Page 1

DCT6088

Dedicated Transit Time Flowmeter

User Guide

P/N 1-0561-006

Revision J

Part of Thermo Fisher Scientific

Page 2

Page 3

DCT6088

Dedicated Transit Time Flowmeter

User Guide

P/N 1-0561-006

Revision J

Page 4

Page 5

©2017 Thermo Fisher Scientific Inc. All rights reserved.

“Microsoft”, “Windows”, and “Excel” are either registered trademarks or trademarks of Microsoft Corporation in

the United States and/or other countries.

“Dow Corning” is a registered trademark of Dow Corning Corporation.

“Krautkramer” is a registered trademark owned by GE Inspection Technologies, Llc, Krautkramer Inc..

“Sil-Glyde” is a registered trademark of American Grease Stick Company.

All other trademarks are the property of Thermo Fisher Scientific Inc. and its subsidiaries.

Thermo Fisher Scientific Inc. (Thermo Fisher) makes every effort to ensure the accuracy and completeness of this

manual. However, we cannot be responsible for errors, omissions, or any loss of data as the result of errors or

omissions. Thermo Fisher reserves the right to make changes to the manual or improvements to the product at

any time without notice.

The material in this manual is proprietary and cannot be reproduced in any form without expressed written

consent from Thermo Fisher.

Page 6

This page intentionally left blank.

Page 7

Revision History

Revision Level Date Comments

B 05-2003 Revised per ECO 3912.

C 03-2005 Revised per ECO 4760.

D 02-2006 Revised per ECO 5077.

E 05-2007 Revised per ECO 5601.

F 06-2007 Revised per ECO 5739.

G 11-2007 Revised per ECO 6016.

H 06-2011 Revised per ECO 7752.

J Revised per ECO 9242.

07-2017

Thermo Fisher Scientific DCT6088 User Guide v

Page 8

This page intentionally left blank.

Page 9

Contents

Safety Information & Guidelines ..................................................................... xi

Safety Considerations.............................................................................xi

Warnings, Cautions, & Notes...............................................................xii

Chapter 1

Chapter 2

Product Overview ............................................................................................. 1-1

Introduction........................................................................................ 1-1

Theory of Operation ........................................................................... 1-1

Transit Time Accuracy........................................................................ 1-2

Ordering Information ......................................................................... 1-3

Specifications ...................................................................................... 1-4

External Features................................................................................. 1-5

System Installation...........................................................................................2-1

Enclosure Mounting ........................................................................... 2-1

Direct Mount Method ..................................................................... 2-1

Mounting Ears Method.................................................................... 2-1

Transducer Installation ....................................................................... 2-2

Site Selection & Preparation ............................................................ 2-2

Spacing & Mounting the Transducers................................................. 2-4

Transducer Mounting Methods .......................................................... 2-7

V Method ........................................................................................ 2-7

W Method ....................................................................................... 2-7

Z Method ........................................................................................ 2-8

WV and WW Methods.................................................................. 2-12

Small Pipe Applications..................................................................... 2-13

Chapter 3

Thermo Fisher Scientific DCT6088 User Guide vii

Wiring.................................................................................................................. 3-1

Cable Routing..................................................................................... 3-1

Power Connections ............................................................................. 3-2

120 Vac Operation........................................................................... 3-3

Single Phase 240 Vac Operation ...................................................... 3-3

Double Phase 240 Vac Operation .................................................... 3-3

12 to 24 Vdc Operation................................................................... 3-3

The Current Loop............................................................................... 3-4

Relay Terminals .................................................................................. 3-5

Communications Terminal Block ....................................................... 3-6

Transducer Wiring.............................................................................. 3-6

Page 10

Contents

Chapter 4

Operating & Configuring the Flowmeter ......................................................4-1

The Keypad & Display ....................................................................... 4-1

Adjusting the Contrast ..................................................................... 4-1

Flowmeter Configuration.................................................................... 4-2

Direct Menu Access ......................................................................... 4-2

Using the Arrow Keys to Access Menus............................................ 4-5

Quick Setup Configuration................................................................. 4-6

Chapter 5 Primary Displays & Menus..............................................................................5-1

Primary Displays ................................................................................. 5-1

Flow/Net Totalizer........................................................................... 5-1

Flow/Velocity................................................................................... 5-1

Flow/Positive Totalizer..................................................................... 5-1

Flow/Negative Totalizer................................................................... 5-2

Signal Strength/Low Signal Cutoff................................................... 5-2

The Pipe Menu ................................................................................... 5-2

The Liner Menu.................................................................................. 5-3

The Fluid Menu.................................................................................. 5-4

The Flow Menu .................................................................................. 5-5

The Total Menu ................................................................................. 5-7

Options Menu .................................................................................... 5-9

The Calibration Menu ...................................................................... 5-13

Zero Set Calibration....................................................................... 5-13

Scale Factor Calibration ................................................................. 5-16

Sound Speed Compensation .......................................................... 5-17

Date and Time............................................................................... 5-17

The 4 –20 mA Menu ........................................................................ 5-18

The Relays Menus............................................................................. 5-20

Programming ................................................................................. 5-20

Viewing Relays............................................................................... 5-24

Testing Relays ................................................................................ 5-24

The Data Log Menu ......................................................................... 5-25

The Diagnostics Menu...................................................................... 5-26

Chapter 6

Chapter 7

viii DCT6088 User Guide Thermo Fisher Scientific

Emergency Override & Master Erase............................................................6-1

Emergency Overrides .......................................................................... 6-1

Performing a Master Erase .................................................................. 6-1

Maintenance & Troubleshooting ...................................................................7-1

Replacing the Fuse .............................................................................. 7-1

Replacing the Current Loop Module................................................... 7-2

Replacing Sonic Coupling Compound................................................ 7-3

Software Upgrades .............................................................................. 7-4

General Troubleshooting .................................................................... 7-4

Contact Information ........................................................................... 7-5

Page 11

Contents

Warranty............................................................................................. 7-6

Chapter 8 Hazardous Area Installation........................................................................... 8-1

General ............................................................................................... 8-1

North American Certification ............................................................. 8-1

European Certification........................................................................ 8-4

North American Hazardous Area Installation Definitions ................... 8-6

European Hazardous Area Installation Definitions.............................. 8-7

European Safety Requirements ........................................................... 8-7

Appendix A

Appendix B

Appendix C

Appendix D

Pipe Schedules................................................................................................. A-1

Fluid Properties................................................................................................ B-1

Fluid Sound Speeds & Kinematic Viscosities ......................................B-1

Clean Water Sound Speed Versus Temperature ................................ B-15

Relationship Between Specific Gravity, Viscosity, & Sound Velocity

for Petroleum Products ...................................................................B-16

Monitoring & Downloading Data Logs Using D-Link ................................C-1

Purpose .............................................................................................. C-1

Installing D-Link ............................................................................... C-1

Establishing Communications with a Flowmeter................................ C-1

Monitoring Data Logs........................................................................ C-2

Saving & Loading Data Logs ............................................................. C-3

Toxic & Hazardous Substances Tables....................................................... D-1

Thermo Fisher Scientific DCT6088 User Guide ix

Page 12

This page intentionally left blank.

Page 13

Safety Information & Guidelines

This section contains information that must be read and understood by all

persons installing, using, or maintaining this equipment.

Safety

Considerations

Failure to follow appropriate safety procedures or inappropriate use of the

equipment described in this manual can lead to equipment damage or

injury to personnel.

Any person working with or on the equipment described in this manual is

required to evaluate all functions and operations for potential safety hazards

before commencing work. Appropriate precautions must be taken as

necessary to prevent potential damage to equipment or injury to personnel.

The information in this manual is designed to aid personnel to correctly

and safely install, operate, and/or maintain the system described; however,

personnel are still responsible for considering all actions and procedures for

potential hazards or conditions that may not have been anticipated in the

written procedures. If a procedure cannot be performed safely, it must not

be performed until appropriate actions can be taken to ensure the safety

of the equipment and personnel. The procedures in this manual are not

designed to replace or supersede required or common sense safety practices.

All safety warnings listed in any documentation applicable to equipment

and parts used in or with the system described in this manual must be read

and understood prior to working on or with any part of the system.

Failure to correctly perform the instructions and procedures in this

manual or other documents pertaining to this system can result in

equipment malfunction, equipment damage, and/or injury to personnel.

Thermo Fisher Scientific DCT6088 User Guide xi

Page 14

Safety Information & Guidelines

W

Warnings, Cautions, & Notes

arnings,

arnings,

Cautions, &

Cautions, &

Notes

Notes

The following admonitions are used throughout this manual to alert users

to potential hazards or important information. Failure to heed the

warnings and cautions in this manual can lead to injury or equipment

damage.

Warning Warnings notify users of procedures, practices, conditions, etc.

which may result in injury or death if not carefully observed or followed. ▲

Caution Cautions notify users of operating procedures, practices,

conditions, etc. which may result in equipment damage if not carefully

observed or followed. ▲

Note Notes emphasize important or essential information or a statement of

company policy regarding an operating procedure, practice, condition,

etc. ▲

xii DCT6088 User Guide Thermo Fisher Scientific

Page 15

Chapter 1

Product Overview

Introduction

Theory of

Operation

The Thermo Scientific DCT6088 dedicated transit time flowmeter is a

microprocessor-based instrument that measures the flow of clean,

homogeneous liquids (liquids without large concentrations of suspended

particles or gasses such as air bubbles). The flowmeter is non-invasive,

which means that it measures flow from outside the pipe. The transducers

can be mounted to a pipe within a matter of minutes, and flow

measurements may be made without interrupting the flow or modifying

pipe work. The instrument can be configured using an integral keypad for

entering variables such as pipe size, pipe material, wall thickness, and fluid

type.

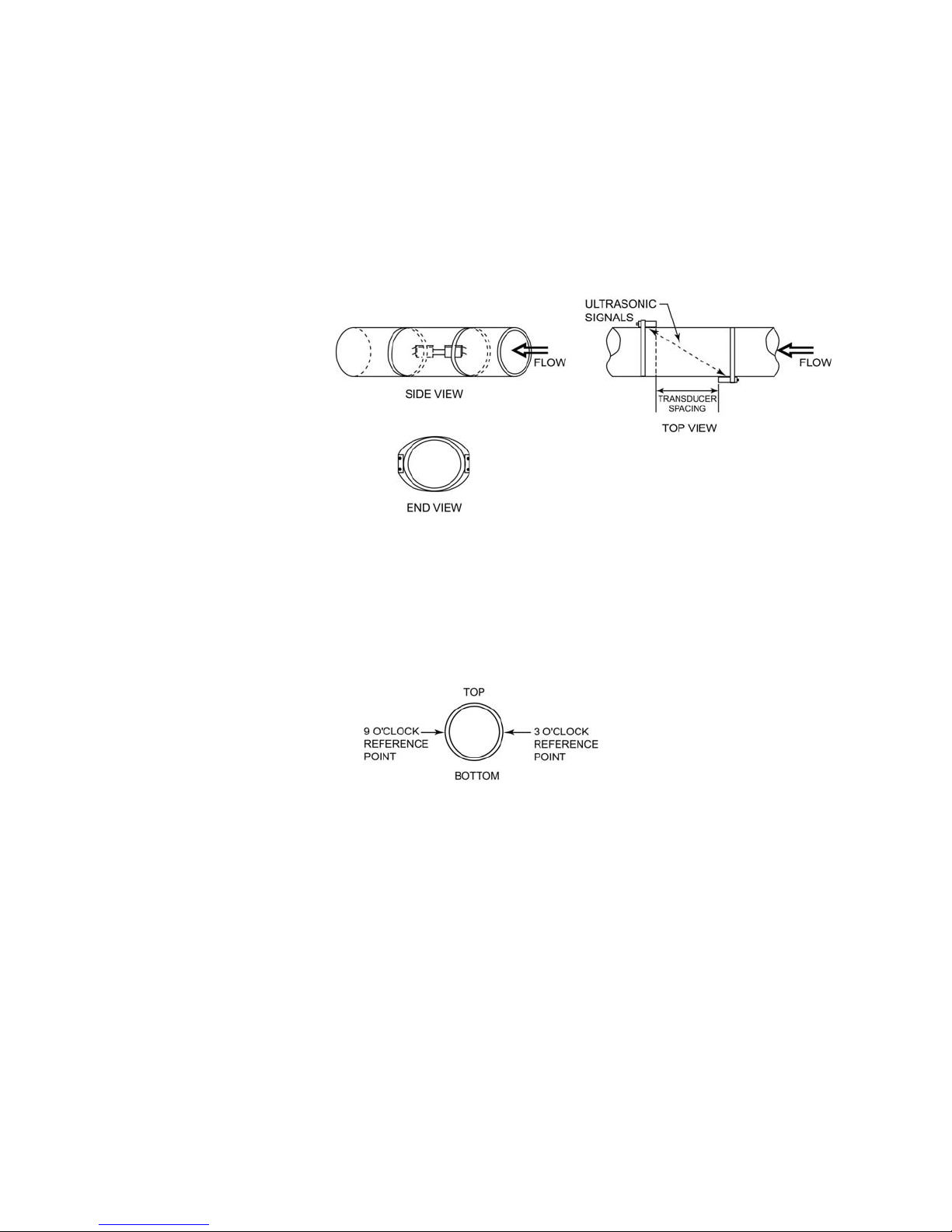

Sound waves travel in fluids at a specific velocity depending on the type of

fluid. If the fluid is moving, the sound wave travels at a velocity equal to

the sum of the speed of sound in the fluid and the velocity of the fluid itself

relative to the transducer. A sound wave traveling in the same direction as

the fluid flow (downstream) will arrive sooner than a sound wave traveling

against the flow (upstream). A transit time flowmeter operates by

measuring both the absolute travel time of each sound wave and the

difference in time required for the waves to travel between externally

mounted downstream and upstream transducers (refer to Figure 1–1).

Based on the transit time of the two sound waves, the flowmeter calculates

the average fluid velocity.

Thermo Fisher Scientific DCT6088 User Guide 1-1

Figure 1–1. Typical transit time system

Page 16

Product Overview

Transit Time Accuracy

Once the differential transit time is calculated, several additional variables

must be taken into consideration. The overall velocity of the fluid is

comprised of many individual local velocities that vary according to their

distance from the pipe wall. The velocities in the center of the pipe are

higher than the velocities near the pipe wall. The combination of these

individual velocities for a specific type of fluid within a specific pipe yield a

velocity distribution known as the flow profile, which is a function of the

Reynolds number (see Figure 1–2). By properly configuring the flowmeter,

the effects of the flow profile are taken into consideration when calculating

the mean fluid velocity. The flowmeter then multiplies this velocity by the

pipe’s cross-sectional area to obtain volumetric flow.

Transit Time

Accuracy

Figure 1–2. Flow profiles

Non-invasive ultrasonic measurements are subject to a variety of effects that

can influence measurement accuracy. All ultrasonic instruments are velocity

measuring devices and only infer volumetric flow from the operatorentered parameter of pipe inside diameter (ID). When this value is squared

to get cross-sectional area, a 1% error yields a 2% error in volumetric flow.

In practice, commercially fabricated pipe seldom has ID consistency much

tighter than 1%, and unless the pipe to be measured has been accurately

measured, this uncertainty is not reducible through instrument calibration.

The more sophisticated transit time flowmeters incorporate flow profile

corrections to compensate for the pipe’s cross-sectional velocity profile with

a changing Reynolds number. However, this requires the operator to know

the inside roughness of the pipe to be measured. The instrument may infer

a roughness if none is entered by the operator, but that is only an estimate

based on the characteristics of new pipe. Pipes can accumulate deposits that

may reduce the ID and affect the roughness as well. Errors on the order of

2% as a result of this phenomenon are not uncommon.

While other factors may influence instrument accuracy to a lesser extent,

the issues described above are the major elements of pipe dependency upon

absolute instrument accuracy. While calibration on a reference flow loop

under known conditions is a useful exercise to determine the accuracy

potential of an instrument, it is not a guarantee of absolute accuracy on

different pipes under field conditions.

1-2 DCT6088 User Guide Thermo Fisher Scientific

Page 17

Product Overview

Ordering Information

Ordering

Information

The table below provides ordering information for the flowmeter.

1–1.

Table

Code Model

DCT6088 Thermo Scientific DCT6088 dedicated digital correlation transit time flowmeter

Code Power Supply

1 90 to 132 Vac, 50/60 Hz

2 190 to 250 Vac, 50/60 Hz

3 12 to 24 Vdc nominal

Code Output

1 For non-hazardous area use only: One relay, 5 amp, SPDT fully programmable

2 For non-hazardous area use only: Two relays, 5 amp, SPDT fully programmable

3 For non-hazardous area use only: Three relays, 5 amp, SPDT fully programmable

4 For non-hazardous area use only: Four relays, 5 amp, SPDT fully programmable

5 For hazardous area use: One relay, 5 amp, SPDT fully programmable

6 For hazardous area use: Two relays, 5 amp, SPDT fully programmable

7 For hazardous area use: Three relays, 5 amp, SPDT fully programmable

8 For hazardous area use: Four relays, 5 amp, SPDT fully programmable

Code Transmitter Enclosure

1 NEMA 4X

2 NEMA 7

Code Transducer Type (set of two)

S Standard cable (100°C/212°F maximum)

H High temperature cable (200°C/392°F maximum)

Code Transducer Cable (set of two)

030 30 ft (9 m) cable length

XXX Optional standard cable lengths: 50 ft, 75 ft, 100 ft, 150 ft, 200 ft, 300 ft

XXX Optional high temperature cable lengths: 50 ft, 100 ft, 150 ft, 200 ft

Code Transducer Hazardous Area Certification

A Non-hazardous

B CSA: Class I, Div. 2 Groups A, B, C, D or Class II, Div. 2 Groups E, F, G (available

with standard transducer configuration only)

C Barriers to use transducer in CSA Class I, Div. 1 Groups C, D or Class II, Div 1

Groups E, F, G (available with standard transducer configuration only)

Thermo Fisher Scientific DCT6088 User Guide 1-3

Page 18

Product Overview

Specifications

Specifications

Results may vary under different operating conditions.

Table 1–2. Performance specifications

Velocity range ±0 m/s to 15 m/s (±0 ft/s to 50 ft/s)*

Accuracy ±0.5% of velocity or ±0.05 ft/s, typical

Fluids Potable water, ultrapure liquids, deionized water, petroleum

products

Pipe size 25.4 mm to 5 m (1 in to 200 in)*

Contact factory for line sizes smaller than 1 inch.

*Large pieps and high velocities cannot be measured simultaneously.

Table 1–3. Physical specifications

Transmitter IP65, flame retardant, fiberglass reinforced polyester

Transducers Two encapsulated transducers suitable for submersion or

underground service; 9 m (30 ft) standard cable length

Weight Approximately 5.4 kg (12 lb)

Table 1–4. Functional specifications

Outputs 4–20 mA (into 1 to 5 kohms), 12-bit, 5 kV, opto-isolated, loop or

self-powered

RS232 serial interface

Power supply 90 to 132 Vac or 190 to 250 Vac, 50/60 Hz (switch selectable)

12 to 24 Vdc

Temperature range Transducers

Surface: -40°C to 100°C (-40°F to 212°F)

Ambient: -28°C to 80°C (-20°F to 176°F)

Transmitters: -40°C to 60°C (-40°F to 140°F)

Contact factory for higher temperature range requirements.

Keypad 19-key with tactile action

Display 2-line x 40-character, alphanumeric, backlit LCD

Data logger 30,000 point data logger, programmable in 1-second intervals

1-4 DCT6088 User Guide Thermo Fisher Scientific

Page 19

External

Features

Product Overview

External Features

Figure 1–3. External features of the DCT6088

Thermo Fisher Scientific DCT6088 User Guide 1-5

Page 20

This page intentionally left blank.

Page 21

Chapter 2

System Installation

Enclosure

Mounting

Direct Mount

Method

Mounting Ears

Method

The enclosure should be mounted to a sturdy vertical surface such as a wall.

The enclosure can be directly mounted with screws or indirectly mounted

with mounting ears. The flowmeter has 5/16” metal threaded inserts

located in the corners of the enclosure. The inserts are located in mounting

wells that are sealed from the interior of the enclosure when the door is

closed, preventing moisture from entering the instrument through the

mounting holes.

The enclosure can be directly mounted to a wall by inserting four 1/4"

screws into the mounting wells from the front of the enclosure. The screws

act as “through bolts” for securing the unit to the wall.

The enclosure can be mounted to a flat, vertical surface using the optional

mounting ears. The mounting ears can be oriented vertically or

horizontally as follows.

1. Screw the four mounting ears to the metal threaded inserts on the back

of the enclosure using the 5/16” screws provided in the mounting ears

kit.

Thermo Fisher Scientific DCT6088 User Guide 2-1

2. Attach the ears to the wall with standard mounting screws.

Figure 2–1. Mounting ears method

Page 22

System Installation

Transducer Installation

Transducer

Installation

Site Selection &

Preparation

Prior to installing the transducers, a proper site must be selected to ensure

accurate measurement. Examples of site recommendations are illustrated

below.

2-2 DCT6088 User Guide Thermo Fisher Scientific

Figure 2–2. Site recommendations

Page 23

System Installation

Transducer Installation

Use the following guidelines when selecting the transducer site:

● Choose a section of pipe that is always full of liquid, such as a vertical

pipe with up flow or a full horizontal pipe.

● The site should have a straight run equivalent to at least 10 pipe

diameters upstream and 5 pipe diameters downstream from any elbows,

tees, throttling valves, orifices, reduced sections, or other flow

disturbances.

● Up to 30 diameters of straight run may be required upstream from the

flowmeter after a pump, control valve, or double piping bend for

greater accuracy. A distance of 5 diameters downstream is usually

sufficient under all circumstances.

● Always mount the transducers on the sides of the pipe in the 3 o’clock

or 9 o’clock position on horizontal pipes. Positioning the transducers in

this manner prevents signal loss that can be caused by sediment along

the bottom of the pipe or gas bubbles and air pockets along the top of

the pipe.

● Ensure that the pipe skin temperature is within the transducer

temperature rating. The transducers are rated for -40°F to +212°F

(-40°C to +100°C). Temperature ratings up to 392°F (200°C) are

available with optional high temperature transducers.

● Pipes with excessive corrosion or scaling create conditions that can

make accurate measurement difficult or impossible. If possible, avoid

selecting these sections of pipe as mounting locations.

● Remove any dirt, grease, rust, loose paint, or scale from the pipe surface

prior to mounting the transducers. To obtain best results on aging and

rough pipes, a file or grinder may be required to clean the pipe down to

bare metal.

If your application cannot follow these guidelines completely, meaningful

flow measurements (with some loss in accuracy and stability) may still be

obtained, depending on signal quality.

Thermo Fisher Scientific DCT6088 User Guide 2-3

Page 24

System Installation

Spacing & Mounting the Transducers

Spacing &

Mounting the

Transducers

Once you have selected a proper transducer site, you must ensure proper

transducer spacing and mounting in order to maximize signal strength and

accuracy. Do this by following the steps below.

1. Determine the mounting method that is appropriate for your

application: V, W, Z, WW, WV.

2. Refer to Chapter 4 to configure the flowmeter via the keypad or to the

UltraScan manual to configure with the UltraScan software. Note the

value required for the transducer spacing (value calculated by and

displayed on flowmeter LCD or in UltraScan).

3. Clean the area of the pipe designated as the mounting location.

Remove any rust, scale, or loose paint. Well-bonded paint does not

need to be removed.

Note On horizontal pipes, the transducers should be mounted in the 3

o’clock and9 o’clock positions in order to avoid situations that can

cause signal loss, such as sediment along the bottom of the pipe or gas

bubbles or air pockets along the top of the pipe. ▲

4. Apply a wide bead of sonic coupling compound lengthwise down the

center of the face of each transducer.

Note The coupling compound should squeeze out from around the

edges of the transducer when placed against the pipe. There should be

no air gaps between the transducer and the pipe. Refer to “Replacing

Sonic Coupling Compound” (Chapter 7) for instructions on how to

apply sonic coupling co

sonic coupling compounds for high temperature, underground, or

submerged installations. ▲

5. Attach the transducers to the pipe using the stainless steel clamps and

referring to one of the following sections to mount the transducers

according to the selected mounting method: V method, W method, Z

method, or WV and WW methods.

Note The transducers should be mounted on the pipe in relation to the

direction of flow, as shown in the follo

position of the upstream and downstream transducers or reversing the

transducer cable connections to the instrument will result in negative

flow readings.

▲

mpound and for information on using other

wing figure. Reversing the

2-4 DCT6088 User Guide Thermo Fisher Scientific

Page 25

System Installation

Spacing & Mounting the Transducers

Figure

2–3.

6. Tighten both straps securely. Ensure the transducer face is aligned

normal to the pipe. The transducer face alignment is particularly

critical on small pipes due to pipe curvature. In the figure below, notice

that the properly installed transducer contacts the pipe at the pipe’s

centerline and that the gaps on either side of the centerline are equal.

Follow these steps for the easiest method of aligning transducers on

small pipes:

a. Secure both transducers to the pipe with pipe clamps, and tighten

the clamps until the transducers fit snugly.

b. Adjust the transducers until the gaps on both sides are equal.

c. While holding the transducers in place, tighten the clamps

sufficiently to prevent the transducers from slipping and to allow

proper flowmeter operation.

Figure 2–4.

Thermo Fisher Scientific DCT6088 User Guide 2-5

Page 26

System Installation

Spacing & Mounting the Transducers

7. The transducer cables connect to the terminal block labeled

TRANSDUCERS.

Note The upstream transducer cable has red-banded ends, and the

downstream transducer cable has blue-banded ends. ▲

Note Refer to Chapter 8 for information on connecting the transducer

cables in hazardous area applications. ▲

Connect the transducer cables to the flowmeter as follows:

a. Connect the center wire of downstream transducer cable to the

XMT (DN) terminal.

b. Connect the braided shield wire of downstream transducer cable to

the XMT GND terminal.

c. Connect the center wire of upstream transducer cable to the RCV

(UP) terminal.

d. Connect the braided shield wire of upstream transducer cable to the

RCV GND terminal.

8. If maximum accuracy at low flow rates is important, calibrate the

flowmeter according to “The Calibration Menu” (Chapter 5).

The flowmeter is now capable of accurately measuring velocity and flow.

2-6 DCT6088 User Guide Thermo Fisher Scientific

Page 27

System Installation

W

Transducer Mounting Methods

Transducer

Mounting

Methods

V Method

There are several methods of mounting the transducers. The best method is

determined by the specific application. Complete steps 1–5 in previous

section, and then refer to the following sections for instructions on how to

properly mount the transducers using one of the available mounting

methods.

The V method is considered the standard method for pipes with diameters

of 4 to 16 inches (101.6 to 406.4 mm). This method typically yields a

more accurate reading than the Z method since it utilizes a longer

measurement path. When configuring the flowmeter, ensure V is the

selected mounting method.

Method

Figure 2–5. V mounting method

In many instances, flowmeter performance on small metallic pipes with

outer diameters of 4 inches (100 mm) or less can be improved by using the

W mounting method. With the W method, the sound wave traverses the

fluid four times and bounces off the pipe walls three times. Like the V

method, both transducers are mounted on the same side of the pipe. When

configuring the flowmeter, ensure W is the selected mounting method.

Figure 2–6. W mounting method

Thermo Fisher Scientific DCT6088 User Guide 2-7

Page 28

System Installation

Transducer Mounting Methods

Z Method

The signal transmitted in a Z method installation has less attenuation than

a signal transmitted with the V method. This is because the Z method

utilizes a directly transmitted (rather than reflected) signal that transverses

the liquid only once. The Z method is used primarily in applications where

the V method cannot work due to signal attenuation from excessive air or

solids in the liquid, thick scale, poorly bonded linings, or very large pipes.

In addition, the Z method generally works better on larger diameter pipes

where less pipe length is required for mounting.

Figure 2–7. Z mounting method

To mount the transducers using the Z mounting method, follow the steps

below.

1. Establish a reference at the 3 o’clock and 9o’clock positions on the

pipe.

Figure 2–8. Z mounting method, step 1

2. Place a transducer at the 3 o’clock position.

3. Trace the shape of the 3 o’clock transducer along its inside edge

(opposite the cable connection). Draw a horizontal line at its center.

Remove the transducer.

2-8 DCT6088 User Guide Thermo Fisher Scientific

Page 29

System Installation

Transducer Mounting Methods

Figure 2–9. Z mounting method, steps 2–3

4. Obtain a continuous sheet of paper longer than the circumference of

the pipe. Calculator paper tape or thermal printer paper works well for

this.

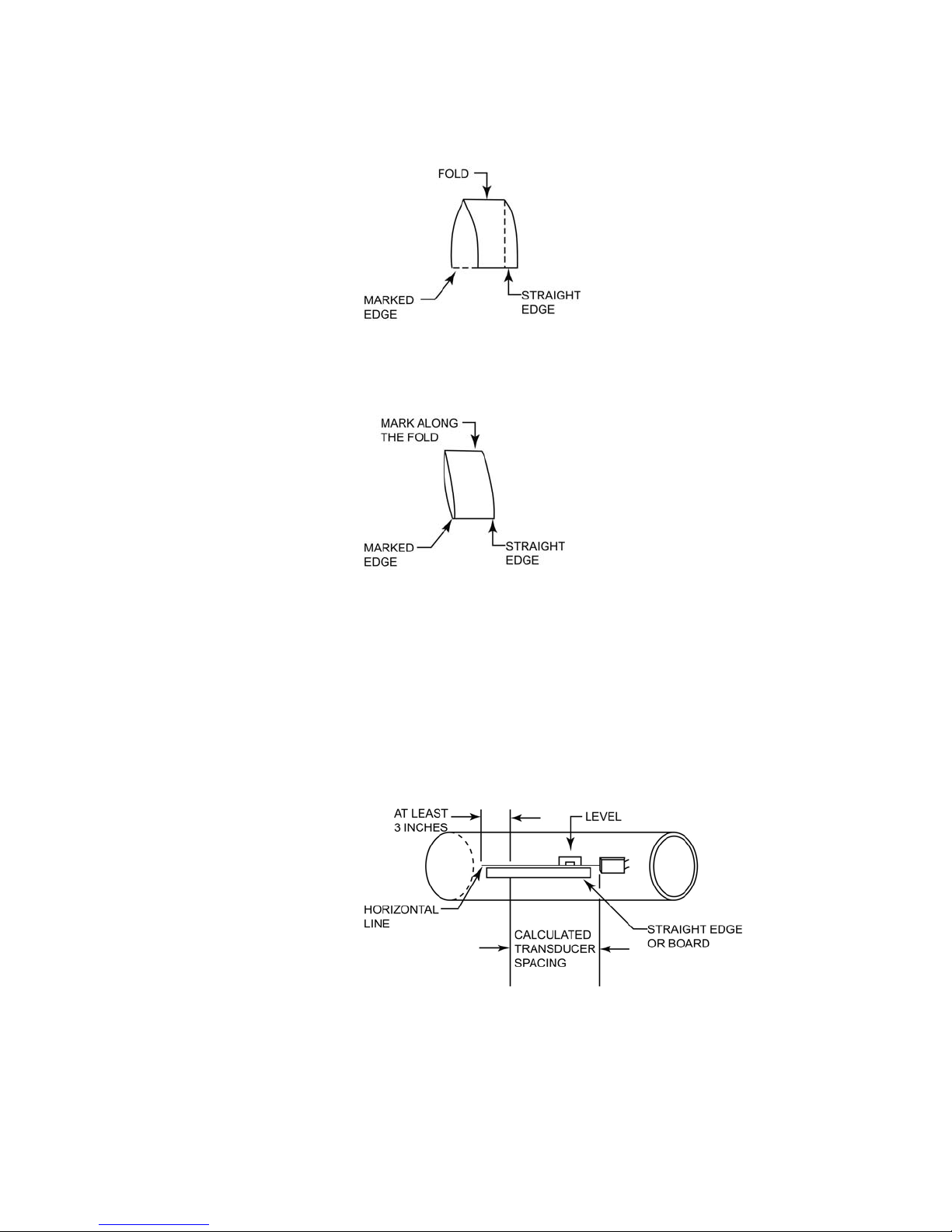

5. Fold one end of the paper across the pipe’s width to produce a clean,

straight edge.

6. Line the fold of the paper up with the horizontal centerline of the 3

o’clock transducer.

Figure 2–10. Z mounting method, steps 4–6

7. Wrap the paper firmly around the pipe, and mark the intersection

point where the fold comes in contact with the rest of the paper.

Figure

2–11. Z mounting method, step 7

Thermo Fisher Scientific DCT6088 User Guide 2-9

Page 30

System Installation

Transducer Mounting Methods

8. Remove the paper from the pipe. Place the fold and intersection mark

together again, and fold the paper exactly in half.

Figure 2–12. Z mounting method, step 8

9. Mark along the new fold.

Figure 2–13. Z mounting method, step 9

10. Draw a horizontal line along the pipe from the centerline of the 3

o’clock transducer position. Use a level to ensure that the line is level

with the top of the pipe. The line should be at least 3 inches (76 mm)

longer than the transducer spacing calculated by the UltraScan software

or via menu 25.

For example, if the software calculates the spacing as 14 inches (356

mm), draw a line 17 inches (432 mm) long.

Figure

2–14. Z mounting method, step 10

2-10 DCT6088 User Guide Thermo Fisher Scientific

Page 31

System Installation

Transducer Mounting Methods

11. Measure the spacing from the inside edge of the 3 o’clock transducer,

and mark this on the pipe.

Figure 2–15. Z mounting method, step 11

12. Wrap the paper firmly back on the pipe. Have the point where the ends

of the paper come together line up with the horizontal line on the 3

o’clock side of the pipe. Ensure that the inside corner of the straight

edge of the paper is aligned with the mark made for the transducer

spacing. Tape the paper down, or have someone hold the paper in

place.

Figure

2–16. Z mounting method, step 12

13. Go to the other side of the pipe (9 o’clock position), and mark the pipe

at the point where the marked fold and the inside edge of the paper

length intersect.

Figure 2–17. Z mounting method, step 13

Thermo Fisher Scientific DCT6088 User Guide 2-11

Page 32

System Installation

W

Transducer Mounting Methods

14. Remove the paper from the pipe and trace the shape of the 9 o’clock

transducer in the same manner you did for the 3 o’clock transducer.

Ensure that the inside edge of the transducer (opposite the cable

connection) is even with the point just marked on the 9o’clock side of

the pipe.

Figure 2–18. Z mounting method, step 14

15. Mount the transducers with pipe straps by following steps 5-6 in

“Spacing & Mounting the Transducers” earlier in this chapter.

V and WW

Methods

Figure 2–19. Z mounting method, step 15

The figure below illustrates the final Z method installation.

Figure 2–20.

For applications with pipe diameters smaller than 2 inches (50 mm), the

WV and WW methods are options that allow higher accuracy and stability

to be achieved when reasonable signal strength can be obtained (10% or

higher).

2-12 DCT6088 User Guide Thermo Fisher Scientific

Page 33

System Installation

Small Pipe Applications

Small Pipe

Applications

In this section, small pipe applications refer to the following pipe sizes:

● Stainless steel or brass: 1.0 to 3.5 inches (25.4 to 88.9 mm)

● PVC, carbon steel, or other: 1.0 to 2.5 inches (25.4 to 63.5 mm)

If signal strength is greater than 10%, we recommend the W mounting

method for pipe sizes 3.5 inches (63.5mm) or smaller and the WW

mounting method for pipe sizes 2.0 inches (50.8 mm) or smaller.

The pipe curve effect on small pipe applications can cause multipath signals

and measurement uncertainty. Removing extra compound along the

transducer sides can eliminate the side wave paths as seen in Figure 2–21

below.

To eliminate these side wave paths, apply coupling compound as usual on

to the coupling surfaces, and clamp the transducers onto the pipe. Use a

pen-sized, standard screwdriver to remove the extra grease between the

transducers and the pipe.

Figure 2–21. Effect of extra compound on small pipes

For high temperature or outdoor small pipe applications, use the foam tape

strips shipped with the flowmeter to block the side wave paths. Other tape

materials generally do not satisfy performance or safety specifications.

Please contact Thermo Fisher when more tape strips are needed.

Apply the foam tape strips according to the steps below.

1. Wipe grease off the coupling surfaces of both transducers. Clean the

surfaces with detergent and let dry.

2. Draw two lines on each transducer surface with a pencil so that the

band defined by the lines is in the middle of the surface. The spacing

between the two lines should be as shown in the following table.

Thermo Fisher Scientific DCT6088 User Guide 2-13

Page 34

System Installation

Small Pipe Applications

Table 2–5.

Pipe Sizes Spacing

3.0 to 3.5 inches (76.2 to 88.9 mm) 0.50 inches (12.7 mm)

2.5 to 3.0 inches (63.5 to 76.2 mm) 0.44 inches (11.2 mm)

2.0 to 2.5 inches (50.8 to 63.5 mm) 0.38 inches (9.7 mm)

1.5 to 2.0 inches (38.1 to 50.8 mm) 0.32 inches (8.13 mm)

1.5 inches (38.1 mm ) and smaller 0.25 inch (6.35 mm)

Figure 2–22.

3. Remove the adhesive protection paper to expose the tape strips. Place a

strip on each side of the surface along the line. Press the strips down to

ensure good adhesion.

Figure

2–23.

4. Apply coupling compound to the space between the tape strips. The

optimum height of the compound layer is approximately half the

height of the tape strips.

2-14 DCT6088 User Guide Thermo Fisher Scientific

Figure 2–24.

Page 35

Chapter 3

Wiring

Cable Routing able Routing

Warning Avoid potential injury or damage to equipment. Ensure the

flowmeter is grounded at ALL times. ▲

Warning Minimize the possibility of explosion in hazardous areas. Do not

disconnect power until the area is known to be non-hazardous. ▲

Warning Prevent the possibility of electrical shock or damage to the

instrument. Disconnect power prior to removing the sheet metal access

cover. Replace the cover before reconnecting power to the unit. ▲

Warning All wiring should be routed through conduit or cable glands to

seal the enclosure. Refer to Figure 3–1 for the recommended cable routing.

Bonding between conduit connections is not automatic and must be

provided as part of the installation. ▲

Thermo Fisher Scientific DCT6088 User Guide 3-1

Page 36

Wiring

Power Connections

Figure 3–1. Recommended cable routing

Power

ower

Connections

Connections

Warning To prevent damage to the instrument, verify that the voltage to

be connected matches the voltage rating of the flowmeter. The voltage

rating is indicated beneath the power input terminals. ▲

Warning Power connections must be made in accordance with local

standards or codes of practice. ▲

The power input terminals shown in Figure 3–1 can be connected to one

of the following voltages:

● 120 Vac, 50/60 Hz (setting should be on 110)

● 240 Vac, 50/60 Hz (setting should be on 220)

● 12 to 24 Vdc (setting should be on 110)

To connect power, remove the sheet metal access cover. Locate the

individual power input terminals. They are marked directly on the main

board or on a sticker attached to the main board. Connect the power

according to one of the following sections.

3-2 DCT6088 User Guide Thermo Fisher Scientific

Page 37

Wiring

Power Connections

120 Vac Operation

Single Phase 240

Vac Operation

To connect the power for 120 Vac operation:

1. Connect the hot wire to the L1(+) terminal.

2. Connect the neutral wire to the L2/N(-) terminal.

3. Connect the ground wire to the GND terminal.

To connect the power for single phase 240 Vac operation:

1. Connect the live wire to the L1(+) terminal.

2. Connect the neutral wire to the L2/N(-) terminal.

3. Connect the ground wire to the GND terminal.

Double Phase 240

Vac Operation

12 to 24 Vdc

Operation

To connect the power for double phase 240 Vac operation:

1. Connect the one hot wire to the L1(+) terminal.

2. Connect the other hot wire to the L2/N(-) terminal.

3. Connect the ground wire to the GND terminal.

Note For DC operation, set the 4 –20 mA current loop function to loop

powered mode to prevent ground loops.

To connect the power for 12 to 24 Vdc operation:

4. Connect the positive wire to the L1(+) terminal.

▲

Thermo Fisher Scientific DCT6088 User Guide 3-3

5. Connect the negative wire to the L2/N(-) terminal.

Page 38

Wiring

The Current Loop

The Current Loop

The 4–20 mA current loop module has an input terminal and an output

terminal, which are indicated on a label on the inside of the flowmeter

door. The current loop output is rated for a loop resistance of up to 1

kohm and is isolated for up to 5 kV when loop-powered.

The 4–20 mA module is shipped in the self-powered configuration. Switch

to loop power by moving a jumper on the module. Current loop modules

that are loop powered must be driven from an external power supply. In

this case the flowmeter acts as a passive two-wire transmitter.

Warning Prevent the possibility of electrical shock or damage to the

instrument. Disconnect power prior to making connections or changing

the loop configuration. ▲

To connect the current loop:

1. Ensure the loop powering option is correct. Locate the jumpers on the

upper right corner of the module. Refer to the figure below to change

the jumper settings.

3-4 DCT6088 User Guide Thermo Fisher Scientific

Figure 3–2. Jumper settings for current loop configurations

Page 39

Wiring

Relay Terminals

2. Refer to the self-powered or loop powered configuration figure below

for wiring.

Figure 3–3. Self-powered current loop configuration

Relay Terminals

Figure 3–4. Loop powered current loop configuration

Up to four relays may be installed in the instrument. The relays are rated at

5 A, 250 Vac. Each relay contains a normally open and normally closed dry

contact accessible at the terminal blocks. The terminals for the relay are

labeled on the module as NO (normally open), C (common), and NC

(normally closed). When the relay is energized, the C terminal is shorted to

the NO terminal (refer to Figure 3–5). When the relay is at rest, the C

terminal is shorted to the NC terminal.

Thermo Fisher Scientific DCT6088 User Guide 3-5

Figure

3–5. Relay schematic

Page 40

Wiring

Communications Terminal Block

The terminal blocks for the relays are labeled on the board as RELAY 1

through RELAY 4. The relay terminal blocks should be wired for either

NO or NC circuits. Figure 3–6 shows RELAY 1 is wired for a NC circuit.

Figure 3–6. Relay terminal block

Note The auxiliary terminal block is for future development. ▲

Communications

Terminal Block

Transducer

Wiring

The communications terminal block is for future development.

The transducer terminals and cables are arranged in pairs and are labeled

DN STREAM and UPSTREAM. The downstream transducer cable has

blue-banded ends, and the upstream transducer has red-banded ends.

Refer to the figure below. The symbol is on both pairs of terminals and

indicates which terminals should connect to the center wire conductors and

which should connect to the coaxial shields.

Figure 3–7.

3-6 DCT6088 User Guide Thermo Fisher Scientific

Page 41

Chapter 4

Operating & Configuring the

Flowmeter

The Keypad &

Display

Figure 4–1. Keypad & display

Adjusting the

Contrast

Interface with the instrument is via the keypad. During operation, the

LCD indicates flow rate and totalizer values. The display is also backlit for

ease of viewing in low-light conditions and has a variable contrast setting.

You may need to adjust the contrast on the display as ambient temperature

changes. Follow the steps below to do so.

Thermo Fisher Scientific DCT6088 User Guide 4-1

1. Press MENU followed by the +/- (plus/minus) key.

2. LCD CONTRAST appears on the display with a bar the indicating

current contrast setting.

3. Press the left or right arrows to adjust the contrast.

4. Press ENTER when complete.

Page 42

Operating & Configuring the Flowmeter

Flowmeter Configuration

Flowmeter

Configuration

Direct Menu Access

Flowmeter configuration is accomplished using the setup menus. Some

setup menus allow a numeric value to be entered, and others offer nonnumeric selections. In non-numeric setup menus, an asterisk is displayed to

the left of the selected currently entered in the flowmeter, as shown in the

figure below.

Figure 4–2.

There are two ways to access the setup menus: via direct access or through

the menu structure.

The unique two-digit address for each setup and diagnostic menu enables

the user to directly access the desired menu. The menu addresses are listed

in Table 4–1. To use them, follow the two steps below.

1. Press MENU, and the letter M appears in the lower right corner of the

display.

2. Enter the desired two-digit address.

Note The address must be entered while the M is displayed (within

approximately 4 seconds). If the M is no longer displayed, press

MENU again followed by the two-digit address. ▲

3. If the setup menu requires a numeric entry, use the numeric keys to

enter the value and press ENTER to accept the value. If you need to

change the entry, press ERASE. If the setup menu offers a non-numeric

selection, press ENTER, and the asterisk changes to a flashing cursor.

Use the arrow keys to scroll through the available selections. When the

cursor is to the left of the desired selection, press ENTER.

4. Complete the process by accessing a Primary display (menus 00

through 04).

Note The flowmeter will not use the new parameters until you access a

Primary display. ▲

4-2 DCT6088 User Guide Thermo Fisher Scientific

Page 43

Operating & Configuring the Flowmeter

Flowmeter Configuration

Table 4–1. Menu addresses

Menu Type Display Address

Primary Flow/Net Totalizer 00

Flow/Velocity 01

Flow/Positive Totalizer 02

Flow/Negative Totalizer 03

Signal Strength/Low Signal Cutoff 04

Pipe Pipe OD 10

Pipe Wall Thickness 11

Pipe ID 12

Pipe Material 13

Pipe Sound Speed 14

Pipe Inside Roughness 15

Liner Liner Material 16

Liner Thickness 17

Liner Sound Speed 18

Liner Inside Roughness 19

Fluid Fluid Type 20

Fluid Sound Speed 21

Fluid Viscosity 22

Transducer Transducer Type 23

Transducer Mounting 24

Transducer Spacing 25

Flow Flow Units 30

Max Flow Range 31

Min Flow Range 32

Damping 33

Low Flow Cutoff 34

Low Signal Cutoff 35

Totalizer Totalizer Units 36

Thermo Fisher Scientific DCT6088 User Guide 4-3

Totalizer Multiplier 37

Net Totalizer 38

Positive Totalizer 39

Negative Totalizer 40

Page 44

Operating & Configuring the Flowmeter

Flowmeter Configuration

Menu Type Display Address

Totalizer Reset 41

Options Measurement Units 42

Site Parameters 43

RS232 Configuration 46

Change System Password 47

Change Scale Factor Password 48

Unit ID 49

Calibration 50

Zero Set 51

Scale Factor 52

Sound Speed Compensation 53

Date and Time 54

Current Loop 56

Current Loop Span 57

Current Loop Calibration 58

Current Loop Test 59

Relays 70

Program Relays 71

View Relays 72

Test Relays 73

Datalog 80

Datalog Interval 81

Diagnostics Signal Strength/Margin 90

Delta Time/Fluid Sound Speed 91

Reynolds#/Profile Factor 92

Current Loop Output 93

Software/Firmware Rev. Level 94

4-4 DCT6088 User Guide Thermo Fisher Scientific

Page 45

Operating & Configuring the Flowmeter

Flowmeter Configuration

Using the Arrow

Keys to Access

Menus

The other method of accessing the flowmeter menus is to use the left and

right arrows to scroll through the menu structure. Menus are organized

into three basic levels:

● Main menu

● Submenus

● Primary displays, setup menus, diagnostic menus.

The Main menu displays various submenus that contain individual setup

and diagnostic menus. Following is an example of how to use the arrow

keys to access the Main menu from any screen.

1. Press MENU twice. The Main menu is displayed with the Pipe and

Line submenu options.

Figure 4–3. The Main menu

2. To view the remaining submenus, press the down arrow.

Figure 4–4. Remaining submenus of the Main menu

3. When the desired submenu is highlighted, press ENTER to display the

first menu of the selected submenu. The figure below shows what is

displayed if the Flow submenu is selected.

Thermo Fisher Scientific DCT6088 User Guide 4-5

Figure 4–5.

Page 46

Operating & Configuring the Flowmeter

Quick Setup Configuration

4. If the setup menu requires a numeric entry, use the numeric keys to

enter the value and press ENTER to accept the value. If you need to

change the entry, press ERASE. If the setup menu offers a non-numeric

selection, press ENTER, and the asterisk changes to a flashing cursor.

Use the arrow keys to scroll through the available selections. When the

cursor is to the left of the desired selection, press ENTER.

5. Complete the process by accessing a Primary display (menus 00

through 04).

Note The flowmeter will not use the new parameters until you access a

Primary display. ▲

Quick Setup

Configuration

The quick setup procedure contains the minimal steps required for

flowmeter configuration. These steps enable the flowmeter to calculate

transducer spacing, acquire ultrasonic signal, and measure flow. The

number in parentheses after the required menu is the two-digit address to

directly access that menu.

1. Select a proper transducer site according to “Site Selection &

Preparation” in Chapter 2.

2. Access the Pipe submenu. This submenu contains setup menus related

to the pipe parameters such as pipe inside diameter (ID) and pipe

outside diameter (OD).

Note Pipe Wall Thickness is an additional setup menu within the Pipe

submenu. If values for two of the following setup menus are entered,

the flowmeter will calculate the remaining parameter automatically:

Pipe OD (10), Pipe Wall Thickness (11), Pipe ID (12). ▲

Note Accuracy is directly affected by the square of an error in pipe

dimensions. Actual measurements (not nominal) must be entered. ▲

4-6 DCT6088 User Guide Thermo Fisher Scientific

a. Select the PIPE OD menu (10). The screen shown in Figure 4–6 is

displayed. Enter the value for the pipe OD and press ENTER.

Press the down arrow, and select Actual.

Page 47

Operating & Configuring the Flowmeter

Quick Setup Configuration

Figure 4–6. Pipe OD menu

If you know the pipe circumference but not the OD, enter the

circumference value instead and press ENTER and the down

arrow. The screen shown in Figure 4–7 is displayed. Select Circum.

The flowmeter will calculate the pipe OD automatically.

Figure 4–7. Pipe OD type options

b. Select the Pipe ID setup menu (12), and enter the pipe ID. Press

Enter.

Figure 4–8. Pipe ID setup menu

c. Select the Pipe Material setup menu (13). Press the up or down

arrow to scroll through the available options.

Note Select OTHER if the material is not listed. You must then

enter the pipe sound speed (14) and pipe inside roughness (15). ▲

Figure

4–9. Pipe Material setup menu

Note Refer to “The Pipe Menu” (Chapter 5) for additional items not

addressed in the quick setup procedure.

▲

3. If there is a liner, continue with this step. Otherwise, skip to step 4.

Thermo Fisher Scientific DCT6088 User Guide 4-7

a. Access the Liner Material setup menu (16). The screen shown in

Figure 4–10 is shown. Select one of the available options.

Page 48

Operating & Configuring the Flowmeter

Quick Setup Configuration

Note Select OTHER if the material is not listed. You must then

enter the liner sound speed (18) and liner inside roughness (19). ▲

Figure 4–10. Liner Material setup menu

b. Access the Liner Thickness setup menu (17), and enter the

thickness.

Figure

4–11. Liner Thickness setup menu

Note Refer to “The Liner Menu” (Chapter 5) for additional items not

addressed in the quick setup procedure.

▲

4. Access the Fluid Type setup menu (20), and select one of the available

options.

Note Select OTHER if the fluid type is not listed. You must then

enter the fluid sound speed (21) and fluid viscosity (22). ▲

Figure 4–12. Fluid Type setup menu

Note Refer to “The Fluid Menu” (Chapter 5) for additional items not

addressed in the quick setup procedure.

▲

4-8 DCT6088 User Guide Thermo Fisher Scientific

Page 49

Operating & Configuring the Flowmeter

Quick Setup Configuration

5. Enter the Transducer submenu.

a. Access the Transducer Type setup menu (23). Currently, the only

selection available is Standard. Standard must be selected for all

applications using clamp-on transducers, including high

temperature transducers.

Figure

4–13. Transducer Type setup menu

b. Access the Transducer Mounting setup menu (24), and select the

desired mounting method.

Figure 4–14. Transducer Mounting setup menu

6. Access the Transducer Spacing view-only menu (25). Note the required

spacing between transducers.

Figure 4–15. Transducer Spacing menu

7. Enter the Flow submenu, and access the Flow Units setup menu (30).

Select the flow rate units.

a. Select one of the available volumetric units.

Figure 4–16. Flow Units setup menu

Thermo Fisher Scientific DCT6088 User Guide 4-9

Page 50

Operating & Configuring the Flowmeter

Quick Setup Configuration

b. Press the down arrow and the Flow Units Per options are

displayed. Select the desired option.

Figure 4–17. Flow Units Per setup menu

Note Refer to “The Flow Menu” (Chapter 5) for additional items not

addressed in the quick setup procedure. ▲

8. Install the transducers on the pipe using the spacing provided by the

flowmeter, and connect the transducer cables to the flowmeter.

9. Access a Primary Display (00 through 04) to complete the

configuration process.

If the flowmeter and transducers are properly installed and a steady flow is

present, the flow and signal strength readings should be relatively stable.

Note If any of the above setup parameters are changed, the flowmeter stops

measuring flow until the new value is entered and a Primary Display is

accessed to accept the new value. ▲

4-10 DCT6088 User Guide Thermo Fisher Scientific

Page 51

Chapter 5

Primary Displays & Menus

Primary Displays

Flow/Net Totalizer

Flow/Velocity

The primary displays are for viewing only and cannot be configured.

Primary displays are menus 00 through 04 and display values for flow rate,

totalizers, velocity, signal strength, or low signal cutoff.

The Flow/Net Totalizer primary display (00) is the standard display used

under normal operating conditions. It displays the flow rate and net

totalizer value. If the net totalizer is not currently enabled, the last net

totalized value is displayed.

Figure 5–1. Flow/Net Totalizer primary display

The Flow/Velocity primary display (01) indicates the flow rate and fluid

velocity. Velocity is displayed in feet per second (FPS) if English is selected

as the measurement unit (menu 42) and in meters per second (MPS) if

Metric is selected.

Flow/Positive

Totalizer

Thermo Fisher Scientific DCT6088 User Guide 5-1

Figure

The Flow/Positive Totalizer primary display (02) indicates the flow rate

and the totalized flow in the positive flow direction. If the positive totalizer

is not currently enabled, the last net totalized value is displayed.

Figure

5–2. Flow/Velocity primary display

5–3. Flow/Positive Totalizer primary display

Page 52

Primary Displays & Menus

The Pipe Menu

Flow/Negative

Totalizer

Signal Strength/Low

Signal Cutoff

The Pipe Menu

The Flow/Negative Totalizer primary display (03) indicates the flow rate

and the totalized flow in the negative flow direction. If the negative

totalizer is not currently enabled, the last net totalized value is displayed.

Figure

5–4. Flow/Negative Totalizer primary display

The Signal Strength/Low Signal Cutoff primary display (04) indicates the

values for signal strength and low signal cutoff.

Figure 5–5. Signal Strength/Low Signal Cutoff primary display

The Pipe menu contains additional items that are not included in the quick

setup procedure described in Chapter 4. These items are listed below.

● Pipe Wall Thickness setup menu (11)

Figure 5–6. Pipe Wall Thickness setup menu

● Pipe Sound Speed setup menu (14)

This menu can only be configured if OTHER was selected as the pipe

material (13). Enter the pipe sound speed. If OTHER was not selected

as the pipe material, this menu is available by the direct access method

only and functions as a view-only display to indicate the pipe sound

speed as programmed in the instrument’s database.

Figure 5–7. Pipe Sound Speed setup menu

5-2 DCT6088 User Guide Thermo Fisher Scientific

Page 53

Primary Displays & Menus

The Liner Menu

● Pipe Inside Roughness setup menu (15)

This menu can only be configured if OTHER was selected as the pipe

material (13). Data on this parameter are available from the Cameron

Hydraulic Data Book published by Ingersoll-Rand. Enter the inside

roughness of the pipe. If OTHER was not selected as the pipe material,

this menu is available by the direct access method only and functions as

a view-only display to indicate the pipe inside roughness as

programmed in the instrument’s database.

Figure 5–8. Pipe Inside Roughness setup menu

The Liner Menu

The Liner menu contains additional items that are not included in the

quick setup procedure described in Chapter 4. These items are listed below.

● Liner Sound Speed setup menu (18)

This menu can only be configured if OTHER was selected as the liner

material (16). Enter the liner sound speed. If OTHER was not selected

as the liner material, this menu is available by the direct access method

only and functions as a view-only display to indicate the liner’s sound

speed as programmed in the instrument’s database.

Figure

● Liner Inside Roughness setup menu (19)

5–9. Liner Sound Speed setup menu

This menu can only be configured if OTHER was selected as the liner

material (16). Enter the liner inside roughness. If OTHER was not

selected as the liner material, this menu is available by the direct access

method only and functions as a view-only display to indicate the inside

roughness of the liner as programmed in the instrument’s database.

Thermo Fisher Scientific DCT6088 User Guide 5-3

Figure 5–10. Liner Inside Roughness setup menu

Page 54

Primary Displays & Menus

The Fluid Menu

The Fluid Menu

The Fluid menu contains additional items that are not included in the

quick setup procedure described in Chapter 4. These items are listed below.

● Fluid Sound Speed setup menu (21)

This menu can only be configured if OTHER was selected as the fluid

type (20). Enter the fluid sound speed. If OTHER was not selected as

the fluid type, this menu is available by the direct access method only

and functions as a view-only display to indicate the fluid sound speed as

programmed in the instrument’s database.

Figure 5–11. Fluid Sound Speed setup menu

● Fluid Viscosity setup menu (22)

This menu can only be configured if OTHER was selected as the fluid

type (20). Enter the fluid viscosity. If OTHER was not selected as the

fluid type, this menu is available by the direct access method only and

functions as a view-only display to indicate the fluid viscosity as

programmed in the instrument’s database.

Figure 5–12. Fluid Viscosity setup menu

5-4 DCT6088 User Guide Thermo Fisher Scientific

Page 55

Primary Displays & Menus

The Flow Menu

The Flow Menu

The Flow menu contains additional items that are not included in the

quick setup procedure described in Chapter 4. These items are listed below.

● Max Flow Range (31) and Min Flow Range (32) setup menus

Use these menus to enter the minimum and maximum flow values for

setting the volumetric flow range. Setting the optimum flow range

generally improves response time.

Figure

5–13. Max Flow Range setup menu

Figure 5–14. Min Flow Range setup menu

Note Whenever the pipe ID is changed, the flowmeter returns the

volumetric flow range to default settings. The default settings are the

maximum and minimum flows for the new pipe ID that occur at +32

and -32 ft/s (+9.76 and -9.76 m/s). ▲

● Damping setup menu (33)

Use this menu to enter the value for the damping coefficient, which

suppresses short-term fluctuations in the indicated flow rate. The

displayed flow rate and the 4–20 mA current loop output is a moving

average of the last n seconds where n is the damping value. Increasing

the coefficient increases the response time to changes. The coefficient is

adjustable from 1 to 99 seconds in1-second increments. Damping

should be kept at a minimum unless the flow rate fluctuates wildly. If

this is the case, increase the damping coefficient just enough to reduce

the fluctuation to an acceptable degree.

Figure 5–15. Damping setup menu

Thermo Fisher Scientific DCT6088 User Guide 5-5

Page 56

Primary Displays & Menus

The Flow Menu

● Low Flow Cutoff setup menu (34)

When a zero flow condition occurs (for example, as the result of a

pump being shut off), internal sloshing, check valve leakage, and other

fluid movement can prevent the flowmeter from reading total zero.

This phenomenon can result in totalizer errors. Minimize these errors

by entering a low flow cutoff, which drives the flowmeter to zero for

flow rates at or below the specified value. If the flow rate falls below the

low flow cutoff value, the indicated flow rate is driven to zero and the

totalizers stop incrementing. This is the case regardless of flow

direction.

Figure 5–16. Low Flow Cutoff setup menu

For example, if you enter a low flow cutoff of 0.1 ft/s (0.03 m/s), the

flowmeter will be driven to zero for flow rates less than 0.1 ft/s in the

positive direction and greater than -0.1 ft/s in the negative direction.

Figure 5–17.

● Low Signal Cutoff setup menu (35)

Empty pipes or solids, bubbles, or voids in the flow stream may cause

temporary drops in signal strength and erroneous readings. Minimize

the effect of these dropouts by setting a low signal cutoff, which drives

the flowmeter to the loss-of-signal (LOS)condition. The low signal

cutoff should be set at the minimum acceptable signal amplitude.

To set the low signal cutoff, access the Low Signal Cutoff setup menu

(35). Enter the low signal cutoff and press ENTER.

Figure 5–18. Low Signal Cutoff setup menu

5-6 DCT6088 User Guide Thermo Fisher Scientific

Page 57

Primary Displays & Menus

The Total Menu

Note The value for the low signal cutoff should usually be set at

approximately half of the value of the signal strength present under

flow conditions. Typically, signal strength is not significantly affected

by flow rate. ▲

From the Low Signal Action setup menu, select one of the following:

● Zero: The flowmeter drops the reading to zero during LOS

condition.

● Hold: The flowmeter holds the last valid reading during LOS

condition for about three seconds.

Figure 5–19. Low Signal Action setup menu

The Total Menu

Access the Total menu to configure the totalizer parameters.

● Totalizer Units setup menu (36)

The flow units elected for the totalizer display may be different from

the flow unit selected for the flow rate display.

Figure 5–20. Totalizer Units setup menu

● Totalizer Multiplier setup menu (37)

The totalizer value can be displayed with one of several multiplier

values. For example, 700 liters can be displayed as ‘700’ if the selected

multiplier value is X1, or it can be displayed as ‘7’ if the selected

multiplier value is X100.

Figure 5–21. Totalizer Multiplier setup menu

Thermo Fisher Scientific DCT6088 User Guide 5-7

Page 58

Primary Displays & Menus

The Total Menu

● Net Totalizer setup menu (38)

Use this menu to enable or disable the net totalizer. The net totalizer

provides the difference between the positive and negative flow values.

For example, if there are 1,000 gallons of flow in the negative direction

and 3,000 gallons of flow in the positive direction, the net totalizer

indicates 2,000 gallons of net flow.

Figure 5–22. Net Totalizer setup menu

● Positive Totalizer setup menu (39)

Use this menu to enable or disable the positive totalizer. The positive

totalizer tracks the flow that moves in the positive direction, from

upstream transducer to downstream transducer. It is not affected by

flow in the opposite direction.

Figure 5–23. Positive Totalizer setup menu

● Negative Totalizer setup menu (40)

Use this menu to enable or disable the negative totalizer. The negative

totalizer tracks the flow that moves in the negative direction, from

downstream transducer to upstream transducer. It is not affected by

flow in the opposite direction.

Figure 5–24. Negative Totalizer setup menu

● Totalizer Reset menu (41)

Use this menu to reset one or all of the totalizers.

Figure

5–25. Totalizer Reset menu

5-8 DCT6088 User Guide Thermo Fisher Scientific

Page 59

Primary Displays & Menus

Options Menu

Options Menu

The Options submenu contains setup menus for several miscellaneous

functions.

● Measurement Units setup menu (42)

Use this menu to select English (feet per second, FPS) or Metric

(meters per second, MPS) measurement units.

Figure 5–26. Measurement Units setup menu

● Site Parameters setup menu (43)

This menu saves the parameters for the pipe, liner, fluid, transducer,

and flow setup menus, allowing them to be recalled later for a specific

measurement site. Several sites are available and are numbered. The site

number is displayed in the lower left corner of the screen and is

followed by a colon. An example of a site numbered 1 is shown below.

Figure 5–27. Site Parameters setup menu

As the setup parameters are entered during normal configuration, they

are saved simultaneously in the Site Parameters setup menu for

whichever site has the asterisk displayed. Access a different site to

automatically enter that site’s stored parameters into the flowmeter for

measuring flow. To access a different site, press Enter, scroll to the

desired site, and press Enter again.

Note To avoid overwriting stored parameters and losing old data,

ensure that the desired site is active prior to entering the new set of

parameters.

▲

Thermo Fisher Scientific DCT6088 User Guide 5-9

Page 60

Primary Displays & Menus

Options Menu

● RS232 Configuration setup menu (46)

Use this menu to configure the RS232 port that allows the flowmeter

to connect to a PC. Communication is established using the Thermo

Scientific UltraScan configuration software (refer to the UltraScan user

guide) or the Thermo Scientific D-Link interface utility (refer to

Appendix C).

To configure the RS232 port, access the RS232 Configuration setup

menu and select ULTRASCAN or D-Link.

Figure 5–28. RS232 Mode setup menu

Press the down arrow to display the baud rate selections. The baud rate

is the only RS232 configuration parameter that can be modified. The

remaining parameters (parity, character size, stop bits) are preset.

Figure 5–29. RS232 Configuration setup menu

Access a Primary display to cause the flowmeter to use the new settings.

● Change System Password setup menu (47)

The flowmeter is shipped from the factory with the system password

disabled. If a password is enabled, the flowmeter requests the password

when a user attempts to enter any configuration data. Entering the

correct password temporarily unlocks the system, allowing the user to

make configuration changes.

To change or disable the system password, access the Change System

Password setup menu.

Figure

5–30. Change System Password setup menu

Enter the new system password and press Enter.

5-10 DCT6088 User Guide Thermo Fisher Scientific

Page 61

Primary Displays & Menus

Options Menu

Note Disable the system password function by entering 0 (zero) as the

system password. Enable the function by changing the password back

to anon-zero number. ▲

Enter the old system password and press Enter. If the old system

password is correctly entered, the software will display that the

password is accepted (Figure 5–31). If the password is incorrectly

entered, it will display that the entry is rejected (Figure 5–32).

Figure 5–31.

Figure 5–32.

Note After the system password is accepted or rejected, the Change

Scale Factor Password setup menu is displayed, which allows you to

change the scale factor password. ▲

Access menu 00 to lock the system with the new password.

● Change Scale Factor Password setup menu (48)

Use this menu to change the scale factor password which is designed to

protect the scale factor from unauthorized or accidental changes. The

flowmeter ships from the factory with the scale factor password

disabled. If the scale factor password is enabled, the flowmeter requests

the password whenever a user attempts to change the scale factor.

To change or disable the scale factor password, access the Change Scale

Factor Password setup menu. Enter the new scale factor password and

press Enter.

Thermo Fisher Scientific DCT6088 User Guide 5-11

Figure 5–33. Change Scale Factor Password setup menu

Page 62

Primary Displays & Menus

Options Menu

Note The system password function must be disabled to allow the scale

factor to be changed without entering a password. ▲

Enter the old scale factor password and press Enter. If entered correctly,

the software will display that the password is accepted (Figure 5–34). If

the password is incorrectly entered, it will display that the entry is

rejected (Figure 5–35).

Figure 5–34.

Figure 5–35.

● Unit ID (identification) Number setup menu (49)

This number is set by the operator to identify the specific instrument or

site. Any whole number between 1 and 60,000 may be entered.

Figure 5–36. Unit ID setup menu

5-12 DCT6088 User Guide Thermo Fisher Scientific

Page 63

Primary Displays & Menus

The Calibration Menu

The Calibration

Menu

Zero Set Calibration

Within the Calibration menu is the Calibration Group menu (50). This

menu contains four setup menus: Zero Set, Scale, SS Comp, and Date

(menus 51 through 54).

Figure 5–37. Calibr menu

An important step in assuring accurate flow measurement is the proper

calibration of the instrument and the installation. The calibration methods

must be performed for the particular pipe that is to be metered. The

following table provides guidelines for selecting a calibration method.

Table 5–2. Calibration methods

Calibration Method Function Application

Zero flow set (zero set

calibration)

Manual zero set (zero

set calibration)

Zeroes the instrument for an

actual no flow condition.

Applies a manually entered

offset to all flow readings.

Installations where flow can be

stopped.

Where an offset is required.

Scale Factor Compensates for manufacturing

variations in the transducers.

Set by the factory to the value

imprinted on the transducers.

After installing the meter, you may find that a small adjustment to the zero

point (zero set calibration) is required. Zero set calibration enables the

meter to read very close to zero under zero flow conditions. There are two

zero set calibration methods: the zero flow set method and the manual zero

set method. View the zero point used by the flowmeter in either of these

methods by selecting Manual in menu 51.

After the instrument is properly zeroed, it should display a stable reading

well below 0.05 ft/s (0.015 m/s) under zero flow conditions with the low

flow cutoff disabled.

Prior to performing a zero set calibration, verify the following:

● Transducers are connected to the pipe.

● Instrument is reading flow.

● Low flow cutoff is disabled to allow verification of calibration.

Thermo Fisher Scientific DCT6088 User Guide 5-13

Page 64

Primary Displays & Menus

The Calibration Menu

Zero Flow Set Method

The best method of zeroing the instrument is to stop the flow and perform

a zero flow set on the pipe. The purpose of the zero flow set is to zero the