Page 1

1

Thermo Scientific F1-ClipTip

Single Channel

Multichannel

Instructions for Use

User Manual

Page 2

2

This product complies with the European Union Directive 98/79/EC, and it is marked with

a CE marking.

When the product is used in applications related to the Directive 98/79/EC, read the

additional information enclosed in the product package or contact the manufacturer at

info.pipettes@thermofisher.com to ensure correct and safe use.

The CE mark covers the system containing the CE marked F1-ClipTip pipette and the CE

marked ClipTip pipette tips.

Product specifications are subject to change without prior notice. ClipTip is a registered

trademark of Thermo Fisher Scientific Inc. and its subsidiaries.

Page 3

3

CONTENTS

1. INTRODUCTION 4

2. PACKAGE 5

3. MAIN ILLUSTRATION 5

4. SAFETY 6

5. OPERATION 7

6. CALIBRATION AND ADJUSTMENT 9

7. MAINTENANCE 11

8. STERILIZATION 16

9. TROUBLESHOOTING 17

10. APPENDICES 18

Page 4

4

1. Introduction

Congratulations on your purchase of a Thermo Scientific® F1-ClipTip® pipette!

The F1-ClipTip is a general purpose air displacement micropipette. Its intended use is for aspirating

and dispensing liquids.

The F1-ClipTip features an innovative interlocking tip interface technology that locks the tip in place

ensuring secure tip attachment and preventing tips from being displaced in the middle of pipetting.

F1-ClipTip operates only with ClipTip

®

tips. For improved ergonomics, tips are attached and ejected

using minimal application pressure. 0.1-2 µl and 10 µl based pipette models use ‘Snap and Lip’ seal

tips.

The F1-ClipTip product offering covers a volume range from 0.1 µl to 1000 µl and includes variable and

fixed volume single channel pipettes as well as multichannel pipettes. The convenient color coding*

system facilitates to identify the correct ClipTip by volume for use.

F1-ClipTip Variable Volume Single Channel

Cat. no. Description Volume range Increment Color Compatible

code ClipTip

4641310N F1-ClipTip 0.1-2 µl 0.1–2 µl 0.002 µl pink ClipTip 12.5 Ext

4641320N F1-ClipTip 1-10 µl 1–10 µl 0.02 µl pink ClipTip 12.5 Ext

4641180N F1-ClipTip 2-20 µl 2–20 µl 0.02 µl pink ClipTip 20

4641190N F1-ClipTip 5-50 µl 5–50 µl 0.1 µl violet ClipTip 50

4641200N F1-ClipTip 10-100 µl 10–100 µl 0.2 µl yellow ClipTip 200

4641210N F1-ClipTip 20-200 µl 20–200 µl 0.2 µl yellow ClipTip 200

4641220N F1-ClipTip 30-300 µl 30–300 µl 1 µl orange ClipTip 300

4641230N F1-ClipTip 100-1000 µl 100–1000 µl 1 µl blue ClipTip 1000

F1-ClipTip Fixed Volume Single Channel

Cat. no. Description Volume range Color code* Compatible ClipTip

4651280N F1-ClipTip 10 µl 10 µl dark blue ClipTip 12.5 Ext

4651200N F1-ClipTip 20 µl 20 µl dark blue ClipTip 20

4651210N F1-ClipTip 25 µl 25 µl dark blue ClipTip 50

4651220N F1-ClipTip 50 µl 50 µl dark blue ClipTip 50

4651230N F1-ClipTip 100 µl 100 µl dark blue ClipTip 200

4651240N F1-ClipTip 200 µl 200 µl dark blue ClipTip 200

4651250N F1-ClipTip 250 µl 250 µl dark blue ClipTip 300

4651260N F1-ClipTip 500 µl 500 µl dark blue ClipTip 1000

4651270N F1-ClipTip 1000 µl 1000 µl dark blue ClipTip 1000

* color coding does not apply to fixed models

F1-ClipTip Multichannel

Cat. no. Description Channels Volume Increment Color Compatible

range code ClipTip

4661210N F1-ClipTip 8-ch 1–10 µl 8 1–10 µl 0.02 µl pink ClipTip 12.5 Ext

4661120N F1-ClipTip 8-ch 5–50 µl 8 5–50 µl 0.1 µl violet ClipTip 50

4661130N F1-ClipTip 8-ch 10–100 µl 8 10–100 µl 0.2 µl yellow ClipTip 200

4661140N F1-ClipTip 8-ch 30–300 µl 8 30–300 µl 1 µl orange ClipTip 300

4661220N F1-ClipTip 12-ch 1–10 µl 12 1–10 µl 0.02 µl pink ClipTip 12.5 Ext

4661160N F1-ClipTip 12-ch 5–50 µl 12 5–50 µl 0.1 µl violet ClipTip 50

4661170N F1-ClipTip 12-ch 10–100 µl 12 10–100 µl 0.2 µl yellow ClipTip 200

4661180N F1-ClipTip 12-ch 30–300 µl 12 30–300 µl 1 µl orange ClipTip 300

Page 5

5

1 Pipetting and volume adjustment button

2 Adjustable finger rest

3 Tip ejector

4 Volume display

5 Space for personal ID tag

6 Tip fitting

7 Tip sealing O-ring

8 Color coding

2. Package

The F1-ClipTip package contains the following items:

1. F1-ClipTip pipette

2. Service tool

3. Multichannel service tool

4. Tip fitting tool

5. Bag of grease 1g (Order No. 3300200)

6. Instructions for Use

7. Calibration certificate / Warranty Certificate

8. O-ring Order No. 2214930 Single Channel Pipette (Scp) 300 (3 pcs)

Order No. 2215540 Scp 1000 (3 pcs)

Order No. 2214920 Multichannel Pipette (Mcp) (12 pcs)

3. Main Illustration

F1-ClipTip

F1-ClipTip

F1-ClipTip

1

2

3

6

1

2

7

7

5

3

4

8

8

8

8

4

6

1

8

8

4

6

Page 6

6

3.1 . Materials

The F1-ClipTip is made of mechanically durable and chemically resistant materials.

For waste disposal instructions, contact your local environmental agency. For more information,

contact us at info.pipettes@thermofisher.com.

Aggressive substances can damage the pipette or pipette parts. Check for material

compatibility before using organic solvents and aggressive chemicals.

ClipTip pipette tips are made of natural color virgin polypropolyene. The tips feature a hydrophobic

surface, which effectively prevents liquid retention. ClipTips pipette tips come in multiple packaging

options including racks and reload packs, in sterile and non-sterile versions. ClipTip tips are also available

with a filter and are certified free of human DNA, RNase, DNase, ATP and endotoxin contamination.

The material used in F1-ClipTip pipettes and ClipTip tips are as follows:

F1-CLIPTIP PIPETTES

Material

External surfaces of the upper parts:

ABS/PC acrylonitrilebutadienstyrene/polycarbonate

PA polyamide

PEI polyetherimide

Foil

Exterior and interior of lower parts:

PEI polyetherimide

PA polyamide

PVDF polyvinyldenfluoride

EPDM ethylene-propylene-diene rubber

FVM fluorosilicone rubber

Steel stainless steel

PPSU Polyphenylsulfone

CLIPTIP TIPS

Tip PP polypropylene

Filters PE polyethylene

4. Safety

Cautions are marked with this symbol .

4.1. Intended use

The intended use of the device is to transfer liquids in the volume range of 0.1 µl to 1000 µl.

The F1-ClipTip pipette and ClipTip tip are designed as a component of an analyzing system for an end

user, who is responsible for validating the system to ensure reliable and safe results.

Damage to health

Follow general procedures for hazard prevention and safety instructions; e.g. wear

protective clothing, eye protection and gloves.

For use and waste disposal of hazardous (e.g. radioactive and potentially infectious) material,

follow the safety instructions and general laboratory practice.

The pipette and tips are not intended for in vivo use. Do not use the pipette for pipetting any liquid

to be injected into a human body.

Do not eject the tip towards anybody.

The F1-ClipTip is to be used by trained personnel with required laboratory skills. The instructions for

use must be read prior to and during the use of the device (pipette and tip). The F1-ClipTip pipette can

be used between +4°C and +40°C.

Page 7

7

Incorrect dispensing results

Performance may vary due to:

a. pipetting method (forward pipetting technique recommended)

b. temperature (air, liquid, vessel, pipette, and tip)

c. pressure

d. humidity

e. operator, e.g. thumb movement, pipetting angle

f. liquid density, viscosity and vapor pressure

g. type of tip

If the pipetting performance is critical to the outcome of a specific application, the result has to

be assured with an alternative test, and if this is not an option, by duplicate testing.

The possibility of an incorrect volume delivery during pipetting cannot be entirely mitigated.

To avoid inaccurate dispensing and/or leakage, check that the tip is properly attached to

the pipette.

When rotating the volume adjustment button, do not exceed the volume range of the pipette.

Otherwise the pipette may be damaged or affect pipetting performance.

Pipetting performance cannot be guaranteed if the tip is reused.

Choose only a tip and pipette with matching color coding.

Disposal of the Materials

Follow laboratory and country-specific procedures for the disposal of biohazardous or radioactive

waste. Refer to local regulations for the disposal of infectious material.

Warning The tips can be potentially infectious. Dispose of all used disposable tips as biohazardous

waste.

Warning Decontaminate the pipette before disposal.

For waste disposal instructions, contact your local environmental agency. For more information,

please contact us at info.pipettes@thermofisher.com

Regarding the original packaging and packing materials, use the recycling operators known to you.

For more information, contact your local Thermo Fisher Scientific representative.

5. Operation

Cautions for incorrect operation

For optimum performance, make sure that the tips, pipette and solution are at the same

temperature.

Before you begin your actual pipetting, fill and empty the tip three to five times with the

solution that you will be pipetting.

Push and release the pipetting button slowly at all times particularly when working with high

viscosity liquids. Never allow the pipetting button to snap back.

Do not hold the pipette horizontally or upside down when there is liquid inside the tip. Sample

liquid may enter the pipette, which will affect the pipetting performance and may damage

the pipette.

Operate the pipetting button gently. If it is quickly released, sample liquid may enter the pipette,

which will affect the pipetting performance and may damage the pipette.

Follow the guidance in the “Thermo Scientific Good Laboratory Pipetting Practices” brochure to

minimize the risk of repetitive strain injury (RSI).

5.1 ID-tag

You can mark the pipette ID-tag with your initials, pipetting

application or calibration date. Remove the pipette’s module to

replace the tag. Mark the label and slide the tag together with

the holder back to its slot (Picture 1).

Picture 1

Page 8

8

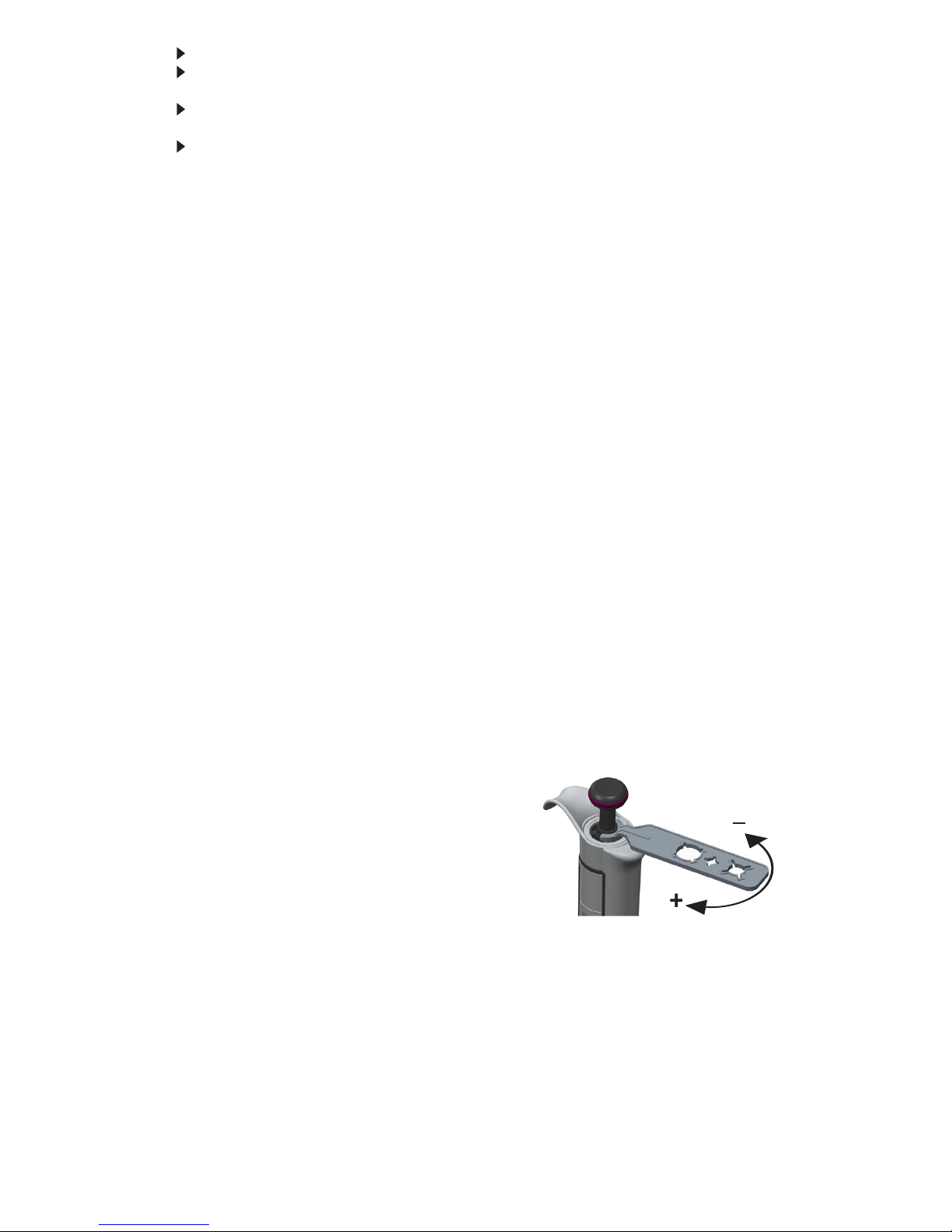

5.2 Adjusting the finger rest

The finger rest supports the position of the pipette on the

index finger, enhancing ergonomics. The finger rest can be

adjusted by rotating it 60 degrees in both directions from the

center position (Picture 2). Usually right-handed operators

turn it left (counter clockwise) to achieve the best possible

position for the thumb to eject the tip.

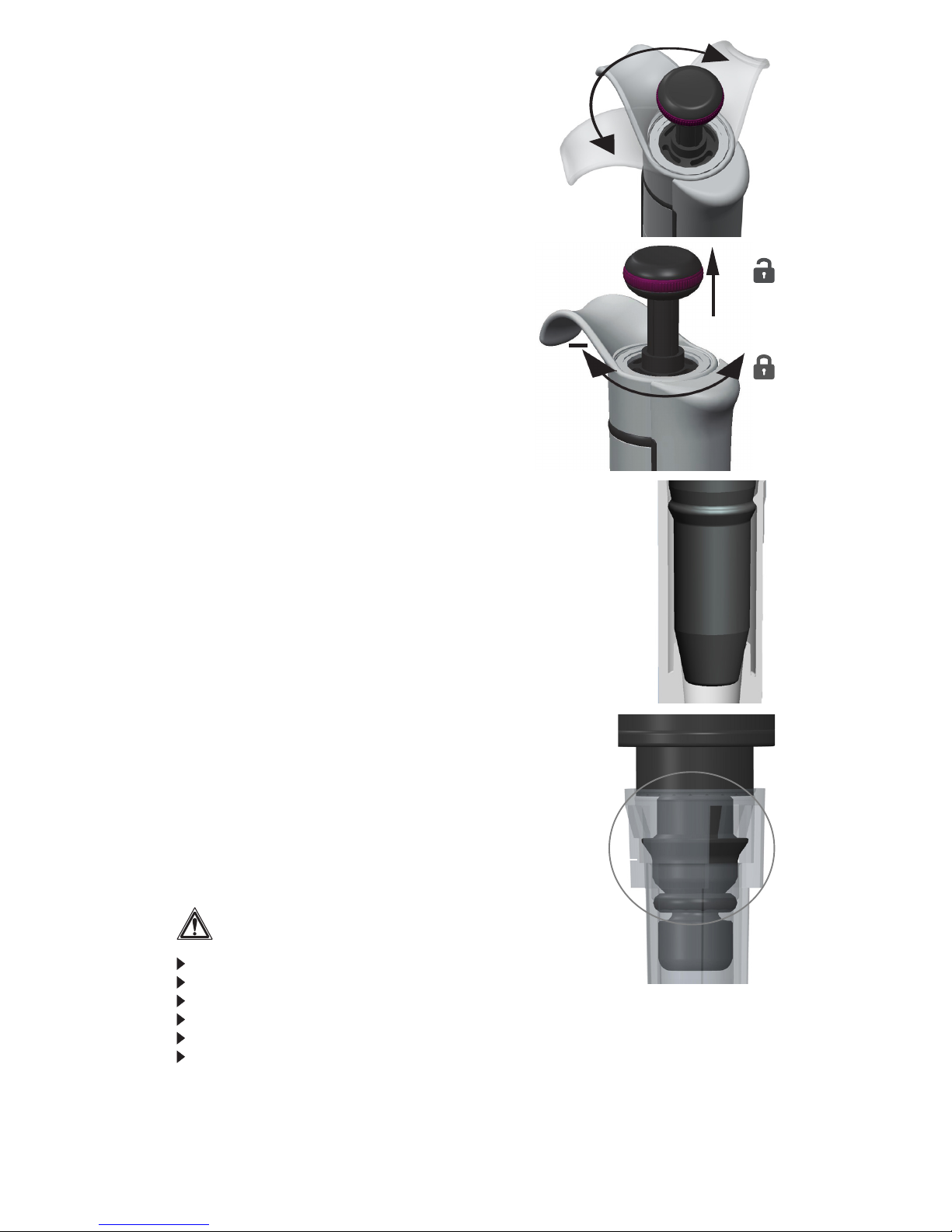

5.3 Setting the delivery volume

1. Set the delivery volume using the volume adjustment

button on the top of the pipette (Picture 3). Pull the

button to activate the volume setting.

2. To increase the delivery volume, turn the button

counterclockwise. To decrease the delivery volume,

turn it clockwise.

3. Lock the volume by pushing the button down.

4. Check the volume on the display.

NOTE! Do not set volumes outside the pipette´s specified

volume range. Using excessive force to turn the volume

adjustment button outside the range may jam the

mechanism and eventually damage the pipette.

5.4 Tip attachment

0.1-10µl models

0.1-2 μl and 10 μl pipette models use ‘Snap and Lip’ seal tips. The tip has small

incorporated protrusions that snap on the tip fitting flange, ensuring secure tip

attachment with little force. The flexible plastic lip design seals the tip against

the tip fitting.

1. To attach the tip, guide the pipette into a ClipTip in a rack and press until

the tip is attached. The tip is attached when it snaps over the tip fitting

flange. Do not use excessive force when attaching the tips as thedevice

requires minimum attachment force. (Picture 4a)

2. Lift the pipette.

3. If the tip is not attached, repeat Steps 1 and 2.

20-1000µl modes

1. To attach the tip, guide the pipette into a ClipTip in a rack and

press with light force until the tip is attached. A delicate click sound

will indicate that the tip is attached. The tip is attached when the

clips* (Picture 4b) are locked to the tip fitting.

Do not use excessive force when attaching the tips as the device

requires minimum attachment force.

2. Lift the pipette.

3. If the tip is not attached, repeat Steps 1 and 2.

Incorrect use of tips

Use only ClipTip tips with an F1-ClipTip pipette.

Check that all clips are locked to ensure tip sealing.

ClipTip tips are designed for single use only.

To ensure sterility and purity of tips check that the package is unbroken.

Check that the tip is complete and unbroken. Check for foreign particles in the tip.

Check that the filter tips have filters in place and that each filter is unbroken and not tilted.

5.5 Aspirating and dispensing liquid

1. Fill a suitable vessel with the liquid to be dispensed.

2. Depress the pipetting button to the first stop (Picture 5).

3. Dip the tip under the surface of the liquid in the reservoir to a depth of about 1 cm

and slowly release the button.

Picture 4b

*

Picture 2

+

1

2

Picture 3

Picture 4a

Page 9

9

Withdraw the tip from the liquid by moving

it against the edge of the reservoir to

remove excess liquid.

4. Deliver the liquid by gently depressing the

button to the first stop. After a delay of

about one second, continue to depress the

button all the way to the second stop. This action

will empty the tip.

5. Withdraw the tip by moving it against the edge of

the target container.

Ensure proper functioning of 2-20µl single channel and 5-50µl pipettes

The F1-ClipTip 2-20µl single channel pipette and 5-50µl pipettes utilize an innovative super blow-out

piston technology to ensure efficient liquid delivery with small volumes. In pipettes with the super

blow-out piston three separate movements are observed (Picture 6) when the plunger is pressed

down to dispense liquid:

1. Primary plunger movement – delivers the set volume amount

2. Blow-out – additional phase to dispense residual liquid

3. Super blow-out – enhances the effectiveness of blow-out

When the pipette is not used for a period of time, the plunger movement may become stiff due to

hardening of grease. In rare cases this can affect the functionality of the super blow-out piston,

which can become temporarily jammed. To ensure proper functionality it is recommended to press

the plunger several times to the final stop (step 3 in picture) before dosing the sample liquid. This

releases the piston and re-distributes the lubricant.

NOTE! If the super blow-out piston is jammed, increased force might be required to release it. Ensure

that plunger moves to the down position (Picture 6).

For more information about different pipetting techniques, check the Good Laboratory Pipetting

Guide online.

5.6 Tip ejection

To release the tip, point the pipette at a suitable waste receptacle and press the tip ejector with

your thumb.

6. Calibration and Adjustment

6.1 Factory calibration limits

F1-ClipTip pipettes are factory calibrated and adjusted to give the volumes as specified with distilled

or deionized water using the forward pipetting technique. Manufacturer specifications are shown on

the pipette calibration certificate and in Appendix 2. The pipette should be recalibrated for use with

any tip type not named on the Calibration Certificate.

Cautions for calibration and pipette adjustment

It should be noted that the use of different pipetting techniques may affect the calibration

results. The pipettes are constructed to permit re-adjustment for other pipetting techniques,

types of tips, or liquids of a different temperature or viscosity.

1 2 3 4

Picture 5

Plunger in down position

Plunger in up position

Picture 6

1

2

3

Page 10

10

The performance of a new and serviced pipette must be checked and documented.

The manufacturer’s specifications should be used as guidelines and the user should establish

acceptable imprecision and inaccuracy performance limits (ISO 8655).

The user determines the performance and applicability of the pipette and tip combination

for a particular application and determine the required interval for performance checking.

Before starting the actual dosing, pre-rinse the tip with the liquid by filling and emptying the

tip three to five times to improve accuracy and precision.

6.2 Test conditions and equipment

An analytical balance must be used. The scale graduation value of the balance should be chosen

according to the selected test volume of the pipette:

Volume range Readable graduation

under 10 µl 0.001 mg

10–100 µl 0.01 mg

above 100 µl 0.1 mg

The test liquid is deionized distilled “grade 3” water in compliance with ISO 3696. Tests are done in a

draft-free room at a constant (±0.5°C) temperature between 15°C to 30°C. The relative humidity must

be above 50%. Especially with volumes under 50 µl, air humidity should be as high as possible to reduce

the effect of evaporation loss. Special accessories, such as an evaporation trap, are recommended.

6.3 Procedure to check calibration

The pipette is checked at maximum volume (nominal volume) and minimum volume (or 10% of the

maximum volume). A new tip is first pre-wetted three to five times and a series of ten pipettings

is done at both volumes. A pipette is always adjusted according to the delivery of the selected

volume. Use of the forward pipetting technique is recommended. The maximum permissible errors

are valid for the forward pipetting method. It is recommended to use the ISO8655 calibration limits in

Appendix 3 or user-defined specifications.

Procedure:

1. Do 10 pipettings at the minimum volume (or 10% of the maximum volume).

2. Do 10 pipettings at the maximum volume.

3. Calculate the inaccuracy (A) and imprecision (CV) of both series.

4. Compare the results to the limits.

If the calculated results are within the selected limits, the adjustment of the pipette is correct.

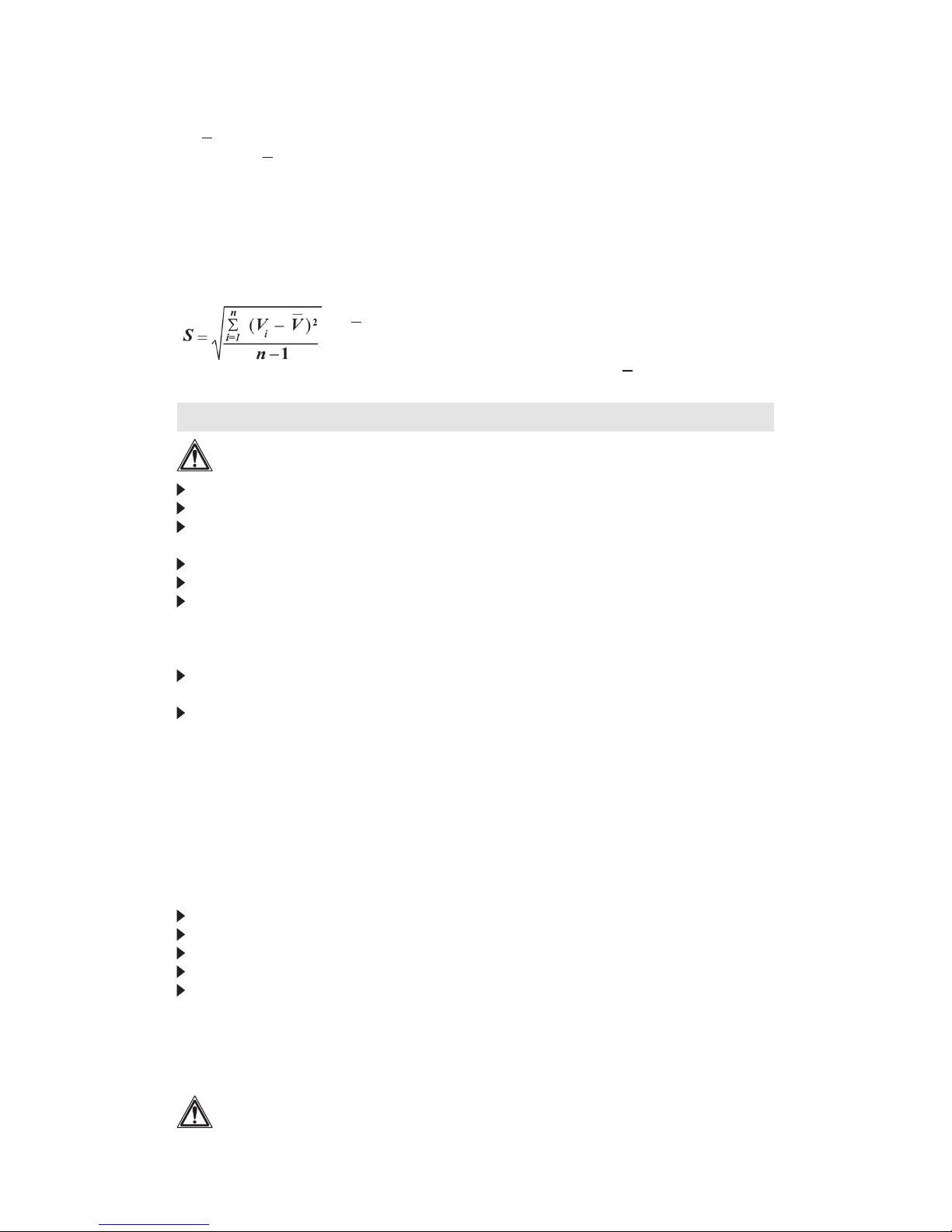

Pipette adjustment

Adjustment is done only for one volume. The recommended adjustment volume is the minimum

volume or 10% of the maximum volume.

1. Fit the service tool (Picture 7) into the openings of the

calibration nut at the top of the handle.

2. Turn the service tool clockwise to increase, or

counterclockwise to decrease the volume.

3. After adjustment, check the calibration according to

the instructions above.

Formulas for calculating results

Conversion of mass to volume

V = (w + e) x Z V = volume (µl)

w = weight (mg)

e = evaporation loss (mg)

Z = conversion factor for µl/mg conversion

Evaporation loss can be significant at low volumes. To determine mass loss, dispense water into the

weighing vessel, note the reading and start a stopwatch. Check and note down how much the reading

decreases during 30 seconds (e.g. 6 mg = 0.2 mg/s).

Compare this to the pipetting time from taring to reading. Typically , the pipetting time might be 10

seconds and the mass loss is then 2 mg (10 s x 0.2 mg/s in this example). If an evaporation trap or lid

on the vessel is used, the correction of evaporation is usually unnecessary.

Picture 7

Page 11

11

The factor Z is for converting the weight of the water to volume at the test temperature and pressure.

A typical value is 1.0032 µl/mg at 22°C and 95 kPa. See the conversion table in Appendix 1.

Inaccuracy (systematic error)

Inaccuracy is the difference between the dispensed volume and the selected volume of a pipette.

A = V - V

0

A = inaccuracy

V = mean volume

V

0

= nominal volume

Inaccuracy can be expressed as a relative value: A% = 100% x A / V

0

Imprecision (random error)

Imprecision refers to the repeatability of the pipettings. It is expressed as standard deviation (S) or

coefficient of variation (CV)

S = standards deviation

V = mean volume

n = number of measurements

Standard deviation can be expressed as a relative value: CV = 100% x S / V

7. Maintenance

Cautions for incorrect maintenance

The pipette should be regularly serviced according to the instructions for use.

The pipette performance and functioning must be checked after maintenance.

Aggressive substances can damage the pipette or pipette parts. Check for material

compatibility before using organic solvents and aggressive chemicals.

Use only original Thermo Scientific spare parts and ClipTip tips.

Avoid excess grease. Use only the grease provided with the pipette.

Annual pipette usage varies significantly among laboratories, and the types of substances being

aspirated and dispensed also vary tremendously among laboratories. In order to maintain proper

care of the pipette, it is the laboratory’s responsibility to develop a proper maintenance program

that meets its specific needs and requirements.

When the F1-ClipTip is not in use, make sure it is stored in an upright position. We recommend

a pipette stand for this purpose.

When shipping the device for service or inspection, make sure that it is completely free of

chemical, biological, or radioactive contamination.

7.1 Daily maintenance

The pipette should be checked at the beginning of each day for dust and dirt on its outside surfaces.

Particular attention should be paid to the tip cone. To clean the pipette, we recommend wiping it with

a napless cloth wetted with 70% ethanol.

Leakage test

A leakage test can be performed at any time. It is recommended to be carried out after maintenance

or autoclaving.

Pre-wet the tip three to five times with water.

Aspirate a nominal volume of water into the tip.

Place the pipette on a stand or keep it firmly in your hand.

Wait for 20 seconds.

If a drop falls within 20 s, the pipette is leaking.

If the pipette leaks, see Chapter 9: “Troubleshooting” for possible reasons and solutions.

7.2 Periodic maintenance

The maintenance procedure starts with the disassembly of the pipette.

F1-ClipTip O-rings 5.1 are wearing parts. It is recommended to replace O-rings regularly to

ensure proper sealing. Always replace the O-rings if they are worn or damaged.

Page 12

12

7.2.1 Disassembly of 1000ul single channel pipettes

1. Remove the tip fitting 5 (Picture 8).

To remove the tip fitting place the star-shaped end of tool 3 (picture 9) into the end of the tip

fitting. Turn the tool counterclockwise to unscrew the tip fitting (picture 10).

2. Press the tip ejector 4.1. Rotate the tip ejector 10

counterclockwise and pull it out (Picture 11).

3. Turn the tip cone 11 counterclockwise with the service tool 1.

There are two slots in the service tool: the smaller one for

pipettes under 300 μl and the bigger one for pipettes over 300 μl.

4. Pull out the piston assembly and other parts from the handle

with the tip cone 11.

Then turn the tip cone upside down and tap all parts from it.

7.2.2 Disassembly of single channel pipettes 300ul and smaller

1. Press the tip ejector 4.1. Rotate the tip ejector 10 counterclockwise and pull it out (Picture 12).

NOTE! If you want to service only parts inside cylinder go to step 4. But then use the bigger slot in

service tool.

2. Remove the tip fitting 5 (Picture 8).

To remove the tip fitting place the star-shaped end of tool 3 (picture 9) into the end of the tip

fitting (tip fitting is removable by hand in models 0.1-2µl and 1-10 µl). Pull the Clip trigger 8

backwards slightly with the other hand.

Turn the tool counterclockwise to unscrew the

tip fitting (picture 10).

Picture 10

4.1

11

1

10

Picture 11

4.1

10

11

1

Picture 12

9

8

5

5.1

5.2

Picture 8

3

Picture 9

Page 13

13

3. Remove the Clip trigger 8 and Clip trigger spring 9.

4. Turn the tip cone 11 counterclockwise with the service tool 1.

There are two slots in the service tool: the smaller one for pipettes under 300 μl and the bigger

one for pipettes over 300 μl.

5. Pull out the piston assembly and other parts from the handle with the tip cone 11.

Then turn the tip cone upside down and tap all parts from it.

You can check the parts of each specific pipette from the pictures starting on page 23.

Remember to keep all parts in order on the table for reassembly.

7.2.3 Cleaning and reassembling single channel pipettes

- General maintenance instructions can be found on page 11.

- Clean the piston, the piston spring and the O-rings with a dry napless cloth.

- Check the tip cone for foreign particles or dirt. Immerse it in a suitable cleaning solution.

Dry before assembly.

- Grease the cleaned parts with the lubricant that comes with the pipette.

- The pipette is assembled in the reverse order to disassembling. Check the volume-specific

reassembling of the piston assemblies starting on page 23.

Piston reassembly procedures

0.1-2μl

- First slide spring support 16 into tip cone 11.

- Slide spring 13 over piston 12.

- Carefully place the piston assembly in the tip cone.

- Very carefully place the tip cone assembly in the handle. When tightening the assembly, make

sure that the head of the piston comes out of the head of the tip cone.

- Place the piston through piston seal 20. Note that there is beveling at the other end of the seal,

to help in assembly.

- Slide excess air remover tube 27 over the piston.

- Slide the tip fitting over the piston assembly, and screw it into place

1-10μl, 10μl Fixed

- First slide spring support 16 into tip cone 11.

- Slide spring 13 over piston 12.

- Carefully place the piston assembly in the tip cone.

- Very carefully place the tip cone assembly in the handle so that the head of the piston comes out

of the head of the tip cone.

- Place the piston through O-ring seal 18.

- Slide the tip fitting over the piston assembly, and screw it into place.

2-20μl, 20μl Fixed, 5-50μl 25 / 50μl Fixed

- Slide the spring 13, spring support 16 and tube 17 back onto the piston 12.

- Compress the spring 13 with your fingers by pressing the piston 12 and the spring support 16

against each other, and then slide the bigger O-ring 18, the smaller O-ring 19, the spring support

20 and spring 21 (smaller diameter against spring support 20) onto the piston.

- Hold the spring 13 compressed and carefully slide the entire assembly into the tip cone 11,

and then release the spring.

- Put the spring 15 and support 14 on top of the tip cone and carefully insert the tip cone assembly

to the handle. Attach the tip cone by turning it first clockwise tight by hand, then do the final

tightening with the service tool.

- Reassemble the Clip trigger spring 9 and Clip trigger 8. Assemble the tip fitting according to

instruction in 7.2.4.

Reassemble the tip ejector 10.

10-100μl, 20-200μl, 100 / 200μl Fixed, 30-300μl, 250μl Fixed

- Slide the spring 13, spring support 16 and O-ring 17 back onto the piston 12.

- Slide the entire assembly into the tip cone 11.

- Put the spring 15 and support 14 on top of the tip cone and carefully insert the tip cone assembly

to the handle. Attach the tip cone by turning it first clockwise tight by hand, then do the final

tightening with the service tool.

Page 14

14

- Reassemble the Clip trigger spring 9 and Clip trigger 8. Assemble the tip fitting according to

instruction in 7.2.4.

Reassemble the tip ejector 10.

100-1000μl, 500 / 1000μl Fixed

- Put the O-ring 17 and support ring 16 onto the tip cone 11.

- Slide the spring 13 onto the piston 12 and slide the entire assembly into the tip cone 11.

- Put the spring 15 and support 14 on top of the tip cone and carefully insert the tip cone assembly

to the handle. Attach the tip cone by turning it first clockwise tight by hand, then do the final

tightening with the service tool.

- Reassemble the tip ejector 11. Assemble the tip fitting according to instruction in 7.2.4.

7.2.4 Reassembly of tip fitting 5 and O-rings 5.1 and 5.2

- Make sure that the tip fitting has both o-rings 5.1 and 5.2 in place (Picture 8). Change o-rings

during maintenance if needed. Place the tip fitting onto the star-shaped end of tool 3 so that the

screw end is facing upwards. (Single channel pipettes 300 µl and smaller: Pull slightly the Clip

trigger 8 backwards with the other hand). Insert the screw end into the cylinder and carefully

screw in the tip fitting by turning the tool clockwise. Rotate the tool and tighten the tip fitting.

Check that there is no gap between tip fitting and cylinder (Picture 13).

Be careful not to overtighten the tip fitting. This may damage the thread in the pipette.

7.2.5 Disassembly of multichannel pipettes

1. Remove the tip fittings (Picture 8).

To remove the tip fitting place the star-shaped end of tool 3 (picture 9) into the end of the fitting.

Turn the tool counterclockwise to unscrew the tip fitting (picture 10).

Change tip fitting o-rings during maintenance if needed.

2. Press tip ejector 4.1 down (Picture 11), so that it presses tip ejector 23 down at the same time.

Manually hold the ejector cover in the down position, and let the tip ejector rise to its normal

position, so that the parts snap apart revealing a square slot. If necessary, manipulate them

gently by hand.

3. Keep the handle 42 still and insert the second end of the service tool 2 into the slot and turn

clockwise to separate the handle and the module 50. from each other. Loosen

until you can pull the parts apart.

4. Pull the holder spring 13 downwards and remove the two locking

pieces 12. Finally, remove the holder spring carefully ensuring that

the spring does not fly off.

5. Remove the two MCP adapter claws and pull the MCP adapter

46 away. Remove the MCP spring base 43 by pulling upwards.

6. Remove the two screws 19 and pull the tip ejector 23 into the

down position as shown in the

picture on page 26

.

Picture 14

No gap

Picture 13

Page 15

15

7. While the tip ejector 23 is in the down position, open its upper end slightly on both sides and

pull downwards. Remove the fastening spring 22. Remove the ejector link 24. Press the piston bar

16 beam into the down position. Finally unfasten the four screws 20/21 and the tip ejector.

The ejector slide 25 and two springs 26 can be removed for maintenance. This does not belong to

the regular long-term service, however.

8. Disengage the housing bottom 17 and piston bar 16 from each other. You can

disengage the tip cone assembly 42 by pulling it away from the piston

assembly 31. Disengage the piston assembly by pulling it out sideways from

the piston bar as shown in the picture on page 26. Remove the piston spring 33.

1-10µl

1. Place service tool head #1 between ring 15 and ejector 23

(Picture 15).

2. Push the tool until the parts snap away from each other ( I ).

3. Check that the ejector lever is in the up position, and pull down

and remove the tip ejector part of the module ( II ).

7.2.6 Service instructions for multichannel pipette tip

cones / cylinders

Volume: 1–10 µl

1. Unscrew the tip fittings ( I ) (Picture 16).

2. Remove O-rings 37.

3. Clean pistons 31 and the O-rings with a dry,

nap-free cloth.

4. If necessary, change O-rings 37.

5. Grease the O-rings with the lubricant provided in

the pipette package.

6. Screw the tip fittings back into the tip cones.

7. Reassemble the tip ejector.

8. Push the tip ejector lever down until you hear a click.

Volumes: 5–50 µl, 10–100 µl, and 30–300 µl

Disengage the tip cone cover 32 from the tip cone B (Picture 17) by easing it off with a flat-head

screwdriver. The tip cone cover and the interior parts of the tip cone, the O-ring spring 34, the

supporter ring 35, and the O-ring 36 ( 5–50µl/10–100µl: also O-ring 37 ), can all be removed in order

by using the piston assembly 31 as shown in the picture. If some parts remain in the tip cone, they

can be removed by turning the tip cone upside down and tapping it.

32

31

32

34

35

31

32

34

35

36

36

30–300µl5-50µl/ 10–100µl

37

B

Picture 17

Picture 16

Picture 15

30

31

37

I

23

15

II

I

Page 16

16

7.2.7 Cleaning and reassembling multichannel pipettes

See the cleaning instructions in Section 7.2.2 “Single channel pipettes”. Check the volume-specific

reassembling of the piston assemblies starting on page 23. The pipette is assembled in the reverse

order to disassembling. Note that the ejector link 24 must be in the down position simultaneously

with the tip ejector 23 (page 26). Clean and lubricate the holder spring 13 before assembling.

NOTE!

To ensure even performance between all channels in a multichannel

pipette, all tip cones have to be changed at the same time, if any of

them needs to be changed. Don’t mix tip cones of different packages,

because one bag contains a matched set of tip cones. Place aligning

studs to the same side when assembling the module (Picture 18).

Make sure that the tip fittings are aligned in same level, adjust if necessary.

8. Sterilization

Before autoclaving, disassemble the tip fitting from the tip cone and autoclave them separately. After

autoclaving, the tip cone and tip fitting must be cooled to room temperature for at least two hours.

When reassembling, make sure that the tip cone and tip fitting are dry. We recommend checking

the calibration after every sterilization cycle. The effectiveness of the autoclaving must be verified

by the user.

8.1 Autoclavable parts:

Single and multichannel pipettes:

- Tip fitting 5 and 30

- Tip fitting O-ring (5.1)

Single channel pipettes:

- Tip cone assembly (42)

Parts can be repeatedly autoclaved at 121°C (252°F) (2 ata) for 20 minutes.

Picture 18

Picture 19

Page 17

17

9. Troubleshooting

The table below lists possible problems and their solutions.

Defect

Leakage

Inaccurate

dispensing

Tip not ejecting

Piston jammed

Broken tip fitting

Dispensing knob

jammed to semi

down position

Possible reason

•Tip fitting incorrectly attached or

loose

•ClipTip clips are bent

•Tip fitting o-ring damaged

•Tip incorrectly attached

•Foreign particles between the tip

and the tip cone

•Foreign particles between the

piston, the O-ring and the cylinder

•Insufficient amount of grease on the

cylinder and the O-ring

•O-ring damaged

•Incorrect operation

•Tip incorrectly attached

•Calibration altered; caused by

misuse, for example

•Wrong tip

•Unsuitable calibration: a list of

factors is presented in Section 4.1

“Calibration and adjustment“

•Tip cone loose

•Pipette not serviced

•Tip fitting not properly attached

•Uneven tip ejecting with the

multichannel

•Pipette has been unused for a long

period

•Grease is removed while pipetting a

highly volatile solvent repeatedly

•Pipette dropped on the floor etc

•One sided force applied to the knob

when adjusting the volume with

one hand

Possible action

►Re-attach/tighten the tip fitting

or replace with new tip fitting(s)

using the tool.

►Discard the tip.

►Change the O-ring.

►Attach firmly.

►Clean the tip cones and attach

new tips.

►Clean and grease the O-ring and

cylinder.

►Grease accordingly.

►Change the O-ring.

►Follow the instructions carefully.

►Attach firmly.

►Recalibrate according to the

instructions.

►Use the correct tip.

►Readjust the pipette.

►Tighten the tip cone with the

service tool.

►Perform pipette service.

►Tighten the tip fitting.

►Tighten the tip fitting with the

tool or replace the tip fitting set.

►Remove the tip if attached.

Press the plunger to the second

stop and release several times

to re-apply the grease.

►Use the tip fitting tool to remove

the remaining part of the tip

fitting. Place the flat head end

of the tool 3 (picture 9) into the

remaining part of the tip fitting

and rotate counterclockwise

to unscrew the remaining part.

Assemble a new tip fitting.

►Pull up the knob and press down

again to locked position

Page 18

18

10. Appendices

Appendix 1. Conversion table

Value of the conversion factor Z (µl/mg), as a function of temperature and pressure, for distilled

water.

Temperature Air pressure

°C kPa

80 85 90 95 100 101.3 105

15.0 1.0017 1.0018 1.0019 1.0019 1.0020 1.0020 1.0020

15.5 1.0018 1.0019 1.0019 1.0020 1.0020 1.0020 1.0021

16.0 1.0019 1.0020 1.0020 1.0021 1.0021 1.0021 1.0022

16.5 1.0020 1.0020 1.0021 1.0021 1.0022 1.0022 1.0022

17.0 1.0021 1.0021 1.0022 1.0022 1.0023 1.0023 1.0023

17.5 1.0022 1.0022 1.0023 1.0023 1.0024 1.0024 1.0024

18.0 1.0022 1.0023 1.0023 1.0024 1.0025 1.0025 1.0025

18.5 1.0023 1.0024 1.0024 1.0025 1.0025 1.0026 1.0026

19.0 1.0024 1.0025 1.0025 1.0026 1.0026 1.0027 1.0027

19.5 1.0025 1.0026 1.0026 1.0027 1.0027 1.0028 1.0028

20.0 1.0026 1.0027 1.0027 1.0028 1.0028 1.0029 1.0029

20.5 1.0027 1.0028 1.0028 1.0029 1.0029 1.0030 1.0030

21.0 1.0028 1.0029 1.0029 1.0030 1.0031 1.0031 1.0031

21.5 1.0030 1.0030 1.0031 1.0031 1.0032 1.0032 1.0032

22.0 1.0031 1.0031 1.0032 1.0032 1.0033 1.0033 1.0033

22.5 1.0032 1.0032 1.0033 1.0033 1.0034 1.0034 1.0034

23.0 1.0033 1.0033 1.0034 1.0034 1.0035 1.0035 1.0036

23.5 1.0034 1.0035 1.0035 1.0036 1.0036 1.0036 1.0037

24.0 1.0035 1.0036 1.0036 1.0037 1.0037 1.0038 1.0038

24.5 1.0037 1.0037 1.0038 1.0038 1.0039 1.0039 1.0039

25.0 1.0038 1.0038 1.0039 1.0039 1.0040 1.0040 1.0040

25.5 1.0039 1.0040 1.0040 1.0041 1.0041 1.0041 1.0042

26.0 1.0040 1.0041 1.0041 1.0042 1.0042 1.0043 1.0043

26.5 1.0042 1.0042 1.0043 1.0043 1.0044 1.0044 1.0044

27.0 1.0043 1.0044 1.0044 1.0045 1.0045 1.0045 1.0046

27.5 1.0045 1.0045 1.0046 1.0046 1.0047 1.0047 1.0047

28.0 1.0046 1.0046 1.0047 1.0047 1.0048 1.0048 1.0048

28.5 1.0047 1.0048 1.0048 1.0049 1.0049 1.0050 1.0050

29.0 1.0049 1.0049 1.0050 1.0050 1.0051 1.0051 1.0051

29.5 1.0050 1.0051 1.0051 1.0052 1.0052 1.0052 1.0053

30.0 1.0052 1.0052 1.0053 1.0053 1.0054 1.0054 1.0054

Page 19

19

Appendix 2. Manufacturer specification limits

Thermo Scientific F1-ClipTip Variable Volume Single Channel

Thermo Scientific F1-ClipTip Fixed Volume Single Channel

Order No. Volume Inaccuracy Imprecision Compatible

µl µl % SD µl CV% ClipTip

4651280N 10 ±0.090 ±0.90 0.080 0.80 12.5 Ext

4651200N 20 ±0.14 ±0.70 0.100 0.50 20

4651210N 25 ±0.15 ±0.60 0.125 0.50 50

4651220N 50 ±0.30 ±0.60 0.20 0.40 50

4651230N 100 ±0.40 ±0.40 0.30 0.30 200

4651240N 200 ±0.80 ±0.40 0.600 0.30 200

4651250N 250 ±1.0 ±0.40 0.75 0.30 300

4651260N 500 ±1.5 ±0.30 1.5 0.30 1000

4651270N 1000 ±3.0 ±0.30 3.0 0.30 1000

Order No. Range Volume Inaccuracy Imprecision Compatible

µl µl % SD µl CV% ClipTip

4641310N 0.1–2 µl 2 ±0.050 ±2.50 0.040 2.00 12.5 Ext

0.2 ±0.024 ±12.00 0.020 10.00

0.1 ±0.033 ±33.00 0.025 25.00

4641320N 1–10 µl 10 ±0.100 ±1.00 0.050 0.50 12.5 Ext

1 ±0.025 ±2.50 0.020 2.00

4641180N 2–20 µl 20 ±0.20 ±1.00 0.08 0.40 20

2 ±0.06 ±3.00 0.05 2.50

4641190N 5–50 µl 50 ±0.30 ±0.60 0.15 0.30 50

5 ±0.15 ±3.00 0.125 2.50

4641200N 10–100 µl 100 ±0.80 ±0.80 0.20 0.20 200

10 ±0.30 ±3.00 0.10 1.00

4641210N 20–200 µl 200 ±1.2 ±0.60 0.4 0.20 200

20 ±0.36 ±1.80 0.14 0.70

4641220N 30–300 µl 300 ±1.8 ±0.60 0.6 0.20 300

30 ±0.45 ±1.50 0.18 0.60

4641230N 100–1000 µl 1000 ±6.0 ±0.60 2.0 0.20 1000

100 ±1.0 ±1.00 0.6 0.60

Page 20

20

Thermo Scientific F1-ClipTip Variable Volume Multichannel

Order No. Range Channel Volume Inaccuracy Imprecision Compatible

µl µl % SD µl CV% ClipTip

4661210N 1–10 µl 8 10 ±0.240 ±2.40 0.160 1.60 12.5 Ext

1 ±0.120 ±12.00 0.080 8.00

4661120N 5–50 µl 8 50 ±0.75 ±1.50 0.35 0.70 50

5 ±0.25 ±5.00 0.10 2.00

4661130N 10–100 µl 8 100 ±1.30 ±1.30 0.50 0.50 200

10 ±0.50 ±5.00 0.20 2.00

4661140N 30–300 µl 8 300 ±3.0 ±1.00 0.9 0.30 300

30 ±1.5 ±5.00 0.6 2.00

4661220N 1–10 µl 12 10 ±0.240 ±2.40 0.160 1.60 12.5 Ext

1 ±0.120 ±12.00 0.080 8.00

4661160N 5–50 µl 12 50 ±0.75 ±1.50 0.35 0.70 50

5 ±0.25 ±5.00 0.10 2.00

4661170N 10–100 µl 12 100 ±1.30 ±1.30 0.50 0.50 200

10 ±0.50 ±5.00 0.20 2.00

4661180N 30–300 µl 12 300 ±3.0 ±1.00 0.9 0.30 300

30 ±1.5 ±5.00 0.6 2.00

Page 21

21

Appendix 3. ISO8655 calibration specifications

Thermo Scientific F1-ClipTip specifications according to ISO8655 standard.

Fixed Volume Inaccuracy Imprecision Compatible

µl µl % SD µl CV% ClipTip

10 ±0.120 ±1.20 0.080 0.80 12.5 Ext

20 ±0.20 ±1.00 0.10 0.50 20

25 ±0.50 ±2.00 0.20 0.80 50

50 ±0.50 ±1.00 0.20 0.40 50

100 ±0.80 ±0.80 0.30 0.30 200

200 ±1.60 ±0.80 0.60 0.30 200

250 ±4.00 ±1.60 1.50 0.60 300

500 ±4.00 ±0.80 1.50 0.30 1000

1000 ±8.00 ±0.80 3.00 0.30 1000

Range Channel Volume Inaccuracy Imprecision Compatible Color

µl µl % SD µl CV% ClipTip code

1–10 µl 8, 12 10 ±0.24 ±2.4 0.16 1.6 12.5 Ext pink

1 ±0.24 ±24 0.16 16

5–50 µl 8, 12 50 ±1.0 ±2.0 0.4 0.8 50 violet

5 ±1.0 ±20 0.4 8.0

10–100 µl 8, 12 100 ±0.80 ±0.8 0.30 0.3 200 yellow

10 ±0.80 ±8.0 0.30 3.0

30–300 µl 8, 12 300 ±8.0 ±2.7 3.0 1.0 300 orange

30 ±8.0 ±26.7 3.0 10.0

Thermo Scientific F1-ClipTip Variable Volume Single Channel

Thermo Scientific F1-ClipTip Fixed Volume Single Channel

Thermo Scientific F1-ClipTip Variable Volume Multichannel

Range Volume Inaccuracy Imprecision Compatible Color

µl µl % SD µl CV% ClipTip code

0.1–2 µl 2 ±0.080 ±4.0 0.040 2.0 12.5 Ext pink

0.2 ±0.080 ±40.0 0.040 20.0

0.1 ±0.080 ±80.0 0.040 40.0

1–10 µl 10 ±0.120 ±1.2 0.080 0.8 12.5 Ext pink

1 ±0.120 ±12 0.080 8.0

2–20 µl 20 ±0.20 ±1.0 0.10 0.5 20 pink

2 ±0.20 ±10 0.10 5.0

5–50 µl 50 ±0.50 ±1.0 0.20 0.4 50 violet

5 ±0.50 ±10 0.20 4.0

10–100 µl 100 ±0.80 ±0.8 0.30 0.3 200 yellow

10 ±0.80 ±8.0 0.30 3.0

20–200 µl 200 ±1.60 ±0.8 0.60 0.3 200 yellow

20 ±1.60 ±8.0 0.60 3.0

30–300 µl 300 ±4.0 ±1.3 1.5 0.5 300 orange

30 ±4.0 ±13 1.5 5.0

100–1000 µl 1000 ±8.0 ±0.8 3.0 0.3 1000 blue

100 ±8.0 ±8.0 3.0 3.0

Page 22

22

Appendix 4. Assembly and spare parts

* Available as a spare part. See model specific order numbers on page 30.

2

1062930

Multichannel service tool

* 50. Module

* 42. Tip cone assembly

1

1062800

Service and

adjustment tool

* 5. Tip fitting

3

0300070 Tip fitting tool

Page 23

23

All

1–300µl

2–20µl

20 µl Fixed

12

14

15

16

17

18*

19*

20

21

13

11

10

8

9

5.2*

5.1*

5*

0.1–2µl

11

13

16

10

28*

20

27

21

12

1–10µl

10 µl Fixed

11

13

16

10

18*

21

12

Page 24

24

10–100µl

12

13

14

15

16

17*

5–50µl

25 / 50 µl Fixed

All

1–300µl

12

14

15

16

17

18*

19*

20

21

13

11

10

8

9

5.2*

5.1*

5*

Page 25

25

100–1000µl

500 / 1000 µl Fixed

12

13

14

15

16

17*

6

8

9

5.2*

5.1*

5*

10

11

30–300µl

250µl Fixed

20–200µl

100 / 200 µl Fixed

12

13

14

15

16

17*

12

13

14

15

16

17*

11

10

8

9

5.2*

5.1*

5*

All

1–300µl

Page 26

26

* 50

8-ch 1-10 µl

15

12

13

16

17

31

33

30

37*

43

46

18

21

21

23

32

27

22

21

21

Page 27

27

* 50

12-ch 1-10 µl

15

46

23

31

33

30

37*

32

18

21

20

22

21

20

12

13

16

17

43

27

Page 28

28

* 50

15

12

13

16

17

31

33

30

37*

35

43

46

18

21

20

22

42*

23

19

25

26

24

32

38

39

40

41

27

5.2*

5.1*

5*

8-ch 5-50 µl

10-100 µl

30-300 µl

21

20

Page 29

29

15

12

13

16

17

43

46

18

21

20

22

31

33

42*

32

23

19

25

26

34

35

36

30

24

27

50*

5.2*

5.1*

5*

12-ch 5-50 µl

10-100 µl

30-300 µl

21

20

Page 30

30

Single Channel

0.1–2µl

28. 2216410

42. 2216480N

1–10µl / 10µl Fixed

18. 1030060

42. 2216390N

2–20µl / 20µl Fixed

5. 2216160 4 pcs

5.1. 2214930 3 pcs

5.2. 1033430

18. 1030380

19. 1033110

42. 2216090N

5–50µl / 25µl / 50µl Fixed

5. 2216160 4 pcs

5.1. 2214930 3 pcs

5.2. 1033430

18. 1030500

19. 1039060

42. 2216100N

10–100µl

5. 2216160 4 pcs

5.1. 2214930 3 pcs

5.2. 1033430

17. 1030510

42. 2216110N

20–200µl / 100µl / 200µl Fixed

5. 2216160 4 pcs

5.1. 2214930 3 pcs

5.2. 1033430

17. 1030160

42. 2216120N

30–300µl / 250µl Fixed

5. 2216160 4 pcs

5.1. 2214930

3 pcs

5.2. 1033430

17. 1033330

42. 2216130N

100–1000µl

500µl / 1000µl Fixed

5. 2216190 4 pcs

5.1. 2215540 3 pcs

5.2. 1033430

17. 1030020

42. 2216220N

Multichannel

8-ch / 12-ch

5. 2216170 8 pcs

5. 2216180 12 pcs

5.1. 2214920 12 pcs

5.2. 1033430

37. 1030060 1 pcs

42. 2214400 5–50µl 12 pcs

42. 2214410 10–100µl 12 pcs

42. 2214420 30–300µl 12 pcs

8-ch

50. 2216440N 1–10µl

50. 2213630N 5–50µl

50. 2213640N 10–100µl

50. 2213650N 30–300µl

12-ch

50. 2216460N 1–10µl

50. 2213670N 5–50µl

50. 2213680N 10–100µl

50. 2213690N 30–300µl

F1-ClipTip single channel and multichannel spare part order numbers

Page 31

31

Appendix 5. ClipTip ordering information

Thermo Scientific ClipTip racked and sterile tips

Code ClipTip Volume Qty

94410060 ClipTip 12.5 Ext 12.5 µl 10x96/rack

94410063 ClipTip 12.5 Ext, sterile 12.5 µl 10x96/rack

94410210 ClipTip 20 20 µl 10x96/rack

94410213 ClipTip 20, sterile 20 µl 10x96/rack

94410250 ClipTip 50 50 µl 10x96/rack

94410253 ClipTip 50, sterile 50 µl 10x96/rack

94410310 ClipTip 200 200 µl 10x96/rack

94410313 ClipTip 200, sterile 200 µl 10x96/rack

94410510 ClipTip 300 300 µl 10x96/rack

94410513 ClipTip 300, sterile 300 µl 10x96/rack

94410610 ClipTip 300 Ext 300 µl 8x96/rack

94410313 ClipTip 300 Ext, sterile 300 µl 8x96/rack

94410710 ClipTip 1000 1000 µl 8x96/rack

94410713 ClipTip 1000, sterile 1000 µl 8x96/rack

Thermo Scientific ClipTip filter tips , sterile

Code ClipTip Volume Qty

94420063 ClipTip Filter 12.5 Ext 12.5 µl 10x96/rack

94420213 ClipTip Filter 20 20 µl 10x96/rack

94420253 ClipTip Filter 50 50 µl 10x96/rack

94420313 ClipTip Filter 200 200 µl 10x96/rack

94420513 ClipTip Filter 300 300 µl 10x96/rack

94420613 ClipTip Filter 300 Ext 300 µl 8x96/rack

94420713 ClipTip Filter 1000 1000 µl 8x96/rack

All ClipTip tips are certified to be free from RNase, DNase, DNA, ATP and endotoxins.

Thermo Scientific ClipTip reloads

Code ClipTip Volume Qty

94410217 ClipTip 20 20 µl 10x96/insert

94410218 ClipTip 20, sterile 20 µl 10x96/insert

94410257 ClipTip 50 50 µl 10x96/insert

94410258 ClipTip 50, sterile 50 µl 10x96/insert

94410317 ClipTip 200 200 µl 10x96/insert

94410318 ClipTip 200, sterile 200 µl 10x96/insert

94410517 ClipTip 300 300 µl 10x96/insert

94410518 ClipTip 300, sterile 300 µl 10x96/insert

94410617 ClipTip 300 Ext 300 µl 10x96/insert

94410618 ClipTip 300 Ext, sterile 300 µl 10x96/insert

94410717 ClipTip 1000 1000 µl 8x96/insert

94410718 ClipTip 1000, sterile 1000 µl 8x96/insert

94420218 ClipTip 20, filter sterile 20 µl 10x96/insert

94420258 ClipTip 50, filter sterile 50 µl 10x96/insert

94420318 ClipTip 200, filter sterile 200 µl 10x96/insert

94420518 ClipTip 300, filter sterile 300 µl 10x96/insert

94420718 ClipTip 1000, filter sterile 1000 µl 8x96/insert

Page 32

32

Appendix 6. F1-ClipTip and ClipTip compatibility table

Non-filter and filter tips

Product code Description

ClipTip 12.5 Ext

ClipTip 20

ClipTip 50

ClipTip 200

ClipTip 300

ClipTip 300 Ext *

ClipTip 1000

4641310N F1-ClipTip 0.1-2µl

x

4641320N F1-ClipTip 1-10µl x

4641180N F1-ClipTip 2-20µl x

4641190N F1-ClipTip 5-50µl x

4641200N F1-ClipTip 10-100µl x

4641210N F1-ClipTip 20-200µl

x

4641220N F1-ClipTip 30-300µl x x

4641230N F1-ClipTip 100-1000µl x

4651280N F1-ClipTip 10µl fixed volume x

4651200N F1-ClipTip 20µl fixed volume x

4651210N F1-ClipTip 25µl fixed volume x

4651220N F1-ClipTip 50µl fixed volume

x

4651230N F1-ClipTip 100µl fixed volume x

4651240N F1-ClipTip 200µl fixed volume x

4651250N F1-ClipTip 250µl fixed volume x x

4651260N F1-ClipTip 500µl fixed volume x

4651270N F1-ClipTip 1000µl fixed volume

x

4661210N F1-ClipTip 8-ch 1-10µl x

4661120N F1-ClipTip 8-ch 5-50µl x

4661130N F1-ClipTip 8-ch 10-100µl x

4661140N F1-ClipTip 8-ch 30-300µl x x

4661220N F1-ClipTip 12-ch 1-10µl x

4661160N F1-ClipTip 12-ch 5-50µl x

4661170N F1-ClipTip 12-ch 10-100µl

x

4661180N F1-ClipTip 12-ch 30-300µl x x

* Performance specifications with CT300 Ext tips differ from the specifications of the standard tips.

Extended length tips will fullfil the ISO8655 specifications.

Page 33

33

Multichannel stand

#9420390

F–stand

#9420400

Reagent reservoir

100 ml #95128085

Reagent reservoir

25 ml #95128093

Reagent reservoir

25 ml divided #951228095

Appendix 7. Pipette accessories

Page 34

34

info.pipettes@thermofisher.com

www.thermofisher.com

150 89 90 -0 5

thermofisher.com

© 2018 Thermo Fisher Scientific Inc. All rights reserved. All trademarks are the property of Thermo Fisher

Scientific Inc. and its subsidiaries. Specifications, terms and pricing are subject to change. Not all products

are available in all countries. Please consult your local sales representative for details.

Thermo Fisher Scientific Oy

Ratastie 2

01620 Vantaa

Finland

Loading...

Loading...