Page 1

Installation and Operation Manual

Thermo Scientific® Harris MBF-700

Refrigeration System

Page 2

©

20 Thermo Fisher Scientific. All rights reserved.

®

“Suva

” is a registered trademark of DuPont.

All other trademarks are the property of Thermo Fisher Scientific Inc. and

its subsidiaries.

Page 3

Table of Contents

Table of Contents

Section 100 – Product Introduction .............................................. 1

Freezer Overview ........................................................................... 1

General Construction .................................................................... 2

Control Panel ............................................................................... 3

Liquid CO2 (LCO2) Backup System .......................................... 4

Section 200 – Installation And Operation ..................................... 17

Installation Check List ................................................................... 17

Operator's Responsibilities ............................................................ 17

Water-cooled Condensing Unit Connections ............................. 19

Cleaning The Freezer Surfaces ....................................................... 21

Storage .......................................................................................... 21

Section 300 – Theory Of Operation .............................................. 22

Overview ....................................................................................... 22

Sequence Of Operation ................................................................. 22

Systems Description ...................................................................... 23

Refrigeration Systems .................................................................. 23

Safety Devices ............................................................................. 24

Temperature Control .................................................................. 24

LCO2 Backup System ................................................................ 25

Halo Passes ................................................................................. 26

Operation ...................................................................................... 26

Cascade Refrigeration System ..................................................... 26

Main Temperature Control ........................................................ 27

Backup Temperature Control System ......................................... 29

Section 400 – Maintenance And Service ........................................ 31

Preventive Maintenance Procedures .............................................. 31

Air Cooled Condensers ............................................................... 31

Compressor Oil Level ................................................................. 31

fan Motors .................................................................................. 31

Defrosting ................................................................................... 31

Thermo Fisher Scientific Generic MBF700 Service Manual i

Page 4

Table of Contents

LCO2 Vent ................................................................................ 32

Trouble Shooting Guide ............................................................... 32

Contactors And Relays ................................................................ 39

Compressor Motors, Three Phase ............................................... 39

Partial Or Complete Loss Of Refrigeration ................................. 40

Checking Refrigerant Charge ...................................................... 40

Installing Gauges ........................................................................ 41

Leak Testing, Repairing And Charging – An Overview ............... 41

Repair Procedures .......................................................................... 43

Compressor Replacement ............................................................ 43

Backflush Procedure ................................................................... 46

Evacuation Procedure ................................................................. 48

Charging Procedure -- 1st (High) Stage ...................................... 51

Charging Procedure -- 2nd (Low) Stage ...................................... 51

Thermocouple Labeling And Locations ...................................... 53

temperature Calibration .............................................................. 53

Section 500 – Appendix ................................................................ 55

Refrigeration System Data ............................................................ 56

Service Parts List ........................................................................... 57

ii Generic MBF700 Service Manual Thermo Fisher Scientific

Page 5

SECTION 100 – PRODUCT INTRODUCTION

SECTION 100 –

PRODUCT

INTRODUCTION

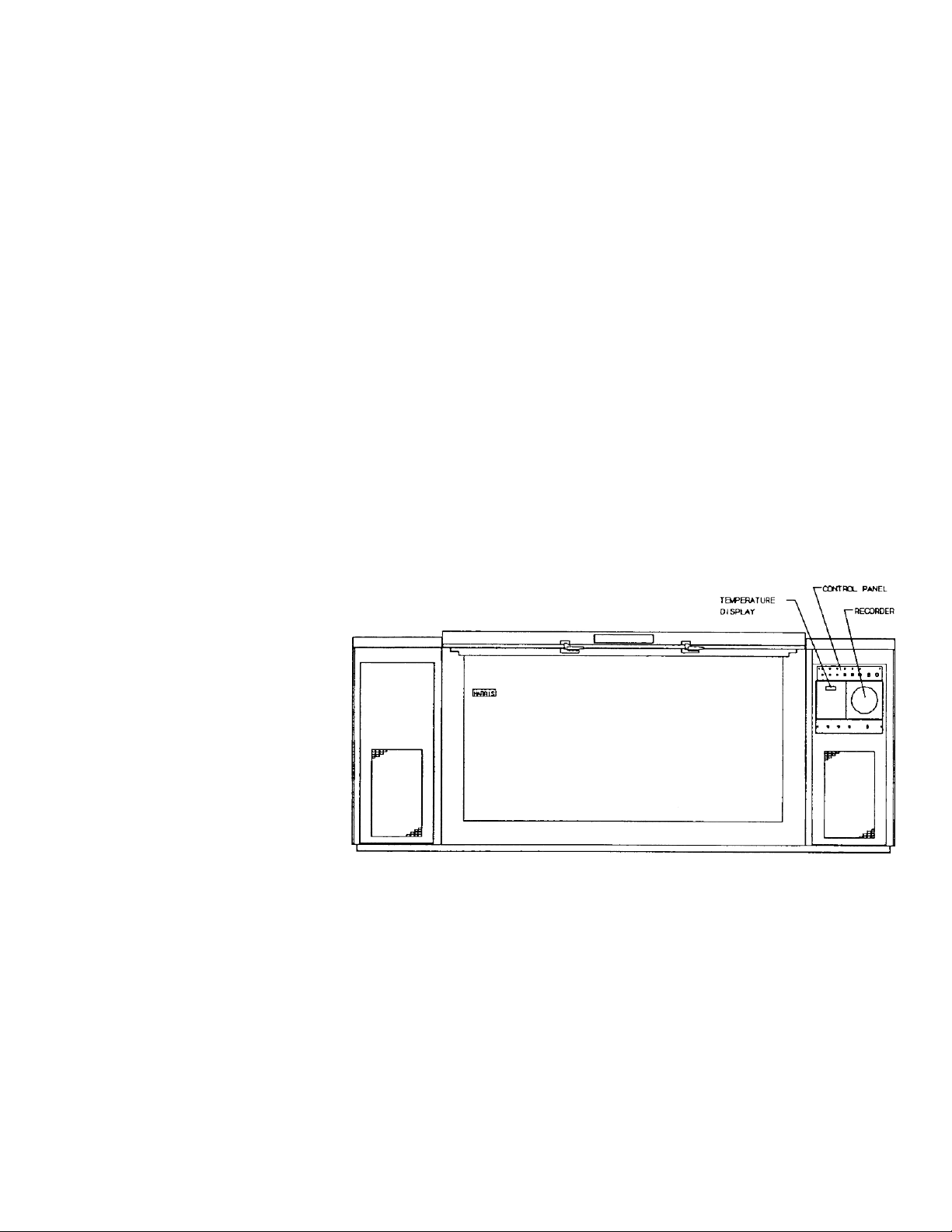

FREEZER OVERVIEW This unit is a low temperature freezer designed to operate with a chamber

temperature in the range of –65 to –85 °C (-85 to –121 °F) and in an

ambient temperature range of 15 to 32 °C (59 to 89.6 °F).

The cabinet configuration is that of a rectangular solid measuring 121” long

(3 07.3cm) x 47.5” high (120.7cm) with lid and all covers in place x

35.312” deep (89.7cm). When installing the freezer, a minimum of six

inches (6”) must be provided on all sides of the freezer for proper air

circulation.

Weight is 1510 lbs. (684.8Kg) net.

Shipping weight is 1790 lbs (811.8Kg).

Power Requirements: 208V - 230VAC, 3 Phase , 60Hz

120VAC, 1 , 60Hz (LCO2 backup system)

Figure 1. General Freezer Outline (see Figure 3 for control panel

details)

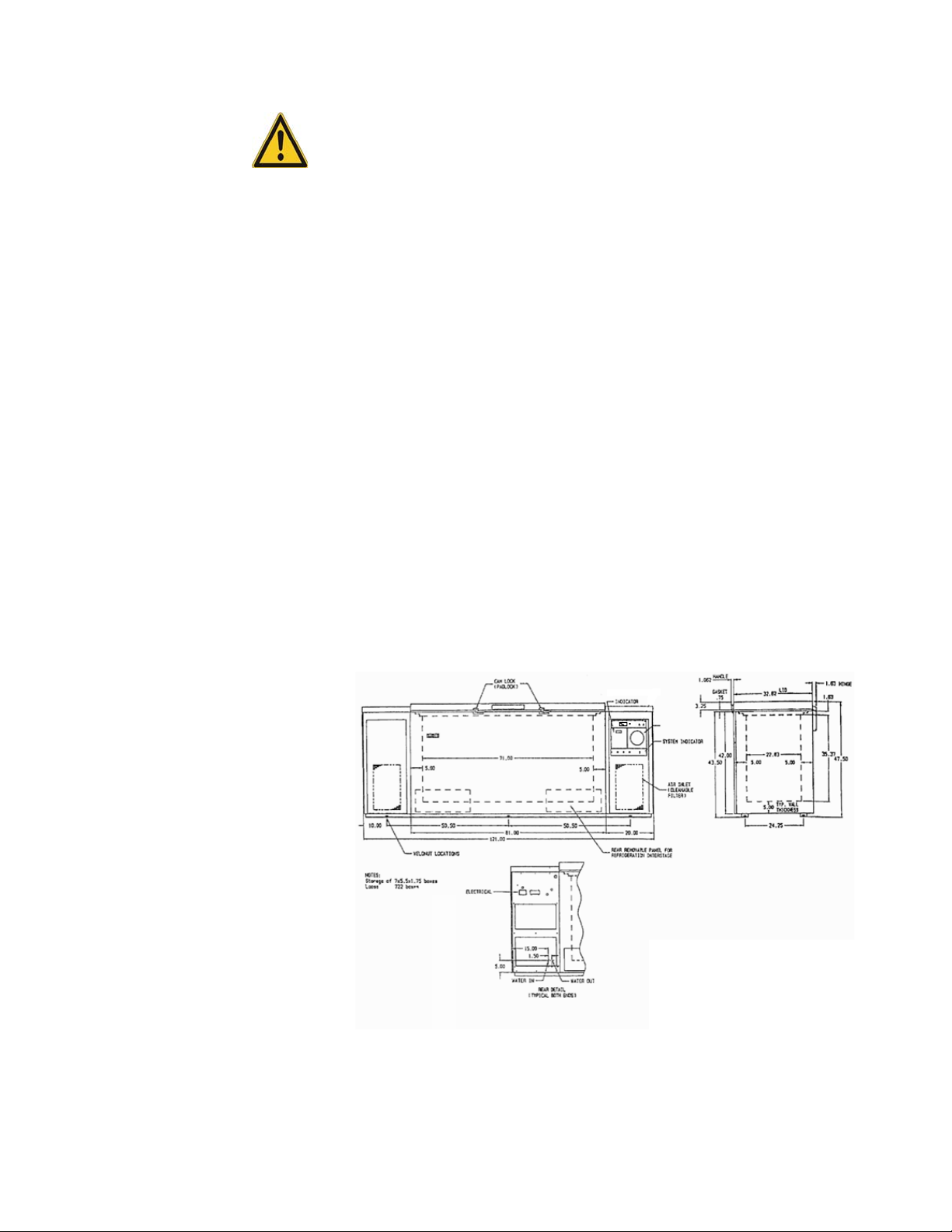

The interior useable space is also rectangular. The four corners are coved.

With insulating sub lids in place it measures 71” long (180.3cm)x 35.37”

high (89.9cm) x 22.63” deep (57.5cm). The interior volume is 31 Ft.

(878.7 liters.)

The cabinet is insulated with nominal 5” of foamed-in-place polyurethane

insulation.

Thermo Fisher Scientific Generic MBF700 Service Manual 1

Page 6

SECTION 100 – PRODUCT INTRODUCTION

CAUTION Do not discard the sub lids. They are necessary for the

operation of the unit.

The refrigeration arrangement employed in this freezer is a specially

designed assembly using four hermetic motor compressors. This design is

termed a “redundant cascade system”. A more complete description of this is

in the pages following. Stainless steel storage racks for inventory control are

avaiable as an option and must be ordered separately.

GENERAL

CONSTRUCTION

The lid is held tightly closed by means of cam locks having provision for a

user supplied padlock.

Durable corrosion protection is provided by an electrostatically applied

epoxy fused powder coating over cold rolled steel.

To provide a redundant refrigeration system, the inner tank is double

wrapped with copper tubing forming a dual circuit evaporator. In addition,

each of these circuits has its own compressor, condenser and liquid

refrigerant control (capillary tube). Each of the redundant systems will

support full operation to maintain the storage temperature. When set to

alternate between system “A” and system “B”, refrigeration is applied to the

freezer chamber alternating between systems on each cycle.

Figure 2. Cabinet Dimensional Drawing

2 Generic MBF700 Service Manual Thermo Fisher Scientific

Page 7

SECTION 100 – PRODUCT INTRODUCTION

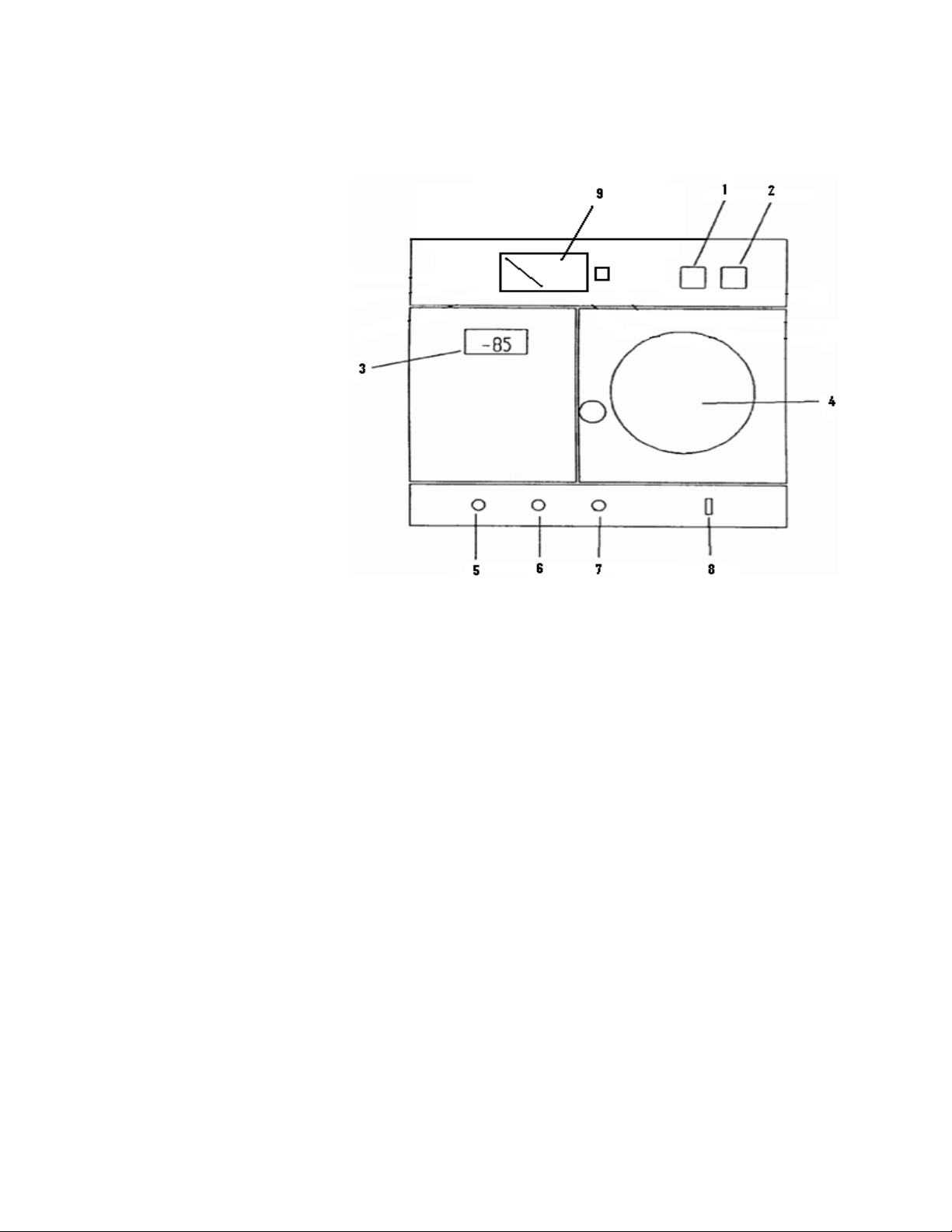

CONTROL PANEL All controls are located at the right end of the cabinet

Figure 3. Control Panel Detail

1. Key-operated alarm ON/OFF switch. Turns on local audio alarm.

2. Key-operated compressor ON/OFF switch. Turns on power to

compressors and control system.

3. Digital temperature indicator and primary control

4. Temperature recorder, 7-day, 6” diameter.

5. System “B” indicator light. “ON” when system “B” 1st stage

running.

6. System “A” indicator light. “ON” when system “A” 1st stage

running.

Thermo Fisher Scientific Generic MBF700 Service Manual 3

Page 8

SECTION 100 – PRODUCT INTRODUCTION

7. Alternate system alarm indicator light. “ON” when auxiliary control

causing both systems to operate.

8. Heater switch. Operates breaker strip condensate heater.

9. Battery meter. Displays state of battery charge when button is

pressed.

The remote alarm contacts were developed to provide an alert for an alarm

condition. The remote alarm contacts are normally closed, and open during

an alarm event. The contacts are rated for a maximum of 36V3A

LIQUID CO2 (LCO2)

BACKUP SYSTEM

When connected to a user supplied siphon tank of liquid CO2, the backup

system will provide a source of backup refrigeration in case of power failure

to the mechanical refrigeration equipment. The control assembly operates

on 1 20VAC, 1, 60Hz. A backup battery supply is continuously charging for

operation of the backup system during power failure.

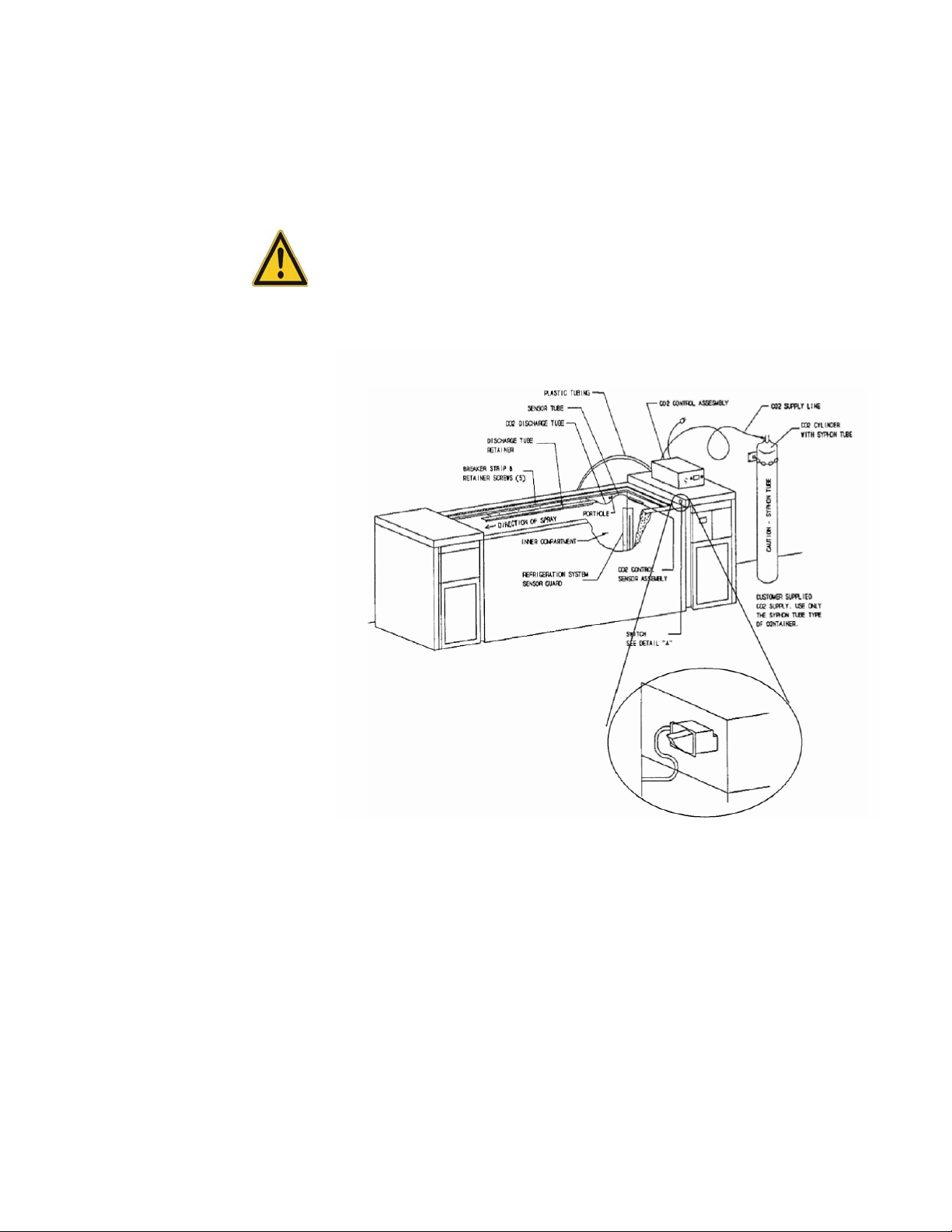

Installation

1. Place the LCO2 control system on top of the System B mechanical

section.

2. Connect the LCO2 supply to the back of the control system.

3. Connect theLCO2 distribution tube to the back of the unit.

4. Connect the LCO2 temperature sensor to the Mate-N-Loc

connector that hangs from the rear of System B mechanical section.

5. Connect the LCO2 control system harness to the Mate-N-Loc

connector that hangs from the rear of System B mechanical section.

6. The assembly of the LCO2 to the cabinet is now complete.

Note An LCO2 supply must be provided by the customer. The supply

pressure must be 900 – 1,000 PSIG.

4 Generic MBF700 Service Manual Thermo Fisher Scientific

Page 9

SECTION 100 – PRODUCT INTRODUCTION

7. Uncoil the tubing from the control unit and connect to the LCO2

tank or supply connection.

8. Turn on the LCO2 valve.

9. Refer to the Backup System Owners Manual for operation

instructions.

Note LCO2 backup systems are typically built with a relief valve set for

1,300 PSIG.

LCO2 Control System Battery Condition

The charge level light illuminates when the battery is below 80% of full

charge. It is also possible that the charge level light will illuminate when the

control system is dispensing LCO2.

Placing LCO2 control system in storage

CAUTION Any rise in temperature will cause a rapid rise of pressure of

liquid CO2 trapped in the supply line. After turning off the LCO2 supply,

bleed the supply line by lowering the LCO2 setpoint sufficiently to cause

the LCO2 solenoid to open. With the solenoid open, disconnect the supply

line from the backup system control unit.

After disconnecting the LCO2 supply line, set the LCO2 control to +50 oC

and plug the unit into the power supply. This will keep the battery charged

and prevent the solenoid from operating.

LIQUID CO

2 BACKUP REFRIGERATION

This accessory, when connected to a user supplied siphon tank of liquid

2, will provide a source of backup refrigeration in case of power failure to

CO

the mechanical refrigeration equipment. The control assembly for this

accessory operates over a range of 200VAC to 240VAC, 10, either 50Hz or

60Hz. There is a continuous charging battery backup power supply for

operation of the accessory during power failure.

Installation:

1. Place the LCO2 control system on top of the System B mechanical

section.

Thermo Fisher Scientific Generic MBF700 Service Manual 5

Page 10

SECTION 100 – PRODUCT INTRODUCTION

2. Place the CO2 control system on top of the freezer lid.

3. Locate the switch hole in the left hand side of the right hand

machine compartment cover and remove the cover plate that was

factory installed.

4. Remove the machine compartment cover by locating and removing

the screws at the back and at front securing the cover to the housing.

5. Locate the lid switch in the accessory kit.

6. Locate the leads from the control unit with two-prong connector.

Feed the leads through the hole provided in the back of the unit,

route through machinery compartment to the left front and up

through the second hole provided. Then feed the leads through the

switch hole provided in the machinery compartment cover and

connect to the switch terminals. Snap the switch into the hole

making sure that the curved side of the plunger is on the bottom

side.

7. Replace the machinery compartment cover securing with the screws

front and back.

8. Identify the CO2 discharge and control assembly mounted in the

perforated housing.

9. Remove the coiled control bulb and the CO

2 discharge tube from

the housing, insert the bulb through the rear cabinet porthole and

reassemble the bulb to the housing inside the cabinet. Mount the

housing to the right inside wall of the cabinet using two of the three

factory installed screws. Route the CO2 discharge tube through the

porthole and, after loosening the screws securing the rear breaker

strip, slide the discharge tube under the retainer strip and re-tighten

the screws.

10. The assembly of the CO

2 to the cabinet is now complete.

6 Generic MBF700 Service Manual Thermo Fisher Scientific

Page 11

SECTION 100 – PRODUCT INTRODUCTION

Note An uninsulated CO2 supply cylinder with siphon tube must be

provided by the customer. The siphon tube allows liquid CO2 to be drawn

from the cylinder. The supply pressure must be between 600 and 1050 psig.

The supply temperature must be between 7 oC and 31 oC (45 oF and 88

o

F). DO NOT INSTALL A PRESSURE REGULATOR BETWEEN THE

CYLINDER AND THE CONTROL UNIT. If you are unfamiliar with

handling compressed gases, refer to a qualified service technician.

11. Uncoil the tubing from the control unit and connect to the CO2

tank or supply connection.

12. Turn on the CO2 valve.

13. Adjust the temperature setpoint to the coldest position.

14. Connect the power cord of the control unit to the voltage source

indicated on the unit serial plate.

15. Open and close the freezer lid to insure that the CO2 dispenses into

the freezer when the lid is closed and does not dispense when the lid

is open. If there is no discharge, check to see that the wires are

fastened securely to the lid switch and that the switch plunger is

actually depressed.

°

16. Set the temperature control at a minimum of 5

operating temperature of the freezer but never colder than -70

°

Setting colder than -70

C will result in a continuous dispensing of

C warmer than the

°

C.

the CO2 supply.

CO

2 Control System Battery Condition:

The charge level light comes ON when the battery is below 80% of full

charge. It is also possible that the charge level light will come on when the

control system is dispensing CO2.

When placing the control unit in storage, set the CO2 control to +50 °C and

plug the unit into the power supply. This will keep the battery charge and

prevent the solenoid from operating. The capillary tube leading from the

control unit to the control bulb may be coiled up for storage but do not

make coils any smaller than 4 inch diameter. There are two screws provided

Thermo Fisher Scientific Generic MBF700 Service Manual 7

Page 12

SECTION 100 – PRODUCT INTRODUCTION

in the back of the control cabinet that match the slots in the back of the

control bulb housing. Slip the slots in the housing under the screw heads

and tighten. This will hold the housing and bulb securely to prevent

damage.

CAUTION Do not turn off the CO2 supply trapping liquid in the supply

line. Any rise in temperature will cause a rapid rise of pressure that will

rupture the protective disk in the control unit.

Figure 4. CO2 Backup System

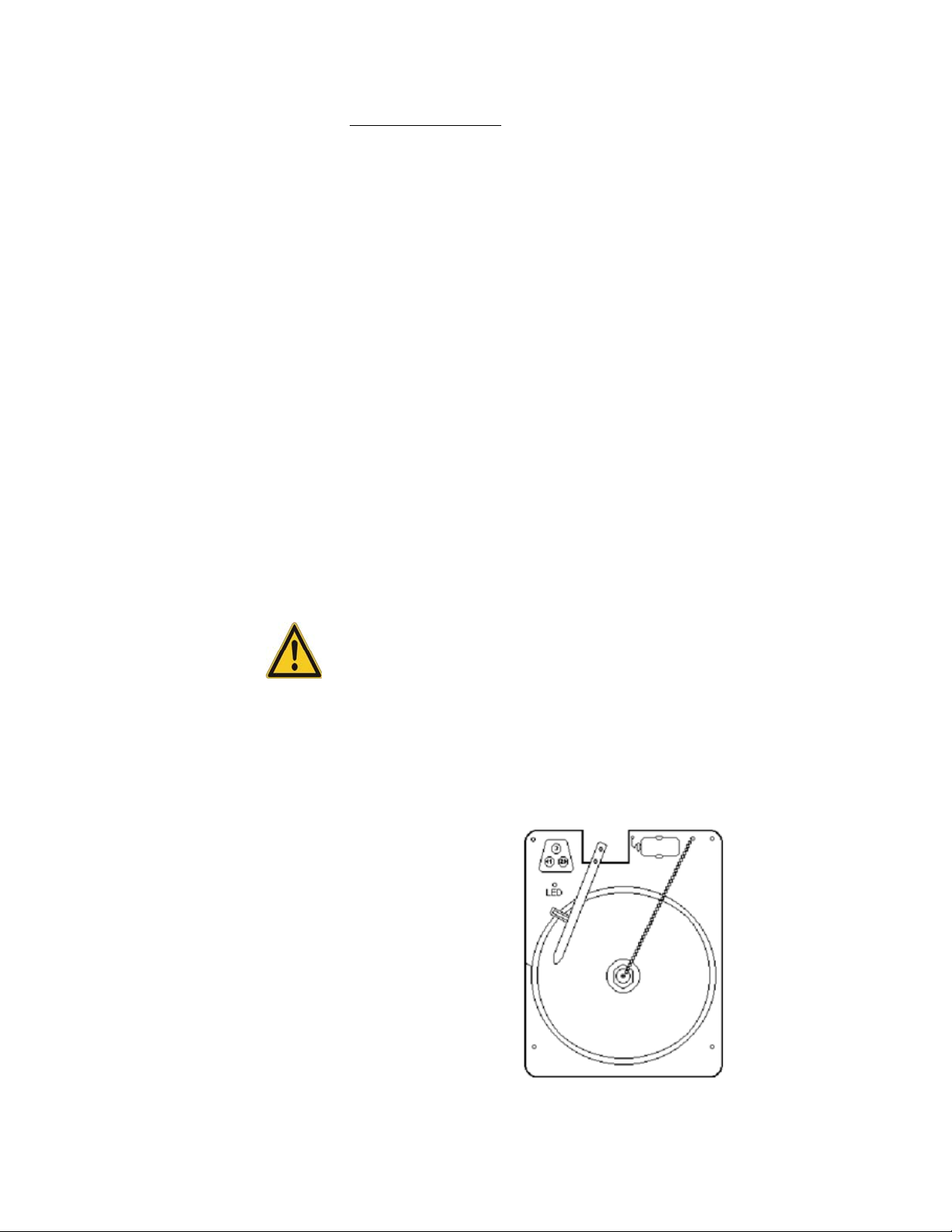

COBEX ELECTRONIC, 7-DAY CIRCULAR CHART

TEMPERATURE RECORDER

This product includes a manufacturer-installed electronic temperature

recorder. These instructions are provided to assist with the initial set-up,

operation and general maintenance of the recorder.

8 Generic MBF700 Service Manual Thermo Fisher Scientific

Page 13

SECTION 100 – PRODUCT INTRODUCTION

CobexRecorder Face

Setup and Operation

The recorder has been factory-installed, programmed, and calibrated for

your new system. Operation will begin when the system is powered on. To

prepare the recorder to function properly, you should perform the following

steps:

1. Review figure below to become familiar with recorder features.

2. Open recorder door to access recorder.

3. For back-up power, connect the 9 volt DC battery located at the

recorder’s upper right hand corner.

4. Install clean chart paper (refer to Changing Chart Paper,below).

5. Remove plastic cap from pen stylus (ink or pressure sensitive) and

close recorder door.

Note Recorder may not respond until the system reaches temperatures

within the recorder’s range.

This should complete operator setup. Additional information is provided

for maintenance and troubleshooting as required.

MAINTENANCE

Thermo Fisher Scientific Generic MBF700 Service Manual 9

Page 14

SECTION 100 – PRODUCT INTRODUCTION

Power Supply

The recorder normally operates with AC power when the system is

operating. If AC power fails the LED indicator flashes to alert you to a

power failure. The recorder will continue sensing cabinet temperature and

the chart will continue turning for approximately 24 hours with back-up

power provided by the 9 volt battery. Both the battery and main power are

O.K. when the LED indicator glows continuously.

Changing Chart Paper

Locate the pressure sensitive buttons at the front, upper left of the recorder

panel. Press and hold the change chart button (#3) for 1 second. Pen will

move off scale. Unscrew center nut, remove old chart paper, and install new

chart paper. Carefully align the day and time with the reference mark on the

recorder panel. Replace center nut and hand tighten. Press the change chart

button (#3) again to resume temperature recording.

Changing Marker Pen

For recorders having a marker pen rather than a stylus for pressure-sensitive

paper, the pen provided is a fiber-tipped cartridge type, and is attached to

the pen arm. As the pen ink supply runs out, the pen color will become

lighter indicating the pen should be replaced. To install a new pen, loosen

the (2) screws at the top of the arm. Slip the pen cartridge out and remove

the “U” shaped clip tab from the pen. Discard the old pen. Insert the clip

tab into a new pen and then re-fasten to the pen arm.

Changing Temperature Range Program

This recorder is capable of operating in multiple pre-programmed

temperature ranges. The correct temperature range program was selected

upon factory installation and is retained even during power interruptions. If

the temperature range is wrong for any reason, it can be easily

reprogrammed as follows:

• Press change chart button #3. Pen arm will move off scale, LED will

glow continuously.

• Press and hold button #1 for 5 seconds. LED indicator will begin

flashing.

• The number of flashes corresponds to the temperature range program as

follows:

10 Generic MBF700 Service Manual Thermo Fisher Scientific

Page 15

SECTION 100 – PRODUCT INTRODUCTION

No. of Flashes Temperature Range Application Option #

1 -40 to +25°C Refrigerators 6*83-7*

2 -115 to+50°C ULT’s 6*83-6*

3 -200 to 0°C Cryogenic 6*83-5*

4 0 to +60 Newer Units Only

Change program to the “-115 °C to +50°C” temperature range by using the

left (#1) button to increase and the right (#2) button to decrease the number

of flashes. Press the change chart button (#3) when the desired program is

set. Pen will move to the outer edge of the chart for 5 seconds. After 5

seconds, the LED indicator will glow continuously and the pen arm will

move to begin recording temperature.

Calibration

Note The pen does not begin to move until the button is held for 5 seconds.

This recorder has been accurately calibrated at the factory and retains

calibration even during power interruptions. If required, however,

adjustments can be made as follows:

1. Run unit continuously at bottom-out temperature. Continue steady

operation at least 30 minutes to provide adequate time for recorder

response.

2. Measures cabinet center air temperature with a calibrated

temperature monitor.

3. Compare recorder temperature to center air temperature. If

necessary, adjust recorder by pressing the left (#1) and right (#2)

chart buttons.

Thermo Fisher Scientific Gener ic MBF700 Service Manual 11

Page 16

SECTION 100 – PRODUCT INTRODUCTION

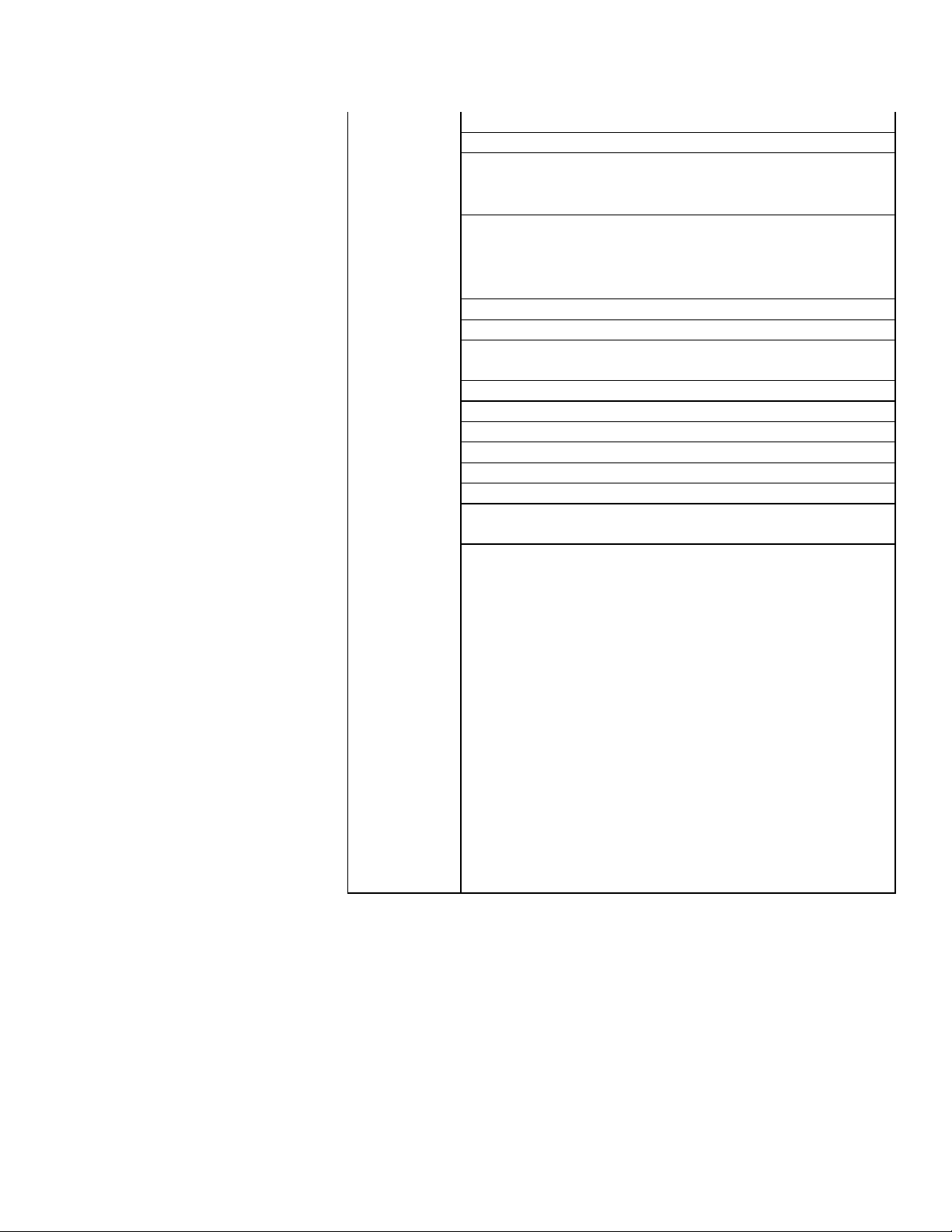

COBEX RECORDER TROUBLESHOOTING GUIDE

LED Flashing Low Battery

Replace with a FRESH 9v alkaline battery. Battery must be

new.

No AC Power

1. Remove battery.

2. If LED goes out, then no power is getting to the unit.

3. Check power and transformer connections.

Transformer secondary is approximately 1 5v AC.

4. Be sure transformer is wired for proper voltage.

LED Out or

Unit “Dead”

Possible bad Board

1. Remove battery.

2. Disconnect or turn off power.

3. Restore power.

4. Reconnect battery.

5. Return entire unit if not working.

Wro ng Ra ng e

1. Push #3 “Chart Change”.

2. With pen off chart, hold #1 for 7 seconds.

3.

Release. (

Note

: No range recall).

4. Green LED Flashes.

5. Push #1 or #2 to change:

• 1 flash -40 to +25C

• flashes -115 to+50C

• flashes -200 to 0C

• flashes 0 to +60C (newer units only)

6. Push #3 again.

12 Generic MBF700 Service Manual Thermo Fisher Scientific

Page 17

Not Calibrated Calibrate Recorder

1. Push #3. Pen comes off chart.

2. Push #3 again. Pen stops briefly on returning to

chart. Stopping point should be at edge of chart. If

not perform the following:

3. Be sure pen arm is aligned with pen arm bracket. If

not, loosen screws a adjust. During stopping interval

adjust pen arm using #1 and #2 to align pen arm with

edge of chart.

4. Place probe in cold water for 5 min. Slow response.

5. Measure the water temperature with a thermometer.

6. Adjust calibration using #1 and #2 to make recorder

read same temperature as thermometer.

7. Put probe back into solution.

8. Wait 5 minutes and adjust to cabinet temperature.

Bad Probe

1. Check probe connections

• Red wire connected to J6 pin 1

• Both black wires to J6 pin 2

2. Measure voltage across J6 approximate voltages are as

follows:

• -150C=35mv

• -85C=75mv

• -30C=1 00mv

• 3.5C=1 10mv

• 25C = 120mv (ambient)

• Probe open circuit 1 .23v (approximately)

• Probe short circuit = 0.0v (recorder possibly) faulty.

Replace probe. If still 0.0v return/replace recorder.

• >2.0v = Replace recorder and probe.

If probe voltage is off by more than a factor of 2 then probe

is faulty.

Possible bad Board

1. Remove battery.

2. Disconnect or turn off power.

3. Restore power.

4. Reconnect battery.

5. Return entire unit if not working.

SECTION 100 – PRODUCT INTRODUCTION

Thermo Fisher Scientific Gener ic MBF700 Service Manual 13

Page 18

SECTION 100 – PRODUCT INTRODUCTION

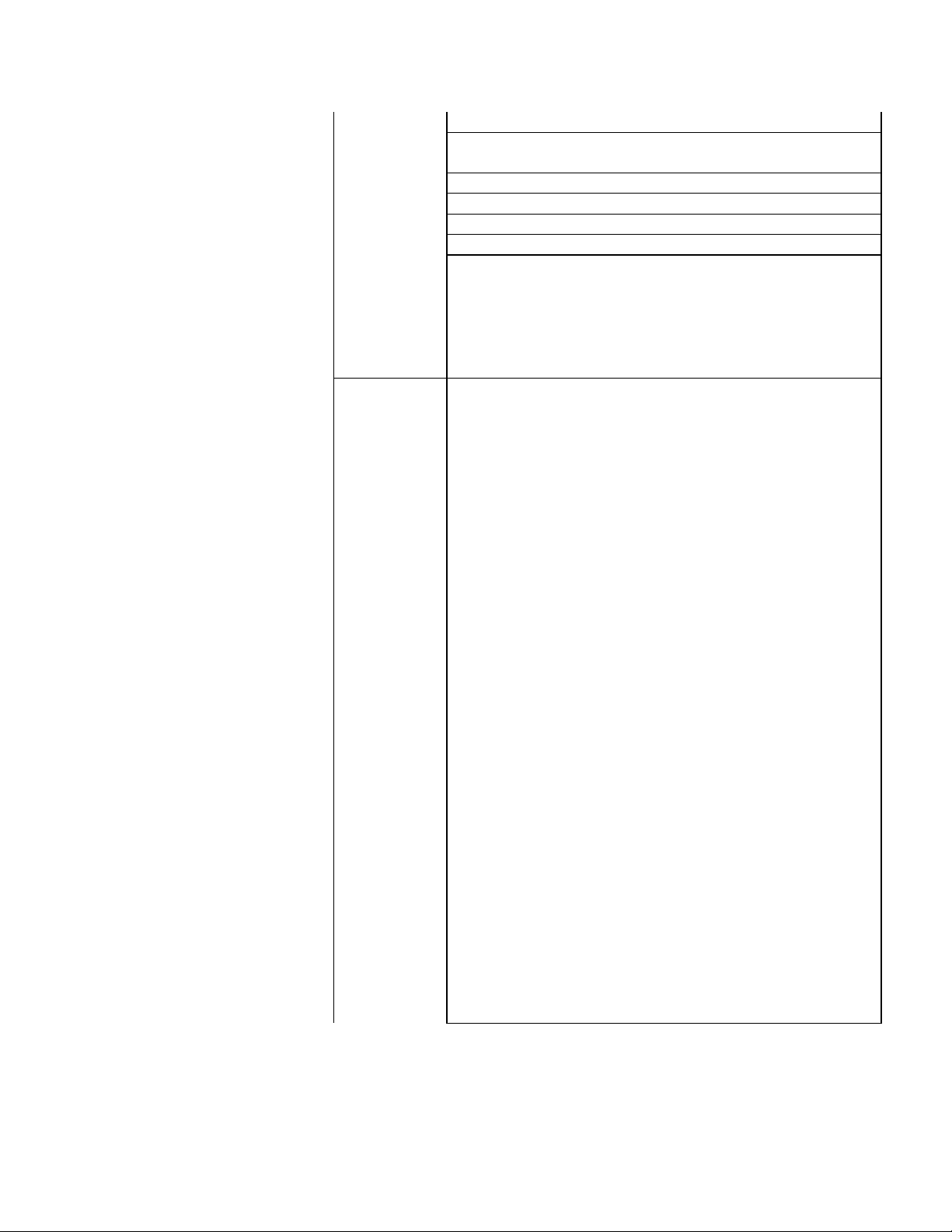

Pen Goes to

Center

Wro ng Ra ng e

1. Momentarily depress button #3 (“Chart Change”

button).

2. With pen off chart, hold #1 for 7 seconds.

3. Release. (Note: No range recall).

4. Green LED Flashes.

5. Momentarily depress #1 or #2 to change:

• 1 flash -40 to +25C

• 2 flashes -115 to+50C

• 3 flashes -200 to 0C

• 4 flashes 0 to +60C (newer units only)

6. Momentarily depress “Chart Change” button again.

7. Not calibrated (see below)

Not Calibrated Calibrate Recorder

1. Push #3. Pen comes off chart.

2. Push #3 again. Pen stops briefly on returning to

chart. Stopping point should be at edge of chart. If

not perform the following:

3. Be sure pen arm is aligned with pen arm bracket. If

not, loosen screws a adjust. During stopping interval

adjust pen arm using #1 and #2 to align pen arm with

edge of chart.

4. Place probe in cold water for 5 min. Slow response.

5. Measure the water temperature with a thermometer.

6. Adjust calibration using #1 and #2 to make recorder

read same temperature as thermometer.

7. Put probe back into solution.

8. Wait 5 minutes and adjust to cabinet temperature.

Bad Probe

1. Check probe connections

• Red wire connected to J6 pin 1

• Both black wires to J6 pin 2

2. Measure voltage across J6 approximate voltages are as

follows:

• -150C=35mv

• -85C = 75mv

• -30C=100mv

• 3.5C=110mv

• 25C = 120mv (ambient)

• Probe open circuit 1 .23v (approximately)

• Probe short circuit = 0.0v (recorder possibly) faulty. Replace

probe. If still 0.0v return/replace recorder.

• >2.0v = Replace recorder and probe.

• If probe voltage is off by more than a factor of 2 then

probe is faulty.

14 Generic MBF700 Service Manual Thermo Fisher Scientific

Page 19

SECTION 100 – PRODUCT INTRODUCTION

Pen Not

Printing

Chart Loose

1. .Tighten chart knob

2. Attempt to turn chart counter-clockwise

3. If chart turns then tighten knob more

No Pen Pressure

1. Unscrew pen arm

2. Bend pen arm slightly downward

3. Reattach

Pen Indicating

Wrong Temp

Pen Will Not

Come

Completely

OffChart

4. Recalibrate (see “Not Calibrated”)

Not Calibrated

Recalibrate (see “Not Calibrated”)

Wrong Chart

Be sure proper chart is used with selected range

• 1 Flash -40 to +25C

• 2 Flashes -115to+50C

• 3 Flashes -200 to 0C

• 4 Flashes 0 to -+60C (newer units only)

Pen Arm Displaced

1. Unscrew pen arm

2. Align pen arm with pen arm bracket

3. Recalibrate (see “Not Calibrated”)

Thermo Fisher Scientific Gener ic MBF700 Service Manual 15

Page 20

SECTION 100 – PRODUCT INTRODUCTION

Pen Arm

Oscillating

No Recorded

Line

Not Calibrated

Recalibrate (see “Not Calibrated”)

No Pen Pressure

1. Unscrew pen arm.

2. Bend pen arm slightly downward.

3. Reattach

4. Recalibrate (“Not Calibrated”).

Chart Loose

1. Tighten chart knob.

2. Attempt to turn chart counter-clockwise.

3. If chart turns, tighten knob more.

16 Generic MBF700 Service Manual Thermo Fisher Scientific

Page 21

SECTION 200 – INSTALLATION AND OPERATION

SECTION 200 –

INSTALLATION

Do not attempt to operate this freezer until the preceding Installation Check

List steps have been completed

AND OPERATION

INSTALLATION

CHECK LIST

The freezer is in place.

The freezer has been leveled.

Check freezer data plate voltage.

Check supply voltage is the same as data plate.

Check that power panel circuit protection rating does not exceed that indicated on the

data plate.

LCO2 supply valve is Off

Date Initial

Facility monitoring system connected to freezer’s remote alarm contacts.

If applicable, water supply and discharge are connected if unit uses a water-cooled

condenser in accordance with WATER-COOLED CONDENSING UNIT

CONNECTIONS, page 19.

No product loaded in freezer.

Main building power panel breakers are On.

Using key provided, turn the compressor key switch to ON.

Set primary control set points. (see Appendix B)

The frame heater switch (#8, Figure 3).is shipped from the factory in the OFF position.

Turn frame heater switch ON only if the humidity is sufficiently high that it may cause

frost on the strips.

Turn LCO2 supply valve On after cabinet reaches operating temperature.

OPERATOR'S

RESPONSIBILITIES

Note These paragraphs define the Operator's responsibilities for reporting

trouble symptoms on startup of the freezer and also observing its operation

on an ongoing basis in order to prevent any mechanical or electrical failures

that could result in loss of blood products.

Thermo Fisher Scientific Gener ic MBF700 Service Manual 17

Page 22

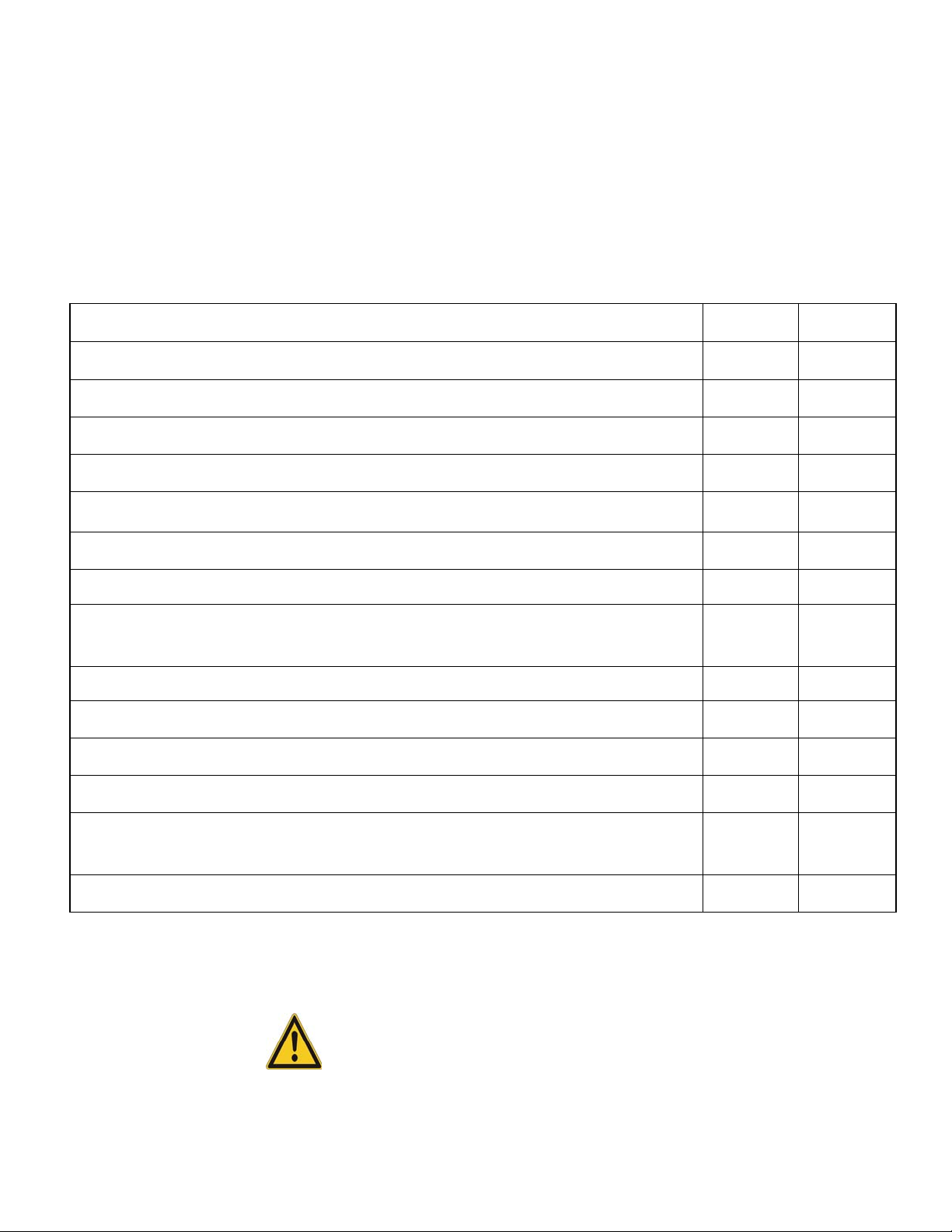

SECTION 200 – INSTALLATION AND OPERATION

Frequency Of

Description Of Tasks, Observations & Record Keeping Requirements

Ta s k

Once on first

start

a. Time required for initial pulldown. If only partial loss of the refrigerant has occurred, the sign

°

will be slow pulldown time required reaching -80

C. Pulldown time should be 2.5 hours or

less. If it is more than 2.5 hours, the technician must either determine the cause and the

remedy therefore or IMMEDIATELY SHUT DOWN THE FREEZER until the problem can

be diagnosed and remedied.

b. Carefully record the first few on-off periods with freezer empty, and then again loaded with

product. Keep this record with the freezer at all times for future reference in troubleshooting.

c. If the installation is made in an air-conditioned area, there will not be much, if any, change in

cycle. However, if the ambient temperature is subject to changes, make a record of cycle times

at these various ambient temperatures.

Daily a. Listen for rattles. If refrigerant-carrying copper tubing is allowed to rub against other tubes or

any object, a leak will very quickly occur resulting in loss of the refrigerant charge and cabinet

temperature.

b. Watch the system operation indicator light. It should not be showing the same system always

operating. For instance, when system A has been operating and shuts off, system B should start

on the next control call for cooling.

Weekly a. Air-Cooled units only: clean the condenser air filter when its original jet-black color has

changed. Attention to this detail will assure shortest running times and prolong the life of the

freezer.

b. Make sure the lid closes without interference and that sub lids are always in place.

c. Ensure that the sub lids are in place.

d. Verify that the LCO2 vent is free of frost accumulation.

On Using a. Watch for lid gasket tears. Streaks of frost will collect inside the freezer at the precise location

of the torn or cut gaskets.

b. Defrost the cabinet if frost or ice build-up exceeds 1/4” thickness: remove product,

turn power key switch Off, leave unit open 48 hours, remove moisture, restart unit.

Call the Maintenance Department or the manufacturer’s Technical Service

group (1-800-438-4851) for assistance.

18 Generic MBF700 Service Manual Thermo Fisher Scientific

Page 23

WATER-COOLED

CONDENSING UNIT

CONNECTIONS

SECTION 200 – INSTALLATION AND OPERATION

CAUTION ONLY QUALIFIED REFRIGERATION TECHNICIANS

ARE TO MAKE CONNECTIONS OR ADJUSTMENTS.

The MBF700 can be purchased with air-cooled condenser, water-cooled

condenser, or both. If purchased with water-cooled condensers, there are

two water supply and two water discharge connections to be made at the

rear of the cabinet (see Figure 12) if you wish to use the water cooling

feature:

1. Locate the machine sections at each end of the freezer as you face the

rear of the cabinet.

2. At the bottom of each machine section are two 3/8” O.D. copper

tubes stubbed out through the cabinet grille (see diagram, next

page). The outermost tubes are the COLD WATER INLET and the

inner-most tube is the WATER OUTLET.

• The four tubes terminate with 3/8” 45 ° SAE flare nuts.

Note If it is necessary to reship these units and water has been connected in

the past, the lines must be blown clear with compressed air in order to

preclude freezing and rupturing the water cooled condenser.

There are normally three possible sources of cooling water for these freezers,

and any one may be satisfactory used. They are:

1. City water supply, discharge water wasted to drain.

2. Chilled water from a building air conditioning chiller. In this case,

the discharge water goes back to the chilled water loop and is

recirculated.

3. Cooling tower water supply, discharge water goes back to the tower

water loop.

Factory specification for maximum water supply temperature is 85 °F. The

automatic water regulating valve allows use of any of these sources. Seasonal

water temperature changes may require slight adjustment of the water

regulating valve. The factory setting is 195 PSIG.

Thermo Fisher Scientific Gener ic MBF700 Service Manual 19

Page 24

SECTION 200 – INSTALLATION AND OPERATION

The Selector Ball Valve can be accessed by removing the end cover on each

of the machine compartments.

The valve may be identified by the square wrench flats on its top. The

flow-indicating arrow will be perpendicular to the tubing when the valve is

closed, and parallel to the tubing when the valve is open.

Adjustment of the Selector Ball Valve is to be performed only by a qualified

refrigeration technician.

Note

• For air cooling only, do not connect water and leave valve closed.

• For use with water cooling, connect water and open the valve.

To adjust the automatic water regulating valve for best operating economy,

install a head pressure gauge; with the compressor operating, turn the

adjusting stem (located on top of the valve) until a head pressure of 195

PSIG is measured. Clockwise rotation of the adjusting stem lowers the head

pressure; counterclockwise rotation raises the head pressure.

20 Generic MBF700 Service Manual Thermo Fisher Scientific

Page 25

SECTION 200 – INSTALLATION AND OPERATION

CLEANING THE

FREEZER SURFACES

STORAGE Before placing the freezer in storage, turn the key switch to Off, unplug the

The inside and outside of the freezer are coated with a heat fused epoxy

powder finish. It may be cleaned with any non-abrasive cleaner such as hand

dish washing detergent. To prevent odors on the inside of the freezer after

cleaning, it is recommended that, after cleaning with detergent, the entire

surface be wiped with a clean cloth soaked with a solution of one-half(1/2)

gallon of water and one-quarter (1/4) cup of baking soda.

power cord, open the lid and allow the interior to warm up to ambient

temperature. Dry out the interior. Prop the lid open at least 6" and secure in

this position. If water cooling has been used, the water lines of BOTH water

cooled condensers must be blown out to prevent freezing.

Thermo Fisher Scientific Gener ic MBF700 Service Manual 21

Page 26

SECTION 300 – THEORY OF OPERATION

SECTION 300 –

THEORY OF

OPERATION

OVERVIEW The MBF700 utilizes alternately-operating redundant refrigeration systems

to maintain -85 °C while extending unit’s life and providing safety in the

event of a system failure. The electronic thermostat is backed up by an

electromechanical thermostat in case of primary control failure. A liquid

CO2 (LCO2) backup system provides safety in case of a catastrophic failure

of both systems. An external alarm connection is provided in case of an

alarm event: Loss of Power and Temperature Warm or Cold alarm.

SEQUENCE OF

OPERATION

When the compressor key switch (Figure 3, key #5) is initially turned On ,

the digital display will illuminate and read actual cabinet temperature.

Note It is normal for the top flange of the freezer cabinet to be warm during

operation of the systems. This is particularly true when the chamber is first

pulling down in temperature.

Within six minutes from the time the compressor power key switch is

energized, the red Backup Control alarm indicator will light and both first

stage compressors will start. They will run until the Reverse Acting Pressure

Control (RALPC) in the high stage system senses a pressure corresponding

to –40 °F, at which time the contact points will close. These points are

connected electrically in the low stage control circuit, causing the low stage

compressor to start. All four compressors will run continuously until cabinet

temperature has dropped to the adjustable setting of the mechanical Backup

Temperature Control setpoint. At this time, one cascade system will shut

down and the second cascade system will continue operating until the

electronic control setpoint is achieved. Typical pull down time from

ambient to -80°C is approximately 2.5 hours.

CAUTION Do not add any product load to a warm cabinet.

After the freezer is down to operating temperature, time and record the

“ON” and “OFF” cycles for the first few hours, noting the date, time of day

and the ambient temperature existing during each cycle. Record this data in

the front of this manual. This will provide a reference point for normal

operation to aid in future diagnostics.

22 Generic MBF700 Service Manual Thermo Fisher Scientific

Page 27

SECTION 300 – THEORY OF OPERATION

Typical Cycle Times at -80°C Setpoint

Power Supply Ambient Temperature On Cycle Duration

60Hz 75°F <27min

SYSTEMS

DESCRIPTION

REFRIGERATION SYSTEMS This freezer is equipped with redundant cascade refrigeration systems.

System “A” and System “B” are identical systems and each is capable of

maintaining the proper temperatures inside the freezer. Both systems are

“On/Off” systems, that is, when the control cycles on, the refrigeration

system is on at full capacity until the setpoint is achieved, at which time the

refrigeration system turns off. During a normal cycling condition, a

sequencing relay cycles first one system and then the other in order to

equalize operating time on both systems. However, when the cabinet is -70 °

C or warmer (such as during start-up or temperature control failure), a

backup mechanical temperature control will cause both systems to run.

The MBF-700 is equipped with identical and redundant cascade

refrigeration systems: System “A” and System “B”. Since each is capable of

maintaining the proper operating temperature inside the freezer, the product

load will be protected if one system should fail. System “A” is located on the

right-hand side and system “B” is located on the left. Both systems are

two-stage, low temperature cascade systems designed to maintain the rated

temperature of –85° C individually. System “A” is located on the right end

of the cabinet (behind the control panel) and System “B” is located on the

left end of the cabinet.

The key components of the A and B systems are carefully selected to achieve

the highest possible reliability of a mechanical freezer. The compressors are

1.5 HP industrial grade hermetic Bristols. These compressors have been

thoroughly tested to give reliable service at ULT conditions. The

condensers, interstage heat exchangers and evaporators on the high and low

stages are designed to provide a reliable operation at an ambient of as high as

32 C. A balancing operation of the stages combined with reliable

components makes MBF freezers suitable for many difficult applications

either in military or civilian fields.

Note When loading the freezer, leave a minimum space of two inches (2”)

between the under side of the freezer sub lids and the top of the topmost

packages for proper air circulation

Thermo Fisher Scientific Gener ic MBF700 Service Manual 23

Page 28

SECTION 300 – THEORY OF OPERATION

SAFETY DEVICES

(see Figure 7, notes 2,3 & 4)

Both first and second stage compressors are protected by an internal pressure

relief valve that will rapidly equalize the high and low sides of a given stage

in the event of a pressure imbalance greater than ~425 psi. Additionally, all

compressors are equipped with internal Klixon-type electrical overloads that

will break the motor circuit in the event of an overcurrent or

overtemperature condition. These two devices form a conservative

application envelope that the compressors should operate in. Under normal

conditions, the trip points are far from actual operating pressures. In the

event of a trip, both devices will automatically reset to their normal

operating mode once the triggering condition has been resolved.

A Reverse Acting Low-Pressure Control (RALPC) is mechanically

connected to the suction side of the first stage. It is however electrically

connected to the control side of the contactor for the second stage

compressor. When the first stage operates properly to trip at the setting of

the control ( 7 PSIG), the switch turns on the second stage compressor.

Therefore, it protects compressors in both stages from starting up

simultaneously. When the suction pressure rises to 21 psig, the 2nd stage is

de-energized to prevent flood back of liquid refrigerant to the 2nd stage

compressor.

High/Low Temperature Alarm (see Figure 9)

Through the main temperature control, both high and low process variable

alarm settings can be made. Should the freezer temperature deviate beyond

these settings, a relay will activate the master alarm circuitry and the control

panel will display an alarm message.

TEMPERATURE CONTROL In addition to the two refrigeration systems, redundancy is also incorporated

into the control system. Two temperature control systems are included – the

main and the back-up controls. The main control is an electronic Dixell

controller that provides the primary refrigeration demand signal, as well as

the high and low alarm setpoints. If the Primary control loses

communication with its sensor probe, it defaults to a 100% run condition.

The back-up control is an electromechanical thermostat. The factory has set

this thermostat 3-5 degrees warmer than the desired cabinet operating

temperature. When this safety thermostat functions, it indicates that the

second cascade system has been required to maintain proper temperature.

This can be the result of a significant heat load added to the freezer or, it can

mean that the system operating as primary at the time it occurred has a

problem. If a failure occurs, the failed system may be switched off by

24 Generic MBF700 Service Manual Thermo Fisher Scientific

Page 29

LCO2 BACKUP SYSTEM

SECTION 300 – THEORY OF OPERATION

selecting the functioning side on the rotary switch on top of the sequencing

relay. This will prevent the relay fron alternating sides, and the indicated

side will run repeatedly.

(see Figure 10)

This fully independent system provides backup cooling in the event both

mechanical refrigeration systems become inoperable, possibly due to a

power loss. The system is designed to meter liquid CO2 to the freezer

compartment with the liquid flow controlled by a battery-supplied solenoid

valve. The solenoid valve opens and closes in response to a closed-loop

electronic control system that monitors the freezer temperature. A built-in

charger maintains the battery charge; the battery is capable of operating the

backup system for approximately 24 hours, depending upon the age and

condition of the battery. The temperature probe, which is a 100 ohm

platinum RTD, is located on the right side of the freezer chamber. The

liquid CO2 distribution (supply) tube is located on the left side.

The LCO2 control is designed to delay injection until the temperature has

risen above the temperature setpoint. LCO2 will then be injected to

maintain the cabinet temperature at the desired setpoint. (Refer to the

LCO2 Operator’s Manual for instructions on programming the temperature

setpoints.

Liquid CO2 may be supplied from a bulk tank or a Dewar. Recommended

supply pressure is 900 to 1,000 PSIG. A compression fitting is provided for

connection from the LCO2 system to the LCO2 supply.

A pressure relief vent is provided to relieve cabinet pressure in the event of

LCO2 deployment; the relief valve opens at a pressure of approximately 0.1”

H2O gauge. A vent for the removal of nitrogen gas can be made. However,

it is recommended that a direct connection not be made because of the

possibility of restricting the vent with frost build-up if the room and “vent

to” spaces are of differing atmospheric pressures and temperatures. A

vacuum relief vent using a non-direct connection is recommended. In this

manner, a venting system will not create a negative-pressure within the

cabinet, nor can it force warm/humid air into the cabinet.

A mechanical lid position limit switch has been provided to ensure that the

lid is fully closed before LCO2 can be injected, to prevent injury to

personnel.

Thermo Fisher Scientific Gener ic MBF700 Service Manual 25

Page 30

SECTION 300 – THEORY OF OPERATION

HALO PASSES Two copper halo passes are installed on the inner wall around the flange of

The backup unit is powered by 115 VAC, 1 phase, 60 hertz and draws 0.35

amps.

the freezer shell. Each of these halo passes is independently and directly

connected to the discharge line of the first stage compressors of "A" and "B"

refrigeration systems. The high discharge gas temperature from the

compressors is thus utilized to raise the flange temperature above the local

dew point to prevent any condensation from forming. When the unit is in

operation, each halo pass can add approximately up to 60 W of heat for

moisture removal in the flange area. The halo heat is only available when the

unit operates.

Ample heat from both halo passes is provided to the flange to prevent frost

accumulation. When the cabinet temperature drops below the auxiliary

temperature control setting only one system (“A” or “B”) will operate.

Therefore, the flange is still kept dry even when the cabinet temperature is at

ultra-cold condition.

OPERATION

CASCADE

REFRIGERATION SYSTEM

Principle of a Low Stage in a Cascade Refrigeration System

A two stage cascade refrigeration system typically is comprised of two

separate complete refrigeration circuits. They are normally referred to as

high stage or first stage and low stage or second stage. While the two stages

work separately, the heat transfer duty is carried from the low stage to the

high stage via an interstage heat exchanger or cascade heat exchanger, then

ultimately to the environment by an air-cooled or water-cooled condenser.

In either stage, the basic elements are a compressor, a condenser, an

expansion device, and an evaporator. The evaporator of low stage circuit is

directly for removing heat from payload. In a storage type of freezer, an

evaporator tubing is wrapped around the storage tank where the products

are placed. As the liquid refrigerant boils within the tubing at a low

temperature of about -90 C, it absorbs heat from the products. The

condenser of the low stage is the high-pressure side of the interstage heat

exchanger where low stage refrigerant is condensed to a high-pressure liquid

at about -40 C. The expansion device, which may be a capillary tube or an

expansion valve, regulates the refrigerant flow from the high condensing

pressure to low evaporator pressure, hence producing an ultra lower

temperature in the evaporator. A special refrigerant such as R508b is ideal to

26 Generic MBF700 Service Manual Thermo Fisher Scientific

Page 31

SECTION 300 – THEORY OF OPERATION

operate in the low stage because its characteristics fit well within the general

capability of the low stage compressor and those of other related

components. The second stage compressor compresses the refrigerant vapor

for a high pressure condensing in the interstage heat exchanger.

Principle of a High Stage in a Cascade Refrigeration System

The cycle of refrigerant in compression, condensing, expansion, evaporating

and compression again applies to the high stage of a cascade system. In this

high stage, however, the evaporator is the low-pressure side of the interstage

heat exchanger where evaporative refrigerant flows in an opposite direction

from that of the condensing flow of the second stage. The evaporating

temperature is lower than that of the second stage condensing temperature,

therefore, second stage can transfer it’s the product heat to the first stage.

With its condenser being water-cooled or air-cooled, the first stage passes

the heat to the cooling media. Refrigerants such as R404a offer good

performance attributes that are compatible with many components used in

the first stage. As can be seen, both first and second stages operate together

to remove heat from products in a chain or cascade fashion. A reliable

operation of the system stems not only from the good quality of each

component, but also a well balance between the two stages to avoid extreme

stresses.

MAIN TEMPERATURE

CONTROL

Under normal conditions, the main control system governs the operation of

the freezer. If the main control system fails to operate, the backup system

will take over operation of the freezer. With the main control system in

operation, three distinct modes are available which are Cycle Mode and

Bypass Mode.

• Cycle Mode: This mode of operation alternates the usage of

refrigeration systems “A” and “B” each time the main control cycles on.

A sequencing relay is used to provide this functionality. This mode of

operation will equalize operating time of both refrigeration systems and

is the standard mode of operation for the MBF-700. In the case of a

temperature excursion above the setpoint of the secondary controller , it

will energize whichever side is not currently being controlled by the

primary controller demand signal.

• Bypass Mode: In this mode of operation, one side of the unit is bypassed

and will not be energized by the primary controller – all of its demand

signals will go to the selected side. This mode can be selected by turning

the rotary switch on top of the sequencing relay to indicate the side that

is desired to run exclusively.

Thermo Fisher Scientific Gener ic MBF700 Service Manual 27

Page 32

SECTION 300 – THEORY OF OPERATION

• With the power key switch in the “Off” position the compressors will

not energize.

The Primary Temperature Control does not directly cycle between sides, but

provides a demand signal when the measured system temperature exceeds

the setpoint plus hysteresis value. A digital display is provided to

continuously show actual chamber temperature; the chamber temperature is

measured with a 1000-ohm RTD.

The sequencing relay is located inside the upper machine compartment. It

alternates the demand signal from the primary controller between side A

and Side B, and also sends the demand signal from the secondary controller

to the side that is currently idle. The alternating function can be disabled by

selecting side A or B on the rotary switch on top of the relay.

MBF-700 Electronic Components

Power Supply A power supply provides 12VDC to drive the alarm circuit,

battery charging circuit, and primary power relay. The nominal output

voltage is 12.4VDC, and can be adjusted via the dashpot on the top surface

of the power supply.

Battery The battery, a 12 V rechargeable gelled-electrolyte, lead-acid type,

supplies power to the system upon loss of AC line power. This keeps the

alarm circuits active in the event of a power or control failure. The current

state of battery charge can be read by pressing the button next to the volt

meter on the front panel display.

Alarm The controller will detect and display high and low temperature

alarms as per the programmed parameters. Additionally, the alarm circuit

will activate in the event of a total loss of unit power. Alarm conditions are

locally sounded by a solid-state audio alert. Additionally, a set of form C

relay contacts are made to change state. These may be used to remotely

indicate alarm conditions.

Alarm Outputs Alarm conditions are indicated locally by a solid-state sonic

device and remotely by Form c relay contacts. A maximum of 36V3A

should be applied to these contacts.

Display Display of the temperature is integrated into the primary controller.

See Appendix B for details on controller operation.

28 Generic MBF700 Service Manual Thermo Fisher Scientific

Page 33

BACKUP TEMPERATURE

CONTROL SYSTEM

SECTION 300 – THEORY OF OPERATION

(See Figure 9, Note 2)

The electromechanical backup control system will take over control of the

refrigeration systems if the main control system should fail to maintain the

desired temperature.

In this mode of operation, the sequencing relay will respond to a demand

signal from the secondary control by energizing the side of the system that is

not currently being controlled by the primary controller. As these two

demand signals are independent, it is possible for both systems to be

running simultaneously with one driven by the primary controller and the

other by the secondary controller. Control operation is transferred to the

backup system simply as a result of a main control system failing to

maintain a temperature colder than the backup control setpoint. (typically

3-5°C warmer than the desired operating temperature) Under normal

operation the freezer will not warm up to the temperature at which the

backup system will engage. However, if the freezer lid is left open for

extended periods or a large product load is placed inside the freezer, the

backup control system may energize both refrigeration systems. Also note

that when the freezer is first turned on at room temperature, the backup

control system will be engaged. As the freezer cools beyond the setting of the

backup control, operation of the freezer will transfer to the main control.

While the “On” cycles are fairly consistent, the off cycles will be very

responsive to the density of product loading inside the cabinet and the ease

of cabinet air circulation as well as ambient temperature. Off cycles can vary

from 4 to 30 minutes. The system is protected against overloading through

the action of the RALPC in the electrical circuit of the second stage.

However; prolonged overloaded operation will shorten the life of all

refrigeration compressors; overloading should be avoided by loading

pre-frozen product after the cabinet interior is at operating temperature.

When the secondary controller is engaged, the red “Backup Control” alarm

light on the lower status indicator panel will be lit. When both systems

operating have cooled the cabinet below the Backup Control’s setpoint, the

Backup Control allows the Sequencing Relay to shut down one of the

refrigeration systems and the Backup Control red warning light will be

extinguished. The second system will continue to run until the cabinet

temperature has lowered to the temperature control set point. At that time,

the operating system will cycle off. Upon cabinet warm-up to the primary

control setpoint, the “lead” system (as determined by the position of the

sequencing relay contacts and indicated by the LED on top of the relay) will

start. When the cabinet control setpoint is once again achieved, the

sequencing relay will de-energize and will exchange the lead systems. The

Thermo Fisher Scientific Gener ic MBF700 Service Manual 29

Page 34

SECTION 300 – THEORY OF OPERATION

amber pilot lights on the lower status indicator panel indicate which system

is in operation. The Backup Control thermostat has been provided to put

both systems in operation if the cabinet temperature rises above its setpoint

and to protect against failure of one refrigeration system or the primary

controller.

30 Generic MBF700 Service Manual Thermo Fisher Scientific

Page 35

SECTION 400 – MAINTENANCE AND SERVICE

SECTION 400 –

MAINTENANCE

AND SERVICE

PREVENTIVE

MAINTENANCE

PROCEDURES

AIR COOLED CONDENSERS Because heavy traffic areas are dustier than others, a cleaning schedule for

air-cooled condensers and filters is difficult to predict. A suggested schedule,

however, is 6 months, which can be adjusted as needed. Access to the filters

is gained by removing the three screws at the outboard edge of both front

hinged panels and swinging them open. The filter will come out and can be

washed with a mild detergent, rinsed and replaced. It is not necessary to dry

the filter. The condenser coil itself may be vacuumed clean at the same time.

COMPRESSOR OIL LEVEL Lubricating oil is retained in the compressor sump. An oil pump at the

bottom of the crankshaft picks up the oil and feeds it to the crankshaft.

Centrifugal force then delivers oil under pressure to the bearings, crank pins,

etc. THE UNIT MUST BE LEVEL. If the compressor is not vertical oil

cannot reach the oil pump; this will result in bearing damage.

FAN MOTORS One or more cooling fans are provided in the machine compartment of

freezers, whether water- cooled or air-cooled. No oiling is necessary. During

periodic maintenance, these fans should be checked for operation. If the

compressors are running but any one of the fan motors is not, the

inoperative one must be replaced.

DEFROSTING Chest type freezers do not require defrosting more often than once every six

months to a year unless they are subject to heavy usage. Frost will begin to

build at first around the top of the inner liner and will decrease in

proportion to the distance from the top. Frost or “snow” will be the most

apparent accumulation and it may be removed with a plastic scraper. If any

hard ice has developed, do not chip it using metallic objects. Instead,

remove all products stored in the freezer, turn the key “off”, unplug the unit,

and allow it to warm up. When temperature has risen far enough, the ice

can be readily dislodged.

Thermo Fisher Scientific Gener ic MBF700 Service Manual 31

Page 36

SECTION 400 – MAINTENANCE AND SERVICE

To check gaskets for proper sealing, use a 2” x 6” piece of paper (a dollar bill

is handy) closed between the gasket and the lid at 12” intervals around the

perimeter of the lid. At each position, pull on the free end of the paper. A

slight resistance should be felt. While performing this test, inspect the gasket

for cuts or tears. An improperly sealing gasket must be replaced.

LCO2 VENT On a semi-annual or monthly basis (depending on frequency of lid

opening), verify that the LCO2 vent is free of dirt and frost/ice

accumulation that might interfere with the venting function.

TROUBLE SHOOTING

GUIDE

CAUTION Only certified Refrigeration or Electronic Technicians should

service the system

Note Before attempting to troubleshoot the unit, perform the following

checks. Correct what is found wrong and re-evaluate the unit before

continuing.

a. Verify that the main power is supplied to the freezer.

b. Verify the integrity of the wiring connections at the 30-pin screw

terminal on the control board (main power and key switch OFF).

c. Verify the integrity of the 30-pin terminal interconnection at the

control board (main power and key switch OFF).

32 Generic MBF700 Service Manual Thermo Fisher Scientific

Page 37

SECTION 400 – MAINTENANCE AND SERVICE

SYMPTOM POSSIBLE CAUSE TEST AND CORRECTION

A. Cabinet

temperature

colder than

Control

Setpoint.

B. Displayed

temperature

does not match

freezer

temperature.

1. Control out of calibration.

2. Inoperative control

3. Cabinet relay points fused.

4. Stuck Sequencing relay

5. Stuck Backup Control

6. Temperature sensor defective

1. Needs calibration.

2. Defective sensor.

1. Recalibrate if necessary.

2. Replace control if necessary.

3. Replace relay if necessary.

4. Replace Sequencing Relay

5. Replace Backup Control

6.

See

G-1 1

1. Recalibrate per specified procedure.

2. See G-1 1

C. Frost buildup

on breaker

strip.

D. No audio

alarm at power

fail or

temperature fail.

E. No remote

alarm function.

1. Gasket not sealing properly. 1. Gasket wrinkled, worn or torn. Check

retaining means and replace if

necessary. Frost will accumulate at

the point of an air leak. Check

carefully in the area of any

concentrated frost buildup.

1. Defective wiring.

1. Checkwiring between control board &

panel.

2. Defective alarm loudspeaker.

2. Replace loudspeaker.

1. Defective wiring. 1. Checkwiring between control board &

remote alarm terminal block.

Thermo Fisher Scientific Gener ic MBF700 Service Manual 33

Page 38

SECTION 400 – MAINTENANCE AND SERVICE

F. High Stage

Compressor

does not run

1. No power.

2. Low voltage.

3. Inoperative control.

4. Loose wiring at terminals.

5. Inoperative compressor contactor.

1. Check power source. If none, call

qualified electrician.

2. Read supply voltage while unit is

running. Reading must equal rated

±10%.If the facility voltage

fluctuates often, add the optional

Voltage Safeguard accessory.

3. Jumper across contacts. If

compressor starts but control is

calling for closed contacts, replace

control.

4. Inspect all electrical connections.

5. Start compressor using test cord or,

momentarily, jumper contactor line

terminals to load.

6. Open or grounded compressor

windings.

7. Defective starting components

8. Stuck compressor

6. Disconnect compressor leads and

read phase to phase ohms@2.38

andfor any phase to ground.8. If

electrical checks are OK, try to start by

disconnecting and exchanging any

two compressor power leads.

7. Replace starting components

8. Install hard-start kit; if unsuccessful,

replace compressor.

34 Generic MBF700 Service Manual Thermo Fisher Scientific

Page 39

SECTION 400 – MAINTENANCE AND SERVICE

G. Low stage

compressor

does not run.

1. No power

2. Inoperative controller, reverse

acting pressure control, high

pressure limit, or circuit relay.

3. Loose wiring at terminals

4. Inoperative compressor contactor.

5. Inoperative overload.

6. Low voltage

1. Check power supply. Refer problem

to qualified electrician.

2. Check each component with high

stage running and down to

temperature. Replace defective

control.

3. Inspect all electrical connections.

Retighten as necessary.

4.

See

G-4

5.

See

G-5

6.

See

G-6

7. Open or grounded compressor

winding.

8. Stuck compressor

9. Failed RALPC

10. Oil seperator failed to return oil to

the compressor.

7.

See

G-7

8.

See

G-8 through G-1 1

9. Replace RALPC

10. Replace oil seperator.

Thermo Fisher Scientific Gener ic MBF700 Service Manual 35

Page 40

SECTION 400 – MAINTENANCE AND SERVICE

H. Unit runs but

little or no

refrigeration.

On-cycles are

getting longer.

1. Loss of refrigerant

2. Compressor will not pump.

3. Restriction in low stage

1. Check for the leak, repair, evacuate and

recharge.

2. Install low-side gauge. If running pressure

is no lower than starting pre ssure, replace

compressor, evacuate and recharge.

3. Shut unit off and install low-side

gauge. If high-side pressure appears on

low-side gauge within 10 minutes, or

no pressure buildup occurs, try

disabling the high stage compressor

and allow the low stage head

pressure to build up to 275 psig. A

sudden rise in low stage suction

pressure will indicate that the

restriction has cleared. If it does not,

allow cabinet to warm up overnight

and restart. If restriction still did not

clear, isolate and back-flush the

evaporator.

4. Inoperative high stage condenser

fan

5. Dirty insufficient air flow

6. High room temperature

7. Refrigerant leak.

8. Condenser fan blade is loose

4. Check for fan blade obstruction.

Replace fan motor if necessary.

5. Remove/clean condenser filter; ensure

cabinet has a minimum of 6”

clearance all around it.

°

6. Ensure room temperature is <90

°

(32.2

C)

7.

See

Charging procedures.

F

8. Tighten fan blade

36 Generic MBF700 Service Manual Thermo Fisher Scientific

Page 41

SECTION 400 – MAINTENANCE AND SERVICE

I. Cabinet

temperature

colder than

Control

Setpoint.

J. Displayed

temperature

does not match

freezer

temperature.

1. Control out of calibration.

2. Inoperative control

3. Cabinet relay points fused.

4. Stuck Backup Control relay

5. Stuck Backup Control

6. Temperature sensor defective

1. Needs calibration.

2. Defective sensor.

1. Recalibrate if necessary.

2. Replace control if necessary.

3. Replace relay if necessary.

4. Replace R4

5. Replace Backup Control

6.

See

G-1 1

1. Recalibrate per specified procedure.

2. See G-1 1

K. Frost buildup

on breaker

strip.

L. No audio alarm

at power fail or

temperature

fail.

M. No remote

alarm function.

1. Gasket not sealing properly. 1. Gasket wrinkled, worn or torn. Check

retaining means and replace if

necessary. Frost will accumulate at

the point of an air leak. Check

carefully in the area of any

concentrated frost buildup.

1. Defective wiring.

1. Checkwiring between control

board& panel.

2. Defective alarm speaker.

1. Defective wiring.

2. Replace alarm speaker.

1. Check wiring between control

board & remote alarm terminal

block.

2. Defective board component.

2. Replace control board.

Thermo Fisher Scientific Gener ic MBF700 Service Manual 37

Page 42

SECTION 400 – MAINTENANCE AND SERVICE

N. Unit runs

continuously.

1. One or more sublids missing. Poor

gasket seal.

2. Machine compartment fan not

running

3. Backup Control set too low.

4. Backup Control will not shut unit off-contacts stuck.

5. System undercharged.

1. Replace missing sub lids. Replace

lid gasket.

2. Check for fan blade

obstruction. Replace fan motor if

defective.

3. Check specifications for lowest design

temperature. Reset control.

4. Replace Backup Control.

5. Check operating pressures. If low, shut

down, warm up overnight and

check soak pressure.

6. System overcharged.

7. Non condensables in system.

8. Restriction.

9. Worn or inefficient compressor.

6. Check operating pressures. If low,

check running wattage. Check low

stage suction service valve for

excessive frost and recover as

necessary. High stage has a receiver

for excess charge. Recover until

head pressure returns to normal.

7. Check operating pressures and

wattage. Wattage will be high and

suction pressure low. Recover

charge, evacuate and recharge.

See

8.

item C-3 above. Replace

Compressor

9. Check data plate for correct

refrigerant. recover charge and

recharge with correct refrigerant.

38 Generic MBF700 Service Manual Thermo Fisher Scientific

Page 43

SECTION 400 – MAINTENANCE AND SERVICE

10. Wrong refrigerant installed

10.Oil return line will be warm.

Discharge pressure will be lower than

normal, suction higher than normal.

Suction gauge may fluctuate.

Replace oil separator.

11. Leaking needle valve in oil separator.

12. Wet insulation.

13. Defective Control.

11. Replace freezer.

12. Replace Control

13. Replace Sensor

14. Defective temperature sensor

O. No Display 1. Defective Control 1. Replace Control

CONTACTORS AND

RELAYS

COMPRESSOR MOTORS,

THREE PHASE

All major failure modes are represented above. In cases where the particular

fault is not listed, component level diagnostics must be performed. This

may be accomplished using the parts list and component layout (see

Appendix).

FAILURE ANALYSIS

CAUTION Dangerous voltages can exist across capacitor terminals. Be

familiar with electrical components and applicable testing procedures.

The two possible failure modes of contactors and control relays are 1). a

burned out coil, or 2). failed contact points. If the coil is burned out or

electrically open, the device will not operate at all. If the points are burned

out or failed mechanically, the relay will operate but the circuit will not

close. In the case of a 3 phase motor contactor with only one faulty contact,

the motor will attempt to start and may actually run if under light load but

it will be “single phasing” and will quickly trip the overloads.

The quickest way to check a compressor motor is through the use of an

ohmmeter to obtain the resistances of the three field windings. First,

disconnect all leads from the motor terminals. Second, set the meter at the

and

lowest scale and read the ohms from T1-T2, T1-T3

T2-T3 terminals.

The readings should be close to the same (within +/-10%). If the variance is

Thermo Fisher Scientific Gener ic MBF700 Service Manual 39

Page 44

SECTION 400 – MAINTENANCE AND SERVICE

greater than 10%, carefully check the refrigerant gas for “burned” odor. Any

burned odor signals a winding breakdown and will require a compressor

change. Also, a system cleanup is indicated. If not familiar with this

procedure, consult the factory.

As part of the motor windings check, always read the resistance from

windings to ground. It should be a high resistance, in the range of 100-130

megohms Confirm Value. Low readings indicate a beginning breakdown of

the winding insulation. Readings that approach 1.0 to 2.0 megohms

between any motor terminal to ground indicate that trouble is imminent.

Some authorities use a hand cranked instrument called a Megger to obtain

these readings. There is an instrument available, however, which gives more

reliable readings than a Megger. This is the High Pot Tester. This meter

gives a reading in milliamps reflecting the value of actual current leakage

when a high potential is applied across windings to ground. Generally, the

tester is set up to deliver 1,000 volts plus twice the nameplate voltage rating

for the motor. The current leakage should be 5 to 10 milliamps or less

PARTIAL OR COMPLETE

LOSS OF REFRIGERATION

CHECKING REFRIGERANT

CHARGE

If both compressors are inoperative, check to see if the unit’s electric service

connections have loosened. Also check the breakers, fuses or other overload

devices in the power circuit. Next, check to see if voltage is present at the

compressor terminals. If the high stage compressor internal pressure relief

valve or electrical overload has tripped , the condenser may be dirty or the

condenser inlet air temperature may be above 80 °F. In the case of a water

cooled condenser, the water supply may have been interrupted. If the low

stage compressor internal pressur relief valve or electrical overload has

tripped, the high stage is not providing enough refrigeration for the cascade

condenser and the trouble will be found in the high stage system. When

cabinet temperature begins an unwanted rise, a shortage of refrigerant could

be the cause. Allow the cabinet to warm up for at least 8 hours with the lid

open, to assure thorough warming of the cascade condenser and the cabinet.

CAUTION At this point in the maintenance and service work, do not

proceed further unless familiar with cascade refrigeration systems and are

qualified to perform service work that involves opening either the high or

low stage system to the atmosphere. The discussion following may seem

elementary to some experienced refrigeration technicians, however, a review

of correct service procedures is never wasted time.

40 Generic MBF700 Service Manual Thermo Fisher Scientific

Page 45

INSTALLING GAUGES

SECTION 400 – MAINTENANCE AND SERVICE

CAUTION Before installing or removing suction service gauges, always

shut down the compressor and warm the valve so that moisture will not be

drawn into a compressor operating in a vacuum. See below.

Note When installing a gauge on the suction side of the system of either

compressor of a unit that is down to operating temperature, always assume

that both systems are operating on a vacuum on the low or suction side.

Shut down the system for two or three minutes to let suction pressure rise

above a vacuum.

Since the high stage refrigerant is R-404a, the system pressures can stay the

same even if a leak is present. If a leak is present in either stage, it will have

to be found and repaired, a deep vacuum drawn on the system, and a

recharge of refrigerant added.

LEAK TESTING, REPAIRING

AND CHARGING – AN

OVERVIEW

CAUTION The following procedure assumes that there has not been a low

side leak that has drawn air and moisture into the system. If this has

happened, the low stage may be shut down on safety device, or the pressure

reading on the low stage discharge gauge will be unusually high or in excess

of normal pulldown pressures. The procedure to be followed in this instance

involves evacuation and refrigerant drier replacement.

Install highside and lowside pressure gauges on both first and second stage

systems.

LEAK TESTING

If it is impossible to find a leak with normal pressure present in the system,

it will be necessary to back up the pressure with dry nitrogen. The nitrogen

cylinder should be equipped with a pressure regulator and gauges. One

gauge reads cylinder pressure and the other reads regulated pressure. When

opening the main cylinder valve, it must be done carefully to avoid ruining

the gauges. Barely crack the main cylinder valve until the cylinder pressure

gauge reading stops rising and then the valve may be opened a full turn.

Connect the regulator outlet port to the system to be leak checked and set

the regulator to 150 psig by rotating the regulator “T”-handle clockwise

until the outlet pressure gauge reads 150.

Thermo Fisher Scientific Gener ic MBF700 Service Manual 41

Page 46

SECTION 400 – MAINTENANCE AND SERVICE

CAUTION Do not pressurize the system over 350 psig under any

circumstances.