Page 1

50125612-3 dicembre 2010

Thermo Fisher Scientific

RC BIOS

Instruction Manual

Page 2

IMPORTANT!

Please reference this page for the most up-to-date information on the

following*

• web site addresses

• contact information

• copyright and trademark information

*All subsequent pages in this manual may have incorrect web site addresses and contact information.

©2013 Thermo Fisher Scientific Inc. All rights reserved. Delrin, TEFLON, and Viton are registered

trademarks of DuPont. Noryl is a registered trademark of SABIC. POLYCLEAR is a registered

trademark of Hongye CO., Ltd. Hypaque is a registered trademark of Amersham Health As. RULON A

and Tygon are registered trademarks of Saint-Gobain Performance Plastics. Alconox is a registered

trademark of Alconox. Ficoll is a registered trademark of GE Healthcare. Haemo-Sol is a registered

trademark of Haemo-Sol. Triton X-100 is a registered trademark of Sigma-Aldrich Co. LLC. All other

trademarks are the property of Thermo Fisher Scientific Inc. and its subsidiaries.

Manufacturer

Thermo Fisher Scientific

Robert-Bosch-Straße 1

D - 63505 Langenselbold

Germany

Thermo Fisher Scientific Inc. provides this document to its customers with a product purchase to use

in the product operation. This document is copyright protected and any reproduction of the whole or

any part of this document is strictly prohibited, except with the written authorization of Thermo Fisher

Scientific Inc.

The contents of this document are subject to change without notice. All technical information in this

document is for reference purposes only. System configurations and specifications in this document

supersede all previous information received by the purchaser.

Thermo Fisher Scientific Inc. makes no representations that this document is complete,

accurate or error-free and assumes no responsibility and will not be liable for any errors,

omissions, damage or loss that might result from any use of this document, even if the

information in the document is followed properly.

This document is not part of any sales contract between Thermo Fisher Scientific Inc. and a

purchaser. This document shall in no way govern or modify any Terms and Conditions of Sale, which

Terms and Conditions of Sale shall govern all conflicting information between the two documents

Page 3

ThermoFisher

SCIENTIFIC

Ko

N

Fo nru

rrÄrsERKLAnu

ruc

(2006

I 421 EG; 2006/95/EG', 20041 108/EG)

DECLARATION

OF

CONFORMITY

(2006

I 421 EC; 2006/95/EC

;

2oo4 I 1

08

t EC)

DECLARATION DE CONFORMITE

(2006

I 42t CE;

2006/95/C E ; 2004 I

1 08

I

CE)

Produkt: Labor-Zentrifuge

Product: Laboratory

centrifuge

Produit: Centrifugeuse de laboratoire

Gerät:

Modet:

Rc12 BP+

Modöte:

Rc Blos

Best.-Nr.:

75007032,

75007033

Cat.-No.:

75007036

,75007097

Röförence:

Dr. Thomas

Reck

Werkleiter

C€

Dieses Produkt

wurde

in

Übereinstimmung

mit den Richtlinien

2006/95/EG

N iederspan nu ng, 2006 I 42lEG Masch

i nen,

20041 108/EG

elektromagnetische

Verträg

lichkeit

(E

M\,f hergestel lt u nd

geprüft.

This

product

is manufactured

and

duly carried out

in

compliance with

directions

2006/95/EC

Low

Voltage,2006142lEC Machinery, 20041108/EC electromagnetic

compatibility

(EMC).

Ce

produit

est fabriqu6

et

testö

selon

les directives

2006/95/CE mat6riel

6lectrique destin6 ä ötre

employ6

dans certaines limites de tension,

2006 I 42 I CE machi nes, 2OO4 I 1

08/CE

I a com

pati

bil it6

6lectroma

g

n6ti

q

ue.

Normen / Standards /

Normes:

EN 61010-1: 2004

I EN

61010-2-020:2006

EN 61 326-1:2006

I EN

5501

18:2007

/ EN 61000-6-2: 2005

Osterode, den 08.09.201 0

Thermo Electron LED GmbH

Werk Osterode

Am

Kalkberg

D-37520 Osterode

atum Jol(ument Revision

"stelll

l8 09 2010 29707033-0 50124625.doc

00

Freioeoeben Abdullah Laaboubr l8 09.201 0

V \HSNOC\KONF

Page 4

WEEE Conformity

This product is subject to the regulations of the EU Waste Electrical & Electronic Equipment (WEEE)

Directive 2002/96 It is marked by the following symbol:

Thermo Fisher Scientific has entered into agreements with recycling and disposal companies in all EU

Member States for the recycling and disposal of this device. For information on recycling and disposal

companies in Germany and on the products of Thermo Fisher Scientific, which fall under the RoHS

Directive (Restriction of the use of certain hazardous substances in electrical and electronic

equipment), please visit the website www.thermo.com/WEEERoHS

Page 5

Thermo Scientific RC BIOS i

T

Preface .......................................................................................................................................iii

Scope of Supply ........................................................................................................................iii

Intended Use ............................................................................................................................. iv

Accident Prevention ................................................................................................................ iv

Precautions ............................................................................................................................... iv

Chapter 1 Introduction and Description ...............................................................................................1-1

Characteristics of the RC BIOS ................................................................................1-2

Technical Data .........................................................................................................1-3

Directives, Standards and Guidelines ....................................................................................... 1-4

Functions and Features ............................................................................................................. 1-4

Mains Supply ...........................................................................................................1-5

Rotor Selection .........................................................................................................1-5

Chapter 2 Before use ................................................................................................................................2-1

Before Setting up ......................................................................................................2-2

Location ...................................................................................................................2-2

Installation ...............................................................................................................2-2

Aligning the Centrifuge ............................................................................................2-5

Transporting the Centrifuge .....................................................................................2-5

Mains Connection ....................................................................................................2-5

Other connections ....................................................................................................2-6

Storage .....................................................................................................................2-6

Chapter 3 Control Panel ...........................................................................................................................3-1

CONTROLL PANEL ..............................................................................................3-2

KEYS ........................................................................................................................3-2

RUN DISPLAY .......................................................................................................3-3

PRIMARY FUNCTION KEYS ...............................................................................3-4

SET DISPLAY .........................................................................................................3-7

KEYPAD LOCK ......................................................................................................3-8

Chapter 4 Operation .................................................................................................................................4-1

Switch on Centrifuge ................................................................................................4-2

Lid Opening .............................................................................................................4-2

Close Lid ..................................................................................................................4-2

Rotor Installation .....................................................................................................4-3

Normal Operation ....................................................................................................4-3

Centrifugation ..........................................................................................................4-5

Table of Contents

Page 6

Contents

ii RC B

IOS Thermo Scientific

Programmed Operation ........................................................................................... 4-6

Using Advanced Features (Options) ......................................................................... 4-8

Temperature Control ............................................................................................. 4-13

Rotor Temperature Equilibration .......................................................................... 4-14

Chapter 5 Customer Control Inspection ..............................................................................................5-1

Speed Controls ........................................................................................................ 5-2

Timer Controls ........................................................................................................ 5-2

Temperature Controls ............................................................................................. 5-3

Chapter 6 Maintenance and Care .........................................................................................................6-1

Cleaning Intervalls ................................................................................................... 6-2

Cleaning .................................................................................................................. 6-2

Disinfection ............................................................................................................. 6-4

Decontamination ..................................................................................................... 6-5

Autoclaving .............................................................................................................. 6-5

Service of Thermo Fisher Scientific .......................................................................... 6-6

Chapter 7 Troubleshooting ....................................................................................................................7-1

Mechanical Emergency Door Release ...................................................................... 7-2

Circuit Breakers ....................................................................................................... 7-3

Failure message ........................................................................................................ 7-3

Chemical Compatibility Chart ..............................................................................A-1

Warranty ...................................................................................................................B-1

Contact Information ................................................................................................C-1

Page 7

Thermo Scientific RC BIOS iii

P

Preface

Before starting to use the centrifuge, read through this instruction manual carefully and follow the

instructions.

The information contained in this instruction manual is the property of Thermo Fisher Scientific. It is

forbidden to copy or pass on this information without explicit approval.

Failure to follow the instructions and safety information in this instruction manual will result in the

expiration of the sellers warranty.

Scope of Supply

If any parts are missing, please contact your nearest Thermo Fisher Scientific representative.

This symbol refers to general hazards.

CAUTION means that material damage could occur.

WARNING means that injuries or material damage or contamination could occur.

This symbol refers to a rotor failure.

3~

This symbol refers 3 phase alternating current.

Article Number Quantity Check

Centrifuge RC BIOS 1

Power supply cable 1

50105346 Instruction manual 1

70907249 Installation kit 1

Page 8

P

Intended Use

iv RC B

IOS Thermo Scientific

Intended Use

• This centrifuge is a laboratory product designed to separate components by generation of Relative

Centrifugal Force. It separates human samples (e.g. blood, urine and other body fluids) collected in

appropriate containers, either alone or after addition of reagents or other additives.

• The centrifuge is designed to also run other containers filled with chemicals, environmental

samples and other non-human body samples.

• This centrifuge should be operated by trained specialists only.

Accident Prevention

Precautions

In order to ensure safe operation of the centrifuge, the following general safety regulations must be

followed. Ignoring the safety regulations can result in severe damage and inguries.

• Do not manipulate the safety devices

• The centrifuge should be operated by trained specialists only.

• The centrifuge is to be used for its intended purpose only.

• Plug the centrifuge only into sockets which have been properly grounded.

• Do not move the centrifuge while it is running.

• Use only rotors and accessories for this centrifuge which have been approved by Thermo Fisher

Scientific. Exceptions to this rule are commercially available glass or plastic centrifuge tubes,

provided they have been approved for the speed or the RCF value of the rotor.

Prerequisite for the safe operation of the centrifuge is a work environment in compliance

with standards, directives and trade association safety regulations and proper instruction of

the user.

The safety regulations contain the following basic recommendations:

• Maintain a radius of at least 30 cm (12 inch) around the centrifuge.

• Implementation of special measures which ensure that no one can approach the

centrifuge for longer than absolutely necessary while it is running.

The mains plug and main switch must be freely accessible at all times. Pull out the power

supply plug or disconnect the power supply in an emergency.

Page 9

P

Precautions

Thermo Scientific RC B

IOS v

• Do not use rotors which show any signs of corrosion and/or cracks.

• Do not touch the mechanical components of the rotor and do not make any changes to the

mechanical components.

• Use only with rotors which have been properly installed. Follow the instructions in section “Rotor

Installation” on page 4-3.

• Use only with rotors which have been loaded properly. Follow the instructions given in the rotor

manual.

• Never overload the rotor. Follow the instructions given in the rotor manual.

• Never start the centrifuge when the lid is open.

• Never open the lid until the rotor has come to a complete stop and this has been confirmed in the

display.

• The lid emergency release may be used in emergencies only to recover the samples from the

centrifuge, e.g. during a power failure (see section “Failure message” on page 7-3).

• Never use the centrifuge if parts of its cover panels are damaged or missing.

• Do not touch the electronic components of the centrifuge or alter any electronic or mechanical

components.

• Please observe the safety instructions.

Please pay particular attention to the following aspects:

• Location: well-ventilated environment, set-up on a level and rigid surface with adequate

load-bearing capacity.

• Rotor installation: make sure the rotor is locked properly into place before operating the

centrifuge.

• Especially when working with corrosive samples (salt solutions, acids, bases), the accessory parts

and vessel have to be cleaned carefully.

• Always balance the samples.

Centrifuging hazardous substances:

• Do not centrifuge explosive or flammable materials or substances which could react violently with

one another.

• The centrifuge is neither inert nor protected against explosion. Never use the centrifuge in an

explosion-prone environment.

• Do not centrifuge inflammable substances.

• Do not centrifuge toxic or radioactive materials or any pathogenic micro-organisms without

suitable safety precautions.

When centrifuging microbiological samples from the Risk Group II (according to the Bio-safety

Manual" of the World Health Organization WHO), aerosol-tight biological seals have to be used.

For materials in a higher risk group, extra safety measures have to be taken.

Page 10

P

Precautions

vi RC B

IOS Thermo Scientific

• If toxins or pathogenic substances have gotten into the centrifuge or its parts, appropriate

disinfection measures have to be taken (see “Disinfection” on page 6-4).

• Highly corrosive substances which can cause material damage and impair the mechanical stability

of the rotor, should only be centrifuged in corresponding protective tubes.

IF A HAZARDOUS SITUATION OCCURS, TURN OFF THE POWER SUPPLY TO THE

CENTRIFUGE AND LEAVE THE AREA IMMEDIATELY.

Normal use

The centrifuge is to be used for separating materials of different density or particle size suspended in a

liquid.

Maximum sample density at maximum speed: 1,2

g

cm

3

---------- -

Page 11

Thermo Scientific RC BIOS 1-1

1

Introduction and Description

Contents

• “Characteristics of the RC BIOS” on page 1-2

• “Technical Data” on page 1-3

• “Directives, Standards and Guidelines” on page 1-4

• “Functions and Features” on page 1-4

• “Mains Supply” on page 1-5

• “Rotor Selection” on page 1-5

Page 12

1

Introduction and Description

Characteristics of the RC BIOS

1-2 RC B

IOS Thermo Scientific

Characteristics of the RC BIOS

The maintenance-free induction motor ensures quiet and low-vibration operation even at high speeds,

and guarantees a very long lifetime.

The user-friendly control panel makes it easy to pre-set the speed, RCF value, running time,

temperature, and running profile (acceleration and braking curves). You can choose between the

display of speed and RCF or the entry mode.

These settings can be changed even while the centrifuge is running.

The RC BIOS is equipped with various safety features:

Housing, rotor chamber, baseframe, and guard ring are made of high-strength, high-quality steel.

• The lid is equipped with a view port and a lock.

• The lid of the centrifuge can only be opened while the centrifuge is switched on and the rotor has

come to a complete stop. The centrifuge cannot be started until the lid has been closed properly.

• Electronic imbalance detection.

• Lid emergency release: For emergencies only, e.g. during power failures (see “Failure message” on

page 6-3)

Page 13

1

Introduction and Description

Technical Data

Thermo Scientific RC B

IOS 1-3

Technical Data

The technical data of the RC BIOS is listed in the following table.

Table 1-1. Technical Data RC B

IOS

Feature Value

Environmental conditions -Use in interior spaces

-Altitudes of up to 2,000 m above sea level

-max. relative humidity 80% up to 31 °C; decreasing linearly up to 50%

relative humidity at 40 °C

permissible ambient temperature +2° C to +40° C +35.6° F to +104° F

Overvoltage category II II II

Pollution degree 2 2 2

Heat dissipation 230V 208V 400V

~5.2 kW ~4.5 kW ~5.8 kW

17700 BTU/h 15300 BTU/h 19700 BTU/h

IP 20 20 20

Running time unlimited unlimited unlimited

Maximum speed n

max

8500 rpm 8500 rpm 8500 rpm

Minimum speed n

min

300 rpm 300 rpm 300 rpm

Minimum sample temperature 4°C at 8500 rpm 4°C at 7800 rpm 4°C at 8500 rpm

Maximum RCF value at n

max

15860 x g 15860 x g 15860 x g

Maximum kinetic energy <212 kJ < 212 kJ < 212 kJ

Noise level at maximum speed

a

< 65 dB (A) < 65 dB (A) < 65 dB (A)

Temperature setting range -10 °C to +40 °C -10 °C to +40 °C -10 °C to +40 °C

Dimensions

Height

Width

Depth

Length power cord

1178 mm

800 mm

905 mm

3000 mm

46.3 inch

31.5 inch

35.6 inch

118.1 inch

Weight without rotor 475 kg 1047 lb

a

front side measurement

Page 14

1

Introduction and Description

Directives, Standards and Guidelines

1-4 RC B

IOS Thermo Scientific

Directives, Standards and Guidelines

Functions and Features

The following table gives an overview of the important functional and performance characteristics of

the RC BIOS.

Table 1-2. Directives, standards and guidelines

Tension /

Frequency

Produced and inspected according to the following

standards and guidelines

220V-230V 50Hz,

400V 50Hz

2006/95/EC Low Voltage Directive:

2006/42/EC Machine Directive:

2004/108/EC EMC Directive

EN 61010-1, 2

nd

Edition

EN 61010-2-020, 2

nd

Edition

EN 61326-1

EN 55011B

EN 61000-6-2

208-220V 60Hz,

230V 60Hz

The centrifuges are produced and inspected

according to the following standards and

guidelines

UL 61010-1, 2

nd

Edition

CAN/CSA-C22.2 No. 61010-1, 2

nd

Edition

IEC 61010-2-20, 2

nd

Edition

(Pollution degree 2, Overvoltage category II)

Emitted interference FCC Part 15 A

NOTE: This equipment has been tested and found to comply with

the limits for a Class A digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is

operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be

required to correct the interference at his own expense.

Table 1-3. Functions and features

Component / Function Description / Features

Structure / Housing Galvanized and powder doated high-strength steel chassis and guard-ring

Chamber Stainless steel

Drive Induction drive without carbon brushes

Keys and display Easy-to-clean keypad and display surface

Controls Microprocessor-controlled

Internal memory The most recent data is saved

Functions RCF-selection, temperature control

Acceleration / braking profiles 11 acceleration and 11 braking curves

Imbalance detection Electronic, contingent on rotor and speed

Lid lock Automatic lid closing and locking starting from an initial hold position

Page 15

1

Introduction and Description

Mains Supply

Thermo Scientific RC B

IOS 1-5

Mains Supply

The following table contains an overview of the electrical connection data for the RC BIOS. This data is

to be taken into consideration when selecting the mains connection socket.

Rotor Selection

RC BIOS is sold commercially in a package solution (unit and rotor included).

The rotor that is available for use in the RC B

IOS:

The technical data of the rotors and the corresponding adapters and reduction sleeves for various

commercially available containers can be found in the corresponding rotor operating manuals.

For more information visit our website at: http://www.thermo.com

Table 1-4. Electrical connection data of the RC BIOS

Cat. Mains voltage Frequency

Rated current

Power consumption

Equipment

fuse

Building

fuse

Supply Power

Plugs

75007034 208-220V 60Hz 23.5 A 4400W 25A & 6A 30 A NEMA 6-30P

SinglePhase

75007035 230V 60Hz 22.5 A 4500 W 25A & 6A 30 A NEMA 6-30P

SinglePhase

75007036 220V-230V 50Hz 22 A 4300 W 25A & 6A 32A IEC60309 CEE 32

A-6h 1P+N+PE

75007037 230V/ 400V 3 50Hz 20.5 A 3800 W 25A & 6A 3x 32A IEC60309 CEE 32

A-6h 3P+N+PE

F8-6x1000y 096-061137

Page 16

Thermo Scientific RC BIOS 2-1

2

Before use

Contents

• “Before Setting up” on page 2-2

• “Location” on page 2-2

• “Installation” on page 2-2

• “Aligning the Centrifuge” on page 2-5

• “Transporting the Centrifuge” on page 2-5

• “Mains Connection” on page 2-5

• “Other connections” on page 2-6

• “Storage” on page 2-6

Page 17

2

Before use

Before Setting up

2-2 RC B

IOS Thermo Scientific

Before Setting up

1. Check the centrifuge and the packaging for any shipping damage.

Inform the shipping company and Thermo Fisher Scientific immediately if any damage is

discovered.

2. Remove the packaging.

3. Check the order for completeness (see “Scope of Supply” on page iii).

If the order is incomplete, please contact Thermo Fisher Scientific.

Location

The centrifuge should only be operated indoors.

The set-up location must fulfil the following requirements:

• A safety zone of at least 30 cm must be maintained around the centrifuge.

People and hazardous substances must be kept out of the safety zone while centrifuging.

• The supporting structure must be stable and free of resonance.

• The supporting structure must be suitable for horizontal setup of the centrifuge.

• The centrifuge should not be exposed to heat and strong sunlight.

• The set-up location must be well-ventilated at all times.

Installation

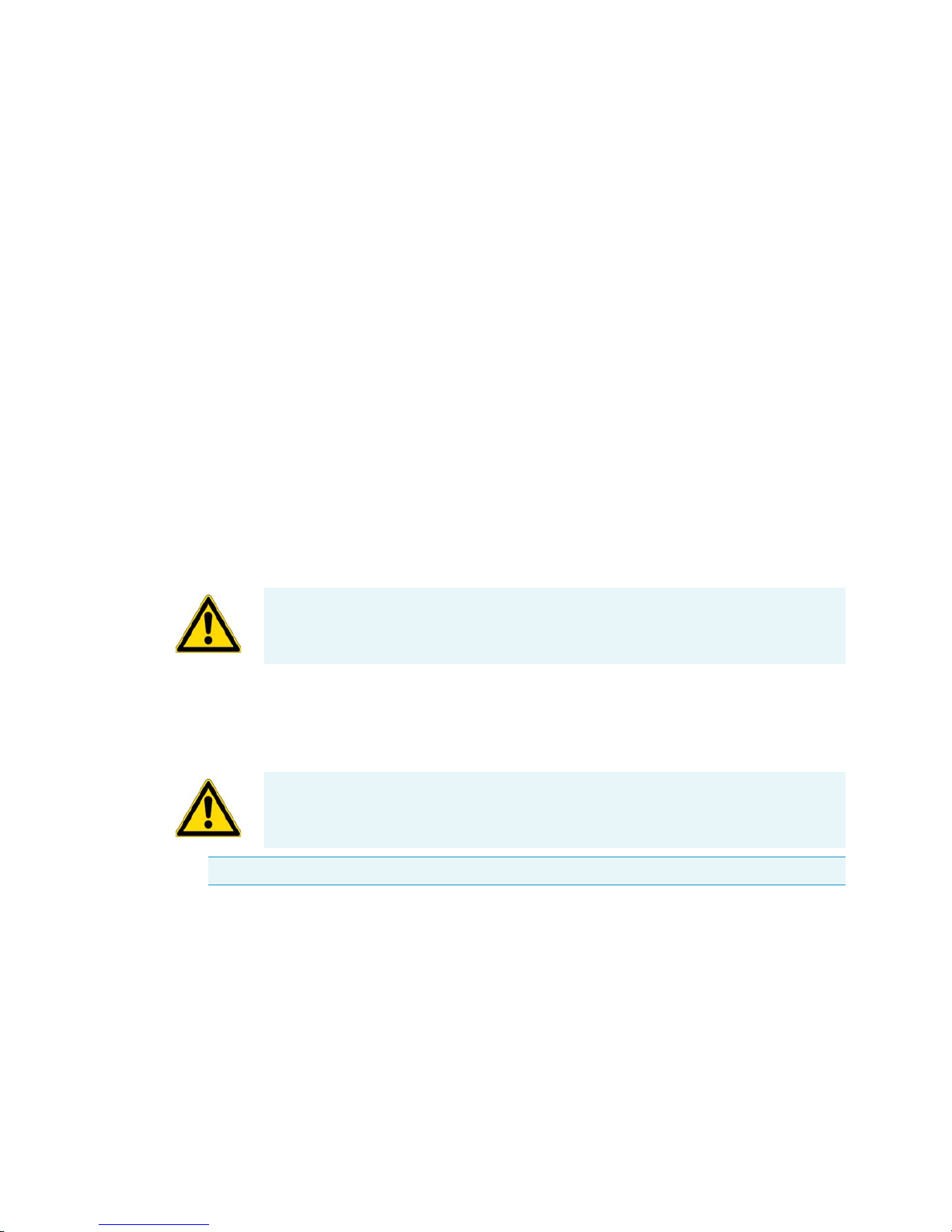

1. Place the pallet with the centrifuge so that you have at leased 2 m room in front of the pallet.

2. Release the rails from the pallet.

3. Screw the rails onto the pallet in front of the centrifuge.

WARNING UV rays reduce the stability of plastics.

Do not subject the centrifuge, rotors and plastic accessories to direct sunlight.

WARNING The centrifuge operates with high kinetic energies. Do not run the centrifuge

without a radius of at least 30 cm (12 inch) around the centrifuge.

Do not run the centrifuge while standing on its casters.

Note The centrifuge is screwed onto the pallet with four screws.

Page 18

2

Before use

Installation

Thermo Scientific RC B

IOS 2-3

4. Place the piece of wood under the rails.

5. Place the rubber feet under the studs with the safety brackets and screw them entirely up.

6. Remove the four screws that fix the centrifuge t the pallet. The heads are upsiede down in the

pallet.

7. Remove the bolt spacers.

8. Screw the studs with the safety brackets entirely up. Otherwise they might get stuck when rolling

the centrifuge off the pallet.

9. Remove the rubber feet.

Rails

Safety brackets

Page 19

2

Before use

Installation

2-4 RC B

IOS Thermo Scientific

10. Check that the stearing casters point to the back.

11. Use several people and other means in order to roll the centrifuge off the pallet.

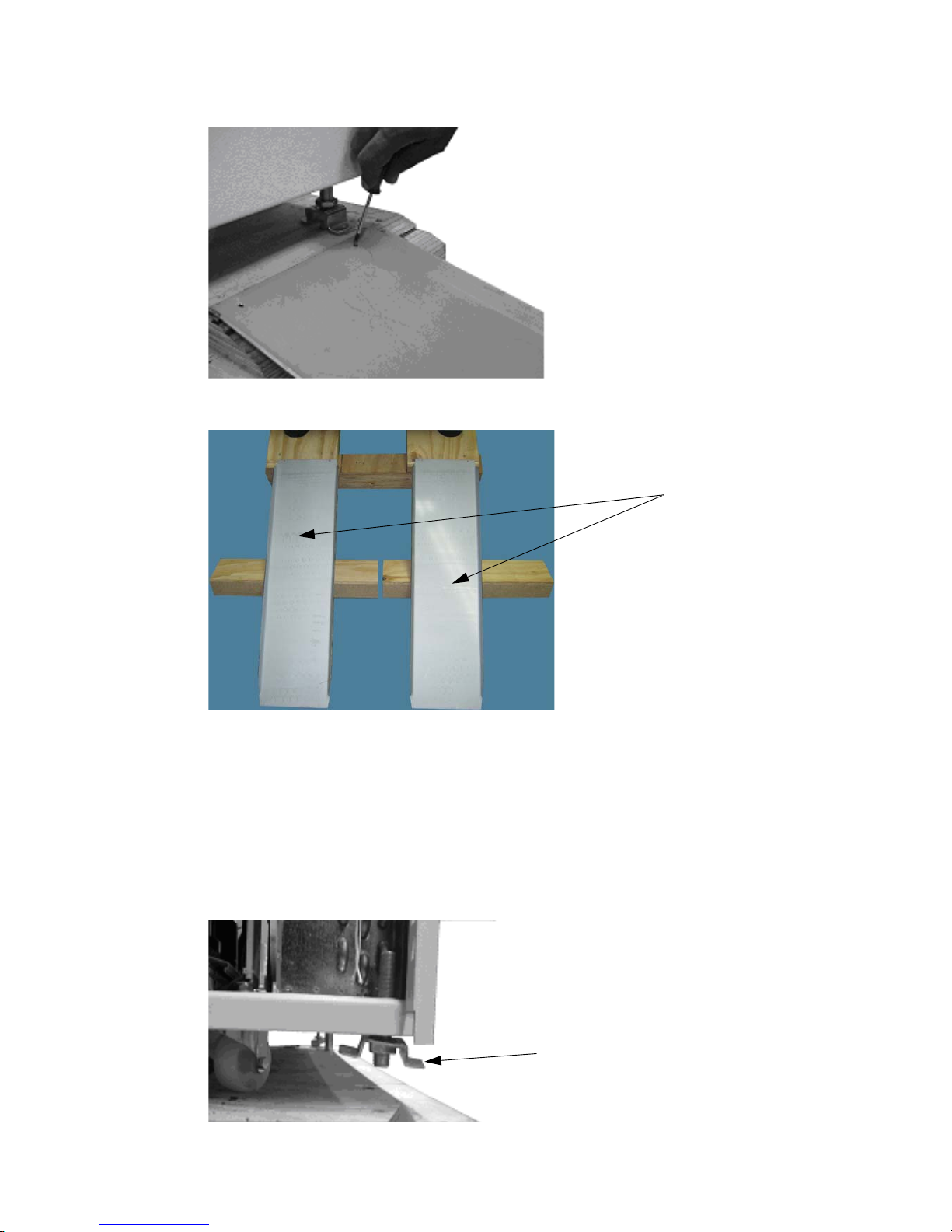

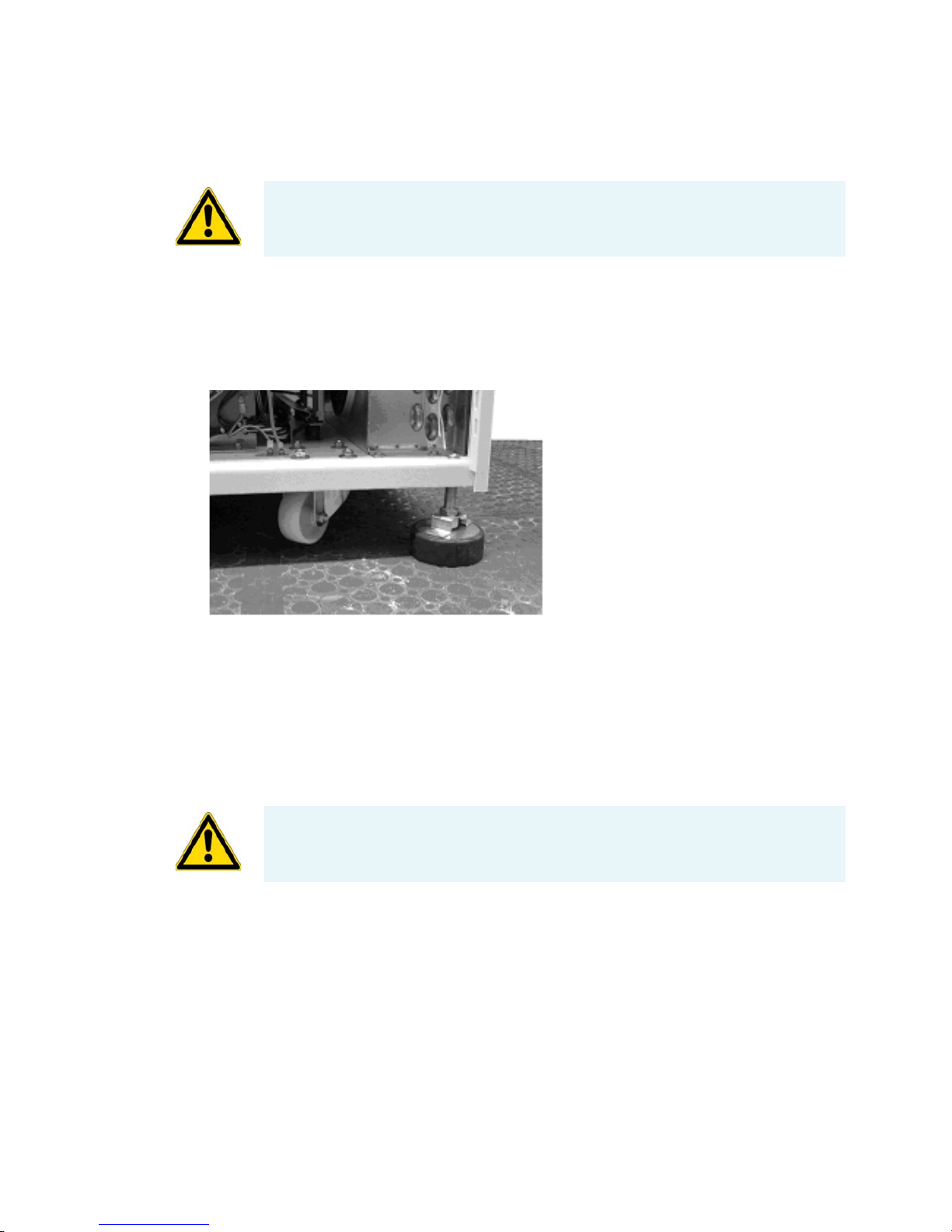

12. Once the centrifuge is in its final position mount the enclosed locking stabilizers.

13. Screw the studs down.

14. Place the rubber feet centrally and align the centrifuge. All the rubber feet should carry uniformly

(check by a tilt test). The casters are at a distance of about 5-15 mm from the ground.

15. Switch on the centrifuge.

16. Open the centrifuge.

17. Put the enclosed water level on the drive spindle.

18. Use a wrench to rotate the safety brackets alternately to raise or lower them until the centrifuge is

leveled.

19. Remove the water level when the centrifuge is leveled.

20. Be sure that the four locking stabilizers stand safe and don't jolt. The final assembly of the safety

brackets is carried out after leveling.

21. Tighten the locking nuts of the locking stabilizers firmly.

Mount the safety brackets by means of an 8 mm open-end wrench on the stabilizers.

22. Optional: To be certain the centrifuge is working properly, refer to the Customer Control

Inspection paragraph located in “Customer Control Inspection” on page 5-1. Perform the

procedures listed under Speed Control, Timer, and Temperature Control.

WARNING Due to the centrifuges weight it must be controlled by several people and

other means when rolling of the pallet. Do not stand in front of the centrifuge when

rolling down for the centrifuge might run you over.

CAUTION If the centrifuge isn’t level, imbalances can occur and the centrifuge can be

damaged.

Do not place anything under the feet to level the centrifuge.

Page 20

2

Before use

Aligning the Centrifuge

Thermo Scientific RC B

IOS 2-5

Aligning the Centrifuge

The horizontal alignment of the centrifuge must be checked every time after moving it to a different

location.

The supporting structure must be suitable for horizontal setup of the centrifuge.

Transporting the Centrifuge

• Use a forklift to lift the centrifuge.

• The centrifuge can be damaged by impacts.

• Transport the centrifuge upright and if at all possible in packaging.

Mains Connection

1. Turn off the power supply switch located on a small recessed panel in the upper right corner of the front

cabinet panel (press "0").

2. Plug the centrifuge into grounded electrical sockets only.

3. Check whether the cable complies with the safety standards of your country.

4. Make sure that the voltage and frequency correspond to the figures on the rating plate.

5. Establish the connection to the power supply with the connecting cable.

Note The packaging is an one-way packaging. Assign a logistic company for the transport. Contact

Customer Service.

WARNING Always remove the rotor before moving the centrifuge.

Page 21

2

Before use

Other connections

2-6 RC B

IOS Thermo Scientific

Other connections

Figure 2-1. Connetors to external devises

Storage

• Before storing the centrifuge and the accesories it must be cleanedand if necessary desinfected and

decontaminated.

• Store the centrifuge in a clean, dust-free location.

• Be sure to place the centrifuge on its feet.

• Avoid direct sunlight.

15 Pol D-Sub Computer

Interface Connector

9 Pol D-Sub Connector Barcode

Reader

Page 22

Thermo Scientific RC BIOS 3-1

3

Control Panel

Contents

• “KEYS” on page 3-2

• “CONTROLL PANEL” on page 3-2

• “RUN DISPLAY” on page 3-3

• “PRIMARY FUNCTION KEYS” on page 3-4

• “SET DISPLAY” on page 3-7

• “KEYPAD LOCK” on page 3-8

Page 23

3

Control Panel

CONTROLL PANEL

3-2 RC B

IOS Thermo Scientific

CONTROLL PANEL

The controll panel consists of the RUN DISPLAY, the SET DISPLAY, the MENU key with the

OPTION INDICATORS, the PRIMARY FUNCTION KEYS, a NUMMERIC KEY PAD, and a

KEYPAD LOCK.

KEYS

Press the START key to start a run.

Press the STOP key to stop a run.

Press the OPEN key to open the door. The key can only be used under the following conditions: The

centrifuge is switched on. The rotor is not spinning. The is now error message in the display. The

message OPEN appears in the RUN DISPLAY.

Press the ENTER key to confirm a selection. Or to step though the menu.

Use the nummeric keypad to enter values into the SET DISPLAY. CLEAR removes input values or

messages from the SET DISPLAY. */- toggles between positive and negative temperature values.

Press the ROTOR key to enter the rotor selection.

Press the SPEED key to enter the speed or RCF selection.

Press HOLD key to select an continues run.

Press TIME key to enter the time selection.

Press ACE key to enter ACE value.

Press TEMP key to enter the temperature.

KEYPAD LOCK

MENU KEY

PRIMARY FUNCTION KEYS

NUMERIC KEYPAD

SET DISPLAY

RUN DISPLAY

OPTION INDICATORS

Page 24

3

Control Panel

RUN DISPLAY

Thermo Scientific RC B

IOS 3-3

Press RECALL to view and select programmed parameters.

Press MENU to enter advanced features.

RUN DISPLAY

The RUN DISPLAY shows the actual values during a run.

SPEED field

The SPEED (RPM/RCF) field indicates either:

• the current measured rotor speed (in rpm) or,

• the relative centrifugal force (or g-force) that is currently being generated at the maximum radius of

the selected rotor if RCF is selected (RCF indicator is lit).

• At run completion (zero speed) the display shows the word "End" until the door is opened.

TEMPERATURE field

The run TEMPERATURE (°C) field indicates the current calculated sample temperature in degrees

Celsius, based on:

• rotor selected,

• rotor speed,

• run time,

• set temperature, and

• measured temperature.

The calculation assumes that the sample temperature, rotor temperature, and SET temperature are all

equal at the start of the run.

TIME field

The run time can be defined as follows:

You can select TIME/HOLD/ACE mode for a time controlled run.

• If controlled by TIME, the display counts down from set time, showing the time remaining (in

minutes and seconds) until the run terminates and deceleration begins.

• If controlled by HOLD (indicated in the smaller SET DISPLAY below), the display during a run

counts up. The RUN DISPLAY shows the time elapsed (expressed in minutes and seconds, up to a

maximum of 99:59) since START was pressed.

• If controlled by ACE (Accumulated Centrifugal Effect™, ACE indicator lit), the RUN display

shows the current Calculated ACE value ( ). When the set ACE value is reached, the run

terminates and decelerates to a stop. The displayed value continues to calculate the centrifugal

effect during deceleration to zero to show total accumulation.

ω2dt

∫

Page 25

3

Control Panel

PRIMARY FUNCTION KEYS

3-4 RC B

IOS Thermo Scientific

PRIMARY FUNCTION KEYS

The Primary Function keys are the keys below the SET DISPLAY.

ROTOR allows selection of rotors to be used.

SPEED allows changing desired speed (rpm) or RCF (g-force).

TEMP allows changing desired calculated sample temperature.

RECALL allows viewing and selecting programmed parameters.

Each key is positioned below a corresponding field in the SET DISPLAY, allowing simple, direct access

to basic run parameter controls:

ROTOR

• Press the ROTOR key to specify a different rotor than the one shown in the SET DISPLAY. This

is necessary if the rotor or bucket/ carrier system installed in the centrifuge are changed.

• The rotors are listed by the rotor name. Press the ROTOR key repeatabely to scroll through the

rotor list for selection.

• The correct identification of the installed rotor is necessary for the set SPEED limits, correctly

calculate RCF, and accurately control sample temperature.

• If a rotor is able to use buckets/carriers with different maximum radii, each configuration will be

listed for selection, to calculate the different RCF.

• The ROTOR key is not active when a run is in progress.

SPEED

• Press the SPEED key to specify a different rotor speed in revolutions per minute (rpm) or relative

centrifugal force (RCF, also known as g-force).

• Speed is selectable from 300 to 4700 rpm, up to the maximum rated speed for the specified rotor,

or as an equivalent RCF calculated at the maximum radius of the specified rotor (rotor geometry

only, with no accounting for adapters).

• Press the SPEED key repeatedly to toggle between rpm and RCF or RCF. Pressing once causes the

value to flash so a change can be made in that mode. Pressing again changes to the other mode and

displays a value equivalent to the previouse. Pressing again causes that value to flash so a change can

be made, pressing again changes the mode back, and so on.

• An entered value will continue to flash (prompting input) when it is out of range for the SET

rotor. The formula used to calculate RCF is:

Note To ensure that the installed rotor will always be correctly identified, make it a practice to

change the SET rotor name immediately after changing the installed rotor.

RCF 11.18 radius in cm×

rpm

1000

----------- -

⎝⎠

⎛⎞

2

×=

Page 26

3

Control Panel

PRIMARY FUNCTION KEYS

Thermo Scientific RC B

IOS 3-5

The run duration (from start to termination, when deceleration begins) setting or control method is

changed by pressing one of these three PRIMARY FUNCTION KEYS:

TIME

• Press the TIME key to specify a length of time (minutes and seconds, to a maximum of 99:59)

from run start to termination.

• In the RUN DISPLAY, minutes and seconds begin counting down from the input value when

START is pressed.

• The run terminates and deceleration begins when the timer reaches zero.

HOLD

• Press the HOLD key to specify a continuous run which, once started, runs until STOP is pressed

(terminating the run and initiating deceleration).

• During a continuous run, HOLD will be in the SET DISPLAY, and the time elapsed from when

START was pressed will appear in the RUN display.

• The timer will accumulate up to 99 minutes 59 seconds - if a run continues beyond that, the

displayed run time will remain fixed at 99:59. Whenever it is possible for such an extended run to

occur, an external timing method is recommended.

ACE

• Press the ACE key to specify an Accumulated Centrifugal Effect™ value.

• When ACE control is selected, the centrifuge calculates the effect of speed in relation to time (the

shaded area in the illustration below), adjusting run duration to account for acceleration variation.

This variation can be attributed to rotor load/configuration differences (affecting inertia),

fluctuations in line voltage (affecting motor power), or slight mechanical differences including

normal wear.

Note When changing mode, rpm/RCF values may appear a digit or two off from the original set

value. The centrifuge translates set RCF values to rpm whole numbers for speed control purposes,

then calculates that rpm whole number to the closest RCF value. There is no cause for concern.

Speed control accuracy is not compromised, and the slight value difference will not affect your run

TIME

SPEED

Termination Set Point

Page 27

3

Control Panel

PRIMARY FUNCTION KEYS

3-6 RC B

IOS Thermo Scientific

• When START is pressed, the realized ACE value begins to accumulate in the RUN DISPLAY.

• The run will terminate and deceleration will begin when the specified ACE value (expressed as

1

value up to 9.99 x 1030 [displayed as 9.99e30]) is reached.

• After termination, the RUN DISPLAY will continue to accumulate until the rotor stops - this run

total is for reference. Care should be taken not to confuse the RUN DISPLAY's final accumulation

with the controlling input/ timeout value, found in the SET DISPLAY.

• Compared to control by time, ACE selection provides a more advanced and relevant form of run

duration control, thereby improving separation consistency, run reproducibility, and dependability

of results.

• During a run, to view in an alternative duration control mode (for example, to monitor

accumulating TIME when an ACE run is in progress), press one of the other two duration control

keys once - this changes the RUN DISPLAY to show an accumulating value in that alternative

mode without altering the way duration is controlled. In this viewing condition, the SET

DISPLAY field header does not change, nor will the status of the ACE indicator (both continuing

to indicate the set control mode), but the SET value will change to show the last value entered in

the alternative mode. If you press the same key a second time, the run will then change to that

control method, using the value that was in the SET DISPLAY as the controlling value until a

different one is entered.

• Between runs, the RUN DISPLAY shows the previous run duration values. You can choose each

control mode.

• Press the TIME key to see the MIN:SEC value at termination (the SET DISPLAY shows the last

TIME input value).

• Press the HOLD key to see the total MIN:SEC value after deceleration to zero.

• Press the ACE key to see the total ACE of an ACE controlled run. value after deceleration to zero

(the termination value is in the SET DISPLAY). If the previous run was not controlled by ACE,

pressing ACE shows the ACE value at termination (the SET DISPLAY shows the last ACE input

value).

• Always be sure of the control method and value before pressing START.

1

The integral value can be calculated deriving the following formula:

Where

and

Note If you change the duration control mode to TIME during a run, time begin to will count

down from the set value the moment the change is made (unless the run was previously controlled

by time, in which case the run will resume counting down from the value that existed when the

TIME mode was exited). If you change mode to ACE control, the set value that exists at the

moment the change is made will control run termination. If you change to ACE after the run has

exceeded the set value, the run will terminate immediately.

ω2dt

ω2dt∫ω2dt∫ω

2

Δt==

Δt Change in time (seconds)=

ω

2

Angular speed=

2= π n/60 ][

n Speed (rpm)=

Page 28

3

Control Panel

SET DISPLAY

Thermo Scientific RC B

IOS 3-7

TEMP

Press the TEMP key to change the desired calculated sample temperature ( °C) that is controlled by the

centrifuge during a run.

The centrifuge automatically considers the rotor selected, rotor speed, run time, set temperature, and

measured temperature to calculate and maintain sample temperature during the run. The calculation

assumes that the sample temperature, rotor assembly temperature, and SET temperature are all equal at

the start of the run (as they must be any time that temperature control is critical).

RECALL

• Press the RECALL key to access program memory.

• Saved parameters are recalled by inputting a specific program number. Press the START key to

begin a run using the run parameters displayed.

• Programs can easily be recalled and modified to create new run parameters without fear of

damaging the original program, because information that is saved in memory cannot be

overwritten by using the RECALL key (modifying or replacing a program is reserved for the

SELECT SAVE RUN option under the MENU key).

MENU and OPTION INDICATORS

• The MENU key accesses advanced feature options listed below it, plus other features such as saving

parameters to memory.

• Pressing the MENU key to enter the advanced features. After that pressing 1 accesses a secondary

screen to view or enter values, plus confirm option selection. Pressing 0 deselects options. Pressing

ENTER steps through options without changing selections or settings, and on secondary screens,

enters values to select the option. Pressing MENU again exits the options and returns to the SET

DISPLAY without entering/selecting a flashing value.

SET DISPLAY

The SET DISPLAY is used to:

• input and display basic run parameters,

• to select options or other advanced features, and

• to display advisory messages.

• The SET DISPLAY displays currently selected values for the basic run parameters: ROTOR,

SPEED/RCF, TIMED/HOLD/ACE, DEG C and, if displaying a recalled program, PROG #.

• The set values appear in the SET DISPLAY after the centrifuge power has been set ON and the

diagnostic test has been completed.

• If you have pressed MENU to access the options screens, pressing MENU again will return the set

values to the SET DISPLAY.

• The SET DISPLAY is the primary interactive screen on the control panel, and has a role in all

aspects of centrifuge use.

Page 29

3

Control Panel

KEYPAD LOCK

3-8 RC B

IOS Thermo Scientific

KEYPAD LOCK

• The KEYPAD LOCK can be used to limit control panel function.

• It uses a 3-position keyswitch with a key that is removable in any of the 3 positions. Functionality

is as follows:

• The upper position, FULL (full function), allows use of all keys and features, without

restriction.

• The lower position, SINGLE (Run Single Program), minimizes functionality so that set

parameters cannot be changed (START, STOP, and CLEAR are the only active keys).

• The middle position, ANY (Run Any Program), makes it so that users may only perform runs

using run parameters recalled from program memory (only RECALL, the numeric keypad

including ENTER and CLEAR, START and STOP are active).

• Use of the KEYPAD LOCK may offer a considerable advantage, improving process control by

reducing the possibility for operator error, as well as restricting unauthorized run parameter or

program memory changes.

Page 30

Thermo Scientific RC BIOS 4-1

4

Operation

Contents

• “Switch on Centrifuge” on page 4-2

• “Lid Opening” on page 4-2

• “Close Lid” on page 4-2

• “Rotor Installation” on page 4-3

• “Normal Operation” on page 4-3

• “Centrifugation” on page 4-5

• “Programmed Operation” on page 4-6

• “Using Advanced Features (Options)” on page 4-8

• “Temperature Control” on page 4-13

• “Rotor Temperature Equilibration” on page 4-14

Page 31

4

Operation

Switch on Centrifuge

4-2 RC B

IOS Thermo Scientific

Switch on Centrifuge

1. Turn on the power switch located on a small recessed panel in the upper right corner of the front

cabinet panel into position “1“.

The device performs a self-check of its software.

2. Watch the control panel LEDs to be sure that all segments light.

During start-up the SET DISPLAY shows:

• If an error is detected, an error message will appear in the SET DISPLAY.

• If no error is found, the SET DISPLAY will display the values that was displayed when the

centrifuge was turned OFF.

• All OPTIONS selections will also be the same as when the centrifuge was turned OFF.

Lid Opening

1. Press the "OPEN" key .

Close Lid

Close the lid by pressing down on it lightly in the middle or on both sides of it. Two locks close the lid

completely. The lid will close automatically.

Note Make sure the centrifuge is properly installed before turning it ON for the first time, (see

Chapter 2, Installation).

Note If any LED segments do not light, note which ones and inform Customer Service. Continued

operation when the centrifuge is unable to display all run information correctly could mislead an

unaware observer.

WARNING Do not reach into the crack between the lid and the housing. The lid is

drawn shut automatically.

Use the emergency release only for malfunctions and power failures (see “Failure message”

on page 7-3).

WARNING Do not reach into the crack between the lid and the housing. The lid is

drawn shut automatically.

Note The lid should audibly click into place.

Page 32

4

Operation

Rotor Installation

Thermo Scientific RC B

IOS 4-3

Door Gas Springs

Periodically check that the two door gas springs are functioning properly.

a. Open the chamber door and making sure it remains open.

The gas springs counterbalance the weight of the door and hold it in the open position.

If the chamber door will not stay in the open position, inform Customer Service.

b. Check that the gas spring bracket is not cracked.

If the gas spring bracket is cracked, inform Customer Service.

Rotor Installation

The approved rotors for the centrifuge are listed in section “Rotor Selection” on page 1-5. Use only the

rotors and accessories from this list in the centrifuge.

Proceed as follows:

1. Open the lid of the centrifuge and if necessary remove any dust, foreign objects or residue from the

chamber.

2. Follow the instructions given in the rotor manual in order to install, load, and balance the rotor.

3. Close the centrifuge lid.

4. Make sure the rotor matches the rotor in the SET DISPLAY.

5. Press the ROTOR key repeatedly until the name of the installed rotor appears.

Normal Operation

Preselecting Speed / RCF

1. Press the SPEED key.

The display shows the RPM or the RCF-value depending on the display setting. Press the SPEED

key to toggle between the two modes.

2. Enter the desired value using the numeric pad.

The digits show in sequential order.

CAUTION The door gas springs must be checked periodically for proper functioning. If gas

pressure is not sufficient the door will not stay open and possible injury could result.

CAUTION Unapproved or incorrectly combined accessories can cause serious damage to

the centrifuge.

Note If you select a value that is to high for the defined rotor it will not be accepted. The value will

continue to blink.

Page 33

4

Operation

Normal Operation

4-4 RC B

IOS Thermo Scientific

3. Confirm your entry by pressing ENTER.

Your entry will also be automatically confirmed if you do not press any key for 5 seconds.

Preselecting Run time

1. Press the TIME key in order to open the runtime selection menu.

2. Enter the desired runtime using the numeric pad.

The maximum selectable run time is 99:59.

The digits show in sequential order.

3. Confirm your entry by pressing ENTER.

Your entry will be automatically confirmed if you do not press any key for 5 seconds.

ACE

1. Press the ACE key in order to open the ACE selection menu.

2. Enter the desired runtime using the numeric pad.

The maximum selectable ACE is 9.99 x 10

30

(read 9.99e30 in SET DISPLAY)

The digits show in sequential order.

3. Confirm your entry by pressing ENTER.

Your entry will be automatically confirmed if you do not press any key for 5 seconds.

HOLD

Press the HOLD key in order to select the HOLD run. During HOLD, the centrifuge will continue

running until you stop it manually with the STOP key.

Note The equivelant value will be calculated and displayed. If an extremely low RCF value has

been selected, it will be corrected automatically if the resulting speed is less than 300 rpm. This is

because 300 rpm is the lowest selectable speed.

Explanation of RCF Value

The relative centrifugal force is given as a multiple of the force of gravity g. It is a unitless numerical

value which is used to compare the separation or sedimentation capacity of various devices, since it

is independent of the type of device. Only the centrifuging radius and the speed come into play in

it:

r = centrifuging radius in cm

n = Rotational speed in rpm

The maximum RCF value is related to the maximum radius of the tube opening.

Remember that this value is reduced depending on the tubes and adapters used.

This can be accounted for in the calculation above if required.

RCF 11 18,

n

1000

-------------

〈〉

2

r××=

Page 34

4

Operation

Centrifugation

Thermo Scientific RC B

IOS 4-5

Preselecting temperature

You can preselect temperatures between -10 °C and +40 °C.

1. Press the TEMP key in order to enter the temperature.

2. Enter the desired temperature using the numeric pad.

The digits show in sequential order.

3. Confirm your entry by pressing ENTER.

Your entry will be automatically confirmed if you do not press any key for 5 seconds.

Centrifugation

Once the rotor has been properly installed, the main switch has been turned on and the door has been

closed, you can start centrifugation

Starting centrifuge program

1. Press the START key on the control panel.

The centrifuge accelerates to the pre-set speed with the time display active.

2. You cannot open the door while the centrifuge is running.

Imbalance indicator

If a load is imbalanced, this will be indicated by the message "ROTOR IMBALANCE - BALANCE

ROTOR".

The run will terminate.

Check the loading and start the centrifuge once again. See the information on proper loading in the

rotor instruction manual. For information on troubleshooting, see section “Troubleshooting by user”

on page 7-3.

Stopping the centrifugation program

Set run time

Usually the run time is preset and you only have to wait until the centrifuge stops automatically when

the preset time limit expires.

As soon as the speed drops to zero, the message "END" will appear in the SPEED field. By pressing the

OPEN key, you can open the lid and remove the centrifuge material.

You can also stop the centrifugation program manually at any time by pressing the STOP key.

ACE

When you select an ACE controll run, the run will determine when the centrifuge has reached the set

ACE value.

Page 35

4

Operation

Programmed Operation

4-6 RC B

IOS Thermo Scientific

HOLD

If you selected continuous operation (see “HOLD” on page 4-4), you will have to stop the centrifuge

manually. Press the STOP key on the control panel. The centrifuge will be decelerated at the

designated rate. The message "END" will illuminate, and after pressing the key OPEN, the lid will

open and you can remove the samples.

Programmed Operation

Storing Selections to Program Memory

1. Establish all desired run parameters as explained above, “Normal Operation” on page 4-3.

To minimize the time it takes to perform a QC RUN, we recommend the following:

• Starting with program 1, save runs to program memory: first by temperature (highest first), then,

by speed (lowest first).

FOR EXAMPLE: The programs below are listed in correct order for using QC RUN function

(program values shown are for example purposes only, actual set parameters will vary).

2. Press the MENU key to access the advanced features screens.

3. Press the ENTER key (six times after first accessing the advanced features) until the following

screen is in the SET DISPLAY:

4. Press 1.

The following screen will appear in the SET DISPLAY:

Note If you plan on using the QC RUN feature, consider the following as you save runs to

program memory:

• QC programs should all apply to using the same rotor.

• QC RUN programs should not use HOLD.

ROTOR SPEED TIMED DEG C PROG #

F8-6x1000y 2900 04:00 22 1

F8-6x1000y 4000 03:00 22 2

F8-6x1000y 3800 03:45 4 3

F8-6x1000y 4700 05:30 4 4

Note Single-digit program numbers 1-9 are for storing sets of standard run parameters.

Double-digit program numbers 10-15 are for storing step-runs.

Page 36

4

Operation

Programmed Operation

Thermo Scientific RC B

IOS 4-7

5. Enter a program number.

6. Press ENTER key.

The SET DISPLAY will then return to the HOME screen, and that program number will appear

in the PROG # field as confirmation:

7. Record saved information on the Program Log Pad (supplied).

To review stored programs before overwriting, refer to your Program Log Pad or press RECALL. If you

press RECALL, you will have to go back and re-establish the run parameters before you can store them

to memory.

Performing a Programmed Run

Read the Safety Information Page at the front of this manual.

1. Press RECALL .

The SET DISPLAY will change to display a program number flashing in the PROG # field.

2. Input the desired program number, then press ENTER key.

The SET DISPLAY and options indicators change to reflect the run parameters that were saved to

that program number.

3. Prepare the rotor according to the rotor manual.

4. Open the chamber door and install the rotor, making sure that the rotor is fully seated and locked

to the drive spindle. Install the rotor cover, if any, then close the chamber door.

5. If using logging software, make sure it is running, then press START key.

The rotor will accelerate according to the recalled parameters, and continue until run termination. At

termination, the rotor will decelerate to a stop. After it stops "End" will appear in the SPEED display

and remains there until the door is opened or the START key will be pressed.

Note To prevent accidental erasure of established programs, if the entered program number has

been previously assigned, the following message will appear:

Note Rotor names are saved within the program. If the rotor is changed by selecting a different

program this will be indicated in the SET DISPLAY. Be sure that the installed rotor is correct for

the recalled program. Make sure that the SET rotor identifies the installed rotor.

Note If you select a program number that has not been used to save a program, a warning message

will be displayed. In this case no program will be recalled.

Page 37

4

Operation

Using Advanced Features (Options)

4-8 RC B

IOS Thermo Scientific

Using Advanced Features (Options)

The advanced features of the centrifuge allow for:

• performing quality control runs, changing speed or time control ranges,

• changing acceleration/deceleration or overtemperature alert settings,

• linking together programmed run parameters, and

• saving run parameters to program memory for simple recall.

Advanced feature selection is usually reflected by LED option status indicators. When a feature has

been selected, the corresponding indicator will be lit (although specific settings for several features

can only be checked by reselecting the feature in the options screens). If changes to advanced feature

selection are required (other than to RPM/RCF or TIME/HOLD/ACE status, which are accessible

through primary function keys). The features are accessed by pressing MENU and then pressing

ENTER until the selection screen of the particular feature appears in the SET DISPLAY.

• The MENU key accesses advanced feature options listed below it, plus other features such as

saving parameters to memory.

Press the MENU key to enter the advanced features. After that pressing 1 accesses a secondary screen

to view or enter values, plus confirm option selection. Pressing 0 deselects options. Pressing ENTER

steps through options without changing selections or settings, and on secondary screens, enters

values to select the option. Pressing MENU exits the options and returns to the SET DISPLAY

without entering/selecting a flashing value.

Page 38

4

Operation

Using Advanced Features (Options)

Thermo Scientific RC B

IOS 4-9

Figure 4-1. Advanced Feature Option Screens

1

MENU

MENU

0 or ENTER

ENTER

START

ENTER

ENTER

ENTER

ENTER

ENTER

1

1

1

1

1

1

MENU

MENU

MENU

MENU

MENU

MENU

0 or ENTER

0 or ENTER

0 or ENTER

0 or ENTER

0 or ENTER

0 or ENTER

HOME SCREEN

Page 39

4

Operation

Using Advanced Features (Options)

4-10 RC B

IOS Thermo Scientific

SELECT QC RUN

• QC RUN allows simple, automatic quality control run speed/ temperature verification when used

with the optional computer interface package. The QC RUN feature will run and document the

data from each set of parameters that has been saved in program memory.

• When QC RUN is selected, the SET DISPLAY will prompt you to prepare for the run and press

the START key to begin. The centrifuge will start running program number 1, and systematically

run each program in-order through program number 9.

• While the QC RUN is in progress, the parameters of the program that is running will be in the

SET DISPLAY.

• During a QC RUN the centrifuge checks if the preset speed and temperature can be reached. In

order to save time during the QC RUN the next program will be run once the desired speed has

been reached and the temperature is within °K of the preset value.

• To minimize the time it takes to perform a QC RUN, we recommend the following: Starting with

program 1, save runs to program memory. Sort first by temperature (highest first), then, if there is

more than one run at a single temperature, by speed (lowest first).

FOR EXAMPLE: The programs below are listed in correct order for using QC RUN (program

values shown are for example purposes only, actual set parameters will vary).

To select the QC RUN feature:

1. Press MENU key .

2. Input 1.

3. Install the correct rotor.

4. Press START key.

The QC RUN sequence will begin, running program number 1.

• If, during a QC RUN, the observed RUN temperature is more than 2°C over SET temperature,

the rotor continues spinning until set temperature is reached.

Note If you plan on using the QC RUN feature, consider the following as you save runs to

program memory:

• QC programs should all apply to using the same rotor.

• QC RUN programs should not use HOLD.

ROTOR SPEED TIMED DEG °C PROG #

F8-6x1000y 2900 04:00 22 1

F8-6x1000y 4000 03:00 22 2

F8-6x1000y 3800 03:45 4 3

F8-6x1000y 4700 05:30 4 4

2±

Page 40

4

Operation

Using Advanced Features (Options)

Thermo Scientific RC B

IOS 4-11

SLOW START

• SLOW START chooses gentle acceleration from 0 to 250 rpm (acceleration transitions to the

normal, maximum rate at 250 rpm), with the slow start rate defined by selection of one of ten

different acceleration profiles.

• The profiles are numbered for ease of selection, with number 1 being the slowest, most gradual

rate, and each successive rate being incrementally faster up to number 10.

• If SLOW START is selected when START is pressed, the rotor will accelerate at a more gradual

rate.

• After SLOW START selections are completed, SELECT SLOW STOP? will appear in the SET

DISPLAY.

SLOW STOP

• SLOW STOP chooses gentle deceleration from 500 to 0 rpm (normal deceleration braking from

set speed transitions to the more gradual rate at 500 rpm), with the rate defined by selection of one

of ten different deceleration profiles.

• The profiles are numbered for ease of selection, with number 1 being the slowest, most gradual

rate, and each successive rate incorporating incrementally more braking up to number 10.

• Selection of BRAKE OFF will have an affect on SLOW STOP (see the NOTE under BRAKE

OFF).

BRAKE OFF

• BRAKE OFF deactivates normal deceleration braking for a coasting stop from any specified speed

(in rpm).

• The time it takes for the rotor to stop depends on the transition speed, windage and inertia of the

rotor.

• BRAKE OFF transition speed is set independently of set run speed, and is not affected by changes

to set run speed. If the transition speed is set higher than the set run speed, at run termination, the

centrifuge will coast to a stop from set speed.

• After BRAKE OFF selections are completed, CHANGE OVERTEMPERATURE LIMIT? will

appear in the SET DISPLAY.

Note If SLOW STOP and BRAKE OFF are both selected:

• If the BRAKE OFF transition speed is set to 500 rpm or higher, the SLOW STOP selection

will be ignored.

• If the BRAKE OFF transition speed is set below 500 rpm, the centrifuge will decelerate with

full braking to 500, transition to the specified SLOW STOP rate, then change to a coasting

stop when the specified BRAKE OFF transition speed is reached.

Page 41

4

Operation

Using Advanced Features (Options)

4-12 RC B

IOS Thermo Scientific

CHANGE OVERTEMPERATURE LIMIT

• CHANGE OVERTEMPERATURE LIMIT allows changing the maximum allowable sample

temperature to establish a new overtemperature offset value.

• The centrifuge calculates the difference between the set and the maximum temperatures, and

retains that value as an offset to apply to future runs, until it is changed. The retained offset will

apply to any normal (manual entry) run.

• Recalling program runs may change the overtemperature limit. Specific overtemperature limit

settings can be saved in run programs. See the EXAMPLE:

EXAMPLE: If you have a set temperature of 22°C and set the maximum temperature to 24°C, an

overtemperature alert will occur if the calculated sample temperature reaches 25°C. If the set

temperature is then changed to 4°C, the maximum temperature setting will automatically change

to 6°C.

• During a run, if the calculated sample temperature in the RUN display goes above the maximum

allowable sample temperature, the run will terminate, a SAMPLE TEMPERATURE OVER

LIMIT message will appear in the SET DISPLAY, and an alarm will sound. This may indicate a

condition requiring simple corrective action, or it could indicate a refrigeration problem

(“SAMPLE TEMPERATURE OVER LIMIT” on page 7-3).

• Overtemperature termination is deactivated when a temperature change between programs occurs

in a QC RUN. The QC RUN is repeated until the temperature is within 2°C of set temperature.

• After CHANGE OVERTEMPERATURE LIMIT selections are completed, SELECT STEP

RUN? will appear in the SET DISPLAY.

STEP RUN

• STEP RUN allows the linking-together of up to three sets of programmed run parameters to

automatically perform step run protocols.

• If the desired parameters have not been entered into memory, you must save each desired set of

parameters to memory before continuing with step run creation.

• If programs are used within a step run, that have not been defined before, a warning message will

be displayed.

• To create a step run, input a program number 1-9 for the first portion of the step run.

• The SET DISPLAY will prompt for another number, input a program number 1-9 for the second

portion of the step run.

• The SET DISPLAY will prompt for another number, and you can either press ENTER (if you are

creating a two-stage step run), or input a program number 1-9 for the third portion of your run.

• Step runs can be saved to program memory (program numbers 10-15) for simple recall in future

use (see SAVE RUN below).

• Runs are not inadvertently corrupted, whenever STEP RUN has been selected (indicator lit).

Note When step run is selected, the specified programs must specify the same rotor at similar

temperatures

Page 42

4

Operation

Temperature Control

Thermo Scientific RC B

IOS 4-13

• Changes to run parameters will be ignored unless STEP RUN is deselected before START is

pressed.

• The only changes that could be made without deselecting would be if a different step run was

recalled from program memory (program numbers 10-15).

• After STEP RUN selections are completed, SAVE TO PROGRAM MEMORY? will appear in the

SET DISPLAY.

SAVE TO PROGRAM MEMORY?

• SAVE RUN allows pre-programming of up to 15 different sets of run parameters (9 standard runs,

and 6 step runs) for future simple recall and error-free run reproducibility.

• In addition to basic parameters, all option selections and settings (excluding rotor name and

overtemperature limit) will also be saved to program memory.

• To eliminate inadvertent loss of existing programs, the save run sequence alerts users before

overwriting.

• The RECALL key allows browsing through existing programs for selection or reference.

• To save a run, all run parameter selections should be made before selecting this option.

• After SAVE RUN selection and assignment of a program number, the SET DISPLAY will return

to the HOME screen.

Temperature Control

The centrifuge controls calculated sample temperature during a run based on the rotor selected, rotor

speed, run time, SET temperature and measured chamber temperature. The complex calculation the

centrifuge performs must assume, however, that the sample and the rotor are at SET temperature at the

start of the run. If temperatures are not equilibrated, adjustments made by the centrifuge's control

system may not be appropriate (although, over time, temperature control should come into range).

Either store the rotor in a controlled temperature environment (such as refrigerator or cold room), or

precool/preheat the rotor in the centrifuge chamber, until the rotor is the same temperature as the

sample and the required SET temperature.

Temperature control needs can vary with the application. In many cases, the centrifuge will be used to

run large volumes of sample for short amounts of time. With such a run, if all components have been

equilibrated, it would be difficult to significantly change sample temperature during the run - even if

the centrifuge's temperature control performance was reduced.

Note If you plan to use the QC RUN feature, specific guidelines should be considered when

saving parameters to memory.

Note When temperature control is critical, the sample, SET temperature, rotor (body, buckets,

adapters, and cover), and rotor chamber should all be at the same temperature when START is

pressed. Also, remove the sample soon after a run has ended, so that it will not be affected if

chamber temperature drops slightly when the rotor is no longer generating heat due to air friction.

Page 43

4

Operation

Rotor Temperature Equilibration

4-14 RC B

IOS Thermo Scientific

Rotor Temperature Equilibration

To equilibrate the rotor temperature in the centrifuge chamber:

1. Install the rotor in the rotor chamber, place empty buckets (if applicable) in all positions, and the

rotor cover, if any.

2. Close the door.

3. Turn off all options (access with MENU key).

4. Check to be sure the correct rotor name is in the ROTOR field of the SET DISPLAY. If not, press

ROTOR until it is.

5. Press SPEED. If cooling, input 1500 rpm. If heating, input a value that is approximately 70% of

the maximum rated speed of the selected rotor.

6. Press HOLD to select a continuous run.

7. Press TEMP and enter the desired temperature.

8. Press START to begin temperature equilibration.

9. The centrifuge will alert you that a sample overtemperature condition exists, and that pre-cooling

is taking place. Press CLEAR.

10. Monitor progress of the value in the RUN TEMPERATURE display, and note the time when the

displayed RUN temperature reaches the SET temperature. From the time it does, allow the run to

continue for an additional 30 minutes, then press STOP.

Page 44

Thermo Scientific RC BIOS 5-1

5

Customer Control Inspection

Contents

• “Speed Controls” on page 5-2

• “Timer Controls” on page 5-2

• “Temperature Controls” on page 5-3

Page 45

5

Customer Control Inspection

Speed Controls

5-2 RC B

IOS Thermo Scientific

To keep your centrifuge in good working condition and ensure accurate test results, Thermo Fisher

Scientific recommends that you check the speed controls, timer controls and temperature controls at

least twice a year. If the bi-annual inspection reveals inaccurate results for any of these controls, inform

Customer Service to recalibrate the controls.

Speed Controls

1. Prepare a sample of test fluid.

2. Load and balance the rotor according to the instructions in the rotor manual.

3. Install the rotor in the chamber.

4. Close the chamber door.

5. Set the run parameters for a commonly used protocol, with SPEED controlled by rpm, and run

duration set to HOLD.

6. Deselect RCF or SLOW START if indicators are lit.

7. Press START key .

8. Wait for the SPEED value in the RUN display to reach the specified SET speed. Wit an additional

5 minutes for speed to stabilize.

9. Check rotor speed through the viewing port in the centrifuge door using a strobe tachometer (in

rpm, following instructions supplied with the tachometer).

The tachometer should indicate rpm equal to the SET value 20 rpm or %, (2000 rpm and

below, , above 2000 rpm, %).

10. If necessary, repeat this procedure at other speeds that are commonly used in your protocols.

Timer Controls

1. Prepare a sample of test fluid.

2. Load and balance the rotor according to the instructions in the rotor manual.

3. Install the rotor in the chamber.

4. Close the chamber door.

5. Set the run parameters for a commonly used protocol, but set the run duration by TIME

(MIN:SEC) to 10:00.

6. Press START key .

7. Using a stopwatch, begin timing precisely as the RUN TIME display counts down to 10:00. Then

stop timing precisely as the RUN TIME display counts down to 00:00.

The stopwatch should read between 9:30 to 10:30, representing 10:00 % (29 seconds) plus an

additional second to allow for cumulative human error.

8. If necessary, repeat this procedure at other time ranges that are commonly used in your protocols.

1±

20± 1±

5±

Page 46

5

Customer Control Inspection

Temperature Controls

Thermo Scientific RC B

IOS 5-3

Temperature Controls

When verifying temperature control, all test run conditions (TEMP, SPEED, TIME, ROTOR and

option selections) should match your required protocol(s). Test fluid must be at the same volume and

temperature as the actual sample (use a calibrated thermometer to confirm). The sample temperature,

rotor assembly temperature, and SET temperature must match also. Ideally, all components would

have been stored in the same controlled-temperature area overnight. If that is not possible, you can

precool or preheat the rotor as required. Immediately after the test run is performed, check test fluid

temperature using the same thermometer that was used before the run.

1. Set the run parameters. Choose the protocol with the longest run time.

2. Equilibrate the rotor chamber and the temperature of all rotor parts (include any tubes, bottles, or