Page 1

P/N 50105748-3

RC 6+

User´s Manual US

Page 2

Page 3

Thermo Fisher Scientific

OPERATION

INSTRUCTIONS

Thermo Scientific RC-6 PLUS

Superspeed Centrifuge

P/N 50105748

Issued January 2008

Page 4

ii Thermo Fisher Scientific

Page 5

Thermo Fisher Scientific RC-6 PLUS i

This manual is a guide for the use of

Thermo Scientific RC-6 PLUS

Superspeed Centrifuge

Data herein has been verified and is believed adequate for the intended use of

the rotor.

Because failure to follow the recommendations set forth in this manual could

produce personal injury or property damage, always follow the

recommendations set forth herein. Thermo Fisher Scientific does not guarantee

results and assumes no obligation for the performance of rotors or other

products that are not used in accordance with the instructions provided. This

publication is not a license to operate under, nor a recommendation to infringe

upon, any process patents.

Publications prior to the Issue Date of this manual may contain data in apparent

conflict with that provided herein. Please consider all data in this manual to be

the most current.

DANGER, WARNING, CAUTION, and NOTE within the text of this manual are

used to emphasize important and critical instructions.

DANGER informs the operator of an extreme hazard or an unsafe practice that

will result in death or serious injury.

WARNING informs the operator of a hazard or an unsafe practice that could

result in serious injury, affect the operator’s health, or contaminate the

environment.

CAUTION informs the operator of an unsafe practice that could result in

damage to equipment.

NOTE highlights essential information.

© 1996, 1999, 2000, 2003, 2004, 2008 by Thermo Fisher Scientific

CAUTION and WARNING are accompanied by a hazard symbol and appear

below or above the information they correspond to.

Page 6

Preface

ii RC-6 PLUS Thermo Fisher Scientific

Important Safety Information

Certain potentially dangerous conditions are inherent to the use of all

centrifuges. To ensure safe operation of this centrifuge, anyone using it should

be aware of all safe practices and take all precautions described below and

throughout these operating instructions.

Mechanical Safety

W A R N I N G

For operator safety, maintain a 30-cm "clearance envelope" around the

instrument while the rotor is spinning. Do not store dangerous substances

capable of developing flammable or explosive vapors in the clearance

envelope.

Do not attempt to unlock the door forcefully while the rotor is spinning.

Do not attempt to slow or stop the spinning rotor by hand.

Do not incline or move the instrument while the rotor is spinning. Do not lean

on the instrument.

If abnormal sound or vibration occurs, stop the operation immediately and

contact Thermo or your local representative of Thermo Fisher Scientific

products.

C A U T I O N

Before using a rotor, be sure to read through the rotor instruction manual.

Maximum rotor speed depends on the rotor, buckets, assemblies, tubes or

adapters to be used. Follow the instructions in the rotor instruction manual.

Do not use corroded, scratched or cracked rotors, buckets and assemblies.

Check that the rotor, buckets and assemblies are free of such abnormalities

before operation.

When using a swinging bucket, check that the buckets are properly engaged

with the rotor pins before operation. An incorrect setting can cause severe

damage to the instrument.

Be sure to mount the rotor cover if provided. Check that the rotor cover is

completely secured with a screw if provided.

Mount the rotor onto the drive shaft (drive spindle) gently and properly. Do not

drop the rotor or apply excessive force to the drive shaft (drive spindle).

Clean the inside of the drive hole (drive spindle hole) of the rotor and the

surface of the drive (drive spindle) of the centrifuge once a week.

If condensation is in the rotor chamber, wipe the chamber dry with a dry

sponge or cloth.

Page 7

Preface

Thermo Fisher Scientific RC-6 PLUS iii

Safety During Installation and/or Maintenance.

Electrical Safety

CAUTION

Do not pour any solution such as water, detergent or disinfectant directly into

the rotor chamber. Otherwise, the bearings of the drive unit may corrode or

deteriorate.

Before relocating the centrifuge, remove the rotor from the rotor chamber to

avoid damage to the drive shaft.

Always keep the liquid crystal panel in a visible position while the POWER

switch is turned on, so that you can check the current operating state (running

or stopping).

DANGER

When servicing the centrifuge, be sure to turn off the POWER switch, turn off

the distribution board of your centrifuge room, and then wait for at least three

minutes before removing covers or tables from the centrifu ge to avoid electr ical

shock hazards.

WARNING

Level the centrifuge by using the four level adjusters and secure them

completely. Improper securing can cause significant movement of the

centrifuge in the event of a rotor disengagement.

Installation or relocation of your centrifuge must be done by Thermo Fisher

Scientific or a Thermo Fisher Scientific representative. Contact Thermo Fisher

Scientific or your local representative of Thermo Fisher Scientific products

CAUTION

Avoid places that are exposed to ultraviolet rays for operation or storage of the

centrifuge. Otherwise, the covers can be discolored and the coating can be

peeled off easily. If installation in such a place is unavoidable, cover the

centrifuge with a cloth after operation to protect from ultraviolet rays.

WARNING

Your centrifuge must be grounded properly to avoid electrical shock hazards.

Page 8

Preface

iv RC-6 PLUS Thermo Fisher Scientific

Safety Against Risk of Fire

Chemical and Biological Safety

Notice for an Earthquake

An abnormality may be found on the centrifuge depending on the magnitude of

an earthquake.

If any abnormality is found, stop using the centrifuge immediately and ask for

inspection by Thermo or your local re presentative of Thermo Fisher Scientific

products.

CAUTION

Do not place containers holding liquid on or near the instrument or in the rotor

chamber. If they spill, liquid may get into the instrument and damage electrical

components.

WARNING

This instrument is not designed for use with materials capable of developing

flammable or explosive vapors or extreme exothermic reactions. Do not

centrifuge such materials in this instrument nor handle or store them near the

instrument.

WARNING

When using radioactive, toxic, or pathogenic materials, be aware of all

characteristics of the materials and the hazards associated with them in the

event leakage occurs during centrifugation. If leakage does occur, neither the

centrifuge nor the rotor can protect you from particles dispersed in the air. To

protect yourself, we recommend additional precautions be taken to prevent

exposure to these materials, for example, use of controlled ventilation or

isolation areas.

Always be aware of the possibility of contamination when using radioactive,

toxic, or pathogenic materials. Take all necessary precautions and use

appropriate decontamination procedures if exposure occurs.

The use of sealed rotors, buckets and/or sample containers will provide

increased protection from contamination during routine operation. However,

these items will not guarantee contaminatio protection from accidents resulting

in damage to the rotor or buckets. Do not run hazardous materials in the

centrifuge unless placed in a biohazard enclosure and operated using all

appropriate safety precautions.

Page 9

Thermo Fisher Scientific RC-6 PLUS iii

Contents

Chapter 1 Description..................................................................1-1

Centrifuge Description..................................................1-1

Centrifuge Specification................................................1-4

CentrifugeAccessories..................................................1-5

Chapter 2 Installation...................................................................2-1

Inspection.....................................................................2-1

Identify the Installation Site...........................................2-1

Levelling the Centrifuge................................................2-3

Electronical Requirements............................................2-4

Relocation.....................................................................2-6

Chapter 3 Controls, Displays & Indicators................................3-1

Controls, Displays, & Indicators....................................3-1

Operation Panel............................................................3-1

Power Switch ...............................................................3-5

Diagnostic Indicators Safety Device.............................3-6

Chapter 4 Operation.....................................................................4-1

Reducing Speed for Loads in Excess of Design Mass.4-1

Basic Operation............................................................4-2

Normal Operating Procedure........................................4-8

Saving and Changing Run Condition .........................4-11

Step-mode operation..................................................4-14

RTC (Real Time Control) Operation...........................4-15

Displaying and Setting RDCF.....................................4-20

Dispplaying and Setting ω2T ......................................4-21

Emergency Recovery from Power Failure..................4-23

Features on Menu Screen..........................................4-26

Lockout System Function...........................................4-28

Chapter 5 Care and Maintenance ...............................................5-1

Rotor Chamber.............................................................5-2

Tapered Drive Shaft (Drive Spindle).............................5-3

Page 10

Contents

iv RC-6 PLUS Thermo Fisher Scientific

Cabinet......................................................................... 5-3

Rotor ............................................................................5-3

Condenser Fins............................................................ 5-3

Replacement Parts....................................................... 5-3

Service Decontamination Policy................................... 5-4

Chapter 6 Troubleshooting......................................................... 6-1

Alarm Messages ..........................................................6-1

Appendix

Rotor Information Table

Warranty

Decontamination Information Certificates

Page 11

Thermo Fisher Scientific RC-6 PLUS 1-1

Chapter 1 INTRODUCTION &

DESCRIPTION

This manual provides you with the information you will need to operate and

maintain your Thermo Scientific RC-6 PLUS Superspeed Centrifuge. If you

encounter any problem concerning either operation or maintenance that is not

covered in the manual, please contact Thermo Fisher Scientific for assistance.

In the United States, call toll-free 1-669-THERMO; outside the United States,

contact your local distributor or agent for Thermo Fisher Scientific products.

Thermo Fisher Scientific product information is available on our internet web

site at http://www.thermo.com

Centrifuge

Description

The RC-6 PLUS is a high-speed (to 22,000 rpm) centrifuge used to separate

substances of different densities at controlled temperatures. Some of the

outstanding features of the RC-6 PLUS are:

• Speeds to 22,000 rpm (55,200 x g) without the need for a vacuum system

• Process 4 liters of sample in a single run

• High-frequency brushless motor for fast separations and reduced

maintenance

• RCF control allows set and display of g-force

• ω

2

dt integrator for run-to-run reproducibility

• Real Time Control for delayed start/stop runs

• 30 program memory

• 9 acceleration and 10 deceleration settings

• On-line rotor catalog

• Pre-cool function for fast rotor pre-cooling

• Wide choice of rotors including SUPER-LITE® composite, SUPER-LITE

aluminum, and RX™ Rapid Access rotors.

The RC-6 PLUS centrifuge is capable of operation in more than one mode to

meet a wide range of applications. Run conditions are selected using the touch

keyboard. Actual and set run conditions are displayed. For your protection,

Page 12

INTRODUCTION & DESCRIPTION

Centrifuge Description

1-2 RC-6 PLUS Thermo Fisher Scientific

system interlocks keep the centrifuge from starting if the chamber door is open,

and prevent the door from being opened if a run is in progress and the rotor is

spinning. System interlocks will also automatically terminate a run in progress if

a system malfunctions.

The RC-6 PLUS drive system has a high-frequency brushless motor for fast

separations and reduced maintenance.

The refrigeration system, charged with environmentally- friendly CFC-free

SUVA® refrigerant, offers reliable performance similar to other Thermo

Scientific Superspeed centrifuges. The high-capacity refrigeration system is a

low temperature, hermetically-sealed unit that consists of a compressor, a

condenser, an evaporator/rotor chamber, and interconnecting tubing. When the

centrifuge is running, the refrigeration system will maintain selected

temperatures within the range specified for the centrifuge.

The RC-6 PLUS accepts the Thermo Scientific Superspeed rotors listed in the

Rotor Information Table in the Appendix.

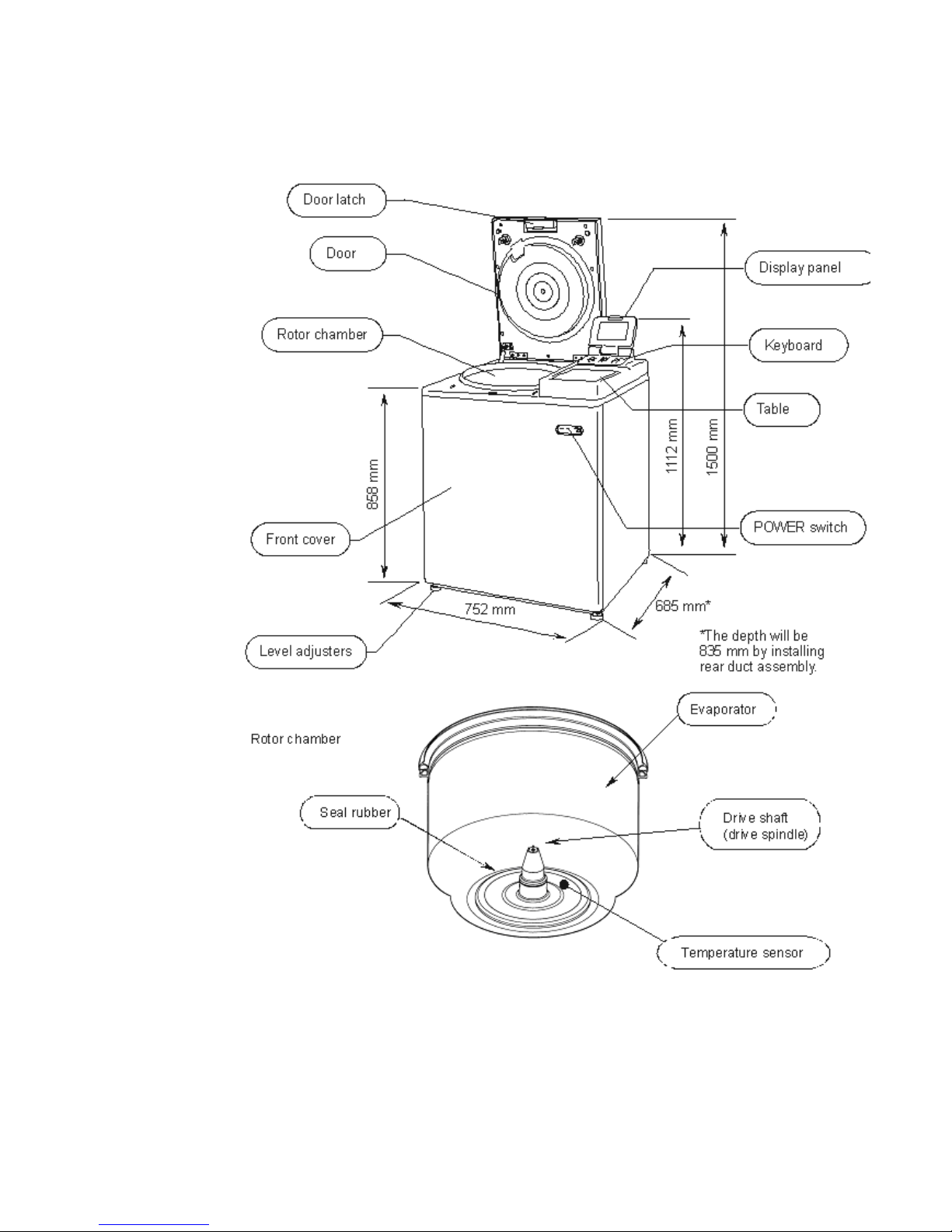

Refer to Figure 1-1 to identify the parts of the RC-6 PLUS.

Page 13

INTRODUCTION & DESCRIPTION

Centrifuge Description

Thermo Fisher Scientific RC-6 PLUS 1-3

Figure 1-1. Centrifuge Parts Location and Identification

Page 14

INTRODUCTION & DESCRIPTION

Centrifuge Specifications

1-4 RC-6 PLUS Thermo Fisher Scientific

Centrifuge

Specifications

Table 1-1. Centrifuge Specifications

Run Speed

*

*

Speed in revolutions per minute (rpm) is related to angular velocity, ω, according to the following:

Where = rad/s. All further references in this manual to speed will be designated as rpm.

Speed Selection Range (rpm) 300 to 22,000

Speed Control Accuracy ±25 rpm

Maximum Relative Centrifugal Force 52,200 x g

(F20MICRO)

Run Temperature

Temperature Selection Range -20°C to 40°C

**

**

The centrifuge will operate at ambient temperatures up to 40°C, but refrigeration system perfor-

mance may be less than optimal above 25°C.

After the centrifuge system has reached equilibrium. Ambient air temperature at the centrifuge air

inlets must be between 2°C to 40°C with maximum relative humidity of 80% at 31°C, linearly decreasing to 50% at 40°C. If the ambient air temperature is above 25°C, the centrifuge may not maintain low temperatures at high speeds, therefore, avoid areas near heat sources (for example, direct

sunlight, heating pipes and radiators). Also, avoid close grouping of centrifuges or other heat-producing laboratory equipment.

Temperature Control Range 2°C to 40°C

Temperature Control Accuracy ±2°C

Run Time Selection Range

1 minute to 99 hours, 59 minutes;

HOLD for continuous operation

Ambient Temperature Range 2°C to 40°C

***

Mass (Weight) 350 kg

Maximum Capacity 4,000 ml (SLC-4000)

Dimensions

Width 752 mm

Height to top of control console 1112 mm

Height with door open 1500 mm

Depth (including rear duct assembly) 835 mm

Depth (without rear duct assembly) 685 mm

From bottom to chamber inlet 858 mm

Noise Level <64 dB

****

Heat Output 3.7 kW (12,600 Btu/h)

*****

Page 15

INTRODUCTION & DESCRIPTION

Centrifuge Accessories

Thermo Fisher Scientific RC-6 PLUS 1-5

Centrifuge

Accessories

The following items are provided with the centrifuge:

***

After the centrifuge system has reached equilibrium. Ambient air temperature at the centrifuge

air inlets must be between 2°C to 40°C with maximum relative humidity of 80% at 31°C, linearly decreasing to 50% at 40°C. If the ambient air temperature is above 25°C, the centrifuge may not maintain low temperatures at high speeds, therefore, avoid areas near heat sources (for example, direct

sunlight, heating pipes and radiators). Also, avoid close grouping of centrifuges or other heat-producing laboratory equipment.

****

As measured with SE-12 rotor at 21,000 rpm (with compressor turned on) 3 feet from the front

of the unit and four feet from the floor.

*****

For the SS-34 rotor spinning 20,000 rpm at 4°C, after it has reached equilibrium. Other rotors,

speeds, and temperatures cause the heat output to vary.

Table 1-2.

Catalog No. Description

50105750 US Instruction manual

50105751 EU Instruction manual

Level

Rear duct assembly (To be mounted to the rear cover at

installation)

65937 Silicon grease

61556 Lubricant grease

Rotor cleaning bar

Page 16

INTRODUCTION & DESCRIPTION

Centrifuge Accessories

1-6 RC-6 PLUS Thermo Fisher Scientific

Page 17

Thermo Fisher Scientific RC-6 PLUS 2-1

Chapter 2 INSTALLATION

Installation or relocation of your centrifuge must be done by an authorized

Thermo Fisher Scientific representative. Contact Thermo Fisher Scientific or

your local representative of Thermo Fisher Scientific products.

After you receive your centrifuge, inspect it for damage before using it. The

RC-6 PLUS centrifuge must be installed in a location that meets all of the

electrical, location, and environment requirements that are specified below and

on the following pages. Installation instructions begin on page 2-3.

Inspection As soon as you receive your RC-6 PLUS Superspeed Centrifuge carefully

inspect it for any shipping damage that may have occurred. If you find any

damage, please report it immediately to the transportation company and file a

damage claim, then notify Kendro. If any parts are missing, contact one of the

Kendro district offices or the local representative of Thermo Fisher Scientific

products. You will find a list of offices on the back cover of this manual.

Identify the

Installation Site

DANGER

When servicing the centrifuge, be sure to turn off the POWER switch, turn off

the distribution board of your centrifuge room, and wait for at least three

minutes before removing covers or tables from the centri fuge to avoid ele ctrical

shock hazards.

WARNING

For operator safety, maintain a 30-cm "clearance envelope" around the

instrument and keep out of that area while the rotor is spinning. Do not store

dangerous substances capable of develo ping flamma ble or explos ive vapor s in

the clearance envelope.

Page 18

INSTALLATION

Identify the Installation Site

2-2 RC-6 PLUS Thermo Fisher Scientific

When choosing an installation site for the RC-6 PL US Centrifuge, consider its

dimensions, weight and noise level:

The location for the centrifuge must meet these requirements:

• A flat, vibration-free concrete floor. Avoid installing on a carpeted floor.

• Maximum altitude of 2000 meters.

• The unit is intended for indoor use only. Ambient air temperature at the

centrifuge air inlets must be between 2°C to 40°C with maximum relative

humidity of 80% at 31°C, linearly de cr ea sing to 50% at 40°C. If the ambient

air temperature is above 25°C, the centrifuge may not maintain low

temperatures at high speeds, therefore, avoid areas near heat sources (for

example, direct sunlight, heating pipes and radiators). Also, avoid close

grouping of centrifuges or other heat-producing laboratory equipment.

• Maintain a 30-cm clearance around the centrifuge. Do not store any

substances in the clearance envelope.

Note The RC-6 PLUS is a Class A product and is not intended for home use. If

used in a domestic environment you must contact your local authorities

for authorization.

Table 2-1.

Dimensions Width: 752 mm

Depth: 835m (including rear duct

assembly)

Depth: 685m (without rear duct assembly)

Height: 1112 mm

Weight 350 kg

Noise Level <64 dB (The maximum noise output with

the centrifuge, measured with the

compressor on at 0.91 m (3 ft) from the

front of the centrifuge and 1.22 m (4 ft)

from the floor.

Pollution Degree 2

Over Voltage Category II

WARNING

The RC-6 PLUS Centrifuge weighs 350 kg (772 lb.). Take the necessary

precautions when installing and moving the centrifuge to avoid personal injury

and/or damage to the centrifuge

Page 19

INSTALLATION

Leveling the Centrifuge

Thermo Fisher Scientific RC-6 PLUS 2-3

Figure 2-1. Clearances for the Centrifuge

Leveling the

Centrifuge

1. Turn on the centrifuge power and open the door. (If power supply is not yet

available, perform the Emergency Recovery from Power Failure procedure

discussed in Chapter 4.)

2. Place the level across the top of the drive spindle.

3. Using a 24 mm wrench, turn each of the four level adjusters until the casters

are 5 to 15 mm off the floor.

4. Level the unit by adjusting the level adjusters.

5. When the centrifuge is level, make sure each of the four level adjusters is

secure and rattle-free.

6. Secure each of the four level adjusters with the lock nuts.

CAUTION

Leave adequate space for airflow around the centrifuge and make sure no

vents are blocked. Blocking the airflow entering and/or exiting the centrifuge

can result in reduced performance, overheating and possible centrifuge

damage.

Page 20

INSTALLATION

Electrical Requirements

2-4 RC-6 PLUS Thermo Fisher Scientific

Figure 2-2. Leveling the Centrifuge

Electrical

Requirements

The appropriate power source must be available to plug in the centrifuge. The

power supply and outlet type required varies, depending on the rating on the

nameplate. Check the nameplate on the back panel of the centrifuge to

determine the electrical configuration of your centrifuge, which should be one of

the following:

CAUTION

The centrifuge can be damaged if it is connected to the wrong voltage, or if it is

connected to a line voltage that varies more than plus/minu s 10% of it s nominal

value. Check the voltage before plugging the centrifuge into any power source.

Thremo Fisher Scientific is not responsible for improper installation.

Table 2-2. Electric al Re qu ire m en ts

NAME PLATE RA TING SUPPLY REQUIRED

AC208/220/230/240

50/60Hz 21-24A single phase

AC208/220/230/240 50/60Hz 30A single

phase (25A single phase may be

acceptable depending on you local

electrical codes).

AC200 50/60Hz

25A single phase

AC200 50/60Hz 30A single phase

AC400 50/60Hz

2x15A 3 phase

AC400 50/60Hz 2x25A 3 phase

Page 21

INSTALLATION

Electrical Requirements

Thermo Fisher Scientific RC-6 PLUS 2-5

To connect to a different voltage, the centrifuge must be rewired and its plug

may also have to be replaced. Contact Thermo Fisher Scientific or your local

representative of Thermo Fisher Scientific products. For connection to a

different outlet, the power cord may also need to be replaced. Follow local

electrical codes.

Provide an emergency switch (circuit breaker) intended for the centrifuge only,

in case of emergency or in the event of failure. It is recommended that the

switch is located outside the centrifuge room or near the exit to the room.

Note For EMC emission the RC-6 PLUS is a Class A product. A slow reacting

circuit breaker is required because of the high startup current of the

compressor

Plug the power cord coming from the rear of the centrifuge in the terminal of the

distribution board. The green/yellow wire is a grounding wire. Your centrifuge

must be grounded properly.

Check the supply line voltage with a voltmeter and verify that the voltage

indicated on the nameplate is in agreement with the measured line voltage. If

the measured line voltage is not within 10% of the voltage specified on the

nameplate, do not connect the power cord and operate the centrifuge. Damage

to the centrifuge may result. To connect the centrifuge to a voltage other than

what is specified on the nameplate (including 3 phase), it will have to be rewired

and its power cord may have to be replaced. Contact Ther mo Fisher Scientific

to have an authorized Thermo Fisher Scientific representative do the rewiring.

Single phase RC-6 PLUS Centrifuges are equipped with a three- wire power

cord with three-prong connector to fit a NEMA 6-30P receptacle or equivalent

or, on 230V 50Hz centrifuges, an IEC 60309-type three-pin receptacle (32A,

2-pole and earth). 230V 50Hz poly phase RC-6 Centri fuge s ar e e quippe d with a

four-wire power cord with five-pin connector to fit an IEC 60309-type five-pin

receptacle (32 A, 3- pole, neutral and earth).

Provide an emergency switch (circuit breaker) intended for the centrifuge only to

turn off the centrifuge power in the event of failure. It is recommended to provide

that switch outside of the centrifuge room or near the exit of the centrifuge room.

WARNING

Your centrifuge must be grounded properly to avoid electrical shock hazards.

Page 22

INSTALLATION

Relocation

2-6 RC-6 PLUS Thermo Fisher Scientific

Relocation

Installation or relocation of your centrifuge must be done by an authorized

authorized Thermo Fisher Scientific representative. Contact Thermo Fisher

Scientific or your local representative of Thermo Fisher Scientific products.

Before relocating the centrifuge, unplug the centrifuge and loosen the locking

nuts. Lower the casters to the floor by turning the leveling bolts with a wrench.

Raise the leveling bolts enough to clear the floor and relocate the centrifuge.

After relocation, the centrifuge must be installed and leveled again.

CAUTION

Remove the rotor from the rotor chamber before relocating the centrifuge.

CAUTION

Be careful not to tip over the unit when moving on uneven or slanted floors.

Page 23

Thermo Fisher Scientific RC-6 PLUS 3-1

Chapter 3 CONTROLS, DISPLAYS

& INDICATORS

This chapter describes the RC-6 PLUS centrifuge controls, displays, and

indicators and includes their locations and functions.

Controls,

Displays, &

Indicators

The RC-6 PLUS control keyboard is used to select desired run parameters.

During a run, digital displays indicate set and actual run conditions, such as

estimated sample temperature, ro to r sp ee d , r ema inin g ru n tim e o r ac cu mu la te d

integral value.

Operation Panel The operation panel of the RC-6 PLUS Superspeed centrifuge is composed of a

display panel and function keys. The liquid cryst al disp lay can be tilted back and

forth for easy viewing. The display panel shows various screen displays such as

programmed operation, rotor list and user customization in addition to the basic

screen (RUN SCREEN) (see Figure 3-1).

The display automatically turns to the ZOOM SCREEN (see Figure 3-2) when

20 seconds have passed after reaching the set speed. The ZOOM screen

returns to the RUN SCREEN by pressing any key on the panel or when the rotor

starts deceleration.

Figure 3-1. Display Panel

Page 24

CONTROLS, DISPLAYS & INDICATORS

Operation Panel

3-2 RC-6 PLUS Thermo Fisher Scientific

Figure 3-2. Zoom Screen

Page 25

CONTROLS, DISPLAYS & INDICATORS

Operation Panel

Thermo Fisher Scientific RC-6 PLUS 3-3

Table 3-1.

No Name Display Panel Function (refer to Figure 3-1)

1 Field display Displays the following run conditions.

For SPEED, TIME and TEMP displays, the upper line

shows the actual run state and the lower line shows

the set value. Refer to Setting Run Conditions for

details.

• SPEED (Speed display)

(Upper line)

Displays rotor speed in increments of 10 rpm under

10,000 rpm and increments of 100 rpm over 10,000

rpm.

(Lower line)

Displays rotor speed in increments of 10 rpm under

10,000 rpm and increments of 100 rpm over 10,000

rpm. Set speed range is from 300 rpm to 21,000

rpm.

• TIME (Run time display)

(Upper line)

Displays remaining run time during operation. If

HOLD is selected, displays elapsed run time.

(Lower line)

Run time range is from 1 minute to 99 hours, 59

minutes in increments of 1 minute.

• TEMPERATURE (Temperature display)

(Upper line)Displays rotor temperature in

increments of 1 degree centigrade.

(Lower line)Temperature range is from - 20

degrees centigrade to 40 degrees

centigrade in increments of 1 degree centigrade.

• ACCEL (Acceleration rate display)

Displays 1 to 9 acceleration rates.

• DECEL (Deceleration rate display)

Displays 1 to 9 deceleration rates and free coast

(0).

Page 26

CONTROLS, DISPLAYS & INDICATORS

Operation Panel

3-4 RC-6 PLUS Thermo Fisher Scientific

Figure 3-3. Function Keys

2 FU NCTION

field

• PROG Used to save run conditions for

programmed operation.

• RCF Used to display and set RCF value.

• ω

2

T Used to display and set for integrator

operation.

3 Message

indicator

Displays alarm message, prompt and rotor model.

4 RUN mode

indicator

Displays operating mode with illustration of a rotor.

Operating modes are as follows:

STOP, ACCEL, RUN (Displayed when rotor is

rotating at set speed), DECEL

And DELAY (Displayed up to RTC operation is

started)

Table 3-1.

No Name Display Panel Function (refer to Figure 3-1)

Table 3-2.

No Name Key Function (refer to Figure 3-3)

5 START key Starts the centrifuge run.

6 STOP key Stops the centrifuge run.

7ROTOR

key

Used to display rotor list or to enter desired rotor

number.

8 ESC key Used to return to the previous screen. (e.g., from

MENU screen to RUN SCREEN)

9 MENU key Displays MENU screen.

You can select user customization, or alarm

information.

Page 27

CONTROLS, DISPLAYS & INDICATORS

POWER Switch

Thermo Fisher Scientific RC-6 PLUS 3-5

POWER Switch The POWER switch is located in the upper right-hand corner of the front cabinet

panel. The switch is an ON/OFF toggle switch, when set to ON applies electric

power to the centrifuge.

" I " : ON

" O " :OFF

10 Cursor keys

(1) Makes the RUN SCREEN ready-to-enter state.

(2) Moves the cursor on the screen.

1. Moves the cursor upward (K).

2. Moves the cursor left (I).

3. Moves the cursor right (J).

4. Moves the cursor downward (L).

11 Ten-key Used to set run conditions with numeric values.

numerical

pad

At time setting : switches between hours and

minutes.

At temperature setting : Used to enter a minus

sign.

At ω

2

T value setting : switches between integer

and mantissa.

At run time setting: used to set continuous

operation.

Used to clear typing errors and alarm messages.

(1) By pressing the CE key, the entered value on the

line where the cursor stays is cleared and the

cursor returns to the previous position.

(2) By pressing the CE key, displayed alarm

message is cleared. If two or more alarm

messages are displayed at a time, clear them

one by one. (Refer to Corrective Actions for

details.)

Used to fix the entered value.

Table 3-2.

No Name Key Function (refer to Figure 3-3)

CAUTION

Always keep the liquid crystal panel in a visible position while the POWER

switch is turned on so that you can check the current operating state.

Page 28

CONTROLS, DISPLAYS & INDICATORS

Diagnostic Indicators Safety Device

3-6 RC-6 PLUS Thermo Fisher Scientific

Do not position the centrifuge so that the movement of the POWER switch may

become difficult.

Figure 3-4. POWER switch

Diagnostic

Indicators Safety

Device

Protection of Rotor Chamber The rotor chamber allows the rotor to rotate at high speeds. A steel protector is

provided around the chamber for the operator’s safety in case of any rotor

mishap during centrifugation.

Imbalance Detector This centrifuge is equipped with a sensor that detects severe vibration of the

rotor due to improper bucket setting or excessive imbalance, and decelerates

the rotor. If an imbalance is detected, the run will be terminated and

IMBALANCE will be displayed.

Door Lock For safety reasons, the door is automatically locked while the rotor is rotating.

The locked state is held even if the instrument power is turned off. The door can

be opened/closed only when the rotor stops.

Page 29

Thermo Fisher Scientific RC-6 PLUS 4-1

Chapter 4 OPERATION

This chapter provides step-by-step instructions on how to set the centrifuge

power ON, open the chamber door, and perform a run in the normal mode. It

also describes how to precool the rotor. Read and observe the Important Safety

Information supplied on page iii at the front of this manual.

The chapter contains supplementary information on how to calculate relative

centrifugal force (RCF); how to do a test run for low speed and low temperature

operation; and what will cause an ENTRY ERROR.

The controls and displays referred to in this chapter are described in detail in

Chapter 3.

Reducing Speed

for Loads in

Excess of Design

Mass

Each rotor has a maximum allowable compartment mass (defined in Appendix

and in the rotor manual). To prevent rotor failure, the total contents of any

compartment, including specimen, tubes, sealing assembly and adapters must

not exceed the specified maximum compartment mass unless rotor speed is

reduced proportionately. Strict adherence to the maximum allowable

compartment mass or reduced rotor speed is required to pr event rotor failure.

If the maximum compartment mass is greater than value specified for the rotor,

use the following formula to determine the redu ce d ro to r sp ee d re qu ire d :

WARNING

1. Use specified Thermo Fisher Scientific rotors only.

2. Do not use corroded, scratched or cracked rotors, buckets and assemblies.

Check that the rotor, buckets and assemblies are free of such abnormalities

before operation.

3. Do not exceed the maximum rated speed of the rotor or buckets in use.

4. Failure to reduce rotor speed when compartment load exceeds maximum

allowable compartment load can lead to rotor failure and result in personal

injury and/or centrifuge damage.

Page 30

OPERATION

Basic Operation

4-2 RC-6 PLUS Thermo Fisher Scientific

Basic Operation

This section describes how to perform a basic run, how to set run conditions on

the RUN SCREEN and how to use the cursor keys.

1. Set the main power switch ON.

2. Open the chamber door.

3. Install the rotor:

• Wipe the rotor centerhole and spindle surfaces clean to reduce the chance

of the rotor sticking to the spindle.

• If applicable, make sure the rotor cover is installed.

• Place the rotor on the drive spindle and lock it in place turning the rotor

locking knob counterclockwise.

4. Close the chamber door.

5. Set the Run Screen as follows.

WARNING

1. Failure to load and install the rotor in accordance with the instructions in the

rotor operating guide could result in damage to the centrifuge. The rotor cover

must be on and locked in place and the rotor must be locked on to the drive

spindle.

2. Use specified Thermo Fisher Scientific rotors ONLY.

3. Do not incline or move the instrument while the rotor is spinning.

4. Do not place any object on the instrument or lean on the instrument while the

rotor is spinning.

Page 31

OPERATION

Basic Operation

Thermo Fisher Scientific RC-6 PLUS 4-3

RUN Screen

The RUN SCREEN shows the set and actual run conditions.

The speed (SPEED), time (TIME) and temperature (TEMP) displays have a

two-line display.

The upper line shows the actual run state and the lower line shows the set

value.

The acceleration (ACCEL) and deceleration (DECEL) displays show the set

value.

Figure 4-1. RUN Screen

CAUTION

1. Do not tilt the display panel forcibly or, mechanical components can be

damaged.

2. Do not press the function keys with a sharp-pointed object such as a ballpoint

pen.

3. If an abnormal sound is heard during the operation, stop the operation

immediately and contact Thermo Fisher Scientific or your local representative

of Thermo Fisher Scientific products.

WARNING

Do not leave rotors or other objects on centrifuge surfaces during operation.

Page 32

OPERATION

Basic Operation

4-4 RC-6 PLUS Thermo Fisher Scientific

Cursor Keys A cursor appears and blinks on the entry line of a run condition display by

pressing a cursor key as shown in Figure 4-2.

The entry line state varies depending on the presence of cursor as shown

below.

1. Fixed-entry state: No cursor appears in normal state.

2. Ready-to-enter state: By pressing any of the four cursor keys in fixed-entry

state, a cursor appears blinking "0" (or other numeric value) on the entry

line. Desired numeric values can be entered in this state. Press the cursor

keys to move the cursor.

To set desired run conditions, put the RUN SCREEN in the ready-to-enter state.

Move the cursor to the desired item and enter a numeric value. If no numeric

value is entered in ready-to-enter state for 30 seconds or more, the display

automatically turns to fixedentry state.

Note To enter desired value when the entry line is fixed-entry state (e.g., the

state of RUN SCREEN after turning on the POWER switch), press any of

the four cursor keys to show a blinking cursor and move the cursor to the

desired item with cursor keys. The cursor keys have two functions. One

is to show a cursor on the screen and the other is to move the cursor. The

cursor on the screen can be moved up, down, left and right according to

the arrow marks on the cursor keys.

Figure 4-2. Entry Line State

Designating the Rotor Before operation, the roto r used must be design ated according to the following

procedure. This centrifuge does not start operation unless a rotor is designated.

This centrifuge performs optimum temperature compensation and maximum

speed checking for the designated rotor.

Page 33

OPERATION

Basic Operation

Thermo Fisher Scientific RC-6 PLUS 4-5

1. When setting two or more run conditions, there is no need to press the

ENTER key after each setting. The set value is entere d by pressing a cursor

key and the cursor moves to the new item in ready-to-enter state.

2. If changing the TIME setting during continuous operation (HOLD), enter a

value adding the desired remaining time to the elapsed time. For example,

to stop the operation after 1 hour and 30 minutes when 5 hours have

elapsed in continuous operation, turn the TIME display to ready-to-enter

state by pressing a cursor key and enter as follows.

Setting RUN Conditions The table below exemplifies how to set run conditions such as rotor speed, run

time and rotor temperature.

Table 4-1.

Step Key Operation Screen Display and Notices

1

Press the ROTOR key on the

KEY BOARD.

Enter the rotor number to be

used with the ten-key numerical

pad and press the NTER key.

(The screen turns to the next

page by pressing the cursor key.)

The screen returns to the RUN

SCREEN.

Page 34

OPERATION

Basic Operation

4-6 RC-6 PLUS Thermo Fisher Scientific

Table 4-2. Set Run Conditions

Item

Example set value

Speed (SPEED)

20,000 rpm

Run Time (TIME)

2 hours, 30 minutes

Procedure

1

Press a cursor to turn the display

to ready-to-enter state.

The display turns to

readyto-enter state.

The display turns to

ready-to-enter state.

2

Move the cursor to the desired

item by pressing the cursor keys.

(The arrow marks on the cursor

keys indicate cursor directions.)

3

The cursor blinks on the entry

line for 30 seconds.

The display is now ready-to-enter

state.

4

Enter the desired value with

the ten-key numerical pad.

Entered numerals are shifted to

the left in order.

The last zero (0) need not

be entered.

The cursor can be moved to the

hours setting position by pressing

the cursor left key.

For continuous run, press the

HOLD key.

5

Check the setting and fix it by

pressing the ENTER key.

Setting can also be fixed by

pressing a cursor key. The CE

key is used to cancel the setting.

The speed setting is "20,000

rpm".

The run time setting is "2:30

(2 hours 30 minutes)".

6

Press the START switch.

7

After the rotor has come to a

stop, lift the door handle. Then

remove the rotor.

Setting range

300 rpm to the maximum speed:

in increments of 10 rpm under

10,000 rpm, and in increments of

100 rpm over 10,000 rpm

1 minute to 99 hours 59 minutes:

in increments of 1 minute

Page 35

OPERATION

Basic Operation

Thermo Fisher Scientific RC-6 PLUS 4-7

Note Keep the chamber door closed af ter the roto r has been r emoved to inhibit

the formation of condensation on the chamber walls.

To repeat the run with the same speed, time and temperature parameters,

install the rotor, close the chamber door, press START and then press ENTER.

Table 4-3. Speed, Time and Temperature Parameters

Temperature (TEMP)

4 degrees centigrade

Acceleration Rate (ACCEL) 9Deceleration Rate (DECEL)

7

The display turns to

ready-to-enter state.

The display turns to

ready-to-enter state.

The display turns to

ready-to-enter state.

The cursor is blinking at the single

digit position.

Enter "0" for selecting free coast.

The temperature setting is "4

degrees centigrade".

The acceleration rate setting is

"9".

The deceleration rate setting is

"7".

-20 degrees centigrade to 40

degrees centigrade: in increments

of 1 degree centigrade

1 to 9 1 to 9 and 0 for free coast

Page 36

OPERATION

Normal Operating Procedure

4-8 RC-6 PLUS Thermo Fisher Scientific

Normal Operating

Procedure

This section describes the procedure for normal operation.

Note Before following the procedur e, read the rotor instr uction manual carefully

and make sure that you have selected the appropria te type of tube for the

sample, and that the amount of sample in the tubes is correct.

The RUN mode indicator is displayed on the panel as follows:

Table 4-4.

Step Procedure State of Centrifuge and Notices

1

Turn ON the POWER

switch of the centrifuge.

• The panel indicators turn on.

• The door lock is released.

2 Mount the rotor.

• Mount the rotor on the drive spindle

properly and tighten the rotor locking knob

securely.

• Press the ROTOR key and enter the

correct rotor number.

3 Set run conditions.

• Set run conditions referring to Set Run

Conditions.

4 Press the START key.

• The rotor starts rot ating and the timer star ts

counting.

• The rotor accelerates up to the set speed.

5

The set run time has

elapsed or the STOP key

is pressed.

• The rotor starts decelerating.

6 The rotor stops.

• The centrifuge makes a beep to notify that

the rotor has stopped.

7 Remove the rotor.

• Wait until the rotor stops completely and

then remove the rotor.

Page 37

OPERATION

Normal Operating Procedure

Thermo Fisher Scientific RC-6 PLUS 4-9

Figure 4-3. RUN Mode Indicator

Acceleration Rate and

Deceleration Rate

The acceleration and deceleration rates can be adjusted for a wide range of

use. The figure below shows how a rotor accelerates and decelerates in

compliance with a code number selected from 1 through 9.

Note These time values vary with the type of rotor in use.

Table 4-5. Acceleration Rate and Deceleration Rate

Code No. Time for acceleration from

0 to 500 rpm

Time for deceleration from

500 to 0 rpm

9 Minimum

*

*

The minimum time is the one that occurs when the rotor is being accelerated

or decelerated with the maximum torque of the driving motor. This time varies

with the type of rotor in use.

Minimum

**

**

The minimum time is the one that occurs when the rotor is being accelerated

or decelerated with the maximum torque of the driving motor. This time varies

with the type of rotor in use.

8 30 sec. 1 min.

7 45 sec. 2 min.

6 1 min. 3 min.

5 2 min. 4 min.

4 3 min. 6 min.

3 4 min. 8 min.

2 6 min. 10 min.

1 10 min. 15 min.

0 - Coasting deceleration from set

speed

Page 38

OPERATION

Normal Operating Procedure

4-10 RC-6 PLUS Thermo Fisher Scientific

Figure 4-4. Acceleration and Deceleration Rates

FUNCTION Field

Figure 4-5. Function Field

The RC-6 Plus Superspeed centrifuge has many add-on features such as

programmed operation and centrifugal force values displaying and setting.

These features are displayed and selected on the FUNCTION field.

PROG : You can save run conditions in memory for later use in repeated

operation.

This feature also allows step-mode operation (three normal operations can be

combined in a sequence of operations).

RCF : The centrifuge automatically computes and displays RCF values from set

speed, or speed from set RCF values.

ω

2

T : The centrifuge automatically computes and displays run time from set

speed and ω

2

T set value.

Programmed Operation Programmed operation capability is an add-on feature that saves set run

conditions in memory for later use. This feature allows you to save frequently

used run conditions in memory and then recall the saved run conditions

whenever you need them, thus making the operation procedure simple. (Even

when the POWER switch is turned off, the saved run conditions remain in

memory.) The memory in the centrifuge can contain 30 sets of run parameters.

Page 39

OPERATION

Saving and Changing Run Conditions

Thermo Fisher Scientific RC-6 PLUS 4-11

Saving and

Changing Run

Conditions

To save or change run conditions in memory, use the following procedure.

Table 4-6. Change Run Conditions in Memory

Step Key operation Screen display and notices

1 Move the cursor to

PROG and press

the ENTER key.

The FUNCTION field turns to the PROGRAM

field.

2 Press the cursor

key to move the

cursor to SAVE

and press the

ENTER key.

The screen turns to the MEMORY No. LIST

screen.

A setting parameter of the RUN SCREEN is

temporary saved at first memory area.

3 Enter the desired

MEMORY No. to

be saved with the

ten-key numerical

pad and press the

ENTER key.

(e.g.: saving run

conditions at

MEMORY No.1)

The cursor moves to the desired MEMORY No.

Page 40

OPERATION

Saving and Changing Run Conditions

4-12 RC-6 PLUS Thermo Fisher Scientific

4 When other

conditions are

saved, selecr the

desired memory

No. (.g.: at

MEMORY NO.2)

And enter run

conditions as

follows.

e.g.: SPEED:

20,000 rpm

TIME: HOLD

TEMP: 4 degrees

centigrade

ACCEL: 9

DECEL: 7

ROTOR No.: 25

(F20/MICRO)

The run conditions are saved at MEMORY No. 2.

* The screen turns to RCF and g.sec values entry

screen by pressing the cursor key.

Table 4-6. Change Run Conditions in Memory

Step Key operation Screen display and notices

Page 41

OPERATION

Saving and Changing Run Conditions

Thermo Fisher Scientific RC-6 PLUS 4-13

Note 1. When the saved run conditions are changed, the previous run

conditions are cleared and the newly saved run conditions are in effect.

2. Run conditions cannot be saved while the rotor is rotating. Check that

the rotor stops completely before saving run conditions.

Using Programmed Operation To recall the saved run conditions and use programmed operation with the

recalled run conditions, take the following procedure.

5 After saving run

conditions, press

the ESC key twice.

*The PROGRAM field appears by the first press

of the ESC key.

*The FUNCTION field appears by the second

press of the ESC key.

Table 4-6. Change Run Conditions in Memory

Step Key operation Screen display and notices

Page 42

OPERATION

Step-mode Operation

4-14 RC-6 PLUS Thermo Fisher Scientific

Table 4-7. Recalled Run Conditions

Step-mode

Operation

This centrifuge has the step-mode operation capability that allows you to save

three different sets of values for a ru n p arameter set in a single memory location

(MEMORY Nos. 31 - 33, 41 - 43, and 51 - 53) and then change some or all of

Step Key operation Screen display and notices

1 Move the cursor to

PROG and press

the ENTER key.

The FUNCTION field turns to the PROGRAM

field.

2 Press the ENTER

key when the

cursor stays on

CALL.

The screen turns to the MEMORY No. LIST

screen.

3

Enter the desired

MEMORY No. with

the ten-key

numerical pad and

press the ENTER

key. (e.g.: r ecalling

run conditions

saved at

MEMORY No. 2

)

The recalled run conditions are displayed.

The MEMORY No. appears on the message display.

Only the saved MEMORY No. can be recalled

.

4 Mount the rotor

and press the

START key.

* The rotor starts rotating.

* When reentering (changing) a run condition of the

recalled MEMORY No. (e.g., SPEED), the MEMORY

No. is canceled.

Recall the MEMORY No. again if necessary.

* The MEMORY No. cannot be changed (or recalled)

while the rotor is rotating.

Page 43

OPERATION

Step-mode Operation

Thermo Fisher Scientific RC-6 PLUS 4-15

the run conditions (e.g., speed, run time, rotor temperature, etc.) for each step

during a step-mode run. Save step-mode run conditions at the MEMORY Nos.

31 - 33 (41 - 43 or 51- 53) in accordance with "3-3-1 Programmed Operation

(1)".

When the MEMORY No. 31 is recalled, the centrifuge automatically performs

step-mode operation in order of MEMORY Nos. 31, 32 and 33.

Procedure for step-mode

operation

[Example]

The table below shows the run parameters and their values required for an

example 3-step run (MEMORY Nos. 31 to 33) . Fig. 4-6 depict s how the example

run will proceed.

Figure 4-6. Details of an example step-mode operation

Note (1) Select the same rotor number for each step. Otherwise, alarm

message "ROTOR NO." is indicated and the centrifuge stops operation.

(Contents of the memory cannot be called up.)

Table 4-8. Example 3-Step Run

1st step

(Memory No.

31)

2nd step

(Memory No.

32)

3rd step

(Memory No.

33)

Speed

1000rpm 2000rpm 5000rpm

Run time

30min 60min 10min

Temperature

4°C 4°C 4°C

Accel rate

999

Decel rate

997

Rotor No.

46

46 46

Page 44

OPERATION

RTC (Real Time Control) Operation

4-16 RC-6 PLUS Thermo Fisher Scientific

Note (2) Use the MEMORY Nos. 32 and 33 (42 and 43 or 52 and 53) for the

step-mode operation with two steps.

RTC (Real Time

Control) Operation

The RC-6 Plus Superspeed Centrifuge can be programmed to perform

automatic centrifugation by setting the incorporated time clock to start and end

centrifugation at the desired time in advance. This is the RTC (Real Time

Control) operation, also referred to as delayed start/stop.

Figure 4-6 illustrates an example of procedure for RTC operation.

Example: The rotor is loaded in the centrifuge and the run conditions listed

below are set in the evening on April 1, to end the operation about 9:30 a.m.

next morning.

Figure 4-7. Example of RTC Operation

In this example, the above run conditions from (2) to (6) are set first and then

the designated time to complete the RTC operation, 9:30 a.m. on April 2. Then

the START key is pressed.

(Otherwise, the same RTC operation can be achie ved b y se tting the desig nated

time to start centrifugation, 8:30 a.m. on April 2.)

Table 4-9. Example of RTC Operation

1 Rotor SS-34

2 Speed 18,000 rpm

3 Run time 60 minutes

4 Temperature 4 degrees centigrade

5 Acceleration rate 9

6 Deceleration rate 7

Page 45

OPERATION

RTC (Real Time Control) Operation

Thermo Fisher Scientific RC-6 PLUS 4-17

Procedure for RTC Operation

Step Key operation Screen display and notices

1 Set the run

conditions.

• Set the run conditions referring to Setting Run

Conditions.

• For time setting, do not select HOLD but enter a

numeric value.

2 Move the cursor to

PROG and press

the ENTER key.

The FUNCTION field turns to the PROGRAM field.

3 Press the cursor

key three times to

move the cursor to

RTC and press the

ENTER key.

The screen turns to the RTC operation setting screen.

4 Select the desired

item.

When selecting "1:

Setting stop time",

press the following

keys.

The cursor is blinking on "day" column.

The date (month and day) is automatically display

ed.

Page 46

OPERATION

RTC (Real Time Control) Operation

4-18 RC-6 PLUS Thermo Fisher Scientific

5

Enter the desired

date and time

(month, day, hour

and minutes) using

the cursor keys and

the ten-key numerical pad. Press the

ENTER key.

• The range for "hour" setting is from 0 to 23

(24-hour display).

• Do not enter any date and time that passed

the current time.

Set a proper stop time considering the

centrifugation time so that the start time will be

later than the current time.

• It is not possible to set an operation that will

start 20 days or more from the current time.

6

Select Yes or No in

response to the

prompt.

• When selecting "Yes":

• The screen turns to the RUN SCREEN and the

RTC time is displayed.

• RTC appears on the message indicator.

• When selecting "No", the display turns to the

screen of Step 2

. Enter the desired setting

again.

Step Key operation Screen display and notices

Page 47

OPERATION

RTC (Real Time Control) Operation

Thermo Fisher Scientific RC-6 PLUS 4-19

1. The RUN mode indicator on the panel turns as follows in RTC operation.

Figure 4-8. Operating Mode (RTC)

2. Note that the RTC setting is not available in the following cases:

i. The time setting on the RUN SCREEN is "HOLD" (continuous run).

Change the run time setting from "HOLD" to a desired numeric

value.

ii. The start time has already passed.

Change the setting so that the start time will be later than the

current time.

iii. The start time is 20 days or more from the current time.

Change the setting so that the start time will be within 20 days.

7 Check the RTC

setting on the

RUN SCREEN

and press the

START key.

• Perform operation according to Operating

Procedure.

• Note that the run time setting cannot be changed

after setting the RTC operation. Clear the RTC

setting and then reset the run time if necessary.

• The centrifuge turns to "DELAY" mode by pressing

the START key and wait until the set time. The

centrifuge automatically starts operation at the set

time and keeps operation during the designated

time.

• The RUN mode indicator on the message displa y

turns to "DELAY".

Step Key operation Screen display and notices

Page 48

OPERATION

Displaying and Setting RCF

4-20 RC-6 PLUS Thermo Fisher Scientific

3. Clear the RTC setting and then reset the run time if it is necessary to

change the run time setting after setting the RTC operation.

4. Recall the saved run conditions and enter the RTC setting when performing

the programmed operation (including the step-mode operation) and the

RTC operation in combination. The centrifuge automatically computes the

total run time of all steps in the programmed operation and also the start

time for RTC operation. Note that the saved run conditions cannot be

recalled after setting the RTC operation.

5. Press the STOP key to stop the operation. The RTC operation is stopped

and the rotor stops.

6. When performing the RCF operation and the RTC operation in combination,

enter the RCF setting first then enter the RTC setting. (See Displaying and

Setting RCF.)

7. When performing the ω

2

T operation and the RTC operation in combination,

enter the ω

2

T setting first then enter the RTC setting. (See Displaying and

Setting

ω

2

T.)

Displaying and

Setting RCF

The RC-6 Plus Superspeed centrifuge, has in its internal memory, data

representing the maximum radii of all available rotors. Based on this data, the

centrifuge automatically computes relative centrifugal force (RCF) values from

set speed, or speed from set RCF values, and then displays the result on the

control panel. This section explains how to use this RCF displaying and setting

capability of the centrifuge.

Page 49

OPERATION

Displaying and Setting w2T

Thermo Fisher Scientific RC-6 PLUS 4-21

Table 4-10. Use of RCF Displaying and Setting

1. Press ESC key to clear the RCF screen.

2. The RCF operation is canceled by changing the set speed or changing the

operation mode to the programmed operation mode.

Displaying and

Setting ω2T

This machine is provided with a function to perform an integrator (ω2T)

operation. To perform an ω

2

T operation, set the ω2T value instead of the run

time.

Step Key operation Screen display and notices

1 Move the cursor to

PROG and press

the ENTER key.

The FUNCTION indicator turns to the RCF display.

RCF(Upper line).

Displays the actual RCF computed for the

motor speed and selected rotor.

(Lower line) Set RCF

Displays the set RCF computed for the motor

speed and selected rotor.

2 Enter the desired

RCF with the

ten-key numeric

pad and press the

ENTER key.

The RPM is computed from the set RCF and selected

rotor is

displayed.

Set RCF

Page 50

OPERATION

Displaying and Setting w2T

4-22 RC-6 PLUS Thermo Fisher Scientific

Step Key operation Screen display and notices

1 Set the speed in

the Run Screen.

See Basic Operation.

2 1. Use cursor

keys to move

cursor to ω

2

T

on the RUN

SCREEN.

2. Press the

ENTER key.

The FUNCTION indicator turns to the ω

2

T set screen.

3 Enter a desired

ω

2

T value.

Example: 9.87E11

Entered value is displayed on the ω2T SET column and

the message indicator respectively.

The TIME display shows “- : -“.

Set ω2T

4 When you press

START key, the

run is controlled by

the set ω2T value

rather than by

time.

Computed and integrated value is displayed on the ω

2

T

indicator.

Page 51

OPERATION

Emergency Recovery from Power Failure

Thermo Fisher Scientific RC-6 PLUS 4-23

Note When the displayed ω

2

Treaches the set value of ω2T, the machine

decelerates and stops. During deceleration,ω

2

T is integrated and its result is

displayed until a stop.

w

2

T is selectable between 0.01E03 and 9.99E17.

The w

2

T operation is canceled by changing the set time or changing the

operation mode to the programmed operation mode. When the FUNCTION

indicator shows the w

2

T mode, the w2T mode is canceled and no value is

indicated on the w

2

T SET column by changing the set time.

The w

2

T indicator shows the current w2T value computed during operation.

Note When performing the RTC operation and the ω

2

T operation in

combination, following phenomenon may occur due to a conversion error from

the set ω

2

T to the run time. (There is no error in operation for the set ω2T.)

Emergency

Recovery from

Power Failure

Table 4-11. Conversion Error in RTCOoperation

RTC Setting Phenomenon

When setting the operation start

time

Actual operation does not start at

the displayed time exactly.

When setting the operation end time Actual operation does not end at the

displayed time exactly.

WARNING

When servicing the centrifuge, be sure to turn off the POWER switch, turn off

the distribution board of your centrifuge room, and then wait for at least three

minutes before removing covers or tables from the centrifu ge to avoid electr ical

shock hazards.

Page 52

OPERATION

Emergency Recovery from Power Failure

4-24 RC-6 PLUS Thermo Fisher Scientific

Rotation of Rotor The rotating rotor coasts free and finally stops if a power failure occurs during

operation. When the power is restored, the centrifuge automatically

re-accelerates the rotor if the rotor is still rotating at 250 rpm or higher, or

decelerates the rotor if the rotor is rotating under 250 rpm.

Operation Panel

During the power failure, all the displays on the display panel are off. When the

power is restored, the centrifuge will restart the control of the run with the set

parameters that were in effect before the power failure (battery-backed), and

will report the occurrence of the power failure by lighting up the alarm message.

Removing the Rotor During

Power Failure

If the power failure continues for an extended time, and you have decided to

remove the rotor from the rotor chamber during the power failure, use the

following procedure.

The rotor needs more than 60 minutes to co ast to a complete stop if the rotor

has been rotating at high speed.

1. Check that the rotor stops completely.

WARNING

Never attempt to open the door while the rotor is rotating.

Never attempt to slow or stop the rotor by hand.

WARNING

Make sure that the rotor has coasted to a complete stop. When the rotor is at

rest, it makes no sound. So listen carefully for any sound coming from the rotor

chamber.

Never attempt to override the door interlock system while the rotor is rotating.

CAUTION

Do not perform any operation not specified in this manual. If any problem is

found with your centrifuge, contact Thermo Fisher Scientific or your local

representative of Thermo Fisher Scientific products.

Page 53

OPERATION

Emergency Recovery from Power Failure

Thermo Fisher Scientific RC-6 PLUS 4-25

2. Turn off the POWER switch of the centrifuge and the distribution board of

your centrifuge room.

3. Remove the two screws from the lower portion of the front cover. Remove

the front cover by pulling the lower portion of the front cover forward and

downward. The upper portion of the front cover is not secured with screws.

4. Raise the weights of the two door locks at the front and secure them with

adhesive tape.

Figure 4-9. Opening the Door

5. Release the door handle and open the door slowly.

Check that the rotor has stoped completely. If the rotor is rotating, close the

door immediately.

Page 54

OPERATION

Features on Menu Screen

4-26 RC-6 PLUS Thermo Fisher Scientific

6. Take out the rotor and remove the adhesive tape from the door lock

solenoids.

Insert the hooks into the square holes and put the front cover on the

support, then secure the front cover with the screws in the reverse order of

removal.

Features on Menu

Screen

WARNING

Never attempt to slow or stop the rotor by hand.

Table 4-12. Features on Menu Screen

Features on Menu Screen

Press the MENU key and a menu

appears as follows.

(1) User customization

(2) Alarm information

Select the desired item with the

numeric key and press the ENTER

key to show the corresponding

screen.

User Customization

The user customizations include the

following items.

(1) Screen utilities

(2) Precool

(3) Melody

Select the desired item with the

numeric key and press the ENTER

key to show the corresponding

screen.

Page 55

OPERATION

Features on Menu Screen

Thermo Fisher Scientific RC-6 PLUS 4-27

Screen Utilities

You can customize the unit’s time

setting, screen contrast level, and

run screen.

Changing RUN SCREEN

1 = NORMAL RUN SCREEN is

displayed.

2 = ZOOM: The display

automatically turns to ZOOM

screen when 20 seconds have

passed after reaching the set

speed. The ZOOM screen

returns to the RUN SCREEN by

pressing any key on the panel or

when the rotor starts

deceleration.

Changing Date and Time

This feature is used when adjusting

the incorporated time clock to

the current date and time

correctly.

Set the correct date and time for

RTC Operation.

Enter the desired date and time

using the cursor keys and the

ten-key numerical pad, then

press the ENTER key.

Screen Contrast

Use cursor keys to adjust the

contrast.

Enter the desired date and time

using the cursor keys and the

ten-key numerical pad, then

press the ENTER key.

Note Press the ESC key return to

the RUN SCREEN.

Note The cursor disappears from

the screen after the keyboard is

idle for more than 30 seconds.

Press a cursor key to show the

cursor on the screen.

Table 4-12. Features on Menu Screen

Page 56

OPERATION

Lockout system function (optional)

4-28 RC-6 PLUS Thermo Fisher Scientific

Lockout system

function

(optional)

The lockout system function is specifically designed for the RC-6 PLUS

centrifuge. This lockout system is used to limit the users of the centrifuge. The

registered users can use this system after the system administrators have

registered the users.

It is necessary for the system administrators to read the separated manual

“RC-6 PLUS LOCKOUT SYSTEM INSTRUCTION MANUAL”. The users are

required to log on to the centrifuge by inputting the ID code and the password

on the initial screen of the lock out system to op era te the c entrifu ge. After usin g

the centrifuge, be sure to log off the lock out system or turn off the main power

switch. This section describes the procedure for the lock out system operation.

Precool

The temperature in the chamber is

controlled at about 15 degrees

centigrade if the door is closed and

Precool is selected.

(The temperature in the chamber

may not hold at 15 degrees

centigrade if the ambient

temperature or the temperature of

the

evaporator is 15 degrees centigrade

or less.)

Melody

You can select a desired melody

from one tune, a beep, or beep off

(silence) with the numeric key. Press

the ENTER key after selection.

Alarm Information

Alarm information and remedies are

displayed on the ALARM

INFORMATION screen.

This feature allows you to cope with

troubles that occurred during

operation. Refer to Troubleshooting

for details.

Table 4-12. Features on Menu Screen

Page 57

OPERATION

Lockout system function (optional)

Thermo Fisher Scientific RC-6 PLUS 4-29

Table 4-13. Lockout System

Step Key operation Screen display and notices

1 When using the lockout system,

turn on the main power switch.

Then the initial screen of the

lockout system is displayed.

Input your (registered user) own

ID code (4digits) and press the

ENTER key.

Then input the password(4digits)

and press the ENTER key.

2 The screen shown in the right

figure is displayed. (This screen

is displayed when using the RC-6

PLUS centrifuge.) The centrifuge

is now operable.

3 Logged on user name can be

displayed.

Press the cursor key to move the

cursor to “LOCK OUT” in the

FUNCTION box and press the

ENTER key.

Page 58

OPERATION

Lockout system function (optional)

4-30 RC-6 PLUS Thermo Fisher Scientific

4 After using the centrifuge, log off

the lockout system according to

the following procedure.

(The lockout system can also be

logged off by turning off the main

power switch.) The lockout

system is not available next time

if this procedure is not

performed.

Press the cursor key to move the

cursor to “LOCK OUT” in the

FUNCTION box and press the

ENTER key.

Press the cursor key to move

the cursor to “LOG OFF” and

press the ENTER key. Then the

initial screen of the lockout

system is displayed(same as the

above step1)

Step Key operation Screen display and notices

Page 59

Thermo Fisher Scientific RC-6 PLUS 5-1

Chapter 5 CARE AND

MAINTENANCE

This section describes routine maintenance activities to ensure your centrifuge

remains in good operating condition. We also recommend that you have the

centrifuge serviced at least once a year, more frequently if you use it heavily.

Contact Thermo Fisher Scienific or your local representative of Thermo Fisher

Scienifi products.

Be sure to read and keep in mind the following cautionary information before

maintenance.

.

DANGER

When servicing the centrifuge, be sure to turn off the POWER switch, turn off

the distribution board of your centrifuge room, and then wait for at least three

minutes before removing covers or tables from the centri fuge to avoid ele ctrical

shock hazards

WARNING

Be sure to take necessary safety measures before using materials that are

toxic, radioactive, or contaminated with pathogenic micro-organisms.

Be sure to take necessary safety measures before using materials that are

toxic, radioactive, or contaminated with pathogenic micro-organisms.

If the instrument, the rotor, and/or accessories has been used with toxic,

radioactive, or pathogenic materials, clean it by following the Service

Deconatamination Policy.

There are no user-serviceable items inside the centrifuge. Due to the hazards

involved, repair should only be attempted by a qualified technician who is

familiar with electronics and trained in the sevicing of the centrifuge..

Page 60

CARE AND MAINTENANCE

Rotor Chamber

5-2 RC-6 PLUS Thermo Fisher Scientific

To ensure that your centrifuge is in safe working order, we recommend that you

have the ground continuity tested at least once a year. Because special

equipment is required for this test, it should be performed by Thermo Fisher

Scientific or your local representative of The rmo Fisher Scientific products as

part of routine servicing.

For information on the maintenance of rotors and tubes, see the rotor instruction

manual.

Rotor Chamber Defrost and clean the rotor chamber periodically to maintain efficient cooling.

CAUTION

Do not operate the instrument in any way other than specified in this manual. If

you encounter any problem with the instrument, call an authorized Thermo

Fisher Scientific Representative.

Chlorides (for example, bleach solutions) are extremely harmuful to aluminum

alloys and can cause stress corrosion cracking. Therefore, do not use

chlorides to decontaminate the chamber.

Use only cleaning and decontamination methods mentioned in this installation

manual or in the Thermo Fisher Scientific Product Guide. Cleaners other than

those specified may be harmuful to the centrifuge chamber.

Before using any cleaning or decontamination method except those

recommended by these operating instructions, you should check with an

authorized Thermo Fisher Scientific Representative that the proposed method

will not damage this centrifuge.

Table 5-1.

Maintenance Activity Frequency

Clean the rotor chamber Daily or immediately after a spill

Wash the t apered spindle Once a week.

Clean the cabinet panels Once a month.

Clean the condenser fins Once every 6 months.

Have centrifuge ground continuity

tested.

*

Once a year when the centrifuge is

serviced.

Clean the inlet on the drive box

(wipe with cloth)

Once a month.

*

Ground Continuity Test

Page 61

CARE AND MAINTENANCE

Rotor Chamber

Thermo Fisher Scientific RC-6 PLUS 5-3

To defrost the chamber:

1. Install a rotor and close the chamber door.

2. Set the RUN temperature switch for 25 degrees C.

3. Run the centrifuge until the frost melts.

4. When defrosting is complete, wipe the chamber dry with a damp sponge or

cloth.

Note To prevent condensation from forming in the rotor chamber, keep the

chamber door closed when the chamber is cold.

When cleaning the rotor chamber, use the appropriate solution followed by

several deionized water rinses:

Routine Cleaning Wash the rotor chamber with a mild non-alkaline dishwashing liquid, then rinse

and dry with a soft absorbent cloth.

Disinfection 70% ethanol (also use for the rubber door seal).

General Radioactive

Decontamination

A solution of equal parts 70% ethanol, 10% SDS, and water, followed by ethanol

rinses, then deionized water. Dry with a soft absorbent cloth. Dispose of all

wash solutions in proper radioactive waste containers.