Page 1

exceptional value

Thermo Scientific

Barnstead Water Purification

Cartridge and Filter Systems

versatile configurations

Page 2

Thermo Scientific Barnstead

Cartridge and Filter Systems

Achieve the desired water types for your

specific applications

Our complete line of cartridge and filter systems offers

solutions for single step and pretreatment purification at an

exceptional value. Cartridge systems are excellent for use

with humidification/environmental chambers, autoclaves,

water baths, CO

incubators, stills, ultrapure water systems,

2

and eliminating corrosion and scaling when used with

cooling loops for lasers and radar systems.

Versatile Configurations

• Versatile configurations for an array of

specific applications

• Customize modular systems to remove

specific impurities. Over-purifying

water can waste time and resources,

not to mention the possibility of being

detrimental to your application

• Quick-release designs provide easy

cartridge change-outs and simplify

maintenance, bypassing the costs of

service calls

• Wall-mounted systems free up

bench space

• Cartridge systems are available for

installation in pressurized and nonpressurized water line environments

• Wide selection of sizes supports space

limitations and volume needs

Page 3

Exceptional Value

• Robust polypropylene cartridge

casings lengthen system life and

prevent impurities leaching into the

purified water

• High quality resins reliably remove

targeted impurities

• Purity (resistivity) meter options

include Pura-Lite “Go/No Go”

indicators and digital purity meters

for quick-glance purity values and

signs cartridge replacement is needed

• Instead of joints and seams that

are chemically adhered, ours are

ultrasonically welded to prevent

contamination and allow for recycling

3

Page 4

Thermo Scientific Barnstead

Cartridge and Filter Systems

Quick Select Guide

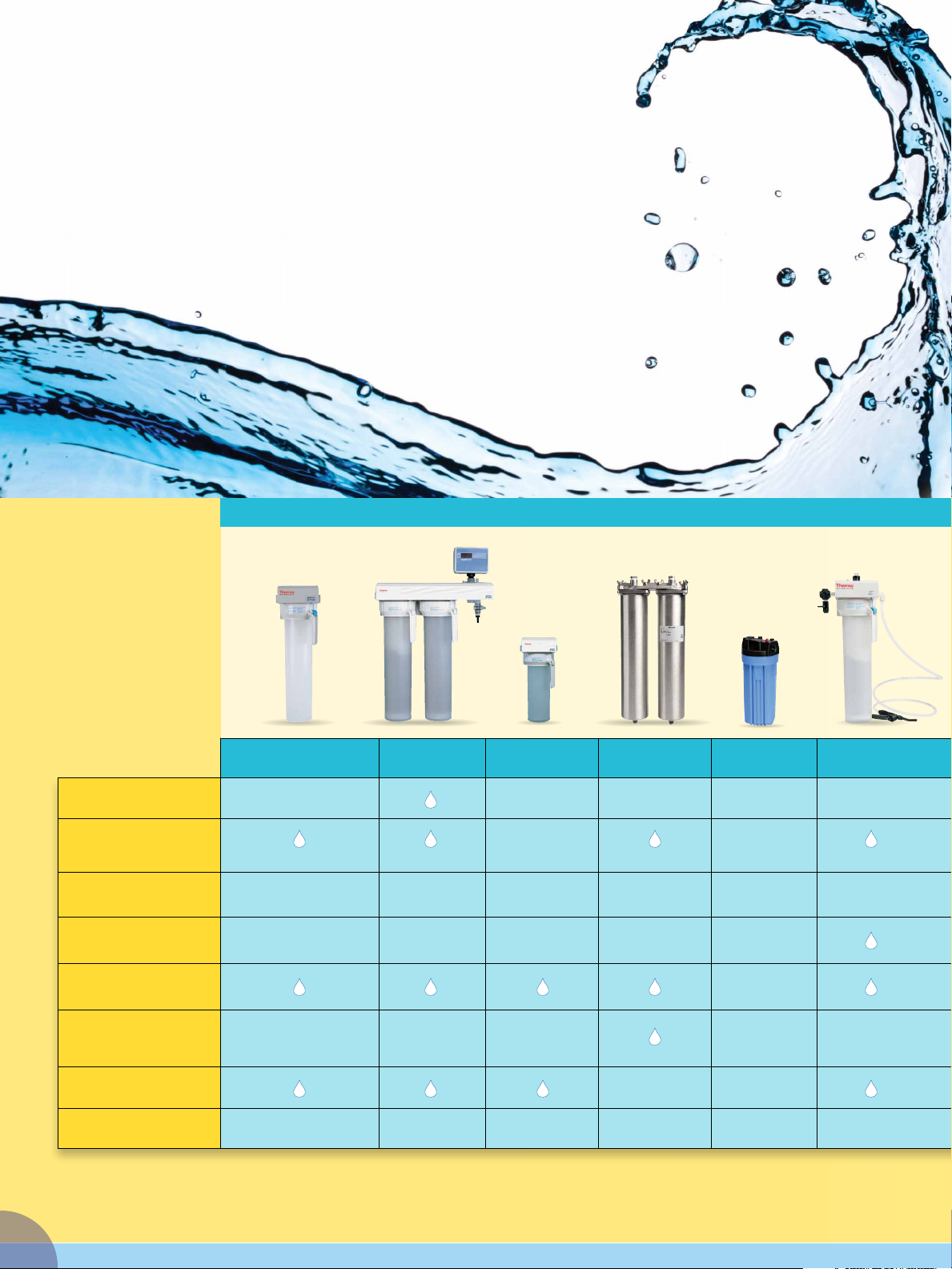

Pressurized Cartridge Systems

B-Pure™ Single Holder B-Pure B-Pure High Temperature Economy Filter Harvey DI+ Hose Nipple* Bantam

Double Holder Half-size Holder Stainless Steel Holder

Digital Purity Meter

Analog Purity Meter

where real-time resistivity is not required

Color Change Indicator

Remote Dispenser

Wall-Mounted

High Temperature Tolerant

37.8°C (100°F)

Quick-Release Canisters

Maximum Flow Rate L/min 4 4 2 3 2 4 1.25 0.63

* All Hose Nipple Cartridges except 7373D contain dyes which change color when resin is exhausted

Indicates when to install new cartridge When feeding lab equipment

Saves laboratory bench space For autoclaves and dishwashers

Fast and simple cartridge change-outs For all applications

See real-time purity values With more sensitive applications

For use where water temperature exceeds Good option for cooling loops

Indicates when to install new cartridge at quick glance If cartridge system feeds equipment, such as autoclave,

Hand-dispense water from the cartridge system For rinsing glassware or filling water bath

4

Page 5

Non-pressurized Cartridge Systems

Identify the best system based

on your unique requirements

•Will the cartridge system be installed in a pressurized

or non-pressurized water line?

•What is your principal application for pure water?

•What do you need removed from your water?

•What is the quality of the feed water?

•What is the water volume you need on a daily basis?

•Do you have temperature or flow rate parameters?

™

Deionizer Benefits Typical Uses

Indicates when to install new cartridge When feeding lab equipment

5

Page 6

What You Need to Remove

from Feed Water Determines

the Right Cartridge

Organics or Chlorine

Organic solids are present in water sources from plant and animal decay as well as

human activity. These may include proteins, alcohols, chloramines, and residues of

pesticides, herbicides, and detergents which foul ion exchange resins and interfere with

organic analysis. Chlorine is an additive used to treat drinking water and may need to

be removed for biological protocols. Activated carbon will remove both organics and

chlorine from the feed water.

Resin needed - activated carbon

Colloids

Colloidal particles typically have a slightly net negative charge ranging in size from

0.01 to 1.0µm and can be either organic or inorganic. Unlike suspended particles,

colloids do not settle out by gravity, but remain suspended in liquid. Colloids clog filters,

interfere with instrument operation, foul reverse osmosis membranes, and can bypass ion

exchange resins, resulting in lower resistivity in deionized water systems. Macroreticular

resins enhance performance of deionization resins and extend final filter life.

Resin needed - macroreticular resin

Chlorinated H2O

CI

2

CI

2

CI

2

(Chlorine and Organics)

Feed water with organic and chlorine

contaminants come into contact with the

activated carbon in the cartridge. The

impurities adhere to the surface of the

carbon, purifying water.

Carbon H

CI

CI

2

O Free of Chlorine

2

and Some Organics

2

CI

2

6

Page 7

Inorganic Ions

Impurities such as silicates, chlorides, fluorides,

bicarbonates, sulfates, phosphates, nitrates, and ferrous

compounds are present as cations (positively charged ions)

and anions (negatively charged ions). Water with a high

concentration of ions will conduct electricity and have high

conductivity and low resistivity, as the two are inversely

related. Ions will adversely affect the results of inorganic

analyses such as IC, AA, ICP/MS, and may retard cell and

tissue growth in biological research. These ions can also

affect the cartridge life in deionized water systems.

Resin needed - ion exchange resin, cation exchange,

or anion exchange

• Two-Bed (high capacity) resin – contains a layer of

cation resin followed by a layer of anion resin within

the same cartridge. This resin will not remove ions as

thoroughly as the mixed-bed, but it will last longer.

• Mixed-Bed (ultrapure) resin – contains a mixture of

anion and cation resins to improve ion exchange

reaction kinetics. It produces high resistivity water at a

pH of 6.8 to 7.2 that is free of silica, carbon dioxide,

and other ionized impurities.

Oxygen

To help prevent corrosion in applications such as closed

cooling loop systems for radar, computer, and laser

systems choose an oxygen removal resin.

Resin needed - oxygen removal

Only high quality resins are used in our

cartridge and filter systems to ensure

consistently high quality product water.

7

Page 8

Thermo Scientific Barnstead

Pressurized cartridge systems

Digital Purity Meter provides

quick-glance notification of

when to install a new cartridge

B-Pure Cartridge Holder Systems

These expandable, modular systems are the best choice when

applications require up to 30 L/day with a maximum flow rate

of 4 L/min. B-Pure systems are engineered to support feed water

pressures up to 100 psi and feature a simple quarter

cartridge exchange design. Standard wall-mounting brackets are

included. Interconnect B-Pure Holders to form custom water

treatment systems.

• B-Pure Single Holder produces water at up to 4 L/min and can

be used separately or in series with other single holders. Pura-Lite

"Go/No Go" analog resistivity indicators are available.

• B-Pure Double Holder includes 2 canisters and draw-off faucet.

Water is dispensed at 4 L/min and optional digital or analog purity

meters are available.

• B-Pure Half-size Holder supports flow rates up to 2 L/min with an

optional pressure gauge kit to monitor inlet and outlet water pressure.

Can support either half-size cartridges or the 10 in (25.43 cm) filters.

Typical applications - pretreatment, deionization, filtration

turn, quick-release

8

Page 9

Step 1:

Change cartridge when

the resistivity is below

the desired level or the

cartridge is more than

1 year old. For filters,

you’ll notice a significant

decrease in pressure or

flow rate

Step 2:

Remove the canister

from the head by

depressing the thumb

lever and rotating the

hand ring quarter turn

to the left

Step 3:

Remove exhausted

cartridge and discard

B-Pure systems

offer easy-to-use,

easy-to-maintain

cartridge

replacement

Other Pressurized

Cartridge Systems

High Temperature Stainless

Steel Cartridge System

This unique system is ideal when water

system temperature routinely exceeds 100 ºF

(37.8 ºC). Available in single or dual cartridge

designs, 316 gauge stainless steel withstands

higher temperatures and allows for pressures

up to 160 psi.

Typical applications - cooling loops

Economy Filter Holder System

This filter holder is a basic holder system.

It accepts 10 in (25.43 cm) double openended filters and can be piped into any

water line.

Typical applications - particle filtration

Step 4:

Replace old cartridge

with a new one

Step 5:

Install canister by

depressing thumb lever

and rotating quarter

turn to the right, until

the locking pin is in the

appropriate position

Harvey DI+ Cartridge System

This turnkey system includes a remote

dispenser, Pura-Lite (50 K Ω-cm) indicator

and a high capacity, two-bed ion exchange

cartridge to remove calcium, magnesium,

and other ions from water. It accepts a broad

range of other cartridges to remove impurities

and produces pure water at a flow rate of

0.5 L/min.

Typical applications - pretreatment,

deionization

9

Page 10

Thermo Scientific Barnstead

Pressurized cartridge systems

Pressurized Cartridge Systems

Inlet Feed Feed Water Dimensions Max Feed Max Flow Voltage Model No.

Line NPTF Temp. °F (°C) W x D x H Water Pressure Rate (L/min) (VAC)

inches (cm) inches (cm) (psig)

B-Pure Single Holder 1/2 (1.3) 40-120 (4-49) 7 x 7 x 15 (17.8 x 17.8 x 38.1) 100 4 120 D4511

B-Pure Double Holder 1/2 (1.3) 40-120 (4-49) 15 x 7 x 27 (38.1 x 17.8 x 68.6) 100 4 120 D4521

with Digital Purity Meter 240 D4522-33

B-Pure Double Holder 1/2 (1.3) 40-120 (4-49) 15 x 7 x 27 (38.1 x 17.8 x 68.6) 100 4 120 D4524

with Pura-Lite Indicator

(50 kΩ-cm)

B-Pure Double Holder 1/2 (1.3) 40-120 (4-49) 15 x 7 x 27 (38.1 x 17.8 x 68.6) 100 4 120 D5831

with Pura-Lite Indicator

(200 kΩ-cm)

B-Pure Double Holder 1/2 (1.3) 40-120 (4-49) 15 x 7 x 27 (38.1 x 17.8 x 68.6) 100 4 120 D5833

with Pura-Lite Indicator

(1 MΩ-cm)

B-Pure Half-size Holder 1/2 (1.3) 40-120 (4-49) 7 x 7 x 15 (17.8 x 17.8 x 38.1) 100 2 120 D5839

High Temperature Stainless 1/4 (.64) 40-180 (4-82) 6 x 7 x 22 (15.2 x 17.8 x 55.9) 100 3 n/a D0807

Steel Single Holder

High Temperature Stainless 1/4 (.64) 40-180 (4-82) 13 x 7 x 22 (33 x 17.8 x 55.9) 100 3 n/a D0855

Steel Double Holder

Economy Filter Holder 3/4 (1.9) 40-120 (4-49) 5.25 x 5.25 x 12 (13.3 x 13.3 x 30.5) 100 2 n/a 15840

Use with filters only

Harvey DI+ 1/4 (.64) 40-120 (4-49) 7 x 13 x 21 (17.8 x 33 x 53.3) 100 4 120 AY1273X4

Ships with Cartridge (D0803),

Pura-Lite Indicator (E3450)

and Dispenser

Optional Accessories for Pressurized Cartridge Systems

Model No.

Description 120V 240V

Digital Purity Meter

Compatible with B-Pure Double Holders exclusively Resistivity range of 0.1 - 18.2 MΩ-cm D2770 D2769

Pura-Lite Indicator

Compatible with all systems above, except with Ecomony Filter Resistivity range of 50 KΩ-cm E3450 E3454

Resistivity range of 200 KΩ-cm E3451 E3455

Resistivity range is up to 1 MΩ-cm E3452 E3456

Flow Meters

Compatible with all systems above, installed in the feed line 1 to 75 LPH using 1/8 in (.32 cm) NPT inlet D0787 D0787

0 to 190 LPH using 1/8 in (.32 cm) NPT inlet D0788 D0788

0.2µM Final Filter

For use with B-Pure Double Holders exclusively D3750 D3750

Dual Pressure Gauge Kit

0 to 160 psi pressure gauge exclusive to the B-Pure Half-size System. Pressure drop greater than 10 psi indicates need for filter change D2780 D2780

Single Pressure Gauge Kit

0 to 160 psi pressure gauge exclusive to the B-Pure Half-size System. Pressure drop greater than 10 psi indicates need for filter change D0780 D0780

10

Page 11

Cartridges and Filters for Pressurized Systems

Cartridge Resin Type(s) Capacity as CaCO3 Model No.

Cartridges Compatible with B-Pure Double/Single Holder and Harvey DI+ Cartridge Systems

Anion Removal Strong Anion Exchange 1680 gr D0760

Cation Removal Strong Cation Exchange 3170 gr D0815

High Capacity, Two-Bed Ion Exchange Two-Bed Ion Exchange 1760 gr D0803

Macroreticular and Organic Removal Macroreticular, Activated Carbon 2000 gal D0836

Organic Removal Activated Carbon 5000 gal D0813

Oxygen Removal Oxygen Removal 30 g D0811

Ultrapure Mixed-Bed 875 gr D0809

Ultrapure and Organic Removal Mixed-Bed, Activated Carbon 785 gr/ 1000 gal D0832

Ultrapure and Oxygen Removal Ultrapure, Oxygen Removal 455 gr/ 30 g D8809

Ultrapure, Oxygen, and Organic Removal Ultrapure, Oxygen Removal, Organic Removal 365 gr/2000 gal /12 g D8811

Cartridges Compatible with B-Pure Half-size Holder Cartridge Systems

Organic Removal Activated Carbon 5000 gal D50215

Mixed-Bed with Organic Removal Mixed-Bed Activated Carbon 275 gr/2000 gal D50217

Oxygen Removal Porous Strong Anion Exchange 18 g D50214

Mixed-Bed with Oxygen Removal Oxygen Removal Mixed-Bed 275 gr/ 9g D50216

Ultrapure Mixed-Bed 550 gr D50213

Cartridges Compatible with High Temperature Stainless Steel Double/Single Holder Cartridge Systems

High Temp, Organic Removal Activated Carbon 5000 gal D8815

High Temp, Oxygen Removal Oxygen Removal 30 g D8817

High Temp, Ultrapure Mixed-Bed 915 gr D8816

High Temp, Ultrapure, Oxygen, and Organic Removal Ultrapure, Oxygen Removal, Organic Removal 365 gr / 2000 gal / 12 g D8818

High Temp, Mixed-Bed, Oxygen Removal Ultrapure, Oxygen Removal, Organic Removal 455 gr / 30 g D8825

Filters Compatible with B-Pure Half-size Holder Cartridge Systems

1 µM Pre-filter FL583X4

5 µM Pre-filter FL583X1

10 µM Pre-filter FL583X2

15 µM Pre-filter FL583X3

0.2 µM Pre-filter FL583X6

0.45 µM Pre-filter FL583X5

Filters Compatible with Economy Filter Holder

5 µM Pre-filter D2729

10 µM Pre-filter 18011

15 µM Pre-filter 18018

Capacity (grains shown as CaCO3)

gr = grain | gal = gallon | g = grams of oxygen

CALCULATING ION EXCHANGE CAPACITY

Cartridge Grain Capacity

Total Dissolved Solids (Grains/Gal)

= Gallons Processed

CARTRIDGE LIFE CALCULATION

Cartridge Grain Capacity

[Feed Water TDS (ppm)]

Cartridge Grain Capacity

[Feed Water TDS (ppm)]

x 64.7 = Pure Water Output (Liters)

x 17.1 = Pure Water Output (Gallons)

11

Page 12

Thermo Scientific Barnstead

Non-pressurized cartridge systems

Hose Nipple Cartridge Systems

An economical and simple approach for purifying

water, this system can be installed by itself or in a

series using simple tubing. Cartridges for this system

provide a selection of removal properties, such as

organic, ion, metal, and oxygen removal within a

100% virgin polypropylene cartridge housing. This

holder offers the flexibility of accepting half-size,

two-third size and full-size cartridges as needed.

Cartridges are also available with color change

indicators so you know when it is time to replace

the cartridge.

Typical applications - deionization,

organic removal, chlorine removal

12

Shown here installed in a series for

greater capacity, our most common

Hose Nipple Cartridge, D8901 and

D8902, is used for generating

deionized water for glassware

washing and rinsing

Bantam Deionizer Cartridge Systems

A good choice for deionization or pretreatment of lab

water. Ideal for applications requiring up to 38 L/hr of

purified water, this system includes an integrated resistivity

meter that measures up to 18 MΩ - cm tolerating

inlet pressure ranging from 5 -70 psi. Designed for

non-pressurized applications, this sytstem requires

diverting output water to an atmospherically vented

receptacle as no back pressure can be accepted.

Typical applications - deionization

Page 13

Non-pressurized Cartridge Systems

Inlet Feed Feed Water Dimensions Max Feed Max Flow Voltage Model No.

Line NPTF Temp. °F (°C) W x D x H Water Rate (L/min) (VAC)

inches (cm) inches (cm) Pressure (psig)

Hose Nipple Cartridge Holder n/a 40-120 (4-49) n/a n/a 1.25 n/a D8900

Bantam Deioinizer

Cartridge System

Integrated purity indicator 3/8 (.95 cm) 40-120 (4-49) 6 x 9 x 28.5 (15.2 x 22.2 x 72.4) 70 0.3 120 D0800

(25 kΩ - 18 MΩ-cm) 240 D0805

Cartridges for Non-pressurized Systems

Cartridge Resin Type(s) Color Indicator* Capacity as CaCO3 Model No.

Cartridges Compatible with Hose Nipple Cartridge Systems

1/2 Size Mixed-Bed Ultrapure Ion Exchange no 430 gr D50220

1/2 Size Mixed-Bed with Oxygen Removal** Ultrapure Mixed-Bed with Strong Anion Exchange no 280 gr/4.4 g D8822

2/3 Size High Capacity** Two-Bed Ion Exchange with Strong Cation Exchange yes 1100 gr D8950

2/3 Size Mixed-Bed and Organic Removal** Mixed-Bed Ion Exchange with Activated Carbon yes 470 gr/200 gal D8951

Full Size Cation Removal Cation Exchange yes 3000 gr D8905

Full Size High Capacity Two-Bed Ion Exchange yes 1650 gr D8901

Full Size Macroreticular, Cation Removal Macroreticular Cation Exchange no n/a D8908

Full Size Organic Removal Activated Carbon no 5000 gal D8904

Full Size Oxygen Removal Strong Anion Exchange no 30 g D8903

Full Size Pretreatment and Scale Eliminator Mixed-Bed and Strong Cation Exchange, Activated Charcoal yes 1250 gr/1000 gal D8921

Full Size Ultrapure Ultrapure Ion Exchange no 915 gr D8911

Full Size Ultrapure Ultrapure Mixed-Bed Ion Exchange yes 915 gr D8902

Full Size Ultrapure with Organic Removal Mixed-Bed Ion Exchange with Activated Carbon yes 730 gr/2000 gal D8922

Cartridges Compatible with Bantam Deionizer Cartridge Systems

Anion Removal Strong Anion Exchange no 1680 gr D0760

Cation Removal Strong Cation Exchange no 3170 gr D0815

High Capacity, Two-Bed Ion Exchange Two-Bed Ion Exchange no 1760 gr D0803

Ultrapure Mixed-Bed no 875 gr D0809

Ultrapure and Organic Removal Mixed-Bed, Activated Carbon no 785 gr/ 1000 gal D0832

*Hose Nipple Cartridge with color indicator to notify user cartridge is expired; Alcohol-containing samples cannot be used with these models

**Hose Nipple Cartridge with tapered straight nipple for 3/8in (.95 cm) ID tubing

Capacity (grains shown as CaCO3)

gr = grain | gal = gallon | g = grams of oxygen

CALCULATING ION EXCHANGE CAPACITY

Cartridge Grain Capacity

Total Dissolved Solids (Grains/Gal)

= Gallons Processed

CARTRIDGE LIFE CALCULATION

Cartridge Grain Capacity

[Feed Water TDS (ppm)]

Cartridge Grain Capacity

[Feed Water TDS (ppm)]

x 64.7 = Pure Water Output (Liters)

x 17.1 = Pure Water Output (Gallons)

13

Page 14

Common Applications for Cartridge Systems

Thermo Scientific Barnstead cartridge systems are ideal for treating

water used in many common laboratory settings:

Supply purified water for general lab equipment

(CO2 incubators, environmental chambers, and water baths)

Pure water is frequently required for humidification and decontamination in common laboratory equipment. The

equipment often requires water with a resistivity ranging from 50 kΩ - 1 MΩ. The use of ultrapure water may

damage equipment, yet poor quality water can cause mineral deposits or contamination. Water used with this

equipment typically does not need to be sterile.

Thermo Scientific

Environmental Chamber

Thermo Scientific

General Purpose Water Bath

Thermo Scientific Forma

Direct Heat CO2 Incubator

Cartridge Systems Suggested for General Lab Equipment

System Cartridge

Application Solution Model No. Model No.

Supply water for one piece of lab equipment, such

as a CO2 incubator or a water purifcation system

Supply water for multiple pieces of lab equipment,

such as a water bath or environmental chamber

Supply water for a couple of pieces of lab

equipment and rinse dishes

Hose Nipple Cartridge System with High Capacity Cartridge

•Non-pressurizedsystem

•Highcapacityionexchangecartridgeproducesrequiredresistivityandfeatures

color indicator to notify user when cartridge is exhausted.

B-Pure Double Holder Cartridge System including

Pura-Lite Indicator with Pretreatment, Organic, and Ultrapure Cartridges

•Pressurizedsystemaccomodatingtwocartridgesforincreasedcapacity

•Pura-Liteindicateswhentochangecartridge

•Pretreatment,organic,andanultrapurecartridgeextendsusefullifeofcartridges

while removing organics and ions

Harvey DI+ System

•Completeoutofthebox,HarveyDI+includesasinglepressurizedcartridge

system, Pura-Lite Indicator (E3450), a high capacity cartridge (D0803), and

a dispenser

D8900 D8901

D4524 D0832 and D0809

AY1273X4 included

14

Page 15

COOLING LOOP DESIGN EXAMPLE

Purify the water used in

cooling loops

Impurities in water can adversely impact the

operational life of laser, radar, sonar, and other heat

exchange systems equipped with water cooling

loops. Untreated or improperly treated cooling loop

water can lead to corrosion, scaling, inefficient heat

HEAT

EXCHANGE

AREA

FLOW

RESTRICTION

DEVICE

PUMP

SIDESTREAM

LOOP AND

CARTIDGE

RESERVOIR

transfer, and ultimately system failures.

Cartridge Systems Suggested for Typical Water Cooling Loops

System Cartridge Accessory

Application Solution Model No. Model No. Model No.

Cooling loops where cartridge system will

experience back pressure; normal temperatures,

is not open to atmosphere

Cooling loops where cartridge system will

NOT experience back pressure; no extreme

temperatures; open to atmosphere

Cooling loops where temperature is typcially

120.2 °F (49 °C); cartridge system may

experience back pressure; is not open to

atmosphere

B-Pure Single Holder Cartridge System, Ultrapure/

Oxygen Removal Cartridge and Pura-Lite Indicator

•Pressurizedsystemtoaccomodatebackpressure

•Ultrapure/oxygenremovalcartridgeproducesrequiredresistivity

and maintains low oxygen level to prevent oxidation

•Pura-Liteindicateswhentochangecartridge

Hose Nipple Cartridge System with High Capacity

Cartridge

•Non-pressurizedsystem

•Highcapacityionexchangecartridgeproducesrequired

resistivity and features color indicator to indicate when to

change cartridge. Since the loop is open to the atmosphere,

there is no need for oxygen removal

High Temperature Cartridge System, Mixed-Bed Oxygen

Removal Cartridge and Pura-Lite Indicator

•Non-pressurizedsystem

•Highcapacityionexchangecartridgeproducesrequired

resistivity. Since the loop is not open to the atmosphere,

there is a need for oxygen removal

D4511 D8809 E3450

D8900 D8901 n/a

D0855 D8816 and D8825* E3450

* See other cartridge options on page 11

Cartridge and Filter

System Applications

•Microbiology - nutrient media preparation;

glassware rinsing; environmental monitoring

•Biochemistry - sample preparation;

spectroscopy

•Chemistry - sample preparation; dilutions;

•Environmental sciences - use in

Biochemical Oxygen Demand (BOD); Total

Soluble Solids (TSS); Mixed-Liquor Volatile

Suspended Solids (MLVSS)

•Education - fly food preparation; humidifiers

reagent prep

15

Page 16

Customized

Let our experts recommend

Cartridges

Don’t see the right

cartridge for

your needs?

We can custom build cartridges.

Call your local sales representative

to walk you through the process.

the right water purification

products for you!

Request a FREE, no obligation

Thermo Scientific H2O Select Analysis Kit

Our comprehensive water analysis program is designed to identify the best

water system and ancillary equipment based on a sample of your feed water.

Upon evaluation, you will receive a recommendation along with estimated

cartridge life. Request one today at www.thermoscientific.com/select.

For more information about these products or our complete water purification portfolio,

please visit www.thermoscientific.com/purewater

© 2011 Thermo Fisher Scientific Inc. All rights reserved. All trademarks are the property of Thermo Fisher Scientific Inc. and its subsidiaries. Specifications, terms and pricing

are subject to change. Not all products are available in all countries. Please consult your local sales representative for details.

North America: USA/Canada +1 866 984 3766 (866-9-THERMO)

Europe: Austria +43 1 801 40 0, Belgium +32 53 73 42 41, France +33 2 2803 2180, Germany national toll free 08001-536 376,

Germany international +49 6184 90 6000, Italy +39 02 95059 448, Netherlands +31 76 579 55 55, Nordic/Baltic/CIS countries +358 9 329 10200,

Russia +7 812 703 42 15, Spain/Portugal +34 93 223 09 18, Switzerland +41 44 454 12 12, UK/Ireland +44 870 609 9203

Asia: Australia +61 39757 4300, China +86 21 6865 4588 or +86 10 8419 3588, India toll free 1800 22 8374, India +91 22 6716 2200,

Japan +81 45 453 9220, New Zealand +64 9 980 6700, Other Asian countries +852 2885 4613 Countries not listed: +49 6184 90 6940

WPBROCARTRIDGE 1111

Loading...

Loading...