Page 1

Sarasota 2000

Ultrasonic Multipath Flowmeter

User Guide

P/N HB-S2000

Revision A

Part of Thermo Fisher Scientific

Page 2

Page 3

Sarasota 2000

Ultrasonic Multipath Flowmeter

User Guide

P/N HB-S2000

Revision A

Page 4

Page 5

©2007 Thermo Fisher Scientific Inc. All rights reserved.

All trademarks are the property of Thermo Fisher Scientific Inc. and its subsidiaries.

Thermo Fisher Scientific (Thermo Fisher) makes every effort to ensure the accuracy and completeness of

this manual. However, we cannot be responsible for errors, omissions, or any loss of data as the result of

errors or omissions. Thermo Fisher reserves the right to make changes to the manual or improvements to

the product at any time without notice.

The material in this manual is proprietary and cannot be reproduced in any form without expressed

written consent from Thermo Fisher.

Thermo Fisher Scientific

1410 Gillingham Lane

Sugar Land, TX 77478

USA

Phone: 713-272-0404

Fax: 713-272-2272

Web: www.thermofisher.com

Thermo Fisher Scientific

14 Gormley Industrial Avenue

Gormley, Ontario L0H 1G0

Canada

Phone: 905-888-8808

Fax: 905-888-8828

Page 6

This page intentionally left blank.

Page 7

Sarasota 2000 Ultrasonic Multipath Flowmeter

SECTION 1

INTRODUCTION

1.2.1 The Standard

1.3 Implementation of principles in Sara sota 2000

1.1 Applications

1.2 Principle of operation

1.2.2 Velocity x area method

1.2.3 Water level

1.2.4 Water velocity

1.2.5 Flow determination

1.2.5.1 Mid section method

1.2.5.2 Mean section method

1.2.6 Path configurations

1.2.7 Transducer frequency

1.2.8 Minimum depth of water

1.2.9 Performance estimates

INDEX

SECTION 2

SYSTEM COMPONENTS

2.1 Flowmeter system overview

2.2 Family tree

2.3 Flowmeter contents and options

2.3.1 Flowmeter layout

2.3.2 Core items

2.3.2.1 Power supply

2.3.2.2 Central processor

2.3.2.3 Keyboard and display

2.3.2.4 Serial connections

2.3.3 Optional items

2.3.3.1 Transducer I/F card

2.3.3.2 Input/output card

2.3.3.2.1 I/O card layout

2.3.3.2.2 Analogue I/O

2.3.3.2.3 16 bit BCD & encoder

2.3.3.3 Relay (VFC) card

2.4 Ultrasonic transducers

2.4.1 1 MHz transducers

2.4.2 500 kHz transducers

2.4.3 Lower frequency transducers

2.4.4 Maximum cable lengths

2.5 Controls and displays

2.5.1 Panel layout

2.5.2 Screen organisation

2.5.3 Status indicator

2.6 Software & firmware

2.6.1 Operating firmware

2.6.2 “GAFA” PC software

2.7 Documentation

INDEX Page 1

Thermo Fisher Scientific

Page 8

Sarasota 2000 Ultrasonic Multipath Flowmeter

SECTION 3

PERIPHERAL EQUIPMENT

SECTION 4

INSTALLATION

4.1 Safety

SECTION 5

COMMISSIONING

5.1 Site dimensions

SECTION 6

CALIBRATION/

VERIFICATION

3.1 Additional items

3.2 Transducer mounting hardware

4.2 General

4.3 Unpacking and laying out

4.4 Installing transducer assemblies

4.5 Connecting transducers to flowmeter

4.6 Transducer alignment

4.7 Output connections

4.8 Power connection

5.2 Powering up

5.3 Programming

5.4 Setting up

5.5 Outputs

6 Calibration/verification

INDEX

SECTION 7

MAINTENANCE

7.1 Channel maintenance

7.1.1 Weed

7.1.2 Profile

7.1.3 Debris

7.2 Flowmeter maintenance

7.3 Routine checks

7.3.1 Remote

7.3.2 On site

INDEX Page 2

Thermo Fisher Scientific

Page 9

Sarasota 2000 Ultrasonic Multipath Flowmeter

APPENDIX 1

LCD SCREENS

A1.1 Screen organisation chart

APPENDIX 2

GAFA PC SOFTWARE

A2 GAFA PC software

A1.2 Screen types

A1.3 Screen selection and data entry

A1.4 Power off mode

A1.5 Screens

INDEX

APPENDIX 3

SPECIFICATION

A3.1 Enclosure

A3.2 Power supply

A3.2.1 AC supply

A3.2.2 12 volt DC supply

A3.3.3 24 volt DC supply

A3.3 Electronics

A3.4 Transducers

A3.4.1 1 MHz

A3.4.2 500 kHz

A3.4.3 Other frequencies

A3.4.4 Transducer ca ble

A3.5 GAFA software

APPENDIX 4

REFERENC ES

A4 References

APPENDIX 5

SITE DATA BOOK

A5.1 Model and serial number

A5.2 Site and customer

A5.3 General description

A5.4 Software issue

A5.5 Card layout in rack

A5.6 Programmed data

A5.7 Schedule of drawings

A5.8 Test certificates

INDEX Page 3

Thermo Fisher Scientific

Page 10

Sarasota 2000 Ultrasonic Multipath Flowmeter

This page is blank

INDEX

INDEX Page 4

Thermo Fisher Scientific

Page 11

Sarasota 2000 Ultrasonic Multipath

Flowmeter

INTRODUCTION

1 INTRODUCTION

1.1 Applications

The Thermo Scientific Sarasota 2000 is a velocity x area open channel flowmeter which uses

the ultrasonic “time of flight”, also known as the “transit time” method.

Unlike traditional methods of open channel flow measurement which use weirs or flumes, the

transit time method creates no obstruction and assumes no relation between level and flow. It

will correctly determine flow throughout its designed range by measuring water velocity and

cross section area (see Section 1.2).

The method is tolerant of backwater effects caused by tides, downstream confluence or

blockages. Unlike a weir or flume it does not drown out at high flow conditions.

The method employs the transmission of ultrasonic “beams” which can be affected by factors

which impede or deflect them. For this reason the method should not be used in situations of:

• Aerated water

• Weed growth between the transducers (unless it is regularly cut)

• High levels of suspended solids (greater than 2000 mg/l) *

• Gradients

• Gradients

* In relatively small channels (up to 5 metres) the method is more tolerant of suspended solids

and therefore is often used in sewage applications.

Though described as an open channel method, the flowmeter may be used in closed

conduits, including those which run full. In the latter case, the cross section area is defined by

the conduit geometry without the need to measure water level.

Suitable applications include water flow measurement of:

• Rivers

• Canals

• Aqueducts

• Irrigation conduits

• Sewage discharges

• Sewage works

• Industrial discharges

• Power generation

Note that although the flowmeter is most often used for open channels or part filled conduits,

it is often used for conduits which always run full. Under these circumstances it is not

necessary to have a depth input but steps need to be taken to ensure that the flowmeter

always takes the conduit as full. This is done via the encoder depth input. The conduit shape

must still be entered.

of salinity (the actual value of salinity is, however, unimportant)

of temperature (the actual temperature is, however, unimportant)

Section 1 INTRODUCTION Page 1-1

Thermo Fisher Scientific

Page 12

Sarasota 2000 Ultrasonic Multipath

Flowmeter

1.2 Principle of operation

1.2.1 The Standard

The Sarasota USMP is a velocity x area open channel flowmeter which uses the ultrasonic

“time of flight” method. This is also known as the “transit time” method. It complies with the

International Standard ISO 6416. The UK version BS 3680 part 3E is identical. The transit

time method belongs to the general category of velocity x area methods. A full description of

the method and its applications is to be found in the Standard. A brief summary is given

below.

1.2.2 Velocity x area method

Velocity x area methods require a means of determining the water velocity and the cross

section area. The product of the two produces the flow rate in a manner which is not

dependent on factors influencing the level, for example downstream constrictions, tidally

influenced wat er level et c.

Assuming the shape of the channel cross section is stable, determination of the area

becomes a matter of measuring water level. This may be done by a variety of methods.

1.2.3 Water level

Water level is required in order to determine the cross section area in an open channel.

Though a single level measurement may be used, it is common to use more than one and to

average them. This has the advantage of a more representative level, particularly if the

measurements are made at different positions, for example on either side of the channel.

Another advantage is that flow may still be computed even if a level sensor fails.

Level may be determined by using one or more ultrasonic transducers in the water facing

upwards. The time taken for a pulse of sound to return to the transducer after being reflected

from the surface is converted into level using the velocity of sound in water as measured on

the water velocity paths (see Section 1.2.4). There is a minimum depth of water required

above the transducer for it to carry out a measurement. This is given in Appendix 3:

Specification.

Water level may also be provided by external auxiliary depth gauges, for example pressure

transmitters, downward facing ultrasonic devices and float systems with shaft encoders.

1.2.4 Water velocity

In the transit time method, water velocity is determined at a number of heights within the body

of water by measurement of time taken for pulses of ultrasound to travel across the channel

at an angle to the flow direction.

Transducers are mounted in the water at or near the sides of the channel with each pair

usually at the same height and aligned so as each one can transmit a “beam” of ultrasound

towards its partner. The ultrasonic “path” between the transducer pairs must be at an angle

(usually about 45

Each transducer acts as a transmitter and receiver and is connected to a processing unit,

which measures the transit time and the time difference.

o

) to the flow direction.

INTRODUCTION

Section 1 INTRODUCTION Page 1-2

Thermo Fisher Scientific

Page 13

Sarasota 2000 Ultrasonic Multipath

θ

Flowmeter

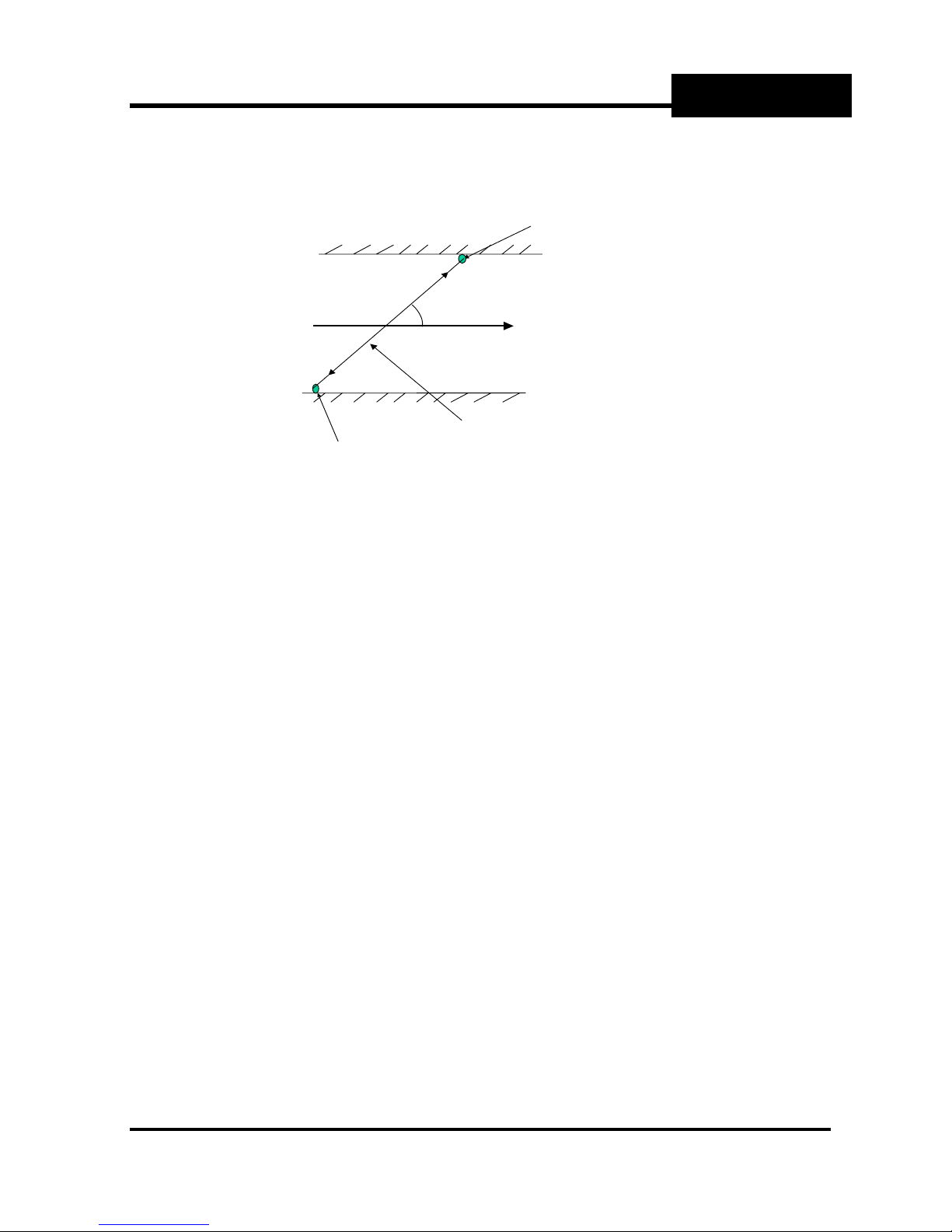

The mean water velocity at the height of each path is determined from these timing

measurements, based on pre-determined geometrical measurements (length of the path and

the angle to the flow direction).

V

It may be shown that the water velocity at the height of the path AB is:

v = L x (T

– TBA) / (TAB x TBA x 2 cosθ)

AB

Where

T

T

= Transit time from transducer A to B

AB

= Transit time from transducer B to A

BA

L = Path length (distance between transducer A and transducer B)

θ = the angle between the “path” and the direction of flow.

1.2.5 Flow determination

The flow is determined by combining the water velocity measurements at the height of each

path with the cross section area defined by the water level and the shape of the channel. The

channel shape need not be the same as the projected width between the transducers. For

example if the transducers are mounted on piles inset from the channel sides. For the

purposes of flow determination the cross section area is divided into horizontal slices

determined by the channel bed, the heights of the paths themselves and the water surface

level.

The channel flow is the sum of the flows in each slice determined by the path velocity or

velocities and the area of the slice. The bottom slice is defined by the bed (which is assumed

not to move) and the top slice by the water level (which is measured). The slice widths may

be determined by the projected width between the transducers or by a separate table defining

the cross section shape.

There are 2 methods, mid section and mean section.

Transducer A

Direction of the Flow

Ultrasonic Path

Transducer B

INTRODUCTION

Section 1 INTRODUCTION Page 1-3

Thermo Fisher Scientific

Page 14

Sarasota 2000 Ultrasonic Multipath

Flowmeter

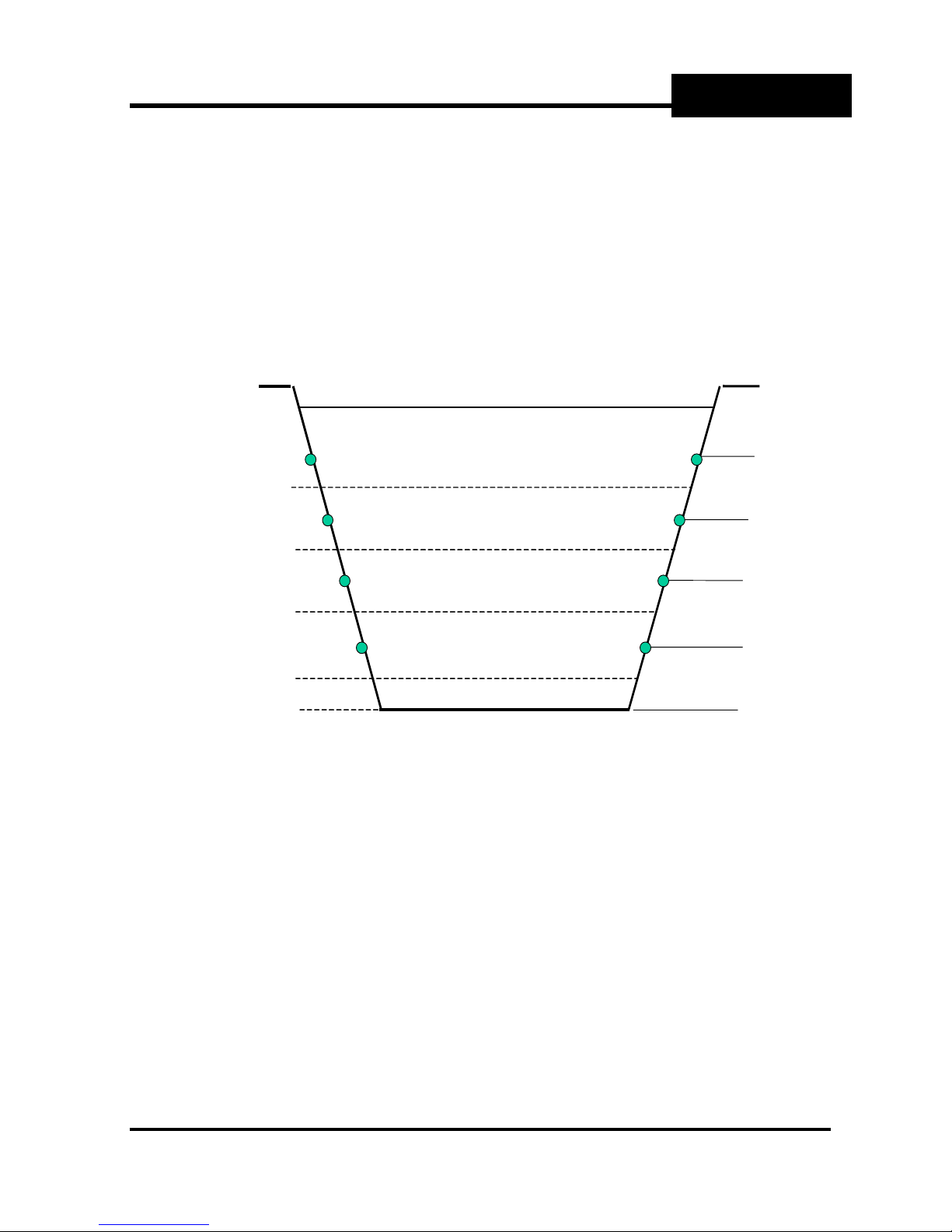

1.2.5.1 Mid section method

In the mid section method, the slice boundaries are defined by lines mid way between the

paths. The slice velocity is taken as that determined by the path within the slice and the slice

area as the product of the slice height and the (average) width. The upper boundary of the top

slice is the water surface. At the bottom, an additional slice is defined between the bed and a

line half way between the bed and the bottom path. This bottom slice has a weighting factor,

K, normally between 0.4 and 0.8 to allow for the slow moving water near the bed. To reduce

the uncertainty of this factor, the bottom path should be positioned as close to the bed as

practical.

INTRODUCTION

Height H

Top panel

½(H

+ H3)

4

S

Water S u rf ac e

QS = V4 {HS − ½(H4 + H3)}W

QS = ½V3 (H4 – H2)W

3

4

½(H3 + H2)

+ H1)

½(H

2

+ H0)

½(H

1

Height H

0

Bottom panel

QS = ½V2 (H3 – H1)W

QS = ½V1 (H2 – H0)W

QS = ½kV1 (H1 – H0)W

2

1

Width W

Bed

Width W

Illustration of the mid section method for 4 paths

Width W

Width W

Width W

1

Bed

4

3

2

Path 4 H e ight H

Path 3 Height H

Path 2 Height H

Path 1 Height H

Bed Height H

4

3

2

1

0

Section 1 INTRODUCTION Page 1-4

Thermo Fisher Scientific

Page 15

Sarasota 2000 Ultrasonic Multipath

4

Flowmeter

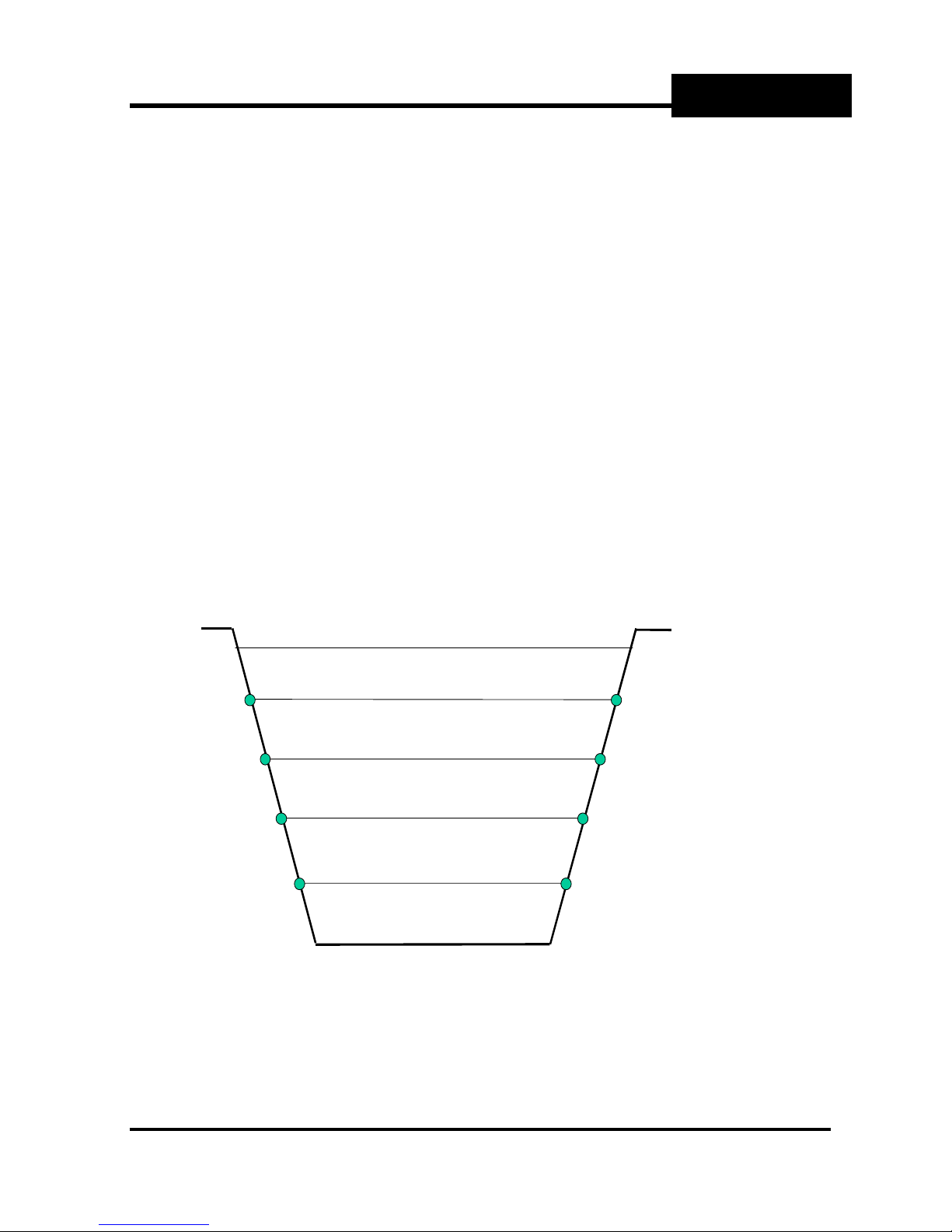

1.2.5.2 Mean section method

In the mean section method, the slice boundaries are defined by the path heights themselves.

The slice velocity is taken as the mean of the upper and lower paths which define the slice

boundaries. The upper boundary of the top slice is the water surface.

The velocit y of the water surface, Vs, is given by:-

Vs = V

Where Ks is a multiplying factor normally between 0 and 1 to allow for the projection

of velocity to the water surface

Vs is limited to a value of V

The lower boundary of the bottom slice is the bed. This bottom slice has a weighting factor,

, normally between 0.4 and 0.8 to allow for the slow moving water near the bed.

K

B

The mean section method is superior in cases where the paths are not near the slice centres,

but the mid section method handles the top slice better. The more paths that are deployed,

the less the differences matter.

The mean section method is illustrated in the following diagram:

+ (V4-V3) x Ks(Hs-H4)/(H4-H3)

4

+ (V4-V3) in the event of (Hs-H4) being greater than (H4-H3)

4

INTRODUCTION

Water Surface

Qs = ½(VS + V4) x (HS – H4) x ½(WS+ W4)

Q

= ½ (V4+ V3) x (H4 – H3) x ½(W4 + W3)

s

= ½ (V3 + V2) x (H3 – H2) x ½(W3 + W2)

Q

s

= ½ (V2 + V1) x (H2 – H1) x ½(W2 + W1)

Q

s

Q

= ½V1(1 + kB) x (H1 – H0) x ½(W1 + W

s

W

W

W

W

Wbed

Width W

4

3

2

1

)

Bed

S

Illustration of the mean section method for 4 paths

Surface Heigh t H

Path 4. Height H

Path 3. H eight H

Path 2. He i ght H

Path 1 Height H

Bed, Height H

S

3

2

1

0

Section 1 INTRODUCTION Page 1-5

Thermo Fisher Scientific

Page 16

Sarasota 2000 Ultrasonic Multipath

Flowmeter

1.2.6 Path configurations

The simplest arrangement is to have a number of paths “in line” above each other. This

would be suitable for a channel of regular cross section shape, which is straight for a long

distance compared with its width (5 to 10 times).

Other configurations are often used in other circumstances. For example:

• Crossed paths where there is uncertainty about the flow direction

• Sloping paths where the de pth is greater on one side compared with the other

• Transducers inset from the banks

• Multiple sets of paths for compound channel shapes

• V configuration used to divide the width because of size or uneven profile

• Multiple channels

• Reflected paths where transducers are on one side only and reflectors “bounce” the

sound pulses back from the far side. This method saves cable but increases path lengths

and is very sensitive to misalignment.

The Sarasota 2000 flowmeter is capable of being configured for these and many other

situations. Please consult Thermo Fisher Scientific for examples and advice.

1.2.7 Transducer frequency

Transducers are manufactured with characteristic frequencies. These will be in the range 1

MHz to 100 kHz. For propagation reasons, the greater the path lengths the lower the

frequency and the larger the transducer. As a guide, path lengths below 10 metres would use

1MHz transducers, 10 to 80 metres 500 kHz, 80 to 150 metres 250 kHz. These figures are for

guidance and the selection may be influenced by other factors relating to the application. For

example, lower frequency transducers may be used to improve penetration in conditions of

high suspended solids provided there is sufficient depth and velocity.

Please consult Thermo Fisher Scientific for advice.

1.2.8 Minimum depth of water

In order to avoid reflections from the bed or surface causing distortion of the ultrasonic

signals, a minimum height of water is necessary above each path. This depends on the

transducer frequency and the path length.

H

= 27 √ ( L / ƒ )

min

INTRODUCTION

Where:

is the minimum height of water above the path, in metres

H

min

L is the path length, in metres

ƒ is the transducer frequency, in hertz

A similar restriction applies to the channel bed, particularly if it is smooth and reflects rather

than absorbs an acoustic signal. The minimum depth of water is therefore usually 2 x H

Section 1 INTRODUCTION Page 1-6

min

Thermo Fisher Scientific

Page 17

Sarasota 2000 Ultrasonic Multipath

Flowmeter

1.2.9 Performance estimates

ISO 6416 describes how to estimate the uncertainty of measurement in any particular

installation. Please consult Thermo Fisher Scientific for advice on this.

1.3 Implementation of the principles of operation in the Sarasota 2000

The principles described in Section 1.2 are used by the Sarasota 2000 subject to certain rules

as listed below. See also Appendix 1:LCD Screens and Appendix 2:GAFA Screens that

describe in detail how the flowmeter is programmed via the LCD screen or PC. Note that the

Sarasota 2000 is a multi-channel device and so paths and levels may be allocated to up to 4

different channels. Overall “station” information (“S” screens) should be entered before

individual channel data (“C” screens). The comments below are how the flowmeter treats

each channel. There are some exceptions, for example, measurement units and flow method

which are common to the station.

Flow

• There is a choice of mean or mid section method of flow calculation.

• The channel cross section shape is entered as a height/width table independent from the

path lengths and angles. (For rectangular or trapezoidal channels it is only necessary to

enter 2 points to define the channels.) The separate table allows the path velocities to be

applied to more accurate slice areas since the defined shape is used rather than a fixed

width for each slice as specified in the Standard.

• Where no path velocity is available, for example at low water height, flow may be inferred

from water level. This is done via a flow estimation table, which may be derived

empiricall y o r by calculation.

Velocity

• The upstream velocity transducers are connected to the upper row of connectors,

downstream to the lower row.

• Path numbering is from the bottom.

• Paths are automatically brought into operation according to the water level and the

programmed minimum water cover.

• Paths entered as being at the same height are taken as crossed, otherwise they are

separate.

• Separate paths may be “normal” with transducers on each side or “reflected” with

transducers on one side only. The latter method saves cable but is not recommended

because of the increased path lengths and sensitivity to alignment.

• The velocities calculated by a pair of paths comprising a crossed path are averaged and

the average velocity used for the slice. The velocity calculated by a separate path is used

alone for the slice.

• When a velocity path fails, the slice boundaries automatically adjust to use only the

working paths.

• A failed path will show on the status indicated on screen C11: Instantaneous Flow &

Level. The path status is a percentage of the “instantaneous” transducer firings which

result in successful reception. If this figure drops below 12% the path is considered to

have failed during the corresponding instantane ous cycle time and is discarded for that

cycle. This could be the result of a fault, misalignment or obstruction.

• Only valid velocity paths which are in the water and covered by sufficient water to be

operating are used for the status indication.

• Each path may have a multiplying factor (“X Factor”) assigned to it. This will normally be 1

but may be different in exceptional circumstances for calibration purposes. An example of

when this might be is when the transducers are not exactly at the channel edges .

• Transducers in each velocity path may be set to operate simultaneously (the norm) or

sequentially. Simultaneous operation allows more measurements in a given time but

INTRODUCTION

Section 1 INTRODUCTION Page 1-7

Thermo Fisher Scientific

Page 18

Sarasota 2000 Ultrasonic Multipath

Flowmeter

there is a small possibility of confusing a signal reflected back to the firing transducer with

one received from the opposite transducer.

Water level

• Levels are combined in the following algorithm:

Only non-faulty measurements are used.

Highest and/or lowest are discarded until 3 remain.

The one furthest from the others is dis carded leaving 2.

The remaining 2 measure ments are averaged for arbitrated level if within an

acceptable band defined on screen C20: Channel Configuration.

If not, level determination fails and flow cannot be calculated.

If only 1 level measurement is installed or only 1 is not discarded, it is used as the

arbitrated level.

If not OK, level fails and flow cannot be calculated.

• Levels defined as valid but rejected by the algorithm will be indicated on the level status,

screen C10: Instantaneous Flow & Level.

• Where the flowmeter is installed in a closed conduit which always runs full, the channel

shape is entered in the usual way but there is no need for a level measurement. The

flowmeter is programmed as though it had an encoder level input (section 2.3.3.2.3) with

a reference level at the top of the conduit and a cal. factor of zero.

Transducer and bed levels

All heights may be set to a fixed datum (local or national) or relative to mean bed level. The

former requires a height for the bed and avoids re-entering all path and level transducer

heights in the event of a change to the bed.

General

• “Instantaneous” means the average over the cycle time scale. This defaults to 10

seconds but may be set to 1 minute for large numbers of paths or long path lengths via

screen S22: Station Configuration.

• The average period is the time over which measurements are averaged for the purpose

of output or logged data. If the cycle time is set to 1 minute, the average period cannot be

shorter.

• At the data logging intervals, the averaged values of the selected data are stored.

• Analogue inputs will normally be linear. However, screen C212: Analogue Input allows

non linear characteristics to be entered.

• When operating on an external 12 volt source, for example from a solar panel, power

saving is possible by using intermittent operation. Power consumption in normal and

intermittent modes is quoted in the Appendix 3:Specification

• The LCD display will turn off 15 minutes after the last keyboard operation. This is to

reduce power and prolong LCD life. Pressing any key will turn it on again.

INTRODUCTION

Section 1 INTRODUCTION Page 1-8

Thermo Fisher Scientific

Page 19

Sarasota 2000 Ultrasonic Multipath

Flowmeter

SYSTEM COMPONENTS

2 SYSTEM COMPONENTS

2.1 Flowmeter system overview

• The Thermo Scientific Sarasota 2000 is an ultrasonic multi-path flowmeter, which

complies with ISO6416.

• It employs state of the art technology to achieve excellent performance in conditions

which have previously be en outside the scope of this type of instrument.

• Smart transducer technology incorporating drive and receiver circuits optimises signal to

noise ratio and minimises losses. The smart circuits are located inside the transducer

housings except for the 1 MHz transducers. In that case they are in sealed in-line

housings known as Tboxes.

• Automatic adjustment of receiver gain and transducer drive voltage (HT).

• Low power consumption and intermittent modes make mains free operation feasible.

• Multi-path operation, (up to 32 via multi-drop facility made possible by smart transducer

addressing.)

• Multiple depth inputs,

- up to 16 ultrasonic depth transducers

- up to 4 auxiliary depth gauges (via 4-20 mA inputs.)

- up to 2 auxiliary depth gauges via BCD inputs

- up to 2 depth inputs via pulses direct from direct from shaft encoder.

• Multiple flow channels – up to 4 separate channels measured by a sin gle instrument. The

velocity pa ths and depths are allocated to the channels durin g set up.

• Up to 4 analogue 4-20 mA outputs and two 16 bit binary coded decimal (BCD) I/Os

• O v er a l l s y st e m al ar m re l ay

• Four relays (volt free contact) option. Programmable, for example for alarms, status,

totaliser pulses.

• Three serial ports. RS232 for PC, RS232 for modem and RS485 for site multi-drop

instrument communications

• IR communication link alternative for PC

• Internal data logger, 1 Mbyte capacity, programmable.

• Water temper ature measurem e nt at each smart transducer (except 1 MHz transduc e r s )

Section 2, SYSTEM COMPONENTS, Page 2-1

Thermo Fisher Scientific

Page 20

Sarasota 2000 Ultrasonic Multipath

Flowmeter

2.2 Family tree

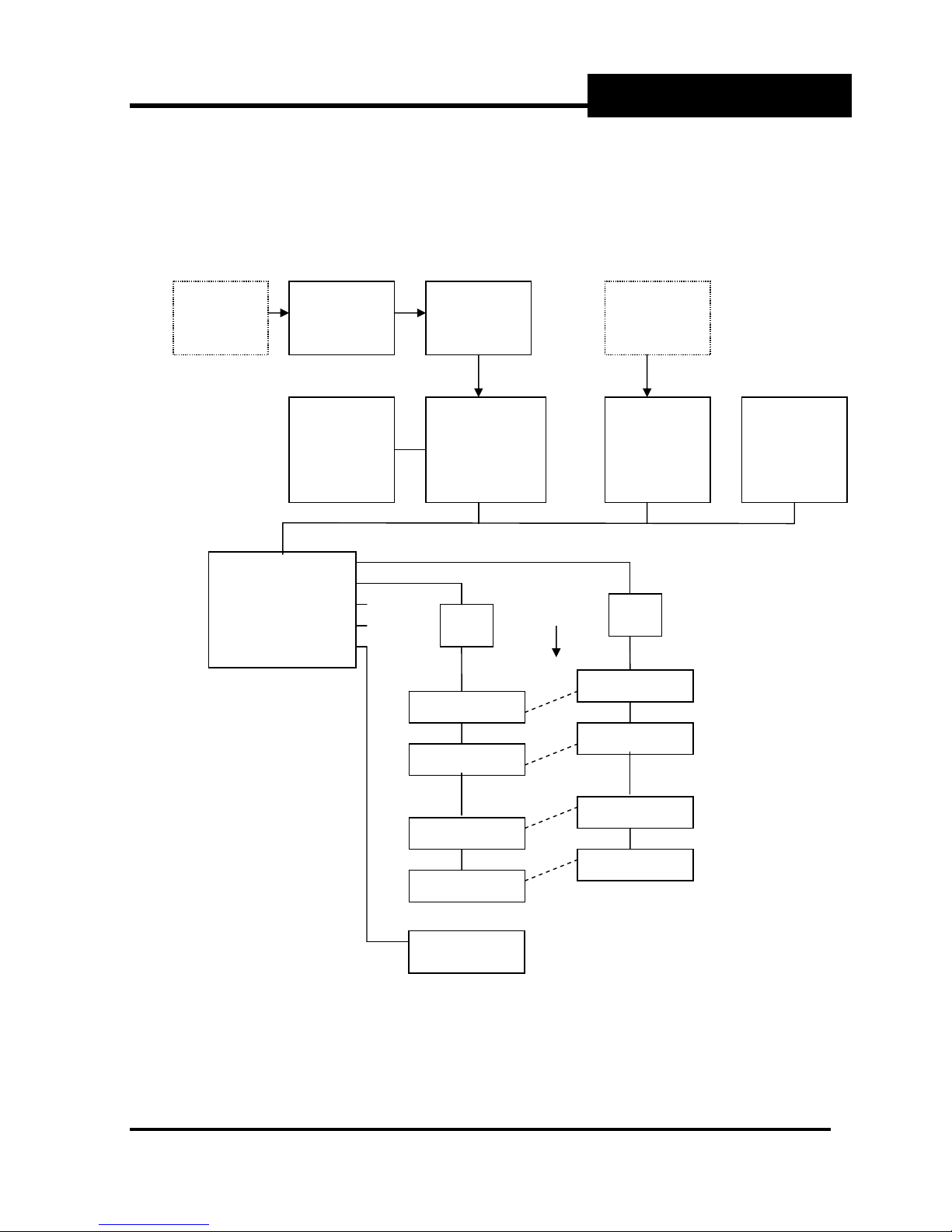

The schematic diagram below is an illustration of a four path system.

SYSTEM COMPONENTS

External

power

source

Transducer A u/s

interface A d/s

(option B u/s

of 1 to 4) B d/s

Level W

Power

supply

Display and

keyboard

Battery

Central

Processor Unit

inc. 3 x serial

I/O & system

relay

Star

J box

Trans. 1 d/s

Trans. 2 d/s

Flow

Auxiliary

depths

Input/output

4-20 mA,

BCD

(option of

none,1,or 2)

Star

J box

Trans. 1 u/s

Trans. 2 u/s

Relays

(4 x VFC)

(optional)

Section 2, SYSTEM COMPONENTS, Page 2-2

Trans. 3 u/s

Trans. 3 d/s

Trans. 4 u/s

Trans. 4 d/s

Level

Transducer

Thermo Fisher Scientific

Page 21

Sarasota 2000 Ultrasonic Multipath

Flowmeter

2.3 Flowmeter contents and options

2.3.1 Flowmeter layout

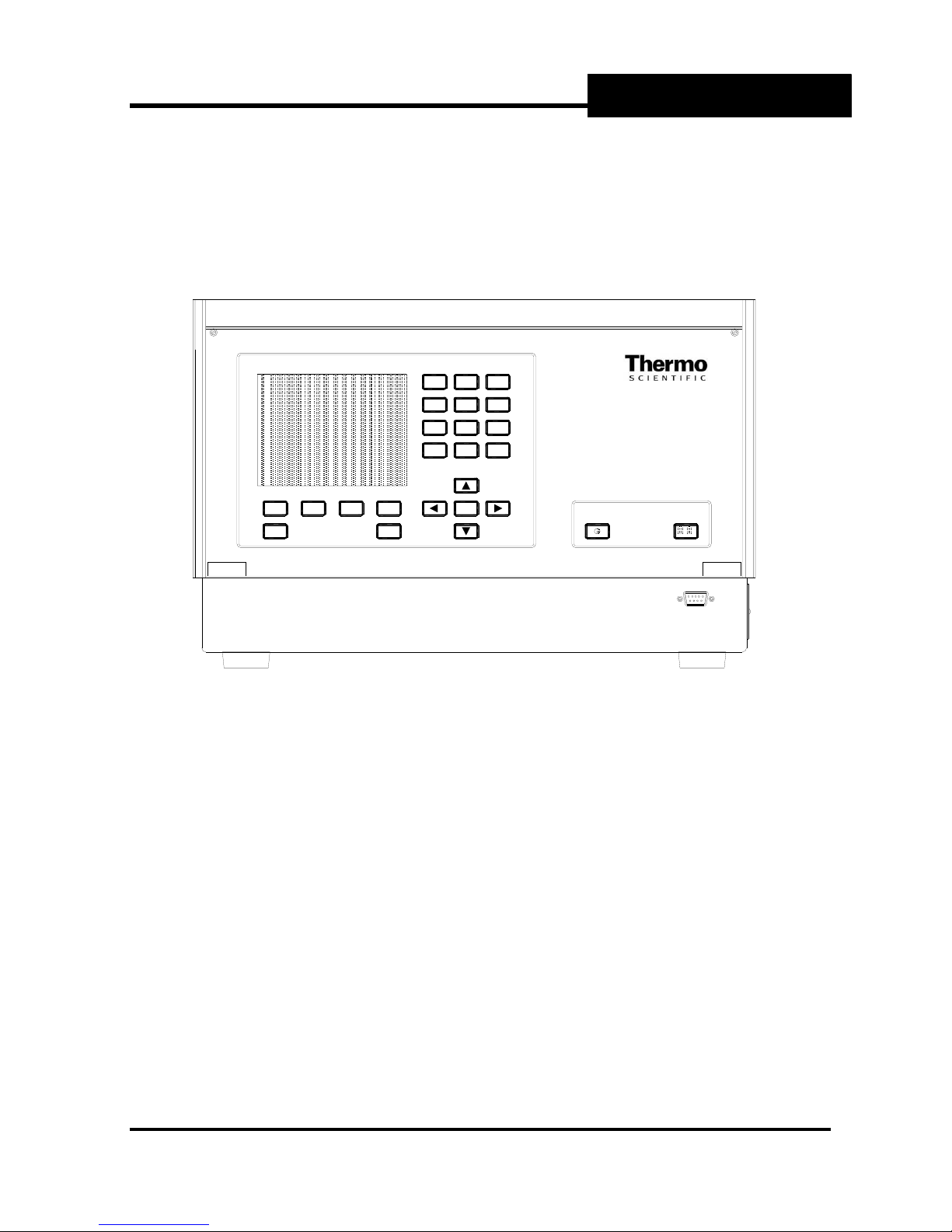

Fig 1 Sarasota 2000 Flowmeter

Fig 1 shows the front panel view with keyboard, LCD display and status indicator. Also shown

are the IR link and RS232 port, which are alternative methods of connection to a PC, see

Section 2.6.

The contents are described in Sections 2.3.2 (the “core” items which are always present) and

Section 2.3.3 (the items which are optional depending on the number of paths and I/O

requirements).

The keyboard allows access to the flowmeter firmware for setting up and interrogation

purposes, using the display. This is described in Section 2.5

Fig 2 is the same view with the front panel removed to show the layout of the electronic cards,

fuses and power switches.

s„˜„™•š„@m›’šŒ–„š‹@u’š˜„™•”Œ†@f’•ž@mˆšˆ˜

esc

alarm

reset

RS

TQUV

W

XY

P

KOMN

enter

SYSTEM COMPONENTS

status

i˜da

rsRSR

Section 2, SYSTEM COMPONENTS, Page 2-3

Thermo Fisher Scientific

Page 22

Sarasota 2000 Ultrasonic Multipath

Flowmeter

T3.15A F5A

MAINS ISOLATE

SYSTEM COMPONENTS

RS232

Fig 2 Sarasota 2000 Flowmeter internal components

Main rack, from left to right:-

Power supply with fuses and powe r s wi t c h es ( s e e 2. 3 .2.1)

Card position 1 - Status/power management card

Card position 2 - I/O card 1 (if fitted) (see 2.3.3.2)

Card position 3 - I/O card 2 (if fitted)

Card position 4 – Reserved for future enhancements

Card position 5 – Reserved for future enhancements

Card position 6 - TIF 4 (Transducer interface card 4) (if fitted)

For connection to up to 8 velocity paths (16 transducers) via rear panel connectors G

and H, upstream (u/s) and downstream (d/s) and up to 4 ultrasonic depth transducers via

connector Z (see Fig 4 and 2.3.3.1)

Card position 7 - TIF 3 (if fitted)

Rear panel connectors E,F for up to 8 velocity paths and Y for up to 4 depths.

Card position 8 - TIF 2 (if fitted)

Rear panel connectors C,D for up to 8 velocity paths and X for up to 4 depths.

Card position 9 - TIF 1 (always fitted)

Rear panel connectors A,B for up to 8 velocity paths and W for up to 4 depths.

Card position 10 - Central Processor (CPU) (see 2.3.2.2)

The plinth, beneath the main rack, houses the internal battery (see Section 2.3.2.1), the

connectors (see Fig 5) and the relay card.

Note

Power should be switched off and the isolate switch turned off before any cards are

removed or plugged in.

Section 2, SYSTEM COMPONENTS, Page 2-4

Thermo Fisher Scientific

Page 23

Sarasota 2000 Ultrasonic Multipath

Flowmeter

2.3.2 Core items

The enclosur e houses t he followi ng core it ems as well as the opt ional items listed i n Sectio n

2.3.3:

• power supply and status/power management.

• internal battery

• central processor

• display and keyboard

• connectors for transducers and peripheral devices.

2.3.2.1 Power supply

The standard power supply requires a mains input between 85 and 264 volts AC, 47 to 64 Hz,

backed by an internal 12 V battery for operation in the event of AC power failure.

The fuses shown above are 3.15AT (slow blow) for the mains electricity input and 5AF (quick

blow) for the low voltage from the power supply module.

The “POWER” switch isolates the flowmeter and its internal battery from the external (AC)

power source. When switched off, the flowmeter will continue to operate from the internal

battery unless the “ISOLATE” switch is also off. The “ISOLA TE” switc h disco nnect s all powe r

from the flowmeter.

The internal battery is automatically charged by the power supply when external power is

being supplied and the “POWER” switch is on, regardless of the position of the ISOLATE

switch. When the external supply is off the battery is capable of operating the flowmeter for a

minimum of 24 hours. This period will be longer in cases when INTERMITTENT OPERATION

is being used.

Alternatives of 12 V dc and 24 V dc power sources are available as described in Appendix 3:

Specification.

See Appendix 3: Specification for details of power saving through intermittent operation

2.3.2.2 Central processor (CPU)

The central processor carries out the control and timing functions, stores and runs the

operating program and stores the data logs. It controls the status indicator, see “controls and

displays”, Section 2.5.

It also controls the three s erial i/o ports. See section 2.3.2.4

2.3.2.3 Keyboard and display

The keyboard allows the operator to program the flowmeter and to display measurements,

computed results and diagnostic information via the display (see Section 2.5). These

functions may alternatively be performed via the PC based GAFA software (see Appendix 2:

GAFA Screens).

SYSTEM COMPONENTS

.

Section 2, SYSTEM COMPONENTS, Page 2-5

Thermo Fisher Scientific

Page 24

Sarasota 2000 Ultrasonic Multipath

Flowmeter

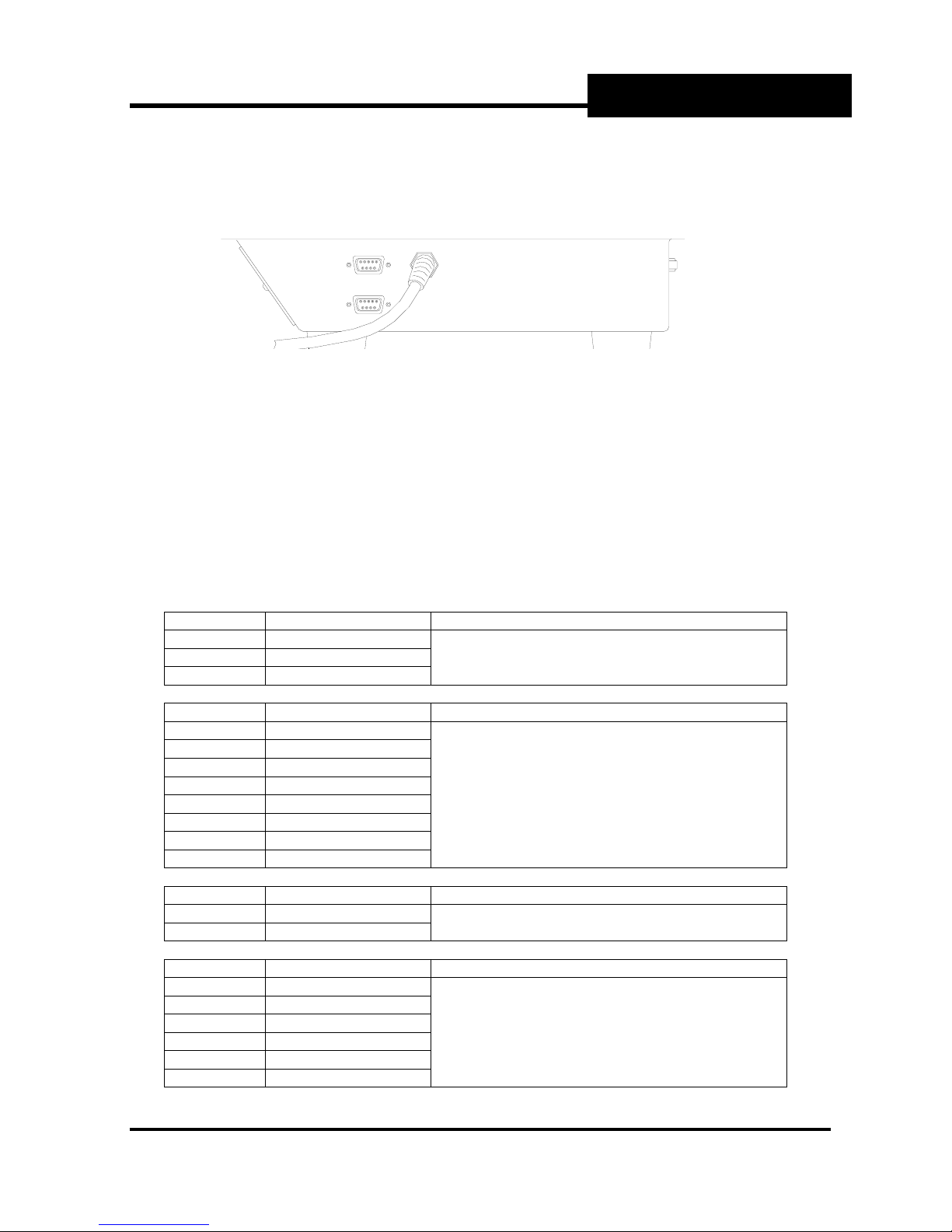

2.3.2.4 Serial connections

MODEM (RS232)

RS485

Fig 3 Side panel serial connections

There are 3 serial ports:

• RS232 via 9 way D connector (female) on the front of the plinth. See Figs 1 & 2. This port

is used for connection to a PC.

• RS232 via 9 way D connector (male) on the side of the plinth. See Fig 3. This port is used

for connection to a modem.

• RS485 via 9 wa y D connect or (female) on the side of the plinth. See Fig 3. This port is

used for multi-drop instrument connection networks using Modbus protocol in full or half

duplex as set up via the front panel (Appendix 1: LCD Screens). Jumper links on the CPU

board may need to be altered depending on the load conditions. Please consult Thermo

Fisher Scientific for instructions on setting these links.

Pin (F) Signal Comment

2 TxD

3 RxD

5 0V

Pin (M) Signal Comment

1 CD

2 RxD

3 TxD

4 DTR

5 0V

7 RTS

8 CTS

9 R1

Pin (F) Signal Comment

8 B

9 A

Pin (F) Signal Comment

3 0V

4 -RxD

5 +RxD

7 0V

8 -TxD

9 +TxD

RS232, PC connection

Front panel 9 way female D connector

RS232, Modem connection

Side panel 9 way male D connector

RS485, 2 wire connection

Side panel 9 way female D connector

RS485, 4 wire connection

Side panel 9 way female D connector

SYSTEM COMPONENTS

Section 2, SYSTEM COMPONENTS, Page 2-6

Thermo Fisher Scientific

Page 25

Sarasota 2000 Ultrasonic Multipath

Flowmeter

2.3.3 Optional items

The flowmeter enclosure also houses an optional number of the following cards:

• Transducer interface cards (TIFs) (up to 4 may be fitted).

• I/O card (none, 1 or 2 may be fitted)

• Relay (VFC) card (none or 1 may be fitted)

Details are given in Appendix 3: Specification section, but in summary:

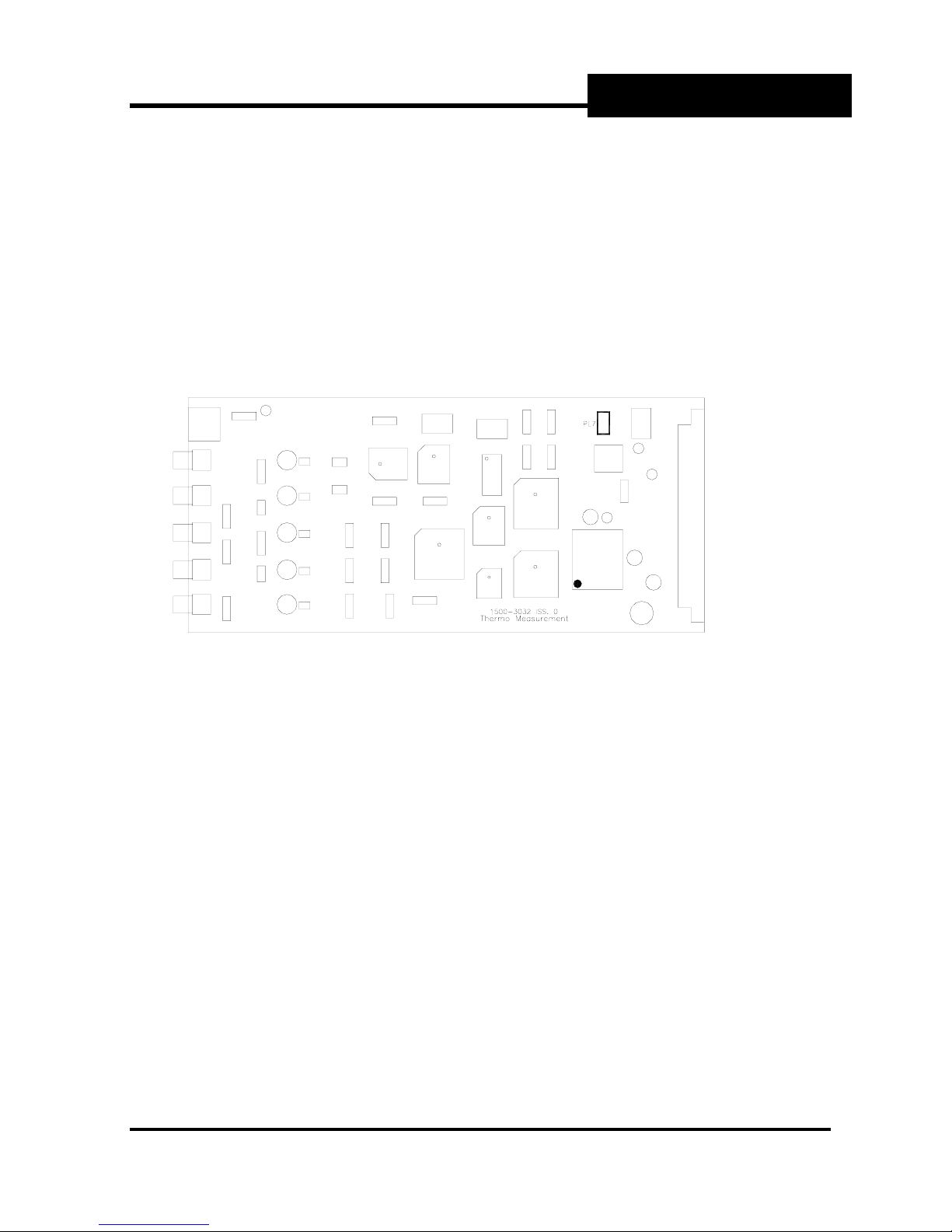

2.3.3.1 Transducer interface card (TIF)

SYSTEM COMPONENTS

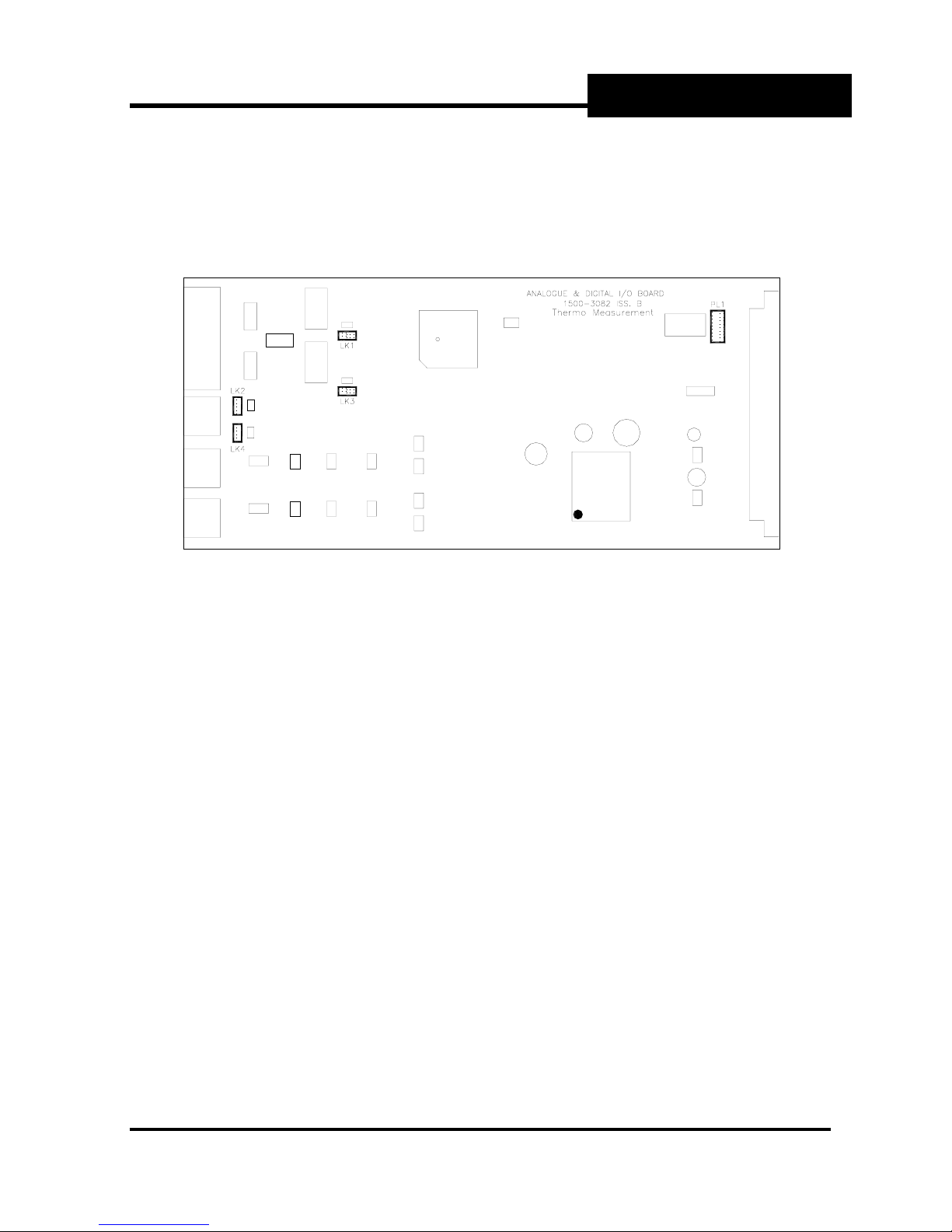

Fig 4 Transducer Interface Card (TIF)

The flowmet er has capacity for up to four TIFs as st andard. Each one is capable o f being

connected to 2 velocity paths (4 transducers) directly or 8 paths (16 transducers) by multidrop, and 1 ultrasonic depth transducer directly or 4 by multi-drop. Each TIF must have its

address set via the jumper links PL7 shown in the diagram above. The addresses are in the

form of a binary code with the least significant digit at the top of PL7. No link for 0; link present

for 1.

TIF1, card position 9, address 4, PL7 Links 0100

TIF2, card position 8, address 5, PL7 Links 0101

TIF3, card position 7, address 6, PL7 Links 0110

TIF4, card position 6, address 7, PL7 Links 0111

When setting up the flowmeter, the cards and their addresses are programmed via the

keyboard and screens as described in Appendix 1: LCD Sc reens or v ia GA FA as desc ribed in

Appendix 2: GAFA Screens. When a TIF is changed during service, the replacement must

have the same address set.

Section 2, SYSTEM COMPONENTS, Page 2-7

Thermo Fisher Scientific

Page 26

Sarasota 2000 Ultrasonic Multipath

Flowmeter

Each TIF plugs into the main rack and is wired to the back panel co-axial connector pairs A to

H for onward connection to the velocity path transducers and W to Z for connection to

ultrasonic depth transducers at the time of installation. Fig 5 shows the rear panel connectors.

TIF 1 in card position 7 is connected to A and B and to W.

TIF 2 in card position 6 is connected to to C and D and X etc.

Note that the upstream velocity transducers must be connected to the upper row of A to H

and the downstream ones to the lower row.

The standard rear panel allows connections to 32 velocity paths (64 transducers) and 16

ultrasonic depths via “multi-drop” wiring of the smart transducers.

The velocity transducers may be allocated to up to 4 water channels without any restriction

other than the total number and cable lengths. Ultrasonic depth transducers are limited to 4

per channel via multi-drop. See Section 2.4.

SYSTEM COMPONENTS

PATH A B C D E F G H

FLOW

W Y

X Z

DEPTH

BCD1

BCD2

21

16

15

543876

1817 19 2120 22

9

1210 11 13 14

23

2624 25 2827

Fig 5 Rear panel connections

The top row of coaxial connectors are for the upstream transducers, the bottom row for the

downstream ones.

Paths may be connected individually, for example, path 1 to A, 2 to B etc, or multi-dropped via

star junction boxes. For example, paths 1 to 4 connected to A etc.

Ultrasonic depths may be connected individually to W,X,Y,Z or multi-dropped via star boxes.

For BCD and analogue connections, see Section 2.3.3.2

Section 2, SYSTEM COMPONENTS, Page 2-8

Thermo Fisher Scientific

Page 27

Sarasota 2000 Ultrasonic Multipath

Flowmeter

2.3.3.2 Input/Output card.

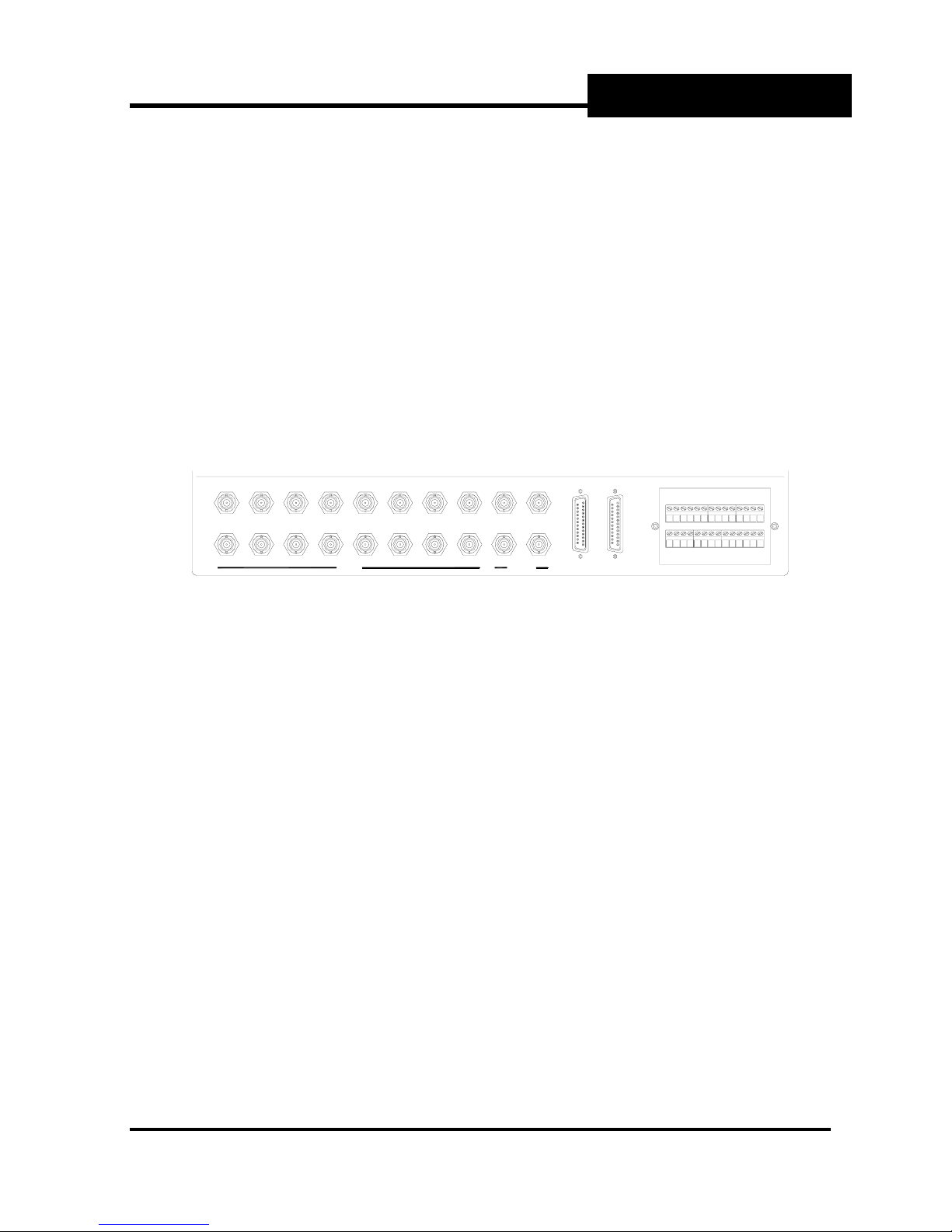

2.3.3.2.1 I/O card layout

SYSTEM COMPONENTS

Fig 6 I/O card

Most flowmeters will require this facility. Up to two I/O cards may be fitted.

The cards have an address which is set on the links PL1 as shown in Fig 6. This is similar to

the TIF addressing, with least significant digit at the top.

I/O 1, card position 2, address 2, PL1 Links 0010

I/O 2, card position 3, address 3, PL1 Links 0011

Each I/O card has:

• Two analogue outputs (normally 4-20 mA)

• Two analogue inputs (normally 4-20 mA)

• 16 bi t di gi ta l I /O (4 x 4 bit b i na ry c od e d dec i mal dig it s (B C D)). I n p ut or ou tp ut , s ele c te d b y

jumper on I/O card.

• Phased encoder depth i/p

Fig 5 shows the positions of the connectors. The phased encoder depth inputs share the BCD

connectors .

Section 2, SYSTEM COMPONENTS, Page 2-9

Thermo Fisher Scientific

Page 28

Sarasota 2000 Ultrasonic Multipath

Flowmeter

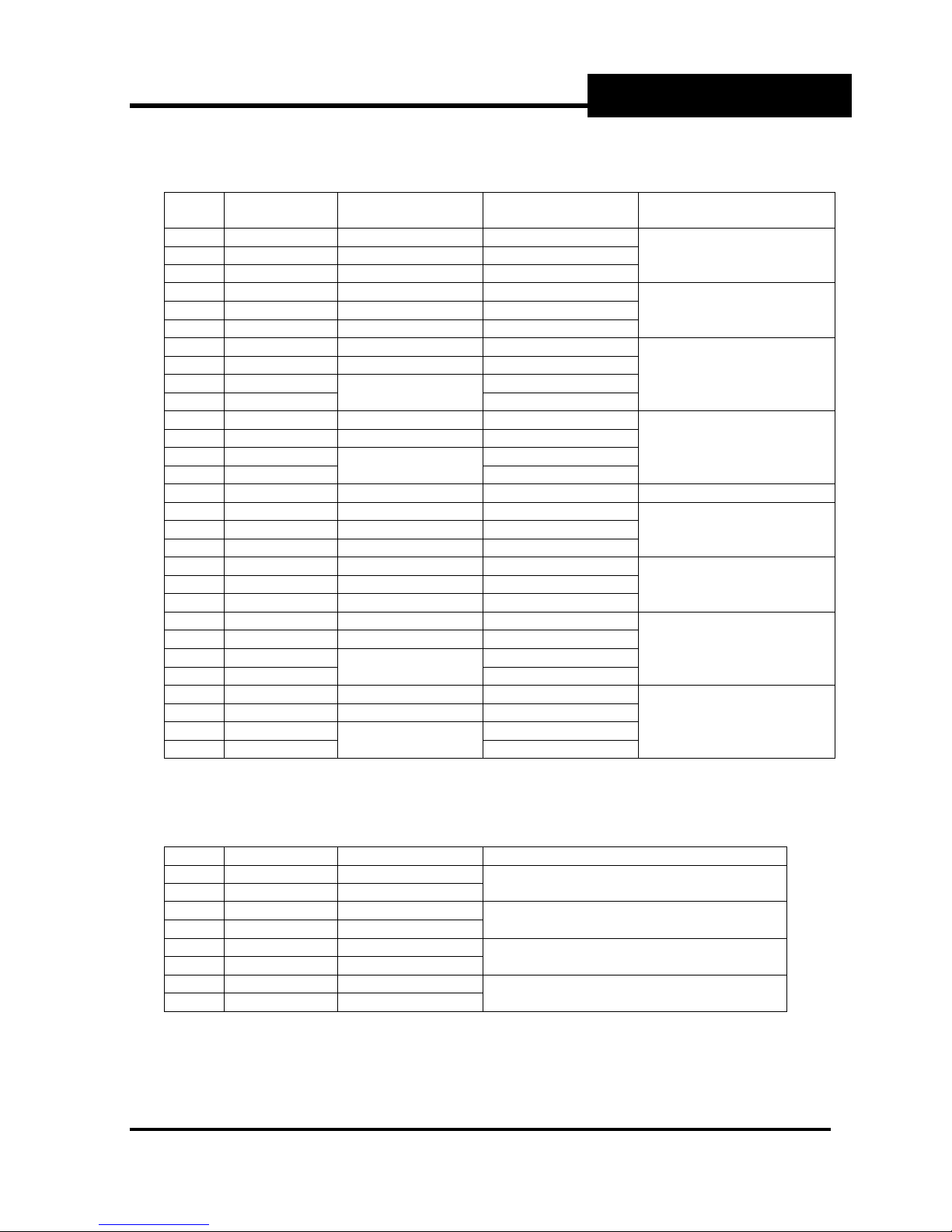

2.3.3.2.2 Analogue I/O

Analogue connections are normally 4-20 mA and are made to the screw terminal blocks at the

right of the rear panel. The upper block connects to I/O board 1 and the lower to I/O board 2.

Connections 1 to 6 (upper) and 15 to 20 (lower) are the analogue inputs. Connections 7 to 14

(upper) and 21 to 28 (lower) are the 4-20 mA outputs.

The table whi c h f ol l o ws s hows the connections.

Analogue inputs, 4-20 mA (0-20mA) or 0-5V

The total input range is 0-20mA though analogue inputs are normally set up as 4-20 mA. On

board links LK2 and LK4 may be removed to accept 0 to 5 volts instead (Fig 6).

Each i/p has 3 connections, 18 V excitation, input and 0V.

If the external signal source supplies the power, connections are made to input (4-20 mA +)

and to 0V (4-20 mA-).

If the Sarasota 2000 flowmeter is to power the loop, connections are made to 18V (4-20 mA+)

and to Input (4-20 mA-)

Analogue outputs, 4-20 mA

Analogue outputs are always 4-20 mA.

Each o/p has 4 connections, 18V excitation, +V, -V and 0V.

If the Sarasota 2000 flowmeter is to power the loop, the output will not be isolated. A link is

made between 18V and +V and the 4-20 mA loop is between –V and 0V.

If the external device powers the loop, the output is isolated. The 4-20 mA loop is between +V

and -V

Note For compliance with EMC emissions control, analogue i/o cables should be screened

and the screen connected to one of the 0V pins for each i/o card.

See the following table for connection details.

SYSTEM COMPONENTS

Section 2, SYSTEM COMPONENTS, Page 2-10

Thermo Fisher Scientific

Page 29

Sarasota 2000 Ultrasonic Multipath

Flowmeter

4-20 mA CONNECTIO N S (Refer to Fig 5)

Pin Signal Connect for Internal

loop power

1 0V N/C 4-20 mA 2 Input 4-20 mA - 4-20 mA +

3 18V excitation 4-20 mA + N/C

4 0V N/C 4-20 mA 5 Input 4-20 mA - 4-20 mA +

6 18V excitation 4-20 mA + N/C

7 0V 4-20 mA - N/C

8 -V 4-20 mA + 4-20 mA 9 +V 4-20 mA +

10 18V

11 0V 4-20 mA - N/C

12 -V 4-20 mA + 4-20 mA 13 +V 4-20 mA +

14 18V

15 0V N/C 4-20 mA 16 Input 4-20 mA - 4-20 mA +

17 18V excitation 4-20 mA + N/C

18 0V N/C 4-20 mA 19 Input 4-20 mA - 4-20 mA +

20 18V excitation 4-20 mA + N/C

21 0V 4-20 mA - N/C

22 -V 4-20 mA + 4-20 mA 23 +V 4-20 mA +

24 18V

25 0V 4-20 mA - N/C

26 -V 4-20 mA + 4-20 mA 27 +V 4-20 mA +

28 18V

Link 9-10

Link 13-14

Link 23-24

Link 27-28

0 – 5 V CONNECTIONS (Refer to Fig 5)

Alternative connections require links LK2 and LK4 to be removed (Fig 6).

Pin Signal Connection Comment

1 0V 0-5 V –ve

2 Input 0-5 V +ve

4 0V 0-5 V –ve

5 Input 0-5 V +ve

15 0V 0-5 V –ve

16 Input 0-5 V +ve

18 0V 0-5 V –ve

19 Input 0-5 V +ve

Connect for external

loop power

N/C

N/C

N/C

N/C

I/O card 1, input 1

I/O card 1, input 2

I/O card 2, input 1

I/O card 2, input 2

SYSTEM COMPONENTS

Comment

I/O card 1, Input 1

I/O card 1, Input 2

I/O card 1, Output 1

Int powered, not isolated

Ext powered, isolated

I/O card 1, Output 2

Int powered, not isolated

Ext powered, isolated

I/O card 2, Input 1

I/O card 2, Input 2

I/O card 2, Output 1

Int powered, not isolated

Ext powered, isolated

I/O card 2, Output 2

Int powered, not isolated

Ext powered, isolated

Section 2, SYSTEM COMPONENTS, Page 2-11

Thermo Fisher Scientific

Page 30

Sarasota 2000 Ultrasonic Multipath

Flowmeter

2.3.3.2.3 16 bit BCD I/O and encoder input

The 16 bit parallel BCD signal may act as either input or output according to the jumper links

LK1 and 3 on the board. See Fig 6. The default condition is for BCD INPUT

example from a shaft encoder counter.

The format is 5 Volt positive logic, though the input can accept inverted logic if specified via

the screens (Appendix 1: LCD Screens).

Handshaking is via strobes STRB1 and STRB2. STRB1 relates to bits 1 to 8 and STRB2 to

bits 9 to 16.

There are two 25 way female D connectors labelled BCD1 and BCD2. BCD1 is connected to

I/O option card 1 if fitted and BCD2 to I/O option card 2 if fitted.

BCD input

• When used as an input, the 4 digit BCD number is normally used as an auxiliary level.

• Operating units are selected via the screens (Appendix 1: LCD Screens) or GAFA

(Appendix 2: GAFA Screens).

• The BCD number may have an offset applied – “level above datum” if B CD zero does not

correspond to the flowmeter zero level.

• The BCD number may also have a scaling factor applied, for example if a BCD

incremental value of 10 corresponds to 5 mm, the scaling factor is 0.5.

• If the scaling factor is given a negative sign, the BCD input will be taken as negative logic

(low is “1”)

• For BCD input, the STRB is pulled low for 0.2 ms by the Sarasota 2000 when it wants

data.

BCD Output

• When used as an output, the function of the 4 digit BCD number and operating units are

selected via the screens (Appendix 1) or GAFA (Appendix 2). Typically the function will

be flow or water level.

•

For BCD output, the STRB is pulled low for 0.2 ms whilst valid data is being presented.

•

BCD output may be uncoded, in which case the BCD number is taken as it appears, or

coded in which case the first digit indicates a range/sign and the remaining 3 digits the

value. The coding is defined as follows:

Coding for flow

The data is represented as a 4 digit number where the most significant digit is the code:

0 = multiply by 10

1 = multiply by 10

2 = multiply by 10

3 = fault condition, no data

4 = negative flow multiply by 10

5 = negative flow multiply by 10

6 = negative flow multiply by 10

The three remaining digits are the three most significant digits of the reading;

e.g. Flow + 4.28 m3/s Output 0428

Flow +34.28 m3/s Output 1342

Flow - 0.15 m3/s Output 4015

Coding for level

The level data is presented as a 4-digit number, representing the last 4 digits of the displayed

value.

e.g. Flow + 4.123 m Output 4123

Flow +52.678 m Output 2678

0

(i.e. x 1)

1

(i.e. x 10)

2

(i.e. x 100)

0

(i.e. x -1)

1

(i.e. x -10)

2

(i.e. x -100)

SYSTEM COMPONENTS

– no links, for

Section 2, SYSTEM COMPONENTS, Page 2-12

Thermo Fisher Scientific

Page 31

Sarasota 2000 Ultrasonic Multipath

Flowmeter

Encoder input

The BCD connector also provides the means of connection to the two-phase outputs direct

from a shaft encoder as an optional means of depth input. The Sarasota 2000 flowmeter will

count the pulses up and down to track the depth changes. It is necessary to set the pulse

scale, i.e. the distance corresponding to each pulse, and the counter value at a known depth.

See Appendix 1: LCD Screens (screen C213: Encoder Input Configuration) for the method of

setting up.

BCD/ENCODER CONNECTIONS (Refer to Fig 5)

25 D Pin Signal Comment

1 0V

2 D1

3 D3

4 D5

5 D7

6 0V

7 D9

8 D11

9 D13

10 D15

11 0V

12 INT Encoder phase 2

13 +5V

14 D0

15 D2

16 D4

17 D6

18 STRB1

19 D8

20 D10

21 D12

22 D14

23 STRB2

24 TC0 Encoder phase 1

25 0V

Note For compliance with EMC emissions control, BCD/Encoder i/o cables should be

screened and the screen connected to one of the 0V pins for each i/o card.

SYSTEM COMPONENTS

Section 2, SYSTEM COMPONENTS, Page 2-13

Thermo Fisher Scientific

Page 32

Sarasota 2000 Ultrasonic Multipath

Flowmeter

2.3.3.3 Relay (Volt free contact) card

The relay card consists of 4 programmable relays and a fa ult relay wit h both normally open

and normally closed contacts. The connections are accessible by removing the cover plate on

the side of the plinth.

Fig 7 Relay connections

The function of each relay is specified by the operator. See Section 2.5.2 and Appendix 1:

LCD Screens.

For example, relay 2 coul d be programmed as a high flow alarm to switch on at a high flow

and off again at a lower value (hysteresis).

Note that if pulses are required for an external totaliser, the selection is limited to relay 1 on

the relay card. However, the standard relay may not be suitable for this if the pulse rate is

high. For this reason the relay card is being changed so that a solid state relay will replace

relay 1. The switching capacity will be lower but the pulse rate will be higher and there will be

no specified limit on the number of operations. Relay 1 will then only have “normally open”

connections. See Appendix 3: Specificat ion.

Please consult Thermo Fisher Scientific if in doubt about which type is fitted.

SYSTEM COMPONENTS

Section 2, SYSTEM COMPONENTS, Page 2-14

Thermo Fisher Scientific

Page 33

Sarasota 2000 Ultrasonic Multipath

Flowmeter

2.4 Ultrasonic transducers

Each velocity path requi res two transducers and each ultrasonic depth requi res one.

The transducers are available in a number of frequencies. See Section 1.2.6 for frequency

selection. The frequency of the ultrasonic depth transducer, if used, is not normally critical.

1 MHz is usually used if the velocity transducer frequency is 1 MHz or 500 kHz otherwise.

The diameter of the transducer is different for different frequencies. This is to maintain the

angular spr ead of the beam which is a function of frequency and di ameter.

The transducers for the Sarasota 2000 are “smart”, with local circuits for the drive voltage

(HT) generation and the receiver amplifier built in to minimise losses and optimise signal-tonoise ratio. In the case of the 1 MHz transducers the size of the transducer is limited and the

local circuit is separated from the transducer in a potted in-line housing called a “Tbox”,

Transducers may be wired individually to the flowmeter (rear panel connections A to H for

velocity and W to Z for depths) or, using the multi-drop method, via “star” junction boxes in

each transducer array. In the latter case up to 4 transducers may be joined to each rear panel

connector. A mixture of multi-drop and direct connections may be used. For example, if there

are 5 transducers in an array, 4 may be wired via a star box and the fifth wired directly.

The maximum capacity with direct connections is 8 paths and 4 ultrasonic depths.

The maximum capacity with multi-drop is 32 paths and 16 depths.

The transducers have programmable addresses. Addresses 1 to 4 are normally used. When

using multi-drop, the transducers connected to each star box must be pre-programmed with

different addresses to enable each one to be operated separately by the flowmeter. Specialist

equipment is necessary to programme the transducers and it is usual to supply them with

specified ad d r esses.

2.4.1 1 MHz transducers

For use with path lengths up to 10 metres. In cases where serious attenuation is anticipated

(for example, sewage) it is recommended that the use be restricted to 5 metres and a lower

frequency be used above that. Of course the lower frequency requires a greater depth of

water in which to operate and this must be taken into account (see Section 1).

An in-line Tbox is fitted in line with each transducer.

The co-axial cable from the T box must be connected t o a star b ox or exten ded to run direc tly

to the flowmeter. Coaxial cables to the flowmeter enclosure are usually made up on site.

Cables may be supplied to length with made up ends if specified with the order but this often

makes the installation more difficult where there is the need to pull cables through ducts.

2.4.2 500 kHz Transducers

For use with path lengths above 10 metres. In cases where serious attenuation is anticipated

(for example, sewage) it is recommended that 500 kHz transducer be used above 5 metres.

At the upper end, they may normally be used up to 80 metres. For cases where serious

attenuation is anticipated, lower frequency transducers should be used for paths above 50

metres.

SYSTEM COMPONENTS

Section 2, SYSTEM COMPONENTS, Page 2-15

Thermo Fisher Scientific

Page 34

Sarasota 2000 Ultrasonic Multipath

Flowmeter

The 500 kHz transducers have the HT and signal amplifiers built in. They are connected

directly to the flowmeter or via star boxes. If ultrasonic depth transducer(s) are being used, it

is usual to use 500 kHz frequency when that frequency is being used for water velocity

measurement.

The transducers are supplied with 5 metres of cable which is connected to a star box or

extended to run directly to the flowmeter. Coaxial cables to the flowmeter enclosure are

usually made up on site. Cables may be supplied to length if so ordered with made up ends

but this often makes the installation more difficult where there is the need to pull cables

through ducts.

2.4.3 Lower frequency transducers

Consult Thermo Fisher Scientific about low frequency transducers for path lengths above 80

metres or where conditions might attenuate higher frequency signals.

If ultrasonic depth transducer(s) are being used, it is usual to use 500 kHz frequency when

lower frequency transducers are being used for water velocity measurement.

2.4.4 Maximum cable lengths

Item From To Max

length

1 500 kHz transducer

(velocity or depth)

2 1 MHz TBox

(velocity or depth)

3 Star box Flowmeter 300 m Multi-drop

4 500 kHz transducer Star box 5 m Multi-drop

5 1 MHz Tbox Star box 5 m Multi-drop

6 500 kHz depth transducer Star box 50 m Multi-drop depth option

7 1 MHz depth TBox Star box 50 m Multi-drop depth option

Flowmeter 300 m Direct connection

Flowmeter 300 m Direct connection

SYSTEM COMPONENTS

Comment

(but see depth options items 6 & 7)

(but see depth option item 6)

(but see depth option item 7)

(star box max 5 m from flowmeter)

(star box max 5 m from flowmeter)

Section 2, SYSTEM COMPONENTS, Page 2-16

Thermo Fisher Scientific

Page 35

Sarasota 2000 Ultrasonic Multipath

Flowmeter

2.5 Controls and displays

2.5.1 Panel layout

Fig 1 shows the layout of the front panel. It contains the keyboard and liquid crystal display

(LCD). The keyboard is used to access the LCD and to:-

• programme the flowmeter with site data, for example. path lengths, angles, heights

• set up the inputs and outputs (including simulation for test purposes)

• set up the relay functions and values on which to switch

• display ultrasonic waveforms

• display measurements and results

• display diagnostic data

2.5.2 Screen organisation

The LCD screens are all numbered as listed in Appendix 1: LCD Screens.

The screens are arranged in levels, the lower levels being selected and accessed from the

one above.

When a lower level is displayed, it overlays the one above so that each is visible.

The ARROW keys move a highlighted area around each screen.

The ENTER key actions the highlighted instruction, for example to select a lower level screen.

The ESCAPE key reverts to the previous screen.

When the highlighted box requires data, the NUMBER keys are used.

The ENTER key st or es t ha t da t a in me m ory.

There are 4 FUNCTION keys at the bottom of the screen. Their function changes according to

what is dis played above them on the screen.

The display goes blank to save power 15 minutes after the last key stroke. Pushing any key

powers it up.

2.5.3 The status in dicator

The status indi cator operat es as fo l l o ws:

• Continuous green – contentment

• Continuous red – alarm condition exists or has occurred earlier and has not been

acknowledged. The meaning of this is defined by the user via screen S30: Fault Relay

Configuration, and details of the fault can be identified in screen S10: Fault Status (for

example, all faulty ultrasonic paths or depth paths).

• Either light flashing evenly – running on battery.

• Either light “blipping” on intermittently – running in power save intermittent mode.

• No light at all – power off and battery run down.

With the alarm reset key the operator acknowledges the alarm and resets it.

The operation and setting up are described in Section 4: Installation, Appendix1: LCD

Screens and Appendix 2: GAFA Screens.

Note that the GAFA PC software provides similar facilities either locally via the front RS232

connector or the IR link, or remotely via a modem.

SYSTEM COMPONENTS

Section 2, SYSTEM COMPONENTS, Page 2-17

Thermo Fisher Scientific

Page 36

Sarasota 2000 Ultrasonic Multipath

Flowmeter

2.6 Software & firmware

There are 2 types of software:

• The internal pre-loaded operating software, normally called “firmware”

• The PC software for communicating with the flowmeter, called “GAFA”

2.6.1 Operating firmware

The flowmeter is supplied with the operating firmware already loaded. It would not normally

be necessary to re-load the firmware. In the event that new firmware is to be loaded, Thermo

Fisher Scientific will provide the procedure or carry out the operation.

2.6.2 “GAFA” PC software

An optional facility is the GAFA software, which runs on a PC under Windows. This allows

communication with the flowmeter:-

• Via the RS232 port on the front of the plinth

• Via the IrDA link on the front panel

• Remotely via a modem connected to the RS232 port on the rear of the plinth

The functions possible via GAFA are:-

• S etting up the flowmete r in the same way as v ia the flowmeter control s and display as

described in 2.5 but with the benefit of superior PC display

• Interrogating the flowmeter for measured parameters and calculated results as 2.5 with

the same benefit

• Downloading logged data.

Appendix 2: GAFA Screens des cribes the GAFA.

2.7 Documentation

In addition to the hardware described in 2.3 and 2.4, and possible peripheral equipment, the

following documentation may also be supplied:

• A copy of this ma nual (additional copies m ay be supplied)

• Site specific data (Appendix A5: Site Data). Configuration and program data completed

by installation and commissioning engineers.

• Site specific drawings – transducer mounts, site layout, civil details (if part of contract)

• Certificate of conformity (specific test sheets available on request)

• Certificate of approval for Quality Management Sys tem

• On site calibration certificate (if included in the installation contract)

SYSTEM COMPONENTS

Section 2, SYSTEM COMPONENTS, Page 2-18

Thermo Fisher Scientific

Page 37

Sarasota 2000 Ultrasonic Multipath

Flowmeter

PERIPHERAL EQUIPMENT

3 PERIPHERAL EQUIPMENT

3.1 Additional items

A number of additional items will be required to complete a flowmeter system. These may

include:-

• Hardware to be installed in the channel on which to mount the transducers.

• Auxiliary depth gauge(s)

• Kiosk to house the flowmeter

• Communications equipment – for example modems, telemetry outstations, GSM

modems.

• Power supplies, for example solar power systems.

plus, often, some civil work for cable ducts, supporting piles etc.

The additional items are often supplied and installed by Thermo Fisher Scientific as part of

the contract, in which case details will be included in Appendix 5: Site Data Book.

3.2 Transducer mounting hardware

Thermo Fisher Scientific has extensive experience of transducer mounting system design and

maintains a comprehensive computerised library. Please consult Thermo Fisher Scientific for

a quotation to design and supply a suitable system.

Section 3, PERIPHERAL EQUIPMENT, Page 3-1

Thermo Fisher Scientific

Page 38

Sarasota 2000 Ultrasonic Multipath

Flowmeter

This page is blank

PERIPHERAL EQUIPMENT

Section 3, PERIPHERAL EQUIPMENT, Page 3-2

Thermo Fisher Scientific

Page 39

Sarasota 2000 Ultrasonic Multipath

Flowmeter

4 INSTALLATION

4.1 Safety

SAFETY NOTICE

The installation of the Thermo Scientific Sarasota 2000

flowmeter may involve a number of steps which require

special skills, training and special equipment. Examples

include:

• Electrical installation

• Working on construction sites

• Working near water (may be deep or fast flowing)

• Lifting equipment

• Working at height

• Working from boats

• Confined space working

It is recommended that prior to the installation the installer

should write a method statement detailing:

• The scope and purpose of the work,

• The steps in the operation,

• Interaction with others,

• The personnel to be involved,

• Their qualifications for the work,

• Protective clothing and equipment,

• Machinery, tools etc.

• Emergency contacts and procedures.

A risk assessment should be carried out and both the

method statement and risk assessment should be

approved by the person responsible for Health and Safety

on the site.

Thermo Fisher Scientific accepts no responsibility for the

safety of personnel other than its own employees in the

installation and commissioning of the Sarasota 2000

flowmeter and accessories supplied.

INSTALLATION

Section 4 INSTALLATION Page 4-1

Thermo Fisher Scientific

Page 40

Sarasota 2000 Ultrasonic Multipath

Flowmeter

4.2 General

It is usually necessary for some preparatory work to be carried out prior to installation of the

flowmeter system. This work is often performed under a separate contract and typically

includes:-

• Installation of supporting structures for transducer mounts, for example, piles in a river,

brackets on concrete channel walls.

• Installation of ducts o r cable tray for the interconnecting cables.

• Installation of a suitable housing for the flowmeter and peripheral equipment. This could

be an existing building or a kiosk.

• Provision of a power supply.

• Provision of a PSTN connection.

The installation of the equipment on site follows the above. It is normal practice to carry out a

risk assessment and to write a method statement to be agreed by the client before startin g

work. The installation work is often restricted to times when suitable site conditions apply.

It is recommended that the installer of the flowmeter should inspect the preparatory work prio r

to mobilising resources for the installation.

4.3 Unpacking and laying out

If site and general assembly drawings were specified as part of the supply contract they will

normally have been supplied and accepted prior to delivery of the equipment. The drawings

will be a useful guide to checking the inventory of equipment delivered.

The equipment supplied should be carefully unpacked and checked for content and damage.

The transducers may have been supplied in rack assemblies ready to be installed to the

supporting structure. There will normally be two or four racks (for in-line or crossed paths). In

large channels or those with complex shapes, there may be more than two racks, for

example, in a stepped channel with a low level channel and a wider high one.

If the racks have not been assembled, this may be carried out on site according to the

assembly drawings.

It is important to check that sufficient cable has been supplied for connecting transducers and

that suitable fixings for all the items have been supplied or separately procured.

4.4 Installing transducer assemblies

WARNING – Installing transducer racks may involve working near deep or

contaminated water and/or in confined spaces. Appropriate precautions and suitably

qualified personnel should be used.

The transducer rack assemblies should be installed in their prepared positions according to

the drawin gs and method statements.

Care must be taken not to damage the coaxial cables during this operation.

See Section 2.4 for transducer and junction box configuration.

Depth gauge transducers or transmitters may be fitted to one or more of the transducer racks

or have a separate fitting.

INSTALLATION

Section 4 INSTALLATION Page 4-2

Thermo Fisher Scientific

Page 41

Sarasota 2000 Ultrasonic Multipath

Flowmeter

4.5 Connecting transducers to flowmeter

Cables for the ultrasonic transducers should be labelled for identification, cut and pulled

through the ducts or laid in trays back to the flowmeter. Connectors should be fitted to each

end according to the instructions supplied with the connectors.

Where 1 MHz transducers are being installed, the connections are via the transducer boxes

(see Section 2.4.1) which are fitted at the rack assemblies.

Cables for depth gauges other than Sarasota ultrasonic transducers should also be pulled

back to the flowmeter. Gene rally, if the de pth gauge is a pres sure transmitt er, the attached

cable will be supplied long enough for this purpose without joining.

The transducer cables are to be terminated at the flowmeter end and plugged in to the

flowmeter back panel as shown in Section 2.3.3.1.

Ultrasonic path numbers are as shown, numbered from the lowest path. If 2 paths are at the

same height the firmware will take them as crossed for the purposes of slice allocation and

flow calculation (see 1.2.5). Upstream transducers should be plugged into the upper row on

the back panel and downstream ones to the lower.

4.6 Transducer alignment

At this stage it is usual practice to align the transducers. Each transducer should point at its

partner to within ±1

• Pre-set alignment derived from construction drawings.

• Visual methods involving pointers and sighting arrangements.

• Low power laser methods.

If the transducers are in the water, only the first of these may be possible and final adjustment

should then be carried out by adjustments to maximise signals during commissioning.

4.7 Output connections

Output signals should be wired to the peripheral devices according to the connection tables

given in section 2.3. In some cases standard cables will hav e been provided, eg RS232, or

pre-made cables will have been ordered as part of the contract.

Note For compliance with EMC emissions control, analogue, BCD and serial i/o cables

should be screened and the screen connected to a 0V pin. Where the connector is a ‘D’ type

connector, the screen may alternatively be connected to the connector body if metal.

4.8 Power Connection

Connection should be made to the external power source according to local or national

regulations. The flowmeter is supplied with a standard 230 volt mains cable for connection to

an AC source in the range 85 to 264 volt AC, 47 to 64 Hertz. This may be connected to the

power outlet via a plug or, more usually via a switched spur. This work should be carried out

by a person with the appropriate qualifications.

See the site data book for details of flowmeters supplied for DC operation.

o

. The method used will vary according to the conditions.

INSTALLATION

Section 4 INSTALLATION Page 4-3

Thermo Fisher Scientific

Page 42

Sarasota 2000 Ultrasonic Multipath

Flowmeter

This page is blank

INSTALLATION

Section 4 INSTALLATION Page 4-4

Thermo Fisher Scientific

Page 43

Sarasota 2000 Ultrasonic Multipath

Flowmeter

COMMISSIONING

5 COMMISSIONING

5.1 Site dimensions

If this information is not already available, it will be necessary to carry out a dimensional

survey of the installed transducers and the channel in order to programme the flowmeter. It

will be necessary to determine the following:-

• length, angle and the heights of each path,

• average cross section profile, if different from that defined by the paths,

• mean bed level (MBL),

• height offset of the level transducers and,

• relationship between the local heights and a fixed datum if not

MBL.

This manual does not cover surveying techniques. However, for small sites physical

measurements are easily carried out by measurement with a tape. Angles may be determined

by triangulation.

5.2 Powering up

Check that the flowmeter contains the specified modules and the cards are plugged in to the

correct rack positions, see Section 2. Also, Appendix 5: Site Data may already have been

partially filled in prior to shipping to indicate the card positions.

Switch on the power source and ensure that the internal power switch is on (Section 2.3).

The main STATION HOME screen will be displayed (Appendix 1: LCD Screens).

5.3 Programming

The flowmeter should be programmed as described in Appendix 1: LCD Screens.

Alternatively a PC may be used rather than the built-in screen and keyboard as shown in

Appendix 2: GAFA Screens. The programme details should be recorded to become part of

Appendix 5: Site Data.

Appendix 5: Site Data is a useful checklist covering all programmed data, some of which may

not be required for any particular site.

5.4 Setting up

5.4.1 Ultrasonic levels

Select “Manual” and set the gain and voltage for each level (screen C216: Level Transducer

Setup) to obtain a clean waveform and detection point (screen C218: Level Waveform

Display).

5.4.2 Auxiliary levels – analogue input

Set the input range via screen C212: Analogue Input Configuration. This allows the input to

be linearised, but most level devices will be suffic iently linear and only n eed 2 points to define

the input. On the table, define 4 mA as the minimum, 20 mA as the maximum and enter the

depth offset (level above datum).

working with respect to

Section 5, COMMI SS I O NIN G Page 5-1

Thermo Fisher Scientific

Page 44

Sarasota 2000 Ultrasonic Multipath

Flowmeter

5.4.3 Auxiliary level – encoder input

Screen C213: Encoder Input Configuration allows the details of a direct input from a shaft

encoder to be programmed. This involves setting a point of reference from which to count up

and down (the current level) and the scaling factor of pulses per unit of depth.

5.4.4 Auxiliary levels – BCD input

Screen C214: BCD Input Configuration is used to define the relationship between the BCD

input and actual depth. The level of the counter zero above datum is entered and the

conversion factor relating counter value to the depth units.

5.5 Outputs

The outputs are selected from analogue, BCD and relays. (Set up via screens S25: Output

Configuration, screen S250: Analogue Output Configuration, screen S251: BCD Output

Configuration and screen S252: Test Output Configuration).

Correspondence between the displayed selected parameter value and the output should be

checked. It is possible to force the outputs by temporarily changing the set-up, for ex ample

changing the level datum will affect not only the apparent level measurement but also the

flow. Alarm thresholds may be altered to check relay operation.

Analogue outputs may be checked by a calibrated multi-meter and verified as being received

by the destination device.

BCD outputs are more difficult to check with a multi-meter and are usually verified by reading

the destination device. A BCD test box with a display is available through Thermo Fisher

Scientific.

Alarm outputs may be checked by a calibrated multi-meter and verified as being received by

the destination device.

COMMISSIONING

Section 5, COMMI SS I O NIN G Page 5-2

Thermo Fisher Scientific

Page 45

Sarasota 2000 Ultrasonic Multipath

Flowmeter

CALIBRATION/

VERIFICATION

6 CALIBRATION/VERIFICATION

Flowmeters of this type do not normally require calibration. Exceptions are where there are

significant unmeasured areas, for example, behind transducers, or where local conditions

might create atypical velocity profiles and a small number of velocity paths are deployed. See

Section 1: Introduction and Appendix 4: References.

However, it is normal to carry out periodic checks to verify the overall performance of the flow

determination.

Whether for calibration or verification purposes, the comparison method to be used will be the

same and will depend on the site.

Reference is made to ISO 748 for details of methods. See Appendix 4: References.

The most common method used is by current metering using a calibrated rotating element or

electromagnetic current meter.

Care should be taken to use repeated checks and to minimise the experimental uncertainties

which could otherwise be greater than the uncertainty of the ultrasonic flowmeter.

Section 6 CALIBRATION/VERIFICATION Page 6-1

Thermo Fisher Scientific

Page 46

Sarasota 2000 Ultrasonic Multipath

Flowmeter

This page is blank

CALIBRATION/

VERIFICATION

Section 6 CALIBRATION/VERIFICATION Page 6-2

Thermo Fisher Scientific

Page 47

Sarasota 2000 Ultrasonic Multipath

Flowmeter

MAINTENANCE

7 MAINTENANCE

There is little maintenance as such relating to the flowmeter itself. However, the river or

channel must be kept free of weed, silt and other obstructions to avoid interruption of the

ultrasonic paths or changing the cross section area which would affect the accuracy of flow

determination.

Periodic checks on the functioning of the flowmeter and verification of the flow as calculated

are recommended.

7.1 Channel maintenance

7.1.1 Weed

• If weed tends to grow in the channel, it must be kept cut.

• Weed must be kept clear from between the transducer arrays where it may stop the

passage of sound between the transducers.

• Weed should also be controlled on the approach to the gauged section and immediately

downstream of it where its presence c ould distort the velocity profile.

The user must decide on the season al cu t t i n g re gime to suit the ch an n el .

7.1.2 Profile

Periodically the channel shape should be checked to determine whether it has changed since

the flowmeter was programmed. It is particularly important to check the bed where silt might

have been deposited or scouring could have occurred.

Changes may be required to the programmed channel shape or mean bed level.

In serious cases, it may be necessary to dredge the channel, taking care not to damage the

transducers.

The user must decide on the che cking regime to suit the channel.

7.1.3 Debris

Under high flow conditions it is not uncommon for debris to be washed along the channel.

Whilst the design of the transducer supports should be such as to minimise the risk of

snagging this debris, separate deflectors or devices intended to capture it may be employed.

If the channel is prone to this phenomenon, the user must instigate an appropriate debrisclearing regime.

7.2 Flowmeter maintenance

There are no parts requiring maintenance except that the transducers should be checked

occasionally for a build-up of surface coating, for example by grease, and for misalignment

caused by physical shocks. These checks may be carried out along with the channel

maintenance.

Normally it is possible to obtain advance warning of problems by checking the signal quality.

This may be done on site or remotely via GAFA (Appendix 2: GAFA Screens).

Section 7, MAI N T E NANCE Page 7-1

Thermo Fisher Scientific

Page 48

Sarasota 2000 Ultrasonic Multipath

Flowmeter

7.3 Routine checks

7.3.1 Remote

Remote checks of operation of all velocity paths and depths are easily carried out via GAFA.

It is recommended that a monthly routine should be set up to handle this.

If the flowmeter is fitted with the relay option, one of the relays may be programmed to initiate

an early warning call via a telemetry outstation.

7.3.2 On site

It is recommended that an annual check be made on site. This should include:

• A visual observation of the equipment in the channel and the flowmeter.

• A functional check of the operation of the paths, levels and outputs.

• A c h ec k on t he operation of the i nternal battery .

• A verification of calculated flow by a comparison method, see Section 6: Calibration