Thermo Scientific Dionex UltiMate 3000 Series, FLD-3100, FLD-3400RS Operating Instructions Manual

Page 1

Thermo Scientific Dionex

UltiMate 3000 Series

Fluorescence Detectors

FLD-3100 and FLD-3400RS

Operating Instructions

(Original Operating Instructions)

Revision: 1.3

Date: September 2013

© 2013 Thermo Fisher Scientific Inc.

Doc. No. 4820.7850

Page 2

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

Operating Instructions

Page 3

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

Declaration of Conformity

(Original Declaration of Conformity)

Product: Thermo Scientific Dionex UltiMate 3000 - Detector

Types: FLD-3100 and FLD-3400RS

Dionex Softron GmbH herewith declares conformity of the above products with

the respective requirements of the following regulations:

• Low-Voltage Directive 2006/95/EC

• EMC Directive 2004/108/EC

The electrical safety of the products was evaluated based on the following

standard:

• DIN EN 61010-1:2010

Safety requirements for electrical equipment for measurement, control

and laboratory use, Part 1: General Requirements

The Electromagnetic Compatibility (EMC) of the products was evaluated based

on the following standard:

• DIN EN 61326:2006

Electrical equipment for measurement, control and laboratory use

EMC Requirements

This declaration is issued for the manufacturer

Dionex Softron GmbH

Part of Thermo Fisher Scientific Inc.

Dornierstraße 4

D-82110 Germering

by the Managing Director, Rüdiger Obst, and

the Vice President HPLC, Fraser McLeod.

September 2, 2013

Operating Instructions Page I

Page 4

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

Page II Operating Instructions

Page 5

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

Table of Contents

1 Introduction ................................................................................................................... 1

1.1 How to Use This Manual ........................................................................................... 1

1.2 Safety ......................................................................................................................... 3

1.2.1 Symbols on the Instrument and in the Manual ................................................. 3

1.2.2 Safety Precautions ............................................................................................ 5

1.2.3 Consignes de Sécurité ....................................................................................... 8

1.3 Intended Use ............................................................................................................ 12

1.4 Federal Communications Commission (FCC) Note ................................................ 14

2 Overview ...................................................................................................................... 15

2.1 Unit Description ....................................................................................................... 15

2.2 Operating Principle .................................................................................................. 16

2.3 Configurations ......................................................................................................... 19

2.4 Interior Components ................................................................................................ 20

2.5 Front Panel Elements ............................................................................................... 21

2.6 Rear Panel ................................................................................................................ 22

2.6.1 Power Switch .................................................................................................. 22

2.6.2 Fuse Cartridge ................................................................................................ 22

2.6.3 USB Port ......................................................................................................... 23

2.6.4 Analog Outputs (Optional) ............................................................................. 23

2.7 Fluid Connections .................................................................................................... 23

2.8 Flow Cells ................................................................................................................ 24

2.9 Lamp ........................................................................................................................ 25

2.10 Leak Sensor .......................................................................................................... 25

2.11 Detector Control .................................................................................................. 26

2.12 System Wellness, Predictive Performance, and Diagnostics ............................... 27

3 Installation ................................................................................................................... 29

3.1 Facility Requirements .............................................................................................. 29

3.2 Unpacking ................................................................................................................ 30

3.3 Positioning the Detector in the UltiMate 3000 System ........................................... 31

3.4 Connecting the Detector .......................................................................................... 32

3.4.1 General Information ....................................................................................... 32

3.4.2 Connecting the USB Cable ............................................................................. 32

3.4.3 Connecting the Power Cord ............................................................................ 34

3.4.4 Connecting the Analog Outputs (Optional) .................................................... 34

3.5 Setting Up the Detector in Chromeleon ................................................................... 37

3.5.1 Loading the USB Driver for the Detector ...................................................... 37

3.5.2 Installing the Detector .................................................................................... 39

3.5.3 Configuring the Detector ................................................................................ 40

3.6 Setting Up the Detector in DCMSLink .................................................................... 44

Operating Instructions Page i

Page 6

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

4 Preparation for Operation (Startup) ........................................................................ 45

4.1 Overview .................................................................................................................. 45

4.2 General Precautions for Connecting Capillaries ...................................................... 46

4.3 Connecting the Drain System .................................................................................. 47

4.4 Installing the Flow Cell ............................................................................................ 48

4.5 Equilibrating the System .......................................................................................... 51

4.6 General Guidelines for Detector Operation ............................................................. 52

4.6.1 Mobile Phases ................................................................................................. 52

4.6.2 Mobile Phase Delivery System ....................................................................... 53

4.6.3 Flow Cells ....................................................................................................... 53

5 Operation and Maintenance ...................................................................................... 55

5.1 Power-Up ................................................................................................................. 55

5.2 Detector Display ...................................................................................................... 55

5.3 Menus on the Detector Display ................................................................................ 57

5.3.1 Detector Menus ............................................................................................... 58

5.3.2 General Menu Layout and Structure ............................................................... 59

5.3.3 Main Menu ...................................................................................................... 61

5.3.4 Configuration Menu ........................................................................................ 62

5.3.5 Diagnostics Menu ........................................................................................... 63

5.3.6 Service Menu .................................................................................................. 63

5.4 Operation with Chromeleon ..................................................................................... 64

5.4.1 Connecting to Chromeleon ............................................................................. 64

5.4.2 Direct Control ................................................................................................. 65

5.4.3 Automated Control ......................................................................................... 67

5.4.4 SmartStartup and SmartShutdown .................................................................. 71

5.5 Operational Settings ................................................................................................. 72

5.5.1 Detecting Liquid Leaks in the Detector .......................................................... 72

5.5.2 Adjusting the screen brightness or contrast .................................................... 72

5.6 Operational Modes of the Detector .......................................................................... 73

5.6.1 Single-Channel Mode ..................................................................................... 73

5.6.2 Multi-Channel Mode (FLD-3400RS Only) .................................................... 73

5.6.3 Zero Order Mode ............................................................................................ 74

5.6.4 2D Scans ......................................................................................................... 74

5.6.5 3D Scans (only Chromeleon 7.1 or later) ....................................................... 76

5.7 Optimizing Detector Performance ........................................................................... 77

5.7.1 Determining the Optimum Excitation and Emission Wavelength.................. 78

5.7.2 Sensitivity (Detector Sensitivity) .................................................................... 81

5.7.3 Filter Wheel Setting (FLD-3400RS only) ...................................................... 85

5.7.4 Response Time and Data Collection Rate ...................................................... 86

5.7.5 Multi-Channel Performance ........................................................................... 87

5.7.6 Flow Cell Temperature ................................................................................... 88

5.7.7 Lamp Mode ..................................................................................................... 88

5.7.8 Baseline Behavior ........................................................................................... 89

5.8 Monitoring System Functions .................................................................................. 90

5.8.1 Wavelength Calibration and Verification ....................................................... 90

Page ii Operating Instructions

Page 7

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

5.8.2 Recording the Flow Cell Temperature ........................................................... 92

5.8.3 Predictive Performance................................................................................... 92

5.8.4 Operational Qualification and Performance Qualification ............................. 92

5.9 Shutting Down the Detector .................................................................................... 93

5.10 Routine and Preventive Maintenance Intervals ................................................... 95

6 Troubleshooting .......................................................................................................... 97

6.1 Overview .................................................................................................................. 97

6.2 Messages on the Detector Display ........................................................................... 98

6.3 Operating Problems ............................................................................................... 102

7 Service ........................................................................................................................ 107

7.1 General Notes and Safety Precautions ................................................................... 107

7.2 Lamp ...................................................................................................................... 108

7.3 Flow Cell ................................................................................................................ 109

7.3.1 Flushing the Flow Cell ................................................................................. 109

7.3.2 Replacing the Flow Cell ............................................................................... 110

7.4 Drying the Leak Sensor ......................................................................................... 113

7.5 Replacing the Main Power Fuses........................................................................... 114

7.6 Updating the Detector Firmware ........................................................................... 115

8 Technical Information .............................................................................................. 117

9 Accessories, Consumables, and Spare Parts .......................................................... 119

9.1 Standard Accessories ............................................................................................. 119

9.2 Optional Accessories ............................................................................................. 120

9.3 Consumables and Spare Parts ................................................................................ 121

10 Appendix: Common Mobile Phases ........................................................................ 123

11 Index ........................................................................................................................... 125

Operating Instructions Page iii

Page 8

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

Page iv Operating Instructions

Page 9

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

1 Introduction

1.1 How to Use This Manual

The layout of this manual is designed to provide quick reference to the sections of interest

to the reader. However, in order to obtain a full understanding of your Thermo Scientific™

Dionex™ detector, Thermo Fisher Scientific recommends that you review the manual

thoroughly before beginning operation.

All descriptions in the manual apply to the following variants of the fluorescence detector in

the UltiMate™ 3000 series:

• FLD-3100

• FLD-3400RS

The following conventions apply to the descriptions throughout this manual:

• The term "the detector" or "the device" is used throughout the manual. If some detail

applies to only one version, the detector is identified by name.

• If not otherwise stated, the descriptions for the Viper™ capillary connections apply also

to the nanoViper™ and possible other Viper capillary connections.

• The device configuration may vary. Therefore, not all descriptions necessarily apply to

your particular module.

• The representation of a component in this manual may be slightly different from the real

component. However, this does not influence the descriptions.

• The descriptions in this manual refer to firmware version 1.41 and Chromeleon™ 6.80

Service Release 13. If you want to operate the detector from Chromeleon 7, note the

information on page 26.

This manual is provided "as is". Every effort has been made to supply complete and

accurate information and all technical specifications have been developed with the utmost

care. The information contained in this manual should not be construed as a commitment

by Thermo Fisher Scientific. Thermo Fisher Scientific assumes no responsibility for any

errors that may appear in this document. This document is believed to be complete and

accurate at the time of publication. In no event shall Thermo Fisher Scientific be liable for

incidental or consequential damages in connection with or arising from the use of this

document.

The information contained in this document is subject to change without notice.

Operating Instructions Page 1

Page 10

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

All rights reserved, including those for photomechanical reproduction and storage on

electronic media. No part of this publication may be copied or distributed, transmitted,

transcribed, stored in a retrieval system, or transmitted into any human or computer language,

in any form or by any means, electronic, mechanical, magnetic, manual, or otherwise, or

disclosed to third parties without the express written permission of Thermo Fisher Scientific

Inc.

Trademarks

Analyst is a registered trademark of AB Sciex.

Compass and Hystar are trademarks of Bruker Daltonics.

Empower is a registered trademark of Waters Corp.

PEEK is a trademark of Victrex PLC.

LiChrosolv is a registered trademark of Merck KGAA.

Windows and Windows Vista are registered trademarks of Microsoft Corp.

All other trademarks are property of Thermo Fisher Scientific Inc. and its subsidiaries.

Page 2 Operating Instructions

Page 11

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

1.2 Safety

The CE Mark label and cTUVus Mark safety label on the instrument indicate that the

detector is compliant with the related standards.

1.2.1 Symbols on the Instrument and in the Manual

The table shows the symbols used on the instrument:

Symbol Description

Alternating current—Courant alternatif

Power supply is on (-)—L'instrument est mis sous tension (-) and Power

supply is off (O)—L'instrument est mis hors tension (O)

Surface becomes hot during operation—La surface devient chaude lors du

fonctionnement.

Refer to the Operating Instructions to prevent risk of harm to the operator and

to protect the instrument against damage.

Référez-vous à ce manuel pour éviter tout risque de blessure à l'opérateur et/ou

protéger l'instrument contre tout dommage

Label according to the "Measures for Administration of the Pollution Control of

Electronic Information Products" (China RoHS) guideline

Étiquette "Measures for Administration of the Pollution Control of Electronic

Information Products" (China RoHS)

WEEE (Waste Electrical and Electronic Equipment) label—For more

information, see the WEEE Information section in the "Installation and

Qualification Documents for Chromatography Instruments" binder. Étiquette

WEEE (Waste Electrical and Electronic Equipment)—Pour plus d'informations,

référez-vous au chapitre WEEE Information dans le classeur "Installation and

Qualification Documents for Chromatography Instruments"

Operating Instructions Page 3

Page 12

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

At various points throughout the manual, messages of particular importance are indicated

by certain symbols:

Tip: Indicates general information, as well as information intended to

optimize the performance of the instrument.

Important: Indicates that failure to take note of the accompanying information

could cause wrong results or may result in damage to the instrument.

Important: Indique que ne pas tenir compte de l'information jointe peut conduire

à de faux résultat ou endommager l'instrument.

Warning: Indicates that failure to take note of the accompanying information

may result in personal injury.

Avertissement: Indique que ne pas tenir compte de l'information jointe peut entraîner

des blessures corporelles.

Page 4 Operating Instructions

Page 13

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

1.2.2 Safety Precautions

When working with analytical instrumentation, you must know the potential hazards of

using chemical solvents.

Tip: Before initial operation of the detector, make yourself familiar with

the contents of this manual.

For the safety precautions in French, see page 8.

Warning: All users of the device must observe the following safety precautions

and all additional safety precautions in this manual to avoid the

possibility of personal injury or damage to the device when

operating the device or carrying out any maintenance or service

procedures.

Observe any warning labels on the device and see the related

sections in these Operating Instructions.

• Protective equipment

When performing any work on or near the HPLC system, wear personal protective

equipment (protective clothing, safety gloves, safety glasses) as required by the hazard of

the mobile phase and sample. For information about the proper handling of a particular

substance and for advice on specific hazards, refer to the material safety data sheet for the

substance you are using. Observe the guidelines of Good Laboratory Practice (GLP).

An eyewash facility and a sink should be close to the device. If any substance splashes on

the eyes or skin, wash the affected area and seek medical attention.

• Hazardous substances

Many organic solvents, mobile phases, and samples are harmful to health. Be sure that

you know the toxic and infectious properties of all substances that you are using. You

may not know the toxic or infectious properties of many substances that you are using. If

you have any doubt about a substance, treat it as if it contains a potentially harmful

substance. For advice on the proper handling of a particular substance, refer to the Safety

Data Sheet (SDS) of the manufacturer. Observe the guidelines of Good Laboratory

Practice (GLP).

Dispose of waste substance in an environmentally safe manner that is consistent with all

local regulations. Do not allow flammable, toxic, and/or infectious substances to

accumulate. Follow a regulated, approved waste disposal program. Never dispose of

flammable, toxic, and/or infectious substances through the municipal sewage system.

• Hazardous gases

Install the HPLC system in a well-ventilated laboratory. If the mobile phase or sample

includes volatile or flammable solvents, do not allow them to enter the workspace. If the

mobile phase or sample includes volatile or flammable solvents, avoid open flames and

sparks.

Operating Instructions Page 5

Page 14

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

• Electrostatic discharge

Discharge of electrostatic energy may lead to sparking and can constitute a fire hazard.

Keep in mind that liquid flowing through capillaries can generate static electricity. This

effect is particularly pronounced in insulating capillaries and with non-conductive

solvents (for example, pure acetonitrile).

Take appropriate measures to prevent the generation of static electricity near the HPLC

system. For example, make sure that the air humidity level in the laboratory is

sufficiently high and provide proper ventilation, wear anti-static clothing or shoes,

prevent accumulation of air bubbles in waste lines, and use grounded waste containers.

Use only non-conductive capillaries to direct solvents into the waste container. With

electrically conductive capillaries, make sure that they are properly grounded.

• Self-ignition of solvents

Do not use solvents for which the self-ignition temperature is below 150 °C. In case of

leakage, these solvents may self-ignite on a hot surface.

• Capillaries, capillary connections, open connections

♦ Capillaries, especially non-metallic capillaries may burst, slip out of their fittings or

may not be screwed in. This may result in substances spraying out of the open

connections.

♦ In an UltiMate 3000 system, some components are made of PEEK™. This polymer

has superb chemical resistance to most organic solvents. However, it tends to swell

when in contact with trichlormethane (CHCl3), dimethyl sulfoxide (DMSO), or

tetrahydrofuran (THF). In addition, it is attacked by concentrated acids, such as,

sulfuric acid and nitric acid or a mixture of hexane, ethyl acetate, and methanol. In

both cases, capillaries may start leaking or they can burst. Swelling or attack by

concentrated acids is not a problem with brief flushing procedures.

♦ Do not use tubing that is stressed, bent, kinked, or damaged.

♦ Capillary connections can be contaminated by harmful substances or harmful

substances can escape from open connections.

♦ Always wear safety glasses when handling fused silica tubing, for example, during

installation or when cutting capillaries to the length.

• Hot surfaces

♦ During operation, the lamps and the surrounding parts become extremely hot and

remain so for some time after the detector is turned off. To avoid possible injury,

allow sufficient time for the lamp to cool down after turning off the detector. Only

then start with the maintenance and repair work.

♦ Flow cells can become extremely hot during operation. To avoid possible injury,

allow sufficient time for the flow cell to cool down before replacing the cell.

• Disconnect the detector from all power sources before removing the panels. When the

panels are removed, dangerous electrical connections will be exposed. The enclosure

must be opened only by Thermo Fisher Scientific service personnel.

Page 6 Operating Instructions

Page 15

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

• Always replace blown fuses with original spare part fuses authorized by Thermo Fisher

Scientific.

• Replace faulty communication cables.

• Replace faulty power cords. Never use a power cord other than the power cords provided

for the device.

• Use only the original spare parts and accessories authorized for the device by Thermo

Fisher Scientific.

• When lifting or moving the detector, always lift the unit by the bottom sides or sides. Do

not lift the detector by the front panel door. This may damage the door.

• Do not place any heavy objects on the open front panel door. This may damage the door.

• After operation, rinse out buffers and solutions that form peroxides.

• Before switching from buffer to organic solution, rinse the analytical system thoroughly

with deionized or HPLC grade water.

• When switching to another solvent, ensure that the new solvent is miscible with the one

contained in the HPLC system. If the solvents are not miscible, the system can be

damaged, for example, by flocculation.

• If a leak occurs, turn off the instrument and remedy the situation immediately.

• Use only standard solvents (HPLC grade or fluorescence grade for highest sensitivity)

and buffers that are compatible with all parts that may be exposed to solvents.

• Before interrupting operation for several days or more or when preparing the detector for

transport, observe the precautions for shutting down the detector (→ page 93).

• Do not use the detector in ways other than those described in these Operating

Instructions.

• Keep the operating instructions near the device to be available for quick reference.

Operating Instructions Page 7

Page 16

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

1.2.3 Consignes de Sécurité

Si vous utilisez d'instrumentation analytique, vous devez connaître les risques d'utilisation

de produit chimiques.

Veuillez noter: Avant de commencer à utiliser l'instrument, assurez-vous que vous

vous êtes familiarisés avec le contenu de ce manuel.

Avertissement: Toutes les personnes utilisant l’instrument doivent observer les

consignes de sécurité suivantes et dans les autres chapitres de ce

manuel pour éviter une mise en danger de sa personne ou de

dommage à l’instrument pendant l’utilisation et des opérations de

maintenance ou service de l’instrument.

Observez les étiquettes d'avertissement sur l'instrument et référezvous aux sections correspondantes dans ce mode d'emploi.

• Equipment de protection

Pour tous les travaux sur le système HPLC ou à proximité, portez l'équipement de

protection personnel (vêtements de protection, gant de sécurité, lunettes de protection)

qui correspond aux risque découlant de la phase mobile et/ou de l'échantillon. Pour les

informations sur la manipulation correcte des composés et des recommandations pour les

situations de risque spécifiques, veuillez consulter la fiche de données de sécurité des

substances que vous utilisez. Veuillez respecter des directives des Bonnes Pratiques de

Laboratoire (BPL).

Une installation permettant de se laver les yeux ainsi qu'un lavabo doivent se trouver à

proximité du système. Si une substance, quelle qu'elle soit, entre en contact avec vos

yeux ou votre peau, rincez abondamment la zone affectée à l’eau, puis.

• Substances dangereuses

De nombreux solvants organiques, phases mobiles et échantillons sont nuisibles à la

santé. Informez-vous de propriétés toxicologiques et infectieuses de toutes les substances

que vous utilisez. Les propriétés toxicologiques et infectieuses de nombreuses substances

peuvent être mal connues. Au moindre doute concernant une substance, traitez-la comme

s'il contenait une substance potentiellement dangereuse. Pour des instructions comment

utiliser correctement des composés particuliers, veuillez consulter à la fiche de données

des sécurités du fabricant respectif. Veuillez respecter des directives des Bonnes

Pratiques de Laboratoire (BPL).

Débarrassez-vous de tous les déchets de substances de manière écologique,

conformément à la règlementation en vigueur au niveau local. Empêchez impérativement

l'accumulation de solvants inflammables, toxiques et/ou infectieux. Suivez un

programme d'élimination des déchets règlementé et approuvé. Ne jetez jamais de

solvants inflammables, toxiques et/ou infectieux dans le système municipal d'évacuation

des eaux usées.

Page 8 Operating Instructions

Page 17

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

• Gaz dangereux

Installez le système HPLC dans un laboratoire bien ventilé. Si la phase mobile ou

l’échantillon contient des solvants volatils ou inflammables, vous devez assurer qu'ils ne

pénètrent dans l'espace de travail. Si la phase mobile ou l’échantillon contient des

solvants volatils ou inflammables, évitez les flammes nues et les sources d’étincelles à

proximité.

• Décharge électrostatique

Décharge électrostatique peut provoquer la formation d'étincelles et peut présenter un

risque d’incendie. Veuillez noter que des solvants fluides dans les capillaires peuvent se

charger automatiquement. Cet effet se peut produire particulièrement forte dans les

capillaires isolants et avec des solvants non-conducteurs (par exemple, l'acetonitrile pur).

Prenez des mesures appropriées pour éviter les charges électrostatiques à proximité du

système HPLC. Par exemple, s'assurez qu'il y a une humidité de l'air suffisante et une

ventilation adéquate dans la laboratoire, portez des vêtements ou équipement de

protection antistatique, évitez l'accumulation de bulles d'air dans les lignes de déchets et

utilisez des réservoirs à déchets mis à la terre.

Utilisez uniquement des capillaires non-conducteurs pour diriger solvants au réservoir de

déchets. Capillaires électriquement conducteur devrait être mis à la terre.

• Inflammation spontanée des solvants

N’utilisez aucun solvants avec une température d‘auto-inflammabilité inférieure à

150° C. Si une fuite se produit, ces solvants peuvent s’auto-enflammer au contact d’une

surface chaude.

• Capillaires, connecteur capillaires, connexions ouvertes

♦ Des capillaires, en particulier les capillaires non-métalliques, pourraient fendre ou

glisser des connecteurs ou ne peuvent pas être vissés. Ceci peut en résulter aussi que

des substances pourraient jaillir des connexions ouvertes.

♦ Dans un système UltiMate 3000, certaines composantes sont en PEEK. Bien que ce

polymère présente une excellente résistance chimique à la plupart des solvants

organiques, il a tendance à gonfler lorsqu'il est en contact prolongé avec du

chloroforme (CHCl3), du diméthyle sulfoxyde (DMSO) ou du tétrahydrofurane

(THF). De plus, il est attaqué par des acides concentrés tels que l'acide sulfurique et

l'acide nitrique ou d'un composé du hexane, éthyle acétate et méthanol. Ceci peut

causer des capillaires de fuite ou risquer des capillaires d’éclater. Ces acides peuvent

cependant être utilisés dans le cadre de procédures de nettoyage, à condition que

l’exposition soit brève.

♦ N'utilisez pas de capillaires écrasés, pliés, abimés ou endommagés.

♦ Les connecteurs capillaires pour pourrait être contaminé par des substances

dangereuses ou des substances dangereuses pourrait sortir des connexions ouvertes.

Operating Instructions Page 9

Page 18

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

♦ Dans un système UltiMate 3000 Bio RS, certains capillaires du système Viper sont

faits d'alliage de nickel-cobalt MP35N. Contact avec la peau peut provoquer une

réaction chez les personnes qui sont sensibles au nickel/cobalt.

♦ Portez des lunettes de protection lorsque vous manipulez des capillaires en silice

fondue (pendant l'installation, découpe, etc.).

• Surface chaude

♦ Lampes et les parties environnantes deviennent très chaudes pendant le

fonctionnement. Pour éviter toute blessure, vous attendez après mise hors tension

jusqu'à ce que les lampes soient refroidies. Commencer seulement alors les travaux

d'entretien.

♦ Les cellules de mesure peuvent devenir très chaudes pendant le fonctionnement. Pour

éviter toute blessure, vous attendez jusqu'à ce que la cellule est refroidi avant de

remplacer le capteur.

• Quand les capots de protection de l’appareil sont démontés, vous êtes exposés à des

connexions électriques sous haute tension deviennent accessibles. Débranchez

l'instrument de toute source d'alimentation électrique avant de retirer les capots. Ne

démontez les capots de protection que si cela est explicitement demandé au cours de ces

instructions. Les capots de protection devraient être démontés uniquement par le

personnel de service de Thermo Fisher Scientific.

• Remplacez toujours les fusibles grillés par des fusibles de rechange autorisés par Thermo

Fisher Scientific (→ page 114).

• Remplacez les câbles de communication défectueux.

• Remplacez les cordons d'alimentation électrique défectueux. Utilisez uniquement les

cordons d’alimentation électrique spécifique à l’instrument.

• Utilisez seulement des pièces de rechange originales et des accessoires autorisés par

Thermo Fisher Scientific.

• Réglez toujours une limite de pression minimum pour le système HPLC. Ceci prévient

les dommages résultant de fuites ou du fonctionnement à sec de la pompe.

• Lorsque vous soulevez ou l’instrument, tenez-le toujours par le dessous ou par les côtés

de l'unité. Soulever l’instrument par la partie avant inférieure ou par le panneau avant

peut endommager la porte.

• Ne placez aucun objet lourd sur la porte ouverte du panneau avant. Ceci pourrait

endommager la porte.

• Après utilisation, purgez le système des tampons et des susceptibles de former des

peroxydes.

• Lorsque vous passez d’une solution saline à un solvant organique, effectuez un rinçage

intermédiaire du système HPLC à l'eau dé-ionisée ou qualité HPLC.

Page 10 Operating Instructions

Page 19

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

• Lorsque vous passez à un autre solvant, assurez-vous que le nouveau solvant soit

miscible avec celui qui se trouve dans le système HPLC. Dans le cas contraire, le

système HPLC peut être endommagé; par exemple, par des floculations!

• Si une fuite se produit, arrêtez immédiatement l’instrument, stoppez le débit de la pompe

et remédiez au problème.

• Utilisez uniquement des solvants de qualité HPLC ou qualité fluorescence (pour

maximiser la sensibilité) et des solutions salines compatibles avec les matériaux exposés

phase mobiles.

• Avant d'interrompre le fonctionnement pendant plusieurs jours ou plus, observez les

précautions figurant en page 114).

• De nombreux solvants organiques et solutions salines sont toxiques. Informez-vous des

propriétés toxicologiques de toutes les phases mobiles que vous utilisez.

• N'utilisez pas l'instrument de manière autre que celles décrites dans ce manuel.

• Conservez ce manuel á proximité de l’instrument pour pouvoir le consulter facilement.

Operating Instructions Page 11

Page 20

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

1.3 Intended Use

For Research Use Only. Not for use in diagnostic procedures. The device is designed to be

operated only be qualified and authorized personnel. All users must know the hazards

presented by the device and the used substances.

The detector is designed for laboratory research use in high-performance liquid

chromatography (HPLC) or ultra-high performance liquid chromatography (UHPLC)

applications. It is part of the UltiMate 3000 system, but can be used also with other HPLC

systems if adequate control inputs and outputs are available.

The detector can be controlled by the Chromeleon Chromatography Management System.

Being part of the UltiMate 3000 system, the detector can also be operated with other data

systems, such as

• Xcalibur™, Compass™/HyStar™, or Analyst®. Installation of the DCMS

Link

(Thermo

Scientific Dionex Chromatography Mass Spectrometry Link) software is required in

addition to the installation of the data system.

• Empower™. Installation of the Thermo Scientific Dionex Instrument Integration

Software is required in addition to the installation of the data system.

For more information, contact the Thermo Fisher Scientific sales organization for Dionex

HPLC Products.

Keep the following in mind:

• Note that the detector may be operated only with accessories and spare parts

recommended by Thermo Fisher Scientific (→ page 119) and within its technical

specifications (→ page 117).

• Note the special properties of the solvents, such as the viscosity, boiling point, and UV

absorption (UV/VIS detector). Also observe the information about the solvent

compatibility of the other UltiMate 3000 system modules. For more information, refer to

the Operating Instructions for the modules.

• Buffer concentration: Typically up to 1 mol/L (< 0.1 mol/L chloride ions).

• Also observe the information about the solvent compatibility and buffer concentrations of

the other UltiMate 3000 system modules. For more information, refer to the Operating

Instructions for the modules.

Page 12 Operating Instructions

Page 21

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

If there is any question regarding appropriate usage, contact Thermo Fisher Scientific before

proceeding.

Warning: If the device is used in a manner not specified by Thermo Fisher

Scientific, the protection provided by the device could be impaired.

Thermo Fisher Scientific assumes no responsibility and will not be

liable for operator injury and/or instrument damage. Whenever it is

likely that the protection is impaired, the instrument must be

disconnected from all power sources and be secured against any

intended operation.

Avertissement: Si l'instrument est utilisé de façon non spécifiée par Thermo Fisher

Scientific, la protection prévue par l'instrument pourrait être altérée.

Thermo Fisher Scientific n'assume aucune responsabilité et ne sera

pas responsable des blessures de l'operateur et/ou des dommages de

l'instrument. Si la protection de l'instrument n'est pas garanti à tout

moment, débranchez l'instrument de toutes les sources d'alimentation

électrique et assurez-vous que l'instrument n'est pas utilisé

involontairement.

Operating Instructions Page 13

Page 22

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

1.4 Federal Communications Commission (FCC) Note

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the U.S. FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference, in which case the user will be required to

correct the interference at his expense.

Page 14 Operating Instructions

Page 23

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

2 Overview

2.1 Unit Description

The detector is a high-quality instrument designed for HPLC analysis as part of the

UltiMate 3000 system.

• A xenon flash lamp is used to exite a wavelength range of 200 to 880 nm.

• With the unique Dual-PMT option, the wavelength range can be extended to the near

infrared spectral region (up to 900 nm) without any loss in sensitivity in the UV/VIS

spectral region.

• Data collection rates in single channel mode of up to 100 Hz (FLD-3100) or up to 200 Hz

(FLD-3400RS under Chromeleon 7) allow rapid separations in UHPLC. The wavelength

switching time is < 250 ms.

• The detector is optimized for high sensitivity (signal-to-noise ratio higher than 550 for

the Raman spectrum of water), over the entire lifetime of the lamp. It is thus possible to

detect even smallest peaks.

• The flow cells are equipped with an active temperature control to ensure improved

reproducibility when ambient temperatures fluctuate.

• To suppress the higher-order radiation typical of grating spectrometers and scattering of

light, the detector is equipped with an optical filter. Users can select the wavelength range

that is suppressed by the filter for FLD-3400RS detectors.

• The FLD-3400RS can measure up to four channels (2D data) with independent

parameters (wavelengths, sensitivity, filter wheel) simultaneously.

• The detector can be controlled by the Chromeleon Chromatography Management

System. This provides a high degree of system integration, as well as maximum analysis

efficiency due to comprehensive data analysis and evaluation features in Chromeleon.

• Various safety and monitoring features are provided for optimum system performance

and reliability (→ page 27).

• All parts that may be exposed to solvents are made of materials that provide optimum

resistance to the most commonly used solvents and buffer solutions in HPLC.

Operating Instructions Page 15

Page 24

UltiMate 3000 Series:

Absorption of light

Emission of

Fluorescence Detectors FLD-3100 and FLD-3400RS

2.2 Operating Principle

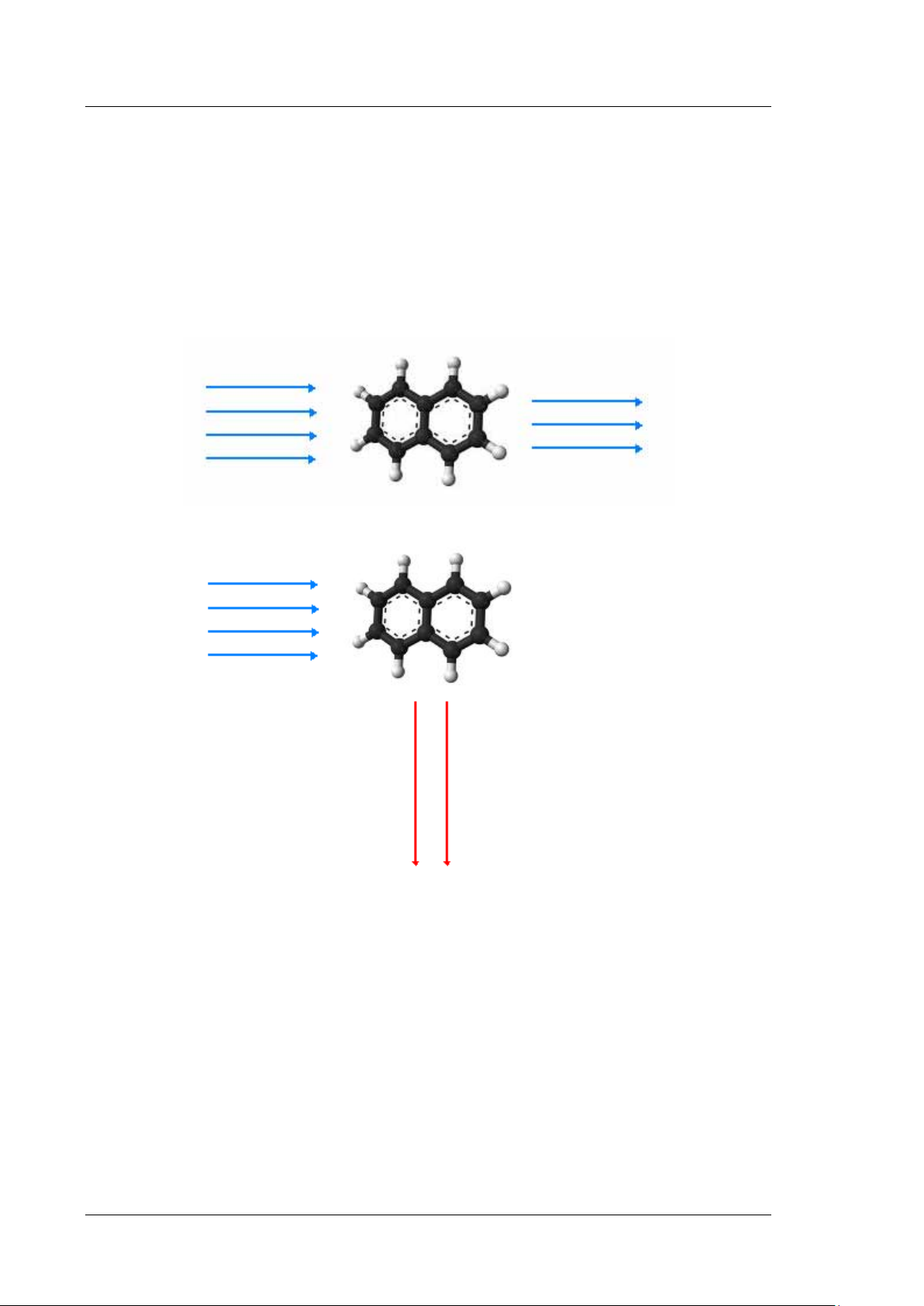

Fluorescence detectors are optical detectors. In a fluorescence detector, the sample is

exposed to light at a defined wavelength (excitation). The thus excited sample substance

emits light at a higher wavelength (emission). The photomultiplier is positioned at an angle

of 90° to the light source and detects the light that was emitted from the fluorescing

substances. In contrast to UV/Vis detectors, a fluorescence detector measures a very weak

light signal rather than the difference between light intensities (absorbance).

Fig. 1: Simplified presentation of absorption in a molecule

light of a longer

wavelength

Fig. 2: Simplified presentation of the light emission in a molecule (fluorescence)

Fluorescence is used, for example, in highlighters or in whitening agents (optical

brighteners). Fluorescent paint used in highlighters reacts to the blue and near, non-visible

ultraviolet range of the daylight and gives off light at a longer wavelength (typically bluegreen, yellow and red).

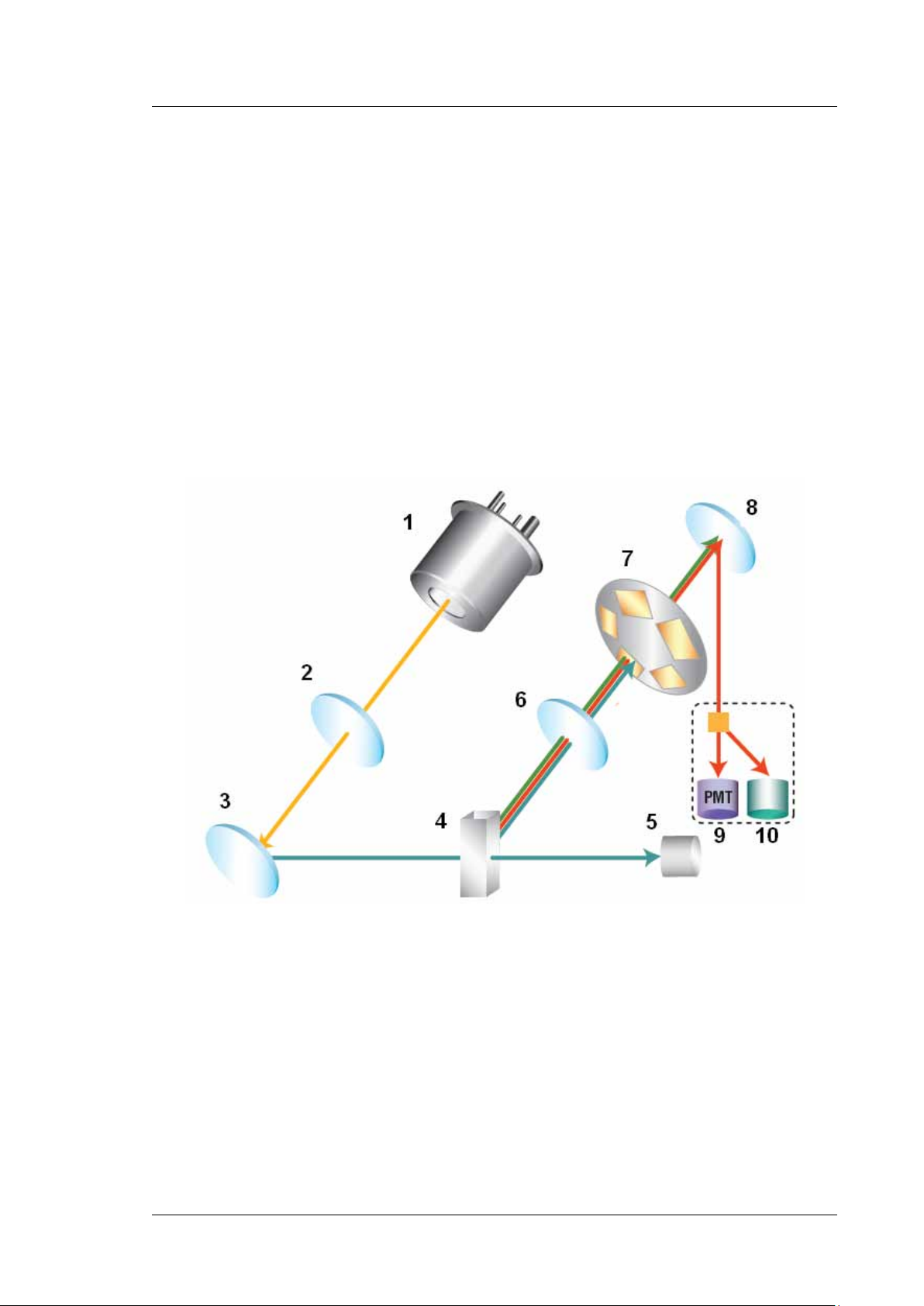

As shown in Fig. 3 (→ page 17), the light beam from the xenon lamp (no. 1) is focused by the

lamp optics (no. 2) through the entrance of the excitation monochromator (no. 3). The

excitation monochromator transmits only light of the user-selected wavelength to the sample

inside the flow cell (no. 4). Most of the light penetrates the sample. A reference detector

(no. 5) behind the flow cell measures the intensity of this light. The excitation light stimulates

the sample to emit fluorescence light.

Page 16 Operating Instructions

Page 25

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

When the light exits the flow cell, it is focused by the emission optics (no. 6) through the

emission monochromator (no. 8).

A cut-off filter, which lets only light above a certain wavelength pass, is located before the

emission monochromator. In the FLD-3100, the filter has a fixed cut-off wavelength

(280 nm). In the FLD-3400RS, a filter wheel (no. 7) is installed. With the help of a motor the

wheel can be moved to 5 different positions with different cut-off wavelengths. The selectable

filter helps to achieve an even better sensitivity and increase flexibility during method

development.

The emission monochromator transmits only the light with the user-selected emission

wavelength to a photomultiplier tube (PMT) (no. 9), where the light is measured. A second

optional red-sensitive photomultiplier tube (no. 10) measures light in the near infrared region

(up to 900 nm).

Fig. 3: Optics setup (schematic)

Operating Instructions Page 17

Page 26

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

No. Component Description

1 Xenon lamp Light source for the UV to near-infrared wavelength range

2 Lamp optics Receives the light beam emitted from the xenon lamp and focuses it so

that the beam passes through the excitation monochromator.

3 Excitation

monochromator

4 Flow cell The eluent with the analyte travels through the flow cell. The excitation

5 Reference detector Measures the excitation light intensity though the flow cell.

6 Emission optics Receives the light beam emitted from the flow cell and focuses it so that

7 Filter wheel Carries the optical filter, which is used to cut off light up to a certain

8 Emission

monochromator

9 PMT Photomultiplier tube (PMT) - Converts the emitted light to a

10 Second PMT (Optional) A second red-sensitive photomultiplier tube measures light in

Lets only light with the selected excitation wavelength pass.

light passes through the flow cell to the reference detector, the

fluorescence light exits the flow cell at an angle of 90° to the excitation

light.

the beam passes through the emission monochromator.

wavelength. The FLD-3400RS provides five filter positions with

different cut-off wavelengths.

Lets only light with the selected emission wavelength pass.

measureable current signal.

the near infrared region (up to 900 nm).

Page 18 Operating Instructions

Page 27

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

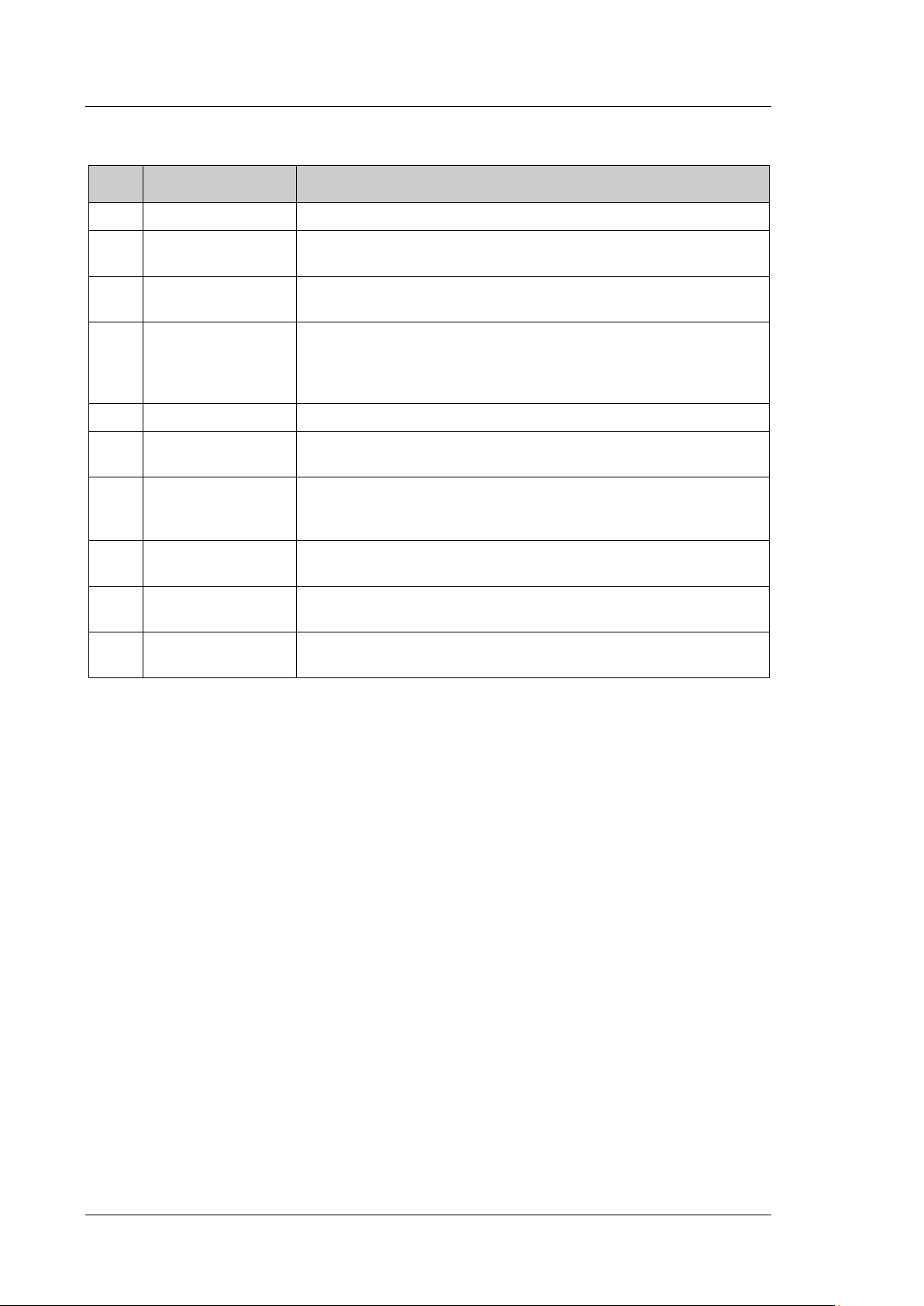

2.3 Configurations

The detector is available in the following configurations:

Detector Description Part no.

FLD-3400RS detector for measurements up to 200 Hz*. Up to four

5078.0020

wavelengths can be recorded simultaneously.

FLD-3400RS detector with Dual-PMT 5078.0025

FLD-3100 detector for measurements up to 100 Hz. However, only

5078.0010

one wavelength can be recorded.

FLD-3100 detector with Dual-PMT 5078.0015

*Only with Chromeleon 7.1 or later

Dual-PMT

The variants of the FLD with Dual PMT are equipped with a second PMT for the near

infrared region (up to 900 nm) (→ no. 10, Fig. 3, page 17). Depending on the PMT setting,

the instrument selects the suitable PMT for each measurement, or you can manually select

which PMT should be used. For emission scans, you can scan with both PMTs

simultaneously.

Detectors with a single PMT can later be upgraded with a second PMT by the Thermo

Fisher Scientific Service for Dionex HPLC Products.

Operating Instructions Page 19

Page 28

UltiMate 3000 Series:

1

1

2

3

Fluorescence Detectors FLD-3100 and FLD-3400RS

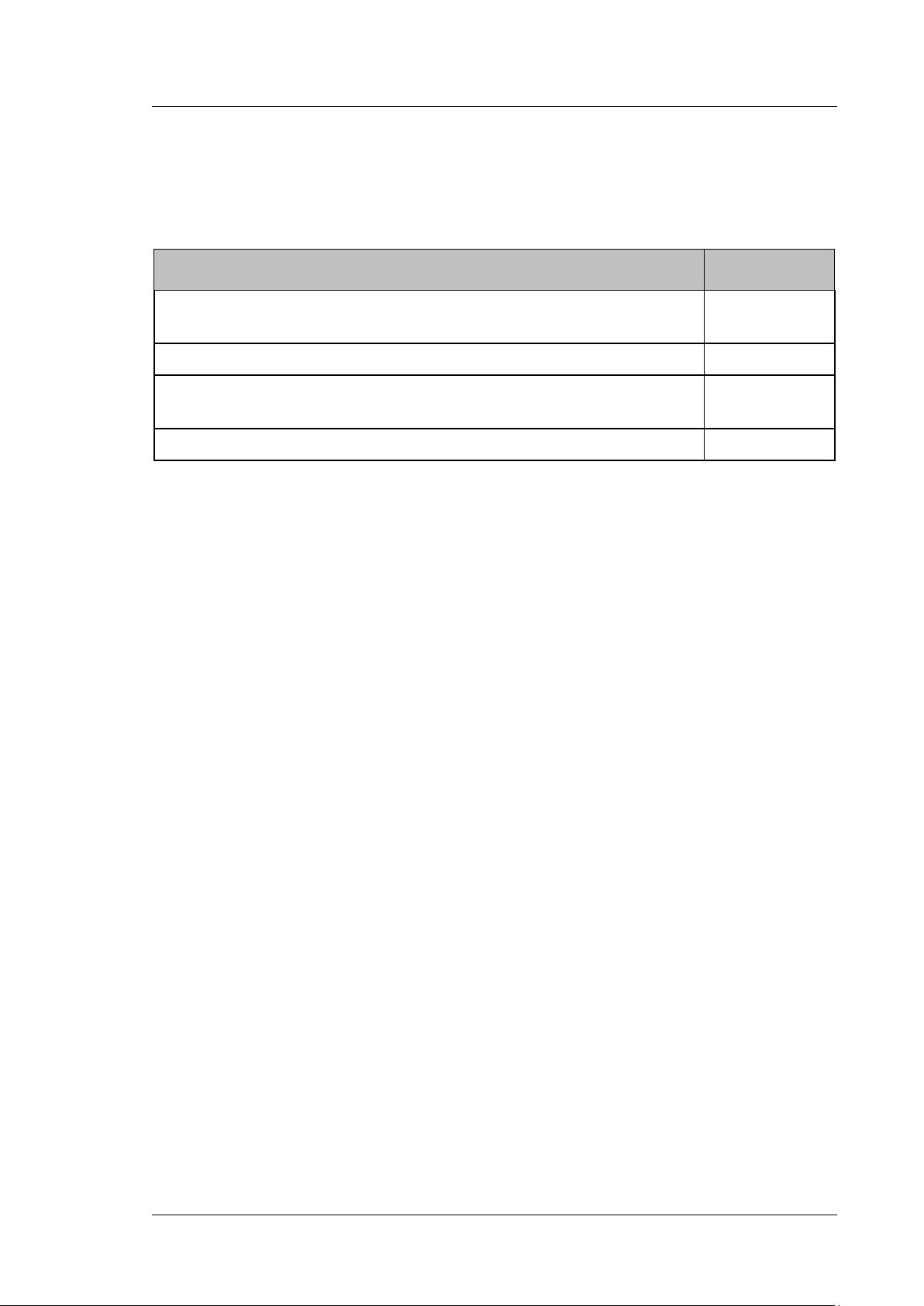

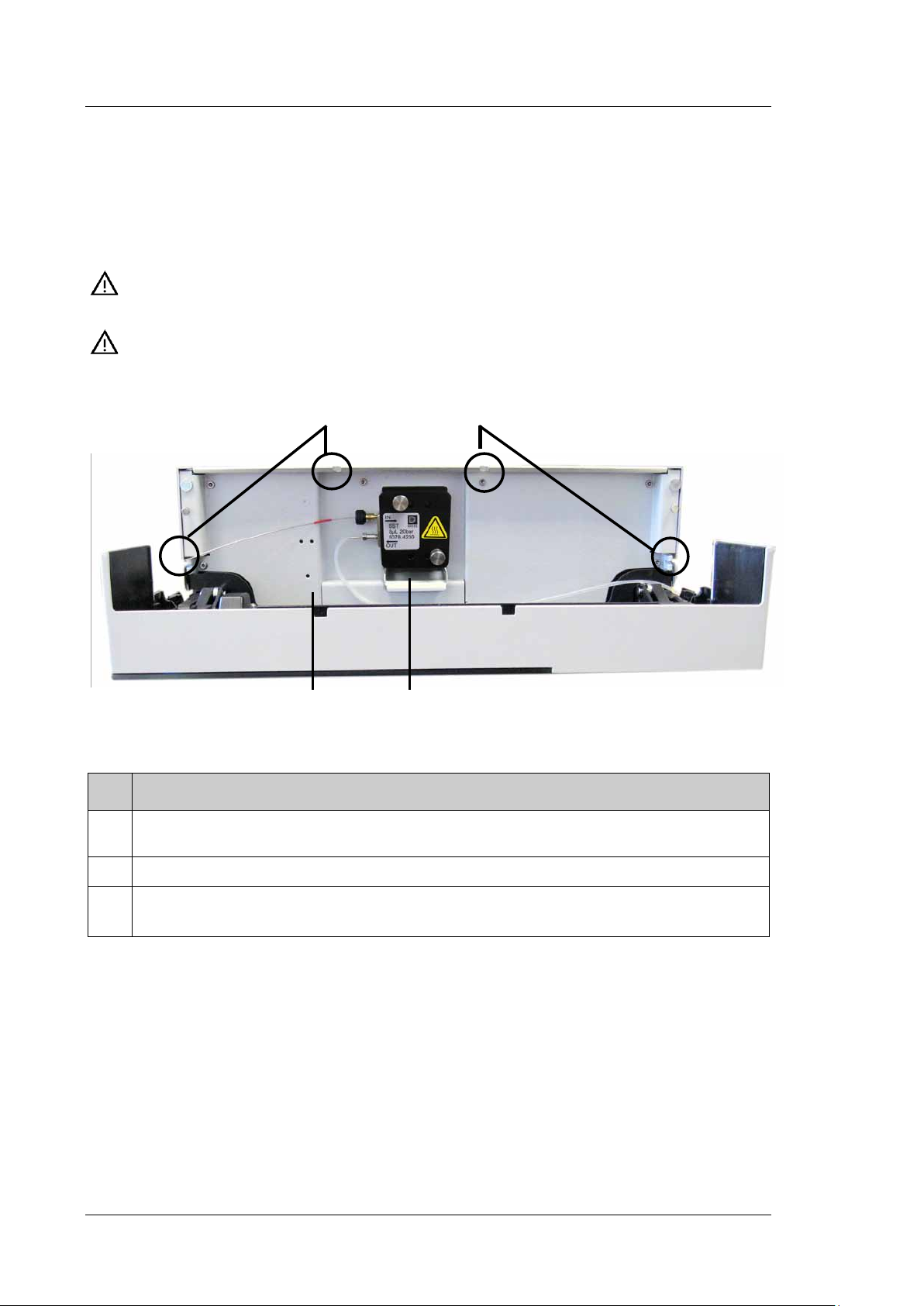

2.4 Interior Components

The front panel door tilts downward to provide easy access to the inside front panel, for

example, for maintenance and repair work.

Important: The open front panel door is not designed to carry weight. Therefore,

you should not place any objects on the open front panel door.

Important: Ne placez aucun objet lourd sur la porte ouverte du panneau avant.

Ceci pourrait endommager la porte.

Fig. 4: Interior view from the front

No. Description

1

Slots in the enclosure to route the flow cell capillaries to the outside (→ page 23)

Two more slots with capillary guides are provided in the enclosure bottom.

2

Leak sensor (→ page 25)

3 Flow cell

No flow cell is installed when the detector is shipped. Before initial operation, install a flow cell.

Page 20 Operating Instructions

Page 29

1

2

3

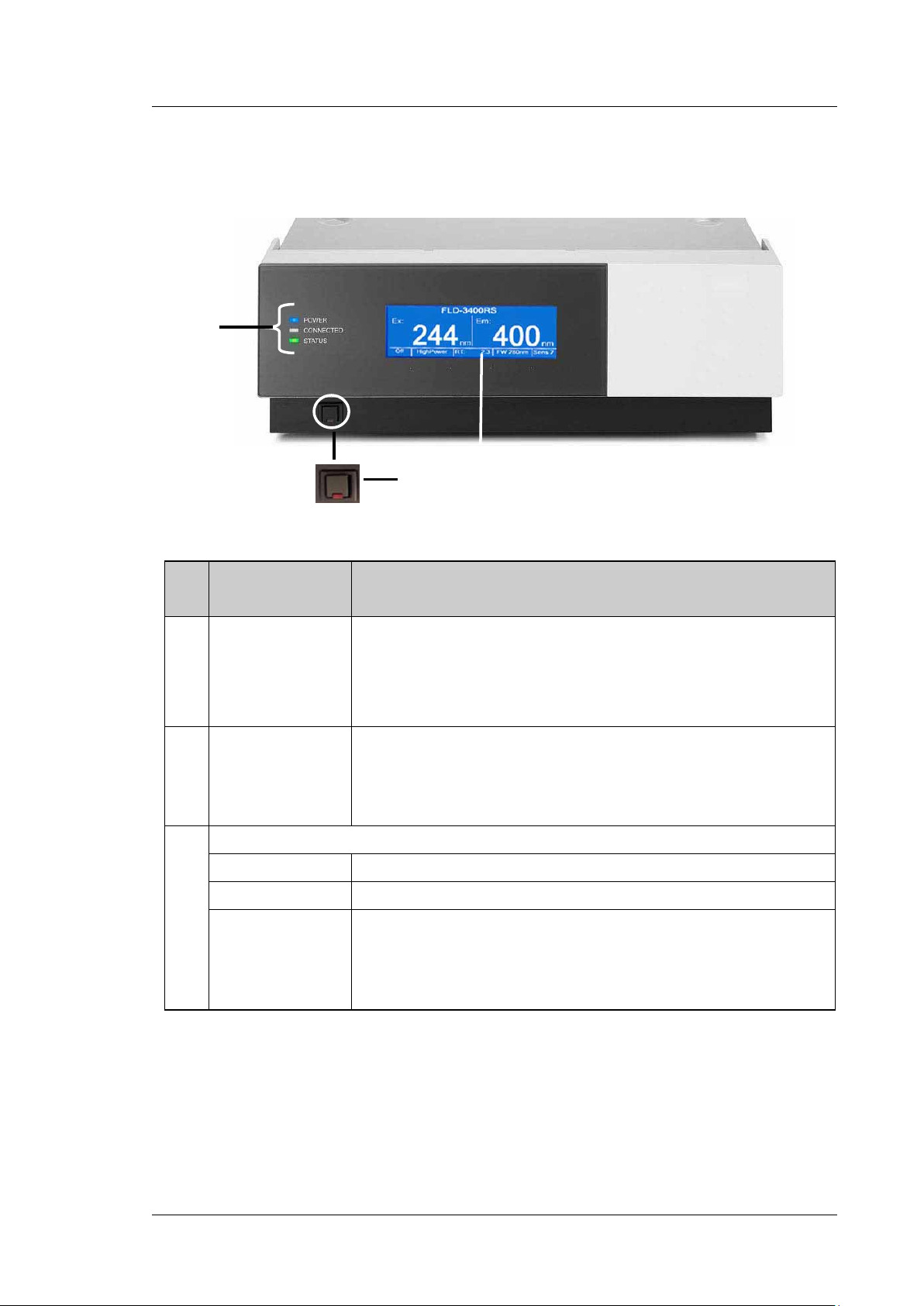

2.5 Front Panel Elements

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

Fig. 5: Front panel view

No. Front Panel

Element

1 Display

2 Standby button Switches the detector to Standby mode (the LED is lighted). To cancel

3

LEDs

Power The LED is blue when the detector is on.

Connected The LED is green when the detector is controlled by Chromeleon.

Status The LED is red when an error has been detected, e.g. when the lamp has

Function

Shows information about the detector:

- General information upon power up (→ page 55)

- Status screen, depending on the operating mode (→ page 55)

- Various menus, accessible via the menu key (→ page 57)

- Messages (→ page 97)

Standby mode and resume operation, press the Standby button again (the

LED is not lighted).

Note: To allow the detector to change the mode, press the Standby button

for at least one second.

failed. In addition, the corresponding message appears on the front panel

display (→ page 97).

The LED is orange, for example, when the detector is booting.

Otherwise, the LED is green.

Operating Instructions Page 21

Page 30

UltiMate 3000 Series:

6

Fluorescence Detectors FLD-3100 and FLD-3400RS

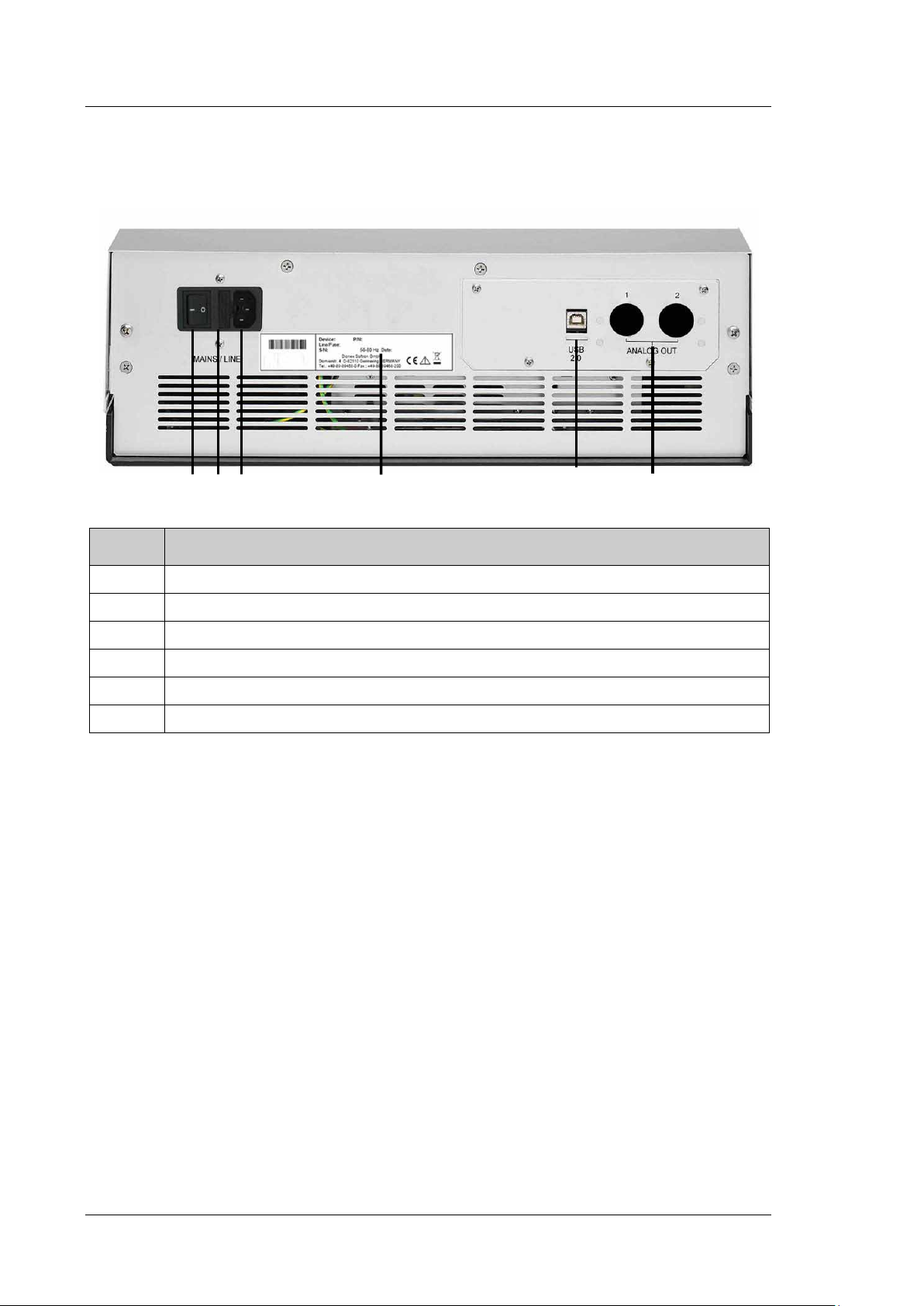

2.6 Rear Panel

1 2 5

3 4

Fig. 6: Rear panel

No. Description

1

2

3

4

5

6

Power switch (→ page 22)

Fuse cartridge (→ page 22)

Main power receptacle (→ page 34)

Type label

USB 2.0 (Universal Serial Bus) port for connection to the Chromeleon computer (→ page 23)

Analog outputs (optional, → page 34)

2.6.1 Power Switch

The power switch on the rear panel is the main power switch for the detector. Turn on the

power switch before initial operation of the detector and leave it on. For routine operation,

leave the main power switch on. For routine on/off control, use the standby button on the

front of the detector (→ page 21). Press and hold the button for about one second to allow

the detector to change the mode. Turn off the main power switch when instructed to do so,

for example, before performing a service procedure or when interrupting operation for

longer periods (one week or more). Observe the precautions on page 93.

2.6.2 Fuse Cartridge

The fuse cartridge contains two slow-blow fuses, rated at 2 A (5 x 20 mm). For

information about how to change the fuses, see page 114.

Page 22 Operating Instructions

Page 31

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

2.6.3 USB Port

The Chromeleon Chromatography Management System uses a USB connection to control

the detector. Data is transferred digitally via the appropriate USB cable (→ page 32). The

PC must be equipped with a USB port. To ensure trouble-free operation, use only the

cables shipped with the detector.

For information about how to connect the detector to the Chromeleon computer, see

sections 3.4.1 and 3.4.2 (→ page 32).

2.6.4 Analog Outputs (Optional)

If the optional DAC plug-in module (part no. 6078.0305) is installed, two analog outputs

with a resolution of 20 bits each are provided. The outputs can be connected to additional

evaluation devices. The analog output voltages are updated with the data rate selected in

Chromeleon (Data Collection Rate), however, not exceeding a maximum data rate of

50 Hz. For information about how to install the board, see page 34. For configuration

details, see page 36.

2.7 Fluid Connections

The detector is designed to provide easy access to the fluid components. Tilt the front

cover downward. At dedicated positions in the front part of the enclosure, six slots are

provided for the capillaries: on the top and bottom of the enclosure (two slots each), and on

the left and right side of the enclosure (one slot each) (→ Fig. 4, page 20).

Capillary guides on the bottom slots facilitate routing the capillaries to devices that are located

underneath the detector in the UltiMate 3000 system stack.

When closing the front panel door, avoid bending the capillaries and make sure that they are

routed to the outside through these slots.

Tip: The volume between the column and the flow cell should be as low as possible

to avoid peak broadening effects and the accompanying loss of

chromatographic efficiency. Preferably use Viper capillaries to prevent dead

volume.

Operating Instructions Page 23

Page 32

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

2.8 Flow Cells

The detector is shipped without a flow cell. The following flow cells are available for the

detector:

Volume

Heat exchanger

and/or inlet capillary

6.3 µL 6078.4230

3.3 µL 6078.4330

Part no.

Flow cell type

Analytical,

pressure limit: 20 bar

Micro,

pressure limit: 40 bar

Flow cell

material

Fused silica,

stainless steel,

PTFE

Fused silica,

stainless steel,

PTFE

Flow cell volume

8 µL,

Ø inlet capillary

0.18 mm

2 µL,

Ø inlet capillary

0.13 mm

All parts of the flow cell that are exposed to solvents are made of fused silica, stainless

steel, or PTFE (Polytetrafluorethylene).

All flow cells are optimized for fast separations with no loss in chromatographic

resolution. An identification chip is fitted to the flow cell in the factory. The chip stores

unique information about the flow cell, including the cell type and serial number. When the

flow cell is installed, a contact on the flow cell connects the chip to the detector

electronics.

The flow cells are equipped with a temperature control. Flow cell and heat exchanger can be

heated to a user-defined temperature (→ page 88). The heat exchanger helps to adapt the

temperature of the mobile phase to the flow cell temperature before the mobile phase enters

the optical part of the cell. Note that the volume of the heat exchanger and inlet capillary

indicated in the table influences the retention times and peak widths.

The micro flow cell is optimized for best resolution in UHPLC, and is recommended for use

with 2.1 mm ID columns. The analytical flow cell provides higher sensitivity and a better

signal-to-noise ratio with most other columns.

To ensure optimum performance of the flow cells, observe the guidelines (→ page 53).

Page 24 Operating Instructions

Page 33

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

2.9 Lamp

The light source is a xenon flash lamp with a power of 15W. The flash frequency of the

lamp varies, depending on the selected lamp mode.

The lamp is turned on when data acquisition starts, and automatically turned off after data

acquisition was stopped to extend its lifetime. It is not required that the lamp is turned on

during the entire chromatographic separation. For example; during re-equilibration of the

chromatographic column, usually no peaks of interest will elute. If you are not interested in

the baseline during the wash and re-equilibration phase, you can turn off the lamp by stopping

data acquisition, or set the lamp mode to a lower frequency. This will save lamp power on

time or reduce the number of lamp flashes, respectively, and thus extend the lamp lifetime. In

addition, you can extend the lamp lifetime by selecting a different lamp mode (→ page 88).

The lamp must be replaced only by Thermo Fisher Scientific Service for Dionex HPLC

Products.

2.10 Leak Sensor

A leak sensor (→ Fig. 4, page 20) is installed inside the detector. If liquid collects in the

drip tray under the fluid connections, the leak sensor reports a leak, and the Status LED on

the front panel door changes to red. In addition, a message appears on the front panel

display and in the Chromeleon Audit Trail and a beep alerts you. Leak sensor settings see

page 72.

When the leak sensor reports a leak, eliminate the cause for the leakage and dry the leak

sensor (→ page 113). If the sensor is not dry, the Status LED remains red. To remove the

message from the display, select Clear on the navigation bar.

Operating Instructions Page 25

Page 34

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

2.11 Detector Control

The detector can be controlled by the Chromeleon Chromatography Management System.

To operate the detector with Chromeleon, an appropriate Chromeleon version and the

corresponding license are required.

Tip: All software details in this manual refer to Chromeleon 6.80, unless stated

otherwise.

If you want to operate the detector with Chromeleon 7, refer to the following

documents for information about how to perform the related processes in

Chromeleon 7 (all documents are included in the Chromeleon 7 shipment):

• Chromeleon 7 Help—provides extensive information and comprehensive

reference material for all aspects of the software.

• Quick Start Guide—describes the main elements of the user interface and

guides you step-by-step through the most important workflows.

• Reference Card—provides a concise overview of the most important

workflows.

• Installation Guide—provides basic information about module installation

and configuration. For specific information about a certain module, refer

to the Chromeleon 7 Instrument Configuration Manager Help.

Note the following:

• Chromeleon 7 terminology is different from the terminology used in

Chromeleon 6.80. For details, refer to the Glossary, which is available in

the Documents folder of your Chromeleon 7 installation.

• Chromeleon 7 may not yet support all functions supported in

Chromeleon 6.80.

Two modes of software control are available:

• Direct Control

With direct control, you select operating parameters and commands in the Commands

(F8) dialog box. Direct commands are executed as soon as they are entered. For routine

operation, most parameters and commands are available also on a control panel. For

more information about direct control, see page 65.

• Automated Control

With automated control, you create a program (or PGM File). This is a list of control

commands, executed in chronological order, for automated operation of the detector.

Programs can be created automatically with the help of a software wizard or manually by

editing an existing program. For more information about automatic control, see page 67.

Page 26 Operating Instructions

Page 35

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

2.12 System Wellness, Predictive Performance, and Diagnostics

System Wellness monitors the health of the detector. Therefore, the detector supports

several performance and reliability features that can help you detect small problems before

they turn into big ones:

• Internal monitoring of all mechanical operations

• Automatic self test upon power up

• Monitoring the lamp age (→ page 108)

• Flow cell identification and documentation of the flow cell type (→ page 63)

• Leak sensor (→ page 25)

• General information for detector diagnostics (→ page 63)

When an error is detected, the Status LED on the front panel is red and a message appears on

the detector display (→ page 98).

In Chromeleon, additional functions for estimating the lifetime of consumables and

monitoring and recording service and (re)qualification information (= predictive performance;

→ page 92) are available to check the performance of the UltiMate 3000 system and certain

system components, and the overall performance of the instrument.

Operating Instructions Page 27

Page 36

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

Page 28 Operating Instructions

Page 37

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

3 Installation

3.1 Facility Requirements

The installation site must meet the following requirements:

• The main power switch and the main power receptacle are on the rear panel. Make sure

that

♦ Free and unrestricted access to the main power switch is ensured at all times.

♦ The power cord of the device can be easily reached and disconnected from the power

line at all times. Provide sufficient space behind the device to unplug the cable.

• Make sure that the installation site meets the power and environmental specifications

listed in the Technical Information section (→ page 117).

• Install the detector in the laboratory on a stable surface that is free of vibrations.

• Make sure that the surface is resistant to solvents.

• Avoid locations with extreme changes in temperature.

• Avoid direct sunlight and high humidity.

• Allow sufficient clearance behind and to the sides of the detector for ventilation.

Operating Instructions Page 29

Page 38

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

3.2 Unpacking

All electrical and mechanical components of the detector are carefully tested before the

instrument is shipped from the factory. After unpacking the detector, inspect the module

for any signs of mechanical damage, which might have occurred during transit.

Tips: Immediately report any shipping damage to both, the incoming carrier and

Thermo Fisher Scientific. Shipping insurance will compensate for the damage

only if reported immediately.

Keep the original shipping container and packing material. They provide

excellent protection for the instrument in case of future transit. Shipping the

unit in any other packaging automatically voids the product warranty.

1. Place the shipping container on the floor and remove the accessories kit and the power

cord.

2. Grasp the detector by the sides. Slowly and carefully, pull the instrument out of the

shipping container and place it on a stable surface.

Important: To prevent the device from falling, grasp the device by the

sides, and then lift the unit together with the foam spacers out

of the shipping container. Do not lift the unit by the

packaging material or the front panel.

Important: Afin d'empêcher l'instrument de tomber, saisissez-la par les

côtés. Ne soulevez l'instrument à l’aide du matériau

d'emballage ou par la porte du panneau avant.

3. Remove the foam spacers, and then remove the polythene packaging.

4. Before connecting the detector to the power source, wait approximately 4 hours to

allow the instrument to come to room temperature and to allow any condensation that

might have occurred during shipping to evaporate. After 4 hours, check the detector; if

condensation still exists, allow the detector to continue to warm up (without

connecting it to the power source) until the condensation is completely gone.

Page 30 Operating Instructions

Page 39

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

3.3 Positioning the Detector in the UltiMate 3000 System

If the detector is part of an UltiMate 3000 system, for example, for analytical HPLC

applications, you should stack the individual modules. However, the arrangement of the

system modules depends on the application.

• In a standard system with only one detector, where all modules are stacked, the

fluorescence detector is always the bottom module.

• In a system that includes a UV detector in addition to the fluorescence detector, the

modules can be arranged as shown in Fig. 7.

Fig. 7: Module arrangement for an UltiMate 3000 RS system with two detectors (example)

Left from top to bottom: SR-3000 solvent rack, LPG-3400RS pump, WPS-3000TRS

autosampler

Right from top to bottom: FLD-3400RS fluorescence detector, UV detector

(VWD-3400RS or DAD-300RS), TCC-3000RS thermostatted column compartment

Tip: As the flow cell of the fluorescence detector has a pressure limit of 20 bar

(analytical flow cell) or 40 bar (micro flow cell), the fluorescence detector

must always be the last module in the fluidic path.

Refer to section 3.4.2 for information how to connect the USB ports on the rear panels.

Operating Instructions Page 31

Page 40

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

3.4 Connecting the Detector

3.4.1 General Information

Verify that Chromeleon is installed on the computer and that the license code is entered

before you connect the detector to the USB port on the Chromeleon computer and turn on

the detector power. Only if you install Chromeleon first, the detector is connected to the

computer and the USB driver for the detector is automatically loaded. The Windows®

operating system can detect the detector when the power is turned on.

3.4.2 Connecting the USB Cable

Connect the detector to the Chromeleon computer via the USB port on the rear panel.

Select one of the following alternatives:

• Connect the detector directly to the USB port on the computer.

• Connect the detector to an internal USB port on the pump. Thermo Fisher Scientific

recommends connecting all modules to the pump, and then connecting the system to the

Chromeleon computer via only one connection (→ Fig. 8, page 33). If the system

includes a UV detector in addition to the fluorescence detector, Thermo Fisher Scientific

recommends connecting the UV detector directly to the Chromeleon computer.

Tip: The USB standard limits the USB cable length to 5 meters. Each USB device

can be separated from the PC or next USB hub by no more than 5 meters.

The following cable is available (provided in the accessories kit for the detector):

USB Cable Part no.

USB cable, type A to type B, high speed USB 2.0 (cable length: 5 m) 6911.0002

Page 32 Operating Instructions

Page 41

UltiMate 3000 Series:

Autosampler

Column

Pump

Solvent rack

Fluorescence

Fluorescence Detectors FLD-3100 and FLD-3400RS

compartment

detector

Fig. 8: Example for the rear panel connections on an UltiMate 3000 system

Operating Instructions Page 33

Page 42

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

3.4.3 Connecting the Power Cord

Use the power cord shipped with the device to connect the detector to the main power

source. No manual adjustment is required to adapt the line voltage to local voltage

requirements.

Warning: Never use a power cord other than the power cords provided for the

device.

Do not use multiple sockets or extension cords. Using defective

multiple sockets or extension cords may cause personal injury or

damage to the device.

Avertissement: Utilisez uniquement les cordons d’alimentation électrique spécifique

à l’instrument.

N'utilisez pas des blocs multiprise ou des câbles prolongateurs. Cela

pourrait entraîner des blessures corporelles ou endommager

l'instrument.

3.4.4 Connecting the Analog Outputs (Optional)

3.4.4.1 Installing the DAC Board

1. Turn off the detector and disconnect the power cord from its source.

2. Use appropriate grounding protection to avoid electrostatic discharge, which may

result in damage to electronic components.

3. Loosen the four screws indicated in Fig. 9 and remove the access panel from the rear

panel.

Fig. 9: Screws on the access panel

Page 34 Operating Instructions

Page 43

UltiMate 3000 Series:

Guide bar

USB port

Fluorescence Detectors FLD-3100 and FLD-3400RS

4. Slide the left guide bar of the DAC board onto the green edge next to the USB port.

Fig. 10: Installing the DAC board

5. Push the board partially into the enclosure. Apply slight pressure between the two

analog outputs to push the board further into the enclosure until it locks into position.

6. Attach the board to the rear panel, by using the 4 screws as shown in Fig. 9.

7. Connect the analog outputs to an evaluation device (→ page 35).

Tip: Installation of the DAC board does not require additional validation, such as

Operational Qualification or Performance Qualification.

3.4.4.2 Connecting an Analog Output to an Evaluation Device

1. Locate the analog output cable (part no. 6074.0002) provided with the DAC board.

Plug the cable connector into the analog output on the detector rear panel.

2. Connect the free end of the cable to the analog input on the evaluation device.

3. Make the required settings in Chromeleon (→ section 3.4.4.3).

Operating Instructions Page 35

Page 44

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

3.4.4.3 Configuring the Analog Outputs

Make the required settings for the analog outputs in Chromeleon.

1. On the Detector page in the Properties dialog of the detector, verify that the DAC

Board check box is selected (→ page 42). When the check box is cleared, the analog

outputs will not be available in Chromeleon.

2. Open the Commands dialog box for the detector.

3. Make the required settings.

Analog Output

Setting

Analog1_Channel

Analog2_Channel

Analog1_Offset

Analog2_Offset

Analog1_Range

Analog2_Range

Analog1_Voltage

Analog2_Voltage

Description

Sets the signal that is available at the analog output.

Adjusts the zero position of the analog output when it is plotted. The value

entered is a percentage of the full-scale analog output. The offset allows the

evaluation device to plot the signal if it becomes negative.

Even with a very small, positive analog output signal an offset of 5 %, for

example, should be set, because the minimum output voltage of the analog

output cannot be exactly 0 V.

Sets the value range, and thus the resolution of the analog output signal.

The range to use depends on the values expected for the application and the

evaluation device to which the output is connected.

Sets the maximum voltage value of the analog output signal (1 or 10). The

range to be used depends on the input voltage of the evaluation device to

which the output is connected.

Page 36 Operating Instructions

Page 45

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

3.5 Setting Up the Detector in Chromeleon

This section provides brief instructions for setting up the detector in Chromeleon. For

details, see the Chromeleon Help.

Tip: When the detector is connected to the Chromeleon computer, verify that the

Chromeleon software is installed before turning on the detector power for the

first time. Only then, the USB driver for the detector is automatically loaded

and the Windows operating system detects the detector when the power is

turned on.

3.5.1 Loading the USB Driver for the Detector

1. Turn on the computer power, if it is not already on.

2. Under Windows Vista® (Windows® XP, Windows® 7, or Windows® Server 2008) log

on as a

• Local administrator if the computer is a local computer.

• User with local computer administrator privileges if the computer is a network

computer.

3. Open the Chromeleon Server Monitor program by double-clicking the Chromeleon

Server Monitor icon on the Windows taskbar.

If the Server Monitor icon is not on the taskbar, click Start on the taskbar, point to

Programs (or All Programs, depending on the operating system), point to Chromeleon,

and then click Server Monitor.

4. Click Start to start the server.

5. Click Close to close the Server Monitor window. The Server Monitor icon

appears on the taskbar.

Tip: Clicking the Quit Monitor button quits (exits) the Server Monitor

program, but does not stop the server. To stop the server, click Stop.

6. Turn on the main power switch on the rear panel of the detector.

Operating Instructions Page 37

Page 46

UltiMate 3000 Series:

Fluorescence Detectors FLD-3100 and FLD-3400RS

7. Windows Vista, Windows 7, and Windows Server 2008

will automatically detect the new detector and perform the USB installation.

If Windows fails to detect the detector and launches a wizard instead, this indicates that

you connected the detector to the computer and turned on the power for the first time

before you installed Chromeleon. To resolve the problem:

a) Click Cancel to exit the wizard.

b) Turn off the detector.

c) Install Chromeleon.

d) Turn on the detector power. Windows will now detect the detector and install the USB

software for the detector automatically.

Windows XP

will automatically detect the new detector and launch the Found New Hardware

Wizard, which guides you through the USB installation. Select the following options:

a) If asked whether Windows can connect to Windows Update to search for software,

select No, not this time.