Thermo Scientific Locator Jr, Locator 4, Locator 6, Locator Jr Plus, Locator 4 Plus User Manual

...Page 1

Visit us online to register your warranty

www.thermoscientific.com/labwarranty

User Manual

Locator and Locator Plus

Cryogenic Storage Vessel with or without

Ultrasonic Level Monitor

Operation Manual and Parts List LT509X9 (7018141) Rev. 4

Page 2

Thermo Scientific

MANUAL NUMBER LT509X9 (7018141)

4 40578 2/23/16 Clarified Do Not Roll warning ccs

3 -- 10/27/15 Updated symbols and labels, added cautions ccs

2 31623 5/15/15 Added caution for moving vessel in Section 3 ccs

1 31528 9/15/14 Updated conformity specs and declaration ccs

0 27564 1/31/14 Original - new PCBA design ccs

REV ECR/ECN DATE DESCRIPTION By

Preface

Cryogenic Storage Vessel i

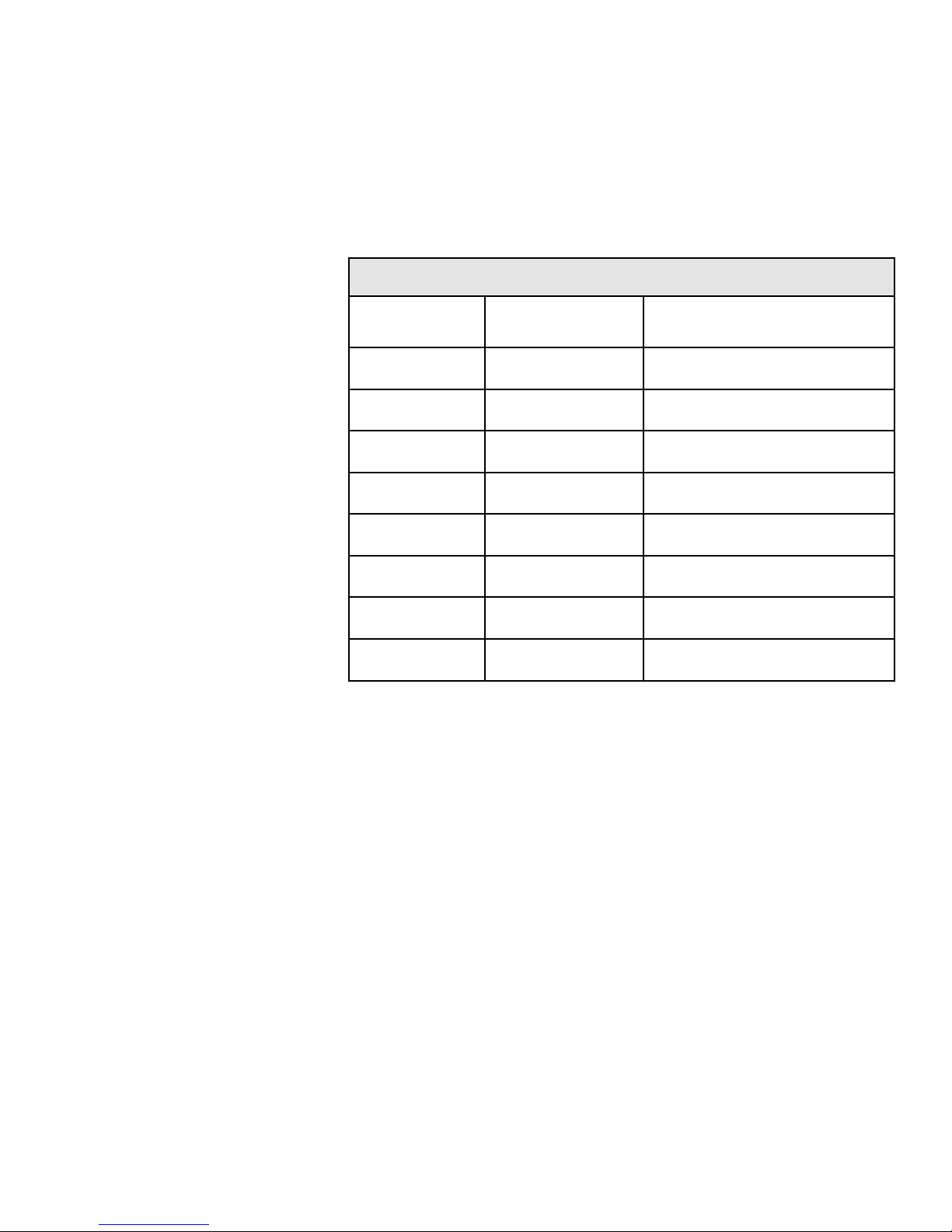

Locator Catalog Number

Locator

Model

Name

CY50925 w/o Monitor 8141 Locator Jr

CY50935 w/o Monitor 8143 Locator 4

CY50985 w/o Monitor 8197 Locator 6

CY50945 w/o Monitor 8145 Locator 8

CY509105 w/ Monitor 8201 Locator Jr.

CY509105CN w/ Monitor 8202 Locator Jr. China

CY509107 w/ Monitor 8246 Locator 4

CY509107CN w/ Monitor 8247 Locator 4 China

CY509113 w/ Monitor 8198 Locator 6

CY509110 w/ Monitor 8211 Locator 8

CY509110CN w/ Monitor 8212 Locator 8 China

Locator Plus Catalog Number

Locator Plus

Model

Name

CY50925-70 w/o Monitor 8142 Locator Jr Plus

CY50935-70 w/o Monitor 8144 Locator 4 Plus

CY50985-70 w/o Monitor 8147 Locator 6 Plus

CY50945-70 w/o Monitor 8146 Locator 8 Plus

CY509106 w/ Monitor 8237 Locator Jr Plus

CY509106CN w/ Monitor 8238 Locator Jr Plus China

CY509108 w/ Monitor 8207 Locator 4 Plus

CY509108CN w/ Monitor 8208 Locator 4 Plus China

CY509109 w/ Monitor 8209 Locator 6 Plus

CY509109CN w/ Monitor 8210 Locator 6 Plus China

CY509111 w/ Monitor 8213 Locator 8 Plus

CY509111CN w/ Monitor 8214 Locator 8 Plus China

Page 3

Thermo Scientificii Cryogenic Storage Vessel

Preface

Important Read this instruction manual. Failure to read, understand and follow instructions in this manual may

result in damage to the unit, injury to operating personnel, and poor equipment performance.

s

Caution All internal adjustments and maintenance must be performed by qualified service personnel. s

Caution It is recommended to have this vessel tested by the manufacturer or qualified cryovessel service

technician every 7-10 years, regardless of any problems (or lack thereof) you may have had in the past.

This will help insure your samples against sudden loss of liquid nitrogen due to vacuum failure.

s

Warning Nitrogen gas can cause suffocation without warning. Store and use liquid nitrogen only in a

well-ventilated place. As the liquid evaporates, the resulting gas displaces the normal air in the area.

(The cloudy vapor that appears when liquid nitrogen is exposed to the air is condensed moisture, not

the gas itself. The issuing gas is invisible.) In closed areas, excessive amounts of nitrogen gas reduces the

concentration of oxygen and can result in asphyxiation. Because nitrogen gas is colorless, odorless, and

tasteless, it cannot be detected by the human senses. Breathing an atmosphere that contains less than

19.5% oxygen can cause dizziness and quickly result in unconsciousness and death. Therefore, the use

of oxygen monitoring equipment is strongly recommended.

s

Warning Contact of liquid nitrogen with the skin or eyes may cause serious (freezing) injury. s

Warning Do not roll. Always keep liquid nitrogen vessel in an upright position. Exercise caution to

prevent spilling and splashing.

s

Material in this manual is for information purposes only. The contents and the product it describes are subject

to change without notice. Thermo Fisher Scientific makes no representations or warranties with respect to this

manual. In no event shall Thermo be held liable for any damages, direct or incidental, arising out of or related to

the use of this manual.

Intended Use:

The Thermo Fisher Scientific cryogenic storage vessels are intended to store biological samples at cryogenic

temperatures. These products are comprised of a vessel and a lid, with or without a level monitor.

Unintended Use:

These products are not intended for use within the patient environment.

When this manual is translated into other languages, the US English version is binding.

© 2010 Thermo Fisher Scientific. All rights reserved. Printed in U.S.A.

CAUTION

Contains Parts and Assemblies

Susceptible to Damage by

Electrostatic Discharge (ESD)

Page 4

Thermo Scientific Cryogenic Storage Vessel iii

Preface

Important operating and/or maintenance instructions. Read the accompanying text carefully.

Potential electrical hazards. Only qualified persons should perform procedures associated with this

symbol.

Extreme temperature hazards. Only qualified persons should perform procedures associated with this

symbol.

Potential biological hazards. Proper protective equipment and procedures must be used.

Marking of electrical and electronic equipment, which applies to electrical and electronic equipment

falling under the Directive 2002/96/EC (WEEE) and the equipment that has been put on the market

after 13 August 2005.

This product is required to comply with the European Union’s Waste Electrical & Electronic

Equipment (WEEE) Directive 2002/96/EC. It is marked with the WEEE symbol. Thermo Fisher

Scientific has contracted with one or more recycling/disposal companies in each EU Member State

European Country, and this product should be disposed of or recycled through them. Further

information on Thermo’s compliance with this directive, the recyclers in your country and

information on Thermo Scientific products will be available at www.thermoscientific.com.

4 Always use the proper protective equipment (clothing, gloves, goggles, etc.)

4 Always dissipate extreme cold or heat and wear protective clothing.

4 Always follow good hygiene practices.

4 Each individual is responsible for his or her own safety.

Page 5

Thermo Scientificiv Cryogenic Storage Vessel

Preface

Do You Need Information or Assistance on

Thermo Scientific Products?

If you do, please contact us 8:00 a.m. to 6:00 p.m. (Eastern Time) at:

1-740-373-4763 Direct

1-800-438-4851 Toll Free, U.S. and Canada

1-877-213-8051 FAX

http://www.thermoscientific.com Internet Worldwide Web Home Page

service.led.marietta@thermofisher.com Tech Support Email Address

Certified Service Web Pagewww.unitylabservices.com

Our staff can provide information on pricing and give you quotations. We canSales Support

take your order and provide delivery information on major equipment items or make

arrangements to have your local sales representative contact you. Our products are listed on the

Internet and we can be contacted through our Internet home page.

Our staff can supply technical information about proper setup, operation orService Support

troubleshooting of your equipment. We can fill your needs for spare or replacement parts or

provide you with on-site service. We can also provide you with a quotation on our Extended

Warranty for your Thermo Scientific products.

Whatever Thermo Scientific products you need or use, we will be happy to discuss your

applications. If you are experiencing technical problems, working together, we will help you

locate the problem and, chances are, correct it yourself...over the telephone without a service

call.

When more extensive service is necessary, we will assist you with direct factory trained

technicians or a qualified service organization for on-the-spot repair. If your service need is

covered by the warranty, we will arrange for the unit to be repaired at our expense and to your

satisfaction.

Regardless of your needs, our professional telephone technicians are available to assist you

Monday through Friday from 8:00 a.m. to 6:00 p.m. Eastern Time. Please contact us by

telephone or fax. If you wish to write, our mailing address is:

Thermo Fisher Scientific (Asheville) LLC

401 Millcreek Road, Box 649

Marietta, OH 45750

International customers, please contact your local Thermo Scientific distributor.

Page 6

Cryogenic Storage Vessel vThermo Scientific

Table of Contents

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Please Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

General Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Measuring Liquid Nitrogen Quantity . . . . . . . . . . . . . . . . . . . . . . . .4-1

General Cleaning Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Storing Samples in Vapor Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Liquid Nitrogen Level Monitor Operation . . . . . . . . . . . . . . . . . . . . . . . .6-1

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Remote Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Alarm Contact Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

Microprocessor Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

Principles of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

Level Monitor Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

Safety Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

Audible and Visual Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

LN2 Level Monitor Troubleshooting and Parts List . . . . . . . . . . . . . . .7-1

Ordering Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

Section 1

Section 2

Section 3

Section 4

Section 5

Section 6

Section 7

Page 7

Page 8

Cryogenic Storage Vessel 1-1Thermo Scientific

Please Read

Section 1 Safety Information

This manual contains important operating and safety information. The

user must carefully read and understand the contents of this manual prior

to the use of this equipment.

Your Thermo Scientific cryogenic vessel has been designed with function,

reliability, and safety in mind. It is the user’s responsibility to install it in

conformance with local electrical codes. For safe operation, please pay

attention to the warnings and cautions throughout the manual.

All cryopreservation vessels, regardless of who manufactures them, use a

vacuum to provide the super insulative properties needed to keep nitrogen

in a liquid form. They are very similar, in fact, to the Thermos® vessels you

may have used to store coffee, soup or milk.

Remember how fragile they were? Since no vacuum is perfect or will last

forever, we suggest that you monitor the consumption of liquid nitrogen

used by your vessel on a regular basis, i.e. every 1-2 days. By monitoring,

you may be able to anticipate subtle changes in consumption and possibly

react to problems before they arise. You may opt to use a level monitor for

this purpose (see page 6-1 for level monitor operation.).

Also, if your samples are super critical, one-of-a-kind, or irreplaceable,

consider allocating your samples to 2 separate vessels. Remember the old

adage about placing all your eggs into one basket….

Finally, because no vacuum will last forever, have your vessel tested by the

manufacturer or a qualified cryovessel service technician every 7-10 years,

regardless of any problems (or lack thereof) you may have had in the past.

This will help insure your samples against sudden loss of nitrogen due to

vacuum failure.

Do not use this product for anything other than its intended usage.

Use of the equipment in a manner not specified by the manufacturer may

impair the protection provided by the equipment.

General Usage

Page 9

1-2 Cryogenic Storage Vessel Thermo Scientific

Section 1

Safety Information

• This unit is intended to be used by trained personnel in a wellventilated environment.

• Liquid nitrogen is extremely cold; it boils at -196°C.

• Follow all necessary precautions and warnings relevant to applicable

hazards such as frostbite, contact burn, asphyxiation, etc. in cryogenic

area.

• To avoid injury due to frostbite or ruptured vials, use extreme care

whenever handling liquid nitrogen, liquid nitrogen storage or transfer

vessels, or any objects which have come in contact with liquid

nitrogen.

• Leave no areas of skin exposed.

• Wear appropriate PPE where necessary; face shield, cryogenic gloves,

cryogenic apron.

• Do not tightly seal liquid nitrogen containers or prevent nitrogen gas

from escaping.

• Always handle ampules with tongs. They may explode when removed

from the vessel.

• Use extreme care to prevent spilling and splashing liquid nitrogen

during transfer and removal of storage contents and holders.

• Immediately remove any clothing or safety attire on which liquid

nitrogen has been spilled or splashed.

• Get immediate medical attention for any frostbite injuries due to

liquid nitrogen.

Warnings

Page 10

• Only use the power supply provided by the unit.

• Never overfill liquid nitrogen vessels. Liquid nitrogen level should

never be above the tops of the racks inside the vessel. The excess

weight may crack the neck and result in vacuum failure.

• When inserting or removing racks, be careful not to come in contact

with the neck tube area of the vessel. Remove or insert racks slowly

in a vertical manner. Scratches on the neck tube area can cause

premature vacuum failure.

• Do not tamper with or remove vacuum port (covered by a black

plastic cap on side of vessel); this will void warranty.

• Do not spill liquid nitrogen on vacuum port - this can cause vacuum

failure.

• Always keep liquid nitrogen vessel in an upright position.

• Do not use this Locator vessel for transport.

Cryogenic Storage Vessel 1-3Thermo Scientific

Section 1

Section title

Cautions

Page 11

Page 12

Cryogenic Storage Vessel 2-1Thermo Scientific

Section 2 General Specifications

Operating temperature: 17°C - 27°C

20% to 80% relative humidity, non-condensing.

Installation Category II (overvoltage) in accordance with IEC 664.

Pollution Degree 2 in accordance with IEC 664.

Altitude limit: 2,000 meters.

Storage: -25°C to 65°C; 10% to 85% relative humidity.

Locator and Locator Plus units are intended for indoor use only.

Locator 4 Locator 4 Plus Locator 6 Locator 6 Plus Locator 8 Locator 8 Plus Locator JR Locator JR Plus

Height

(including lid)

1

37.5”

(95.2cm)

39.5” (100.3cm)

39.5”

(100.3cm)

39.5” (100.3cm)

37.5”

(95.2cm)

39.5” (100.3cm)

26.5”

(67.3cm)

28.9” (73.4cm)

Diameter

22”

(55.9cm)

22” (55.9cm) 26” (66cm) 26” (66cm)

22”

(55.9cm)

22” (55.9cm) 22” (55.9cm) 22” (55.9cm)

LN2 Capacity,

Liquid Phase

Storage

111L 121L 184L 184L 111L 121L 60L 71L

Static LN2

Evaporation

rate - L/Day

3

.99 .99 .99 .99 .60 .60 .85 .85

Liquid Phase

Capacity (2mL

Vial2actually

submerged in

liquid nitrogen)

3600 4000 6000 6000 1800 2000 1600 2000

1

The liquid nitrogen level monitor will add 1 inch to these heights. The transportation cart will add 4 inches to these heights.

2

Using Nalgene System 100 cryoboxes with a 10 x 10 vial configuration (Nalgene System 100 vial or equivalent are needed).

3

Actual working time may vary due to current atmospheric conditions, container history, manufacturing tolerances, and any individual patterns

of use.

Environmental

Conditions

Page 13

(CE models only) We hereby declare under our sole responsibility that this

product conforms with the technical requirements of the following

standards:

EMC:

EN 61000-3-2: Limits for Harmonic Current Emissions

EN 61000-3-3: Limits for Voltage Fluctuations and Flicker

EN 61326-1 Electrical Equipment for Measurement, Control, and

Laboratory Use; Part I: General Requirements

Safety:

EN 61010-1 Safety Requirements for Electrical Equipment for

Measurement, Control and Laboratory Use; Part I: General

Requirements

per the provisions of the Electromagnetic Compatibility Directive

2004/108/EC.

Medical Device Directive 93/42/EEC as amended by 2007/47/EC

Copies of the Declaration of Conformity are available upon request.

2-2 Cryogenic Storage Vessel Thermo Scientific

Section 2

General Specifications

Declaration of

Conformity

Electrical

(cover with monitors only)

Inputs . . .100-240VDC, .08 - .04 amps, single phase

Frequency . . . . . . . . . . . . . . . . . . . . . . . .47-63 Hz

Output . . . . . .15VDC (±10%), 0.2 amps, 3.0 watts

0543

Page 14

Cryogenic Storage Vessel 3-1Thermo Scientific

Section 3 Unpacking

Before using your new Locator or Locator Plus vessel, carefully inspect the

vessel prior to use. Check for signs of damage which may have occurred in

shipment. It is advisable to fill (see filling instructions) all new units with

liquid nitrogen and watch liquid nitrogen loss rate for a few days. If there

are any problems, call Customer Service as soon as possible.

The warranty registration card enclosed with the vessel must be completed

and returned to the factory within 30 days to make warranty effective.

This information must include the serial number, which is located on the

label on the vessel.

Note The most prevalent cause of failure of liquid nitrogen storage vessels

is mechanical. The vessel necktube supports the full weight of the inner

shell and all the liquid nitrogen it contains. A side blow to the vessel causes

the inner shell to swing in a pendulum-like motion causing the necktube

to be damaged. Any storage vessel which has been in an accident, has been

dropped, or lowered to hit on its side, will tend to fail more rapidly than

one that has not.

Caution Exercise caution when moving your Locator or Locator Plus

vessel. Locator and Locator Plus cryobiological storage systems are not

transportation vessels. Transport carts are designed for mobility within the

lab, or lab to lab only. Moving full vessels long distances, over cracks in

floor, thresholds, on inclined ramps or in elevators can cause premature

vacuum failure. Avoid using excessive force when moving vessel; this can

cause tipping, resulting in damage and/or spilling of liquid nitrogen.

s

Note If samples must be transported under cryogenic conditions, consider

Arctic Express line of Dry Shippers available from Thermo Scientific.

Page 15

Page 16

Cryogenic Storage Vessel 4-1Thermo Scientific

Section 4 Operation

Caution Never overfill your Locator or Locator Plus vessel with liquid

nitrogen. The liquid nitrogen level in your tank (with racks inserted)

should never be above 20 inches (50cm) for Locator 4 and Locator 8, 10

inches (25cm) for Locator Jr., 22 inches (55.8cm) for Locator 4, 6, and 8

Plus and 12 inches for Locator Jr. Plus. Filling the tank up to or above the

bottom of the necktube may cause immediate or premature vacuum failure

to occur.

s

Caution When inserting or removing racks, be careful not to come in

contact with the necktube area of the vessel. Remove or insert racks slowly

in a vertical manner. Scratches on the necktube area can cause premature

vacuum failure.

s

Caution Do not spill liquid nitrogen on vacuum port (covered by a black

plastic cap on side of vessel). This can cause vacuum failure. s

To avoid damage to your Locator or Locator Plus cryogenic storage vessel

which may result in premature vacuum loss, it is important that the

following procedure be used when adding liquid nitrogen to a warm vessel.

1. Add only a small amount of liquid nitrogen (5-10 liters) to a new or

warm vessel.

2. Allow this small amount of liquid nitrogen to sit in the covered vessel

for a minimum of 2 hours. This will limit stress caused by the sudden

temperature change associated with adding liquid nitrogen to a warm

vessel.

3. Add an additional 15 liters of liquid nitrogen to the vessel.

4. Allow vessel to sit for 48 hours and monitor liquid nitrogen

consumption with a wooden yarsdstick, optional dip measurer (part

#180143) or Level Monitor.

5. Fill Locator or Locator Plus as indicated (see Caution in this section).

Allow for displacement of liquid nitrogen when racks and boxes are

inserted.

6. Insert and remove racks slowly. Allow liquid nitrogen to run out of

boxes and off racks.

Filling Instructions

Page 17

4-2 Cryogenic Storage Vessel Thermo Scientific

Section 4

Operation

1. Use a wooden yardstick or optional dip measurer (part #180143) to

measure liquid nitrogen level. NEVER use a hollow tube or plastic

dipstick to measure the liquid nitrogen level.

2. Level will be indicated by the frostline which develops when dipstick is

removed.

3. Level Monitor can be used for constant measurements. See Section 6.

1. Remove the 2 bottom-most cryoboxes from each rack.

2. Measure the height of 2 cryoboxes stacked on top of each other.

3. Fill vessel with liquid nitrogen to the height obtained from Step 2,

using a yardstick to measure liquid level in vessel.

4. Place racks into vessel without the 2 bottom-most cryoboxes. Samples

are now above the liquid nitrogen and are stored in the vapor phase.

Important A level monitor should always be used when you store your

samples in the vapor phase because of the already low levels of liquid

nitrogen. Refer to Section 5 for correct level monitor for your system.

s

Wipe exterior surfaces with lightly dampened cloth containing mild soap

solution.

Storing Samples in

Vapor Phase

General Cleaning

Instructions

Measuring Liquid

Nitrogen Quantity

Page 18

Cryogenic Storage Vessel 5-1Thermo Scientific

Section 5 Replacement Parts

Locator and Locator Plus Covers w/o Monitor

Type Standard Covers

Covers and Rack Kits (for units with

lids made before 3/2010)

Locator Jr. CV509X51 (321746) 1950514

Locator Jr. Plus CV509X51 (321746) 1950515

Locator 4 CV509X51 (321746) 1950516

Locator 4 Plus CV509X51 (321746) 1950517

Locator 6 CV509X50 (321651) 1950513

Locator 6 Plus CV509X50 (321651) 1950513

Locator 8 CV509X23 (317227) CV509X23 (317227)

Locator 8 Plus CV509X23 (317227) CV509X23 (317227)

Page 19

5-2 Cryogenic Storage Vessel Thermo Scientific

Section 5

Replacement Parts

Catalog # Rack Description

HR509X15A (317050) For Locator Jr (8141, 8201, 8202) with 4 - 2 inch boxes

HR509X2A (317161) For Locator 4 (8143, 8246, 8247) with 9 - 2 inch boxes

HR509X19A (315903) For Locator Jr (8141, 8201, 8202) with 2 - 4 inch boxes

HR509X20A (315905) For Locator 4 (8143, 8246, 8247) with 5 - 4 inch boxes

HR509X15A-70 (317148) For Locator Jr Plus (8142, 8237, 8238) with 5 - 2 inch boxes

HR509X2A-70 (317175) For Locator 4 Plus (8144, 8207, 8208) with 10 - 2 inch boxes

HR509X31A-70 (317192) For Locator 6 and 6 Plus (8147, 8197, 8198, 8209, 8210) with 10 - 2 inch boxes

HR509X1A (317205) For Locator 8 (8211, 8212, 8145) with 9 - 2 inch boxes (25 cell)

HR509X1A-70 (317217) For Locator 8 Plus (8146, 8213, 8214) with 10 - 2 inch boxes (25 cell)

HR509X19A-70 (315904) For Locator Jr. Plus (8142, 8237, 8238) with 2 - 4 inch boxes + 1 - 2 inch box

HR509X20A-70 (315906) For Locator 4 Plus (8144, 8207, 8208) with 5 - 4 inch boxes + 1 - 2 inch box

HR509X32A-70 (315907) For Locator 6 and 6 Plus (8147, 8197, 8198, 8209, 8210) with 5 - 4 inch boxes + 1 - 2 inch box

Page 20

Section 6 Liquid Nitrogen Level

Monitor Operation

The liquid nitrogen (LN2) level monitor provides a constant indication of

the LN2 level and notifies you to low level conditions through audible and

visual alarms. It alerts you when your vessel needs filling. The level

monitor is shipped mounted directly to the appropriate Locator or Locator

Plus cover. It can be wired to a remote alarm system to alert you to

problems when you are not in your laboratory. This equipment was

intended to be operated with an external power supply provided by the

manufacturer. It is designed for use with Thermo Scientific LN2 vessels

only.

Caution Use this product for its intended usage only.

s

Warning Potential electrical hazards. Only qualified persons should

perform procedures associated with this symbol. s

Note If the level monitor was purchased as part of a Locator or Locator

Plus system, skip to Step 3. If it is a retrofit for an existing Locator or

Locator Plus, begin with Step 1.

s

1. Remove the level monitor and Locator or Locator Plus cover from box.

2. Remove present cover from your Locator or Locator Plus and replace

with your new level monitor and cover.

3. Check the electrical specifications on the power supply for electrical

data and plug in to appropriately grounded receptacle.

Cryogenic Storage Vessel 6-1Thermo Scientific

Installation

Page 21

1. Disconnect the liquid nitrogen level monitor from the power supply.

Disconnect power to your alarm system.

2.

Remove the three screws securing the liquid nitrogen level monitor’s

cover. Pull the cover up and out of the way (see Figure 6-1).

When connected to your remote alarm system, the LN2 level monitor will

alert you to a problem even when your laboratory is unoccupied. The

unit’s alarm contacts are activated at the same time the audible alarm

sounds (see Microprocessor Functions).

3. Remove the black plug from the side of the cover. Insert the wires for

the remote alarm through this hole.

4. Connect the remote alarm wires as shown in Figures 6-1, 2 and 3.

5. Replace the LN2 level monitor’s cover. Reconnect power to the LN2

level monitor and to your remote alarm system.

Note The LN2 level monitor can be configured with either a normally

open contact or a normally closed contact. Which mode is currently

operative depends on the placement of a single jumper on the circuit

board. For a normally open contact, the jumper should be placed on J6.

For a normally closed contact, the jumper should be placed on J4 (see

Figure 6-2). Verify that the jumper is set appropriately for your remote

alarm system.

s

The LN2 level monitor’s alarm contact is a Photomos type relay.

Contact Form: Type 1 form B

Load Voltage Maximum: 24VDC Max

Load Current Maximum: 120mA

Typical On Resistance: Maximum 26 Ω

6-2 Cryogenic Storage Vessel Thermo Scientific

Section 6

LN2 Level Monitor Operation

Alarm Contact

Specifications

Level Monitor

Remote Alarm

Connection to Remote

Alarms

Page 22

Cryogenic Storage Vessel 6-3Thermo Scientific

Section 6

LN2 Level Monitor Operation

1

Figure 6-1. Connect to Remote Alarm

Figure 6-2. Jumper Location

Remote Alarm wires connect here

(Note polarity.)

- +

J3

J4 J6

1

1

For normally open contact, place jumper here.

For normally closed contact, place jumper here.

Page 23

The innovative Thermo LN2 Level Monitor utilises ultrasonic sound

waves to sense the level of liquid nitrogen inside a Locator or Locator Plus

cryogenic storage vessel. A microprocessor control provides continuous

indication of the liquid nitrogen level inside the Locator or Locator Plus,

with accuracy to ±2”. Audible and visual alarms also provide an early

warning of low level conditions.

Ultrasonic sound waves sense the level of liquid nitrogen inside the Locator

or Locator Plus vessel.

By using ultrasonic sound waves to sense the level of liquid nitrogen, no

physical probe is required to sense the level of liquid nitrogen.

Conventional devices use probes which must be in physical contact with

the liquid. This physical contact increases liquid nitrogen consumption.

There is NO increase in liquid nitrogen consumption by using the

Thermo level monitor.

The LED display is graduated in 8 segments and provides quick and

reliable visual indication of the level of liquid nitrogen inside the Locator

or Locator Plus vessel, from Full to Empty, similar to a fuel gauge on an

automobile.

6-4 Cryogenic Storage Vessel Thermo Scientific

Section 6

LN2 Level Monitor Operation

Principles of

Operation

Microprocessor

Functions

Figure 6-3. Remote Alarm Connections Schematic

U4

1

2

36

The position of J4 and J6 indicate

whether the relay is normally open

or normally closed.

4

5

J3-1

J3-2

Load

V

L

Load Voltage

(DC)

Page 24

1. “LOW LEVEL” indicator light illuminates continuously when liquid

nitrogen level is below the approximate 2" level. In this situation, the

level of liquid nitrogen is low, and you are alerted to refill the vessel as

soon as possible.

2. An AUDIBLE and remote alarm activates continuously when liquid

nitrogen is below the approximate 1” level inside the Locator or

Locator Plus vessel, additionally, “LOW LEVEL” light will continue to

flash. In this situation, the liquid nitrogen is dangerously low, and you

are alerted to refill the vessel immediately.

3. The AUDIBLE and remote alarms activate continuously, the 8segment LED display and “Low LEVEL” lights flash, to indicate an

emergency event. This alarm event occurs when the Locator or Locator

Plus vessel is empty of liquid nitrogen, or the monitor has an error and

is incapable of detecting LN2 levels.

The microprocessor must be reset each time the cover is removed from the

Locator or Locator Plus. Before removing the cover, the RESET button

must be pressed, illuminating the RESET light. While in this Reset/Hold

mode, the monitor is not sensing. After five minutes in the Reset/Hold

mode, an audible and remote alarm will activate, alerting you to deactivate

the Reset/Hold mode when the cover is replaced on the vessel.

Once the cover with the monitor has been placed on the vessel and

plugged in, wait about 15 minutes for the system to equilibrate before

pressing the Reset button for an accurate measurement of the liquid

nitrogen to be indicated. This equilibration process will occur each time

the cover is removed. Each time a vessel is opened or moved, the stabilized

chamber temperature and/or liquid level is disrupted. The system requires

a stable temperature and liquid level to determine an accurate liquid

nitrogen level.

If you have just purchased a new Locator or Locator Plus along with your

monitor, allow at least 1 day for the liquid nitrogen to equilibrate the

vessel before plugging in the unit. This will avoid false alarms.

Note The Level Monitor may take up to 10 minutes to establish a reading

after the unit is placed on the cryovessel, or the cryovessel is moved.

Remember to press “Reset” after placing unit on the vessel. The green

LED on the switch should be “OFF.”

s

Cryogenic Storage Vessel 6-5Thermo Scientific

Section 6

LN2 Level Monitor Operation

Audible and Visual

Alarms

Safety Feature

Level Monitor

Operation

Page 25

Page 26

Section 7 LN2 Level Monitor

Troubleshooting and Parts List

Cryogenic Storage Vessel 7-1Thermo Scientific

Problem Cause Solution

Level monitor alarm sounds

intermittently. Unit measuring liquid

level incorrectly.

Ice or frost buildup on the

transducer.

Remove the cover w/ monitor from vessel and place in room for approximately two hours, or until no ice is visible on the transducer or tube.

NOTE: Do not use an external heat source (i.e. heat gun) to accelerate

the thawing process as it can damage the cork. Make sure lid is standing upright on the cork to allow moisture to drain out of cover w/ monitor. Wipe any moisture away from the inside of the tube and face of the

transducer with a clean soft cloth. Place cover w/ monitor back on unit.

(Remember to press “Reset” button.)

Level monitor measuring “Full” after

removing samples and replacing lid.

Fog in top part (neck area) of

cryogenic vessel.

The density of the fog that is formed after removing the lid and accessing samples is dependent on the humidity of the room where the cryovessel is located. The fog dissipates after about fifteen minutes and at

this time, the level monitor will take an accurate reading of the liquid

nitrogen level.

Ordering Procedures

Refer to the Specification Plate for the complete model number, serial

number, and series number when requesting service, replacement parts or

in any correspondence concerning this unit.

All parts listed herein may be ordered from the Thermo Scientific dealer

from whom you purchased this unit or can be obtained promptly from the

factory. When service or replacement parts are needed, check first with

your dealer. If the dealer cannot process your request, then contact

Technical Services.

Prior to returning any materials, contact our Technical Services

Department for a “Return Materials Authorization” number (RMA).

Material returned without an RMA number will be refused.

Caution - Preventative Maintenance Depending on environmental

conditions and the number of lid openings, the lid should be periodically

inspected for ice and frost buildup. Refer to chart below.

s

Page 27

7-2 Cryogenic Storage Vessel Thermo Scientific

PART LOCATOR JR LOCATOR JR PLUS LOCATOR 4

LOCATOR 4 PLUS

LOCATOR 6 LOCATOR 6 PLUS LOCATOR 8 LOCATOR 8 PLUS

Cover with Monitor

and Power Supply *

CN509X16

(316306)

CN509X16-70

(316308)

CN509X17

(316374)

CN509X17-70

(316376)

CN509X15

(316304)

CN509X15

(316304)

CN509X7

(316137)

CN509X7-70

(316138)

Cover with Monitor

and Power Supply

(China) **

CN509X16CN

(316307)

CN509X17CN

(316309)

CN509X18CN

(316375)

CN509X19CN

(316377)

CN509X15CN

(316305)

CN509X15CN

(316305)

CN509X7CN

(316139)

CN509X20CN

(316390)

Cover and Rack

Kits* (for units with

lids made before

03/2010)

1950503 1950505 1950507

1950509

1950501 1950501

CN509X7

(316137)

CN509X7-70

(316138)

Cover and Rack Kits

(China) ** for units

with lids made

before 03/2010

1950504 1950506

1950508

1950510

1950502

1950502

CN509X7CN

(316139)

CN509X20CN

(316390)

Cover CV509X13 CV509X13 CV509X13

CV509X13

CV509X13 CV509X13 CV509X13 CV509X13

Power Supply w/

connectors*

90-240VAC

TN509X2 (317133) *includes US, EU, UK and AUS connectors

Power Supply**

90-264VAC (China)

TNX136 (317143)

Vent Port Cap 1950343

Table 7-1. Parts List By Model

Page 28

Cryogenic Storage Vessel 8-1Thermo Scientific

ISO

9001

REGISTERED

Rev. 0 5/10

(LN2 Vacuum)

THERMO FISHER SCIENTIFIC STANDARD PRODUCT WARRANTY

2 Vacuum Integrity is covered for three years. Installation and calibration are not

The Warranty Period starts two weeks from the date your equipment is shipped from our facility. This allows for shipping

time so the warranty will go into effect at approximately the same time your equipment is delivered. The warranty protec-

tion extends to any subsequent owner during the first year warranty period.

During the first year, component parts proven to be non-conforming in materials or workmanship will be repaired or replaced

at Thermo's expense, labor included. LN

covered by this warranty agreement. The Technical Services Department must be contacted for warranty determination and

direction prior to performance of any repairs. Expendable items, glass, filters and gaskets are excluded from this warranty.

Replacement or repair of components parts or equipment under this warranty shall not extend the warranty to either the

equipment or to the component part beyond the original warranty period. The Technical Services Department must give prior

approval for return of any components or equipment. At Thermo's option, all non-conforming parts must be returned to

Thermo postage paid and replacement parts are shipped FOB destination.

THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, WHETHER WRITTEN, ORAL OR

IMPLIED. NO WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE SHALL APPLY.

Thermo shall not be liable for any indirect or consequential damages including, without limitation, damages relating to lost

profits or loss of products.

Your local Thermo Sales Office is ready to help with comprehensive site preparation information before your equipment

arrives. Printed instruction manuals carefully detail equipment installation, operation and preventive maintenance.

If equipment service is required, please call your Technical Services Department at 1-800-438-4851 (USA and Canada) or

1-740-373-4763. We're ready to answer your questions on equipment warranty, operation, maintenance, service and

special application. Outside the USA, contact your local distributor for warranty information.

Page 29

Page 30

thermoscientific.com

© 2014 Thermo Fisher Scientific Inc. All rights reserved. All trademarks are the property of Thermo Fisher Scientific and its

subsidiaries. Specifications, terms

and pricing are subject to change. Not all products are available in all countries. Please consult your local sales representative

for details.

Thermo Fisher Scientific (Asheville) LLC

401 Millcreek Road

Marietta, Ohio 45750

United States

A Thermo Fisher Scientific Brand

Loading...

Loading...