Page 1

EX Series

Bath Circulators

Thermo NESLAB Manual P/N 000259

Rev. 10/26/00

Instruction and Operation ManInstruction and Operation Man

Instruction and Operation Man

Instruction and Operation ManInstruction and Operation Man

ualual

ual

ualual

Page 2

PREFACEPREFACE

PREFACE

PREFACEPREFACE

SECTION ISECTION I

SECTION I

SECTION ISECTION I

SafetySafety

Safety

SafetySafety

SECTION IISECTION II

SECTION II

SECTION IISECTION II

General InformationGeneral Information

General Information

General InformationGeneral Information

SECTION IIISECTION III

SECTION III

SECTION IIISECTION III

InstallationInstallation

Installation

InstallationInstallation

SECTION IVSECTION IV

SECTION IV

SECTION IVSECTION IV

ControllersControllers

Controllers

ControllersControllers

SECTION VSECTION V

SECTION V

SECTION VSECTION V

MaintenanceMaintenance

Maintenance

MaintenanceMaintenance

SECTION VISECTION VI

SECTION VI

SECTION VISECTION VI

TroubleshootingTroubleshooting

Troubleshooting

TroubleshootingTroubleshooting

SECTION VIISECTION VII

SECTION VII

SECTION VIISECTION VII

Programming SoftwareProgramming Software

Programming Software

Programming SoftwareProgramming Software

APPENDIXAPPENDIX

APPENDIX

APPENDIXAPPENDIX

WARRANTYWARRANTY

WARRANTY

WARRANTYWARRANTY

EX-Series Bath CirEX-Series Bath Cir

EX-Series Bath Cir

EX-Series Bath CirEX-Series Bath Cir

TT

abab

le of Contentsle of Contents

T

ab

le of Contents

TT

abab

le of Contentsle of Contents

Compliance ............................................................................................. 2

Unpacking ............................................................................................... 2

Warranty ................................................................................................. 2

NES-care ................................................................................................ 2

After-sale Support ................................................................................... 2

Warnings................................................................................................. 3

Description .............................................................................................. 4

Specifications.......................................................................................... 4

Site.......................................................................................................... 6

Electrical Requirements .......................................................................... 6

Plumbing Requirements.......................................................................... 7

Fluids ...................................................................................................... 9

Filling Requirements ............................................................................... 9

Autorefill (Optional) .................................................................................10

Controllers...............................................................................................11

Analog Controller ....................................................................................11

Digital Controller .....................................................................................12

Tap Water Cooling Coils .........................................................................13

Boost Heater...........................................................................................13

High Temperature/Low Liquid Level Safety ............................................14

15-pin Accessory Connector (Optional) ..................................................15

Service Contracts ...................................................................................16

Reservoir Cleaning..................................................................................16

Algae.......................................................................................................16

Checklist .................................................................................................17

Service Assistance and Technical Support.............................................17

NEScom Programming Software ............................................................18

International Quick Reference Guides

culatorculator

culator

culatorculator

- 1 -

Page 3

ComplianceCompliance

Compliance

ComplianceCompliance

UnpackingUnpacking

Unpacking

UnpackingUnpacking

PrefacePreface

Preface

PrefacePreface

Products tested and found to be in compliance with the requirements defined

in the EMC standards defined by 89/336/EEC as well as Low Voltage Directive

(LVD) 73/23/EEC can be identified by the CE label on the rear of the unit. The

testing has demonstrated compliance with the following directives:

LVD, 73/23/EEC Complies with UL 3101-1:93

EMC, 89/336/EEC EN 55011, Class A Verification

EN 50082-1:1992

IEC 1000-4-2:1995

IEC 1000-4-3:1994

IEC 1000-4-4:1995

For any additional information refer to the Letter of Compliance that shipped

with the unit (Declaration of Conformity).

Retain all cartons and packing material until the unit is operated and found to

be in good condition. If the unit shows external or internal damage, or does

not operate properly, contact the transportation company and file a damage

claim. Under ICC regulations, this is your responsibility.

WarrantyWarranty

Warranty

WarrantyWarranty

NES-care NES-care

NES-care

NES-care NES-care

Warranty ContractWarranty Contract

Warranty Contract

Warranty ContractWarranty Contract

After-sale SupportAfter-sale Support

After-sale Support

After-sale SupportAfter-sale Support

ExtendedExtended

Extended

ExtendedExtended

Units have a warranty against defective parts and workmanship for one full

year from date of shipment. See back page for more details.

• Extend parts and labor coverage for an additional year.

• Worry-free operation.

• Control service costs.

• Eliminate the need to generate repair orders.

• No unexpected repair costs.

Other contract options are available. Please contact NESLAB for more

information.

Thermo NESLAB is committed to customer service both during and after the

sale. If you have questions concerning the operation of your unit, contact our

Sales Department. If your unit fails to operate properly, or if you have

questions concerning spare parts or Service Contracts, contact our Customer Service Department. Before calling, please obtain the following

information from the unit's serial number label:

- BOM number _____________________

- Serial number _____________________

- 2 -

Page 4

WarningsWarnings

Warnings

WarningsWarnings

Section I SafSection I Saf

Section I Saf

Section I SafSection I Saf

etyety

ety

etyety

Make sure you read and understand all instructions and safety precautions

listed in this manual before installing or operating your unit. If you have any

questions concerning the operation of your unit or the information in this

manual, contact our Sales Department.

Performance of installation, operation, or maintenance proceduresPerformance of installation, operation, or maintenance procedures

Performance of installation, operation, or maintenance procedures

Performance of installation, operation, or maintenance proceduresPerformance of installation, operation, or maintenance procedures

other than those described in this manual may result in a hazardousother than those described in this manual may result in a hazardous

other than those described in this manual may result in a hazardous

other than those described in this manual may result in a hazardousother than those described in this manual may result in a hazardous

situation and may void the manufacturer's warranty.situation and may void the manufacturer's warranty.

situation and may void the manufacturer's warranty.

situation and may void the manufacturer's warranty.situation and may void the manufacturer's warranty.

Observe all warning labels.Observe all warning labels.

Observe all warning labels.

Observe all warning labels.Observe all warning labels.

Never remove warning labels.Never remove warning labels.

Never remove warning labels.

Never remove warning labels.Never remove warning labels.

Never operate damaged or leaking equipment.Never operate damaged or leaking equipment.

Never operate damaged or leaking equipment.

Never operate damaged or leaking equipment.Never operate damaged or leaking equipment.

Never operate the unit without bath fluid in the bath.Never operate the unit without bath fluid in the bath.

Never operate the unit without bath fluid in the bath.

Never operate the unit without bath fluid in the bath.Never operate the unit without bath fluid in the bath.

Never use pure ethylene glycol as a bath fluid. A minimum 80/20Never use pure ethylene glycol as a bath fluid. A minimum 80/20

Never use pure ethylene glycol as a bath fluid. A minimum 80/20

Never use pure ethylene glycol as a bath fluid. A minimum 80/20Never use pure ethylene glycol as a bath fluid. A minimum 80/20

mixture of Ethylene Glycol and tap water is allowed.mixture of Ethylene Glycol and tap water is allowed.

mixture of Ethylene Glycol and tap water is allowed.

mixture of Ethylene Glycol and tap water is allowed.mixture of Ethylene Glycol and tap water is allowed.

For 220 - 240 volt units supplied without a line cord, use a harmonizedFor 220 - 240 volt units supplied without a line cord, use a harmonized

For 220 - 240 volt units supplied without a line cord, use a harmonized

For 220 - 240 volt units supplied without a line cord, use a harmonizedFor 220 - 240 volt units supplied without a line cord, use a harmonized

(HAR) grounded 3-conductor cord, type H05VV-F, with conductors(HAR) grounded 3-conductor cord, type H05VV-F, with conductors

(HAR) grounded 3-conductor cord, type H05VV-F, with conductors

(HAR) grounded 3-conductor cord, type H05VV-F, with conductors(HAR) grounded 3-conductor cord, type H05VV-F, with conductors

listed below. A suitable cord end is required for connecting to thelisted below. A suitable cord end is required for connecting to the

listed below. A suitable cord end is required for connecting to the

listed below. A suitable cord end is required for connecting to thelisted below. A suitable cord end is required for connecting to the

equipment (see unit socket) and must terminate with an IEC approvedequipment (see unit socket) and must terminate with an IEC approved

equipment (see unit socket) and must terminate with an IEC approved

equipment (see unit socket) and must terminate with an IEC approvedequipment (see unit socket) and must terminate with an IEC approved

plug for proper connection to power supply.plug for proper connection to power supply.

plug for proper connection to power supply.

plug for proper connection to power supply.plug for proper connection to power supply.

22

2

NON-BOOST HEATER UNITSNON-BOOST HEATER UNITS

NON-BOOST HEATER UNITS

NON-BOOST HEATER UNITSNON-BOOST HEATER UNITS

BOOST HEATER UNITSBOOST HEATER UNITS

BOOST HEATER UNITS

BOOST HEATER UNITSBOOST HEATER UNITS

Always turn off the unit and disconnect the line cord from the powerAlways turn off the unit and disconnect the line cord from the power

Always turn off the unit and disconnect the line cord from the power

Always turn off the unit and disconnect the line cord from the powerAlways turn off the unit and disconnect the line cord from the power

source before performing any service or maintenance procedures, orsource before performing any service or maintenance procedures, or

source before performing any service or maintenance procedures, or

source before performing any service or maintenance procedures, orsource before performing any service or maintenance procedures, or

before moving the unit.before moving the unit.

before moving the unit.

before moving the unit.before moving the unit.

Always empty the bath before moving the unit.Always empty the bath before moving the unit.

Always empty the bath before moving the unit.

Always empty the bath before moving the unit.Always empty the bath before moving the unit.

Never operate equipment with damaged line cords.Never operate equipment with damaged line cords.

Never operate equipment with damaged line cords.

Never operate equipment with damaged line cords.Never operate equipment with damaged line cords.

Refer service and repairs to a qualified technician.Refer service and repairs to a qualified technician.

Refer service and repairs to a qualified technician.

Refer service and repairs to a qualified technician.Refer service and repairs to a qualified technician.

Nominal 1.0 mmNominal 1.0 mm

Nominal 1.0 mm

Nominal 1.0 mmNominal 1.0 mm

Unit Socket: IEC - 320 C13Unit Socket: IEC - 320 C13

Unit Socket: IEC - 320 C13

Unit Socket: IEC - 320 C13Unit Socket: IEC - 320 C13

Nominal 1.5 mmNominal 1.5 mm

Nominal 1.5 mm

Nominal 1.5 mmNominal 1.5 mm

Unit Socket: IEC - 320 C19Unit Socket: IEC - 320 C19

Unit Socket: IEC - 320 C19

Unit Socket: IEC - 320 C19Unit Socket: IEC - 320 C19

22

cross section rated 10 Amps cross section rated 10 Amps

cross section rated 10 Amps

cross section rated 10 Amps cross section rated 10 Amps

22

2

22

cross section rated 16 Amps cross section rated 16 Amps

cross section rated 16 Amps

cross section rated 16 Amps cross section rated 16 Amps

In addition to the safety warnings listed above, warnings are posted

throughout the manual. These warnings are designated by an exclamation

mark inside an equilateral triangle with text highlighted in bold print. Read

and follow these important instructions. Failure to observe these instructions

can result in permanent damage to the unit, significant property damage,

personal injury or death.

- 3 -

Page 5

DescriptionDescription

Description

DescriptionDescription

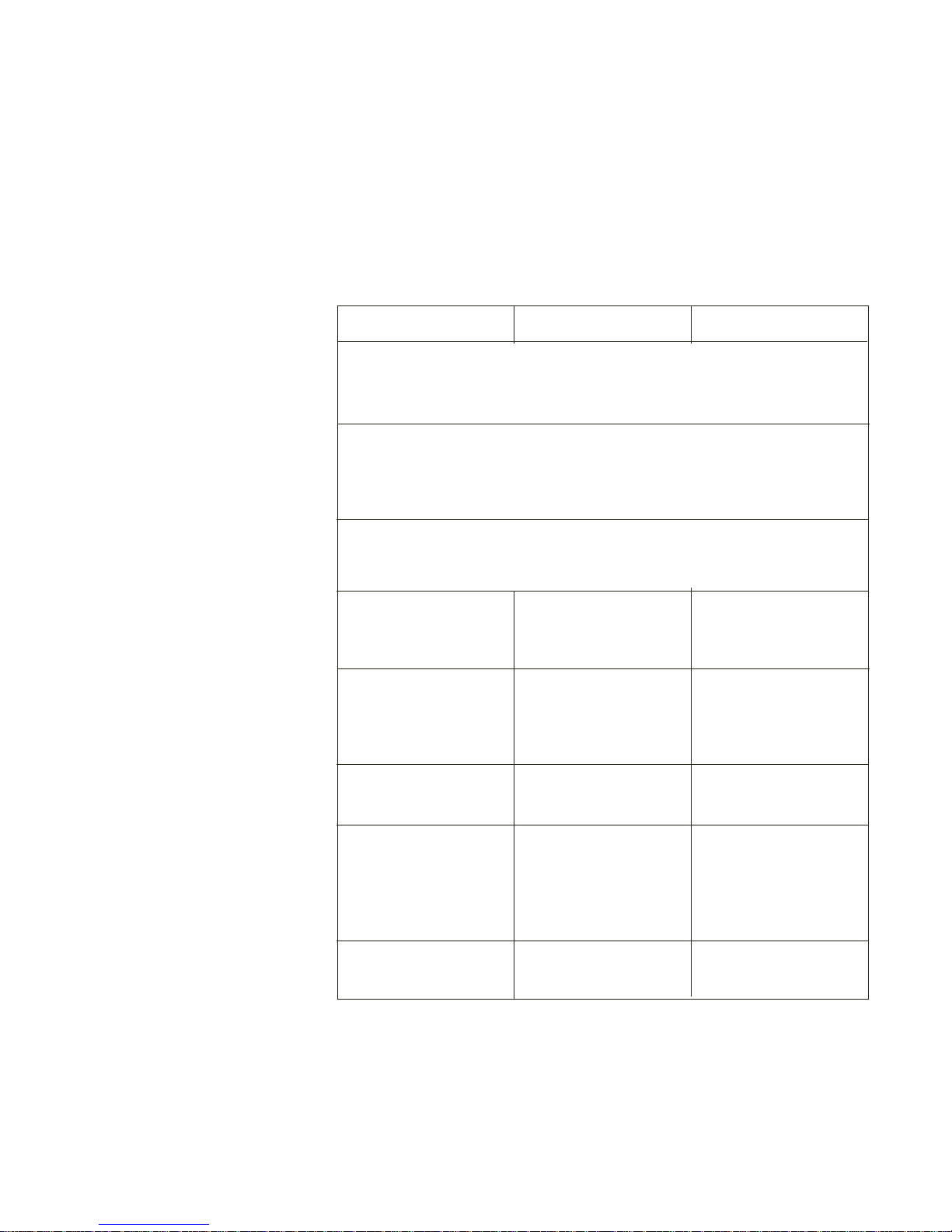

SpecificationsSpecifications

Specifications

SpecificationsSpecifications

Section II General InfSection II General Inf

Section II General Inf

Section II General InfSection II General Inf

ormationormation

ormation

ormationormation

The EX Series Bath Circulators are designed to provide temperature control

for applications requiring a fluid work area or pumping to an external system.

The units consist of a circulation pump, stainless steel bath, a work area

cover, and a temperature controller.

Temperature RangeTemperature Range

Temperature Range

Temperature RangeTemperature Range

Analog controller

Digital controller

Temperature StabilityTemperature Stability

Temperature Stability

Temperature StabilityTemperature Stability

Analog controller

Digital controller

Pumping CapacityPumping Capacity

Pumping Capacity

Pumping CapacityPumping Capacity

HeaterHeater

Heater

HeaterHeater

Watts

50 Hz Models

Bath Work AreaBath Work Area

Bath Work Area

Bath Work AreaBath Work Area

(H x W x D)

Inches

Centimeters

Bath VolumeBath Volume

Bath Volume

Bath VolumeBath Volume

Liters

Case DimensionsCase Dimensions

Case Dimensions

Case DimensionsCase Dimensions

(L x W x D)

Inches

Centimeters

EX-111EX-111

EX-111

EX-111EX-111

11

1

11

EX-211EX-211

EX-211

EX-211EX-211

Ambient +3°C to +100°C

Ambient +3°C to +150°C

22

2

22

±0.1°C

±0.01°C

15 lpm at 0' (0 M)

0 lpm at 16' (4.9 M)

800

1000

4 3/4 x 8 x 6

12.1 x 20.3 x 15.2

9 1/4 x 10 x 6

23.5 x 25.4 x 15.2

12.257.0

17 x 10 5/16 x 15 7/8

43.2 x 26.2 x 40.3

17 x 12 3/8 x 18 3/8

43.2 x 31.4 x 46.7

33

3

Power RequirementsPower Requirements

Power Requirements

Power RequirementsPower Requirements

33

1. Low-end temperature with tap water cooling. The controller may be set to -30°C, however to

2. Stability is a function of the bath fluid temperature. The use of a work area cover and tap

3. Power Board Transformer Fuse–Analog T 0.5A 250V (Qty 1), Digital T 0.8A 250V (Qty 2)

115 V, 60 Hz, 9 Amps

220/240 V, 50 Hz, 5.5 Amps

achieve temperatures below the specified range requires accessory cooling. Contact Thermo

Neslab for more details.

water cooling may optimize bath stability for your work. For some applications, agitation and

stability above ambient temperatures may be may be improved by connecting a small length

of hose between the PUMP INLET and PUMP OUTLET connections on the rear of the unit.

[T=Time Delay]

- 4 -

Page 6

SpecificationsSpecifications

Specifications

SpecificationsSpecifications

Temperature RangeTemperature Range

Temperature Range

Temperature RangeTemperature Range

Analog controller

Digital controller

Temperature StabilityTemperature Stability

Temperature Stability

Temperature StabilityTemperature Stability

Analog controller

Digital controller

Pumping CapacityPumping Capacity

Pumping Capacity

Pumping CapacityPumping Capacity

HeaterHeater

Heater

HeaterHeater

Watts

50 Hz Models

Bath Work AreaBath Work Area

Bath Work Area

Bath Work AreaBath Work Area

(H x W x D)

Inches

Centimeters

EX-221EX-221

EX-221

EX-221EX-221

11

1

11

EX-411EX-411

EX-411

EX-411EX-411

EX-511 EX-511

EX-511

EX-511 EX-511

Ambient +3°C to +100°C

Ambient +3°C to +150°C

22

2

22

±0.1°C

±0.01°C

15 lpm at 0' (0 M)

0 lpm at 16' (4.9 M)

800/800 boost

1000/800 boost

9 1/4 x 10 x 9

23.5 x 25.4 x 22.9

800

1000

19 1/4 x 10 x 6

48.9 x 25.4 x 15.2

800/800 boost

1000/800 boost

16 1/4 x 10 x 12

41.3 x 25.4 x 30.5

Bath VolumeBath Volume

Bath Volume

Bath VolumeBath Volume

Liters

Case DimensionsCase Dimensions

Case Dimensions

Case DimensionsCase Dimensions

(L x W x D)

Inches

Centimeters

33

3

Power RequirementsPower Requirements

Power Requirements

Power RequirementsPower Requirements

33

20.5 22.0 41.5

20 x 12 3/8 x 18 3/8

50.8 x 31.4 x 46.7

115 V, 60 Hz, 16 Amps

220/240 V, 50 Hz, 10 Amps

1. Low-end temperature with tap water cooling. The controller may be set to -30°C, however to

achieve temperatures below the specified range requires accessory cooling. Contact Thermo

Neslab for more details.

2. Stability is a function of the bath fluid temperature. The use of a work area cover and tap

water cooling may optimize bath stability for your work. For some applications, agitation and

stability above ambient temperatures may be may be improved by connecting a small length

of hose between the PUMP INLET and PUMP OUTLET connections on the rear of the unit.

3. Power Board Transformer Fuse–Analog T 0.5A 250V (Qty 1), Digital T 0.8A 250V (Qty 2)

[T=Time Delay]

17 x 12 3/8 x 28 3/8

43.2 x 31.4 x 72.1

115 V, 60 Hz, 9 Amps

220/240 V, 50 Hz, 5.5 Amps

23 x 12 3/8 x 25 3/8

58.4 x 31.4 x 64.5

115 V, 60 Hz, 16 Amps

220/240 V, 50 Hz, 10 Amps

- 5 -

Page 7

SiteSite

Site

SiteSite

ElectricalElectrical

Electrical

ElectricalElectrical

RequirementsRequirements

Requirements

RequirementsRequirements

Section III InstallationSection III Installation

Section III Installation

Section III InstallationSection III Installation

Never place the unit in a location where excessive heat, moisture, orNever place the unit in a location where excessive heat, moisture, or

Never place the unit in a location where excessive heat, moisture, or

Never place the unit in a location where excessive heat, moisture, orNever place the unit in a location where excessive heat, moisture, or

corrosive materials are present.corrosive materials are present.

corrosive materials are present.

corrosive materials are present.corrosive materials are present.

Lift the unit by grasping it under the case, near the rubber feet.

Locate the unit on a sturdy table or bench top. Ambient temperatures should

be inside the range of +50°F to +80°F (+10°C to +27°C).

Line voltage may be easily accessible inside the pump/control box.Line voltage may be easily accessible inside the pump/control box.

Line voltage may be easily accessible inside the pump/control box.

Line voltage may be easily accessible inside the pump/control box.Line voltage may be easily accessible inside the pump/control box.

Always unplug the unit prior to removing pump/control box cover.Always unplug the unit prior to removing pump/control box cover.

Always unplug the unit prior to removing pump/control box cover.

Always unplug the unit prior to removing pump/control box cover.Always unplug the unit prior to removing pump/control box cover.

Refer to the serial number label on the rear of the unit to identify the specific

electrical requirements of your unit.

En sure the voltage of the power source meets the specified voltage, ±10%.

The unit construction provides extra protection against the risk of electric

shock by grounding appropriate metal parts. The extra protection may not

function unless the power cord is connected to a properly grounded outlet. It

is the user's responsibility to assure a proper ground connection is provided.

For 220 - 240 volt units supplied without a line cord, use a harmonizedFor 220 - 240 volt units supplied without a line cord, use a harmonized

For 220 - 240 volt units supplied without a line cord, use a harmonized

For 220 - 240 volt units supplied without a line cord, use a harmonizedFor 220 - 240 volt units supplied without a line cord, use a harmonized

(HAR) grounded 3-conductor cord, type (HAR) grounded 3-conductor cord, type

(HAR) grounded 3-conductor cord, type

(HAR) grounded 3-conductor cord, type (HAR) grounded 3-conductor cord, type

listed below. A suitable cord end is required for connecting to thelisted below. A suitable cord end is required for connecting to the

listed below. A suitable cord end is required for connecting to the

listed below. A suitable cord end is required for connecting to thelisted below. A suitable cord end is required for connecting to the

equipment (see unit socket) and must terminate with an IEC approvedequipment (see unit socket) and must terminate with an IEC approved

equipment (see unit socket) and must terminate with an IEC approved

equipment (see unit socket) and must terminate with an IEC approvedequipment (see unit socket) and must terminate with an IEC approved

plug for proper connection to power supply.plug for proper connection to power supply.

plug for proper connection to power supply.

plug for proper connection to power supply.plug for proper connection to power supply.

NON-BOOST HEATER UNITSNON-BOOST HEATER UNITS

NON-BOOST HEATER UNITS

NON-BOOST HEATER UNITSNON-BOOST HEATER UNITS

BOOST HEATER UNITSBOOST HEATER UNITS

BOOST HEATER UNITS

BOOST HEATER UNITSBOOST HEATER UNITS

Nominal 1.0 mmNominal 1.0 mm

Nominal 1.0 mm

Nominal 1.0 mmNominal 1.0 mm

Unit Socket: IEC - 320 C13Unit Socket: IEC - 320 C13

Unit Socket: IEC - 320 C13

Unit Socket: IEC - 320 C13Unit Socket: IEC - 320 C13

Nominal 1.5 mmNominal 1.5 mm

Nominal 1.5 mm

Nominal 1.5 mmNominal 1.5 mm

Unit Socket: IEC - 320 C19Unit Socket: IEC - 320 C19

Unit Socket: IEC - 320 C19

Unit Socket: IEC - 320 C19Unit Socket: IEC - 320 C19

H05H05

VVVV

-F-F

H05

VV

H05H05

VVVV

22

2

22

cross section rated 10 Amps cross section rated 10 Amps

cross section rated 10 Amps

cross section rated 10 Amps cross section rated 10 Amps

22

2

22

cross section rated 16 Amps cross section rated 16 Amps

cross section rated 16 Amps

cross section rated 16 Amps cross section rated 16 Amps

, with conductors, with conductors

-F

, with conductors

-F-F

, with conductors, with conductors

- 6 -

Page 8

PlumbingPlumbing

Plumbing

PlumbingPlumbing

RequirementsRequirements

Requirements

RequirementsRequirements

Ensure the unit is off before connecting tubing to the unit.Ensure the unit is off before connecting tubing to the unit.

Ensure the unit is off before connecting tubing to the unit.

Ensure the unit is off before connecting tubing to the unit.Ensure the unit is off before connecting tubing to the unit.

To prevent damage to the plumbing lines, always support theTo prevent damage to the plumbing lines, always support the

To prevent damage to the plumbing lines, always support the

To prevent damage to the plumbing lines, always support theTo prevent damage to the plumbing lines, always support the

¾" fittings while installing/removing the pumping caps and lines.¾" fittings while installing/removing the pumping caps and lines.

¾" fittings while installing/removing the pumping caps and lines.

¾" fittings while installing/removing the pumping caps and lines.¾" fittings while installing/removing the pumping caps and lines.

Hose ConnectionsHose Connections

Hose Connections

Hose ConnectionsHose Connections

The pump connections are located at the rear of the pump box and are

labelled PUMP INLET and PUMP OUTLET. These connections are bent

upward so the recirculating fluid will drain back into the reservoir when the

hoses are disconnected. The connections are capped with stainless steel

serrated plugs.

The pump lines have ¼" MPT for mating with standard plumbing fittings. For

your convenience two stainless steel adapters, ¼" FPT to 3/8" O.D. serrated

fitting, are provided. (To assure proper fit, they should be installed using 1½

turns of Teflon® tape around the threads.)

Flexible tubing, if used, should be of heavy wall or reinforced construction.

Make sure all tubing connections are securely clamped. Avoid running

tubing near radiators, hot water pipes, etc. If substantial lengths of tubing

are necessary, insulation may be required to prevent loss of cooling capacity.

Tubing and insulation are available from Thermo NESLAB. Contact our Sales

Department for more information (see Preface, After-sale Support).

It is important to keep the distance between the unit and the external system

as short as possible, and to use the largest diameter tubing practical. Tubing

should be straight and without bends. If diameter reductions must be made,

make them at the inlet and outlet of the external system, not at the unit.

If substantial lengths of cooling lines are required, they should be pre-filled

with bath fluid before connecting them to the unit. This will ensure that a

adequate amount of fluid will be in the bath once it is in operation.

PumpingPumping

Pumping

PumpingPumping

The pump is designed to deliver a flow of 15 liters/minute (4 gallons per

minute) at 0 feet head. To prevent external circulation, the PUMP INLET and

PUMP OUTLET lines are capped. The caps must be removed when external

circulation is required.

To properly secure the external hose connections to the unit, wrap teflon

tape around the pipe line threads before installation. Once the hose connections are made, the pump must be properly plumbed to an external system.

It is important the bath is not in operation until all plumbing is complete.

If the bath is not used for external circulation, make sure the stainless steel

caps are in place prior to operating the bath.

- 7 -

Page 9

Circulating to an open containerCirculating to an open container

Circulating to an open container

Circulating to an open containerCirculating to an open container

Levelling

Device

Outlet

Bath (Rear View)

Inlet

Open Container

A stainless steel leveling device is available to aid circulation to an open

vessel. Contact our Sales Department for more information (see Preface,

After-sale Support).

Support the leveling device over the open container with a ringstand. Stagger

the tubes in the leveling device so one tube is submerged in the vessel fluid,

and the other tube is level with the fluid surface. Connect the deeper tube to

the PUMP OUTLET and the shorter tube to the PUMP INLET.

Adjust the flow rate using the accessory flow control valve connected to the

PUMP OUTLET, or by partially restricting the outlet tubing. When properly

adjusted, the pump inlet will draw an occasional air bubble to prevent over

flow, and the pump outlet will force fluid through the submerged tube to

prevent aeration of the vessel.

To avoid siphoning the bath work area when the unit is shut off, lift the

leveling device out of the vessel and above the level of the unit.

Circulating through two closed loopsCirculating through two closed loops

Circulating through two closed loops

Circulating through two closed loopsCirculating through two closed loops

Pump Box

System #1

Bath

Work Area

System #2

Bath (Top View)

- 8 -

Page 10

FluidsFluids

Fluids

FluidsFluids

The pump can be used to circulate through two closed loop systems.

Connect the shortest practical length of flexible tubing from the PUMP

OUTLET to the inlet of external system #1. Connect the outlet of system #1

directly into the bath work area. Connect tubing from the bath work area to

the inlet of system #2. Connect the outlet of system #2 to the PUMP INLET.

DrainDrain

Drain

DrainDrain

Ensure the temperature of the bath fluid is safe before draining the unit.Ensure the temperature of the bath fluid is safe before draining the unit.

Ensure the temperature of the bath fluid is safe before draining the unit.

Ensure the temperature of the bath fluid is safe before draining the unit.Ensure the temperature of the bath fluid is safe before draining the unit.

The unit is equipped with a drain located at the back of the unit at the base of

the bath. The drain has ¼ inch male pipe threads and is capped with a

stainless steel plug. To drain the reservoir simply remove the cap.

To assure proper fit when replacing the cap, be sure to line the threads with

Teflon tape.

Never use flammable or corrosive fluids with this unit.Never use flammable or corrosive fluids with this unit.

Never use flammable or corrosive fluids with this unit.

Never use flammable or corrosive fluids with this unit.Never use flammable or corrosive fluids with this unit.

FillingFilling

Filling

FillingFilling

RequirementsRequirements

Requirements

RequirementsRequirements

Tap water is the recommended fluid for operation to +80°C.

Above +80°C, the user is responsible for fluids used.

Never use pure ethylene glycol as a bath fluid. A minimum 80/20Never use pure ethylene glycol as a bath fluid. A minimum 80/20

Never use pure ethylene glycol as a bath fluid. A minimum 80/20

Never use pure ethylene glycol as a bath fluid. A minimum 80/20Never use pure ethylene glycol as a bath fluid. A minimum 80/20

mixture of Ethylene Glycol and tap water is allowed.mixture of Ethylene Glycol and tap water is allowed.

mixture of Ethylene Glycol and tap water is allowed.

mixture of Ethylene Glycol and tap water is allowed.mixture of Ethylene Glycol and tap water is allowed.

The bath work area has a high and low level marker to guide filling. The

markers are 1 inch horizontal slits located in the center of the stainless steel

baffle separating the work area and the pump assembly. The correct fluid

level falls between these two markers. The heating coils will be exposed and

may become damaged if the correct fluid level is not provided.

When pumping to an external system, keep extra fluid on hand to maintain

the proper level in both the circulating lines and external system.

Never run the unit when the work area is empty. Avoid overfilling.Never run the unit when the work area is empty. Avoid overfilling.

Never run the unit when the work area is empty. Avoid overfilling.

Never run the unit when the work area is empty. Avoid overfilling.Never run the unit when the work area is empty. Avoid overfilling.

Overfilling the bath may damage the insulation and affects stability.Overfilling the bath may damage the insulation and affects stability.

Overfilling the bath may damage the insulation and affects stability.

Overfilling the bath may damage the insulation and affects stability.Overfilling the bath may damage the insulation and affects stability.

- 9 -

Page 11

Autorefill (Optional)Autorefill (Optional)

Autorefill (Optional)

Autorefill (Optional)Autorefill (Optional)

An optional autorefill device is designed to maintain the correct level of fluid

in the reservoir. The device consists of a float switch and a solenoid valve. If

the fluid level falls, the float switch will open the solenoid valve and allow

makeup fluid to fill the reservoir. Once the fluid reaches the proper level, the

float switch will rise and the solenoid valve will close.

The plumbing connection for the autorefill device, labeled WATER INLET, is

located on the rear of the autorefill assembly. The connection is 3/8 inch OD

stainless steel. Remove the nut and install the tubing from your makeup fluid

source. Reinstall the nut and tubing on to the connection.

Tubing is available from Thermo NESLAB. Contact our Sales Department for

more information (see Preface, After-sale Support).

The autorefill device requires its own source of electrical power. The connector for the line cord (provided with the assembly) is also located on the rear

of the autorefill device. The connector is labelled POWER.

Autorefill Device

- 10 -

Page 12

ControllersControllers

Controllers

ControllersControllers

AnalogAnalog

Analog

AnalogAnalog

Section IV ContrSection IV Contr

Section IV Contr

Section IV ContrSection IV Contr

Two standard temperature controllers are available with the unit: Analog and

Digital. This section explains the installation and operation of the controllers.

Start UpStart Up

Start Up

Start UpStart Up

Before starting the unit, check all electrical and plumbing connections and

make sure the work area has been properly filled with bath fluid.

To start 115V units press the I/O switch on the side of the controller to the

I I

I (power on) position. The pump will start and the POWER LED will light.

I I

220V units have a circuit breaker instead of a switch. The circuit breaker is

labeled

I I

I position.

I I

II

I (power on) and

II

olleroller

ss

oller

s

olleroller

ss

OO

O (power off). Ensure the circuit breaker is in the

OO

HEAT

POWER

SETPOINT ADJUST

Analog Controller

The HEAT LED indicates the status of the heater. As the temperature of the

fluid in the bath approaches the temperature setpoint, the lamp will cycle on

and off to indicate the approximate duty cycle of the heater.

Temperature AdjustmentTemperature Adjustment

Temperature Adjustment

Temperature AdjustmentTemperature Adjustment

Units with Analog temperature controller are equipped with a glass tube

thermometer. Insert the thermometer in the grommet located on the left side

of the work area.

FAULT

To adjust the bath temperature, turn the dial to the desired setpoint. Use the

bath thermometer to make fine adjustments to the bath temperature.

- 11 -

Page 13

DigitalDigital

Digital

DigitalDigital

Start UpStart Up

Start Up

Start UpStart Up

Before starting the unit, check all electrical and plumbing connections and

make sure the work area has been properly filled with bath fluid.

To start 115V units press the I/O switch on the side of the controller to the

I I

I (power on) position. The pump will start and the POWER LED will light.

I I

220V units have a circuit breaker instead of a switch. The circuit breaker is

labeled

I I

I position.

I I

II

I (power on) and

II

OO

O (power off). Ensure the circuit breaker is in the

OO

°C

HEAT

DISPLAY

Digital Controller

SETPOINT ADJUST

FINE

FAULT

COARSE

The HEAT LED indicates the status of the heater. As the temperature of the

fluid in the bath approaches the temperature setpoint, the lamp will cycle on

and off to indicate the approximate duty cycle of the heater.

Temperature AdjustmentTemperature Adjustment

Temperature Adjustment

Temperature AdjustmentTemperature Adjustment

To display the temperature setpoint, press the DISPLAY switch. To adjust

the setpoint, press and hold the DISPLAY switch and turn the COARSE and

FINE dials until the temperature setpoint is indicated on the LED display.

NOTE:NOTE:

NOTE: Inadvertent movement of the COARSE and FINE dials, regardless of

NOTE:NOTE:

the position of the DISPLAY switch, will result in a change of the setpoint.

The change will not be immediately reflected on the LED display unless the

DISPLAY switch is pressed. The display will eventually change as the unit

responds to the new setpoint.

- 12 -

Page 14

Tap WaterTap Water

Tap Water

Tap WaterTap Water

Cooling CoilsCooling Coils

Cooling Coils

Cooling CoilsCooling Coils

Boost HeaterBoost Heater

Boost Heater

Boost HeaterBoost Heater

The unit is equipped with a cooling coil located behind the stainless steel

baffle in the bath. The bath can be cooled and temperature stability improved

by circulating cold fluid through the coil. For best results, the fluid should be

at least 5°C below the temperature setpoint. The required fluid flow rate

depends on the type of fluid, the setpoint, and the desired stability.

The plumbing connections for the cooling coil are 3/8 inch OD stainless steel

tubes located on the rear of the unit. These connections will accept 3/8 inch or

5

/16 inch ID tubing. Tubing is available from Thermo NESLAB.

Connect the COOLING COIL IN tube to the cold fluid source. Connect the

COOLING COIL OUT tube to the cold fluid return (or drain if tap water is

being used).

EX-221 and EX-511 units are equipped with a boost heater. The boost

heater is designed to provide additional heat to the unit.

To start the heater press the BOOST HEAT switch, located on the front of

the temperature controller, to the ON position. Even though the switch

automatically returns to the OFF position, the boost heater will start to

function. (You can verify this by observing the fluid temperature rising.) The

boost heater automatically ceases operation when the setpoint is reached.

- 13 -

Page 15

High Temperature/High Temperature/

High Temperature/

High Temperature/High Temperature/

Low Liquid Level SafetyLow Liquid Level Safety

Low Liquid Level Safety

Low Liquid Level SafetyLow Liquid Level Safety

To protect your application, the adjustable High Temperature/Low Liquid

Level Safety (HIGH TEMP/LOW LEVEL) ensures the heater will not exceed

temperatures which can cause serious damage to your unit. A single temperature sensor, located on the heater coils in the bath, monitors both conditions. A High Temperature/Low Liquid Level fault occurs when the temperature of the sensor exceeds the set temperature limit.

In the event of a fault, the unit will shut down. The cause of the fault must be

identified and corrected before the unit can be restarted.

The safety on single heater systems is not preset and must be adjusted

during initial installation.

Units with a boost heater have an additional nonadjustable safety located

behind the main safety. It has a red reset button but no adjustment knob.

To set the safety, locate the HIGH TEMP/LOW LEVEL SAFETY adjustment

dial on the right side of the pump box. Turn the dial fully clockwise and press

the red RESET switch. The RESET switch is located next to the adjustment

dial. NOTE: For units without a reset switch turn the I/O switch off then back on.

Start the unit. Adjust the setpoint for a few degrees higher than the highest

desired fluid temperature and allow the bath to stabilize at the temperature

setpoint. Turn the HIGH TEMP/LOW LEVEL SAFETY dial counterclockwise

until you hear a click and the unit shuts down. The red FAULT LED on the

temperature controller will light to indicate a fault has occurred.

Cool the bath and then, without moving the adjustment dial, press the red

RESET switch or turn the I/O switch off then back on.

NOTE:NOTE:

NOTE: For units with a reset switch, the minimum high temperature safety

NOTE:NOTE:

setting is 50°C. For units without a reset switch the safety has a temperature

range of 0°C to 180°C.

High Temperature/Low Liquid Level Safety (Typical)

(Some units do not have a reset switch.)

- 14 -

Page 16

15-Pin Accessory15-Pin Accessory

15-Pin Accessory

15-Pin Accessory15-Pin Accessory

Connector (Optional)Connector (Optional)

Connector (Optional)

Connector (Optional)Connector (Optional)

Digital units are equipped with a 15 pin D-subminiature female receptacle on

the right side of the power box. An ENABLE/DISABLE switch is located just

below the receptacle. Place the switch to the ENABLE position to control the

bath via the receptacle connection. (The sensor temperature and setpoint, pin

7 and 8, can be read with the switch in either position.) The pin-out information

is listed below.

87 654 32 1

Pin #Pin #

Pin #

Pin #Pin #

FunctionFunction

Function

FunctionFunction

1 Chassis ground.

15 14 13 12 11 10 9

15 pin D-subminiature female receptacle

2 No connection.

3 Span +. Indicates the maximum setpoint value the unit can be set

to operate. The temperature scale is 10mV/°C, referenced to

analog ground, pin 6 (example: +350mV = +35.0°C).

4 Span -. Indicates the minimum setpoint value the unit can be set

to operate. The temperature scale is 10mV/°C, referenced to

analog ground, pin 6 (example: +50mV = +5.0°C).

5 No connection.

6 Analog ground. The analog ground is physically separated from

the power ground throughout the unit. To prevent offsets that

result from ground currents, the analog and power grounds are

only connected at the unit's power supply. Analog ground should

only be used as a reference pin.

7 Sensor temperature (current limited through 2.7K OHM resistor).

The fluid temperature, as measured by the controller’s sensor

located in the reservoir, can be read at this pin. The temperature

scale is 10mV/°C, referenced to analog ground, pin 6 (example:

+150mV = +15.0°C).

8 Setpoint out. The present temperature setpoint can be read at

this pin. The temperature scale is 10mV/°C, referenced to analog

ground, pin 6 (example: +150mV = +15.0°C).

9 Power Ground.

10 No connection.

11 No connection.

12 Digital display (input only). An external voltage can be displayed

on the operator panel digital display by applying the voltage to this

pin. The display has a low input resistance and a full scale rating

of ±1.99VDC. Input is referenced to analog ground, pin 6. The

maximum voltage applied to the display should be limited to

±2VDC.

13 - 5V. Power supply of -5VDC (15mA maximum).

14 +5V. Power supply of +5VDC (50mA maximum).

15 Setpoint in. The temperature setpoint can be controlled by

applying a known voltage to this pin. The temperature scale is

10mV/°C, referenced to analog ground, pin 6

(example: +230mV = +23.0°C).

NOTE: With the switch in the ENABLE position and no input to pin 15, the bath will slowly go to

the setpoint value set on the digital controller.

- 15 -

Page 17

Service ContractsService Contracts

Service Contracts

Service ContractsService Contracts

Reservoir CleaningReservoir Cleaning

Reservoir Cleaning

Reservoir CleaningReservoir Cleaning

Section Section

Section

Section Section

To avoid electrical shock, disconnect the mains cord prior to removingTo avoid electrical shock, disconnect the mains cord prior to removing

To avoid electrical shock, disconnect the mains cord prior to removing

To avoid electrical shock, disconnect the mains cord prior to removingTo avoid electrical shock, disconnect the mains cord prior to removing

any access panels or covers.any access panels or covers.

any access panels or covers.

any access panels or covers.any access panels or covers.

Thermo NESLAB offers on-site Service Contracts that are designed to

provide extended life and minimal down-time for your unit. For more information, contact our Service Department (see Preface, After-sale Support).

Routine cleaning can be achieved by simply sponging down the seamless

stainless steel tank with tap water. (Dish washing detergent may be used but

the tank must be thoroughly rinsed.)

To gain access to the entire reservoir the pump box and reservoir cover

should be removed.

Remove the line cord from the rear of the unit.

Remove the four screws securing the reservoir's cover.

V MaintenanceV Maintenance

V Maintenance

V MaintenanceV Maintenance

AlgaeAlgae

Algae

AlgaeAlgae

Carefully raise the controller and cover assembly to remove it from unit.

Place the cover on its side.

To restrict the growth of algae in the bath, we recommend the bath cover be

kept in place and that all circulation lines be opaque. This will eliminate the

entrance of light required for the growth of most common algae.

Thermo NESLAB also recommends the use of Chloramine-T, 1 gram per

3.8 liters.

- 16 -

Page 18

ChecklistChecklist

Checklist

ChecklistChecklist

Section Section

Section

Section Section

Unit will not startUnit will not start

Unit will not start

Unit will not startUnit will not start

Make sure the voltage of the power source meets the specified voltage,

±10%. Refer to the serial number label on the rear of the unit to identify the

specific electrical requirements of your unit.

Check the High Temperature/Low Liquid Level Safety. If the FAULT light is

on, make sure the fluid level in the bath is between the marks in the baffle

and the HIGH TEMP/LOW LEVEL SAFETY setting is greater than the fluid

temperature. Push the RESET switch(es) or, for units without a reset

switch, turn the I/O switch off then back on and attempt to restart.

No external circulationNo external circulation

No external circulation

No external circulationNo external circulation

Make sure the stainless steel plugs on the PUMP INLET and PUMP

OUTLET have been removed.

Check for obstructions, kinks, or leaks in the circulation tubing.

VI VI

VI

VI VI

TT

T

TT

rr

ouboub

r

oub

rr

ouboub

leshootingleshooting

leshooting

leshootingleshooting

Service Assistance andService Assistance and

Service Assistance and

Service Assistance andService Assistance and

Technical SupportTechnical Support

Technical Support

Technical SupportTechnical Support

Circulation will cease when the pump head has been exceeded.

If, after following these troubleshooting steps, your unit fails to operate

properly, contact our Customer Service Department for assistance (see

Preface, After-sale Support). Before calling, please obtain the following

information:

Part number

Serial number

Voltage of unit

Voltage of power source

Our Service Department can provide you with a wiring diagram and a

complete list of spare parts for your unit. Before calling, please obtain the

following information:

Part number

Serial number

- 17 -

Page 19

NEScom SoftwareNEScom Software

NEScom Software

NEScom SoftwareNEScom Software

Section Section

Section

Section Section

The Thermo NESLAB Communications Software is a user friendly software

that allows you to automate your temperature control process. The software

includes a 3½" disk, Comprehensive Operator’s Manual and a toll-free

number to a trained technical staff.

NEScom Software allows you to write custom temperature programs for our

Digital or Microprocessor based temperature control apparatus. Choose

upper or lower temperature limits and monitor system status with an alarm.

NEScom can also record your results on a user selectable graph. NesCom

must be used with an IBM or 100% compatible computer.

Select from easy to use product icons.

Create graphs and charts.

Easily configure ramping functions which set the setpoint over time.

View pop-up alarm windows which display if an alarm condition occurred.

VII PrVII Pr

VII Pr

VII PrVII Pr

ogramming Softwareogramming Software

ogramming Software

ogramming Softwareogramming Software

Select software functions from the easy to use pulldown menus.

View a virtual controller screen which allows

remote monitoring and operation of product

control panel.

- 18 -

Page 20

AppendixAppendix

Appendix

AppendixAppendix

International QuicInternational Quic

International Quic

International QuicInternational Quic

EX - Serie KEX - Serie K

EX - Serie K

EX - Serie KEX - Serie K

Installation

Stellen Sie das Gerät auf einen stabilen Tisch

oder Labortisch. Die Umgebungstemperatur sollte

zwischen +10 °C und +27 °C liegen.

Vergewissern Sie sich, daß die Spannung Ihrer

Stromanschlüsse mit der für das Gerät

vorgesehenen Spannung übereinstimmt (+ 10%).

Die Schlauchanschlüsse (1/4 Zoll MPT) des

Gerätes befinden sich an der Rückseite und sind

mit PUMP INLET und PUMP OUTLET

bezeichnet. Entfernen Sie die Kappen, falls

externe Zirkulation gewünscht wird. Schließen Sie

den PUMP OUTLET-Anschluß an den Eingang

Ihres Instruments und den PUMP INLET-Anschluß

an den Ausgang Ihres Instruments an.

Füllen Sie das Reservoir bis zu einem Stand, der

zwischen den horizontalen Markierungen liegt, die

auf dem Blech markiert sind, das den

Arbeitsbereich von der Pumpeneinheit trennt.

urzbedienurzbedien

urzbedien

urzbedienurzbedien

k Refk Ref

k Ref

k Refk Ref

erence Guideserence Guides

erence Guides

erence Guideserence Guides

ungsanleitungungsanleitung

ungsanleitung

ungsanleitungungsanleitung

Geräte, die bei 220 Volt betrieben werden,

verfügen über einen Stromkreisunterbrecher auf

der Rückseite des Gerätes. Vergewissern Sie sich,

daß dieser auf ON gestellt ist. Um das Gerät

einzuschalten, müssen Sie den I/O-Schalter auf „I“

stellen. Die Power-Lampe leuchtet auf, wenn das

Gerät in Betrieb ist. Um das Gerät abzuschalten,

muß der I/O-Schalter auf „O“ gestellt werden.

Die HEAT-LED-Anzeige zeigt den Status des

Heizelements an. Sie leuchtet auf, wenn das

Heizelement arbeitet. Wenn die Arbeitstemperatur

den gewünschten Setpoint erreicht, blinkt die

LED-Anzeige, um den ungefähren

Arbeitsrhythmus des Heizelements anzuzeigen.

Einstellung der Analog-Temperatursteuerung

Um die Temperatur einzustellen (setpoint), drehen

Sie den SETPOINT ADJUST-Schalter an der

Vorderseite des Gerätes auf die gewünschte

Temperatur.

Verwenden Sie niemals entflammbare oder

Korrosion verursachende Flüssigkeiten. Für den

Betrieb im Arbeits-Temperaturbereich bis +80°C

empfiehlt Thermo NESLAB Leitungswasser.

Oberhalb +80 °C ist der Anwender selbst für die

verwendeten Flüssigkeiten verantwortlich. Über

+115 °C dürfen Sie niemals pures Ethylenglykol

als Badflüssigkeit verwenden.

Wenn sie zu einem externen System zirkulieren,

sollten Sie zusätzliche Kühlflüssigkeit zur Hand

haben, um den Kühlflüssigkeitsstand in den

Zirkulationsleitungen und dem externen System

beibehalten zu können.

Betreiben Sie das Gerät niemals mit leerem

Arbeitsbereich!

Inbetriebnahme

Vor Inbetriebnahme des Gerätes vergewissern Sie

sich bitte, daß die elektrischen Anschlüsse und die

Rohr- u. Schlauchanschlüsse sachgemäß

installiert sind und daß das gesamte System mit

Kühlflüssigkeit gefüllt ist.

Einstellung der Digital-Temperatursteuerung

Um sich den Temperatur-Setpoint anzeigen zu

lassen, drücken Sie den DISPLAY-Schalter und

halten Sie ihn gedrückt. Um den TemperaturSetpoint einzustellen, drücken Sie den DisplaySchalter, halten diesen, und drehen gleichzeitig

den SETPOINT ADJUST-Schalter so lange, bis

die gewünschte Temperatur in der Digitalanzeige

angezeigt wird. Wenn die Temperatur eingestellt

ist, lassen Sie den Display-Schalter los. Die

Digitalanzeige zeigt dann die Temperatur der

Kühlflüssigkeit im Reservoir an.

Wartung

Überprüfen Sie das Reservoir regelmäßig. Sollte

eine Säuberung notwendig sein, spülen Sie das

Reservoir mit einer speziellen

Reinigungsflüssigkeit, die mit dem Umlaufsystem

und der Zirkulationsflüssigkeit kompatibel ist.

Für umfassende Informationen einschließlich

Fehlerbeseitigungsmöglichkeiten schlagen Sie

bitte in der Betriebsanleitung nach oder wenden

Sie sich an unsere Service-Abteilung: 069/50 91

90 32.

- 19 -

Page 21

EX Serie Kvik ReferanceEX Serie Kvik Referance

EX Serie Kvik Referance

EX Serie Kvik ReferanceEX Serie Kvik Referance

Installation:

Operationstemperatur ved 100% udnyttelse er fra

stuetemperatur til+750 C under forudsætning af, at

netspændingen er den nominelle 240V +/- 10%.

Tilslutning af slanger er på bagsiden mærket

„PUMP INLET“ (ind) and „PUMP OUTLET“ (ud).

Tilslutningerne er 1/4" MPT-gevind.

Fyld resovoiret til mærket placeret på bafflen

mellem arbejdsområdet og pumpeenheden.

Anvend aldrig brandbare væsker, rent ionbyttet

eller dobbeltdestilleret vand kan anvendes op til

+800 C, over denne temperatur anbefales

specialvæsker.

Sørg altid for at den rette mængde væske er til

stede i termostatkarret, og husk at kompensere for

den væske, der medgår til ekstern cirkulation.

Betjening:

Før opstart checkes elektriske forbindelser,

slangeforbindelser og kølevæske stand.

Check hovedkontakten på bagsiden af badet, og

sørg for at den er tændt. Når badet skal startes

trykkes I/O kontakten på siden i I position, og

strømindikatoren tænder. Skal

badet slukkes, trykkes I/O kontakten i O stilling, og

indikatoren slukker.

Analog temperatur kontrol:

Drej 0C tasten til den ønskede temperatur og lad

systemet stabiliserer sig.

Digital temperatur kontrol:

Tryk på „DISPLAY“ tasten for at se den indstillede

temperatur. Indstilling af ny temperatur, tryk på

„DISPLAY“ og drej på „ADJUST“ indtil den rigtige

temperatur vises, slip derefter „DISPLAY“ tasten.

Skærmen vil nu vise den aktuelle temperatur i

badet.

Periodisk vedligeholdelse:

Check standen af kølevæske periodisk. Før skift af

væske indstilles temperaturen på „de-ice“. Check

med mellemrum vakuummet på pumpesiden, rens

systemet og check for aflejringer, vækst,

utætheder og evt. filtre. Husk åben aldrig

instrumentet uden strømmen er afbrudt, og

strømkablet er taget ud!

Dioden på frontpanelet angiver status på badet,

der lyser ved opvarmning og

slukker, når den indstillede temperatur er nået.

- 20 -

Page 22

EX Series,EX Series,

EX Series,

EX Series,EX Series,

Handleiding v Handleiding v

Handleiding v

Handleiding v Handleiding v

oor snelle installatieproor snelle installatiepr

oor snelle installatiepr

oor snelle installatieproor snelle installatiepr

oceduresocedures

ocedures

oceduresocedures

Installatie

Plaats het apparaat op een tafel of werkbank.

Omgevingstemperaturen moeten liggen tussen de

+10°C en +27°C.

Let erop dat de netspanning gelijk is aan het

aangegeven voltage, +/- 10%.

De slangaansluitingen zijn bevestigd aan de

achterkant van het apparaat en zijn voorzien van

de labels PUMP INLET en PUMP OUTLET. Deze

aansluitingen zijn 1/4 inch MPT. Verwijder de

pluggen indien externe circulatie gewenst is.

Bevestig de PUMP OUTLET aan de ingang van

uw applicatie. Bevestig de PUMP INLET aan de

uitgang van uw applicatie.

Vul nu het reservoir tot het niveau tussen de

horizontale strepen op de roestvrij stalen

scheidingsplaat, die de werkruimte van het

pompgedeelte scheidt.

Gebruik nooit brandbare of andere

koelvloeistoffen, die het toestel kunnen aantasten.

Kraanwater wordt in het algemeen aanbevolen

wanneer u bij temperaturen werkt van +8°C tot

+80°C. Boven de + 80C. zal de gebruiker

verantwoordelijk zijn voor de benodigde

vloeistoffen. Indien men boven de 115°C. werkt,

gelieve nooit puur ethylene glycol als badvloeistof

te gebruiken.

Wanneer u wilt pompen naar een extern systeem,

dient u altijd extra vloeistof achter de hand te

houden om met juiste vloeistofniveau’s zowel in

het interne als het externe gedeelte van het

systeem, te handhaven.

Gebruik het apparaat nooit wanneer het reservoir

leeg is.

Operationeel gebruik

Alvorens het apparaat in gebruik te nemen, dient

u eerst alle elektrische- en slangaansluitingen te

controleren. Tevens dient u te controleren of het

systeem gevuld is met vloeistof.

220 Volt apparaten hebben een z.g. “circuit

breaker” aan de achterkant van het apparaat.

Controleer of deze in werking is gesteld. Om het

apparaat te starten, gelieve de I/O knop aan de

zijkant van het apparaat te draaien naar de I

positie. Het lampje zal oplichten als indicatie dat

het systeem in werking is gesteld. Om het

apparaat uit te zetten, gelieve de I/O knop naar de

O positie te draaien.

Het “HEAT LED” duidt de actuele status van het

verwarmings-element aan. Het zal oplichten

indien het verwarmingselement in werking is

gesteld. Als de ingestelde temperatuur de setpoint heeft bereikt, zal de LED aan en uit gaan om

het proces van de heater aan te duiden.

Analog Controller Temperature Adjustment

Om de temperatuur set-point aan te passen, draai

de SETPOINT ADJUST knop aan de voorkant

van het apparaat naar de gewenste temperatuur.

Digital Controller Temperature Adjustment

Om de temperatuur set-point af te kunnen lezen,

houdt u de DISPLAY knop ingedrukt. Om de

temperatuur set-point aan te passen, houdt u de

DISPLAY knop ingedrukt en draait u de set-point

set point knop, totdat de gewenste temperatuur

set-point af te lezen is van de display. Als de setpoint is aangepast, kunt u de DISPLAY knop weer

loslaten. De display zal nu de temperatuur

weergeven van de vloeistof in het reservoir.

Periodiek Onderhoud

Het reservoir dient regelmatig gecontroleerd te

worden. Indien reiniging noodzakelijk is, zal het

reservoir schoongespoeld moeten worden met

een vloeistof, welke verenigbaar is met het

systeem en de koelvloeistof.

Indien u meer informatie wenst, inclusief

procedures in geval van problemen, kunt u de

handleiding raadplegen of contact opnemen met

de Thermo NESLAB service-afdeling: (+31) - 40 -

300066.

- 21 -

Page 23

Kortfattad Bruksanvisning för EX SerieKortfattad Bruksanvisning för EX Serie

Kortfattad Bruksanvisning för EX Serie

Kortfattad Bruksanvisning för EX SerieKortfattad Bruksanvisning för EX Serie

Installation

Ställ maskinen på ett stadigt bord eller en bänk.

Temperaturen i rummet bör vara mellan +50°F

(10°C) och +80°F (27°C).

Försäkra att spänningen är den samma som den

som är given i instruktionerna ± 10%.

Röranslutning finns på baksidan av maskinen och

har följande beskrivning: SUPPLY och RETURN.

Anslutningarna är 1/4 inch MPT. Ta bort de

skyddande plast bitarna från röranslutningarna.

Anslut SUPPLY kopplingen till intaget av din

anordning och RETURN kopplingen till uttaget.

Lösgör skruvarna och ta bort luckan för att fylla

tanken. Ta bort tank locket och fyll tanken med ren

kylnings vätska.

Använd aldrig eldfarliga eller frätande vätskor.

Kran vatten rekommenderas upp till +80°C. Över

+80°C är användaren ansvarig för vilken vätska

som används. Använd aldrig ren etylen glykol som

vätska över 115°C.

För att ändra den önskade förbestämda

temperaturen, vrid °C knappen på framsidan av

maskinen tills den önskade temperaturen är nådd.

Digital Kontroll, Temperatur Ändring

Håll Display knappen intryckt för att visa den

önskade temperaturen. Håll Display knappen

intryckt och vrid Adjust knappen för att ändra den

önskade temperaturen. Släpp Display knappen

efter att den önskade temperaturen visas på

kontroll panelen. Temperaturen på vätskan i

tanken visas nu på kontroll panelen.

Periodiskt Underhåll

Inspektera vätskan i tanken periodvis. Om det är

nödvändigt med rengöring, spola tanken med en

vätska som är förenlig med cirkulations sytemet

och med kylvätskan.

Ha extra vätska redo om din anordning kräver det

så att den rätta nivån behålls i cirkulations sytemet.

Användning

Kontrollera alla elektriska och alla rör anslutningar

innan maskinen startas. Se till att cirkulations

systemen har fyllts med vätska.

220V maskiner har en ström brytare på baksidan

av maskinen. För att starta maskinen, sätt I/O

knappen på sidan av maskinen på I. Lampan lyser

för att visa att maskinen är på. Sätt knappen på O

för att stänga av den.

Analog Kontroll, Temperatur Ändring

- 22 -

Page 24

NOTICE D’UTILISATION

BAINS EX

INSTALLATION

Placer l’appareil sur une table ou une paillasse

suffisamment robuste. La température de la pièce

doit être comprise entre 10 et 25°C.

S’assurer que l’alimentation électrique soit celle

requise à ±10%.

Les connections sont situées à l’arrière de

l’appareil et sont étiquetées “ PUMP INLET ” et

“ PUMP OUTLET ”. Ces connections sont en inox

d’un diamètre 3/8eme de pouce. Retirer les

embouts en inox si vous souhaitez recirculer.

Enficher le connecteur “ PUMP OUTLET ” à

l’entrée de votre équipement et le connecteur

“ PUMP INLET ” à la sortie.

Remplir le réservoir à un niveau compris entre les

deux graduations “ maxi ” et “ mini ”.

Ne pas utiliser de liquide inflammable, corrosif, ou

dont la viscosité serait inférieure à 50 centistokes

aux températures les plus basses. Pour un

fonctionnement jusqu’à 80°C, l’eau du robinet est

la plus indiquée. En phase d’amorçage (au début

de la recirculation), rajouter rapidement du liquide.

Ne jamais l’utiliser sans liquide ou en dessous du

niveau minimum.

REGLAGE DU CONTROLEUR DE TEMPERATURE ANALOGIQUE

Tourner le potentiomètre situé à l’avant jusqu’à ce

que la température désirée coïncide avec la

graduation.

REGLAGE DU CONTROLEUR DE TEMPERATURE NUMERIQUE

Pour afficher la température souhaitée, maintenir

appuyé l’interrupteur et tourner le bouton de

réglage jusqu’à ce que la température souhaitée

soit affichée. Relâcher ensuite l’interrupteur.

L’affichage indique alors la température du fluide

dans le réservoir.

MAINTENANCE PREVENTIVE

Vérifier régulièrement le fluide dans le réservoir,

Changer de temps à autre le liquide utilisé,

En cas de nettoyage, rincer avec un produit de

lavage compatible,

Ces bains sont équipés d’un robinet de vidange

situé à l’arrière.

MISE EN ROUTE

Vérifier les connections électriques, les tuyaux

d’eau ainsi que le niveau de remplissage.

Les modèles en 220V ont un interrupteur général à

l’arrière. Vérifier qu’il est sur “ on ”, placer

l’interrupteur sur la position 1. La pompe, ainsi que

le système de réfrigération se mettent en route. Le

controleur de température numérique indique la

température dans le bain. Pour éteindre, mettre

l’interrupteur sur la position 0.

Le témoin lumineux “ heat ” indique que le bain

fonctionne en mode “ chauffage ”. Quand la

température approche de celle souhaitée, la diode

s’éteint et s’allume.

- 23 -

Page 25

PRPR

OCEDIMIENTOCEDIMIENT

PR

OCEDIMIENT

PRPR

OCEDIMIENTOCEDIMIENT

INSTALACIONINSTALACION

INSTALACION

INSTALACIONINSTALACION

Sitúe la unidad sobre una mesa resistente o sobre

un banco de trabajo. Las temperaturas ambientes

deben estar dentro del rango de + 50 ºF a + 80 ºF.

Asegúrese de que el voltaje de la fuente de

energía sea igual que el voltaje especificado, +/10%.

OS DE OPERAOS DE OPERA

OS DE OPERA

OS DE OPERAOS DE OPERA

PP

ARA LA SERIE EXARA LA SERIE EX

P

ARA LA SERIE EX

PP

ARA LA SERIE EXARA LA SERIE EX

CION DE REFERENCIA RAPIDCION DE REFERENCIA RAPID

CION DE REFERENCIA RAPID

CION DE REFERENCIA RAPIDCION DE REFERENCIA RAPID

El LED HEAT indica la situación del sistema del

calentador. Se ilumina para indicar que el

calentador está funcionando. A medida que la

temperatura de funcionamiento se aproxima al

punto fijado, el LED ciclará para indicar el ciclo de

trabajo del calentador.

AA

A

AA

Las conexiones de tuberías están situadas en la

parte trasera de la unidad y están marcadas como

PUMP INLET y PUMP OUTLET. Estas conexiones

son 1/4" MPT. Saque las tapas cuando requiera

circulación externa. Conecte el adaptador PUMP

OUTLET a la entrada de su aplicación. Conecte el

adaptador PUMP INLET a la salida de su

aplicación.

Llene el reservorio a un nivel entre los marcadores

horizontales situados en la puerta de acero

inoxidable que separa la zona de trabajo de la

bomba.

No utilice nunca fluidos inflamables o corrosivos.

Se recomienda utilizar agua corriente para operar

a +80 ºC. Por encima de +80 ºC, el usuario es

responsable de los fluidos que utilice. Por encima

de 115 ºC no utilice nunca etileno glicol puro como

fluido de baño.

Cuando bombee a un sistema externo, tenga

fluido extra a mano para mantener el nivel

apropiado tanto en las lineas circulantes como en

el sistema externo.

Nunca haga funcionar el instrumento con el área

de trabajo vacía.

OPERACIONOPERACION

OPERACION

OPERACIONOPERACION

Antes de poner en marcha la unidad, compruebe

todas las conexiones eléctricas y de tuberías.

Asegúrese de que el sistema circulador se ha

llenado con fluido.

Las unidades de 220 V. tienen un cortador de

circuito en la parte trasera de la unidad. Asegúrese

de que está en posición ON. Para poner en

marcha la unidad, ponga el interruptor I/O situado

en el lateral de la unidad en posición I. La lámpara

Power se iluminará para indicar que el sistema

está funcionando. Para apagarlo, ponga el

interruptor de encendido en posición O.

AJUSTE DE LA TEMPERATURA CON ELAJUSTE DE LA TEMPERATURA CON EL

AJUSTE DE LA TEMPERATURA CON EL

AJUSTE DE LA TEMPERATURA CON ELAJUSTE DE LA TEMPERATURA CON EL

CONTROLADOR ANALOGICOCONTROLADOR ANALOGICO

CONTROLADOR ANALOGICO

CONTROLADOR ANALOGICOCONTROLADOR ANALOGICO

Para fijar el punto de ajuste de la temperatura, gire

el dial SETPOINT ADJUST situado en el frontal de

la unidad hasta la temperatura deseada.

AJUSTE DE LA TEMPERATURA CON ELAJUSTE DE LA TEMPERATURA CON EL

AJUSTE DE LA TEMPERATURA CON EL

AJUSTE DE LA TEMPERATURA CON ELAJUSTE DE LA TEMPERATURA CON EL

CONTROLADOR DIGITALCONTROLADOR DIGITAL

CONTROLADOR DIGITAL

CONTROLADOR DIGITALCONTROLADOR DIGITAL

Para que el punto de ajuste de temperatura

aparezca en pantalla, mantenga presionado el

interruptor DISPLAY. Para fijar el punto de ajuste

de temperatura, mantenga presionado el

interruptor DISPLAY y gire los botones SETPOINT

ADJUST hasta que la pantalla digital indique el

punto de ajuste de temperatura deseado. Una vez

fijado el punto de ajuste, suelte el interruptor

DISPLAY. La pantalla indicará la temperatura del

fluido en el reservorio.

MANTENIMIENTO PERIODICOMANTENIMIENTO PERIODICO

MANTENIMIENTO PERIODICO

MANTENIMIENTO PERIODICOMANTENIMIENTO PERIODICO

Inspeccione periódicamente el fluido del

reservorio. Si es necesaria una limpieza, rocíe el

reservorio con un fluido de limpieza compatible

con el sistema de circulación y el fluido

recirculante.

Para una información completa, incluyendo

solución de problemas, refiérase al manual de

instrucciones o contacte con el Departamento de

Servicio al Cliente en el teléfono 1-800-258-0830.

Page 26

WARRANTY

Thermo NESLAB Instruments, Inc. warrants for 12 months from date of shipment any Thermo NESLAB unit

according to the following terms.

Any part of the unit manufactured or supplied by Thermo NESLAB and found in the reasonable judgment of

Thermo NESLAB to be defective in material or workmanship will be repaired at an authorized Thermo

NESLAB Repair Depot without charge for parts or labor. The unit, including any defective part must be

returned to an authorized Thermo NESLAB Repair Depot within the warranty period. The expense of returning the unit to the authorized Thermo NESLAB Repair Depot for warranty service will be paid for by the

buyer. Thermo NESLAB’s responsibility in respect to warranty claims is limited to performing the required

repairs or replacements, and no claim of breach of warranty shall be cause for cancellation or recision of the

contract of sales of any unit.With respect to units that qualify for field service repairs, Thermo NESLAB’s

responsibility is limited to the component parts necessary for the repair and the labor that is required on site

to perform the repair. Any travel labor or mileage charges are the financial responsibility of the buyer.

The buyer shall be responsible for any evaluation or warranty service call (including labor charges) if no

defects are found with the Thermo NESLAB product.

This warranty does not cover any unit that has been subject to misuse, neglect, or accident. This warranty

does not apply to any damage to the unit that is the result of improper installation or maintenance, or to any

unit that has been operated or maintained in any way contrary to the operating or maintenance instructions

specified in Thermo NESLAB’s Instruction and Operation Manual. This warranty does not cover any unit that

has been altered or modified so as to change its intended use.

In addition, this warranty does not extend to repairs made by the use of parts, accessories, or fluids which are

either incompatible with the unit or adversely affect its operation, performance, or durability.

Thermo NESLAB reserves the right to change or improve the design of any unit without assuming any

obligation to modify any unit previously manufactured.

THE FOREGOING EXPRESS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING BUT NOT LIMITED TO WARRANTIES OR MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE.

Thermo NESLAB’S OBLIGATION UNDER THIS WARRANTY IS STRICTLY AND EXCLUSIVELY LIMITED

TO THE REPAIR OR REPLACEMENT OF DEFECTIVE COMPONENT PARTS AND Thermo NESLAB

DOES NOT ASSUME OR AUTHORIZE ANYONE TO ASSUME FOR IT ANY OTHER OBLIGATION.

Thermo NESLAB ASSUMES NO RESPONSIBILITY FOR INCIDENTAL, CONSEQUENTIAL, OR OTHER

DAMAGES INCLUDING, BUT NOT LIMITED TO LOSS OR DAMAGE TO PROPERTY, LOSS OF PROFITS

OR REVENUE, LOSS OF THE UNIT, LOSS OF TIME, OR INCONVENIENCE.

This warranty applies to units sold in the United States. Any units sold elsewhere are warranted by the affiliated

marketing company of Thermo NESLAB Instruments, Inc. This warranty and all matters arising pursuant to it shall

be governed by the law of the State of New Hampshire, United States. All legal actions brought in relation hereto

shall be filed in the appropriate state or federal courts in New Hampshire, unless waived by Thermo NESLAB.

Loading...

Loading...