Page 1

1

2 5 .0

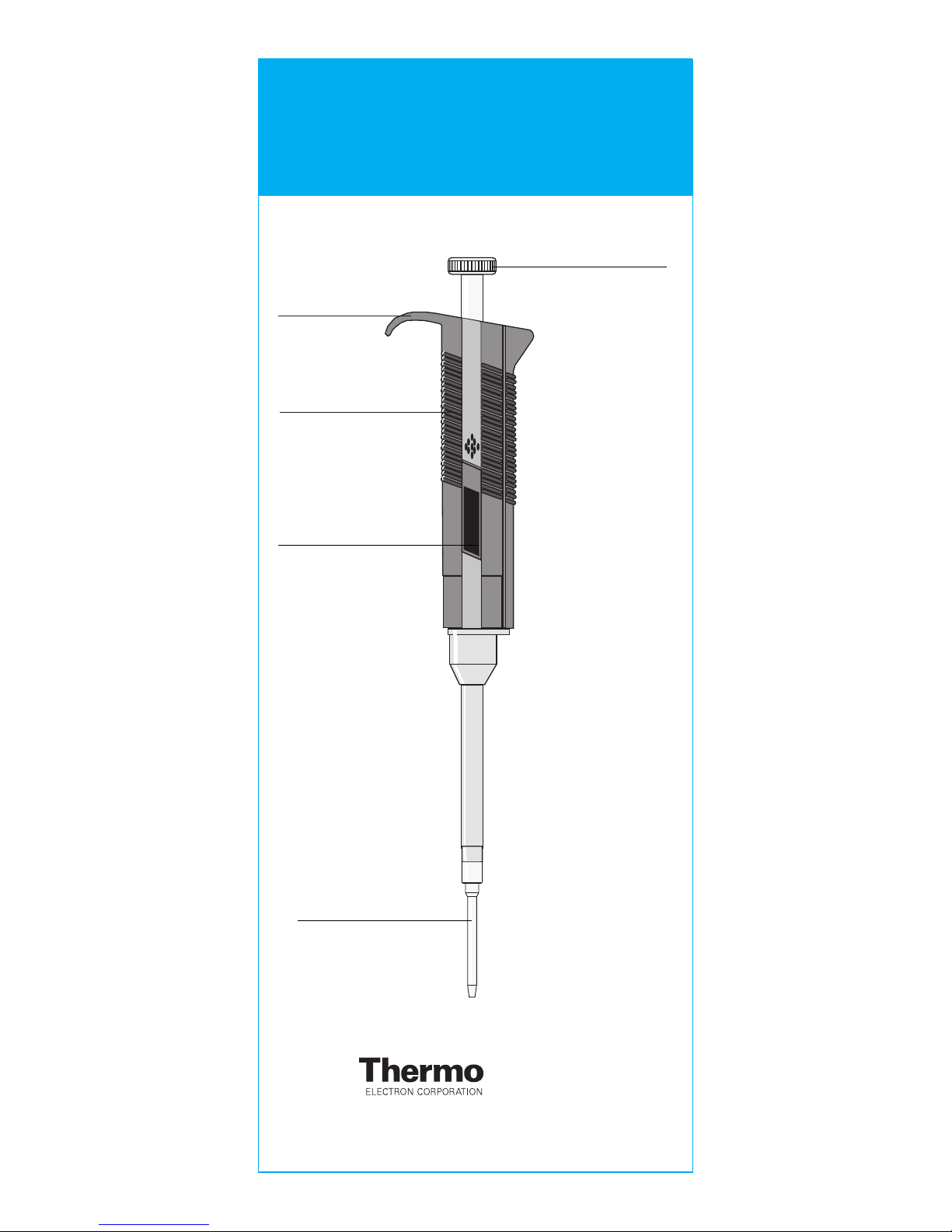

Labsystems

GRIPPY

HANDLE

DIGITAL

DISPLAY

FINNTIP PDP

OPERATING

BUTTON

FINNPIPETTE PDP

INSTRUCTIONS FOR USE

Thermo Electron Oy

P.O.Box 100, Fin-01621 Vantaa, Finland

Tel. +358-9-329 100, fax -358-9-3291 0414

www.thermo.com/finnpipette

Page 2

2

PRODUCT DESCRIPTION

The FINNPIPETTE PDP is a continuously adjustable,

positive displacement pipette specially designed for PCR

(Polymerase Chain Reaction) [1] work.

It operates on the positive displacement principle (i.e. no

air interface) and uses detachable, disposable tips with a

pre-assembled plunger.

FINNPIPETTE PDP pipettes cover a volume range of 0.5 µl

to 200 µl.

RAW MATERIALS

The FINNPIPETTE PDP is made of mechanically durable and

chemically resistant materials:

Operating button PA

Handle polyamide

Tip ejector polyamide

Tip cone PVDF

THE DIGITAL DISPLAY (Fig.1)

The adjusted delivery volume is clearly indicated by the

digital display on the pipette handle.

[1] The Polymerase Chain Reaction process PCR, is

covered by US patents issued to the Cetus Corporation.

DESCRIPTION OF FINNTIP PDP (Fig.4)

FINNPIPETTE PDP tips are supplied in racks of 96 or bags

of 960. The product code numbers are as follows:

Cat.No. Volume Qty

9403070 0.5-25µl 960/bag

9403080 20-200µl 960/bag

PIPETTE OPERATION

SETTING THE DELIVERY VOLUME (Fig.2)

A) The delivery volume is set using the operating button

on the top of the pipette. To increase the delivery

volume turn the operating button counterclockwise. To

decrease, turn it clockwise.

B) Make sure that the desired delivery volume clicks into

place and that the digits are completely visible on the

handle display.

C) Do not set volumes outside of the pipette´s specified

volume range!

ATTACHING A TIP (Fig.5)

Attach a Finntip PDP from a rack as follows:

1. Push the pipette firmly onto the tip until the tip and cone

snap.

2. Without removing the tip from the tray press the

operating button to the first stop to engage the plunger.

3. The tip and plunger are now attached for pipetting.

Page 3

3

TIP EJECTION (Fig.3)

1. To remove the tip and plunger from the pipette simply

press the operating button all the way down.

2. Then release the operating button.

3. This action simutaneously ejects the tip and the

plunger.

PIPETTING TECHNIQUE

Figure 6

A = Ready Position

B = Pipetting Stop

C = Tip Ejection

Ensure that clean tips are firmly pushed on to the tip cones

of the pipette.

The operation of the pipette is controlled by the operating

button. For the best possible accuracy:

Operate the button slowly and with steady speed at all

times, particularly when working with liquids having high

viscosity. Never let the operating button snap back. When

working with serum or biological fluids prime the tips with

the liquid before pipetting. This is done by filling and

emptying the tips.

Hold the pipette vertically (10 degrees maximum from

vertical) during the liquid intake. For maximum hand

control, hold the pipette tightly in the hand with the

"Grippy" resting on the index finger.

Fill a clean reagent reservoir with the liquid to be

dispensed.

1. Depress the operating button to the pipetting stop.

2. Dip the tip just under the surface of the liquid in the

reservoir (2-3 mm) and slowly release the operating

button. Withdraw the tip from the liquid touching them

against the edge the reservoir to remove excess liquid.

3. Deliver the liquid by gently depressing the operating

button to the pipetting stop.

4. Release the operating button to the ready position.

If necessary, change the tips and continue with the

pipetting.

Page 4

4

MAINTENANCE

When the FINNPIPETTE PDP is not in use make sure it is

safely stored in a vertical position, preferably on a

Finnpipette Stand.

SHORT TERM CHECKING

The pipette should be checked at the beginning of each

day for dust and dirt on outside surfaces of the pipette.

Particular attention should be paid to the tip cones.

Solvents should not be used for cleaning the pipette.

LONG TERM MAINTENANCE

If the pipette is used daily it should be checked at least

twice a year. The servicing procedure starts with

disassembly of the pipette.

1. To remove tip cone cover:

Insert the tooth of the service tool into the opening at

the base of the tip cone cover.

2. Pull away the tip cone cover

3. Remove the tip cone by turning it counterclockwise

with the service tool.

4. Pull out the piston.

5. Clean the piston and the piston spring with a dry

napless cloth.

6. Grease the cleaned parts with lubricant provided in

the package.

7. Reassemble the parts.

CALIBRATION

All Finnpipettes are factory calibrated and adjusted to

give the volumes as specified with distilled or deionized

water. Normally, the pipettes do not need adjustment,

but they are constructed to permit recalibration and

adjustment for liquids of different temperature and

viscosity.

DEVICE REQUIREMENTS AND TEST CONDITIONS

An analytical balance must be used. The scale graduation

value of the balance should be chosen according to the

selected test volume of the pipette:

Volume range readable graduation

under 10µl 0.001mg

10-100µl 0.01mg

above 100µl 0.1mg

Page 5

5

Test liquid: Water, distilled or deionized, “grade 3” water

conforming ISO 3696. Tests are done in a draft-free room

at a constant (±0.5°C) temperature of water, pipette and

air between 20°C to 25°C. The relative humidity must be

above 55%. Especially with volumes under 50 µl the air

humidity should be as high as possible to reduce the

effect of evaporation loss. Special accessories, such as

the evaporation trap, are recommended.

CHECKING THE CALIBRATION

A new tip is first pre-wetted 3-5 times and a series of ten

pipettings are done with both volumes.

A pipette is always adjusted for delivery (Ex) of the

selected volume. Measuring volumes taken from balance

is not allowed. If the calculated results are in the limits, the

calibration of the pipette is correct.

Procedure:

1. Do 10 pipettings with the lower volume.

2. Do 10 pipettings with the maximum volume.

3. Calculate the accuracy (A) and precision (cv) of both

series.

4. Compare the results to the limits in the Table 1.

If the results are in the limits of Table 1, then the calibration

of the pipette is correct. Otherwise the pipette must be

adjusted and checked again.

Range Volume Accuracy Precision

µl µl % s.d. µl cv%**

0,5-25 µl 25 µl ±0.625 ±2.5 0.250 1.0

5 µl ±0.250 ±5.0 0.125 2.5

0.5 µl * * * *

20-200 µl 200 µl ±3.0 ±1.5 0.40 0.2

50 µl ±2.0 ±4.0 0.25 0.5

20 µl * * * *

*User dependent **s.d. = Standard Deviation, CV =

Coefficient of Variation

ADJUSTMENT (Fig.7)

Adjustment is done with the service tool.

1. Place the service tool into the openings of the

calibration nut at the top of the handle.

2. Turn the service tool clockwise to decrease, or

counterclockwise to increase the volume.

3. After adjustment check the calibration according to the

instructions above.

Page 6

6

FORMULAS FOR CALCULATING RESULTS

Conversion of mass to volume

V = (w + e) x Z

V = volume (µl)

w = weight (mg)

e = evaporation loss (mg)

Z = conversion factor for mg/µl conversion

Evaporation loss can be significant with low volumes. To

determine mass loss, dispense water to the weighing

vessel, note the reading and start a stopwatch.

See how much the reading decreases during 30 seconds

(e.g. 6 mg = 0.2 mg/s). Compare this to the pipetting time

from tareing to reading. Typically pipetting time might be 10

seconds and the mass loss is 2 mg (10s x 0.2mg/s) in this

example. If an evaporation trap or lid on the vessel is used

the correction of evaporation is usually unnecessary.

The factor Z is for converting the weight of the water to

volume at test temperature and pressure. A typical value

is 1.0032 µl/mg at 22°C and 95 kPa. See the conversion

table on page 8.

Accuracy (systematic error)

Accuracy is the difference between the dispensed

volume and the selected volume of a pipette.

A = V - V

0

A = accuracy

V = mean volume

V0= nominal volume

Accuracy can be expressed as a relative value:

A% = 100% x A / V

0

Precision (random error)

Precision refers to the repeatability of the pipettings. It is

expressed as standard deviation (s) or coefficient of

variation (cv)

1

)(

2

-

-

=

n

VV

S

i

S

i=1

n

PACKAGE

The FINNPIPETTE PDP is shipped in a specially designed

package containing the following items:

1. The pipette

2. Instruction manual

3. Service tool

4. Calibration certificate

5. Sample of Finntip PDP

s = standards deviation

v = mean volume

n = number of measurements

cv is the relative value of standard

deviation.

cv = 100% x s / v

Page 7

7

TROUBLE SHOOTING

The following table is a guide to possible problems and

their solutions.

Fault

Leakage

Inaccurate

dispensing

Inaccurate

dispensing

with certain

liquids

Possible reason

Tip incorrectly

attached

Foreign bodies

between tips and

tip cones

Incorrect operation

Tips incorrectly

attached

Calibration altered:

e.g. caused by

misuse

Unsuitable

calibration. Many

high viscosity

liquids require

recalibration

Solution

Attach firmly

Clean tip cones

thoroughly and

attach new tips

Follow instructions

carefully

Attach firmly

Recalibrate

according to

instructions

Recalibrate with the

liquids in question

CAUTION!

The Finnpipette is designed to allow easy in-lab service.

If you, however, want to send the pipette to us or to our

local representative for service, please, enclose a list of

any infectious, radioactive or otherwise hazardous

materials that have been pipetted.

Also, please, note that the postal authorities in your

country may limit the sending of contaminated material

by mail.

Page 8

8

Temper- Air pressure

ature °C hPA (mbar)

800 853 907 960 1013 1067

15 1.0018 1.0018 1.0019 1.0019 1.0020 1.0020

15.5 1.0018 1.0018 1.0019 1.0020 1.0020 1.0021

16 1.0019 1.0020 1.0020 1.0021 1.0021 1.0022

16.5 1.0020 1.0020 1.0021 1.0022 1.0022 1.0023

17 1.0021 1.0021 1.0022 1.0022 1.0023 1.0023

17.5 1.0022 1.0022 1.0023 1.0023 1.0024 1.0024

18 1.0022 1.0023 1.0024 1.0024 1.0025 1.0025

18.5 1.0023 1.0024 1.0025 1.0025 1.0026 1.0026

19 1.0024 1.0025 1.0025 1.0026 1.0027 1.0027

19.5 1.0025 1.0026 1.0026 1.0027 1.0028 1.0028

20 1.0026 1.0027 1.0027 1.0028 1.0029 1.0029

20.5 1.0027 1.0028 1.0028 1.0029 1.0030 1.0030

21 1.0028 1.0029 1.0030 1.0030 1.0031 1.0031

21.5 1.0030 1.0030 1.0031 1.0031 1.0032 1.0032

22 1.0031 1.0031 1.0032 1.0032 1.0033 1.0033

22.5 1.0032 1.0032 1.0033 1.0033 1.0034 1.0035

23 1.0033 1.0033 1.0034 1.0035 1.0035 1.0036

23.5 1.0034 1.0035 1.0035 1.0036 1.0036 1.0037

24 1.0035 1.0036 1.0036 1.0037 1.0038 1.0038

24.5 1.0037 1.0037 1.0038 1.0038 1.0039 1.0039

25 1.0038 1.0038 1.0039 1.0039 1.0040 1.0041

25.5 1.0039 1.0040 1.0040 1.0041 1.0041 1.0042

26 1.0040 1.0041 1.0042 1.0042 1.0043 1.0043

26.5 1.0042 1.0042 1.0043 1.0043 1.0044 1.0045

27 1.0043 1.0044 1.0044 1.0045 1.0045 1.0046

27.5 1.0044 1.0045 1.0046 1.0046 1.0047 1.0047

28 1.0046 1.0046 1.0047 1.0048 1.0048 1.0049

28.5 1.0047 1.0048 1.0048 1.0049 1.0050 1.0050

29 1.0049 1.0049 1.0050 1.0050 1.0051 1.0052

29.5 1.0050 1.0051 1.0051 1.0052 1.0052 1.0053

30 1.0052 1.0052 1.0053 1.0053 1.0054 1.0055

CONVERSION TABLE

Value of the conversion factor Z (µl/mg), as a function of

temperature and pressure, for distilled water.

2

1

1 5 . 0

La

Page 9

9

2 5 .0

Labsystems

1 2

3

3

2 5 .0

Labsystems

5

25 µl 200 µl

4

Page 10

10

absystems

6

A

C

B

1 2

3 4

7

Pipetting

Tip Ejection

Page 11

11

No. Item Product Codes

25 µl 200 µl

1. Service Tool 10589070 10589070

2. Cap 1057490 1057500

3. Handle Back 10588030 10588030

4. Limiter 1092990 1092990

5. Handle 2204030 2204040

6. Locking Pieces 1058180 1058180

7. Plunger 1106230 1106300

8. Oper. Spring 1130720 1130720

9. Ring 1006500

10. Tip Cone 1058790 10588000

11. Tip Cone Cover 10588011 10588011

SPARE PARTS

1

2

4

5

3

6

7

8

9

10

11

Page 12

12

1504760-06

Product specifications are subject to change without

prior notice. Finpipette

®

and Finntip® are registered

trademarks of Thermo Electron Oy.

Thermo Electron Oy

P.O.Box 100, Fin-01621 Vantaa, Finland

Tel. +358-9-329 100, fax -358-9-3291 0414

www.thermo.com/finnpipette

Loading...

Loading...