado a, desconectar cuando no está en uso) y los

planes de respuesta para hacer frente en el peor de

los escenarios. Si se produce un fallo de exceso de

temperatura, la temperatura de la supercie superior

podría elevarse a una temperatura máxima de (300-540

° C dependiendo de las especicaciones de su modelo)

y permanecer a esa temperatura indenidamente.

En estas condiciones, el material se calienta en la

supercie de la plancha calefactora que podría alcanzar

niveles que superen la temperatura máxima permitida.

Este manual contiene información importante acerca del

funcionamiento y seguridad. Antes de utilizar el equipo

el usuario debe leer cuidadosamente y entender el

contenido de este manual.

8

Advertencias

Para evitar descarga eléctrica, siempre:

1. Utilice una toma eléctrica con polo a tierra con

la correcta tensión y la capacidad de manejo de

corriente.

2. Desconecte de la red eléctrica antes de hacer

cualquier mantenimiento y/o reparación.

Page 9

nformación de Seguridad

I

Para evitar lesiones personales:

1. No utilizar cerca de materiales inamables o

combustibles - podría conllevar a un incendio o una

explosión. Este dispositivo contiene componentes que

pueden encender estos materiales. No está clasicado

para ser usado en entornos peligrosos.

2. Tenga cuidado al calentar materiales volátiles; la

supercie superior y el elemento puede alcanzar a

una "Temperatura Punto de inamación" de muchos

productos químicos. Estas planchas no son a prueba

de explosiones. Podría producirse un incendio o una

explosión. La unidad contiene componentes que

pueden encender estos materiales.

3. Mantenga limpia la parte superior supercie. Use

un limpiador no abrasivo. Los vertidos alcalinos, los

derrames de ácido uorhídrico o derrames de ácido

fosfórico pueden dañar la parte superior y conllevar

a una insuciencia térmica. Desconecte la unidad

y elimine los derrames de inmediato. No sumerja la

unidad en líquidos para su limpieza.

4. Remplace la tapa inmediatamente si está dañada por

el efecto de los químicos, rayado o astillado. Una tapa

dañada puede romperse durante su uso.

5. No utilice papel de aluminio en la plancha caliente

este puede bloquear el ujo de aire dando lugar a un

sobrecalentamiento.

6. Se debe revisar y apretar el cable desmontable

periódicamente para asegurarse de que es seguro.

Si esta aojado, el cable se podría calentar y/

o provocar chispas siendo un peligro potencial de

incendio. Sustituya el cable inmediatamente si el

cable está dañado. Si el cable se aoja continuamente

se recomienda comprar un mòdulo de entrada

de alimentación (número de pieza CIC0000793 o

dependiendo del modelo CIC0000469)que aparece en

la sección de piezas de repuesto de este manual.

7. No retire o modique el enchufe con polo a tierra.

Utilice sólo enchufes con polo a tierra para evitar el

riesgo de descarga eléctrica.

8. Utilice la protección adecuada para manos y ojos al

manipular productos químicos peligrosos.

9. El peso bruto de los objetos que se pongan en la parte

superior de las planchas calientes no debe exceder

las 35 libras. (15,9 kg.) En los modelos10 "x 10", 25

libras. (11.3 kg) en los modelos 7 "x 7" .

10."Precaución: Hot Top. Evite el contacto. "La placa

superior de la unidad puede permanecer caliente

durante algún tiempo después de su uso. Una luz de

"PRECAUCIÓN - HOT TOP" permanecerá encendida

hasta que la temperatura plancha superior se enfríe

por debajo de los 50 ° C.

11.No deje una sonda activa fuera del uido. Esto puede

causar un calentamiento incontrolado del uido en la

plancha caliente y podría producirse una ebullición o

una explosión.

12.El elemento de temperatura del calentador localizado

puede ser signicativamente mayor que la temperatura

indicada en la pantalla. Si las concentraciones

inamables alcanzan algún componente interno,

podrían provocar un incendio.

13.Debe tener en cuenta que la carcasa exterior

permanecerá caliente durante su uso y por un periodo

de tiempo después de su uso.

14.Siempre solicite los servicios del personal cualicado.

9

Page 10

Sicherheitshinweise

Ihre Thermo Scientic Cimarec Rühr- Heizplatte

wurde unter den Gesichtspunkten der Funktionalität,

Zuverlässigkeit und Sicherheit entworfen. Es obliegt

Ihrer Verantwortung diese in Übereinstimmung

Gefahrensymbole

Warnung

Eine Warnung weist Sie auf die Möglichkeit

einer -Verletzung hin.

Vorsicht

Das Symbol Vorsicht weist Sie auf die

mögliche Beschädigung der Ausrüstung

hin.

Hinweis

Hinweise weisen Sie auf einschlägige

Fakten und Bedingungen hin.

Heiße Oberäche

Das Symbol heiße Oberäche weist Sie auf

das Risiko von Verletzungen hin, sollten

Sie während des Betriebs oder für einen

bestimmten Zeitraum danach in Kontakt mit

einer Oberäche kommen.

mit den örtlichen elektrischen Vorschriften zu

installieren. Für einen sicheren Betrieb beachten

Sie bitte die Gefahrensymbole in der gesamten

Bedienungsanleitung.

Warnung: Diese Produkte sollten nur unter den in der

Betriebsanleitung angegebenen Betriebsbestimmungen

eingesetzt werden. Wenden Sie immer sichere

Laborpraktiken an und lassen Sie die Heizplatte nicht

eingeschaltet, während diese unbeaufsichtigt ist, da das

Fehler der Produktfunktionalität oder der Laborpraktiken

zu unkontrollierter oder übermäßiger Erwärmung

der Oberäche führen kann. Sicherheitsverfahren

(einschliesslich, aber nicht beschränkt auf das

Ziehen des Netzsteckers bei Nichtgebrauch) und

Reaktionspläne sollten erstellt werden, um auf den

Ernstfall vorbereitet zu sein. Wenn eine Störung zu einer

Überhitzung führt, könnte die Oberächentemperatur

auf die Maximaltemperatur ansteigen (300-540°C,

je nach Modellspezikation) und für unbestimmte

Zeit auf dieser Temperatur verbleiben. Unter diesen

Bedingungen kann das zu erhitzende Material an der

Oberäche der Heizplatte ein höhere Temperatur als die

Höchsttemperatur erreichen.

Dieses Handbuch enthält wichtige Bedienungs- und

Sicherheitshinweise. Der Benutzer muss dieses

Handbuch sorgfältig durchlesen und die Inhaltevor der

Verwendung dieses Geräts verstehen.

10

Warnungen

Zur Vermeidung von Stromschlag, immer:

1. Eine ordnungsgemäß geerdete Steckdose

verwenden, welche auf die korrekte Spannung und

Strombelastbarkeit ausgelegt ist.

2. Das Gerät vor der Wartung und Reparatur von der

Stromversorgung abtrennen.

Page 11

ICHERHEIT SHINWEISE

S

Um Verletzungen zu vermeiden:

1. Nicht in der Nähe von entzündlichen oder brennbaren

Materialien verwenden - es besteht Brand- oder

Explosionsgefahr. Dieses Gerät enthält Komponenten,

die solche Materialien entzünden können. Nicht für

den Einsatz in Bereichen freigegeben, in denen

Explosionsgefahr besteht.

2. Vorsicht beim Erhitzen üchtiger Materialien. Die

Oberäche und das Element können die Temperatur

des "Entammungspunkts" vieler Chemikalien

erreichen.

Die Heizplatten sind nicht explosionsgeschützt. Dies

kann zu einem Brand oder einer Explosion führen.

Dieses Gerät enthält Komponenten, die solche

Materialien entzünden können.

3. Halten Sie die Oberäche sauber. Verwenden Sie

ein nicht scheuerndes Reinigungsmittel. Leckagen

von Alkali, Flußsäure oder Phosphorsäure können

die Oberäche beschädigen und zum Ausfall der

Heizkomponenten führen. Ziehen Sie den Netzstecker

der Einheit und entfernen Sie Leckagen unverzüglich.

Nicht zur Reinigung in Flüssigkeiten eintauchen.

4. Ersetzen Sie die Oberäche sofort, falls es durch

Verätzungen, Kratzer oder Absplitterungen beschädigt

ist. Eine beschädigte Oberäche kann während dem

Gebrauch brechen.

5. Verwenden Sie keine Metallfolie auf der Heizplatte,

welches den Luftstrom blockieren kann. Das kann

Überhitzung zur Folge haben.

6. Überprüfen und ziehen Sie das abnehmbare Kabel

regelmäßig an und gewährleisten, dass es sicher ist.

Wenn gelockert, kann das Kabel heiß werden und/oder

Funken schlagen und eine potentielle Brandgefahr

darstellen. Wenn das Kabel beschädigt erscheint,

sofort ersetzen. Wenn das Kabel sich wiederholt

lockert, wird empfohlen, das Netzeingangsmodul

(Teilenummer CIC0000793 oder CIC0000469, je

nach Modell), wie im Abschnitt Ersatzteile in diesem

Handbuchs aufgeführt, zu erwerben.

7. Den geerdeten Netzstecker nicht entfernen oder

modizieren. Verwenden Sie nur geerdete Steckdosen,

um einen Stromschlag zu vermeiden.

8. Benutzen Sie geeigneten Hand und Augenschutz beim

Umgang mit gefährlichen Chemikalien.

9. Das Bruttogewicht der Gegenstände, die auf die

Heizplatten gegeben werden sollte 15,9 kg nicht

überschreiten (35 lbs). Auf den 10 Zoll x 10 Zoll

Modellen, 11,3 kg (25 lbs) auf den 7 Zoll x 7 Zoll

Modellen.

10."Vorsicht: Heiße Oberäche. Kontakt vermeiden."

Die obere Heizplatte des Geräts kann für einige Zeit

nach der Benutzung heiß bleiben. Eine Warnleuchte

"ACHTUNG - HEISSE OBERFLÄCHE" wird

aueuchten bis die Temperatur der oberen Heizplatte

auf unter 50°C abkühlt.

11.Lassen Sie keine Flüssigkeit aus der aktiven Probe

entweichen. Dies kann eine unkontrollierte Erwärmung

der Flüssigkeit auf der Heizplatte zur Folge haben

und ein unbeabsichtigtes Sieden oder eine Explosion

verursachen.

12.Die lokalisierte Heizelementtemperatur kann

wesentlich höher sein als die Temperatur die auf dem

Display angegeben ist. Wenn brennbare Mischungen

innenliegende Elemente erreichen, könnte dies zu

einem Brand führen.

13.Beachten Sie, dass das Außengehäuse während dem

Gebrauch und eine gewisse Zeit danach heiß ist.

14.Kontaktieren Sie für alle Wartungsarbeiten

qualiziertes Servicepersonal.

11

Page 12

Informations de sécurité

Votre Plaque Chauffante Agitatrice Cimarec Thermo-

Scientique a été conçue, tout en ayant à l'esprit:

la fonction, la abilité et la sécurité. Il est de votre

responsabilité de l'installer en conformité aux codes

Signaux d'alerte

Avertissement

Les avertissements vous alertent de la

possibilité de blessures corporelles.

Mise en garde

Les mises en garde vous avertissent

de la possibilité d'endommagement de

l'équipement.

Remarque

Les remarques vous alertent de conditions

et de faits pertinents.

Surface chaude

Les surfaces chaudes vous avertissent de

la possibilité de blessures corporelles, si

vous entrer en contact avec une surface en

cours d'utilisation ou pour une période de

temps après l'utilisation.

électriques locaux. Pour un fonctionnement en toute

sécurité, veuillez prêter attention aux signaux d'alerte

mentionnés à travers le manuel.

Avertissement: Ces produits ne devraient être utilisés

que dans des conditions d'utilisation spéciées dans le

manuel d'utilisation. Employer toujours des pratiques

de laboratoire sûres et ne laissez pas la plaque

chauffante fonctionner sans surveillance puisque

des défaillances de fonctionnement du produit ou de

pratique de laboratoire pourraient survenir et conduire

à un chauffage incontrôlé ou excessif de la surface

supérieure. Des procédures de sécurité (y compris,

mais non limité au débranchement lorsqu'il n'est pas en

cours d'utilisation) et des plans d'intervention devraient

être mis en place pour résoudre le pire des scénarios.

Si une panne de surchauffe se produit, la température

de la surface supérieure pourrait augmenter jusqu'à

la température maximale (300-540°C, en fonction

des spécications de votre modèle) et demeurer

indéniment à cette température . Dans ces conditions,

le matériel chauffé sur la surface de la plaque chauffante

pourrait atteindre des nivaux au-delà de la température

maximale.

Ce manuel contient d'importantes informations relatives

au fonctionnement et à la sécurité. L'utilisateur doit

attentivement lire et comprendre le contenu de ce

manuel avant d'utiliser cet équipement.

12

Avertissements

Pour éviter tout risque de choc électrique,

toujours:

1. Utiliser une prise électrique correctement mise à la

terre avec une tension et capacité de gestion du

courant correctes.

2. Débrancher de la source d'alimentation, avant de

procéder à l'entretien et la maintenance.

Page 13

NFORMATION DE SÉCURITÉ

I

Pour éviter les blessures:

1. Ne pas utiliser en présence de matériaux inammables

ou combustibles - cela peut entraîner un incendie ou

une explosion. Cet appareil contient des composants

qui peuvent enammer ces matériaux. Ne pas utiliser

dans des lieux dangereux.

2. Faire preuve de prudence lors du chauffage de

matériaux volatils; la surface supérieure et l'élément.

3. Garder propre la surface supérieure. Utiliser un

produit de nettoyage non abrasif. Les déversements

alcalis, les déversements d'acide uorhydrique ou

les déversements d'acide phosphorique peuvent

endommager la partie supérieure et conduire à une

défaillance thermique. Débrancher l'appareil et enlever

rapidement les déversements. Ne pas plonger l'unité

dans de l'eau pour le nettoyer.

4. Remplacer immédiatement la partie supérieure, si

elle est endommagée par une attaque chimique,

une rayure ou un écaillage. Une partie supérieure

endommagée peut tomber en passe en cours

d'utilisation.

5. Ne pas utiliser la feuille de métal sur la plaque chaude,

cela peut bloquer la circulation d'air. Une surchauffe

pourra se produire.

6. Vérier et serrer périodiquement le cordon amovible,

pour s'assurer qu'il est sécurisé. S'il est desserré,

le cordon pourrait devenir chaud et/ou produire une

étincelle et constituer un risque potentiel d'incendie.

Si le cordon semble endommagé, le remplacer

immédiatement. Si le cordon se desserre à maintes

reprises, il est conseillé d'acheter le module d'entrée

de l'alimentation (numéro de pièce CIC0000793 ou

CIC0000469, selon les modèles) inventorié dans la

section Pièces de Rechange de ce manuel.

7. Ne pas retirer ou modier la che d'alimentation mise

à la terre. Utiliser uniquement des prises mises à la

terre correctement, an d'éviter tout risque de choc

électrique.

8. Utiliser des lunettes et des gants de protection, lors de

la manipulation de produits chimiques dangereux.

9. Le poids brut des éléments placés sur la partie

supérieure des plaques chauffantes ne doit pas

dépasser 35 lbs. (15,9 Kg.) sur les modèles 10" x 10",

25 lbs. (11,3 Kg) sur les modèles 7" x 7" .

10."Mise en garde: Partie supérieure Chaude. Éviter

tout contact." La partie supérieure de la plaque de

l'unité peut rester chaude pendant un certain temps

après utilisation. Un témoin "ATTENTION - PARTIE

SUPÉRIEURE CHAUDE" restera allumé jusqu'à ce

que la température de la partie supérieure de la plaque

descende en-dessous de 50°C.

11.Ne pas laisser de sonde active hors du liquide. Cela

peut provoquer un réchauffement incontrôlé du liquide

sur la plaque chaude et une ébullition involontaire ou

une explosion pourraient se produire.

12.La température de l'élément chauffant localisé peut

être sensiblement plus élevée que la température

indiquée sur l'afchage. Si des concentrations

inammables atteignent l'élément interne, un incendie

pourrait se produire.

13.Notez que le boîtier extérieur sera chaud pendant et

pour une période de temps après utilisation.

14.S'adresser à un personnel qualié pour la

maintenance.

13

Page 14

Informação de Segurança

A sua Chapa Eléctrica Cimarec Térmica foi desenhada

com funcionalidade, conança e segurança em mente.

É sua responsabilidade instalar de acordo com os

regulamentos eléctricos locais. Para operação segura,

Sinais de Aviso

Aviso

Os avisos alertam para a possibilidade de

ferimentos pessoais.

Cuidado

Os sinais de cuidados alertam para a

possibilidade de danos no equipamento.

Nota

As notas alertam para factos e condições

pertinentes.

preste atenção aos sinais de alerta presentes no

manual.

Aviso: Estes produtos devem ser unicamente utilizados

sob as condições de operação especicadas no

Manual de Utilização. Siga sempre todas as práticas

de laboratório seguras e não deixe a chapa eléctrica

em funcionamento sem supervisão, uma vez que a

funcionalidade do produto ou falhas de práticas de

laboratório podem ocorrer e conduzir ao aquecimento

não controlado ou excessivo na superfície superior.

Os procedimentos de segurança (incluindo, mas não

limitado a, desligar da cha quando não estiver em

utilização) e planos de resposta devem ser postos em

prática no pior caso possível. Em caso de falha de

sobreaquecimento, a temperatura da superfície superior

pode aumentar para a temperatura máxima (300 -

540ºC dependendo das especicações do seu modelo)

e manter-se na mesma durante um tempo indenido.

Sob estas condições, o material a ser aquecido na

superfície da chapa pode alcançar níveis excessivos de

temperatura.

Superfície Quente

Os sinais de superfície quente alertam para

a possibilidade de ferimentos pessoais se

entrar em contacto com uma superfície

durante a utilização ou por um período de

tempo após a utilização.

14

Este manual contém informação de operação e

segurança importante. O utilizador deve ler atentamente

e compreender os conteúdos deste manual antes de

utilizar o equipamento.

Avisos

Para evitar choque eléctrico:

1. Utilize sempre uma tomada eléctrica aterrada com a

voltagem e capacidade de manuseamento de corrente

correctas.

2. Desligue sempre a alimentação antes da manutenção

e assistência.

Page 15

NFORMAÇÃO DE SEGURANÇA

I

Para evitar ferimentos pessoais:

1. Não utilize na presença de materiais combustíveis

ou inamáveis - poderá resultar em incêndio e

explosão. Este dispositivo contém componentes que

podem incendiar esses materiais. Não aprovado para

utilização em atmosferas perigosas.

2. Tenha cuidado quando aquecer materiais voláteis;

a superfície e elemento superiores podem alcançar

a "Temperatura de Ponto de Incêndio" de muitos

químicos. Estas chapas eléctricas não são à prova de

explosão. Poderá resultar em incêndio ou explosão. A

unidade contém componentes que.

3. Mantenha a superfície superior limpa. Utilize um

detergente não abrasivo. Derramamentos de

alcalinos, ácidos hidrouóricos ou ácidos fósforos

podem danicar a superfície e conduzir a falha

termal. Desligue a unidade da tomada e limpe os

derramamentos de imediato. Não mergulhe a unidade

para limpeza.

4. Substitua a superfície de imediato se danicada por

cauterização, arranhões ou lascas. A superfície pode

partir durante a utilização.

5. Não utilize folha de metal na chapa, pois poderá

bloquear o uxo de ar. Poderá resultar em

sobreaquecimento.

6. Verique e aperte o cabo removível periodicamente

para se certicar que está seguro. Se estiver solto, o

cabo pode car quente e/ou faiscar, sendo um perigo

potencial de incêndio. Se o cabo estiver danicado,

substitua de imediato. Se o cabo estiver solto várias

vezes, recomendamos que compre um adaptador de

energia (número de peça CIC0000793 ou CIC0000469

dependendo do modelo) listado na secção de Peças

de Substituição deste manual.

7. Não retire nem modique a cha de alimentação

aterrada. Utilize unicamente tomadas correctamente

aterradas para evitar perigo de choque eléctrico.

8. Utilize protecção de mãos e olhos quando manusear

químicos perigosos.

9. O peso bruto dos produtos colocados em cima da

chapa não deve exceder os 35 lbs. (15.9 kg.) em

modelos 10” x 10”, 25 lbs. (11.3 kg.) em modelos 7” x

7”.

10."Cuidado: Topo Quente. Evite Contacto." A chapa

superior da unidade pode permanecer quente durante

algum tempo após a utilização. A luz "CUIDADO

- TOPO QUENTE" irá permanecer ligada até a

temperatura descer abaixo dos 50ºC.

11.Não deixe um estilete activo fora do uído. Isto

poderá causar aquecimento descontrolado do uído

na chapa e poderá resultar em fervura ou explosão

não intencional.

12.A temperatura de elemento de aquecimento

localizada pode ser signicantemente superior à

temperatura indicada no ecrã. Se as concentrações

inamáveis alcançarem o elemento interno, poderá

resultar em incêndio.

13.Note que o revestimento exterior estará quente

durante a utilização e após a mesma.

14.Rera a assistência ao pessoal qualicado.

15

Page 16

Информация по безопасности

Ваша термо нагревательная плита была

разработана с функцией надежности и безопасности.

Вам необходимо установить ее в соответствии

с местными нормативами. Для безопасной

Сигналы тревоги

Предупреждение

Символы предупреждения указывают на

возможность получения травмы.

Осторожно

Символы осторожно указывают

на возможность повреждения

оборудования.

Примечание

Примечания указывают на

соответствующие факты и условия.

Горячая поверхность

Символ горячей поверхности

предупреждает о возможности получения

травмы, если вы вступите в контакт с

поверхностью во время использования

или в течение периода времени после

использования.

эксплуатации, пожалуйста, обратите внимание на

сигналы тревоги по всему руководству.

Предупреждение: Данные продукты следует

использовать только в рабочих условиях, указанных

в руководстве по эксплуатации. Всегда следуйте

технике безопасности и не оставляйте работающую

плиту без присмотра, так как функциональность

продукта или несоблюдение техники безопасности

может привести к неконтролируемому или

чрезмерному нагреву верхней поверхности. Техника

безопасности (включая, но не ограничиваясь,

отсоединение от розетки, во время, когда плита не

используется) и планы реагирования должны быть

приняты для решения крайней необходимости.

Если происходит сбой из-за перегрева, температура

верхней поверхности может подняться до

максимальной температуры (300-540°C в

зависимости от спецификации вашей модели)

и оставаться при этой температуре в течение

длительного времени. В этих условиях, продукты,

нагреваемые на поверхности плиты, могут достичь

уровня выше максимальной температуры.

Это руководство содержит важную операционную

информацию и информацию по безопасности.

Пользователь должен внимательно прочитать и

понять содержание данного руководства перед

началом использования данного оборудования.

16

Предупреждения

Во избежание поражения электрическим

шоком, всегда:

1. Используйте правильно заземленную розетку

соответствующего напряжения и пропускной

способностью тока.

2. Отсоединяйте от источника питания перед

обслуживанием и сервисом.

Page 17

Во избежание получения травмы:

1. Не используйте возле легковоспламеняющихся или

горючих материалов – это может привести к пожару

или взрыву. Это устройство содержит компоненты,

которые могут воспламенить эти материалы. Не

предназначено для использования в опасной

атмосфере.

2. Будьте внимательны при нагревании летучих

веществ; верхняя поверхность и элемент могут

достигнуть "температуры вспышки" многих

химических веществ. Данные нагревательные

плиты не взрывозащищенные. Это может привести

к пожару или взрыву. Блок содержит компоненты,

которые могут воспламенить эти материалы.

CIC0000469 в зависимости от модели), имеющийся

в разделе Запасные части данного руководства.

7. Не удаляйте или не изменяйте заземленную вилку.

Используйте только правильно заземленные

розетки, чтобы избежать поражения электрическим

током.

8. Используйте соответствующие защитные средства

для рук и глаз при работе с опасными химическими

веществами.

9. Общий вес предметов, помещаемых на плиту, не

должен превышать 35 фунтов (15,9 кг) на 10" х 10"

модели, 25 фунтов (11,3 кг) на 7” x 7” модели.

3. Держите верхнюю поверхность в чистоте.

Используйте неабразивный очиститель. Щелочные

растворители, растворители с содержанием

фтористоводородной кислоты или фосфорной

кислоты могут повредить верхний слой и привести

к термическим повреждениям. Отключайте

устройство и тщательно удаляйте растворители.

Не опускайте прибор в воду для чистки.

4. Немедленно замените верхнюю поверхность,

если она повреждена в результате травления,

царапин или обкалывания. Поврежденная

верхняя поверхность может сломаться во время

использования.

5. Не используйте металлическую фольгу на

нагревающей плите, это может блокировать поток

воздуха и привести к перегреву.

6. Периодически проверяйте и затягивайте съемный

шнур для того, чтобы убедиться в безопасности.

Ослабленный шнур может нагреваться и/или

искрить и стать потенциальной опасностью

возгорания. Если шнур поврежден, немедленно

замените его. Если шнур неоднократно

ослабляется, рекомендуется приобрести блок

входного питания (номер детали CIC0000793 или

10."Осторожно: Горячая поверхность. Избегайте

контакта." Верхняя плита блока может оставаться

горячей некоторое время после использования.

Надпись "ОСТОРОЖНО – ГОРЯЧАЯ

ПОВЕРХНОСТЬ" будет гореть до тех пор, пока

температура верхней плиты не остынет до

температуры ниже 50°C.

11.Не оставляйте активную емкость с чрезмерным

количеством жидкости. Это может привести к

неконтролируемому нагреву жидкости на горячей

плите и непреднамеренному кипению или взрыву.

12.Локализованная температура нагревательного

элемента может быть значительно выше, чем

температура, указанная на дисплее. Если горючие

концентрации достигают внутреннего элемента, это

может привести к пожару.

13.Необходимо принять во внимание, что внешний

корпус будет горячим во время и в течение периода

времени после использования.

14.За сервисным обслуживанием обращайтесь к

квалифицированному персоналу.

17

Page 18

General Specication

Ceramic Hot Plate Specications

Overall Dimensions HP88857190 HP88857195 HP88850190 HP88850195

Width - in.(cm) 8.2 (20.8) 8.2 (20.8) 11.3 (28.8) 11.3 (28.8)

Height - in.(cm) 4.1 (10.5) 4.1 (10.5) 4.1 (10.5) 4.1 (10.5)

Depth - in.(cm) 14.2 (36) 14.2 (36) 17.2 (43.8) 17.2 (43.8)

Weight - lbs.(kg) 7.5 (3.4) 7.5 (3.4) 11.5 (5.2) 11.5 (5.2)

Top Plate Dimensions

Width - in.(cm) 7.25 (18.4) 7.25 (18.4) 10.5 (26.7) 10.5 (26.7)

Height - in.(cm) 1.0 (2.5) 1.0 (2.5) 1.0 (2.5) 1.0 (2.5)

Depth - in.(cm) 7.25 (18.4) 7.25 (18.4) 10.5 (26.7) 10.5 (26.7)

Volts 100-120 220-240 100-120 220-240

Amps 12.3 4.4 13.2 6.0

Watts 1480 1056 1580 1440

Freq. 50/60 50/60 50/60 50/60

Phase 1 1 1 1

Max. Temp °C (°F) 450°C(842°F) 450°C(842°F) 400°C(752°F) 400°C(752°F)

Ceramic Stirrer Specications

Overall Dimensions S88857190 S88857195 S88850190 S88850195

Width - in. (cm) 8.2 (20.8) 8.2 (20.8) 5.1 (13) 5.1 (13)

Height - in. (cm) 4.1 (10.5) 4.1 (10.5) 4.1 (10.5) 4.1 (10.5)

Depth - in. (cm) 14.2 (36) 14.2 (36) 17.2 (43.8) 17.2 (43.8)

Weight - lbs. (kg) 9.0 (4.1) 9.0 (4.1) 13.0 (5.9) 13.0 (5.9)

Top Plate Dimensions

Width - in. (cm) 7.25 (18.4) 7.25 (18.4) 10.5 (26.7) 10.5 (26.7)

Height - in. (cm) 1.0 (2.5) 1.0 (2.5) 1.0 (2.5) 1.0 (2.5)

Depth - in. (cm) 7.25 (18.4) 7.25 (18.4) 10.5 (26.7) 10.5 (26.7)

Volts 100-120 220-240 100-120 220-240

Amps 0.2 0.1 0.2 0.1

Watts 24 24 24 24

Freq. 50/60 50/60 50/60 50/60

Phase 1 1 1 1

18

Page 19

ENERAL SPECIFICATIONS

G

Ceramic Stirring Hotplate Specications

Overall Dimensions SP88857190 SP88857195 SP88850190 SP88850195

Width - in. (cm) 8.2 (20.8) 8.2 (20.8) 5.1 (13) 5.1 (13)

Height - in. (cm) 4.1 (10.5) 4.1 (10.5) 4.1 (10.5) 4.1 (10.5)

Depth - in. (cm) 14.2 (36) 14.2 (36) 17.2 (43.8) 17.2 (43.8)

Weight - lbs. (kg) 9.0 (4.1) 9.0 (4.1) 13.0 (5.9) 13.0 (5.9)

Top Plate Dimensions

Width - in. (cm) 7.25 (18.4) 7.25 (18.4) 10.5 (26.7) 10.5 (26.7)

Height - in. (cm) 1.0 (2.5) 1.0 (2.5) 1.0 (2.5) 1.0 (2.5)

Depth - in. (cm) 7.25 (18.4) 7.25 (18.4) 10.5 (26.7) 10.5 (26.7)

Volts 100-120 220-240 100-120 220-240

Amps 12.3 4.4 13.2 6.0

Watts 1480 1056 1580 1440

Freq. 50/60 50/60 50/60 50/60

Phase 1 1 1 1

Max. Temp °C (°F) 450°C(842°F) 450°C(842°F) 400°C(752°F) 400°C(752°F)

Aluminum Hot Plate Specications

Overall Dimensions HP88857194 HP88857198 SP88857194 SP88857198

Width - in. (cm) 8.2 (20.8) 8.2 (20.8) 8.2 (20.8) 8.2 (20.8)

Height - in. (cm) 4.1 (10.5) 4.1 (10.5) 4.1 (10.5) 4.1 (10.5)

Depth - in. (cm) 14.2 (36) 14.2 (36) 14.2 (36) 14.2 (36)

Weight - lbs. (kg) 7.5 (3.4) 7.5 (3.4) 9.0 (4.1) 9.0 (4.1)

Top Plate Dimensions

Width - in. (cm) 7.25 (18.4) 7.25 (18.4) 7.25 (18.4) 7.25 (18.4)

Height - in. (cm) 1.0 (2.5) 1.0 (2.5) 1.0 (2.5) 1.0 (2.5)

Depth - in. (cm) 7.25 (18.4) 7.25 (18.4) 7.25 (18.4) 7.25 (18.4)

Volts 100-120 220-240 100-120 220-240

Amps 6.0 2.6 6.0 2.6

Watts 720 624 720 624

Freq. 50/60 50/60 50/60 50/60

Phase 1 1 1 1

Max. Temp °C (°F) 300°C(572°F) 300°C(572°F) 300°C(572°F) 300°C(572°F)

19

Page 20

ENERAL SPECIFICATIONS

G

Heating Specications*

Top Plate Surface - Solid Ceramic

Temperature range: 30°C - 450°C (86°F - 842°F)* 7” x 7”

30°C - 400°C (86°F - 752°F)* 10” x 10”

Heat-up time to maximum temperature (unloaded top plate).

Accuracy of the temperature display vs. the actual average

temperature of a 2” diameter of setting area at the center of the top

plate (setpoint 100°C unloaded).

- Temperature stability at the center of the top plate

surface (@ 100°C unloaded).

Accuracy of remote probe at user selected calibration temperature after

calibration procedure.

- Temperature stability using remote probe

(500 ml of water in a 1000 ml ask at 70°C)

7” x 7”

5 minutes 7 minutes

± 5.0°C ± 5.0°C

± 1.0°C ± 1.0°C

±0.5 typical ±0.5 typical

±0.5°C ±0.5°C

10” x 10”

Top Plate Surface - Solid Aluminum

Temperature range: 30°C - 300°C (86°F - 572°F)* 7” x 7”

Heat-up time to maximum temperature (unloaded top plate).

Accuracy of the temperature display vs. the actual average

temperature of a 2” diameter of setting area at the center of the top

plate (setpoint 100°C unloaded).

- Temperature stability at the center of the top plate

surface (@ 100°C unloaded).

Accuracy of remote probe at user selected calibration temperature after

calibration procedure.

- Temperature stability using remote probe

(500 ml of water in a 1000 ml ask at 70°C)

** As the top plate becomes dirty, the maximum temperature will decrease. To return the unit to its maximum

temperature performance, use a mild abrasive to remove stained areas.

7” x 7”

5 minutes

± 5.0°C

± 1.0°C

±0.5 typical

±0.5°C

Stirring Speed Specications

Speed Range 50 to 1500 RPM(Maximum speed is dependent on the viscosity of the solution).

Stability of the stirring speed setpoint (600 ml of water in a 1000 ml glass ask) ± 5.0% at 1000 RPM

Top Plate Size Max Recommended Flask Size Max Weight on Top Plate

7 x 7 4 liters 25 lbs

10 x 10 6 liters 35 lbs

* The specication dened in this section is derived from testing data statistics of Thermo Fisher Scientic lab. We

reserve the right to make changes in design and specication without prior notice.

20

Page 21

ENERAL SPECIFICATIONS

G

Environmental Conditions

Operating:

Storage:

5°C to 35°C; 20% to 80% relative humidity,

non-condensing.Installation category II

(overvoltage) in accordance with IEC 664.

Pollution degree 2 in accordance with IEC

664. Altitude Limit: 2,000 meters.

-25°C to 65°C

10% to 85% relative humidity

Declaration of Conformity

We hereby declare under our sole responsibility that this product conforms with the technical requirements of the

following standards:

EMC: EN 61000-3-2 Limits for harmonic current emissions

EN 61000-3-3

EN 61326-1

Limits for voltage uctuations and icker

Electrical equipment for measurement, control, and

laboratory use; Part I: General Requirements

Safety: EN 61010-1 Safety requirements for electrical equipment for

measurement, control, and laboratory use;

Part I: General Requirements

EN 61010-2-010 Part II: Particular requirements for laboratory

equipment for the heating of materials

EN 61010-2-051 Part II: Particular requirements for laboratory

equipment for mixing and stirring

per the provisions of the Electromagnetic Compatibility Directive 2014/30/EU, and per the provisions of the Low

Voltage Directive 2014/35/EU.

Copies of the Declaration of Conformity are available upon request.

21

Page 22

Introduction

+

SUPER-NUOVA

Stirring Hotplate

Please read all the information in this manual before

operating the unit.

Your SUPER-NUOVA

hot plate is a heating and/or stirring plate designed

for laboratory procedures requiring precise control

of temperature and/or stirring speed. Each SUPERNUOVA+ model includes a liquid crystal display for

monitoring actual and setting temperature and/or

stirring speed. The hot plate is capable of producing

accurately controlled top plate temperatures from

30°C through 300°C, 400°C or 450°C depending on

models. The temperature is controlled at the plate

surface by an internal Type K thermocouple sensor, or

the solution temperature may be controlled by utilizing

the included PT100 probe. A PT1000 probe may be

ordered separately. The 7 x 7 or 10 x 10 top plate on

the SUPER-NUOVA+ units are solid ceramic or solid

aluminum, and are suitable for use with glass or metal

vessels and sand baths.

Other features of the SUPER-NUOVA

time feature that can be used to shut off heating.

Specic temperature setpoints may be set using the

PROGRAM buttons on the SUPER-NUOVA+. An over

temperature protection (OTP) can be displayed in the

system conguration menus. See details in “System

Conguration”.

Your SUPER-NUOVA

purpose heating applications including sample

preparation, heating reagents, melting parafn,

warming resinous chemicals, content analysis, solvent

evaporations, digestions, media preparation and

sterilization, titrations, sand baths, and micro-scale

chemistry applications.

+

hot plate, stirrer or stirring

+

include a

+

model may be used for general

22

General Cleaning Instructions

Keep top surface clean. Use a non-abrasive cleaner.

Alkali spills, hydrouoric acid spills or phosphoric acid

spills may damage top and lead to thermal failure.

Unplug unit and remove spills promptly. Do not immerse

unit for cleaning. Wipe exterior housing with lightly

dampened cloth containing mild soap solution.

Page 23

Unpacking and Installation

Warning

Use a properly grounded electrical outlet

of correct voltage and current handling

capacity.

Do not remove or modify grounded power

plug. Use only properly grounded outlets

to avoid shock hazard. Not rated for use in

hazardous atmospheres.

Do not use in the presence of ammable or

combustible materials; re or explosion may

result. This device contains components

which may ignite such materials. If

explosion proof models are required,

contact Customer Service at 1-800-5530039 for more information.

Do not use in highly corrosive atmospheres; corrosive fumes and spills may

damage top and internal components,

creating shock hazard.

Unpacking

Remove your SUPER-NUOVA+ unit from the carton.

Inspect to ensure that the unit has not been damaged

during shipment. If the unit appears to have sustained

shipping damage contact the distributor from whom you

purchased this product or Customer Service at 800-553-

0039. Check for remote probe and thumbscrew prior to

discarding packaging.

The following items are included in the shipment:

+

SUPER-NUOVA

Cord

Remote Probe – PT100

Stir Bar (Stirring models only)

Knob

Operation's Manual

If any of these items are missing from the carton,

contact Customer Service.

unit

Note

Some misalignment of the motor bearings

in this product may have occurred during

shipping. Prior to using this product, run the

stirrer at maximum speed for ten minutes to

realign the bearings.

Installation

Set the unit on a at stable surface at least 12" away

from combustible materials, and plug the cord set into a

properly grounded electrical outlet of correct voltage and

current handling capacity.

23

Page 24

NPACKING AND INSTALLATION

U

SUPER-NUOVA+ Hot Plate Control Panel

+

SUPER-NUOVA

Stirrer Control Panel

+

SUPER-NUOVA

24

Stirring Hot Plate Control Panel

Page 25

NPACKING AND INSTALLATION

U

Control Panel

Key Description

1 CAUTION! HOT TOP Indicator

2 Display

3 Knob

4 Temperature Set Button

5 Speed Set Button

6 Time Set Button

7 Program Buttons

25

Page 26

Principles of Operation

Each SUPER-NUOVA+ unit utilizes the latest

microprocessor technology to deliver the most reliable,

accurately controlled, ceramic top or aluminum top hot

plate on the market.

+

Your SUPER-NUOVA

an electronic, closed-loop feedback control which will

accurately maintain temperature setpoints from 30°C

through 300°C, 400°C or 450°C depending on models.

The SUPER-NUOVA

for measuring the top plate temperature, OTP and

the external probe. Both top plate surface and OTP

temperature are measured with independent analog

circuits. This provides a signicant increase in safety

due to the redundancy of the circuits. It is possible to

heat certain types of metal vessels and sand baths on

the SUPER-NUOVA+ without damaging the ceramic top

or aluminum top.

unit with heating functionality has

+

units use a Type K thermocouple

The electronic stirring speed control will maintain the

speed setpoint when the unit is loaded. The motor is

combined with a powerful magnet to provide exceptional

magnetic coupling with a stir bar.

+

The time feature on the SUPER-NUOVA

programmed to turn off the stirring, heating or both. See

“Setting the Time” section of this manual.

can be

26

Page 27

Warning

Use caution when heating volatile

materials; top surface and element can

reach the “Flash Point Temperature” of

many chemicals. These hot plates are not

explosion proof. Fire or explosion may

result. Unit contains components which

may ignite such materials.

Use appropriate hand and eye protection

when handling hazardous chemicals.

Operation

Hard Switch

The SUPER-NUOVA+ unit has a hard switch on the

left side of the unit. The unit may be powered on by

pressing the hard switch. When the unit is turned on, the

unit will initialize and then model name will be displayed

on the rst row of display screen while software version

in second row. To turn off power to the unit, press the

hard switch off.

“Caution: Hot Top. Avoid Contact.” The

top plate of the unit can remain hot for

some time after use. A “CAUTION - HOT

TOP” light will remain on until top plate

temperature cools to below 50°C.

Note

Boiling times are dependent on solution volume and the surface area of the

ask that is exposed to the hot plate. For

example, when heating the same amount

of solution in a 2L ask vs. a 1L ask, the

solution will heat about 20% faster.

Note

The top plate temperature will be higher

than the solution temperature.

Setting the Stirring Speed

The SUPER-NUOVA+ stirring unit has an electronic

feedback speed control which will maintain a precise

speed setpoint from 50 rpm through 1500 rpm.

(Maximum speed is dependent on viscosity of the

solution.) The SUPER-NUOVA+ stirring hot plates are

equipped with a strong magnet and high torque motor

which will draw a vortex in uids up to 700 cp.

To set the stirring speed, press “SPEED” key located

under display. Then the speed setpoint will ash. Use

the knob on the front panel to set a speed. Turn the knob

clockwise to increase the speed or counterclockwise to

decrease the speed. When desired setpoint has been

reached, press the “SPEED” key or wait 10 seconds, the

speed setpoint will no longer ash indicating that it has

been set.

Once the unit begins stirring, the display will indicate

both actual speed and setpoint. To stop the stirring

action without changing your setpoint press the knob

once. To resume stirring at the set speed, press the

knob again.

To turn stirring off, press “SPEED” key under the display

and turn the knob counterclockwise until the display

reads “OFF.”

27

Page 28

PERATION

O

Note

Boiling times are dependent on solution volume and the surface area of the

ask that is exposed to the hot plate. For

example, when heating the same amount

of solution in a 2L ask vs. a 1L ask, the

solution will heat about 20% faster.

Note

The top plate temperature will be higher

than your solution temperature.

Setting the Temperature

The SUPER-NUOVA+ heating unit has an electronic

closed-loop feedback control which will accurately

maintain temperature setpoints from 30°C through

300°C, 400°C or 450°C(depending on the model). An

unloaded hot plate will heat to maximum temperature

in just 5 minutes. A “CAUTION HOT TOP” light on the

front panel will illuminate whenever the top surface

temperature exceeds 50°C. The temperature may be

controlled either at the top plate by the internal Type

K thermocouple sensor, or in the solution using an

accessory ungrounded PT100 probe. If a probe is used,

the display will indicate “R” after actual temperature.

The SUPER-NUOVA+ heating units will accept any

ungrounded PT100(PT1000) probe, however the

accuracy of probes other than those tested and specied

may not reach the probe accuracy rating designated.

28

To set the temperature, press “TEMP” key located

under display. Then the temp setpoint will ash. Use the

knob on the front panel to select a temp. Turn the knob

clockwise to increase the temp or counterclockwise to

decrease the temp. When desired setpoint has been

reached, press the “TEMP” key or wait 10 seconds, the

temp setpoint will no longer ash indicating that it has

been set.

Page 29

PERATION

O

Controlling Solution Temperature Using External Probe

To control the solution temperature plug a PT100 probe into the probe receptacle located on the back side of the unit.

Place the probe into the solution. The display will indicate the actual temperature of the solution as measured by the

probe.

The external probe offers more exact temperature control than regulating the top plate by the internal sensor. If you

need to maintain a precise setpoint it is recommend to use a probe to control the solution temperature instead of

controlling by the top plate temperature.

+

When using a probe with the SUPER-NUOVA

the probe in the solution.

To ensure accurate probe readings, as much of the probe sheath as possible should be immersed in the solution. Make

sure the probe is immersed in the liquid and is not located in air or outside of the solution. If the probe is plugged into

the hot plate, but is not in solution while the heat control is operating, the temperature display will continue to indicate

an ambient temperature, and a probe out of solution error will occur. Because the set point cannot be reached the

heating element will continue to supply heat to the top plate, and the maximum top plate temperature(300°C, 400°C or

450°C) may be reached. If the remote probe does not sense a temperature change in three minutes the unit will display

ExProbe Err and shut down.

unit it is recommended that a clamp on a support rod be used to hold

Using Preset Programs

The SUPER-NUOVA+ unit features the option of presetting 3 setpoints into its memory. To program a preset, press any

preset button, and the indicator LED on the number button will be illuminated. Then adjust the time, speed and heat

features to your desired setpoints. Press the number button again to exit the preset program. The setpoints are stored

in memory automatically. The presets will be held in memory, even if the unit is unplugged, until you choose to override

it with another preset.

To activate one of the presets, press the corresponding number then press the knob, the time, speed and heat features

will automatically adjust itself.

It may be helpful to set one of the presets at “OFF.” This way, the heating can be shut off quickly.

+

The SUPER-NUOVA

Continue is being utilized. The default setting is to turn off the function. By pressing 1 and then pressing the knob

the unit will run by continuous presets by order 1, 2, 3. By selecting 2 and then pressing the knob the unit will run by

continuous presets by order 2, 3.

See “System Conguration” section of the manual to activate the Preset Continue function.

unit has a Preset Continue function. It means different presets can run continuously when Preset

29

Page 30

PERATION

O

Heating Metal Vessels and Sand Baths

Metal vessels and sand baths cannot be heated on most solid ceramic tops because of the tendency for the metal

and the sand to reect heat back into the top, eventually exceeding the maximum temperature rating for a ceramic

top, which causes it to break. Because of its advanced electronic control, the SUPER-NUOVA+ is capable of precisely

regulating the top plate temperature. Metal vessels and sand baths may be heated safely without the danger of the

ceramic top breaking.

Setting the Time

The time function on the SUPER-NUOVA+ can be set to shut off heating. To set the time, press “TIME” key located

under display. Hold will begin to ash.Turn the knob until time shows then press "TIME" key again.Use the knob on the

front panel to select a time. Turn the knob clockwise to increase the time or counterclockwise to decrease the time.

When desired setpoint has been reached, press the “TIME” key or wait 10 seconds, the time setpoint will no longer

ash indicating that it has been set.In the temperature rising mode, when the temperature is more than 2 degree below

the temperature setpoint, the timer will start to count.In the temperature declining mode, when the temperature is less

than 2 degree above the temperature setpoint ,the timer will start to count.

When the time setpoint display shows “HOLD” it means there is no setting for time function.

Hardware Over-Temperature-Protection

A hardware Over-Temperature-Protection(OTP) analog circuit is designed separately to protect unexpected heating.

A small straight blade screwdriver can be used to adjust the scale at right side of the unit. The protection value can be

set from 60°C to 500°C(or 300°C/450°C depending on models).

Please notice that this function is only purposed to avoid abnormal heating if unit is out of control. Users should not use

this function to limit the temperature in normal applications. Refer to the section ’Over-temperature Set Point – OTP ’for

accurate temperature protection.

Default set is at maximum scale.

30

Page 31

System Conguration

The System Conguration has three features that will allow a user to customize their unit.

A table of the features available in the System Conguration is given below. The features are given in order of their

appearance in the System Conguration when rotating the knob in a clockwise rotation. The Feature column is the

name of the feature, the Display column is the designation of that feature as shown on the display of the unit, the

Availability column gives which type of unit the feature is applicable (HP = hot plate SP = stirring hot plate S=stir plate),

and the last column gives a brief description of the purpose of the feature.

Feature Display Availability Brief Description

Temperature Unit

Conversion Overtemperature Set Point

Over-temperature Set

Point

Preset Continue Setting Preset Continue HP , S, SP

Temperature Probe

Calibration

Temp Unit HP , SP

User OTP HP , SP

Calibrate Temp HP , SP

Allows the user to converse temperature unit

between °C and F.

Allows the user to see the setting of the Over

Temperature Protection control.

Allows the user to set the program presetting

function.

Allows calibration of the temperature probe

and associated circuitry.

31

Page 32

ystem Conguration

S

Temp Unit

This option is only available for units that have heating functionality.

Plug the unit into the appropriate power, enter the System Conguration by pressing and holding the knob. After about

5 seconds you may remove your nger from the knob. The display indicate “System Cong” on the rst row, the “Temp

Unit” will show on the second row of the display.

Press the knob to enter the Temp Unit setting interface.(Long press will return to operation menu.) The “Temp Unit” will

display on the rst row, the Actual temperature and unit “c” or “F” ash on the second row. Turn the knob clockwise or

counterclockwise to change the temperature unit. When the desired temperature unit has reached, wait 10 seconds,

the display will return to operation menu indicating that it has been set.

Over-temperature Set Point –OTP

This option is only available for units that have heating functionality. The Over-temperature Set Point is the set point

of the independent temperature control. The purpose of the control is to limit the top temperature of the element

independently of the standard heating control. This is helpful if there is a failure of the main control that would cause

the top to heat excessively. Typically the set point will be adjustable from 60 to 300°C, 400°C or 540°C(depending on

the model).

The Over-temperature can be set or viewed with this menu option. To do so, follow the instructions given below:

Enter the System Conguration by pressing and holding the knob. After about 5 seconds a single you may remove your

nger from the knob. The display indicate “system cong” on the rst row, the “Temp Unit” will show on the second row

of the display.

Turn the knob clockwise until the “User OTP” show on the second row of the display. If you do no action, the display will

return to the operation status.

32

Page 33

ystem Conguration

S

Press the knob to enter the Over-temperature setting interface.(Long press will return to operation menu.) The “User

OTP” will display on the rst row, the Over-temperature setpoint ash on the second row. Turn the knob clockwise to

increase the temp or counterclockwise to decrease the temp. When the desired Over-temperature setpoint has been

reached, wait 10 seconds, the display will return to operation menu indicating that it has been set.

Preset Continue

Enter the System Conguration by pressing and holding the knob. After about 5 seconds a single you may remove your

nger from the knob. The display indicate “system cong” on the rst row, the “Temp Unit” will show on the second row

of the display. Turn the knob clockwise until the “Preset Continue” show on the second row of the display. If you do no

action, the display will return to the operation status.

Press the knob to enter the Preset Continue setting interface.(Long press will return to operation menu.) The “User

OTP” show on the rst row, “OFF” ash on the second row. Turn the knob clockwise to change the status. When “On”

has reached, wait 10 seconds, the display will return to operation menu indicating that it has been set.

33

Page 34

ystem Conguration

S

Temperature Probe Calibration

This section applies only to the calibration of the temperature probe system. The hot plate surface and the motor speed

cannot be calibrated. This method is only applicable to units that have heating functionality.

Enter the System Conguration by pressing and holding the knob. After about 5 seconds a single you may remove your

nger from the knob. The display indicate “system cong” on the rst row, the “Temp Unit” will show on the second row

of the display. Turn the knob clockwise until the “Calibrate Temp” show on the second row of the display. If you do no

action, the display will return to the operation status. The option “Calibrate Temp” will only show when there is a remote

probe PT100 or PT1000 adopted.

Press the knob to enter the Calibrate Temp setting interface. The “Calibrate Temp” show on the rst row, the measured

temperature ash on the second row. If the data is not matched the temperature you measure by external thermo

detector, you can turn the knob to calibrate. When it’s matched, press the knob to complete the calibration.

When setting and/or viewing is complete, the knob can be pressed to return to the previous operation menu.

34

Page 35

Troubleshooting

Error Codes

Error Handler will lock out heating functions if heating error is detected. Stirring functionality is unaffected. Error Handler

will lock out stirring functions if stirring error is detected. Heating functionality is unaffected. If the condition that caused

the error is no longer present, the unit will clear Errors automatically.

Displayed Message Intended to Detect Cause Solution

InProbe Err Internal thermocouple

out of range.

Internal thermocouple not

connected.

Ensure proper connection

and polarity of thermocouple.

Check Heater Excessive top heat-up

time

ExProbe Err External Probe left out

of solution.

Thermocouple open.

Thermocouple connected

backwards (reversed polarity).

Internal thermocouple short

circuit.

Failure in Internal thermocouple.

Failure in Element.

Failure in optocoupler/triac

circuit.

External Probe left out of

solution.

External probe connected

backwards.

Replace thermocouple

(attached to element).

Ensure proper connection

and polarity.

Remove short.

Replace thermocouple

(attached to element).

Replace Element.

Replace Control Board.

Place external probe into

solution.

Correct orientation of external

probe.

Over Temp OTP thermocouple

out of range.

Check Motor Motor system failure. Locked rotor condition.

OTP Circuit failure.

OTP potentiometer set too low.

Failure of motor.

Failure of motor circuit.

Failure of motor sensor.

Replace Control Board.

Increase OTP setting.

Free locked rotor.

Replace motor.

Replace Control Board.

Replace motor sensor.

35

Page 36

Exploded Views

7x7 Hot Plate - Exploded View

36

Page 37

XPLODED VIEWS

E

7x7 Hot Plate - Top Assembly

37

Page 38

XPLODED VIEWS

E

10x10 Hot Plate - Exploded

38

Page 39

XPLODED VIEWS

E

10x10 Hot Plate - Top Assembly

39

Page 40

Wiring Diagram

REF. DESCRIPTION (7X7) (10X10)

C1 INLET CIC0000469 CIC0000469

EL1(100-120V) HEATING ELEMENT CIC0000541 CIC0000543

EL1(220-240V) HEATING ELEMENT CIC0000540 CIC0000542

C2 PROBE CONNECTOR CIC0000589 CIC0000590

PC1(SP) CONTROL PCB CIC0000573 CIC0000582

PC1(HP) CONTROL PCB CIC0000574 CIC0000583

PC1(S) CONTROL PCB CIC0000589 CIC0000590

PC2 DISPLAY PCB CIC0000575 CIC0000584

S1 SPEED SENSOR SC1313X1 SC1313X1

S2 ENCODER SWX217 SWX217

S3(SP) MEMBRANE SWITCH CIC0000523 CIC0000532

S3(HP) MEMBRANE SWITCH CIC0000524 CIC0000533

S3(S) MEMBRANE SWITCH CIC0000525 CIC0000534

MT1(100-120V) MOTOR CIC0000482 CIC0000484

MT1(220-240V) MOTOR CIC0000483 CIC0000485

40

Page 41

Replacement Parts List

To insure your safety and for proper operation, the ceramic top plates for hot plates and stir plates are only sold as

complete assemblies. This assembly includes the ceramic top, element, thermocouple, insulation, bafe plate, and 2

ceramic top holders. We recommend not replacing individual components of the top plate.

Key 7x7 Part No. 10x10 Part No. Description

1 FTX34 FTX34 Foot (4)

2 CIC0001145 CIC0001145 CIC0001145 Clips for Triac

3 CIC0000573 CIC0000582 Control Board SP - 120V/230V

3 CIC0000574 CIC0000583 Control Board HP- 120V/230V

3 CIC0000575 CIC0000584 Control Board S- 120V/230V

3 CIC0000576 Control Board SP Al top - 120V/230V

3 CIC0000577 Control Board HP Al top - 120V/230V