Page 1

Ion GeneStudio™ S5 Food Protection

Instrument

USER GUIDE

Catalog Numbers A39513

Publication Number MAN0017965

Revision A.0

For testing of Food and Environmental samples only.

Page 2

Manufacturer: Life Technologies Corporation | 5781 Van Allen Way | Carlsbad, CA 92008

The information in this guide is subject to change without notice.

DISCLAIMER: TO THE EXTENT ALLOWED BY LAW, THERMO FISHER SCIENTIFIC INC. AND/OR ITS AFFILIATE(S) WILL NOT BE LIABLE FOR SPECIAL,

INCIDENTAL, INDIRECT, PUNITIVE, MULTIPLE, OR CONSEQUENTIAL DAMAGES IN CONNECTION WITH OR ARISING FROM THIS DOCUMENT,

INCLUDING YOUR USE OF IT.

Revision history: Pub. No. MAN0017965

Revision Date Description

A.0 18 October 2018 New document.

Trademarks: All trademarks are the property of Thermo Fisher Scientific and its subsidiaries unless otherwise specified.

©2018 Thermo Fisher Scientific Inc. All rights reserved.

Page 3

Contents

About this guide ............................................................ 5

Purpose of the guide ............................................................ 5

■

CHAPTER 1 Product information ....................................... 6

Contents ....................................................................... 6

Optional materials and equipment ................................................ 6

Instrument installation by trained personnel only ................................... 7

Nucleic acid contamination ....................................................... 7

Instrument vibration and clearances ............................................... 7

■

CHAPTER 2 System components ....................................... 8

Network configuration .......................................................... 8

Internet connectivity ............................................................. 9

Ion GeneStudio™ S5 Food Protection System component positions .................... 10

Ion GeneStudio™ S5 Food Protection Instrument input and output connections ......... 11

■

CHAPTER 3 Instrument operation .................................... 12

Power the Ion GeneStudio™ S5 Food Protection Instrument on or off .................. 12

Power on ................................................................. 12

Power off ................................................................. 12

Update the Ion GeneStudio™ S5 Food Protection System software .................... 12

Instrument run times ........................................................... 13

Maintain the Ion GeneStudio™ S5 Food Protection Instrument ........................ 14

Materials required ......................................................... 14

Clean or decontaminate the instrument ...................................... 14

Manually clean the instrument .............................................. 14

Perform an instrument reset run with an initialized, unused Ion S5™ Wash

Solution cartridge ......................................................... 16

Ion GeneStudio™ S5 Food Protection Instrument User Guide

3

Page 4

Contents

■

APPENDIX A Touchscreen reference ................................. 17

Clean, Initialize, and Run ........................................................ 17

Settings ....................................................................... 18

Network Settings .......................................................... 18

System Tools .............................................................. 21

Check for software updates ................................................. 26

Data Management ......................................................... 27

Manually delete run data ................................................... 29

Perform the instrument Clean operation ...................................... 30

Instrument settings ........................................................ 31

Touchscreen icons ............................................................. 33

Alarms, Notifications, and Events ................................................ 35

■

APPENDIX B Troubleshooting ......................................... 38

Instrument alarms and events ................................................... 38

Initialization fails ............................................................... 39

Troubleshooting using control libraries ........................................... 41

Solid-state buffer leak .......................................................... 41

Pulse clean the Ion GeneStudio™ S5 Food Protection Instrument ................. 42

■

APPENDIX C Instrument warranty .................................... 43

■

APPENDIX D Safety ..................................................... 45

Safety alerts on this instrument .................................................. 45

Location of safety labels on the instrument ................................... 46

Safety information for instruments not manufactured by Thermo Fisher Scientific ..... 46

Instrument safety .............................................................. 47

General .................................................................. 47

Cleaning and decontamination ............................................... 47

Electrical safety ........................................................... 48

Safety and electromagnetic compatibility (EMC) standards .......................... 49

Safety .................................................................... 49

EMC ...................................................................... 49

Environmental design ...................................................... 50

Chemical safety ................................................................ 51

■

Documentation and support ............................................. 53

Related documentation ......................................................... 53

Food Safety support ............................................................ 53

4

Ion GeneStudio™ S5 Food Protection Instrument User Guide

Page 5

IMPORTANT! Before using this product, read and understand the information in the

“Safety” appendix in this document.

Purpose of the guide

This Ion GeneStudio™ S5 Food Protection Instrument User Guide (Pub. No. MAN0017965)

provides reference information for using and maintaining the Ion GeneStudio™ S5

Food Protection System (Cat. No. A39513).

About this guide

CAUTION! ABBREVIATED SAFETY ALERTS. Hazard symbols and hazard

types specied in procedures may be abbreviated in this document. For the

complete safety information, see the “Safety” appendix in this document.

Ion GeneStudio™ S5 Food Protection Instrument User Guide

5

Page 6

1

Contents

Product information

The Ion GeneStudio™ S5 Food Protection System (Cat. No. A39513) contains the

following boxes and components.

Ion GeneStudio™ S5 Food Protection System (Cat. No. A39513)

Components

Ion GeneStudio™ S5 Food Protection

Instrument

Ion S5™ Installation Kit A27215

Ion S5™ Installation Kit (Part No. A27215; Not available for separate purchase.)

Contents

Ion 540™ Chip Kit A27766 4 pack 15°C to 30°C

Ion S5™ Sequencing Solutions A27767 1

Ion S5™ Sequencing Reagents A27768 1 –30°C to –10°C

Ion 540™ Control Ion Spheres A28195 1

Ion 540™ Loading Reagents OT2 A27897 1

Ion S5™ Cartridge Tool A28308 2 15°C to 30°C

Ion Chef™ S5 Series Chip Balance A29022 1

Part No. Quantity Storage

Part No.

A37904

Optional materials and equipment

Unless otherwise indicated, all materials are available through thermosher.com.

MLS: Fisher Scientic (sherscientic.com) or other major laboratory supplier.

(

Optional

[1]

[2]

) Non-interruptible Power Supply (UPS)

IMPORTANT! Thermo Fisher Scientific has verified the procedures in this user guide using these specific materials. Substitution may adversely

affect system performance.

For laboratories that experience frequent power outages or line voltage fluctuations, we recommend that you use a non-interruptible power

supply that is compatible with 2500 W output or higher.

6

Item

[1]

[2]

Source

MLS

Ion GeneStudio™ S5 Food Protection Instrument User Guide

Page 7

Instrument installation by trained personnel only

Chapter 1 Product information

Instrument installation by trained personnel only

1

IMPORTANT! The Ion GeneStudio

service personnel and must not be relocated without assistance from trained service

personnel. See “Food Safety support“ on page 53.

Nucleic acid contamination

IMPORTANT! A primary source of contamination is DNA fragments from previously

processed samples. Do not introduce amplied DNA into the library preparation

laboratory or work area.

Instrument vibration and clearances

IMPORTANT! Signicant vibration during sequencing may add noise and reduce the

quality of the measurements. The Ion GeneStudio™ S5 Food Protection System must

be installed on a bench that is free from vibrations or in contact with equipment that

can cause vibrations to the bench (freezers, pumps, and other similar equipment).

IMPORTANT! Place the instrument at least 40 in. (1 meter) away from major sources

of electronic noise such as refrigerators or microwaves.

™

S5 Food Protection System is installed by trained

Ion GeneStudio™ S5 Food Protection Instrument User Guide

7

Page 8

5

3

4

1

2

2

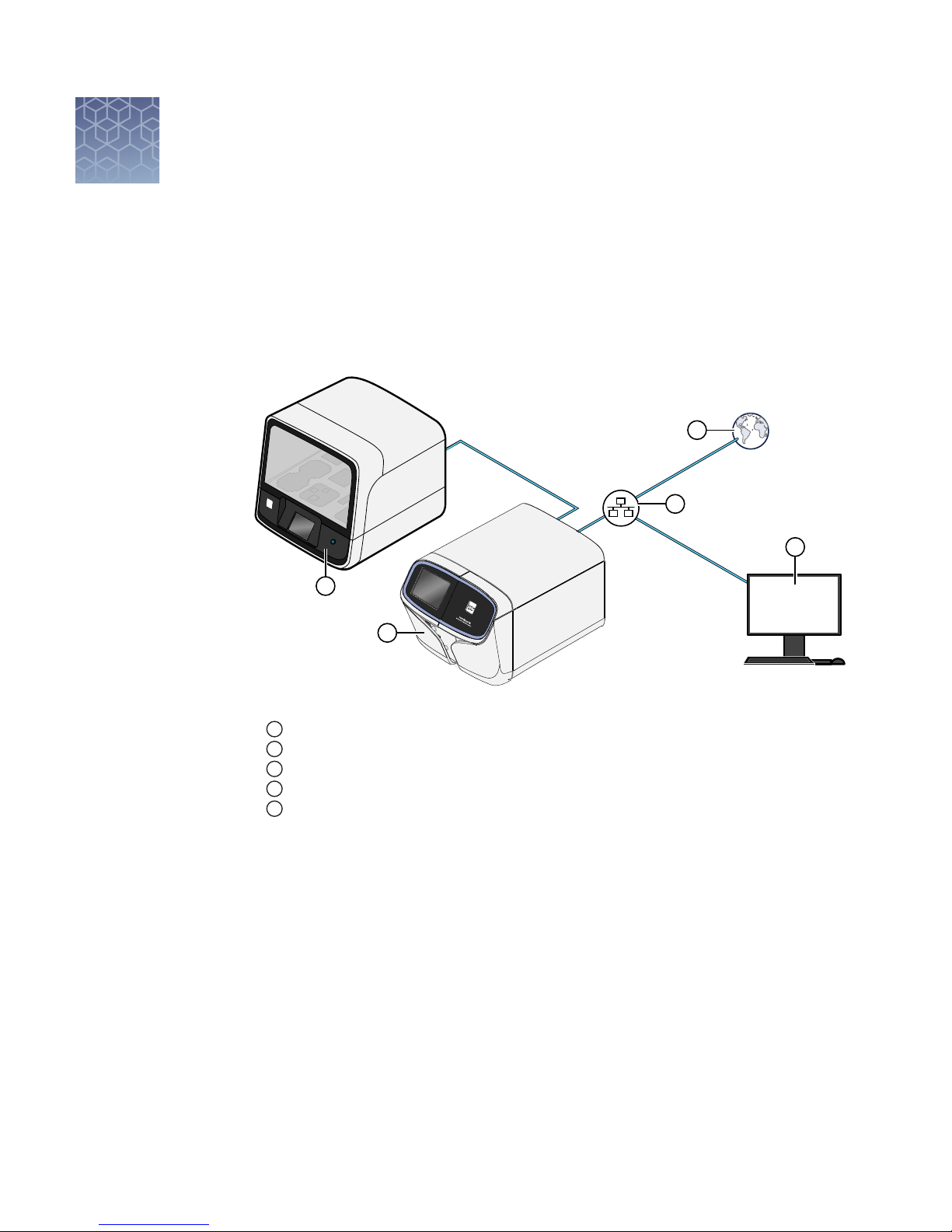

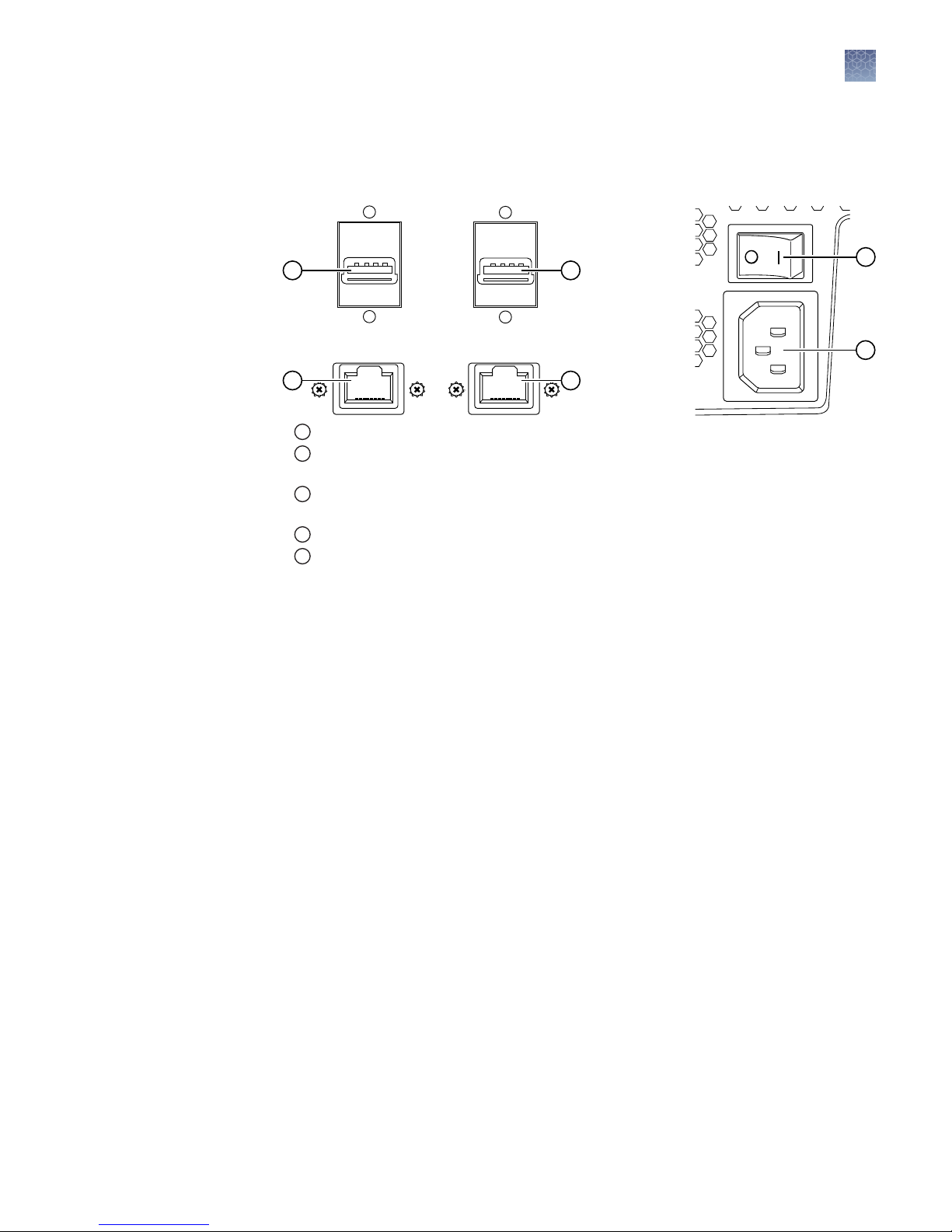

Network configuration

The Ion GeneStudio™ S5 Food Protection Instrument is not connected to an external

Torrent Server and requires connection only to a local area network (see gure).

System components

Figure 1 Network configuration

1

Ion GeneStudio™ S5 Food Protection Instrument

2

Ion Chef™ Food Protection Instrument

3

Local area network

4

Internet

5

Client computer

Note: The Ion Chef™ Food Protection Instrument must be connected to the Torrent

Server either directly using a category 6 Ethernet cable, or indirectly through a local

area network that has been congured to allow HTTP-443, SSH-22, and FTP-20/21

trac.

8

Ion GeneStudio™ S5 Food Protection Instrument User Guide

Page 9

Internet connectivity

The Ion GeneStudio™ S5 Food Protection Instrument should be connected to a

network with Internet access. Connecting to the Internet allows you to update your

software and access remote system support easily. Software updates through the

network/Internet are free. If you do not connect your instrument or server to a

network, software updates must be manually installed via USB.

IMPORTANT! Thermo Fisher Scientic does not support the USB method for

updating software.

Any problems (for example, le corruption, incomplete updates) resulting from

update of the instrument or server using a USB device that require correction of the

faulty update is not covered by your Ion GeneStudio™ S5 Food Protection System

warranty or any service contract you may have bought. You are required to schedule

an on-site Time and Materials visit by a eld service engineer to correct the problem

at your own expense.

In providing outbound access to the Internet from the server, you enable the support

team to provide inbound support. The Ion GeneStudio™ S5 Food Protection

Instrument runs a remote monitor agent that can provide service personnel with

critical system information, such as installed software versions and instrument

alarms. With your permission, the agent also allows service personnel to access

remotely the Ion GeneStudio™ S5 Food Protection Instrument, which is required for

system support. Without remote access, service personnel cannot access, view, and

troubleshoot problems regarding machine performance.

Chapter 2 System components

Internet connectivity

2

Ion GeneStudio™ S5 Food Protection Instrument User Guide

9

Page 10

7

2

3

5

6

4

1

Ion GeneStudio S5

Ion GeneStudio S5

Ion GeneStudio S5

Chapter 2 System components

2

Ion GeneStudio™ S5 Food Protection System component positions

Ion GeneStudio™ S5 Food Protection System component positions

1

Touchscreen

2

Power button

3

Ion S5™ Sequencing Reagents cartridge

4

Chip clamp

5

Ion S5™ Wash Solution bottle. Waste reservoir located behind the Ion S5™ Wash Solution

bottle (shown on the right).

6

Ion S5™ Cleaning Solution bottle

7

Waste reservoir

Note: The system uses RFID technology to verify that the proper reagents are loaded

in positions 3, 5, and 6. Reagents that exceed their expiration date or usage count

generate an error message prompting the user to replace the reagent before

performing the run.

Note: RFID regulatory information can be found on the main screen under

Options4Regulatory info.

10

Ion GeneStudio™ S5 Food Protection Instrument User Guide

Page 11

5

4

2

1

3

1

Ion GeneStudio™ S5 Food Protection Instrument input and output connections

Chapter 2 System components

Ion GeneStudio™ S5 Food Protection Instrument input and output

connections

1

USB ports–Connects a USB device to the instrument.

2

Ethernet port—An RJ45 port that provides Ethernet (gigabit) communication between the

instrument and a local area network.

3

Ethernet port—An RJ45 port that provides Ethernet (gigabit) communication with the

Ion Chef™ Food Protection Instrument.

4

On/off switch—Power switch, where the states are on ( | ) or off ( O ).

5

Power port—100–240VAC port that provides power to the instrument.

2

Ion GeneStudio™ S5 Food Protection Instrument User Guide

11

Page 12

Instrument operation

3

Power the Ion GeneStudio™ S5 Food Protection Instrument on or off

Note: If the Ion GeneStudio™ S5 Food Protection Instrument is powered on, and the

touchscreen is blank, touch the screen to "wake" the touchscreen.

Power on

Power off

If the touchscreen is unresponsive, check the power switch on the back of the

instrument to ensure that the switch is in the on (|) position. If the power switch is in

the o (0) position, proceed with step 1. If the power switch is already in the on

position, proceed to step 2.

Turn the power switch on the back of the instrument to the on (|) position.

1.

Press the power buon on the left side of the instrument.

2.

The buon illuminates. When the instrument touchscreen Main Menu appears,

the instrument is ready for use.

It is not necessary to power o the instrument overnight or over the weekend. If

needed, the instrument can be powered o as follows:

In the Main Menu, press Seings4System Tools4Shut Down.

1.

Select either Shut Down or Reboot.

2.

Note: If you select Shut Down, a conrmation message appears. Select Yes to

power o the instrument.

Note: Do not press the power buon during a run. Interrupting power to the

instrument during a run may result in sequencing run failure and loss of sample.

Update the Ion GeneStudio™ S5 Food Protection System software

Note: An internet connection is required for the Ion GeneStudio™ S5 Food Protection

System to receive alerts that software updates are available.

If an update to the Ion GeneStudio™ S5 Food Protection Instrument software is

available, the Notications/Alarms buon illuminates red in the touchscreen Main

Menu. Press the red Alarms buon to see the detailed messages. If a message states

New Software Available, follow these steps to update the software:

In the Main Menu, press Seings4Check for Updates.

1.

Press Update to download and install the updates automatically.

2.

Press Done.

3.

12

Ion GeneStudio™ S5 Food Protection Instrument User Guide

Page 13

The instrument automatically restarts when the software update is complete.

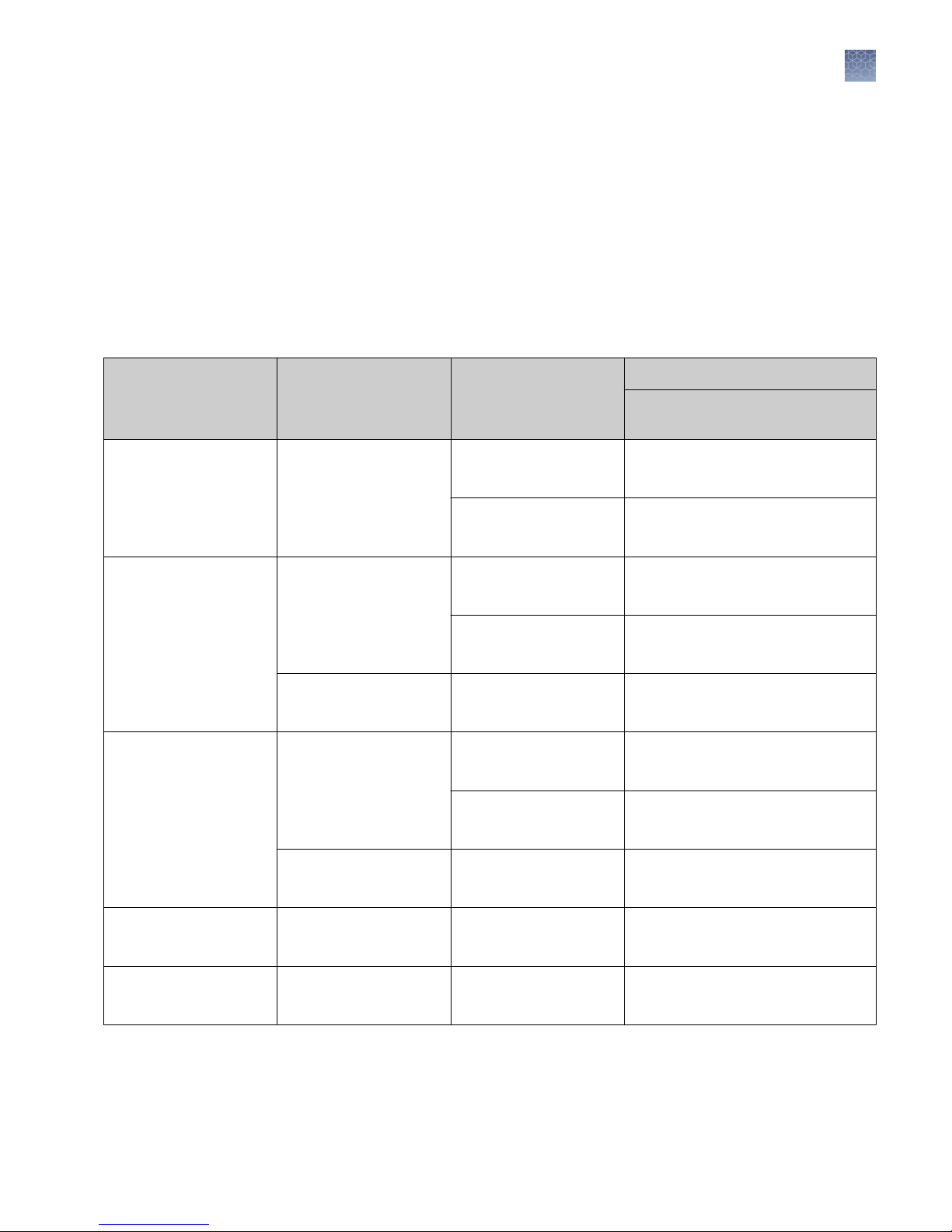

Instrument run times

Approximate run times for the Ion GeneStudio™ S5 Food Protection Instrument for a

given chip type, read length, and number of reads are shown in the following table.

Run times indicate the typical time from run start to delivery of a BAM le

(1 run/initialization).

For the Food Authenticity application, a FASTQ le is created instead of a BAM le.

The instrument run time is shorter for this application.

Chip type Number of reads Read length/output

Chapter 3 Instrument operation

Instrument run times

Instrument run time

Ion GeneStudio™ S5 Food Protection

Instrument

3

Ion 510™ Chip 2–3 M

4–6 M

Ion 520™ Chip

3–4 M

15–20 M

Ion 530™ Chip

9–12 M

200 bases

4.5 hours

0.3–0.5 Gb

400 bases

10.5 hours

0.6–1 Gb

200 bases

7.5 hours

0.6–1 Gb

400 bases

12 hours

1.2–2 Gb

600 bases

12 hours

0.5–1.5 Gb

200 bases

10.5 hours

3–4 Gb

400 bases

21.5 hours

6–8 Gb

600 bases

21 hours

1.5–4.5 Gb

Ion 540™ Chip 60–80 M

Ion 550™ Chip 100–130 M

Ion GeneStudio™ S5 Food Protection Instrument User Guide

200 bases

19 hours

10–15 Gb

200 bases

—

20–25 Gb

13

Page 14

Chapter 3 Instrument operation

3

Maintain the Ion GeneStudio™ S5 Food Protection Instrument

Maintain the Ion GeneStudio™ S5 Food Protection Instrument

Materials required

Clean or

decontaminate the

instrument

Manually clean

the instrument

• Lint-free wipes

• 70% isopropanol

• (Optional) 10% bleach solution

In the event of a spill or leak on or inside the Ion GeneStudio™ S5 Food Protection

Instrument, perform the following steps.

Note: Dispose of all waste in appropriate liquid or solid waste containers.

Remove the Ion S5™ Wash Solution bole, then remove and empty the waste

1.

reservoir.

Remove the Ion S5™ Sequencing Reagents cartridge.

2.

Inspect the waste and nucleotide reagent bays for liquid.

3.

Using absorbent paper soak up as much liquid as possible, then wash the

4.

aected area with 10% bleach solution.

Wipe the aected surfaces with 70% isopropanol, then allow to air-dry.

5.

The Ion GeneStudio™ S5 Food Protection Instrument requires cleaning before

initialization. Cleaning is normally performed automatically at the completion of the

previous sequencing run. To enable two sequencing runs on a single initialization,

you must deselect the Enable post-run clean checkbox for the rst sequencing run.

The post-run cleaning is then performed normally after the second sequencing run.

However, if the Enable post-run clean checkbox is deselected for the second run, the

cleaning is not performed after either run. If the second sequencing run is not

performed, or the cleaning is not performed automatically after the second run, the

instrument will not allow the subsequent initialization to proceed until a manual

cleaning is performed.

Do not perform a manual cleaning if the Ion GeneStudio™ S5 Food Protection

Instrument is initialized and

• a sequencing run is not started within 24 hours, or

• a run is not started or completed due to a power failure or an abort

In these cases, an instrument reset run is required before reinitialization. See “Perform

an instrument reset run with an initialized, unused Ion S5™ Wash Solution

cartridge“ on page 16 for more information.

14

Ion GeneStudio™ S5 Food Protection Instrument User Guide

Page 15

1

2

3

Maintain the Ion GeneStudio™ S5 Food Protection Instrument

Chapter 3 Instrument operation

When a manual cleaning is necessary, use the following procedure:

On the home screen, press Seings4Clean Instrument.

1.

The instrument door unlocks allowing access to the consumables.

Remove the Ion S5™ Wash Solution bole to access the waste reservoir, then

2.

remove and empty the waste reservoir.

3

Reinstall the empty waste reservoir and a used Ion S5™ Wash Solution bole.

3.

Ensure that the Ion S5™ Sequencing Reagents cartridge and Ion S5™ Wash

4.

Solution bole are properly installed.

IMPORTANT! Perform the cleaning with a used reagent cartridge and wash

solution bole installed. The cleaning procedure pumps cleaning solution into

the wash solution bole and reagent cartridge making them unsuitable for

sequencing.

Place a used sequencing chip in the chip clamp, then push the chip clamp in all

5.

the way to engage.

Close the instrument door, then press Next.

6.

Cleaning takes ~35 minutes to complete. On completion, the instrument door

automatically unlocks and the chip and cartridge clamps disengage.

Ion GeneStudio™ S5 Food Protection Instrument User Guide

15

Page 16

Chapter 3 Instrument operation

3

Maintain the Ion GeneStudio™ S5 Food Protection Instrument

Perform an

instrument reset

run with an

initialized, unused

Ion S5™ Wash

Solution cartridge

Cleaning is normally performed automatically at completion of a sequencing run.

If the Ion GeneStudio™ S5 Food Protection Instrument is initialized and

• a sequencing run is not started within 24 hours after initialization, or

• a sequencing run is not completed due to a power failure or an abort, and <200

ows occurred before the stoppage

then an instrument reset run is required to ensure proper cleaning before

reinitialization

Do NOT perform a manual cleaning with an unused, initialized Ion S5™ Wash

Solution cartridge.

Note:

If a power failure or abort occurs during the second of two runs that are started

·

after a single initialization, a manual cleaning is sucient (see “Manually clean the

instrument“ on page 14).

If the number of ows that occurred before a power failure or abort is unknown,

·

perform an instrument reset run.

To perform an instrument reset run, use the following procedure before

reinitialization:

In the instrument touchscreen main menu, touch Run.

1.

The instrument door unlocks and the chip clamp disengages.

Ensure that a used sequencing chip is in the chip clamp, then push the chip

2.

clamp in all the way to engage.

Close the instrument door, then touch Next.

3.

When prompted, select Planned Run (none). Ensure that the Enable post-run

4.

clean checkbox is selected, then press Review.

In the Select Run screen, touch Edit, then in the Detail screen set the number of

5.

ows to 200. Ensure that the Post-Run/Clean checkbox is selected, then touch

Close.

Touch Start run, then touch Accept to conrm that Post-Run Clean is enabled,

6.

and to start the run.

When the instrument reset run completes, the instrument automatically performs the

cleaning procedure. After cleaning, the touchscreen returns to the main menu.

16

Ion GeneStudio™ S5 Food Protection Instrument User Guide

Page 17

Ion GeneStudio S5

A

Clean, Initialize, and Run

Touchscreen reference

In the Home screen, the Clean, Initialize, and Run programs lead you through the

necessary steps to prepare the instrument for sequencing and to start a sequencing

run. Press the main dial to start a program. Simple, easy to follow instructions are

provided on the touchscreen.

• Cleaning must be performed before each initialization to ensure that the reagents

from the previous run are cleared from the uid lines. The Clean program is

normally performed automatically at the completion of the previous sequencing

run. Perform a Clean if for any reason the sequencing run was not properly

completed. Follow the instructions that are provided on the touchscreen.

• The Initialize program must be performed before each run to load and prepare

the run reagents. The Initialize program walks you through:

– Emptying the waste reservoir

– Loading the reagent cartridge, wash solution, and cleaning solution

• The Run program walks you through steps leading up to and through

sequencing, including:

– Placing a loaded chip on the instrument

– Selecting a Planned Run created in the Torrent Suite™ Software

– Performing sequencing

Ion GeneStudio™ S5 Food Protection Instrument User Guide

17

Page 18

Appendix A Touchscreen reference

A

Settings

Settings

In the Seings menu, users can view and/or change instrument seings, manage data

and network congurations, and update the installed software.

Network Settings

Note: The Service tools option is for use by trained service personnel only.

Use the Network Seings menu to congure IP address, Torrent Server, and FTP

seings.

18

Ion GeneStudio™ S5 Food Protection Instrument User Guide

Page 19

Appendix A Touchscreen reference

Settings

Item Description When/How to use

A

IP Address

Configuration

Torrent Server

Configuration

Set or change the IP configuration (DHCP or Static IP).

Change the Torrent Server IP address and user

information.

1. Select either the DHCP or

Static IP option.

2. Touch the screen in the field you

want to edit to activate the field. A

virtual keyboard appears.

3. Enter the new information, then

press Done.

When a change to the Torrent Server IP

address or user information is

required.

Enter the IP addresses in the

Ion GeneStudio™ S5 Food Protection Instrument User Guide

TSUrl field.

19

Page 20

Appendix A Touchscreen reference

A

Settings

Item Description When/How to use

FTP Server

Configuration

Update Server Update the software update server.

Change the FTP Server IP address and user information.

Enter the IP address in the FTPserver field.

When a change to the FTP Server IP

address or user information is

required.

When a change to the URL for the

software server update is required. The

values on this screen are set at

installation. Do not change the settings

except at the direction of Thermo

Fisher Scientific service staff.

Enter the IP address in the

20

UpdateUrl field.

Ion GeneStudio™ S5 Food Protection Instrument User Guide

Page 21

Appendix A Touchscreen reference

Settings

A

System Tools

The System Tools menu enables you to upload instrument diagnostics, manage data,

and shut down or reboot the instrument.

Item Description When/How to use

RFID Lists the product, product expiration date, and remaining

uses of the product.

To determine if reagents that were left

on an instrument during a period of

instrument shutdown have expired.

1. Press the screen within the row of

the product to view an RFID Tag

Detail page.

2. Press Done to return.

Ion GeneStudio™ S5 Food Protection Instrument User Guide

21

Page 22

Appendix A Touchscreen reference

A

Settings

Item Description When/How to use

Noise Test Provides real-time measurement of electrical noise

readings on the chip.

Chip Calibration Checks the status of a chip.

For troubleshooting if directed to do so

by Technical Support.

1. Insert a chip into the chip clamp.

2. Press Chip Calibration to start the

chip calibration.

3. In the dropdown lists, select the

Image to display and the type of

Calibration to perform.

4. Press Cancel to quit the chip

calibration.

22

Ion GeneStudio™ S5 Food Protection Instrument User Guide

Page 23

Appendix A Touchscreen reference

Settings

Item Description When/How to use

A

Reagent Check Reagent Check, performed by the instrument as part of

initialization, confirms that initialization passes by testing

reagent flow and signal detection.

If directed to do so by Technical

Support as part of a troubleshooting

procedure.

• Press Run to start the reagent

check.

• Press Last Trace to review the

most recent reagent check result

trace.

Note: Reagent Check confirms that

the chip calibration passes, and will

only fail if the chip is defective, or Ion

S5™ Wash Solution is not flowing.

Example Reagent Check for an Ion 540™ Chip

Example Reagent Check for an Ion 550™ Chip

Ion GeneStudio™ S5 Food Protection Instrument User Guide

23

Page 24

Appendix A Touchscreen reference

A

Settings

Item Description When/How to use

Filesystems

and disks

Provides real-time drive activity status and disk space

used.

Use if directed to do so as part of a

troubleshooting procedure:

1. In the System Tools menu, press

Disk Drives. The Filesystems

screen opens.

2. Press the screen within the row of

the Filesystem you want to view,

then press Details. The Disk

Drives in <Filesystem> screen

opens.

3. Press the screen within the row of

the Drive to view details of the

disk drive. The Details for <Drive>

screen opens.

4. Press Done to return to the

previous screen.

24

Ion GeneStudio™ S5 Food Protection Instrument User Guide

Page 25

Appendix A Touchscreen reference

Settings

Item Description When/How to use

A

Pulse clean Provides step by step instruction to perform a pulse clean

of the instrument if a solid‑state buffer leak occurs.

Upload

Diagnostics

Allows upload of instrument diagnostics files for review by

support personnel.

Use if directed to do so by Technical

Support as part of a troubleshooting

procedure:

1. Install consumables and a used

sequencing chip.

Note: Install Cleaning solution in

both the Wash solution (1) and

Cleaning solution (2) locations.

Use an empty Reagent cartridge.

2. Close the instrument door, then

press Next.

The pulse cleaning procedure starts

automatically.

For troubleshooting if directed to do so

by Technical Support.

Note: The system must be connected

to an active network port. If no network

is present, the file is pushed to the

Torrent Browser. You can then

download the file and email it to

Technical Support.

To retrieve the file using the Torrent

Browser, navigate to Help4Instrument

Diagnostics, then follow the on-screen

instructions.

Ion GeneStudio™ S5 Food Protection Instrument User Guide

25

Page 26

Appendix A Touchscreen reference

A

Settings

Item Description When/How to use

Shut Down Access to "Shut Down" and "Reboot" commands.

Note: It is not necessary/recommended to shut down the

instrument overnight or over the weekend. If needed to

shut down the instrument, see “Power off“ on page 12.

Check for

software updates

When software updates are available users will receive a Notication through the

home screen.

If directed to do so by Technical

Support as part of a troubleshooting

procedure.

In the Seings menu, press Check for Updates.

1.

The Software Update screen lists the available updates.

Press Update to automatically download and install the updates.

2.

26

Ion GeneStudio™ S5 Food Protection Instrument User Guide

Page 27

Appendix A Touchscreen reference

Settings

A

Data Management

The Data Management function allows users to manually delete run data, analyze the

data, or transfer the data to the Torrent Server. Under normal conditions, run data is

automatically transferred to the server, then deleted from the instrument hard drive.

Item Description When/How to use

Delete data Manually delete run data from the instrument. If the instrument hard drive becomes

full, see “Manually delete run data“ on

page 29.

Transfer data Transfer run data from the instrument

hard drive to the Torrent Server.

1. Touch the screen in the

Experiment Name row of the

individual experiment to be

transferred.

2. Press Transfer.

3. Select the radio button of the

action to be performed.

4. Select the radio button of the files

to be transferred.

5. Press OK.

Ion GeneStudio™ S5 Food Protection Instrument User Guide

27

Page 28

Appendix A Touchscreen reference

A

Settings

Item Description When/How to use

Analysis

Controls

Allows the user to stop or reanalyze the data of individual

runs.

1. Touch the screen in the

Experiment Name row of the

individual experiment to be

analyzed, then press Analysis.

2. Select the Stop Analysis or

Restart Analysis radio button,

then press OK.

3. If performing a re-analysis, follow

the on-screen instructions, then

press OK.

28

Ion GeneStudio™ S5 Food Protection Instrument User Guide

Page 29

Appendix A Touchscreen reference

Settings

A

Manually delete

run data

To troubleshoot data management issues the Data Management function allows users

to manually delete run data or transfer the data to the server. Under normal

conditions, run data is automatically transferred to the Torrent Server, then deleted

from the instrument hard drive.

In the Seings menu, press Data Management to access the Data Management

1.

screen, then press Manage.

Press Select All to select all the available experiments, or touch the screen in the

2.

Experiment Name row of the individual experiment to be managed.

Press Delete Selected.

3.

Ion GeneStudio™ S5 Food Protection Instrument User Guide

29

Page 30

Appendix A Touchscreen reference

A

Settings

Perform the

instrument Clean

operation

The Clean operation is normally performed automatically at the completion of the

previous sequencing run. Manually run the Clean operation under any of the

following conditions:

• The sequencing run was aborted or there was a power failure during the second

of two runs started after a single initialization.

• The sequencing run was not completed, and >200 ows occurred before the

stoppage.

• The post-sequencing Clean operation was not completed.

IMPORTANT! Do NOT perform a manual cleaning with an unused, initialized Ion

S5™ Wash Solution cartridge. Perform an instrument reset run instead. See “Perform

an instrument reset run with an initialized, unused Ion S5™ Wash Solution

cartridge“ on page 16 for more information.

In the Seings menu, press Clean Instrument.

1.

Follow the on-screen instructions (see “Manually clean the instrument“ on

2.

page 14 for more information), then press Next to start the Clean operation.

30

Ion GeneStudio™ S5 Food Protection Instrument User Guide

Page 31

Appendix A Touchscreen reference

Settings

The user interface returns to the Home screen when the cleaning is complete.

A

Instrument

settings

The Instrument Seings menu provides information about the instrument and allows

you to set the instrument name and calibrate the touchscreen.

Ion GeneStudio™ S5 Food Protection Instrument User Guide

31

Page 32

Appendix A Touchscreen reference

A

Settings

Item Description When/How to use

About Provides instrument details. To view instrument reference

information or access regulatory

information.

Regulatory Info Lists instrument-specific regulatory information. To view instrument regulatory

information.

Instrument

Name

32

To change the instrument name.

Ion GeneStudio™ S5 Food Protection Instrument User Guide

Page 33

1 432 5 6 7 8 9

Appendix A Touchscreen reference

Touchscreen icons

Item Description When/How to use

A

Screen

Calibration

Language To set the user interface language. Set to customer preference during

For troubleshooting if directed to do so

by Technical Support.

Touch the red cross with your finger or

a stylus each time it appears. In total,

you will touch the screen 4 times, one

time in each corner.

instrument installation.

Touchscreen icons

Ion GeneStudio™ S5 Food Protection Instrument User Guide

33

Page 34

Appendix A

A

Touchscreen icons

Touchscreen reference

Number

Icon Description

1 Network connectivity – connected

Network connectivity – not connected

2

Instrument idle

Sequencing in progress

Instrument ready

Error

3 Chip status – Absent

Chip status – Standby

Chip status – Connecting

Chip status – Ready

Chip status – Imaging

Chip status – Error

4 Manifold air pressure – Good

Manifold air pressure – Bad. If the icon reads "0" and

there is an alarm, contact Technical Support.

5 Regulator air pressure – Good

Regulator air pressure – Bad. If the icon reads "0" and

there is an alarm, contact Technical Support.

6 Manifold temperature – Good

Manifold temperature – Bad. Check for related alarms.

If the alarm persists contact Technical Support.

7 Chip block temperature – Good

Chip block temperature – Bad. If the icon reads "0" and

there is an alarm, contact Technical Support.

8 Instrument File System Space, the percent of file space

used is indicated.

[1]

The instrument checks for sufficient

disk space before each run and notifies the user if there

is not enough.

9 Torrent Server File System Space, the percent of file

space used is indicated.

Note: If the indicator turns red, archive data from the

server to free up disk space. Refer to the Torrent Suite

Software help for more information on archiving data.

[1]

Indicator turns yellow when disk space is ≥67% full, indicator turns red when ≥90% full.

™

34

Ion GeneStudio™ S5 Food Protection Instrument User Guide

Page 35

Alarms, Notifications, and Events

Ion GeneStudio S5

Ion GeneStudio S5

1

If the Alarms/Notications indicator appears, press the indicator to open the

Notications screen, then press Alarms or Events to see detailed messages.

Appendix A Touchscreen reference

Alarms, Notifications, and Events

A

1

Alarms and Notifications indicator.

Alarm Description Recommended Action

Fatal alarms

Fluidics Calibration Needed. — Contact Technical Support.

Chip Cooler can not reach desired

temperature.

Drive sdX failed smartctl health

check.

Failed to mount the results

filesystem.

System sensor check failed ipmi sensors.

System sensor check failed, CC.CC V

(LL.LL/HH.HH)

CPU temperature check failed,

Physical Id X.

Where X is the letter of the drive that

failed. Indicates that a drive is failing.

One or more drives are missing from

the RAID that makes up sw_results.

A component on the motherboard is

failing or has failed.

Where CC.CC = current voltage, LL.LL

= the low voltage threshold, HH.HH =

the high voltage threshold. Indicates

a voltage drop on the motherboard.

Where X is the processor number.

Indicates that the processor is

overheating.

—

Ion GeneStudio™ S5 Food Protection Instrument User Guide

35

Page 36

Appendix A Touchscreen reference

A

Alarms, Notifications, and Events

Alarm Description Recommended Action

Front/Rear FanX speed below

threshold YYYY.

FPGA failed to connect in emulate

mode.

Valve Link Failure.

OIA (On Instrument Analysis) is not

running.

FPGA temperature is above the

threshold of 70°C.

Boot drive exceeded 75%. The boot drive is unexpectedly full.

RAID degraded one disk has failed. One of the Torrent Server drives has

RAID failure detected, more than one

disk failed.

/sw_results directory not mounted. One or more of the drives used during

is the low threshold speed for the

system fan.

Internal error.

One or more of the system fans has

failed.

failed. System is still operational but

must be serviced soon.

More than one of the Torrent Server

drives has failed. System is no longer

operational.

data collection has failed.

Contact Technical Support.Where X is the fan number and YYYY

No GPU detected. GPU has failed.

No GPU Driver detected.

Air Compressor failure. Air compressor is either leaking or

has stopped working.

Nonfatal alarms

Instrument must be cleaned before

starting another run.

Ambient temperature is above the

threshold of 35°C.

RAID degraded one disk has failed. One of the Torrent Server drives has

No Connectivity to Torrent Server. Check that the Ethernet cable

No Connectivity to FTP server. Reconfigure the FTP server as

Maximum number of runs since last

clean has been exceeded.

Verify the temperature in the lab. Contact Technical Support if the

failed. System is still operational but

must be serviced soon.

connecting the instrument to the

server is properly connected. See

“Ion GeneStudio™ S5 Food Protection

Instrument input and output

connections“ on page 11 for the

Ethernet port location.

Perform an instrument cleaning (see

“Manually clean the instrument“ on

page 14).

temperature of the lab is within

normal operating temperature (20°C

to 30°C).

Contact Technical Support.

Reconfigure the Torrent Server as

needed (see “Network Settings“ on

page 18.

needed, see “Network Settings“ on

page 18.

36

Ion GeneStudio™ S5 Food Protection Instrument User Guide

Page 37

Appendix A Touchscreen reference

Alarms, Notifications, and Events

Alarm Description Recommended Action

A

Network Manager not connected. Check that the Ethernet cable

connecting the instrument to the

local area network is properly

connected. See “Ion GeneStudio™ S5

Food Protection Instrument input and

output connections“ on page 11 for

the Ethernet port location.

Newer Software Available Notification that software updates are

available.

If the problem persists, contact

Technical Support.

Update your software. See “Check for

software updates“ on page 26.

Ion GeneStudio™ S5 Food Protection Instrument User Guide

37

Page 38

Ion GeneStudio S5

B

Instrument alarms and events

Observation Possible cause Recommended action

Red "Alarms" and/or "Events" message in Main

Menu

• Available

software

updates were

detected.

• Connectivity

problems were

detected.

• Instrument did

not detect

required files

or hardware.

Troubleshooting

Press the red Alarms icon to see

detailed messages.

• If a message states "Newer

Software Available":

IMPORTANT! After updates are

installed, the instrument must be

restarted.

a. In the main menu, press

Settings4Check for Updates.

b. Select the Released Updates

checkbox, then press Update.

c. When installation is complete,

follow the onscreen prompts

to restart the instrument.

Note: Sometimes the

instrument restarts

automatically after software

installation.

• If a message states "No

Connectivity to Torrent Server", "No

Connectivity to ftp server", or

"Network Manager not connected",

disconnect and reconnect the

Ethernet cable, confirm that the

router is operational, and verify

that the network is up and running.

• For any other messages:

a. Power off the instrument: On

the home screen, press

Settings4System Tools4Shut

Down4Shut Down.

b. Wait 30 seconds, then press

the button on the side of the

instrument to power on the

instrument.

• If the red "Alarms" and/or "Events"

message still appears in the main

menu, contact Technical Support.

38

Ion GeneStudio™ S5 Food Protection Instrument User Guide

Page 39

Initialization fails

Observation Possible cause Recommended action

Chip Check fails • The chip clamp was not

closed.

• The chip was not

properly seated.

• The chip was damaged.

Reagent Check fails

A chip failure was detected. 1. Replace the used

Appendix B Troubleshooting

Initialization fails

1. Open the chip clamp,

remove the chip, and

look for signs of water

outside the flow cell.

2. If the chip appears

damaged, replace it with

a new one.

3. Close the clamp, then

repeat the Chip Check.

4. If the chip passes, click

Next. If the chip fails,

replace it with a new

chip, then press Chip

Check.

5. If Chip Check continues

to fail, there could be a

problem with the chip

socket. Contact

Technical Support.

sequencing chip used

during initialization with

a different used chip.

2. Press Retry.

3. If the initialization

completes without

failure, touch Home,

then continue with your

sequencing run.

4. If the Reagent Check

continues to fail, contact

Technical Support.

B

Ion GeneStudio™ S5 Food Protection Instrument User Guide

39

Page 40

Appendix B Troubleshooting

B

Initialization fails

Observation Possible cause Recommended action

Reagent Check fails A wash failure was detected. 1. Manually clean the

instrument (see

“Manually clean the

instrument“ on page 14.)

2. Replace the Reagents

cartridge, Wash Solution

bottle, and Cleaning

Solution bottle, then

repeat initialization of

the instrument.

3. If the initialization

completes without

failure, press Home,

then continue with your

sequencing run.

4. If the Reagent Check

continues to fail, contact

Technical Support.

Ensure that you install the Ion

S5™ Wash Solution bottle with

the instrument door fully

open. If you install the bottle

impeded by a partially closed

door, the port can be

obstructed, and a faulty

installation and wash failure

can result.

Bottle leak check fails • Bottle seal was not tight.

• Bottle was damaged or

defective.

1. Finger-tighten the

bottles.

2. If the bottle continues to

leak, replace the bottle.

3. If leak check continues

to fail, contact Technical

Support.

40

Ion GeneStudio™ S5 Food Protection Instrument User Guide

Page 41

Troubleshooting using control libraries

Observation Possible cause Recommended action

Ion Sphere™ Test Fragments

are not present in the Test

Fragment Report section of the

run report, and library

sequencing is poor

Control Ion Sphere™ Particles

are present in the run report,

but AQ20 throughput is poor

• Chip loading was poor.

• Control Ion Sphere

Particles were not added

to the sample

• The quality of the library

was poor.

• The quality of the template

preparation was poor.

™

Appendix B Troubleshooting

Troubleshooting using control libraries

1. Confirm that the Control Ion Sphere

Particles (included in the Ion S5

Installation Kit) were added.

2. If controls were added, contact Technical

Support.

Verify the quality of the library and template

preparations using quality assessment

procedures recommended in the appropriate

library and template preparation user guides.

1. Use the Human CEPH Genomic DNA

Control or Human CEPH Control 200

Library, included in the Ion S5™ Controls

Kit (Cat. No. A27760), to prepare

template-positive ISPs with the Ion Chef

Food Protection Instrument.

2. Use the ISPs in an Ion GeneStudio™ S5

Food Protection Instrument run.

3. If AQ20 throughput is still below

specification, verify the quality of

unenriched and enriched ISPs to identify

a problem in template preparation.

4. If ISP quality is good, but AQ20 throughput

is below specification, contact Technical

Support.

™

™

B

™

Solid-state buffer leak

Observation

Two or more of the following

observed

• Excessive read trimming

or the number of short

reads is significantly

higher than expected.

• Percentage of low quality

reads is significantly

higher than expected.

• Poor sequencing

performance or no Test

Fragments.

Ion GeneStudio™ S5 Food Protection Instrument User Guide

A solid-state buffer leak

occurred.

Possible cause Recommended action

Contact Technical Support.

Perform the pulse cleaning protocol if directed

to do so by Technical Support or your Field

Service Engineer (FSE).

41

Page 42

Appendix B Troubleshooting

B

Solid-state buffer leak

Pulse clean the

Ion GeneStudio

S5 Food

Protection

Instrument

You should pulse clean the Ion GeneStudio™ S5 Food Protection Instrument only if

™

directed by Technical Support, or your Field Service Engineer (FSE), to recover

instrument performance from a diagnosed solid-state buer leak.

Note: You must contact Technical Support, or your FSE, to diagnose whether a solidstate buer leak has occurred and obtain the required materials to perform the pulse

cleaning.

Ensure that the instrument has completed a normal post-run cleaning. In the

1.

main menu:

Display text Description

Run Instrument requires cleaning before a pulse cleaning can be

performed, see “Manually clean the instrument“ on page 14.

Clean Instrument requires cleaning before a pulse cleaning can be

performed, see “Manually clean the instrument“ on page 14.

Initialize Instrument is ready to be pulse cleaned. Proceed to step 2.

Press

2.

Follow the onscreen prompts to prepare the instrument.

3.

• Install new boles of Ion S5™ Cleaning Solution in both the Wash and

• Replace the Ion S5™ Sequencing Reagents cartridge with an empty used

• Install a used sequencing chip.

(Seings)4System Tools4Pulse clean.

Cleaning solution positions.

cartridge.

Close the instrument door, then touch Next.

4.

The pulse cleaning procedure begins automatically. The user interface returns to

the main menu when the cleaning is complete and the instrument is ready to be

initialized.

42

Ion GeneStudio™ S5 Food Protection Instrument User Guide

Page 43

C

Instrument warranty

For new Ion Torrent™ instruments, Life Technologies warrants to and only to buyer

for twelve (12) months from the date of shipping, that the Ion Torrent™ software and

Ion Torrent™ instruments are free from defects in material and workmanship and

conform to Life Technologies’ published specications in all material respects. Where

a valid and timely claim in respect of breach of Ion Torrent™ warranty is submied to

Life Technologies, Life Technologies may, at its discretion, replace, repair or modify

the Ion Torrent™ instrument. Any agreed replacement shall be at 1:1, like-kind basis,

at no cost to the buyer. For Ion Torrent™ chips or reagents reasonably determined by

Life Technologies to be defective, independent of user error, shall be replaced by Life

Technologies on a 1:1, like-kind basis at no cost to buyer, provided that such defective

Ion Torrent™ chips or reagents were used by buyer prior to their expiration date, or if

there is no expiration date, the Ion Torrent™ chips or reagents were used within six (6)

months of receipt, and the defect was promptly reported with appropriate detail to

Life Technologies’ technical support.

NO OTHER WARRANTIES SHALL BE APPLICABLE TO ION TORRENT

PRODUCTS (WHETHER OR NOT ANY FURTHER WARRANTY

DOCUMENTATION MAY BE INCLUDED IN THE SHIPMENT), WITH THE

EXCEPTION OF THIRD PARTY WARRANTIES WITH RESPECT TO THIRD PARTY

PRODUCT. ANY THIRD PARTY PRODUCTS ARE NOT COVERED BY THIS

SECTION AND ANY WARRANTIES FOR THIRD PARTY PRODUCTS ARE

PROVIDED BY THE ORIGINAL MANUFACTURER OF THE THIRD PARTY

PRODUCT. Warranties are made only to buyer purchasing the Ion Torrent™ Product

directly from Life Technologies, are not transferable and do not extend to the benet

of any other person or entity, unless otherwise expressly stated in writing by Life

Technologies. ANY PRODUCT NOT COVERED BY AN EXPRESS WRITTEN

WARRANTY IS SOLD AND PROVIDED “AS IS,” WITHOUT WARRANTY OF ANY

KIND, STATUTORY, EXPRESS OR IMPLIED. Any description of Ion Torrent

Product recited in Life Technologies’ quotation is for the sole purpose of identifying

Ion Torrent™ Product, and any such description is not part of any contract between

Life Technologies and buyer and does not constitute a warranty that Ion Torrent

Product shall conform to that description. Any sample or model used in connection

with Life Technologies’ quotation is for illustrative purposes only, and is not part of

any contract between Life Technologies and buyer and does not constitute a warranty

that Ion Torrent™ Product will conform to the sample or model. No armation of fact

or promise made by Life Technologies, whether or not in Life Technologies’ quotation,

shall constitute a warranty that Ion Torrent™ Product will conform to the armation

or promise. Unless otherwise specied in writing in documentation shipped with Ion

Torrent™ Product or otherwise agreed by Life Technologies in writing. Life

Technologies does not provide service or support for custom products or other

products made to buyer’s specications. THE WARRANTIES IDENTIFIED IN THIS

CLAUSE ARE LIFE TECHNOLOGIES’ SOLE AND EXCLUSIVE WARRANTIES

WITH RESPECT TO Ion Torrent™ PRODUCT AND ARE IN LIEU OF ALL OTHER

WARRANTIES, STATUTORY, EXPRESS OR IMPLIED, ALL OF WHICH OTHER

WARRANTIES ARE EXPRESSLY DISCLAIMED, INCLUDING WITHOUT

LIMITATION ANY IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR

™

™

Ion GeneStudio™ S5 Food Protection Instrument User Guide

43

Page 44

Appendix C Instrument warranty

C

Solid-state buffer leak

A PARTICULAR PURPOSE, NON-INFRINGEMENT, OR REGARDING RESULTS

OBTAINED THROUGH THE USE OF ANY PRODUCT (INCLUDING, WITHOUT

LIMITATION, ANY CLAIM OF INACCURATE, INVALID OR INCOMPLETE

RESULTS), WHETHER ARISING FROM A STATUTE OR OTHERWISE IN LAW OR

FROM A COURSE OF PERFORMANCE, DEALING OR USAGE OF TRADE.

44

Ion GeneStudio™ S5 Food Protection Instrument User Guide

Page 45

D

WARNING! GENERAL SAFETY. Using this product in a manner not specied

in the user documentation may result in personal injury or damage to the

instrument or device. Ensure that anyone using this product has received

instructions in general safety practices for laboratories and the safety

information provided in this document.

Before using an instrument or device, read and understand the safety

·

information provided in the user documentation provided by the

manufacturer of the instrument or device.

Before handling chemicals, read and understand all applicable Safety Data

·

Sheets (SDSs) and use appropriate personal protective equipment (gloves,

gowns, eye protection, and so on). To obtain SDSs, see the “Documentation

and Support” section in this document.

Safety alerts on this instrument

Safety

Additional text may be used with one of the symbols described above when more

specic information is needed to avoid exposure to a hazard. See the following table

for safety alerts found on the instrument.

English

CAUTION! Hazardous chemicals.

Read the Safety Data Sheets (SDSs)

before handling.

CAUTION! Hazardous waste. Refer

to SDS(s) and local regulations for

handling and disposal.

MISE EN GARDE ! Produits

chimiques dangereux. Lire les

fiches signalétiques (FS) avant de

manipuler les produits.

MISE EN GARDE ! Déchets

dangereux. Lire les fiches

signalétiques (FS) et la

réglementation locale associées à la

manipulation et à l’élimination des

déchets.

Français

Ion GeneStudio™ S5 Food Protection Instrument User Guide

45

Page 46

Made in USA

Ion Torrent S5™ XL Sequencer

1234987

00000000

Made in USA

INS0000000 Rev

A

Rated 100-240VAC 50/60Hz, 14.5-6.5A

Life Technologies Corp.

5791 Van Allen Way

Carlsbad, CA 92008

YYYY-MM-DD

EMC Class A

For Research Use Only.

Not for use in diagnostic procedures

Safety and

regulatory

symbols

Appendix D Safety

D

Safety information for instruments not manufactured by Thermo Fisher Scientific

Location of safety

labels on the

instrument

The Ion GeneStudio™ S5 Food Protection Instrument has warnings at the location

shown:

Ion GeneStudio™ S5 Food Protection Instrument label

Safety information for instruments not manufactured by Thermo

Fisher Scientific

Some of the accessories provided as part of the instrument system are not designed or

built by Thermo Fisher Scientic. Consult the manufacturer's documentation for the

information needed for the safe use of these products.

46

Ion GeneStudio™ S5 Food Protection Instrument User Guide

Page 47

Instrument safety

Appendix D Safety

Instrument safety

D

General

Cleaning and

decontamination

CAUTION! Do not remove instrument protective covers. If you remove the

protective instrument panels or disable interlock devices, you may be exposed

to serious hazards including, but not limited to, severe electrical shock, laser

exposure, crushing, or chemical exposure.

CAUTION! Cleaning and Decontamination. Use only the cleaning and

decontamination methods specied in the manufacturer's user documentation.

It is the responsibility of the operator (or other responsible person) to ensure

the following requirements are met:

No decontamination or cleaning agents are used that could cause a

·

HAZARD as a result of a reaction with parts of the equipment or with

material contained in the equipment.

The instrument is properly decontaminated a) if hazardous material is

·

spilled onto or into the equipment, and/or b) prior to having the instrument

serviced at your facility or sending the instrument for repair, maintenance,

trade-in, disposal, or termination of a loan (decontamination forms may be

requested from customer service).

Before using any cleaning or decontamination methods (except those

·

recommended by the manufacturer), users should conrm with the

manufacturer that the proposed method will not damage the equipment.

MISE EN GARDE ! Neoyage et décontamination. Utiliser uniquement les

méthodes de neoyage et de décontamination indiquées dans la documentation

du fabricant destinée aux utilisateurs. L’opérateur (ou toute autre personne

responsable) est tenu d’assurer le respect des exigences suivantes:

Ne pas utiliser d’agents de neoyage ou de décontamination susceptibles de

·

réagir avec certaines parties de l’appareil ou avec les matières qu’il contient

et de constituer, de ce fait, un DANGER.

L’instrument doit être correctement décontaminé a) si des substances

·

dangereuses sont renversées sur ou à l’intérieur de l’équipement, et/ou

b) avant de le faire réviser sur site ou de l’envoyer à des ns de réparation, de

maintenance, de revente, d’élimination ou à l’expiration d’une période de

prêt (des informations sur les formes de décontamination peuvent être

demandées auprès du Service clientèle).

Avant d’utiliser une méthode de neoyage ou de décontamination (autre que

·

celles recommandées par le fabricant), les utilisateurs doivent vérier auprès

de celui-ci qu’elle ne risque pas d’endommager l’appareil.

Ion GeneStudio™ S5 Food Protection Instrument User Guide

47

Page 48

Appendix D Safety

D

Instrument safety

Electrical safety

WARNING! Ensure appropriate electrical supply. For safe operation of the

instrument:

Plug the system into a properly grounded receptacle with adequate current

·

capacity.

Ensure the electrical supply is of suitable voltage.

·

Never operate the instrument with the ground disconnected. Grounding

·

continuity is required for safe operation of the instrument.

AVERTISSEMENT ! Veiller à utiliser une alimentation électrique appropriée.

Pour garantir le fonctionnement de l’instrument en toute sécurité :

Brancher le système sur une prise électrique correctement mise à la terre et

·

de puissance adéquate.

S’assurer que la tension électrique est convenable.

·

Ne jamais utiliser l’instrument alors que le dispositif de mise à la terre est

·

déconnecté. La continuité de la mise à la terre est impérative pour le

fonctionnement de l’instrument en toute sécurité.

WARNING! Power Supply Line Cords. Use properly congured and approved

line cords for the power supply in your facility.

AVERTISSEMENT ! Cordons d’alimentation électrique. Utiliser des cordons

d’alimentation adaptés et approuvés pour raccorder l’instrument au circuit

électrique du site.

WARNING! Disconnecting Power. To fully disconnect power either detach or

unplug the power cord, positioning the instrument such that the power cord is

accessible.

AVERTISSEMENT ! Déconnecter l’alimentation. Pour déconnecter

entièrement l’alimentation, détacher ou débrancher le cordon d’alimentation.

Placer l’instrument de manière à ce que le cordon d’alimentation soit accessible.

48

Ion GeneStudio™ S5 Food Protection Instrument User Guide

Page 49

Safety and electromagnetic compatibility (EMC) standards

Appendix D Safety

Safety and electromagnetic compatibility (EMC) standards

The instrument design and manufacture complies with the standards and

requirements for safety and electromagnetic compatibility as noted in the following

table:

D

Safety

EMC

Reference

EU Directive

2014/35/EU

IEC 61010-1

UL 61010-1

CSA C22.2 No.

61010-1

IEC 61010-2-010

Directive 2014/30/EU European Union “EMC Directive”

EN 61326-1

AS/NZS CISPR 22 2009+A1 2010

European Union “Low Voltage Directive”

Safety requirements for electrical equipment for measurement,

control, and laboratory use – Part 1: General requirements

Safety requirements for electrical equipment for measurement,

control and laboratory use – Part 2-010: Particular requirements

for laboratory equipment for the heating of materials

Reference

Description

Description

Electrical Equipment for Measurement,

Control and Laboratory Use – EMC

Requirements – Part 1: General

Requirements

Limits and Methods of Measurement of

Electromagnetic Disturbance

Characteristics of Industrial, Scientific, and

Medical (ISM) Radiofrequency Equipment

ICES-003, Issue 5

FCC Part 15 Subpart B (47 CFR)

Ion GeneStudio™ S5 Food Protection Instrument User Guide

Industrial, Scientific and Medical (ISM)

Radio Frequency Generators

U.S. Standard Radio Frequency Devices

49

Page 50

Appendix D Safety

D

Safety and electromagnetic compatibility (EMC) standards

Environmental

design

Waste and hazardous substances

Reference Description

Directive 2012/19/EU European Union “WEEE Directive” – Waste electrical and

electronic equipment

Directive 2011/65/EU European Union “RoHS Directive” – Restriction of hazardous

substances in electrical and electronic equipment

Radio compliance

Reference Description

Directive 2014/53/EU European Radio Equipment Directive (RED)

RFID

FCC Notice (for U.S. Customers):

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following conditions:

1. This device many not cause harmful interference, and

2. This device must accept any interference received, Including

interference that may cause undesired operation

Changes and Modifications not expressly approved by

Thermo Fisher Scientific can void your authority to operate

this equipment under Federal Communications Commissions

rules.

Canada:

This device complies with Industry Canada licence-exempt RSS

standard(s).

(1) this device may not cause interference, and (2) this device must

accept any interference, including interference that may cause

undesired operation of the device.

Le présent appareil est conforme aux CNR d'Industrie Canada

applicables aux appareils radio exempts de licence. L'exploitation

est autorisée aux deux conditions suivantes : (1) l'appareil ne doit

pas produire de brouillage, et (2) l'utilisateur de l'appareil doit

accepter tout brouillage radioélectrique subi, même si le

brouillage est susceptible d'en compromettre le fonctionnement.

Operation is subject to the following two conditions:

50

Ion GeneStudio™ S5 Food Protection Instrument User Guide

Page 51

Chemical safety

Appendix D Safety

Chemical safety

WARNING! GENERAL CHEMICAL HANDLING. To minimize hazards,

ensure laboratory personnel read and practice the general safety guidelines for

chemical usage, storage, and waste provided below. Consult the relevant SDS

for specic precautions and instructions:

Read and understand the Safety Data Sheets (SDSs) provided by the

·

chemical manufacturer before you store, handle, or work with any chemicals

or hazardous materials. To obtain SDSs, see the “Documentation and

Support” section in this document.

Minimize contact with chemicals. Wear appropriate personal protective

·

equipment when handling chemicals (for example, safety glasses, gloves, or

protective clothing).

Minimize the inhalation of chemicals. Do not leave chemical containers open.

·

Use only with adequate ventilation (for example, fume hood).

Check regularly for chemical leaks or spills. If a leak or spill occurs, follow

·

the manufacturer's cleanup procedures as recommended in the SDS.

Handle chemical wastes in a fume hood.

·

Ensure use of primary and secondary waste containers. (A primary waste

·

container holds the immediate waste. A secondary container contains spills

or leaks from the primary container. Both containers must be compatible

with the waste material and meet federal, state, and local requirements for

container storage.)

After emptying a waste container, seal it with the cap provided.

·

Characterize (by analysis if necessary) the waste generated by the particular

·

applications, reagents, and substrates used in your laboratory.

Ensure that the waste is stored, transferred, transported, and disposed of

·

according to all local, state/provincial, and/or national regulations.

IMPORTANT! Radioactive or biohazardous materials may require special

·

handling, and disposal limitations may apply.

D

AVERTISSEMENT ! PRÉCAUTIONS GÉNÉRALES EN CAS DE

MANIPULATION DE PRODUITS CHIMIQUES. Pour minimiser les risques,

veiller à ce que le personnel du laboratoire lise aentivement et mee en œuvre

les consignes de sécurité générales relatives à l’utilisation et au stockage des

produits chimiques et à la gestion des déchets qui en découlent, décrites cidessous. Consulter également la FDS appropriée pour connaître les précautions

et instructions particulières à respecter :

Lire et comprendre les ches de données de sécurité (FDS) fournies par le

·

fabricant avant de stocker, de manipuler ou d’utiliser les matériaux

dangereux ou les produits chimiques. Pour obtenir les FDS, se reporter à la

section « Documentation et support » du présent document.

Limiter les contacts avec les produits chimiques. Porter des équipements de

·

protection appropriés lors de la manipulation des produits chimiques (par

exemple : lunees de sûreté, gants ou vêtements de protection).

Limiter l’inhalation des produits chimiques. Ne pas laisser les récipients de

·

produits chimiques ouverts. Ils ne doivent être utilisés qu’avec une

ventilation adéquate (par exemple, sorbonne).

Ion GeneStudio™ S5 Food Protection Instrument User Guide

51

Page 52

Appendix D Safety

D

Chemical safety

Vérier régulièrement l’absence de fuite ou d’écoulement des produits

·

chimiques. En cas de fuite ou d’écoulement d’un produit, respecter les

directives de neoyage du fabricant recommandées dans la FDS.

Manipuler les déchets chimiques dans une sorbonne.

·

Veiller à utiliser des récipients à déchets primaire et secondaire. (Le récipient

·

primaire contient les déchets immédiats, le récipient secondaire contient les

fuites et les écoulements du récipient primaire. Les deux récipients doivent

être compatibles avec les matériaux mis au rebut et conformes aux exigences

locales, nationales et communautaires en matière de connement des

récipients.)

Une fois le récipient à déchets vidé, il doit être refermé hermétiquement avec

·

le couvercle fourni.

Caractériser (par une analyse si nécessaire) les déchets générés par les

·

applications, les réactifs et les substrats particuliers utilisés dans le

laboratoire.

Vérier que les déchets sont convenablement stockés, transférés, transportés

·

et éliminés en respectant toutes les réglementations locales, nationales et/ou

communautaires en vigueur.

IMPORTANT ! Les matériaux représentant un danger biologique ou

·

radioactif exigent parfois une manipulation spéciale, et des limitations

peuvent s’appliquer à leur élimination.

52

Ion GeneStudio™ S5 Food Protection Instrument User Guide

Page 53

Related documentation

Documentation and support

Ion 510™ & Ion 520™ & Ion 530™ Food Protection Kit–Chef User

Guide

Ion GeneStudio™ S5 Food Protection System Site Preparation

Guide

Food Safety support

Website: thermoscientic.com/foodmicro or thermosher.com/foodsafety

Support email:

• Europe, Middle East, Africa: microbiology.techsupport.uk@thermosher.com

• North America: microbiology@thermosher.com

Phone: Visit thermosher.com/support, select the link for phone support, and select

the appropriate country from the dropdown menu.

Title

Pub. No.

MAN0017967

MAN0017966

Ion GeneStudio™ S5 Food Protection Instrument User Guide

53

Page 54

thermofisher.com/support | thermofisher.com/askaquestion

thermofisher.com

18 October 2018

Loading...

Loading...