Page 1

Instruction Manual

HAAKE RotoViscoHAAKE RotoVisco

HAAKE RotoViscoHAAKE RotoVisco

HAAKE RotoVisco

®®

®®

®

1 1

1 1

1

HAAKE RheoStressHAAKE RheoStress

HAAKE RheoStressHAAKE RheoStress

HAAKE RheoStress

®®

®®

®

1 1

1 1

1

version 2.3

“Translation of the original instruction manual“

Page 2

Page 3

Table of Contents

1

1. Key to Symbols 3...........................

1.1 Symbols used in this manual 3.................

1.2 Symbols used on the unit 3....................

1.3 Information concerning the CE sign 4...........

1.4 WEEE Compliance 5.........................

2. Quality Assurance 6........................

3. Your Contacts at Thermo Fisher Scientific 6..

4. Warranty 7.................................

5. Safety Notes and Warnings 8................

6. Unpacking / Ambient conditions 11...........

6.1 Transportation damage? 11....................

6.2 Contents of Delivery 11........................

6.2.1 Standard Delivery Rheometer 11...........

6.2.2 Sensor Systems 13......................

6.2.3 Accessories for the Temperature Control

Units 13

6.2.4 Application software 13...................

6.3 Space Requirements 14.......................

6.4 Mains supply 14..............................

6.5 Cooling air for the measuring head

(HAAKE RotoVisco 1) 14.......................

6.6 Requirements for the air supply 15..............

6.7 Pipes in the building 15........................

6.8 Air compressors 15............................

6.9 Ambient conditions according to EN 61010 15....

7. Unit Description 16..........................

7.1 HAAKE RotoVisco1 17........................

7.2 HAAKE RheoStress1 18.......................

7.3 Temperature control: 19........................

7.4 Main features of the HAAKE rheometers: 20......

8. Installation 21...............................

8.1 Setting up the Rheometer 21...................

8.2 Connecting up 22.............................

8.2.1 PT100 connection 22.....................

8.3 Hose connections 23..........................

8.3.1 Temperature control unit (with liquid): 23....

8.3.2 Air bearing (measuring unit) 24............

9. Functional Elements 25......................

9.1 Temperature control units 25...................

9.2 External filter 26..............................

9.3 Measuring Instrument with no

temperature control unit. 27....................

9.4 Measuring Instrument with

TCL/Z -- temperature control unit. 29.............

9.5 Measuring Instrument with

TCL/P / TCE/P / TCP/P / TCP/PE

-- temperature control unit. 31...................

9.6 Measuring unit with TCE/PC-temperature

stabilisation unit and cone heater TC1 33........

9.7 Measuring Instrument with

SHRP -- temperature control unit. 35.............

9.8 Display unit (optional) 37......................

9.9 Menu tree of the display unit 38.................

Page 4

Table of Contents

2

10. Operating 39................................

10.1 Switching on 39...............................

10.2 Working with the display unit 39.................

10.3 Starting the software 45........................

10.4 The ”Upload Mode” for the Display Unit

(RheoWin 2.6 or higher) 46.....................

10.5 Quick Cut-off 55..............................

11. Temperature control units 56.................

11.1 Temperature control unit TCO 56................

11.2 Temperature control unit TCL/Z 57..............

11.3 Temperature control unit TCL/P 59..............

11.4 Temperature control unit TCE/P 60..............

11.5 Temperature control unit TCP/P and TCP/PE 61..

11.6 Temperature stabilisation unit TCE/P with

cone heater TC1 67..........................

11.7 Cone heater TC1 67...........................

11.7.1 Correct application of the ceramic rotors 67.

11.7.2 Operation 68............................

11.7.3 Compressed air distributor for TC1 69......

11.8 Temperature control unit SHRP 70..............

12. Sensor Systems 78..........................

12.1 Cylinder Sensor Systems 82....................

12.2 Cylinder Sensor Systems Z-DIN 82..............

12.3 Cylinder Sensor System Z 88...................

12.4 Double Gap Cylinder Sensor DG43

according to DIN 53544 93.....................

12.5 Solvent trap for Z10, Z20, Z31,

Z34, Z38, Z41 und DG43 97....................

12.6 Solvent trap for Z43 98........................

12.7 Cone-Plate and Plate-Plate Sensor Systems 99...

12.8 Cone-Plate Sensor Systems 99.................

12.9 Plate-Plate Sensor Systems 115.................

12.10Platter--platter measuring equipment with

profiled surface. 119............................

12.11 High Shear Cylinder Sensor System HS 122.......

12.12SHRP Plate-Platte Sensor System PP 1 mm 126...

12.13Immersion Sensor System FL 129................

13. Optional sensor systems 132..................

14. Hints on Measurement 133....................

14.1 Temperature programs with Series 1 units 133.....

14.2 Range Limits in Oscillation 134..................

14.3 Correction of Dynamic Measurement 135..........

14.4 Determination of the massmoment of inertia 137...

15. Maintenance 138..............................

15.1 Maintenance Instructions HAAKE RheoStress1 139

15.2 Maintenance Instructions HAAKE Rotovisco1 140..

15.3 Filter unit 141..................................

15.4 Flat sieve 142.................................

15.5 Repairs 143...................................

16. Pin Wiring 144................................

17. External Connections 146.....................

18. Technical Specifications 147...................

19. Terms of Rheological Measurements 149.......

Page 5

!

Key to Symbols

3

1. Key to Symbols

1.1 Symbols used in this manual

Warns the user of possible damage to the unit, draws

attention to the risk of injury or contains safety notes

and warnings.

Denotes an important remark.

1

Indicates the next operating step to be carried out and

what happens as a result thereof.

Draws attention to the risk of injury.

1.2 Symbols used on the unit

Caution: Read the instruction manual!

Caution: danger of injury your hands

Caution: Unit becomes hot

Connection for cooling air support

Display operationa

Display heating

Page 6

Information concerning the CE sign / WEEE compliance

4

1.3 Information concerning the CE sign

Thermo Scientific electrical equipment for measurement,

control and laboratory use bears the CE marking.

The CE marking attests the compliance of the product with

the EC-Directives which are necessary to apply and confirms that the apparatus meets all relevant essential requirements of the directive, the defined relevant protection

requirements.

The conformity assessment procedures were performed

following a defined methodology according to each applicable directive.

The council decision 93/465/EEC shall be authoritative

concerning the modules of the various phases of the conformity assessment procedures and the rules for the affixing and use of the CE marking, which are intended to be

used in the technical harmonization directives.

To confirm compliance with the EC-Directive 2004/108/EC

Electromagnetic Compatibility (EMC) our product was tested according to the EMC requirements for emission and

immunity for electrical equipment for measurement, control and laboratory use.

Compliance with the protection requirements areas (domestic establishments and establishments directly connected to a low voltage power supply network which supplies buildings used for domestic purposes) and industrial

areas is ensured.

Our strict standards regarding operating quality and resulting considerable amount of time and money spent on development and testing reflect our commitment to guarantee the high level of quality of our products even under extreme electromagnetic conditions.

Practice however also shows that even electrical equipment which bears the CE marking such as monitors or

analytical instruments can be affected if their manufactures accept an interference (e.g. the flickering of a monitor)

as the minimum operating quality under electromagnetic

compatibility phenomena. For this reason we recommend

you to observe a minimum distance of approx. 1 m from

such equipment.

Page 7

Information concerning the CE sign / WEEE compliance

5

1.4 WEEE Compliance

This product is required to comply with the European

Union’s Waste Electrical & Electronic Equipment (WEEE)

Directive 2002/96/EC. It is marked with the following symbol:

Thermo Fisher Scientific has contracted with one or more

recycling/disposal companies in each EU Member State,

and this product should be disposed of or recycled

through them. Further information on Thermo Fisher

Scientific compliance with these Directives, the recyclers

in your country, and information on Thermo Fisher Scientific products which may assist the detection of substances

subject to the RoHS Directive are available at

www.thermo.com/WEEERoHS

Page 8

Quality Assurance/Contacts at Thermo Fisher Scientific

6

2. Quality Assurance

Dear customer,

Thermo Fisher Scientific implements a Quality Management System certified according to ISO 9001:2008.

This guarantees the presence of organizational structures

which are necessary to ensure that our products are developed, manufactured and managed according to our customers expectations. Internal and external audits are carried out on a regular basis to ensure that our QMS is fully

functional.

We also check our products during the manufacturing process to certify that they are produced according to the

specifications as well as to monitor correct functioning and

to confirm that they are safe. The results are recorded for

future reference.

The “Final Test” label on the product is a sign that this unit

has fulfilled all requirements at the time of final manufacturing.

Please inform us if, despite our precautionary measures,

you should find any product defects. You can thus help us

to avoid such faults in future.

3. Your Contacts at Thermo Fisher Scientific

Please get in contact with us or the authorized agent who

supplied you with the unit if you have any further questions.

International / Germany

Thermo Fisher Scientific

Dieselstraße 4

D-76227 Karlsruhe, Germany

Tel. +49(0)721 4094--444

Fax +49(0)721 4094--300

support.mc.de@thermofisher.com

www.thermoscientific.com/mc

The following specifications should be given when product

enquiries are made:

Unit name printed on the front of the unit and specified on

the name plate.

Typ: Order No. (e.g.: 557--3001)

Ser.:Nr.:

_ ___________

_ Manufacturing order no.: ( 1--9)

__ Manufacturing year ( e.g. 09)

______

Production order no.:

(000001 --99999)

___ Serial--number

Mains voltage in V / power input:

e.g. 115 V/ 50 Hz/ 2 A

Page 9

Warranty

7

4. Warranty

For the warranty and any potential additional warranty, the

user shall have to ensure that the devices are serviced by

an expert at the following intervals:

The maintenance is required after approx. 2000 operating

hours, at the latest, however, twelve months after the initial operation or the last maintenance, respectively.

Two thousand operating hours are achieved:

at an operating period of eight hours daily (five days

a week)

about once a year

at an operating period of more than eight to sixteen

hours daily

about every six months

at an operating period of more than sixteen hours

daily

about every three months

We recommend to have the maintenance carried out by

Thermo Fisher Scientific or by staff authorised by Thermo

Fisher Scientific as special knowledge and tools are required.

The maintenance and calibration work carried out has to

be recorded by certificates in conformity with ISO 9000 ff.

Page 10

!

!

!

!

!

!

!

!

!

!

!

!

Safety Notes and Warnings

8

5. Safety Notes and Warnings

The Rheometer corresponds to the relevant safety regulations. However you are solely responsible for the correct

handling and proper usage of the instrument.

This instrument exclusively determines the rheological behavior of fluid and half-solid materials. These materials may not

be tested if people can be hurt or devices be damaged.

Do not lift or move the unit at the ends of the glass pane.

Do not measure / temperature control any materials that

may give off dangerous vapours or may be inflammable

within the working temperature range of the rheometer.

The device may not be operated if there are any doubts

regarding a safe operation due to the outer appearance

(e.g. damages).

A safe operation of the instrument cannot be guaranteed if the user does not comply with this instruction

manual.

Ensure that this instruction manual is made readily

available to every operator.

Do not bend connection and/or mains cable, do not

subject cables to stress or high temperatures (higher

than 70 C).

Check cables visually at regular intervals.

The operator must have an uninterrupted view of the

machine and its surroundings.

The rheometer must be fully visible from the PC control stand.

This unit should only be used for the applications it was

designed for.

The rheometer is designed for use with a rotor. All existing safety devices are based on the correct installation

of the rotor. Is the lift (of the measuring table) used without a rotor installed injuries may occur when reaching in

the lift area.

Make sure that the unit has been switched off before you

connect or disconnect the cables. This is to avoid electrostatic charging resulting in a defect of the electronic

circuit boards.

Page 11

!

!

!

!

!

!

!

!

!

!

Safety Notes and Warnings

9

Once the probe attains appropriate viscosity,cylindrical

tube (Order no. 222--1394) protectors that prevent

probe’s radial exit must be used when measuring. An

operational error when using the measuring device can

lead to the probe’s radial exit from the measuring gap; it

is therefore recommended to wear protective goggles.

Do not operate the unit with wet or oily hands.

Do not immerse the unit in water or expose it to spray

water.

Do not clean the unit using solvents (fire danger!) -- a

damp cloth applied with a household cleaning substance is often sufficient.

Complete separation from the mains is required when

repairs or maintenance work is about to be carried out.

Suitable personal protective gear, consisting of lab

coat, protective eyewear and safety gloves, must be

worn at all times when working with the instrument

Repairs, alterations or any work involving opening up

the unit should only be carried out by specialist personnel. Considerable damage can be caused by incorrect

repair work. The Thermo Fisher Scientific service department is at your disposal for any repairs you may require.

Have the unit serviced by specialists at regular intervals.

RheoStress1: The pressure of the air supply for the air

bearing must not exceed 4 bar. Higher pressure will

damage the air bearing permanently!

For applications at elevated temperatures above 250C

it is a must to switch the fan for the air bearing cooling

on stage 2 (on the rear) and use ceramic shafts only.

Furthermore use the cone heater TC1 as thermal shield

to prevent the heating up of the air bearing housing!

Severe skin burns can be caused by contact with hot

unit parts!

The rheometer can reach temperatures up to 350 C, depending on the temperature control unit installed. This can result

in parts of the rheometer heating up to such an extent, even

when taking the cooling and insulation into account, that serious burns can result if they come into contact with the skin.

Thermo Fisher Scientific recommends shielding the rheometer when operating at high temperatures and handling it only

with high temperature proof gloves and safety glasses.

A danger symbol on the glass plate warns the user of possible danger (burn injury).

Page 12

!

Safety Notes and Warnings

10

We do not know which substances you intend to test using this unit. Many substances are

inflammable, easily ignited, explosive

hazardous to health

environmentally unsafe

i.e.: dangerous

You alone are responsible for your handling of these

substances!

Our advice:

If in doubt, consult a safety specialist

Read the product manufacturer ’s or supplier’s

“EU SAFETY DATA SHEET”

Read the REGULATIONS CONCERNING DANGER-

OUS MATERIALS

Observe the “Guidelines for Laboratories”

Page 13

!

!

!

!

Unpacking / Ambient conditions

11

6. Unpacking / Ambient conditions

6.1 Transportation damage?

Notify carrier (forwarding merchant, railroad,

post office) etc,

Compile a damage report.

Before return delivery:

Inform dealer or manufacturer

(Small problems can often be dealt with on the spot).

Do not lift or move the unit at t he ends of the glass

pane.

Use the transport handles provided for the instrument when unpacking.

The instrument must be carried by two persons.

Unpacking the instrument and putting it into operation is part of the installation and is carried out by

trained personnel from Thermo Scientific.

6.2 Contents of Delivery

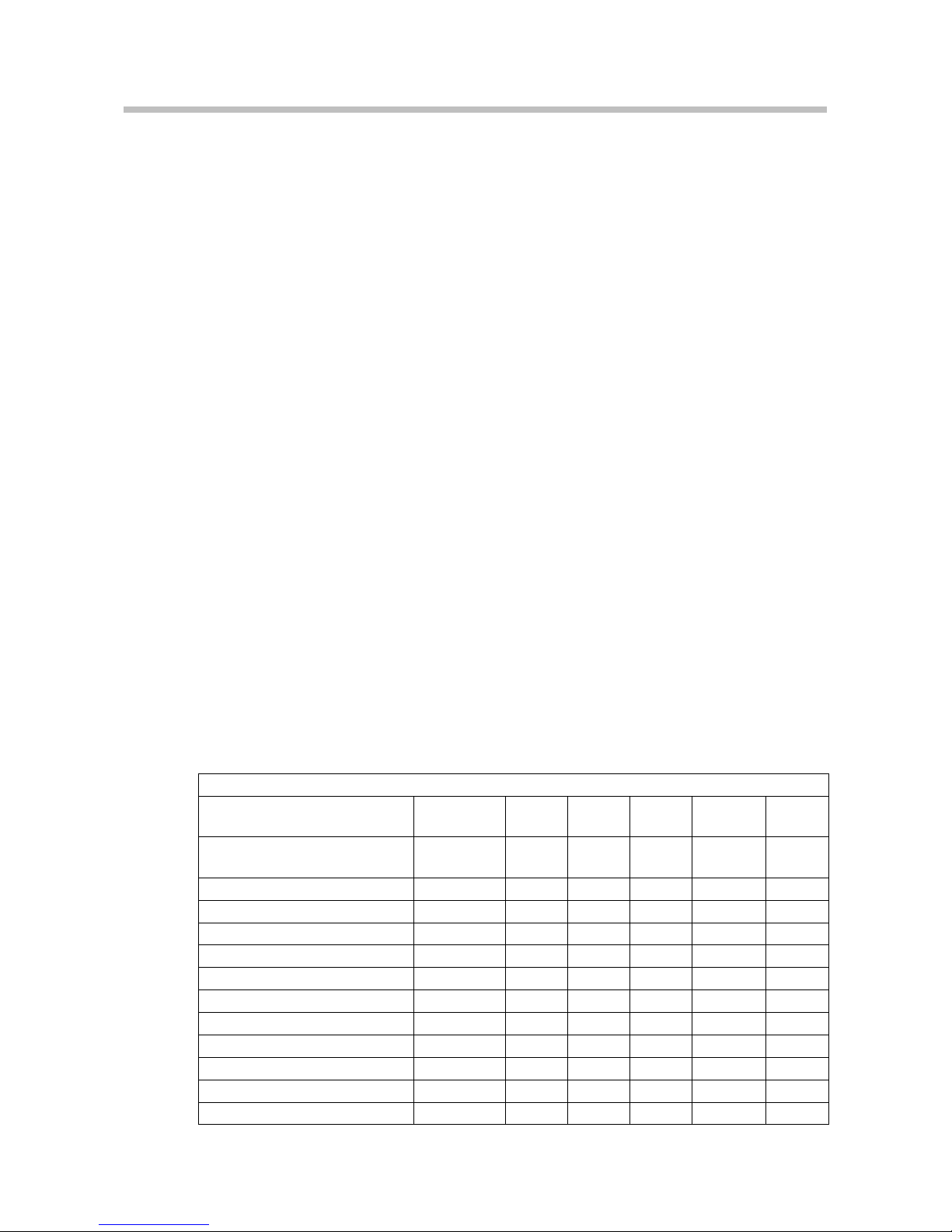

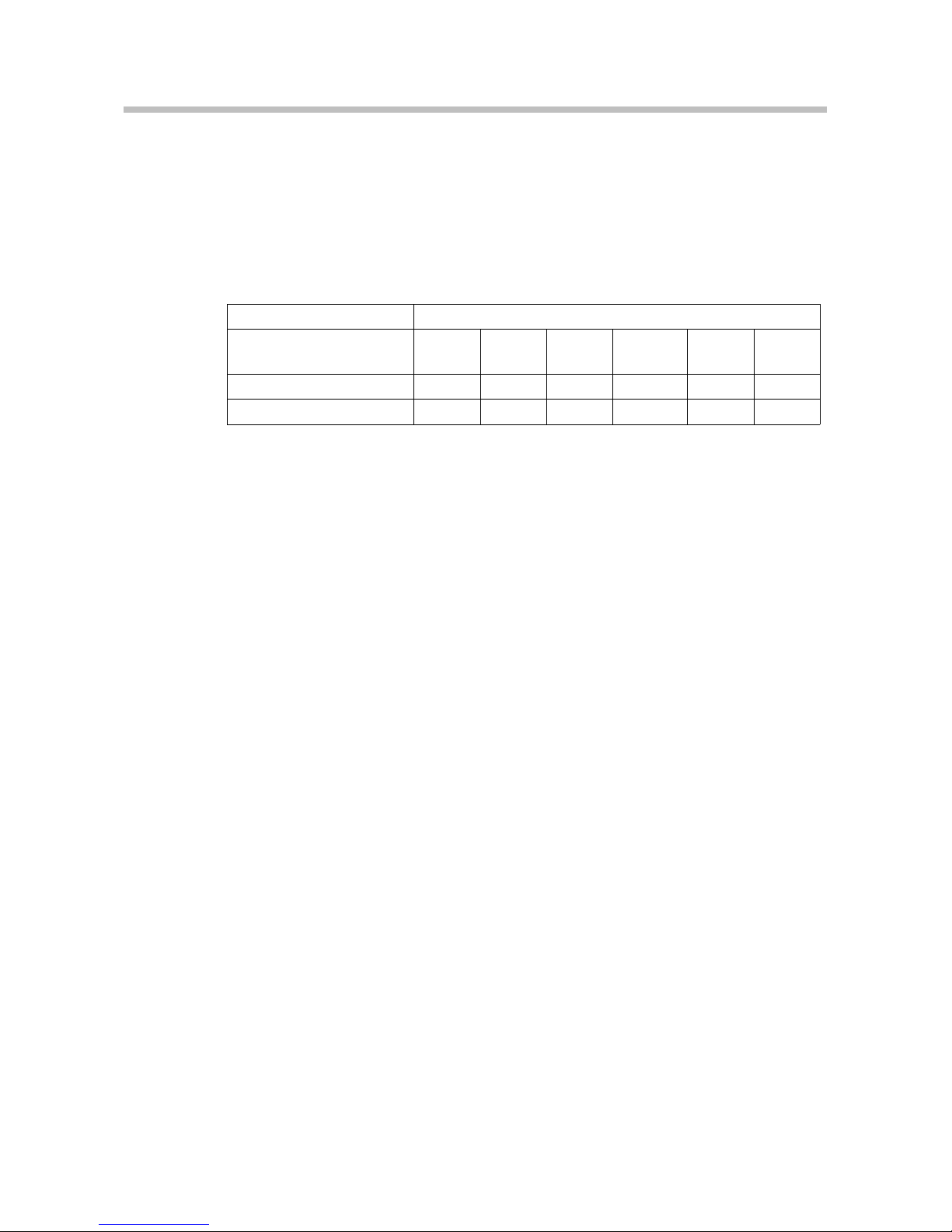

6.2.1 Standard Delivery Rheometer

The Rheometer is delivered in a recyclable package

with the following accessories:

HAAKE RotoVisco 1

Part.No. TCO TCL/Z TCL/P TCE/P

TCE/PC

TCP/P

Connection cable

conntry specific

1 1 1 1 1

Instruction Manual ger. 003--5212 1 1 1 1 1

Instruction Manual uk. 003--5213 1 1 1 1 1

RS232 cable to PC, 9 pole 222--1490 1 1 1 1 1

Protection ring 222--1394 1 1 1

Splashboard 003--5172 1 1 1

Lever for cylinders 222--1639 1

Fuses 230V/T1.6A 087--0532 2 2 2

Fuses 230V/T3,15A 087--0533 2 2

Fuses 100/115V/T3.15A 087--0533 2 2 2

Fuses 100/115V/T5A 087--3353 2 2

Leveling indicator 002--4696 1 1 1 1

Page 14

Unpacking / Ambient conditions

12

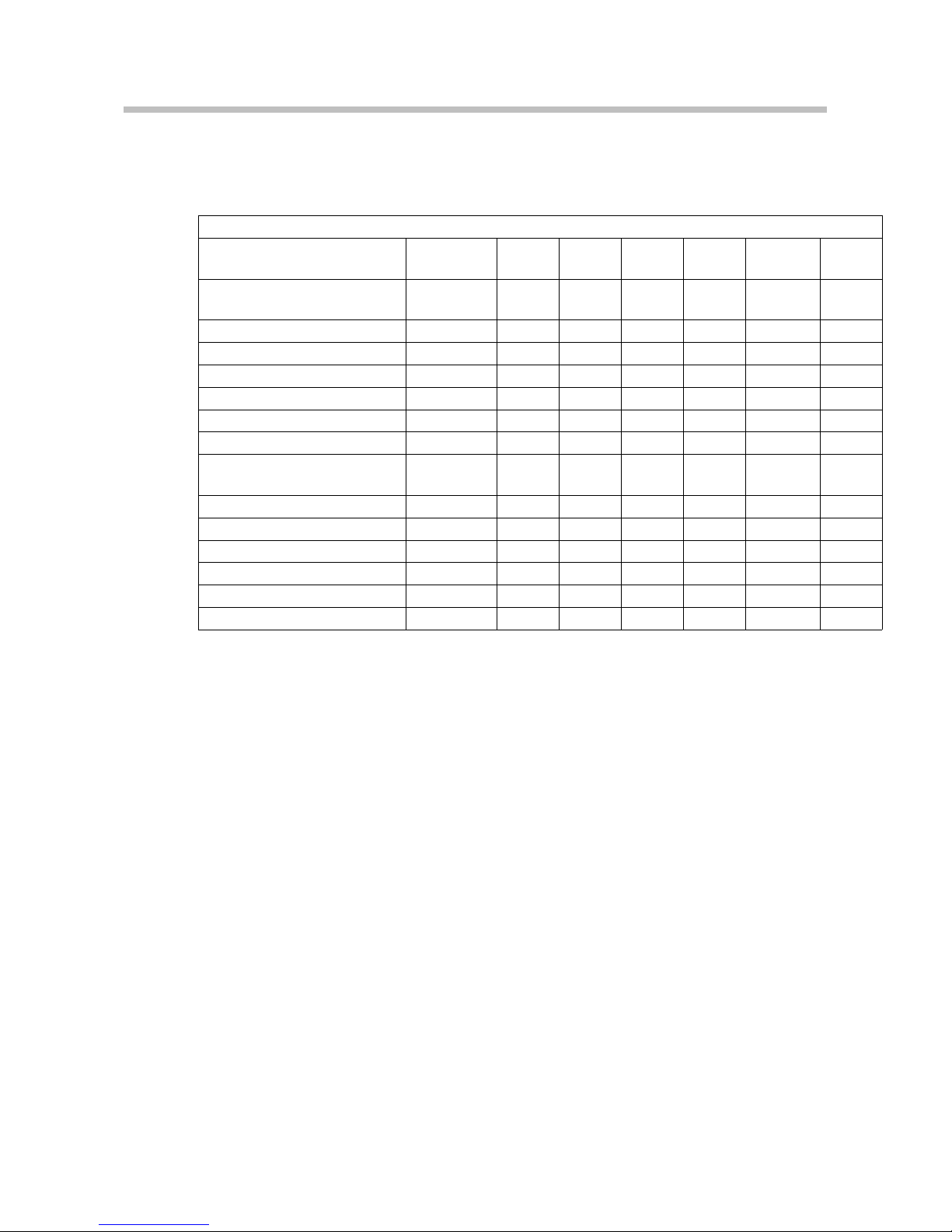

HAAKE RheoStress 1

Part.No. TCO SHRP TCL/Z TCL/P TCE/P

TCE/PC

TCP/P

Connection cable

conntry specific

1 1 1 1 1 1

Instruction Manual ger. 003--5212 1 1 1 1 1 1

Instruction Manual uk. 003--5213 1 1 1 1 1 1

RS232 cable to PC, 9 pole 222--1490 1 1 1 1 1 1

Compressed air hose 10m 082--2451 1 1 1 1 1 1

Protection ring 222--1394 1 1 1

Splashboard 003--5172 1 1 1

Ring for Peltier tempera-

ture control unit

222--1720 1

Lever for cylinders 222--1639 1

Fuses 230V/T1.6A 087--0532 2 2 2 2

Fuses 230V/T3,15A 087--0533 2 2

Fuses 100/115V/T3.15A 087--0533 2 2 2 2

Fuses 100/115V/T5A 087--3353 2 2

Leveling indicator 002--4696 1 1 1 1 1

Page 15

!

Unpacking / Ambient conditions

13

6.2.2 Sensor Systems

Various sensor systems are available for the Rheometer which differ also in their temperature control specifications.

6.2.3 Accessories for the Temperature Control

Units

The temp. control units for liquid temp. control may be

operated with different hoses:

For the temperature control units, the open-bath circulators and heating circulators the necessary tubing

hoses are not part of the standard accessories. They

have to be ordered separately.

Temperature range up to 150C:

Viton-hoses with quick coupling 222--0610

Hose nozzle set 222--1492

Temperature range of 100 up to 350C:

Metal hoses (150 cm each) 333-0294

Hose nozzle set 222--1492

Secure all hose connections using hose clamps!

6.2.4 Application software

HAAKE RheoWin Rheometer software for

Windows XP

Software RheoWin

for HAAKE RotoVisco1 098--5003

for HAAKE RheoStress1 098--5004

Page 16

!

!

230 V

115 V

230V

115V

6

!

Unpacking / Ambient conditions

14

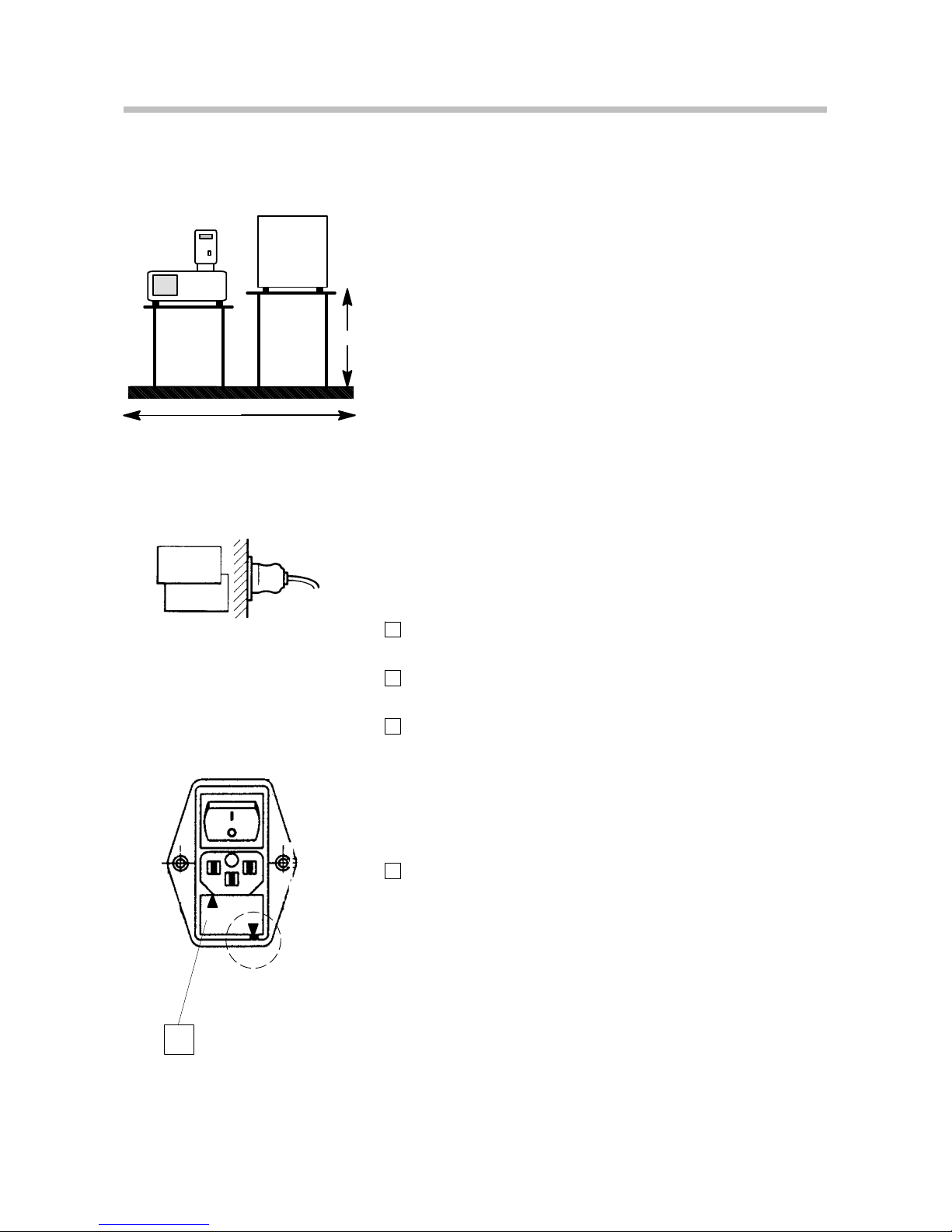

6.3 Space Requirements

Good working conditions for a complete installation require

an area of about 1 x 0.6 meters. The two benches should be

rigid with a level surface and easy to clean. The circulator

used for temperature control should be located below the

rheometer on a separate bench to avoid backflow of thermal

fluid and possible mechanical oscillation.

A suitable laboratory bench must be provided for

the installation.

The circulator has to be located below the level of

the rheometer, otherwise the thermal fluid flows

back in the cup holder and flushes the instrument.

6.4 Mains supply

Only attach the units to mains sockets with a

grounded earth. Compare the local mains voltage

with the specifications written on the name plates

of the measuring instrument and the control unit.

Voltage deviations of 10 % are permissible.

Mains cable and unit fuses:

1

Use the mains cable according to your local mains voltage ( see chapter “Contents of delivery”).

2

Insert the fuses according to your local mains voltage

below the mains connection 6.

3

For TCO, SHRP, TCL/Z, TCL/P:

230 V 2 x T1.6 A

100/115 V 2 x T3.15 A

For TCE/P, TCE/P, TCE/PC, TCP/P:

230 V 2 x T3.15 A

100/115 V 2 x T5A

4

Insertion of the fuses:

Pull out the fuse holder from the mains socket and

insert the fuses. Reinsert according to the marked voltage.

6.5 Cooling air for the measuring head

(HAAKE RotoVisco 1)

Compressed air is connected at nozzle 9 to avoid overheat-

ing under extreme load (high torque, high temperature

(200--350 C)) and at use of the measuring instrument at

temperatures > 100 C in the continuous operation respectively.

maximum conduction pressure 0.5 bar.

(RheoStress are cooled by the outgoing air of the air bearing.)

1.0 m

0.85

Rheometer

Circulator

Page 17

!

Unpacking / Ambient conditions

15

6.6 Requirements for the air supply

HAAKE RheoStress RS1 / RW1F

Pure air pressure is connected at nozzle for the air bearing

with a pressure by 2.5 bar (ideal way).

The air supply must have the following conditions:

-- max. 4 bar,

-- consumption approx. 10 dm3/minute

(1 dm3= 1 thousandth of a cubic meter),

-- no synthetic oil in the line,

-- max. oil contents 3mg/m3air,

-- dry air with a residual moisture < 40 %

Use the filter unit (order no. 222-1211) or the HAAKE

compressor (order no. 222-1434 for 230 V and 222-1435 for

115 V).

HAAKE RheoStress1: The pressure of the air supply for the

air bearing must not exceed 4 bar. Higher pressure will damage the air bearing permanently!

The air bearing reacts highly sensitive to dirt like particles (dust an

lint) or liquids (oil or water which condenses at high humidity levels). It is therefore recommended to have new air compressors run

for a longer period of time (0,5 hrs.) without actually connecting

it to the Rheometer. In the case of internal supply systems polluted

air might have collected near the connection nozzle when the line

has not been used for some time. Therefore, we also recommend

to ”flush” this line for a period of approx. 0.5 hrs.

6.7 Pipes in the building

Oil is generally applied to air pipes in the buildings of materialprocessing plants in order to prevent rusting in the workshops. By

means of complex filters the oil content may be reduced by rarely

so much that the air bearing does not suffer damage.

Thermo Fisher Scientific air bearings must not be used in plants in

which oil is added.

6.8 Air compressors

There are ”oil-free” and ”lubricated” versions of air compressors.

Only oil-free compressors (e.g. the HAAKE compressor) are admissible for Thermo Fisher Scientific air bearings.

If the hose length is larger then 5 m (between compressor and

measurement unit), it must be separately attached pressure controller located next to the measurement unit (see instruction

manual Air compressor Carat).

6.9 Ambient conditions according to EN 61010

It is recommended to run tests in an air-conditioned room,

(T = approx. 23 C):

indoors, max. 2000 meters above sea level,

ambient temperature 15 ... 40 C,

relative humidity max. 80%/31 C( 50%/40 C)

excess voltage category II, contamination level 2

Page 18

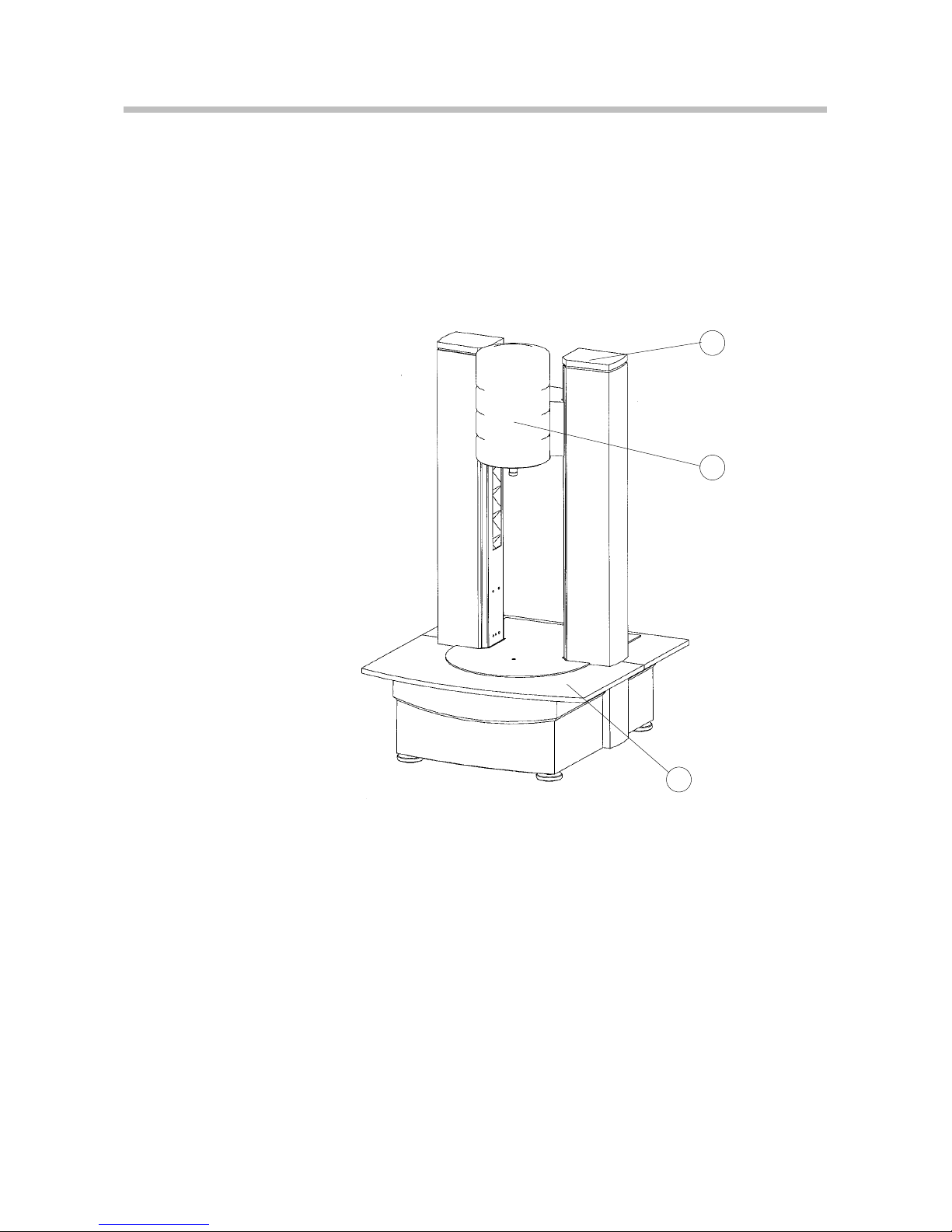

Unit Description

16

7. Unit Description

lntroduction

The viscoelastic behavior of a fluid or a soft solid can be characterized in two ways; either the fluid is deformed and the resulting stress is measured (CR mode), or the stress is applied and the deformation monitored (CS mode). The principle benefits of the CS mode are:

Software

Software control and evaluation with HAAKE RheoWin or

OS1 to program the display unit for production laboratories.

Measurements and evaluation

The Rheometers is controlled either by the HAAKE RheoWin Software or with one of 10 pre--programmable measuring procedures by the display unit. The results are available for further processing on a PC with the HAAKE RheoWin Software. Alternatively up to 50 measurements can be

stored internally and be evaluated, displayed or printed out

for documentation purposes.

Sensors

For HAAKE RotoVisco1 and HAAKE RheoStress1 plates,

cones, coaxial cylinders and immersion systems are available.

Page 19

Unit Description

17

7.1 HAAKE RotoVisco1

Thixotropy and flow curve

The determination of the flow behavior of a test substance

requires a speed ramp up, a holding time and a return curve

for the determination of the thixotropy. This hysteresis

method can like all other measuring procedures be PC controlled or can be loaded as procedure in the display and control unit.

Time curve

Is the viscosity of a test substance changing with time this

can be monitored objectively with the HAAKE RotoVisco1.

This is especially important for substances which are curing

(adhesives, building materials), change their viscosity with

storage time or show considerable changes of viscosity after

shearing during the production process (cosmetics, paint,

food).

Temperature programs

Temperature programs are very time consuming when the

rheometer has to be operated and supervised. With the RotoVisco1 these tasks can be taken over by the PC which controls t he rheometer as well as the temperature control units

-- everything without intervention of the operator.

Determination of the yield point

As soon as substances are strained beyond the Hookean

range they start to flow. This can be defined as yield point

and is an important characteristic value in quality control.

With the HAAKE RotoVisco1 this value can be established

relevant to practical applications, fast and easily by applying

a small deformation through extremely low speed values.

CD Mode

In the CD mode (speeds lower than 0.1 min

–1

) it is only measured at constant speeds. When ramps or steps are preset,

the following speed table is run:

Speed ( min

–1

)

0.0125

0.0250

0.0375

0.0500

0.0630

0.0750

0.0875

0.1000

Page 20

Unit Description

18

7.2 HAAKE RheoStress1

Flow curves

in CR and CS mode can be recorded as ramp or steps

(steady state).

Time curves

for reactions (e.g. curing) at constant temperature, shear

rate, shear stress or frequency.

Temperature programs

are software controlled to determine the temperature dependence with controlled shear stress, shear rate or frequency.

Yield points

can be determined with creep/recovery tests or with stress

controlled ramps.

Viscoelasticity

of a fluid can be quantified by a creep/recovery test or by dynamic measurements in CD (Controlled Deformation) or CS

(Controlled Stress) mode.

Multiwave

even allows the determination of the frequency spectra as a

function of time or temperature by overlay within shortest

time.

Page 21

!

Unit Description

19

7.3 Temperature control:

For applications at elevated temperatures above 250C

it is a must to switch the fan for the air bearing cooling

on stage 2 (on the rear) and use ceramic shafts only.

Furthermore use the cone heater TC1 as thermal shield

to prevent the heating up of the air bearing housing!

TCO Glass plate with a Pt100 temperature sensor

(not temperature controlled).

TCL/Z Liquid temperature controlled receptacle for cylinder

measuring systems with direct contact of the thermal

fluidfrom--40upto200C.

TCL/P Liquid temperature controlled measuring plate for

parallel plate or cone & plate measurements (with

external circulator from --20 up to 300C).

TCP/P Measuring plate with Peltier temperature control for

TCP/PE parallel plate or cone & plate measurements from

--40 up to 180C (external heat transfer required).

TCE/P Electrically temperature controlled measuring plate for

parallel plate or cone & plate measurements from

-- 2 0 Cupto350C.

TCE/PC Electrically temperature controlled measuring plate for

parallel plate or cone & plate measurements with

electrical cone heating from --40Cupto350C.

SHRP Special temperature controlled system utilizing

thermal liquid as standardized for asphalts and

bitumen.

Temperature range: 0C(--25C)... +90C

(for HAAKE RheoStress 1)

Page 22

Unit Description

20

7.4 Main features of the HAAKE rheometers:

Quick fitting sensor with a high precision even if not

perfectly clean.

Remote and manually controlled lift with variable

speed to preserve the fluid’s structure and ensure

reproducible test conditions.

Microprocessor controlled positioning of the sensor to

ensure the highest accuracy for routine tests.

Standard temperature range of --40 to 250 C using a

heating circulator; utilizing electrical cone heating

extends this up to 350 C.

Controlled rate mode for characterizing rheologically

complicated fluids (HAAKE RotoVisco 1 and HAAKE

RheoStress 1).

Controlled stress mode for characterizing sensitive

substances (HAAKE RheoStress1).

Forced oscillation tests at very low frequencies and

very low strains allow destruction free measurements

(HAAKE RheoStress 1).

Sophisticated application software packages with

userfriendly window menus and an on-line help key.

Page 23

Installation

21

8. Installation

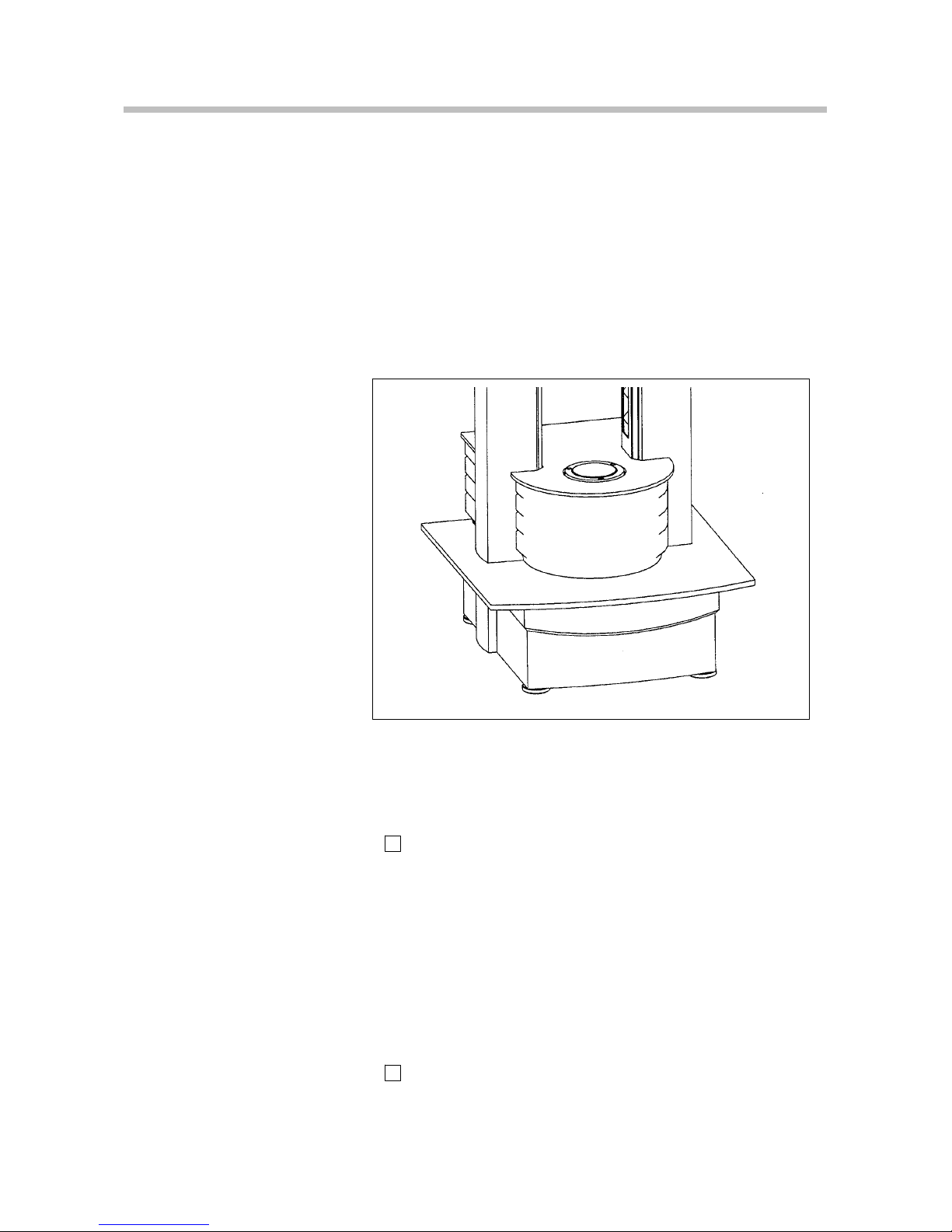

8.1 Setting up the Rheometer

Lift the Rheometer out of the package and place onto a

stable, level table. Do not lift the unit at the glass pane or

at the measuring head ! For sensible measurements a

plane table is recommended.

In the base of the measuring instrument, there are four feet

which can be screwed in or out for levelling the unit.Upon

completion of the preliminary visual levelling, exact precision

levelling can be carried out using the spirit level supplied.

1

The spirit level:

is put on the measuring plate at temperature control

unitTCL/P;TCE/P;TCE/PCandTCP/P.

is put into connection with a vessel at temperature con-

trol unit TCL/Z.

is put on the measuring plate in the vessel at tempera-

ture control unit SHRP.

is not used at temperature control unit TCO.

2

Adjust the feet so that the air bubbles remain in the center of the spirit level.

This adjustment process should be repeated at least once a

week.

Page 24

!

Installation

22

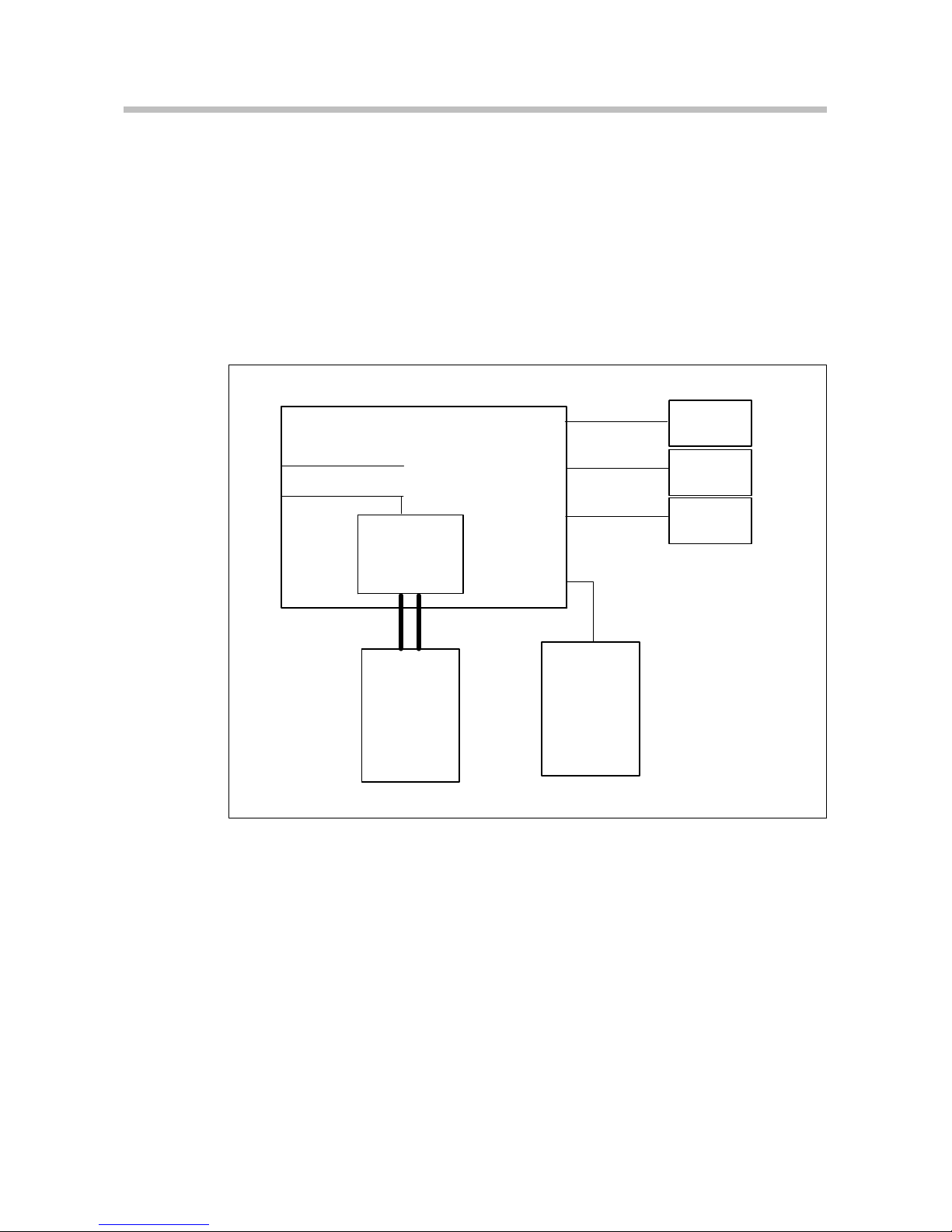

8.2 Connecting up

Make sure that the unit has been switched off before you connect or disconnect the cables.

The cable connections between the sensor system, the control unit, the PC and the printer have to be established

( see. chapter Pin Wiring)

Measuring

Instrument

PC

Air

supply

unit

Heating

Bath

and

Circulator

Control

unit

Printer

and/or

Temperature

Control Units

RS 232

Centronics

Display

Luft / Air

PT100 ( output )

PT100 ( input )

Shielded RS232 cable with ferrite core

e.g.

filter unit 222-1211

or

compressor 222-1435

(RheoStress 1)

222-1490

222-0572

8.2.1 PT100 connection

PT100 (input) socket for external PT100 sensor only

when using TCO

PT100 (output) socket for PT100 sensor only when using

TCL/Z and TCL/P

The connections are described in chapter “Pin Wiring”.

Page 25

!

!

Installation

23

8.3 Hose connections

8.3.1 Temperature control unit (with liquid):

The temperature control unit with liquid temperature

control is connected with hoses to a heating bath and

circulator.

While fastening the hose connections at the connecting nozzles (14) of the temperature control unit

the connecting nozzles must be held up by

wrenches.

Direction of flow of the liquid

Temperature range up to 150 C:

Viton hoses

Hoes nozzle -Set 222--1492

Temperature range of 100 Cupto350 C:

Metal hoses 333-0294

Hoes nozzle -Set 222--1492

Liquid temperature control:

Temperature range up to 100 C:

Thermal liquid in the temperature range between --50

C and 30 C: water with anti-freeze.

Temperature range from 5 Cto90 C: distilled water.

Distilled water

Normal mains water causes cable deposits and

frequently requires the unit to be descaled.

In principle, water up to 95 C can be used. However,

above 80 C, so much water evaporates that it requires

frequent topping--up.

Water with anti--freeze

If you intend working at temperatures below 5 C,

anti--freeze must be added to the water. The added

amount of anti--freeze should be sufficient for a

temperature that is about 10C lower than the intended

working temperature. This prevents the freezing of

water on the evaporator coil of the cooling circuit, the

surface of which is always much colder than the

Page 26

Installation

24

working temperature. However, too much anti--freeze

worsens the temperature constancy due to its high

viscosity.

Temperature range from 100 Cto200 C:

Silicone oils or other suitable liquids are used as thermal liquid.

8.3.2 Air bearing (measuring unit)

The air bearings of the measuring units HAAKE

RheoStress1 require cooling air at port 9

(see “Requirements for the air supply”).

Page 27

Functional Elements

25

9. Functional Elements

9.1 Temperature control units

Rheometer Temperature control units

TCO TCL/Z TCL/P TCE/P

TCE/PC

TCP/P SHRP

HAAKE RotoVisco1 X X X X X

HAAKE RheoStress1 X X X X X X

Page 28

Functional Elements

26

9.2 External filter

An external filter is part of the standard range of items

supplied with the temperature control units for Series 1

TCP/P (Peltier-Temperature control system), TCE/P

(electrical temperature control unit), TCL/PO (liquid

temperature control unit for HAAKE RheoScope) and the

UTCP/P (Peltier-Temperature control system for HAAKE

RSXXX units). It consists of the filter itself, a plastic cone

contained inside it, and clamps.

Using this filter enables the interior of the relevant

temperature control unit to be protected against any

impurities carried in by the temperature liquid. The external

filter represents an additional protection. On the standard

model a sieve is built in to the intake of each temperature

control unit.

As shown in Fig. X, the filter is installed in the intake hose

leading into the temperature control unit between the

thermostat and the measurement instrument. The intake

and outlet directions must be noted (IN and OUT on the

filter). It is fastened with the clamps that are supplied with it.

Hoses with a diameter of 8 mm can be installed and fastened

with the clamps supplied. The plastic cone on the inside of

the filter serves as a direction of flow indicator, and its

movements show the through-flow of the tempering liquid. If

there are impurities in the filter it can be taken out, cleaned,

and used again. The use of the external filter is

recommended because any impurities can be recognised

and removed more readily than with the sieve that is built in

to the temperature control unit. The screw-in sieve (internal)

must of course be checked for impurities from time to time

in order to ensure t he functional capability of the temperature

control unit.

Order numbers:

003-5266 Screw-in sieve (internal) for TCL/P, TCP/P,

TCE/P, TCL/Z

222-1667 External filter for TCP/P, TCE/P, TCL/PO

Page 29

Functional Elements

27

9.3 Measuring Instrument with no

temperature control unit.

Front

1

4

3

1. Measuring unit

3. Quick cut-off switch

4. Green LED display: operational

Page 30

Functional Elements

28

Rear

6

12

13

11

7

8

10

A

9

A. Caution: Read the instruction manual

6. Mains switch with mains socket and fuses

7. RS 232 interface (PC)

8. Connection for printer

9. Connection for cooling air

(RheoStress1 for the air bearing)

10. PT 100 Connection

11. Connection for display unit

12. Reset switch

13. Switch for bootstrap loader

Page 31

!

Functional Elements

29

9.4 Measuring Instrument with

TCL/Z -- temperature control unit.

Front

3

1

2

4

5

18

A

A. Caution: Read the instruction manual

Glass pane can heat up!

Use safety gloves!

1. Measuring unit

2. Temperature control unit

3. Quick cut-off switch

4. Green LED display: operational

5. Yellow LED display: heating

18. Clamping lever

When using a circulator for temperature control,

this must be located lower than the measuring device, other via the temperature control liquid will

flow back in to the measuring beaker location and

over the measuring device.

Page 32

Functional Elements

30

Rear

14

6

12

13

20

11

7

8

9

14

IN OUT

A. Caution: Read the instruction manual

6. Mains switch with mains socket and fuses

7. RS 232 interface (PC)

8. Connection for printer

9. Connection for cooling air

(RheoStress1 for the air bearing)

11. Connection for display unit

12. Reset switch

13. Switch for bootstrap loader

14. Liquid cooling for temperature control unit

20. Connection for PT100 (output)

Page 33

Functional Elements

31

9.5 Measuring Instrument with

TCL/P / TCE/P / TCP/P / TCP/PE

-- temperature control unit.

Front

3

1

2

4

5

19

A

A. Caution: Read the instruction manual

Glass pane can heat up!

Use safety gloves!

1. Measuring unit

2. Temperature control unit

3. Quick cut-off switch

4. Green LED display: operational

5. Yellow LED display: heating

19. Measuring plate

Page 34

Functional Elements

32

Rear

OUT IN

14

6

12

13

11

7

8

9

A

20

A. Caution: Read the instruction manual

6. Mains switch with mains socket and fuses

7. RS 232 interface (PC)

8. Connection for printer

9. Connection for cooling air

(RheoStress1 for the air bearing)

11. Connection for display unit

12. Reset switch

13. Switch for bootstrap loader

14. Liuid cooling for temperature control unit

20. Connection for PT100 (output) only at TCL/P

Page 35

Functional Elements

33

9.6 Measuring unit with TCE/PC-temperature

stabilisation unit and cone heater TC1

Front side

3

1

2

4

5

19

A

21

A. Caution: Read the operating instructions!

Unit parts can get hot!

Wear protective gloves!

1. Measuring unit

2. Temperature stabilisation unit

3. Emergency OFF switch

4. Green LED: Ready for operation

5. Yellow LED: Heating

19. Measuring plate

21. Cone heater TC1

Page 36

Functional Elements

34

Rear

OUT IN

14

6

12

13

11

7

8

9

A

20

22

23

24

2

5

A. Caution: Read the operating instructions!

6. Mains switch with mains socket and fuses

7. RS 232 interface (PC)

8. Connection for printer (Centronics)

9. Connection for cooling air

(RheoStress1 for the air bearing)

11. Connection for display unit

12. Reset switch

13. Switch for bootstrap loader

14. Liuid cooling for temperature control unit

20. Connection for PT100 (output)

22. Fuse T1.25A

23. Fuse T8.0A

24. Fuse T3.15A

25. Connection for cooling air (for TC1)

Page 37

!

Functional Elements

35

9.7 Measuring Instrument with

SHRP -- temperature control unit.

Front

3

1

2

4

5

17

A

A. Caution: Read the instruction manual

Glass pane can heat up!

Use safety gloves!

1. Measuring unit

2. Temperature control unit

3. Quick cut-off switch

4. Green LED display: operational

5. Yellow LED display: heating

17. Influx control

When using a circulator for temperature control,

this must be located lower than the measuring device, other via the temperature control liquid will

flow back in to the measuring beaker location and

over the measuring device.

Page 38

Functional Elements

36

Rear

14

6

12

13

11

7

8

9

14

16

A

A. Caution: Read the instruction manual

6. Mains switch with mains socket and fuses

7. RS 232 interface (PC)

8. Connection for printer

9. Connection for cooling air

(RheoStress1 for the air bearing)

11. Connection for display unit

12. Reset switch

13. Switch for bootstrap loader

14. Liquid cooling for temperature control unit

16. Overflow port

Page 39

down

up

MenuEnter

Tast e 4Tast e 1

Tast e 2

Tast e 3

Tast e 5

Tast e 6

Nr.(HEADER)

(Status)

Functional Elements

37

9.8 Display unit (optional)

(Order no. 222--1472)

DOWN

UP

MENÜ

ENTER

Tas t e 4

Tas t e 1

Tas t e 2

Tas t e 3

Tas t e 5

Tas t e 6

Nr.MENÜ

Status

General display screen splitting

Header gives the display title

see mask number on the right;

Keys1to6 are reserved differently under each display

title

Up/Down increase or decrease e.g. number values;

short pressing - small increments,

long pressing - increasingly higher

increments;

Enter is the confirmation of an entry or selection;

Menu goes back to an overview display;

Status shows date/time, internal store capacity

for measurements, help texts

Page 40

Functional Elements

38

9.9 Menu tree of the display unit

Page 41

Menu

Temp. controlDiagnosis

Time / Date

Display

Language

Lift

100CONFIGURATION

OperatorConfiguration

Jobs

Lift

Sample name

010MENU

Status

OperatorConfiguration

Jobs

Lift

Sample name

010MENU

Status

Status

!

!

Operating

39

10. Operating

10.1 Switching on

1

When all connections have been established and the

supply lines are active, switch--on the mains switch 6:

The green display 4 on the measuring table of the

rheometer indicates the ready state for operation.

The following operation sequence should be used to be able

to make the measurements at short notice:

-- Instrument:

Automatic device initialization

Raises the lift. Never switch off the unit during lift move-

ment.

In case of loss of power during the lift movement,

the unit has to be initialized again.

Then the following display appears:

-- Operator: Insert sensor if necessary

-- Instrument: Lowers the lift for zero point determination.

Due to the rotation of the pin spots can appear on

the measuring plate. This is normal and does not

constitute any damage to the unit.

Then move the lift again to cleaning position (i.e. up), the instrument immediately shows the MENU selection window

(A) for defining, if necessary,the operator, sample name etc.

10.2 Working with the display unit

In MENU activate CONFIGURATION by pressing the key.

Pressing the key leads directly into the submenu.

Page 42

Menu

Full

Print

200DIAGNOSIS

Status

Menu

203DATA MEMORY

Status

Start

Change

Change

Menu

Cancel

Date: xx xx xxxx

Time: yy:yy:yy

201TIME /DATE

Status

Menu

Online displayContrast

Units

Country

Online graph

202DISPLAY

Status

Enter

Operating

40

Diagnosis

FULL-DIAGNOSIS:

-- The complete device diagnosis contains all internal tests

which are possible at present;

HARDCOPY:

-- Sends a diagnosis report to the printer.

Date / Time

Display

Pressing each key leads directly into the respective submenu:

CONTRAST

Contrast number: xx increase or decrease

UNITS

Switch over facility for

Temperature: Cor F

Viscosity: Pas or mPas

COUNTRY SETTINGS

Choice of one of two available date formats.

ON-LINE-VALUES

ONE predefined display mask with 6 fields (3x large fields on

left and 3x small fields on right, respectively assigned to the

keys) appears. On pressing a key at the respective field, this

field is activated and any desired physical parameter can be

assigned to it.

Fields with no parameter assigned to them do not appear

during the measurement.

ON-LINE-GRAPHICS

Twoy--axes and one x--axis can here be assigned to any desired respective physical parameters.

Data memory

Page 43

Menu

SpanishGerman

English

French

204LANGUAGE

Status

More

OperatorConfiguration

Jobs

Lift

Sample name

110MENU

Status

Batch ID

Menu

Open

Together

Stop

110LIFT

Status

Contact

Measurement

Sensor

Operating

41

Language

Measure

The measurement sequence as a whole is described under

”Measuring sequence”.

Lift

LIFT activation takes place in MENU by pressing the key.

Pressing the key leads directly into the submenu:

OPEN

-- The lift raises to t he top position and stops there

(cleaning position).

CONTACT

-- The lift moves down to t he contact point (zero point)

-- and then up again to the cleaning position with status

message reporting successful zero point determination.

TOGETHER

-- The lift runs max. (if STOP is not actuated before) to

the contact point and stops there.

STOP

-- Stops the lift immediately.

MEASURING POSITION

-- Runs from the current position (usually the cleaning

position) to the measuring position.

Page 44

More

OperatorConfiguration

Jobs

Lift

Sample name

010MENU

Status

Batch ID

Menu

SchleimTei g #1

Teig #2

PE-Lösung

More

010SAMPLE NAME

Status

More

OperatorConfiguration

Jobs

Lift

Sample name

Batch ID

010MENU

Status

More

Muster

115OPERATOR

Status

Menu

Operating

42

Operator

In MENU activate OPERATOR by pressing the key.

Pressing the key leads directly into the submenu:

-- The list of OPERATORs is defined in RheoWin and downloaded from there.

Sample name

In MENU activate SAMPLE NAME by pressing the key.

Pressing the key leads directly into the submenu:

-- The list of SAMPLE NAMEs is defined in RheoWin and

downloaded from there.

Page 45

More

OperatorConfiguration

Jobs

Lift

Sample name

Batch ID

010MENU

Status

More

Polyethyl. CreepSnap-shot test

Manual Measurement

Multiwave

Linearitätstest

105JOBS

Status

Aushärtungstest

Menu

SampleMethode:

Sensor:

Multiwave:

210MEASUREMENT DEFINITION

Status

125BATCH ID

Status

More

OperatorConfiguration

Jobs

Lift

Sample name

Batch ID

010MENU

Status

ID: ABC87--D2/F

ABCDEFGHIJKL MNOPQRSTUVW

up

down

Menu

MenuÜbersicht ausdrucken

Batch ID:

Sample number

Start test

Operating

43

Batch ID

In MENU activate BATCH ID by pressing the key.

Pressing the key leads directly into the submenu:

-- Batch ID must be entered on the display unit.

Measuring sequence

In MENU activate MEASURE by pressing the key.

Pressing the key leads directly into the submenu:

(The names of the jobs are defined by the user in the RheoWin--Software.)

”Snap--Shot Test” and ”Manual measurement” are permanently assigned.

Pressing a key leads directly to the ”Measurement definition

screen”.

-- If all specifications are correct, the operator can press

”START TEST”.

Page 46

Stop JOB

Stop element

320TEST RUN

Status

Start test

Menu

321TEST STOP

Status

Lift

Operating

44

-- After the operator has started the measurement, the job

starts and the display shows the predefined online form.

-- The operator waits until the job is completed or discontinues the job or the current element (jumps to the next element).

On completion or discontinuation of the job, the following display appears:

The operator sees the results of the job on the display and

has 3 options for continuing:

1

Insert new sample: Press LIFT (lower lift), display No.

110 appears, replace old sample with new one and

then continue.

2

Next measurement (same job) with same sample but

possibly other parameters:

Press STARTNEW MEASUREMENT. Any existing parameter place holders of this job are shown again for

editing.

3

General continuation of operation of the instrument via

MENU.

Page 47

Operating

45

10.3 Starting the software

1

Switch on the PC and load MS Windows.

2

In the Windows Program Manager double-click t he

RheoWin Job Manager icon.

RheoWin is started.

3

Click the Device Manager icon in the menu bar.

4

Select the connected unit in the Device Manager and

check the connection with ”Test”.

For extensive operation please read the instruction

manual of your software.

Page 48

Operating

46

10.4 The ”Upload Mode” for the Display Unit

(RheoWin 2.6 or higher)

The rheometers can be operated by the software RheoWin

in ”direct mode” or it can be loaded by special functions measuring programs in the store of the measuring device. By

that, the measuring device gets independent of the PC and

it is only connected for programming or data transfer. The

measuring programs (”JOBs”) are started after the corresponding programming with the display unit.

For programming or data transfer the Rheometer must be

connected to the PC via RS232 cable as usual and Thermo

Fisher Scientific Haake software RheoWin must be loaded.

After installing the rheometer two versions per model can be

found in the device manager . The device e.g. RotoVisco1

is running in the software direct mode as usual. Model RV1

(Upload mode) has already been pre--defined as independent device.

The characteristic ”Upload Mode” is transferred to the device

driver on the following card which can be found under ”Edit”.

So you can give the device driver the characteristic ”Upload”

or ”Software” mode. For practical reason it is advisable to define a new device for each operation.

Page 49

Operating

47

Other options on the device record card are:

Torque Compensation

When the torque compensation is activated, the present

value of the torque display is set on zero ”0” right before the

measurement so that possible faults (offset faults) can be reduced. This is always advisable when samples without ”yield

point” are to be measured. In case of doubt it is measured

first without ”Torque Compensation” and after that it is decided whether the function can be used.

Inertia of Masses Correction Ramp

If fast speed ramps (< 180 s) are driven, the dampening set

at the sensors (usually 30%) and also the inertia of the

masses of the measuring device (motor and rotor) enter the

result. Fast ramp speeds make up a hysteresis curve which

does not come from the sample but from the test conditions

and the measuring device. The influence can be seen qualitatively in the following diagram. It is recommended to drive

measurements with ramp times of less than 120s without

correction only in special cases. With correction, the influences of the inertia of masses are compensated. This can

be tested individually at examples relating to practice.

Page 50

Operating

48

Communication Record

This function has been installed for service use. If this function is activated, all commands between the measuring device and the PC are recorded in a file named Driver.log

(RV1.log, RS1.log,) and are managed in the directory \rheo-

win\driver\.

Upload

Under ”Upload” you can find the present data for user, sample and sensor. These data are entered with RheoWin and

are read out . In the display unit these exact terms can be selected. If you are connected to the measuring device at the

running time the present level of the store is read out with

”READ” and is displayed. Changes can be made. They are

transferred to the measuring device while leaving the menu

and are available now. If the device has not been programmed yet (state at delivery) all lists are empty.

Now the three record cards can be filled with information.

With the mouse and the cursor the first position is clicked and

e.g. a name is entered. After that the second line can be

clicked and other entries can be made.

Page 51

Operating

49

When all names of possible users are entered, the names of

the samples which are to be measured can be entered. Only

these names can be recalled from a selection list.

In principle the same is valid for the sensors of the rheometer. It is recommended to enter only the sensors which are

really in existence from the list of all variants to keep the display clearly organized.

Page 52

Operating

50

The sensors of the right window are transferred to the measuring device if you leave the menu with <OK> . With Cancel

the existing adjustments are kept. If the factors are changed,

e.g. after a calibration, the values of the sensors can be renewed with <READ> after the reading of the store.

Drawing up JOBS for Uploading

JOBs or measuring and evaluation procedures are drawn up

with the RheoWin Job manager. The distinction takes place

before the drawing up of a JOB at the selection of the measuring device. If existing JOBs are changed afterwards unexpected reactions can take place. The following proceeding is recommended:

First the measuring device is selected. After that the procedure is drawn up.

Page 53

Operating

51

After the selection of the measuring device, the sensor and

a temperature control unit are selected. If no temperature

control unit is selected, no temperature control can take

place. No selection (--------)also means that the temperature

control unit is switched off.

The measuring process is now composed according to the

requirements of the application or of the user just as in the

PC mode. There are some restrictions of the length of names

and the selection of elements. These restrictions are visible

only at editing.

After the drawing up of a JOB it can directly be started for a

test or it can be uploaded to the measuring device. On this

Page 54

Operating

52

occasion a list gets visible that shows an empty list or already

existing JOBs. The order or position of the list corresponds

to the reservation in the measuring device. So you can make

an allocation indirectly. Empty positions have to be avoided,

because otherwise the following entries would be ignored.

Uploaded JOBs can be called in via the display unit and can

be carried out directly.

Reading back uploaded JOBs from the measuring device

JOB’s can be read back from the measuring device with the

RheoWin function /File/Open Job of Measuring Device/.

This function corresponds to the reading of the hard disk.

If this function is selected, all installed unit drivers are called

in and it is tested if a connection can be made. Drivers that

are not installed correctly cause error messages and should

be cancelled from the device list (device manager). If a measuring device with the possibility of managing JOBs responds it is selected and displayed immediately.

Page 55

Operating

53

In the white area the existing JOBs are listed for selection.

Measuring result

The measuring result is a chart with measuring and preset

values according to the measuring definition. It can be transferred, if defined in the JOB, directly to a printer. The result

is then shown as selected. Segments can be printed or ignored. The selection of the column contents takes place via

the list menus:

Importing the measuring result in RheoWin

The last measuring result can also be imported directly to the

RheoWin software (measuring device connected to PC and

RheoWin active).For this the file in the DATA manager is

opened.

Page 56

Operating

54

From the following list the device of your choice is selected

for reading out the data. This is necessary because the software RheoWin can drive and read several units by multitasking.

After the selection the data are transferred via RS232 interface from the measuring device to the PC/RheoWin software. The data are treated like comparable values of the local hard disc or of the network.

Page 57

Operating

55

10.5 Quick Cut-off

The switch (3) at the top of the right column switches off the

measuring drive, heating and lift.

Internal measuring jobs are interrupted.

Page 58

Temperature Control Units

56

11. Temperature control units

11.1 Temperature control unit TCO

The sample is in the measuring gap of the sensor system.

The rotator is driven by a preset speed (n). Due to its viscosity, the sample is resistant against the rotation. This resistance gets active as (braking) torque (Md) at the measuring

shaft of RV1. The torque is measured.

From the values of speed, torque and measuring system geometry (system factor) the installed PC calculates the the

measuring values for

If a temperature sensor is connected, the temperature T (in

C) is also calculated.

The results are shown on the display (operating panel) and

and can be passed on to a computer (PC) or printer via interface connection RS232.

Page 59

open

closed

!

!

Temperature Control Units

57

11.2 Temperature control unit TCL/Z

Place the beaker into the temperature control unit and fix it

with the clamping lever.

The sensor system and the temperature control unit require

cooling according to load and temperature during the measurement.

Connect the rheometer to a Thermo Fisher Scientific Haake

circulator with optional hoses ( 8 mm).

While fastening the hose connections at the connecting nozzles(14) of the temperature control

unit::

-- ensure the correct flow direction (IN/OUT)

-- the connecting nozzles must be held secured

using a wrench.

maximum conduction pressure 0.5 bar (water circulation).

For the TCL/Z sensor system and the open--bath and heat-

ing circulators the necessary tubing hoses are not part of the

standard accessories. They have to be ordered separately.

When the measuring beaker is inserted in the t emperature control unit, a valve is automatically opened as it is

pressed in and temperature control liquid flushes the

beaker. The valve is closed again when the beaker is

removed.

The displacement path of the valve means that the

beaker must be moved 3mm. If the seal is missing or an

incorrect closing screw has been fitted, the valve can

remain closed and the temperature control function is

inoperative.

Remedy:

Fit a new seal, a correct closing screw or a

spacer.

The circulator must be located lower than the measuring device, other via the temperature control

liquid will flow back in to the measuring beaker

location and over the measuring device.

For the TCL/Z measuring unit and the open--bath and heating circulators the necessary tubing hoses are not part of the

standard accessories. They have to be ordered separately.

The lever (222--1639) for cylinders is an accessory for t he

RheoStress 1 and RotoVisco 1 rheometer models, which are

equipped with a liquid temperature control unit (TCL/Z) for

coaxial cylinder measuring geometries.

The lever enables the removal of the measuring cup, e.g. for

cleaning at the end of a measurement.

Page 60

Temperature Control Units

58

The following procedure is recommended:

1

Switch the circulator off, in order to reduce the low pressure of the temperature liquid.

2

Position the lever as illustrated in Fig. and move the lever upwards till the measuring cup is free to move.

3

The measuring cup can be now easily removed by

hand.

Hendling of the lever

lever

measuring cup

Page 61

!

Temperature Control Units

59

11.3 Temperature control unit TCL/P

The temperature control unit has a holding for the measuring

plate. The measuring plate is put on the thermal liquid heated

temperature control unit and is fastened.

Cones and measuring plates should have the same diameter e.g. as cone C60/1 and the measuring plate MP60 or

plate PP35 and measuring plate MP35. If not, huge measuring faults are the consequence !

For measurements at temperatures higher than 70Citis

recommendable to use at least the sample protection shield

(222-0608) to reduce the loss of heat. In any case, the application of measuring cones and measuring plates with a

ceramic shaft that do carry off less heat is recommendable.

The sensor system and the temperature control unit need

cooling that is dependent on the load and the temperatures

during the measurement.

While fastening the hose connections at the connecting nozzles(14) of the temperature control

unit::

-- ensure the correct flow direction (IN/OUT)

-- the connecting nozzles must be held secured

using a wrench.

For the cooling of the temperature control unit hoses (with

8mm) can be connected to a liquid circulator.

maximum conduction pressure 0.5bar (water circulation).

Page 62

!

Temperature Control Units

60

11.4 Temperature control unit TCE/P

The temperature control unit has holding a for the measuring

plate. The measuring plate is put on the thermal liquid heated

temperature control unit and is fastened.

Cones and measuring plates should have the same diameter e.g. as cone C60/1 and the measuring plate MPC60 or

plate PP35 and measuring plate MPC35. If not, huge measuring faults are the consequence !

For measurements at temperatures higher than 80Citis

recommendable to use at least the sample protection shield

(222-0608) to reduce the loss of heat. In any case, the application of measuring cones and measuring plates with a

ceramic shaft that do carry off less heat is recommendable.

The temperature control unit is connected to a liquid circulator via hoses ( 8mm) .

For the TCE/P measuring unit and the open--bath and heating circulators the necessary tubing hoses are not part of the

standard accessories. They have to be ordered separately.

The cooling (liquid or gas) is controlled directly in

the measuring device via the built-in solenoid

valve according to the requirements. It is important

that the cooling medium used is selected in the

RheoWin software, as the control parameters (PID)

are thus selected.

The switching condition of the valve is „open“.

Utilizing the optional electrical cone heating extends the

temperature range up to 350C.

Page 63

Temperature Control Units

61

11.5 Temperature control unit TCP/P and TCP/PE

The temperature control unit has a measuring plate 60,

which is at the same time the location for other measuring

plates. The measuring plate is put on the Peltier temperature

control unit and fastened.

The additional plates MPC are only necessary if the same

cone--plate diameter is used for measuring.

Temperature control is carried out electrically via a Peltier

element within a temperature range of --40 to 180C.

The Peltier process

The temperature control system is based on a component

which uses the Peltier effect. This effect which is the reverse

of the thermoelectric effect (e.g. used by thermocouples),

was discovered in 1834 by the French physicist Jean Peltier.

Peltier elements consist of two semiconductor bridges of differing doping (p- and n-type). Stimulated by a (regulated direct-)current flow, the electrons transport heat from one connection point to the next.

Diagram of a

Peltier module

n- and p-doped elements

contact bridges

electric insulation

Cold side

Hot side

The heat flow direction is dependent on the current flow

direction. Peltier temperature control systems can thus be

used for both heating and cooling depending on the current

flow direction.

The heating or cooling capacity i.e. the transported heat

quantity is proportional to the current strength depending on

the semiconductor material used and the number of Peltier

elements electrically connected in series within the Peltier

module.

Page 64

!

!

!

Temperature Control Units

62

Peltier modules transport heat from one side of the module

to the other and thus can be understood as the thermoelectric system of a solid state heat pump. Heat itself is scarcely

absorbed during this process. The heat side is in any case

exposed to the dissipated energy in addition to the transported Peltier heat which has the result of causing the heating and cooling measuring curves not to be identical. The

maximum heating rate is therefore higher than the maximum

cooling rate.

Operation

In the temperature control unit a cooling coil (with hose connections for liquid cooling) is built in to cool the Peltier element.

The connector nozzles of the heat exchanger may

not be closed during operation. A high overpressure may exist during the heating up.

The temperature control plate is set in a plastic part (TEKAPEEK).

Recommended couling liquids are water or

mixtures of water / alcohol as well as water / glycol.

The maximum for the temperature of the couling

liquid is 100 C.

Cooling and Heating

Since the Peltier temperature control unit is cooled by circulating water the temperatures as well as the heating and

cooling rates (times to reach t hose temperatures) depend on

the temperature and of the flow through rate of the coolant.

By variation of the flow-through temperature and the flowthrough volume optimum conditions can be reached for

every working range desired.

In general, the following applies:

During heating the temperature control unit will reach

a max. temperature difference of abt. 100C between

temperature control plate and the temperature of the

coolant under optimum conditions.

During cooling the temperature control unit will reach

a max. temperature difference of abt. 20--40C

between temperature control plate and the temperature of the coolant under optimum conditions.

Page 65

Temperature Control Units

63

Heating

1

2

3

20

140

Final temp.

[ C]

600

t[s]

1

2

3

Cooling curve with water circulator

(DC50--K20) of about 80C

Cooling curve with high temperature supply of about 100C

Cooling curve with room temperature

coolant fluid

80

In general, the following applies for the heating:

Increasing the temperature of the coolant will result in

higher final temperatures and higher heating rates (the

final temperature will be reached faster).

Decreasing the flow through volume will result in higher

final temperatures and higher heating rates.

Example:

With a preset temperature of 20C the Thermo Fisher

Scientific Haake circulator DC50-K20 will reach max. heating

rates up to 1 K/s and a final temperature of about 100C after

about 10 minutes.

Page 66

Temperature Control Units

64

Cooling

Cooling curve with high temperature of

the coolant (room temperature)

Cooling curve with coolant water circulator

(DC50--K20) (reservoir temperature 20C)

1

2

20

360

t[s]

3

Final temp.

[ C]

0

1

2

3

Cooling curve with low temperature of the

coolant (reservoir temperature 5C)

-- 2 0

10

In general, the following applies for the cooling:

Decreasing the temperature of the coolant will result in

lower final temperatures and higher cooling rates (the

final temperature will be reached faster).

Increasing the flow through volume will result in lower

final temperatures and higher cooling rates.

Example:

With a preset temperature of 20C at the Thermo Fisher

Scientific Haake circulator DC50--K20, the Peltier system will

reach max. cooling rates up to 1 K/s and a final temperature

of 0C. Starting at +20C the final temperature of 0C will

be reached after about 6 minutes.

For a given ambient or room temperature there is a low-

est temperature which can be reached. This is usually

about 0C.

lower temperature values can be realized if the loss of

cooling capacity is reduced by insulation.

Page 67

Temperature Control Units

65

Explanation for the cooling

The cooling rate is limited especially for a value when cooling

below the ambient temperature. Therefore, the settings of

the software have to be adapted in order to reach the temperature desired:

1. For the measuring definition of temperature ramps

downwards the ”rising” will be tested -- for cooling negatively. That means that it has to be calculated according to the set values for start and end temperature as

well as the duration using a formula to find out whether

the cooling rate can be achieved. If it is not possible an

error message shows the possible cooling rate.

2. At the beginning of a segment cooling down to the set

starting temperature can be necessary. This coolingdown time will be calculated. In case the time being

higher that 10 s the band width will be set from 0.0 to

0.1 to reach the desired start temperature. In this case

a message window appears as always whenever the

band width for the start temperature is unequal 0.0. The

system waits until the band width of 0.1 has been

reached.

Attention: An abortion using the F7 key would also

abort the cooling process. Then the segment would be

measured with the temperature reached until then.

3. For temperature segments the waiting time set by the

user might be too short to hold the possible cooling

rate. In case the time being more than 10 s too short it

will be set to the required value.

The sensor system and the temperature control unit require

cooling that is dependent on the load and the temperatures

during the measurement.

Page 68

!

Temperature Control Units

66

For the cooling of the temperature control unit hoses (with

8mm) can be connected to a liquid circulator.

While fastening the hose connections at the connecting nozzles(14) of the temperature control

unit::

-- ensure the correct flow direction (IN/OUT)

-- the connecting nozzles must be held secured

using a wrench.

maximum conduction pressure 0.5bar (water circulation).

For the TCP/P measuring unit and the open--bath and heat-

ing circulators the required tubing hoses are not part of the

standard accessories. They have to be ordered separately.

Page 69

!

Temperature Control Units

67

11.6 Temperature stabilisation unit TCE/P with

cone heater TC1

The temperature stabilisation unit has a holder for the measuring plate. The measuring plate is placed and secured

onto the electrically heated temperature stabilisation unit.

The wedge and measuring plates should have the same diameter, for example like the taper C60/1 with the measuring

plate attachment MPC60 and the plate PP35 with the measuring plate attachment MPC35. Otherwise unavoidable

measuring errors arise!

11.7 Cone heater TC1

The high temperature system TC1 was developed for the

measuring units with a TCE/P temperature stabilisation unit

for rheological measurements at temperatures of > 0Cto

350C with and without external cooling. Inert gas should be

used for cooling.

A PID controller is used to control the temperature, with the