Thermo Scientific Sarasota 200, HB-S200 User Manual

Sarasota 200

Ultrasonic Multipath Flowmeter

User Guide

P/N HB-S200

Revision A

Part of Thermo Fisher Scientific

Sarasota 200

Ultrasonic Multipath Flowmeter

User Guide

P/N HB-S200

Revision A

©2007 Thermo Fisher Scientific Inc. All rights reserved.

All trademarks are the property of Thermo Fisher Scientific Inc. and its subsidiaries.

Thermo Fisher Scientific (Thermo Fisher) makes every effort to ensure the accuracy and completeness of

this manual. However, we cannot be responsible for errors, omissions, or any loss of data as the result of

errors or omissions. Thermo Fisher reserves the right to make changes to the manual or improvements to

the product at any time without notice.

The material in this manual is proprietary and cannot be reproduced in any form without expressed

written consent from Thermo Fisher.

Thermo Fisher Scientific

1410 Gillingham Lane

Sugar Land, TX 77478

USA

Phone: 713-272-0404

Fax: 713-272-2272

Web: www.thermofisher.com

Thermo Fisher Scientific

14 Gormley Industrial Avenue

Gormley, Ontario L0H 1G0

Canada

Phone: 905-888-8808

Fax: 905-888-8828

This page intentionally left blank.

Sarasota 200 Ultrasonic Multipath Flowmeter

SECTION 1

INTRODUCTION

1.2.1 The Standard

1.3 Implementation of principles in Sarasota 200

1.1 Applications

1.2 Principle of operation

1.2.2 Velocity x area method

1.2.3 Water level

1.2.4 Water velocity

1.2.5 Flow determination

1.2.5.1 Mid section method

1.2.5.2 Mean section method

1.2.6 Path configurations

1.2.7 Transducer frequency

1.2.8 Minimum depth of water

1.2.9 Performance estimates

INDEX

SECTION 2

SYSTEM COMPONENTS

2.1 Flowmeter system overview

2.2 Family tree

2.3 Flowmeter contents and options

2.3.1 Flowmeter layout

2.3.2 Internal components

2.3.2.1 Mother board

2.3.2.1.1 Power supply & internal battery

2.3.2.1.2 Transducer connections

2.3.2.1.3 Depth input signals

2.3.2.1.4 Output signal connections

2.3.2.1.5 Relay connections

2.3.2.1.6 Digital signal connections

2.3.2.1.7 Serial communications

2.3.2.2 Central processor (CPU)

2.3.2.3 LCD display

2.3.2.4 Transducer interface card (TIF)

2.3.2.5 AC power adapter

2.4 Ultrasonic transducers

2.4.1 1 MHz transducers

2.4.2 1 MHz I.S. transducers

2.4.3 500 kHz transducers

2.4.4 Lower frequency transducers

2.4.5 Maximum cable lengths

2.5 Controls and displays

2.6 Software & firmware

2.6.1 Operating firmware

2.6.2 “GAFA” PC software

2.7 Documentation

INDEX Page 1

Thermo Fisher Scientific

Sarasota 200 Ultrasonic Multipath Flowmeter

SECTION 3

PERIPHERAL EQUIPMENT

SECTION 4

INSTALLATION

4.1 Safety

SECTION 5

COMMISSIONING

5.1 Site dimensions

SECTION 6

CALIBRATION/

VERIFICATION

3.1 Additional items

3.2 Transducer mounting hardware

4.2 General

4.3 Unpacking and laying out

4.4 Installing transducer assemblies

4.5 Connecting transducers to flowmeter

4.6 Transducer alignment

4.7 Output connections

4.8 Power connection

5.2 Powering up

5.3 Programming

5.4 Setting up

5.5 Outputs

6 Calibration/verification

INDEX

SECTION 7

MAINTENANCE

7.1 Channel maintenance

7.1.1 Weed

7.1.2 Profile

7.1.3 Debris

7.2 Flowmeter maintenance

7.3 Routine checks

7.3.1 Remote

7.3.2 On site

APPENDIX 1

GAFA PC SOFTWARE

A2 GAFA PC software

INDEX Page 2

Thermo Fisher Scientific

Sarasota 200 Ultrasonic Multipath Flowmeter

APPENDIX 2

SPECIFICATION

A2.1 Enclosure

A2.2.1 DC supply

A2.3 Electronics

A2.4.1 1 MHz

A2.5 GAFA software

A2.2 Power supply

A2.2.2 AC power adap ter modu le

A2.3.3 Internal battery option

A2.4 Transducers

A2.4.2 500 kHz

A2.4.3 Other frequencies

A2.4.4 Transducer ca ble

INDEX

APPENDIX 3

REFERENC ES

A3 References

APPENDIX 4

SITE DATA BOOK

A4.1 Model and serial number

A4.2 Site and customer

A4.3 General description

A4.4 Software issue

A4.5 Card layout in rack

A4.6 Programmed data

A4.7 Schedule of drawings

A4.8 Test certificates

APPENDIX 5

I.S. INTERFACE AND

TRANSDUCER

A5.1 Introduction

A5.2 Installation Guidelines

A5.3 Marking

A5.4 Maintenance

INDEX Page 3

Thermo Fisher Scientific

Sarasota 200 Ultrasonic Multipath Flowmeter

This page is blank

INDEX

INDEX Page 4

Thermo Fisher Scientific

Sarasota 200 Ultrasonic Multipath

Flowmeter

INTRODUCTION

1 INTRODUCTION

1.1 Applications

The Thermo Scientific Sarasota 200 is a velocity x area open channel flowmeter which uses

the ultrason ic “ tim e of fli ght ”, also kno wn as th e “tr ans it t ime” m et hod. It is sim ilar to the l arge r

Sarasota 2000 but with fewer ultrasonic velocity paths (up to 4) and just one water channel.

Unlike traditional methods of open channel flow measurement which use weirs or flumes, the

transit time method creates no obstruction and assumes no relation between level and flow. It

will correctly determine flow throughout its designed range by measuring water velocity and

cross section area (see Section 1.2).

The method is tolerant of backwater effects caused by tides, downstream confluence or

blockages. Unlike a weir or flume it does not drown out at high flow conditions.

The method employs the transmission of ultrasonic “beams” which can be affected by factors

which impede or deflect them. For this reason the method should not be used in situations of:

• Aerated water

• Weed growth between the transducers (unless it is regularly cut)

• High levels of suspended solids (greater than 2000 mg/l) *

• Gradients

• Gradients

* In relatively small channels (up to 5 metres) the method is more tolerant of

** Provided the velocity of sound in water (VOS) remains within the range 1350 to 1650

Though described as an open channel method, the flowmeter may be used in closed

conduits, including those which run full. In the latter case, the cross section area is defined by

the conduit geometry without the need to measure water level.

Suitable applications include water flow measurement of:

• Rivers

• Canals

• Aqueducts

• Irrigation conduits

• Sewage discharges

• Sewage works

• Industrial discharges

• Power generation

Note that although the flowmeter is most often used for open channels or part filled conduits,

it is often used for conduits which always run full. Under these circumstances it is not

necessary to have a depth input but steps need to be taken to ensure that the flowmeter

always takes the conduit as full. This is done via the fixed level input PC screen. The conduit

shape must sti ll be ent e red.

of salinity (the actual value of salinity is, however, unimportant**)

of temperature (the actual temperature is, however, unimportant**)

suspended solids and therefore is often used in sewage applications.

m/s

Section 1 INTRODUCTION Page 1-1

Thermo Fisher Scientific

Sarasota 200 Ultrasonic Multipath

Flowmeter

1.2 Principle of operation

1.2.1 The Standard

The Thermo Scie ntific Sarasota 200 is an ultrasonic “tra nsit time” flowmet er which complies

with the International Standard ISO 6416. The UK standard BS 3680 part 3E is identical. The

transit time method belongs to the general category of velocity x area methods. A full

description of the method and its applications is to be found in the Standard. A brief summary

is given below.

1.2.2 Velocity x area method

Velocity x area methods require a means of determining the water velocity and the cross

section area. The product of the two determines the flow rate in a manner which is not

dependent on factors influencing the level, for example downstream constrictions, tidally

affected water level etc.

Assuming the shape of the channel cross section is stable, determination of the area

becomes a matter of measuring water level. This may be done by a variety of methods.

1.2.3 Water level

Water level is required in order to determine the cross section area in an open channel.

Though a single level measurement may be used, it is common to use more than one and to

average them. This has the advantage of a more representative level, particularly if the

measurements are made at different positions, for example on either side of the channel.

Another advantage is that flow may still be computed even if a level sensor fails.

Level may be determined by using one or more ultrasonic transducers in the water facing

upwards. The time taken for a pulse of sound to return to the transducer after being reflected

from the surface is converted into level using the velocity of sound in water as measured by

the water velocity paths (see Section 1.2.4). There is a minimum depth of water required

above the transducer for it to carry out a measurement. This is given in Appendix 2:

Specification.

Water level may also be provided by external auxiliary depth gauges via 4-20 mA signals, for

example pressure transmitters, downward facing ultrasonic devices and float systems with

shaft encoders.

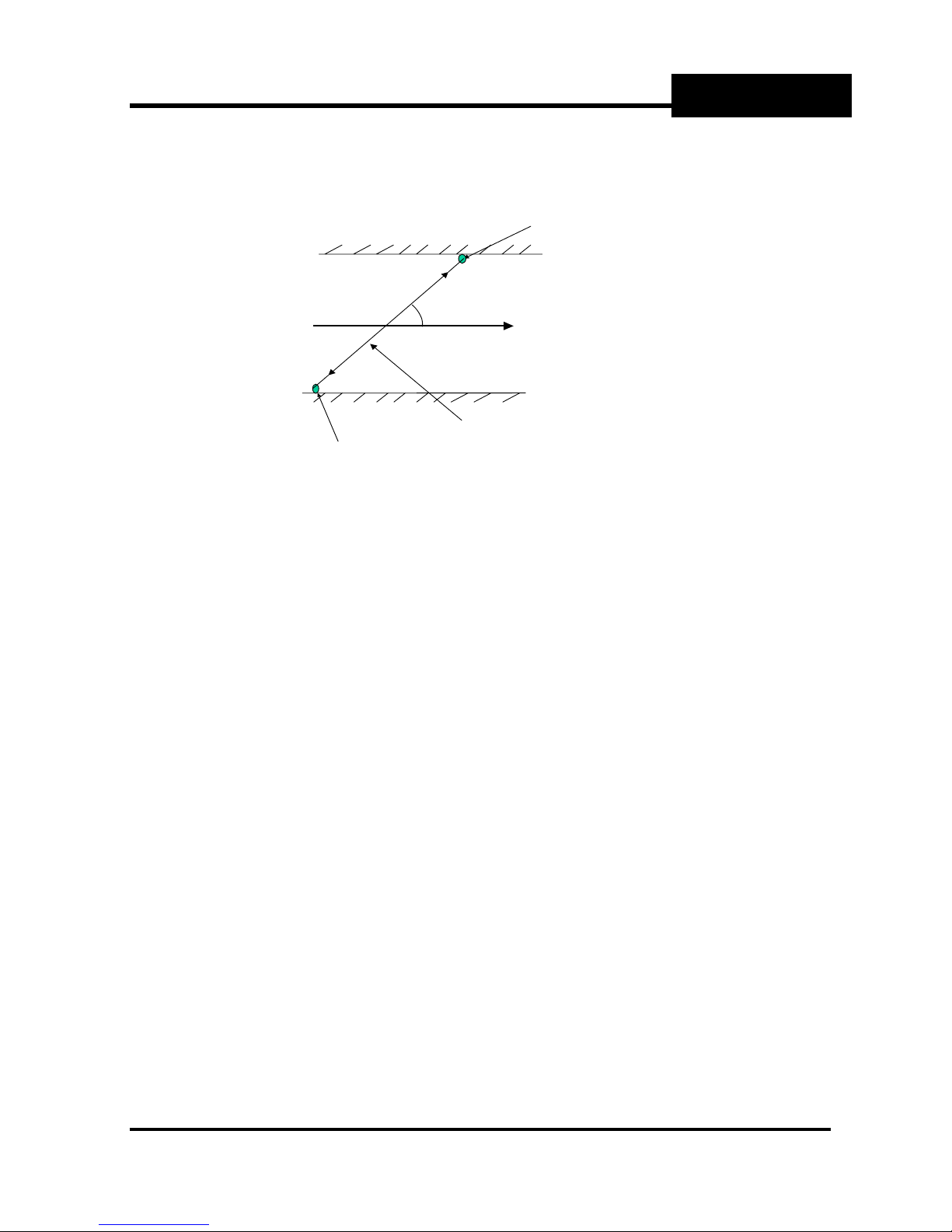

1.2.4 Water velocity

In the transit time method, water velocity is determined at a number of heights within the body

of water by measurement of time taken for pulses of ultrasound to travel across the channel

at an angle to the flow direction.

Transducers are mounted in the water at or near the sides of the channel with each pair

usually at the same height and aligned so that each one can transmit a “beam” of ultrasound

towards its partner. The ultrasonic “path” between the transducer pairs must be at an angle

(usually about 45

Each transducer acts as a transmitter and receiver and is connected to a processing unit,

which measures the transit time and the time difference.

o

) to the flow direction.

INTRODUCTION

Section 1 INTRODUCTION Page 1-2

Thermo Fisher Scientific

Sarasota 200 Ultrasonic Multipath

θ

Flowmeter

The mean water velocity at the height of each path is determined from these timing

measurements, based on pre-determined geometrical measurements (length of the path and

the angle to the flow direction).

V

It may be shown that the water velocity at the height of the path AB is:

v = L x (T

– TBA) / (TAB x TBA x 2 cosθ)

AB

Where

T

T

= Transit time from transducer A to B

AB

= Transit time from transducer B to A

BA

L = Path length (distance between transducer A and transducer B)

θ = the angle between the “path” and the direction of flow.

1.2.5 Flow determination

The flow is determined by combining the water velocity measurements at the height of each

path with the cross section area defined by the water level and the shape of the channel. The

channel shape need not be the same as the projected width between the transducers. For

example if the transducers are mounted on piles inset from the channel sides. For the

purposes of flow determination the cross section area is divided into horizontal slices

determined by the channel bed, the heights of the paths themselves and the water surface

level.

The channel flow is the sum of the flows in each slice determined by the path velocity or

velocities and the area of the slice. The bottom slice is defined by the bed (which is assumed

not to move) and the top slice by the water surface (the level of which is me asured by the

flowmeter). The slice widths may be determined by the projected width between the

transducers or by a separate table defining the cross section shape. The latter method is

used by the Sarasota 200.

There are 2 methods, mid section and mean section.

Transducer A

Direction of the Flow

Ultrasonic Path

Transducer B

INTRODUCTION

Section 1 INTRODUCTION Page 1-3

Thermo Fisher Scientific

Sarasota 200 Ultrasonic Multipath

Flowmeter

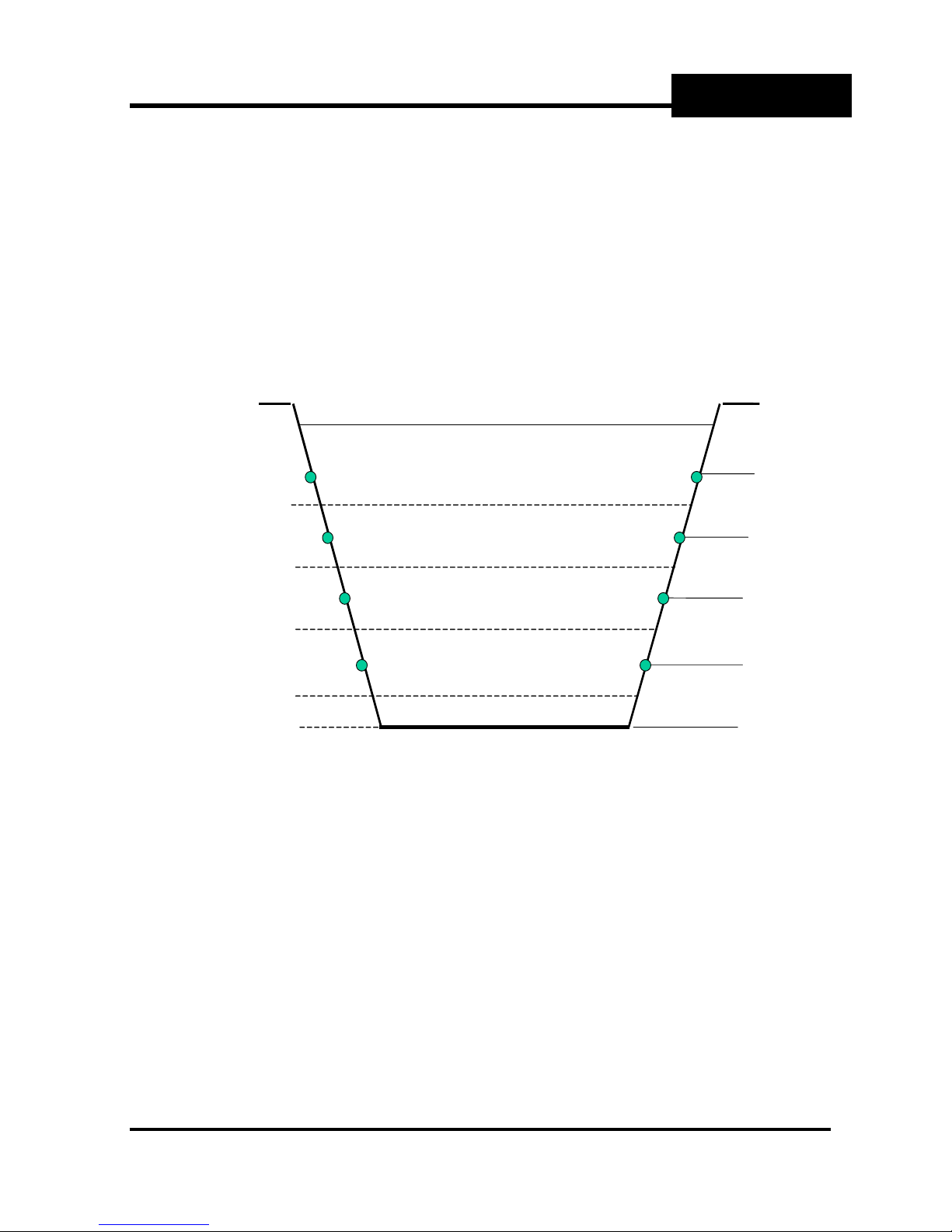

1.2.5.1 Mid section method

In the mid section method, the slice boundaries are defined by lines mid way between the

paths. The slice velocity is taken as that determined by the ultrasonic path within the slice and

the slice area as the product of the slice height and the (average) width. The upper boundary

of the top slice is the water surface. At the bottom, an additional slice is defined between the

bed and a line half way between the bed and the bottom path. This bottom slice has a

weighting factor, K, normally between 0.4 and 0.8 to allow for the slow moving water near the

bed. To reduce the uncertainty of this factor, the bottom path should be positioned as close to

the bed as practical.

INTRODUCTION

Height H

Top panel

½(H

+ H3)

4

S

Water S u rf ac e

QS = V4 {HS − ½(H4 + H3)}W

QS = ½V3 (H4 – H2)W

3

4

½(H3 + H2)

+ H1)

½(H

2

+ H0)

½(H

1

Height H

0

Bottom panel

QS = ½V2 (H3 – H1)W

QS = ½V1 (H2 – H0)W

QS = ½kV1 (H1 – H0)W

2

1

Width W

Bed

Width W

Illustration of the mid section method for 4 paths

Width W

Width W

Width W

1

Bed

4

3

2

Path 4 H e ight H

Path 3 Height H

Path 2 Height H

Path 1 Height H

Bed Height H

4

3

2

1

0

Section 1 INTRODUCTION Page 1-4

Thermo Fisher Scientific

Sarasota 200 Ultrasonic Multipath

4

Flowmeter

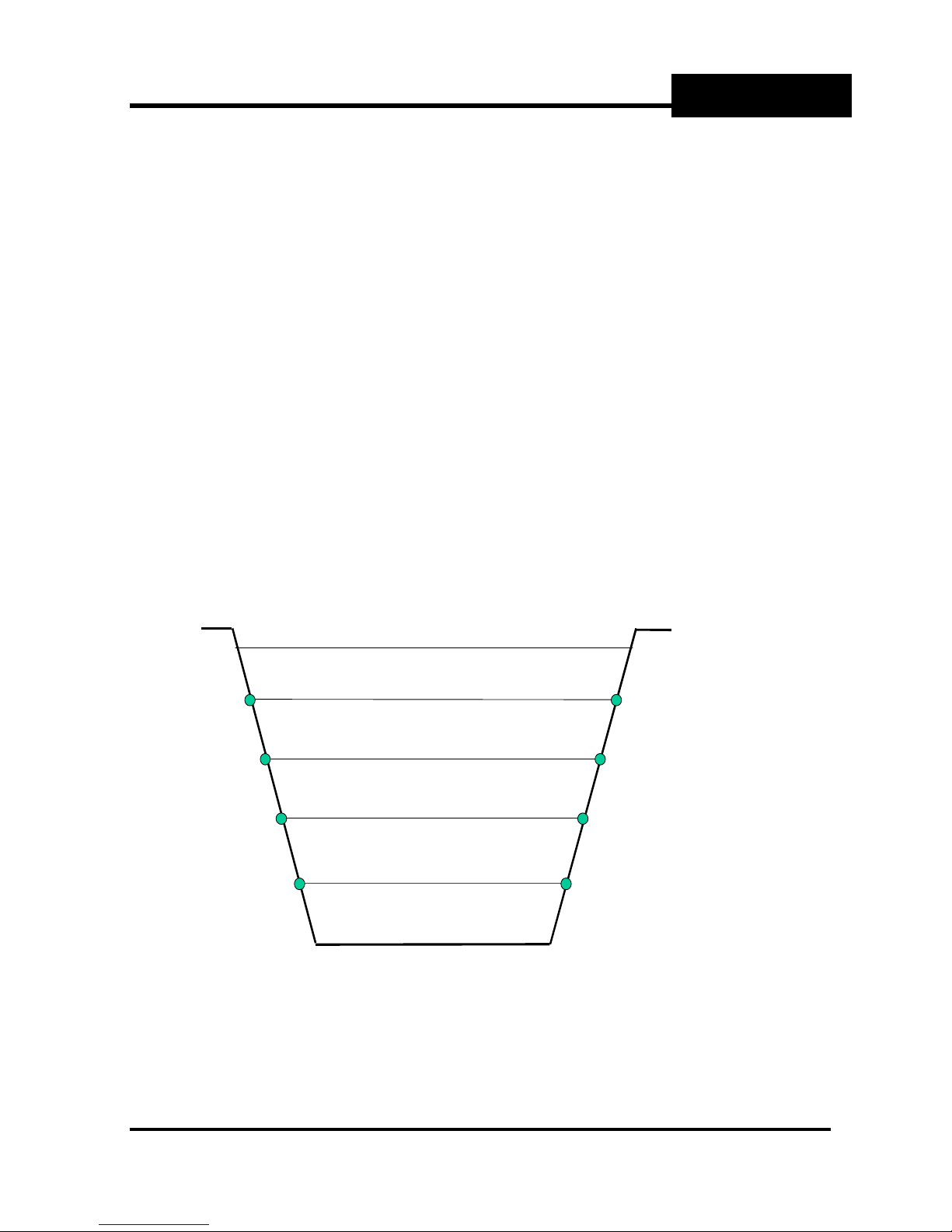

1.2.5.2 Mean section method

In the mean section method, the slice boundaries are defined by the path heights themselves.

The slice velocity is taken as the mean of the upper and lower paths which define the slice

boundaries. The upper boundary of the top slice is the water surface.

The velocit y of the water surface, Vs, is given by:-

Vs = V

Where Ks is a multiplying factor normally between 0 and 1 to allow for the projection

of velocity to the water surface

Vs is limited to a value of V

The lower boundary of the bottom slice is the bed. This bottom slice has a weighting factor,

, normally between 0.4 and 0.8 to allow for the slow moving water near the bed.

K

B

The mean section method is superior in cases where the paths are not near the slice centres,

but the mid section method handles the top slice better. The more paths that are deployed,

the less the differences matter.

The mean section method is illustrated in the following diagram:

+ (V4-V3) x Ks(Hs-H4)/(H4-H3)

4

+ (V4-V3) in the event of (Hs-H4) being greater than (H4-H3)

4

INTRODUCTION

Water Surface

Qs = ½(VS + V4) x (HS – H4) x ½(WS+ W4)

Q

= ½ (V4+ V3) x (H4 – H3) x ½(W4 + W3)

s

= ½ (V3 + V2) x (H3 – H2) x ½(W3 + W2)

Q

s

= ½ (V2 + V1) x (H2 – H1) x ½(W2 + W1)

Q

s

Q

= ½V1(1 + kB) x (H1 – H0) x ½(W1 + W

s

W

W

W

W

Wbed

Width W

4

3

2

1

)

Bed

S

Illustration of the mean section method for 4 paths

Surface Heigh t H

Path 4. Height H

Path 3. H eight H

Path 2. He i ght H

Path 1 Height H

Bed, Height H

S

3

2

1

0

Section 1 INTRODUCTION Page 1-5

Thermo Fisher Scientific

Sarasota 200 Ultrasonic Multipath

Flowmeter

1.2.6 Path configurations

The simplest arrangement is to have a number of paths “in line” above each other. This

would be suitable for a channel of regular cross section shape, which is straight for a long

distance compared with its width (5 to 10 times).

Other configurations are often used in other circumstances. For example:

• Crossed paths where there is uncertainty about the flow direction

• Sloping paths where the depth is greater on one side compared with the other

• Transducers inset from the banks

• Reflected paths where transducers are on one side only and reflectors “bounce” the

sound pulses back from the far side. This method saves cable but increases path lengths

and is very sensitive to misalignment.

The Sarasota 200 f l o wm e t e r is capable of being con f i gured for these and ot her situation s .

For more complex configurations requiring more than 4 paths or compound channels, the

Sarasota 2000 offers more flexibility. Examples are:

• Multiple sets of paths for compound channel shapes

• V configuration used to divide the width because of size or uneven profile

• Multiple channels

Please consult Thermo Fisher Scientific for examples and advice.

1.2.7 Transducer frequency

Transducers are manufactured with characteristic frequencies. These are in the range 1 MHz

to 250 kHz. For propagation reasons, the greater the path lengths the lower the frequency

and the larger the transducer. As a guide, path lengths below 10 metres would use 1MHz

transducers, 5 to 80 metres 500 kHz, 50 to 200 metres 250 kHz. These figures are for

guidance and the selection may be influenced by other factors relating to the application.

Where there is overlap, lower frequency transducers may be used to improve pen etration in

conditions of high suspended solids provided there is sufficient depth and velocity.

Please consult Thermo Fisher Scientific for advice.

1.2.8 Minimum depth of water

In order to avoid reflections from the bed or surface causing distortion of the ultrasonic

signals, a minimum height of water is necessary above each path. This depends on the

transducer frequency and the path length.

INTRODUCTION

H

= 27 √ ( L / ƒ )

min

Where:

is the minimum height of water above the path, in metres

H

min

L is the path length, in metres

ƒ is the transducer freque ncy, in Hertz

A similar restriction applies to the channel bed, particularly if it is smooth and reflects rather

than absorbs an acoustic signal. The minimum depth of water is therefore usually 2 x H

Section 1 INTRODUCTION Page 1-6

min

Thermo Fisher Scientific

Sarasota 200 Ultrasonic Multipath

Flowmeter

1.2.9 Performance estimates

ISO 6416 describes how to estimate the uncertainty of measurement in any particular

installation. Please consult Thermo Fisher Scientific for advice on this.

1.3 Implementation of the principles of operation in the Sarasota 200

The principles described in Section 1.2 are used by the Sarasota 200 subject to certain rules

as listed below. See also Appendix 1: GAFA Screens that describe in detail how the

flowmeter is programmed via a PC.

Flow

• There is a choice of mean or mid section method of flow calculation.

• The channel cross section shape is entered as a height/width table independent from the

path lengths and angles. (For rectangular or trapezoidal channels it is only necessary to

enter 2 points to define the channel.) The separate table allows the path velocities to be

applied to more accurate slice areas since the defined shape is used rather than a fixed

width for each slice as specified in the Standard.

• Where no path velocity is available, for example at low water height, flow may be inferred

from water level. This is done via a flow estimation table, which may be derived

empiricall y o r by calculation.

Velocity

• The upstream velocity transducers are connected as shown in section 2.

• Path numbering is from the bottom.

• Paths are automatically brought into operation according to the water level and the

programmed minimum water cover.

• Paths entered as being at the same height are taken as crossed, otherwise they are

separate.

• Separate paths may be “normal” with transducers on each side or “reflected” with

transducers on one side only. The latter method saves cable but is not recommended

because of the increased path lengths and sensitivity to alignment.

• The velocities calculated by a pair of paths comprising a crossed path are averaged and

the average velocity used for the slice. The velocity calculated by a separate path is used

alone for the slice.

• When a velocity path fails, the slice boundaries automatically adjust to use only the

working paths.

• A failed path will show on the status indicated. The path status is a percentage of the

“instantaneous” transducer firings which result in successful reception. If this figure drops

below 12% the path is considered to have failed during the corresponding instantaneous

cycle time and is discarded for that cycle. This could be the result of a fault, misalignment

or obstruction.

• Only valid velocity paths which are in the water and covered by sufficient water to be

operating are used for the status indication.

• Each path may have a multiplying factor (“X Factor”) assigned to it. This will normally be 1

but may be different in exceptional circumstances for calibration purposes. An example of

when this might be is when the transduce rs are not exactly at the channel edges.

• Transducers in each velocity path may be set to operate simultaneously (the norm) or

sequentially. Simultaneous operation allows more measurements in a given time but

there is a small possibility of confusing a signal reflected back to the firing transducer with

one received from the opposite transducer.

INTRODUCTION

Section 1 INTRODUCTION Page 1-7

Thermo Fisher Scientific

Sarasota 200 Ultrasonic Multipath

Flowmeter

Water level

• Levels are combined in the following algorithm:

Only non-faulty measurements are used.

Highest and/or lowest are discarded until 3 remain.

The one furthest from the others is discarded leaving 2.

The remaining 2 measurements are averaged for arbitrated level if within an

acceptable band defined via the PC GAFA software.

If they are not within the acceptable band, level determination fails and flow cannot

be calculated.

If only 1 level measurement is installed or only 1 remains after arbitration, it is used

as the arbitrated level.

If not OK, level fails and flow cannot be calculated.

• Levels defined as valid but rejected by the algorithm will be indicated on the level status.

• Where the flowmeter is installed in a cl osed conduit which always runs full, th e channel

shape is entered in the usual way but there is no need for a level measurement. The

flowmeter is programmed with a fixed level input corresponding to the top of the conduit.

Transducer and bed levels

All heights may be set to a fixed datum (local or national) or relative to mean bed level. The

former requires a height for the bed and avoids re-entering all path and level transducer

heights in the event of a change to the bed.

General

• “Instantaneous” means the average over the cycle time scale. This defaults to 10

seconds for fast response suitable for small channels. It may be set to 1 minute for

smoother averaging where the rate of change of flow conditions is slower.

• The average period is the time over which measurements are averaged for the purpose

of output or logged data. The average period cannot be shorter than the cycle time.

• At the data logging intervals, the averaged values of the selected data are stored.

• Analogue inputs will normally be linear. However, non linear characteristics may be

entered via the PC, see Appendix 1

• When operating on a 12 volt source, for example from a solar panel, power saving is

possible by using intermittent operation. Power consumption in normal and intermittent

modes is quoted in the Appendix 2: Specification.

INTRODUCTION

Section 1 INTRODUCTION Page 1-8

Thermo Fisher Scientific

Sarasota 200 Ultrasonic Multipath

Flowmeter

SYSTEM COMPONENTS

2 SYSTEM COMPONENTS

2.1 Flowmeter system overview

• The Thermo Scientific Sarasota 200 is an ultrasonic multi-path flowmeter, which complies

with ISO6416.

• It employs state of the art technology to achieve excellent performance in conditions

which have previously be en outside th e scope of this type of instrument.

• Smart transducer technology incorporating drive and receiver circuits optimises signal to

noise ratio and minimises losses. The smart circuits are located inside the transducer

housings except for the 1 MHz transducers. In that case they are in sealed in-line

housings known as Tboxes.

• Automatic adjustment of receiver gain and transducer drive voltage (HT).

• Low power consumption and intermittent modes make mains free operation feasible.

• Multi-path operation, (up to 4) with multi-drop facility made possible by smart transducer

addressing to save cable.

• Multiple water level inputs, subject to a maximum of 4 overall:

- up to 4 ultrasonic level transducers

- up to 2 auxiliary level gauges (via 4-20 mA inputs.)

• Up to 2 analogue 4-20 mA outputs

• System fault relay (volt free contacts)

• 2 programmable relays, 1 volt free contact, 1 high speed solid state. Programmable, f or

example for alarms, status, totaliser pulses.

• Two serial ports. RS232 for PC, RS232 for modem.

• Internal data logger, 1 Mbyte capacity, programmable.

• Water temper ature measurem e nt at each smart transducer (except 1 MHz transduc er s )

Section 2, SYSTEM COMPONENTS, Page 2-1

Thermo Fisher Scientific

Sarasota 200 Ultrasonic Multipath

Flowmeter

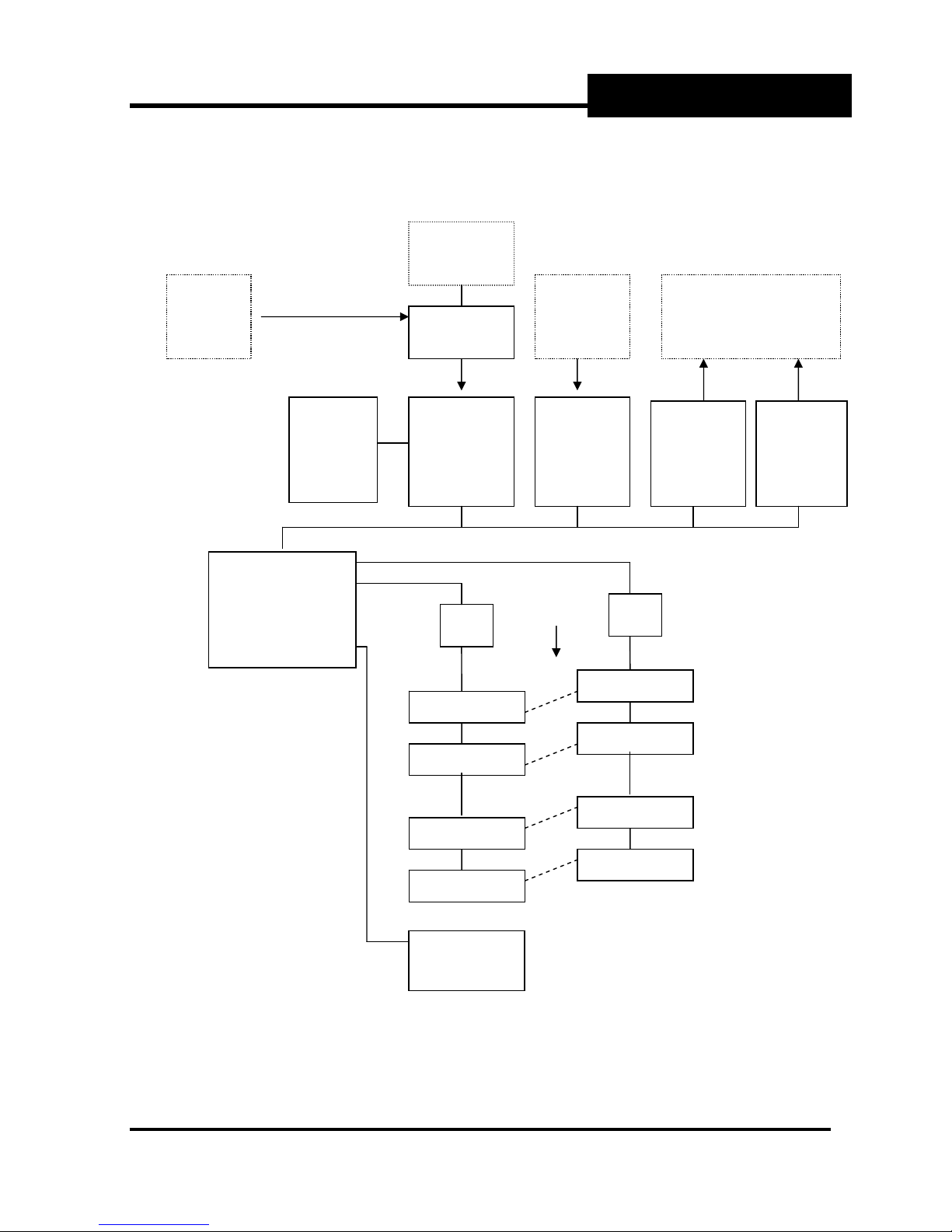

2.2 Family tree

The schematic diagram below is an illustration of a four path system.

Internal

Battery

option

External

power

source

11 to 30 V DC

Auxiliary

depths

Power

control

SYSTEM COMPONENTS

External equipment

Display

Transducer u/s

interface d/s

Level

Central

Processor

inc.

2 x serial I/O

Star

J box

Trans. 1 d/s

Trans. 2 d/s

Trans. 3 d/s

Trans. 4 d/s

Inputs

2 x

4-20 mA,

Flow

Star

J box

Trans. 1 u/s

Trans. 2 u/s

Trans. 3 u/s

Trans. 4 u/s

Outputs

2 x

4-20 mA,

Relays

2 x VFC

Section 2, SYSTEM COMPONENTS, Page 2-2

Level

Transducer

Option

Thermo Fisher Scientific

Sarasota 200 Ultrasonic Multipath

Flowmeter

2.3 Flowmeter contents and options

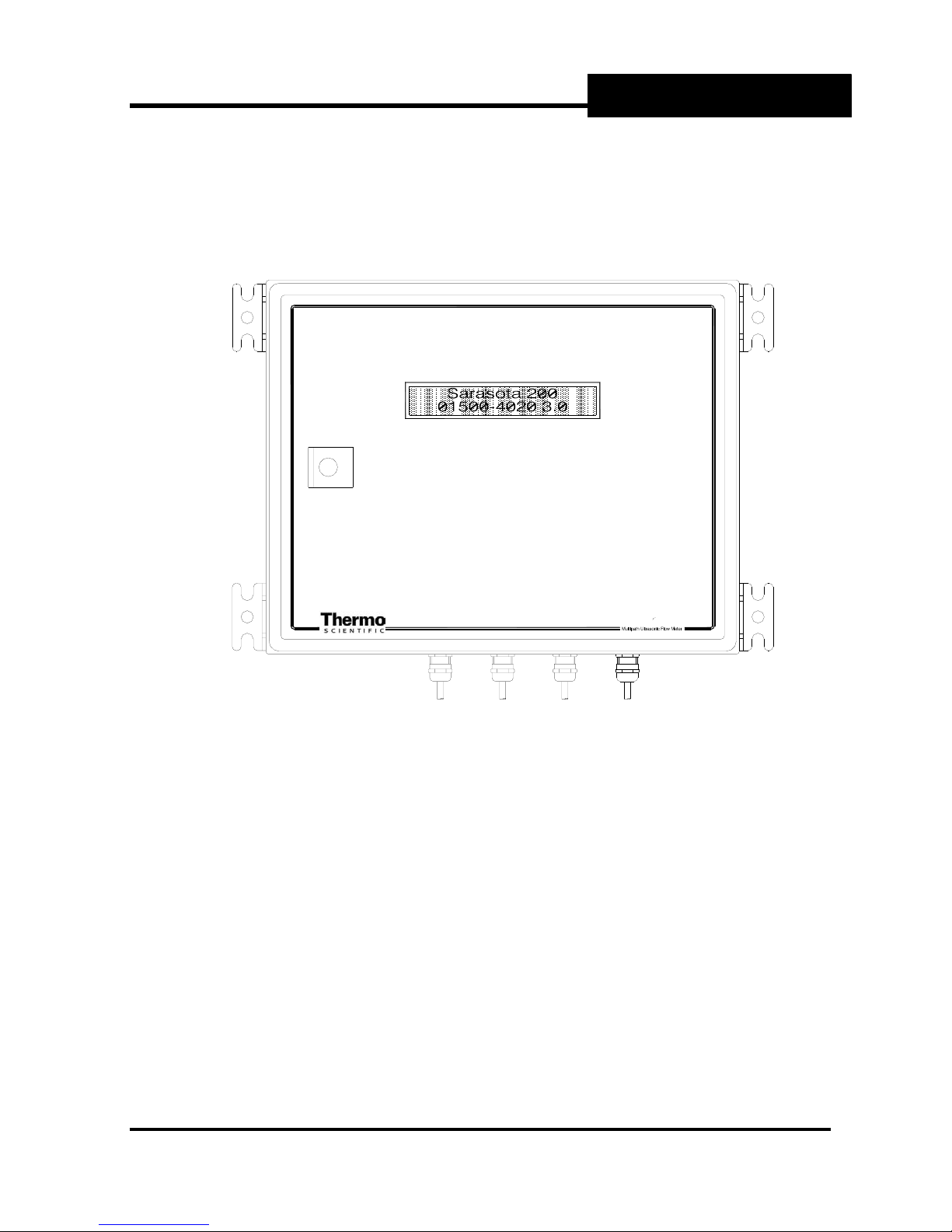

2.3.1 Flowmeter layout

SYSTEM COMPONENTS

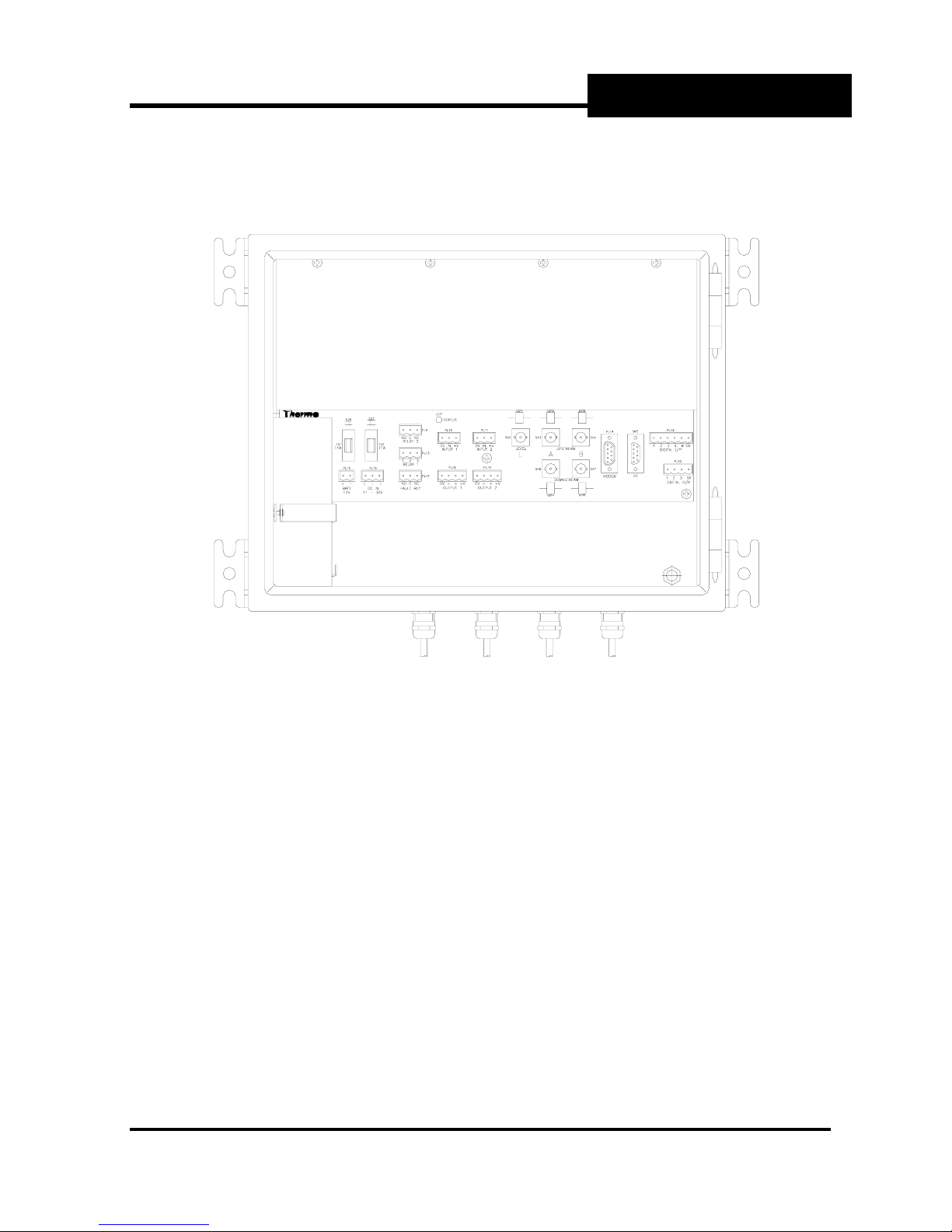

s„˜„™•š„@RPP

Fig 1 Sarasota 200 Flowmeter. Front panel view

This view of the Sarasota 200 shows:

• the LCD display (see section 2.3.2.3)

• the cable entry glands at the bottom

• the wall mounting brackets (see Appendix 2 for mounting dimensions)

Section 2, SYSTEM COMPONENTS, Page 2-3

Thermo Fisher Scientific

Sarasota 200 Ultrasonic Multipath

Flowmeter

SYSTEM COMPONENTS

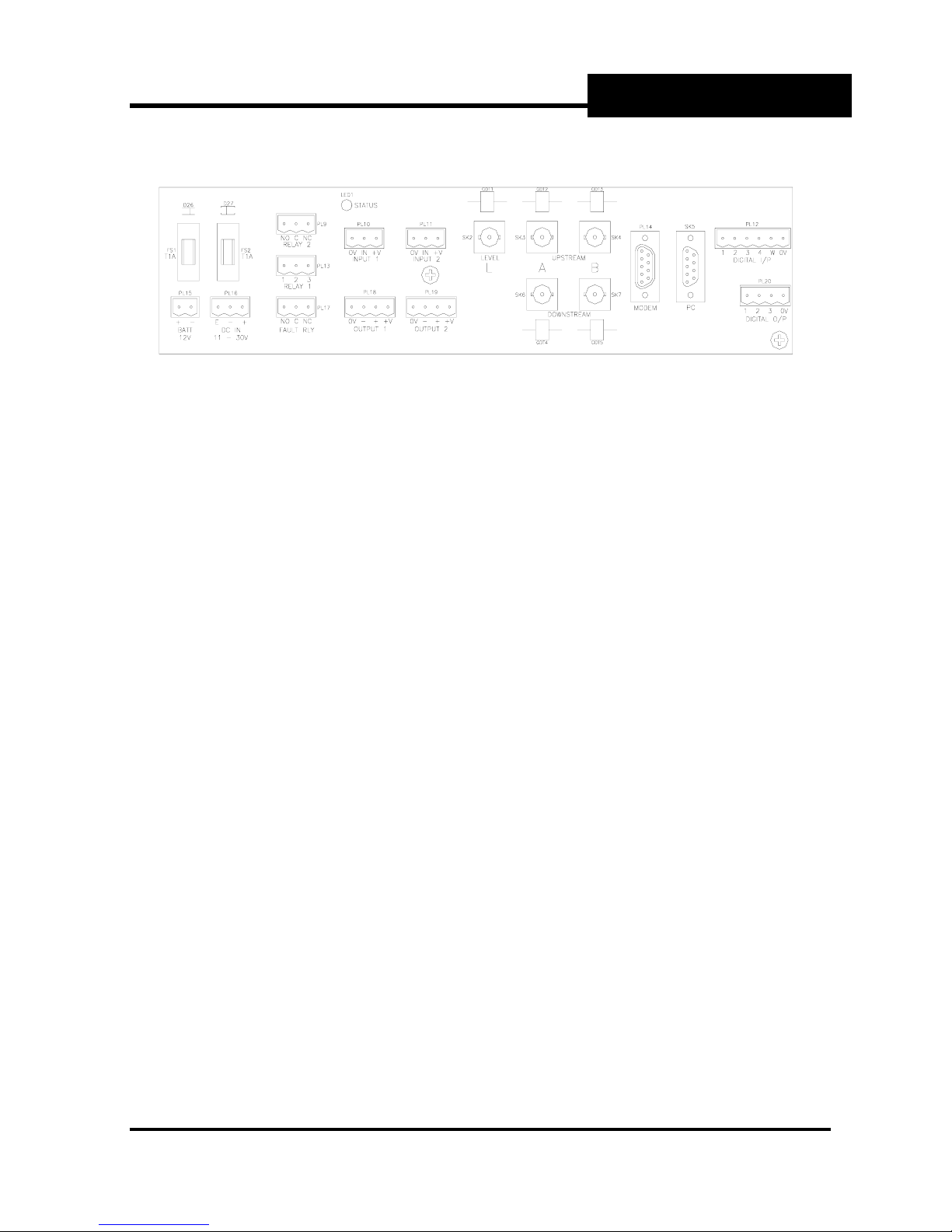

Fig 2 Sarasota 200 with lid open showing internal components

This view shows the connection panel protruding from the protective cover and the internal

battery in the bottom left corner.

The connection panel is part of the mother board which contains the input, output and power

management functions. It supports the main processor (CPU) card and the transducer

interface (TIF) card which plug in beneath the protective cover. The connection panel is

shown on a larger scale in Fig 3.

The internal battery allows operation to continue when the external power source has failed.

This is an optional facility which may only be fitted for certain external power sources. See

section 2.3.2.1.1

Section 2, SYSTEM COMPONENTS, Page 2-4

Thermo Fisher Scientific

Sarasota 200 Ultrasonic Multipath

Flowmeter

Fig 3. Connection panel - enlarged view.

This panel is where all the connections are made and where the power fuses are located.

Before making any connections the external power source and the internal battery (if fitted)

should be unplugged. The connections are in groups from left to right:

Power connections. See section 2.3.2.1.1

• PL15 – BATT. 2 pin plug for connection to the internal 12volt battery if one is to be fitted.

• PL16 – DC IN. 3 pin plug for connection to the external dc supply.

• Fuses FS1 and FS2

Relay connections. See Specification, Appendix 2

• PL9 – RELAY 2 - VFC, 3 pins, NC, Common and NO

• PL13 – RELAY 1 - SOLID STATE, 3 pins. See Appendix 2

• PL17 – FAULT RLY, 3 pins, NC, Common and NO

Status LED

Inputs See section 2.3.2.1.3

• PL10 – INP 1. 3 pin plug, 4-20 mA

• PL11- INP 2. 3 pin plug, 4-20 mA

Outputs See section 2.3.2.1.4

• PL18 – OUT 1. 4 pin plug, 4-20 mA

• PL19 – OUT2. 4 pin plug, 4-20 mA

Ultrasonic transducer connections. See section 2.3.2.1.2

• SK2 – LEVEL (L). BNC coaxial socket for ultrasonic water level transducer(s) if fitted.

• SK3 – UPSTREAM (A). BNC coaxial socket for upstream velocity transducer(s)

• SK6 – DOWNSTREAM (A). BNC coaxial socket for downstream velocity transducer(s)

• SK4 – UPSTREAM (B). BNC coaxial socket for upstream crossed path velocity

transducer(s) if fitted.

• SK7 – DOWNSTREAM (B). BNC coaxial socket for downstream crossed path velocity

transducer(s) if fitted.

Communications See section 2.3.2.1.7

SK5 – PC. 9 way D socket for RS232 serial link to PC

PL14 – MODEM. 9 way D plug for RS232 serial link to modem.

Digital See section 2.3.2.1.6

PL12, External connection W to 0V to wake up if in intermittent (external control) mode.

PL12 1 to 4 and PL20 – not used.

SYSTEM COMPONENTS

Section 2, SYSTEM COMPONENTS, Page 2-5

Thermo Fisher Scientific

Sarasota 200 Ultrasonic Multipath

Flowmeter

2.3.2 Internal components

The enclosure houses the following components

• Mother board with power connections, connectors for transducers and peripheral devices.

• Internal battery option.

• Transducer interface card

• Central processor card, with data storage, input/output and communications circuits

• LCD display

2.3.2.1 Mother board

2.3.2.1.1 Power supply and internal battery option

The power supply input is 11 to 30 Volts DC (see specification in Appendix 2)

For operation from an AC source, an external adapter is required.

If the DC input is 15 Volts or more, the internal battery option may be fitted to allow operation

to continue in the event of power failure. The internal battery is automatically charged by the

power supply when external power is being supplied.

Power consumption and the period of operation from the internal battery option depend on the

mode of operation and are given in the specification.

The fuse values are both T1A.

2.3.2.1.2. Transducer connections

For an in-line configuration of velocity paths there will be 2 star junction boxes, 1 for each

transducer array. The coaxial cable from the upstream star box terminates at SK3. The

coaxial cable from the downstream star box terminates at SK6.

For a crossed configuration of velocity paths there will be 4 star junction boxes, 1 for each

transducer array. The coaxial cable from the upstream left star box terminates at SK3 and the

downstream right at SK6. The coaxial cable from the upstream right star box terminates at

SK4 and the downstream left at SK7.

If an upward facing depth transducer is being used, the coaxial cable from it terminates at

SK2.

SYSTEM COMPONENTS

Section 2, SYSTEM COMPONENTS, Page 2-6

Thermo Fisher Scientific

Loading...

Loading...