Page 1

Thermo Scientific CW3 Cell Washer

Instruction Manual

50144259_h • 06 / 2018

Visit us online to register your warranty:

www.thermofisher.com/labwarranty

Page 2

Page 3

Page 4

Table of Contents

1. Preface ............................................................... 5

1. 1. Items Supplied .............................................................5

1. 2. Intended Use ...............................................................7

1. 3. Precautions ................................................................7

1. 4. Symbols Used on the Cell Washer .............................................10

1. 5. Symbols Used in the Manual .................................................11

2. Technical Specifications ................................................12

2. 1. Directives and Standards ....................................................13

2. 2. Mains Supply .............................................................13

2. 3. Location and Function of Parts ................................................14

2. 4. Control Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2. 5. Condition-setting Panel .....................................................18

3. Transport and Set Up ...................................................20

3. 1. Before Setting Up ..........................................................20

3. 2. Location .................................................................20

3. 3. Transporting ..............................................................20

3. 4. Leveling ..................................................................21

3. 5. Check Mains Connection ....................................................21

3. 6. Setting Up ................................................................21

3. 7. Storage ..................................................................32

3. 8. Shipping .................................................................32

4. Operation ............................................................ 33

4. 1. Preparation ...............................................................33

4. 1. 1. Injection Volume Adjustment and Pump Ventilation ..........................................33

4. 1. 2. Setting the Operating Conditions .......................................................35

4. 1. 3. Preparation of the Sample ............................................................35

4. 2. Operation Modes ...........................................................36

Thermo Scientic CW3 | 3

Page 5

4. 2. 1. Automatic Mode ...................................................................36

4. 2. 2. Manual Mode .....................................................................36

4. 2. 3. Agitation-Centrifugation ..............................................................36

4. 2. 4. Operational Sequence for Antiglobulin Test ................................................37

5. Maintenance .......................................................... 38

5. 1. Cleaning .................................................................38

5. 1. 1. Pump, Tank and Tubing ..............................................................39

5. 1. 2. Rotor, Distributor and Bowl ...........................................................39

5. 1. 3. Chamber, Splash Guard, Drain Cover and Door Stopper Parts ..................................40

5. 2. Preventive Maintenance .....................................................41

5. 3. Shipping and Disposal ......................................................41

6. Troubleshooting ....................................................... 42

6. 1. Mechanical Emergency Door Release ..........................................42

6. 2. Error Codes ...............................................................43

6. 3. Troublshooting when no Error Code is indicated ..................................44

Decontamination Information Certificate ..................................... 45

Chemical Compatibility ................................................... 46

Index ..................................................................49

4 | CW3 Thermo Scientic

Page 6

1. Preface

1. 1. Items Supplied

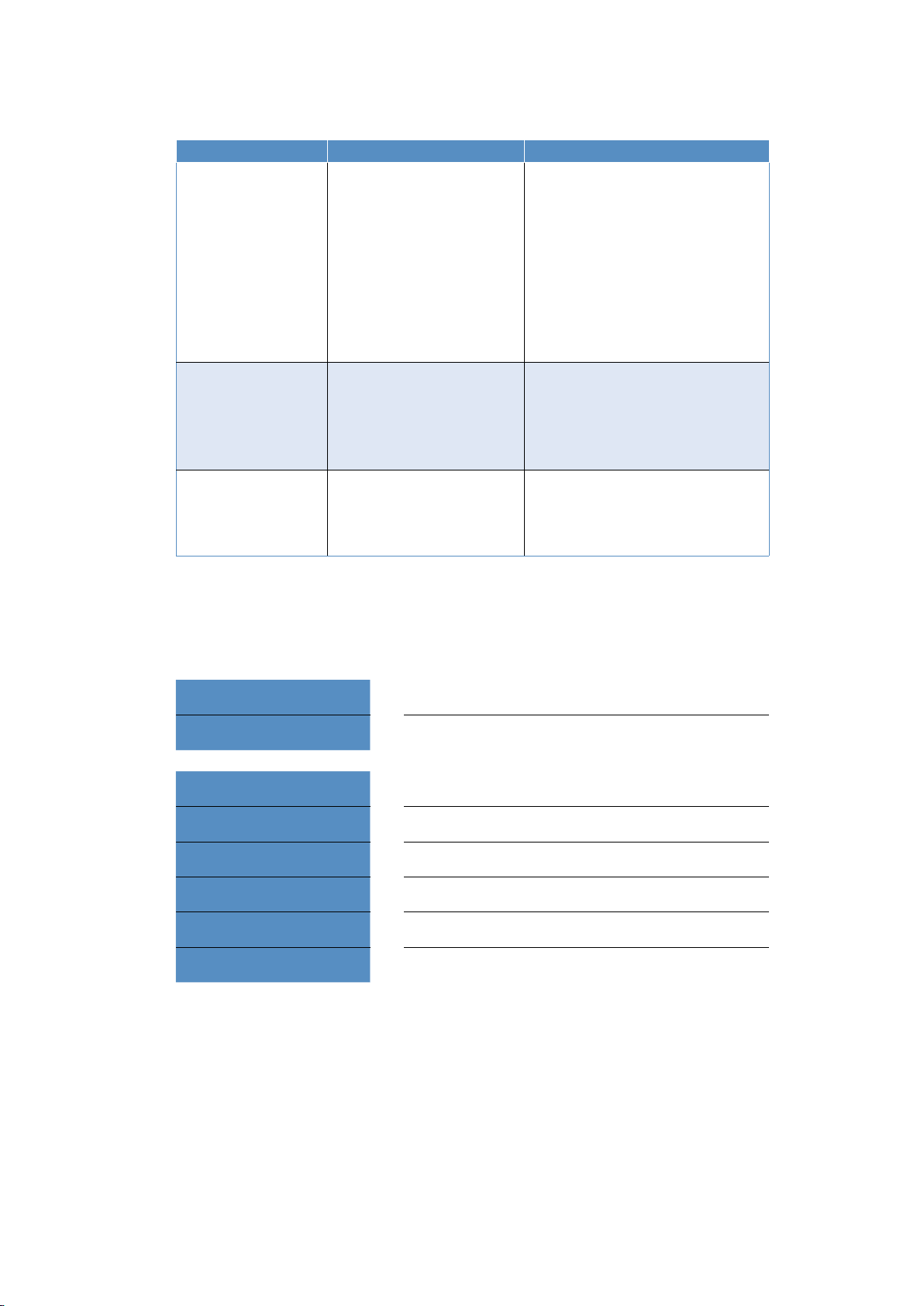

Article No. Description Quantity

Thermo Scientific CW3 cell washer 1

S402776A Bowl Assembly 1

S413259C Tank (5 L) 1

4744346 Tubing 3 m

75000015 Tube Connector 1

S4011034 Drain Tube 2.5 m

Items Supplied

480270

483719 Grease 1

8046004 Hex. Wrench 1

S411107 Motor Guard Plate 1

4666354

4666357

4666355

S413181A L-shaped Adapter 1

480879 D10 Adapter 25

Rotor Assembly Options 1

75000020 24 place rotor assembly with distributor

75000021 12 place rotor assembly with distributor

Test Tubes (12 mm in diameter and 75

mm in length)

Hose Band

Small

Medium

Big

Power Cord 1

Instruction Manual 1

50 (1 box)

1

1

2

Thermo Scientic CW3 | 5

Page 7

Items Supplied

Article No. Description Quantity

Replacement Parts

Rotor Assembly 1

75000022 24 places

75000023 12 places

Distributor Assembly 1

75000024 24 places

75000025 12 places

6 | CW3 Thermo Scientic

Page 8

1. 2. Intended Use

The Thermo Scientific CW3 cell washer is designed to perform cell washing in multiple washing cycles using saline

solution. The cell washer provides blood cells after sample separation, which can be used for further blood testing such

as Antiglobulin test, ABO compatibility, Rh testing, Cross-matching and Antibody screening.

The centrifuge should always be operated by a trained individual such as a clinical laboratory technologist or a person

with a similar education.

1. 3. Precautions

Carefully read the following safety precautions for a thorough understanding.

Protection is impaired if the cell washer is not used as specified in the intended use.

Follow the instructions and procedures described in this instruction manual to operate this cell washer safely.

Be sure to observe the precautions in this instruction manual and on your equipment.

It is the general obligation of the operator to make sure, that the proper protective clothing is used. Mind the „Laboratory

Biosafety Manual“ of the World Health Organization (WHO) and the regulations in your country.

Safety messages are indicated as follows. They are stated with signal words combined with the safety alert symbol to call

your attention to items or operations that could be dangerous to you or other persons using this equipment. The definitions

of signal words are as follows:

WARNING: Warning notes indicate any condition or practice, which if not strictly observed, could result in seri-

ous injury or possible death.

CAUTION: Caution notes indicate any condition or practice, which if not strictly observed or stopped, could

result in personal injury, damage or destruction of the equipment.

NOTICE: Notes indicate an area or subject of special merit, emphasizing either the product’s capabilities or

common errors in operation or maintenance.

Do not operate this cell washer in any manner not described in this Instruction Manual. Should you have any troubles with

this cell washer, call a Thermo Fisher Scientific authorized sales/service representative.

The precautions described in this Instruction Manual are carefully developed to cover all possible risks. It is important that

you are alert for unexpected incidents. Be careful when operating this cell washer.

Intended Use

Thermo Scientic CW3 | 7

Page 9

Precautions

WARNING

1. The cell washer is neither inert nor protected against explosion. Never use the cell washer in an explosion-prone

environment.

2. Do not set up the cell washer in or near places where flammable gases are generated or chemicals are stored.

3. If centrifuging any hazardous materials mind the „Laboratory Biosafety Manual“ of the World Health Organization

(WHO). Look on the internet page of the World Health Organization (www.who.int) for the „Laboratory Biosafety

Manual“.

For materials in a higher risk group, extra safety measures have to be taken.

4. Take all necessary safety measures before using samples that are toxic or radioactive, or blood samples that are

pathogenic or infectious. You use such samples at your own responsibility.

a. If the cell washer, rotor, or an accessory is contaminated by samples that are toxic or radioactive, or blood

samples that are pathogenic or infectious, be sure to decontaminate the item according to good laboratory

procedures and methods.

b. If there is a possibility that the cell washer, rotor, or an accessory is contaminated by samples that might

impair human health (for example, samples that are toxic or radioactive, or blood samples that are

pathogenic or infectious), it is your responsibility to sterilize or decontaminate the cell washer, rotor, or

the accessory properly before requesting repairs from a Thermo Fisher Scientific authorized sales/service

representative.

c. It is your responsibility to sterilize and/or decontaminate the cell washer, rotor, or parts properly before

returning them to a Thermo Fisher Scientific authorized sales/service representative.

5. Do not centrifuge explosive or flammable materials or substances which could react violently

6. Because the liquid samples, the saline, etc. are used in this cell washer, your cell washer must be grounded

properly.

7. To avoid electrical shocks, do not handle the power cord or turn on or off the POWER switch with wet hands.

8. The cell washer itself may move if the rotor fails during high-speed rotation. Make sure there is a 30 cm area

around the cell washer that will allow for such movement and do not allow individuals to enter into that area

during operation. Also do not place dangerous objects such as flammable or explosive materials on top of the

cell washer or in the surrounding area.

9. While the rotor spins, never unlock the door.

10. Repairs, disassembly, and other modifications to the cell washer are strictly prohibited unless performed by a

Thermo Fisher Scientific authorized sales/service representative.

8 | CW3 Thermo Scientic

Page 10

CAUTION

1. Turn off the cell washer at the main switch. The mains plug must be freely accessible at all times.

Press STOP to shut the cell washer down.

Pull out the power supply plug or disconnect the power supply in an emergency.

2. Use the cell washer only with correct installed rotor and distributor assembly and correct inserted bowl, splash

guard and drain cover.

3. Do not move or relocate the cell washer while the rotor spins.

4. Do not lean on the cell washer.

5. Do not pour any solution such as water, detergent, or disinfectant directly into the rotor chamber. If you do so,

the bearings of the drive unit might corrode or deteriorate.

6. Connect the saline tank to the pump inlet connector of the cell washer correctly with the hose bands (standard

accessories). Otherwise the liquid might leak from the tube and the liquid might get into the inside of the cell

washer. If you think liquid is inside of the cell washer, contact a Thermo Fisher Scientific authorized sales/service

representative to clean and dry the cell washer.

7. Before you operate the cell washer, remove any dropped objects and tube fragments from inside the rotor

chamber.

8. Always check for corrosion and damage on the rotor before using it. Do not use a corroded or damaged rotor.

9. Be sure to use the specified test tubes with a wall thickness of 1 mm or more. When using thin test tubes such

as disposable test tubes, do not use them repeatedly. If any scratches, crack, inside warp, etc. is found on the

test tubes, do not use them because they cannot bear a centrifugal force.

10. Be sure to load test tubes to all the holders.

11. Use one or two drops (about 50 μl) of 3-5% erythrocyte suspension as sample volume for blood cell washing.

When using precipitated erythrocyte layer, use one or two drops (about 50 μl or less) per test tube. Use the 80%

or less of the test tube capacity as sample volume for centrifugation.

12. If you observe some abnormality in this product, stop using it immediately and contact a Thermo Fisher Scientific

authorized sales/service representative. Notify the service representative of the alarm code if displayed.

13. If the cell washer will not be used for a long time, remove the power cord from the socket.

14. For connection to a different outlet, the power cord might be needed to be replaced.

15. Follow local electrical codes.

16. Depending on the magnitude, an earthquake might damage the cell washer.

If you observe some abnormality, contact a Thermo Fisher Scientific authorized sales/service representative.

Precautions

NOTICE

Usually the control panel and the surface of the cell washer get warm during operation.

Thermo Scientic CW3 | 9

Page 11

Symbols Used on the Cell Washer

1. 4. Symbols Used on the Cell Washer

This symbol refers to general hazards.

CAUTION means that material damage could occur.

WARNING means that injuries or material damage or contamination could occur.

This symbol refers to biological hazards.

Observe the information contained in the instruction manual to keep yourself and your environment safe.

This symbol refers to information on hazards, described within the manual.

This symbol demands to disconnect mains before transporting or servicing the cell washer.

This symbol demands to not pour the open cell washer with water.

This symbol shows the inflow and draining directions of the cell washer. The arrow pointing towards the cell

washer shows the inflow direction. The arrow pointing away from the cell washer shows the draining

direction.

This symbol demands to make sure, that the drain cover is installed in the cell washer door before you start

the CW3 cell washer. If not, biological hazard is possible when contaminated samples are used.

See “5. 1. 4. 4. Drain Cover” on page 40 for removing and installation.

Caution: Federal law restricts this device to sale by or on the order with a qualified clinical facility manager or

equivalent.

10 | CW3 Thermo Scientic

Page 12

The CE mark states that this product is meeting all requirements for the European Economic Area.

This CSA mark states that this product is meeting all requirements for Canada and USA.

This symbol marks the manufacturer of this product.

Symbols Used in the Manual

This symbol marks the manufacturing date of this product.

This symbol marks the catalogue number of this product.

This symbol marks this product as intended to be used as an in vitro diagnostic medical device.

1. 5. Symbols Used in the Manual

This symbol refers to general hazards.

CAUTION means that material damage could occur.

WARNING means that injuries or material damage or contamination could occur.

This symbol refers to biological hazards.

Observe the information contained in the instruction manual to keep yourself and your environment safe.

Thermo Scientic CW3 | 11

Page 13

Symbols Used in the Manual

2. Technical Specifications

Environmental Conditions Altitudes of up to 2000 m above sea level

Environmental Conditions

during Storage and Shipping

Permissible Ambient Temperature

during Operation

Average Heat Dissipation 54 Wh / 184 Btu/h / 194 kJ/h

Overvoltage Category II

Pollution Degree 2

IP 20

Running Time Automatic: 1 – 99 sec / manual: 1 – 999 sec

Max. relative humidity 80% up to 31°C;

decreasing linearly up to 50% relative humidity at 40°C

Temperature: -10 °C to +55 °C

Humidity: 15% to 85%

+2 °C to +35 °C

Maximum Speed² n

Minimum Speed³ n

Maximum RCF-Value at n

max

min

max

Noise Level at Maximum Speed

¹

3000 rpm

330 rpm

1180 x g

< 53 dB (A)

Maximum Kinetic Energy 0.46 kJ

Dimensions

Height (open door / closed door) 630 mm / 410 mm

Width

Depth

²

Weight

1

Front Side Measurement, 1 m in fr ont of the instrument at 1.6 m height. 3 washing-cycles each with about 35 s centrifugation.

2

Mode manual centrifuge

2

Mode manual decant

370 mm

450 mm

28 kg

12 | CW3 Thermo Scientic

Page 14

2. 1. Directives and Standards

Region Directive Standard

Europe

220-230 V, 50/60 Hz

USA & Canada

120 V, 60 Hz

China

220-230 V, 50/60 Hz

98/79/EC In Vitro Diagnostic Medical

Devices (IVD)

2014/35/EU Low Voltage (protective goals)

2006/42/EC Machinery (protective goals)

2014/30/EC Electromagnetic Compatibility

(EMC) (protective goals)

2011/65/EC RoHS – Directive on the

Restriction of the use of certain Hazardous

Substances in electrical and electronic

equipment

FDA – 510(k) cleared

Regulation Name: Automated Cell-Washing

Centrifuge for Immunohematology

Regulatory Class: 2

Product Code: KSN

EN 61010-1

EN 61010-2-020

IEC 61010-2-101

EN 61326-1 Class B

EN ISO 13485

CAN/CSA-C22.2 No. 61010-1-04

UL Std. No. 61010-1

CAN/CSA-C22.2 No. 61010-2-020-09- Part 2-020

IEC 61010-2-020

IEC 61010-2-101

IEC 61010-1

IEC 61010-2-020

IEC 61010-2-101

EN 61326-1 Class B

Directives and Standards

2. 2. Mains Supply

The following table contains an overview of the electrical connection data. This data is to be taken into consideration, when

selecting the mains connection socket.

Unit Thermo Scientific CW3 cell washer

Article No. 75007404 75007405

Mains Voltage 120 V 220-30 V

Frequency 60 Hz 50 / 60 Hz

Rated Current 2.7 A 1.5 A

Power Consumption 135 W 135 W

Equipment Fuse 10 AT 10 AT

Building Fuse 15 AT 16 AT

Thermo Scientic CW3 | 13

Page 15

Location and Function of Parts

2. 3. Location and Function of Parts

Front view

1

11

2

3

10

4

9

5

8

7

6

No. Part Description

1 Nozzle Through this nozzle, saline is supplied from the pump to the distributor.

2 Drain cover Receives the waste liquid decanted from the rotor and discharges it to the outside.

3 Distributor Distributes the saline supplied from the pump to each test tube held on the rotor.

4 Rotor A 12 or 24-sample rotor.

5 Splash guard Designed to keep saline, waste liquid, etc. from leaking to the internal mechanism of the

cell washer. Removable.

6 Condition-setting panel See “2. 5. Condition-setting Panel” on page 18.

7 POWER switch Switches on and o the cell washer power. It doubles as a circuit protector. It

automatically switches o the cell washer power if abnormal current passes.

8 Control panel See “2. 4. Control Panel” on page 17.

9 Door lock lever Keeps the door locked while the rotor is running.

10 Bowl Rotates together with the rotor. It determines the angle to which the test-tube holders of

the rotor swing.

11 Door Test tubes are set on the rotor after opening the door. The drain cover and nozzle are

installed on the back of the door.

14 | CW3 Thermo Scientic

Page 16

Rear view

1

3

Location and Function of Parts

8

7

6

2

5

4

No. Part Description

1 View port You can measure the rotor speed through the view port by an optical reflection type

rotation meter.

2 Drain connector The overflowed waste liquid is drained through this connector.

3 Power connector To be connected to a power supply.

4 Sensor connector To be connected to the sensor which detects the level of saline in the tank.

5 Auxiliary drain tube The chamber is drained through this tube if the drain connector is blocked.

6 Pump Provided for supplying saline into the cell washer.

7 Pump inlet connector To be connected to the saline tank by tubing.

8 Door stopper parts Designed to keep the open angle (60°) of the door to prevent the door to be wide-open.

Thermo Scientic CW3 | 15

Page 17

Location and Function of Parts

1

2

3

Top view

No. Part

1 Decatation coil

2 O-ring (2x)

3 Rubber gasket

2

3

16 | CW3 Thermo Scientic

Page 18

2. 4. Control Panel

1

2

21

10

9

8

7

6

3 4 5

No. Name Function

1 PROCESS LED Shows the current process of blood cell washing. Indicates the process setting in manual

mode. While the cell washer operates, the LED of the active process blinks.

2 CYCLE indicator Indicates the number of washing cycles. While the cell washer operates, the CYCLE

indicator shows the number of the remaining cycles.

3 MANUAL switch To manually start a single process (WASH, CENTRIFUGE, DECANT or AGITATE). The LED

lights when the manual mode is set.

4 OPEN switch To open the door. If it is pressed continuously, the cell washer does not accept any input

of the other switches for 4 seconds (alarm buzzer sounds).

5 STOP switch To stop a process. It is also used for stopping the end buzzer and alarm buzzer. When the

operation is stopped in the automatic mode or in the agitation/centrifugation (see No. 9),

the operation can be restarted at the stopped point by pressing the START switch. When

the operation is stopped in the manual mode, the operation is not restarted at the

stopped point by pressing the START switch.

The LED lights when the operation is stopped. When the operation is stopped in

automatic mode, its LED blinks.

6 AGI/CENT switch Sets the agitation time (agitation of liquid in test tubes) and the centrifugation time

(manual mode) (see the figure below). Its LED lights when it is set.

Operation is started when START is pressed.

Manual-mode set speed

Control Panel

1 Agitation set time

2 Manual-mode centrifugation time

This cell washer does not accept the input of START when the agitation set time is

0second.

7 START switch To start a series of processes or a single process.

8 FEED switch In automatic mode, it causes the value of washing cycle setting to count down. In manual

mode, it is used for settings desired for one of the processes.

9 AUTO switch To start automatic washing cycles. The LED lights when the automatic mode is set.

10 TIME indicator Indicates the remaining time of centrifugation (in 3 digits). In case of an abnormality, the

proper error code is shown. It also shows the rotor speed (×10 rpm) when PUSH SPEED

on the condition-setting panel is pressed.

Thermo Scientic CW3 | 17

Page 19

Condition-setting Panel

2. 5. Condition-setting Panel

1

6 1211109875432

No. Name Function

1 CYCLE setting switch Sets the number of the washing cycles to be repeated (9 cycles at maximum).

2 AUTO CENTRI TIME setting switch Sets the centrifugation time of automatic-mode operation (99 seconds at

maximum). The standard centrifugation time is 35 seconds.

3 MANUAL CENTRI TIME setting switch Sets the centrifugation time of manual-mode operation (999 seconds at

maximum).

4 MANUAL SPEED setting switch Sets one of the following rotor speeds for manual-mode centrifugation:

3,000 rpm (High) and 1,200 rpm (Low)

5 DECANT SPEED setting switch Sets the rotor speed for automatic- or manual-mode decantation using the H/L

switch and adjusting a number. If the number is set between 4 and 9, the rotor

speed is the same as if 0 is set.

Switch

H 350 rpm 400 rpm 450 rpm 500 rpm

L 330 rpm 370 rpm 410 rpm 450 rpm

Decantation is completed in a short time. Note that the above value may not

necessarily match the speed indicated by the PUSH SPEED switch.

If you increase the DECANT SPEED, the amount of the remained blood cells

tends to decrease.

If you decrease the DECANT SPEED, the amount of the remained blood cells

tends to increase.

6 PUSH SPEED switch Keep the PUSH SPEED switch pressed when the cell washer started spinning.

The actual spinning speed of the rotor will be shown (×10rpm) on the TIME

indicator on the control panel. Example: 1200 rpm are shown as 120 on the

TIME indicator (120 x 10 = 1200).

7 OVERFLOW setting switch When the pump is set to overflow the cell washer will overflow the inserted

tubes with solution from the saline tank.

Setting Pumping operation for overflow

0 No operation

1 Operates only the first cycle.

2 Operates only the first and the second cycles.

3 Operates only the first, second and the third cycles.

4 Operates only the first, second, third and the fourth cycles.

5 Operates only the first, second, third, fourth and the fifth cycles.

6 to 9 Selectable up to 9 in the same manner.

0 1 2 3

Number

18 | CW3 Thermo Scientic

Page 20

No. Name Function

8 PROGRAM switch Sets the operation program.

Setting Program (No setting more than 1)

0 5-second centrifugation is not performed at the final process of

the final cycle in automatic mode.

1 5-second centrifugation is performed at the final process of the

final cycle in automatic mode.

2 You can add the conditions to the centrifugation process at

manual mode:

“3000 rpm for 15 seconds”: “H” is displayed on the

CYCLE indicator and “15” is displayed in the TIME

indicator.

“1200 rpm for 60 seconds”: “L” is displayed on the

CYCLE indicator and “60” is displayed in the TIME

indicator.

See the following procedure:

1. Press MANUAL.

The condition displayed on the condition-setting panel

is performed.

2. Press FEED.

Centrifugation (3000 rpm for 15 seconds) is performed.

3. Press FEED again.

Centrifugation (1200 rpm for 60 seconds) is performed.

Condition-setting Panel

5-second centrifugation is not performed at the final process of

the final cycle in the automatic mode.

(If the dial is set between 3 and 9, the operation program is the same as that of

dial setting 0.)

9 AGITATE TIME setting switch Sets the agitation time (99 seconds at maximum).

10 MELODY setting switch Sets the end buzzer.

Setting Tunes

0 No sound

1 Electronic beep (three beeps)

2 Oh Susanna

3 My Bonnie

4 My Old Kentucky Home

5 De Camptown Races

6, 7, 8 or 9 Electronic beep (two beeps)

You can turn down the sound level by covering the hole with an adhesive tape

(this hole is above the right side of the CYCLE setting switch).

11 OPTION switch This is a push-button switch for saline calibration purpose.

12 SALINE PRIME switch To be used for pump bleeding at the time of initial operation. The pump for

saline supply operates while this switch is kept depressed.

This switch is ineective while the cell washer is in operation.

Thermo Scientic CW3 | 19

Page 21

Before Setting Up

3. Transport and Set Up

3. 1. Before Setting Up

1. Check the cell washer and the packaging for any shipping damage. Inform the shipping company and Thermo Fisher

Scientific immediately if any damage is discovered.

2. Remove the packaging.

3. Check, if the items supplied are complete. „Items Supplied“ on page 5.

If the items supplied are incomplete, please contact Thermo Fisher Scientific.

3. 2. Location

WARNING The cell washer is neither inert nor protected against explosion. Never use the cell washer in an explosion-

prone environment.

WARNING UV rays reduce the stability of plastics. Do not subject the cell washer, rotor and plastic accessories to direct

sunlight.

The cell washer is only to be operated indoors.

The set-up location must fulfill the following requirements:

Set up the cell washer in a room where the ambient temperature is 5 to 35 °C.

A safety zone of at least 30 cm must be maintained around the cell washer.

People have to stay out of this safety zone while centrifuging.

The supporting structure must be stable and free of resonance.

The supporting structure must be suitable for horizontal setup of the cell washer.

The set-up location must be well-ventilated at all times.

The cell washer is not to be exposed to heat and strong sunlight.

3. 3. Transporting

Due to its weight, the cell washer should be carried by at least two people. Always lift the cell washer at both sides.

To prevent possible injuries at least two people should lift and carry the cell washer by holding it at the bottom from

opposite sides.

WARNING Always lift the cell washer from both sides. Never lift the cell washer by its front panel, its back panel or at its

door. Always remove the rotor before moving the cell washer.

Transport the cell washer and accessories upright within the associated packaging, if possible.

NOTICE The original cell washer packaging is a one way packaging. Only keep the two styropor pieces for setting up

the cell washer (“3. 6. Setting Up” on page 21). Do not keep the rest of the one way packaging. Contact a shipping

company or the customer service for the transport. Always remove the rotor before moving the cell washer. If you do not

remove the rotor you might damage the cell washer drive or cell washer spindle.

20 | CW3 Thermo Scientic

Page 22

3. 4. Leveling

CAUTION

If the cell washer is not leveled, imbalances can occur and the cell washer can be damaged.

Do not place anything under the cell washer feet to level the cell washer.

The cell washer is to be placed in horizontal and level supporting structures or benching.

Horizontal level is to be checked when moving the cell washer to a new location.

3. 5. Check Mains Connection

NOTICE

Plug the cell washer in grounded electrical sockets only.

1. Turn off the power supply switch.

2. Check whether the cable complies with the safety standards of your country.

3. Make sure that the voltage and frequency correspond to the figures on the rating plate.

Leveling

3. 6. Setting Up

NOTICE

Setting up the CW3 Cell Washer is easier when done by 2 people.

1. Install the motor guard plate

1. Lift the front bottom of the cell washer. Put the two styropor pieces from the one way cell washer packaging

below the cell washer feet. Carefully put the cell washer on the styropor pieces.

2. Loose the wing nuts counterclockwise. ➀

Thermo Scientic CW3 | 21

Page 23

Setting Up

➀ ➀

➁➁

Do not unscrew the wing nuts completely to ensure easier completion of the following steps.

3. Remove the motor holder. ➁

4. Place the motor guard plate. ➀

5. Secure the motor guard plate with the wing nuts clockwise. ➁

➀

➁

NOTICE Keep the removed motor holder for future transportation.

2. Connect power cable

Connect the power cord to the power connector at the rear of the cell washer.

Plug the power cord in the socket.

Check for grounding.

3. Connect sensor cable

Connect the sensor cable from the top of the tank with the sensor connector at the backside of the cell washer. (See

the green highlighted sensor cable on the picture in „Connect tubing“ on page 30)

4. Switch on cell washer

Switch on the power supply switch.

The liquid level sensor in the tank activates. Error code “E2” (the saline tank needs to be refilled) is indicated and the

buzzer sounds during the power-on. The buzzer stops as STOP is pressed or on its own after a short time.

➀

➁

5. Open lid

Press OPEN and open the door.

6. Switch off cell washer

Switch off the power supply switch.

22 | CW3 Thermo Scientic

Page 24

7. Remove packaging

Remove the packagings from the rotor chamber.

Setting Up

8. Remove the drain cover

1. Slide the pins in direction of the arrows at both sides.

2. Pull the drain cover forward to remove it.

9. Remove the splash guard

Remove the splash guard from the rotor chamber.

Thermo Scientic CW3 | 23

Page 25

Setting Up

10. Check rubber gasket

Make sure that the rubber gasket is in position. The rubber gasket must cover the base of the decantation coil.

To get the rubber gasket in position: push the decantation coil in one direction and push the rubber gasket in the

opposite direction. Do this until the rubber gasket is in position as shown in the picture.

✓

3

2

1

4

No. Part

1 Rubber gasket

2 O-ring (2x)

3 Decantation coil

4 Magnet base

1

2

No. Part

1 Rubber gasket

2 Magnet base

If the rubber gasket is not in position, fluids can damage the cell washer.

24 | CW3 Thermo Scientic

Page 26

11. Install splash guard

Install the splash guard in the rotor chamber.

12. Install drain cover

1. Insert the drain cover into the drain cover holder to install it.

Setting Up

2. Push the pins in the door until a click is heard.

CAUTION When installing the drain cover, check that the nozzle at the center of the door is put through the hole of

the drain cover. Install the drain cover correctly.

13. Install bowl

1. Lightly apply silicone grease (483719) to the inner rim of the bowl and both o-rings of the decantation coil.

Thermo Scientic CW3 | 25

Page 27

Setting Up

2. Push the bowl down evenly with both hands.

3. Push the bowl all the way down until the bottom of the decantation coil becomes even with the bottom of the

bowl. Make sure that they are even by passing fingers over the surface.

NOTICE The bowl must be installed correctly and aligned with the decantation coil before performing a test run.

Make sure that the surface of the decantation coil and the surface of the bowl are at the same level. Both o-rings

are visible if the bowl is installed correctly.

If the bowl is not installed correctly, the door lock will not work, the door cannot be opened, the bowl will contact

the drain cover and the cell washer will be out of order. If you set the bowl correctly, the tube holders will touch the

metal part of the bowl when the rotor is installed.

Check that the bowl can be turned freely. If the bowl cannot be turned freely, the rubber gasket might not be

mounted properly. Error message E14 or E16 might be displayed if the bowl is not installed correctly („Check rubber

gasket“ on page 24).

26 | CW3 Thermo Scientic

Page 28

Cross Section

4

5

4

5

2

1

2

Setting Up

Detail View

1

3

1

2

1 – Flush

2 – Decantation coil

3 – Bowl

1 – Tube holder

✓

1 – Bowl

2 – Flush

3 – Decantation coil

✓

1

4 – Bowl

5 – Tube holder

3

Thermo Scientic CW3 | 27

Page 29

Setting Up

1

2 3

4

14. Install rotor

NOTICE The rotor is just set on the drive shaft. The rotor is not screwed down or otherwise tightend to the drive

shaft.

No. Part

1 Drive shaft

2 Rotor

3 Coupling pins

4 Bowl

1. Remove the rubber bands from the rotor.

2. Set the rotor on the drive shaft.

3. Turn the rotor about a quarter so that the coupling pins are inserted into the rotor shaft holes.

4. Turn the top of the rotor clockwise and counterclockwise to check that the coupling pins are inserted into the

rotor shaft holes (no free turn) after setting.

28 | CW3 Thermo Scientic

Page 30

Setting Up

CAUTION If the rotor is not set correctly, the rotor holder may come off the bowl and overswing.

15. Install distributor

Set the distributor on the top of the rotor.

Make sure that the coupling pins at the bottom of the distributor move in the holes at the top of the rotor.

Thermo Scientic CW3 | 29

Page 31

Setting Up

16. Connect tubing

➃

➁

➄

➅

➂

➀

➀

➁

➂

➃

➄

➅

1. Do not set the saline tank at a place higher than the cell washer. ➀

2. Put the waste drain at a place lower than the cell washer. ➁

Make sure that the waste drain is lower than the cell washer to prevent backward flow of waste liquid.

Prepare the saline tank and a drain for waste following your laboratory standards. A waste liquid tank is

shown as an example in the picture.

3. Connect the sensor cable of the saline tank to the connector at the rear of the cell washer. ➂

4. Connect the drain tube or the L-shaped adapter, which can be connected to the drain tube, to the drain connector. ➃

Apply a thin layer of grease (483719) to the inner side of the tubing or the outer side of the connector. Do not

force the drain tube or the L-shaped adapter into the drain connector.

Tighten it with the hose band (big).

Hold the L-shaped adapter facing downward and connect it to the drain connector. If not waste liquid can

stow and result in bad drainage.

Saline tank

Waste drain

Sensor cable

Drain tube

Gray outlet

Inlet tube

30 | CW3 Thermo Scientic

Page 32

✓

Make sure to position the L-shaped adapter correctly.

Place the end of the drain tube in the waste liquid tank or a sink. Position them higher than the liquid level.

5. The gray outlet at the rear center of the cell washer is used for draining off waste liquid from the chamber. ➄

After blood cell washing, waste liquid keeps draining off through the connector. The auxiliary drain tube under

the connector is to drain waste liquid flowed from the chamber into the vicinity of the driving motor. Waste liquid

may not always drain off through it. Prepare a drain or tank for waste liquid coming out of the auxiliary drain

tube of the rear of the cell washer when operated. Instead of preparing an additional drain or tank for waste

liquid, you may lengthen the tube (You can use the rest of the tube of the tank). You can insert the tube in the

waste liquid drainage you use for the drain tube.

CAUTION Make sure that the tips of the drain tubes are above the waste liquid level in the tank. Otherwise, the

chamber cannot be drained completely and waste liquid stagnates in the chamber because of poor drainage. Poor

drainage can also be caused if the tube is bent or flattened or if waste liquid stagnates in the middle of the tube.

Set the tubes properly so that waste liquid drains off smoothly. Be careful not to set the drain tubes at a place higher

than the drain outlet of the cell washer.

Setting Up

6. Connect the saline tank to the pump inlet connector of the cell washer. ➅

Apply a thin layer of grease (483719) to the inner side of the tubing or the outer side of the connector.

Connect the tubing to the pump inlet connector. Tighten it with the hose band (medium).

Connect the tubing with the nozzle of the tank carefully. Tighten it with the hose band (small).

If it is not connected using the hose bands liquid can leak from the tube and might get inside of the cell

washer. If the liquid might have leaked into the inside of the cell washer, contact a Thermo Fisher Scientific

authorized sales/service representative for cleaning and drying the cell washer.

Thermo Scientic CW3 | 31

Page 33

Storage

3. 7. Storage

WARNING If necessary clean, disinfect or decontaminate the entire system when removing the cell washer and

accessories from use. In doubt contact the Thermo Fisher Scientific customer service.

Before storing the cell washer and the accessories, it must be cleaned and if necessary desinfected and decon-

taminated.

Cell washer and accessories have to be thoroughly dried before storage.

Store the cell washer in a clean and dust-free location.

Be sure to place the cell washer on its feet.

Avoid direct sunlight.

3. 8. Shipping

WARNING Before shipping the cell washer and accessories you have to clean and if necessary disinfect or decontaminate

the entire system. In doubt contact the Thermo Fisher Scientific customer service.

Before shipping the cell washer please bear the following in mind:

The cell washer must be clean and decontaminated.

The decontamination must be confirmed in a decontamination certificate (“Decontamination Information

Certificate” on page 45). Contact customer service for more details.

Install the motor holder for shipping.

32 | CW3 Thermo Scientic

Page 34

4. Operation

WARNING

Use the cell washer only with correct installed rotor, distributor assembly and correct inserted bowl, splash guard

and drain cover.

Hazardous substances can leak out of the cell washer, if bowl and drain cover are missing.

CAUTION

Open the door carefully after blood cell washing. Otherwise the remaining waste liquid from the inside of the drain

cover might splash.

CAUTION

Close the door by pushing down at the forward center of the door until a short beep is heard.

If the door is closed insufficiently, an alarm (E1: DOOR OPEN) is indicated and the cell washer does not start operation. If this alarm is indicated, close the door and press START again.

Preparation

4. 1. Preparation

1. Prepare the test tubes (10 or 12 mm in diameter and 75 mm in length). When using the test tubes 10 mm in diameter, set the attached D10 adapter to the rotor holder. Make sure that the brim of the adapter is pointing outwards.

CAUTION Be sure to use specified test tubes with a wall thickness of 1mm or more. Test tubes with wall thickness

less than 1mm, such as disposable test tubes, are still acceptable to be used as long as the tubes are free from

scratches, cracks, warping or other abnormalities that may compromise the structural integrity of the tubes under

the centrifugal force exerted by this device, and are not re-used after their initial use is complete. It is recommended

to use tempered glass test tube for this cell washer.

2. Check and prepare the saline tank and a drain for waste following your laboratory standards.

CAUTION Make sure that the tips of the drain tubes are above the waste liquid level in the tank. Otherwise, the

chamber cannot be drained completely and waste liquid stagnates in the chamber because of poor drainage. Poor

drainage can also be caused if the tube is bent or flattened or if waste liquid stagnates in the middle of the tube.

Set the tubes properly so that waste liquid drains off smoothly. Be careful not to set the drain tubes at a place higher

than the drain outlet of the cell washer.

4. 1. 1. Injection Volume Adjustment and Pump

Ventilation

Adjustment of saline injection volume

The CW3 cell washer is factory-adjusted to the injection volume of saline for use with the 24 place rotor and the 12 mm

diameter test tubes.

When using the 24 place rotor and 12 mm diameter test tubes with this cell washer, there is no need to adjust the injection volume. When using the 12 place rotor or 10 mm diameter test tubes, adjust the flow rate of the pump as follows:

Thermo Scientic CW3 | 33

Page 35

Preparation

1. Remove the protective cover of the pump at the rear of the cell washer (it is secured with two screws).

2. Loosen the two locking screws of the pump counterclockwise.

3. Turn the adjusting screw to set the indicator value appropriate to your rotor and tube settings.

4. Tighten the two locking screws clockwise.

Reference (Index of injection volume)

Rotor Test tube Injection volume

(+/- 10%)

12 place 12 mm diameter 48 ml 45 %

12 place 10 mm diameter 32 ml 30 %

24 place 12 mm diameter 96 ml 80 %

24 place 10 mm diameter 64 ml 60 %

Indicator setting

➀

➀

➁

➂

5. Saline calibration

a. Press OPTION with a beaker held against the nozzle. The saline pump runs for 5 seconds.

b. Compare the preset volume in the above table and the actual volume injected in the beaker.

c. Set the adjusting dial screw when the actual volume is not in the preset volume range.

Repeat step a and b until calibration is succesful.

6. Reinstall the protective cover of the pump.

➁

➂

Adjusting screw

Indicator (red dot)

Locking screws

Pump ventilation

Fill the saline tank with saline. Hold a beaker or other container to the nozzle. Press SALINE PRIME on the condition-setting panel that is located at the front bottom of the device to discharge saline from the nozzle until no bubbles

come out of the nozzle.

34 | CW3 Thermo Scientic

Page 36

4. 1. 2. Setting the Operating Conditions

The operating conditions are factory-set as follows.

Setting dials and switches Factory-setting

1 CYCLE 3 cycles

2 AUTO CENTRI TIME 35 seconds

3 MANUAL CENTRI TIME 60 seconds

4 MANUAL SPEED L (1200 rpm)

5 DECANT SPEED H-1 (400 rpm)

6 OVERFLOW 1 (Operates only the first cycle)

7 PROGRAM 1 (5-second centrifugation is performed at the final cycle in automatic mode)

8 AGITATE TIME 5 seconds

9 MELODY 1 (Electronic beep (three beeps))

Agglutination of blood cells is influenced by centrifugal force and centrifugation time. If centrifugal force and centrifugation

time are insufficient, agglutination can be insufficient causing incorrect results. Excessive centrifugation can harden the

blood cells causing incorrect agglutination or difficult resuspension. The weak reaction may disappear. Centrifugal conditions are influenced by the amount of blood cells, specific gravity of blood cells, etc. The above settings are just a guide.

Determine the optimum conditions according to the following evaluation.

Preparation

1. The supernatant is transparent and no blood cell is suspended after centrifugation.

2. The blood cells that are precipitated at the bottom of the test tubes show clear outlines after centrifugation.

3. The blood cells are easily removed from the bottom and disentangled by a light agitation after decantation.

4. Check the reaction using reagents whether negative or positive.

5. Check the amount of the remained blood cells. If the amount of the remained blood cells is small, lower the

DECANT SPEED.

4. 1. 3. Preparation of the Sample

CAUTION

When the sample or liquid spilled, it can leak into the cell washer.

If the sample or liquid leaked into the cell washer, contact Thermo Fisher Scientific service for cleaning and drying.

Blood cell washing

Use one or two drops (about 50 μl) of 3-5% erythrocyte suspension in one test tube.

CAUTION When centrifuging precipitated erythrocyte layer, use one or two drops (about 50 μl or less) per test tube. If

not a series of blood cell washing processes can be not complete.

Centrifugation

Use the 80% or less of the test tube capacity as sample volume for centrifugation. The tubes are centrifuged at an angle

of 38.5°.

1

38.5°

Thermo Scientic CW3 | 35

2

12Centrifugal force

Drive shaft

Page 37

Operation Modes

4. 2. Operation Modes

4. 2. 1. Automatic Mode

Step Operation Description

1 Switch on AUTO. AUTO lights up.

The automatic mode is selected automatically when the power switch is

switched on.

2 Switch on STA RT. STA RT lights up.

To stop the cell washer temporarily in the middle of a process, press the STOP

switch and the cell washer stops at once.

For restarting the process, press the START switch.

3 Upon finish of all processes The end buzzer sounds and START lights o.

The door is opened.

The buzzer stops as STOP is switched on.

NOTICE In automatic mode, the set number of cycles can be decreased if you push FEED. For example, if three cycles

are set, the number changes 321 as FEED is pressed.

4. 2. 2. Manual Mode

In manual mode the process steps (WASH, CENTRIFUGE, DECANT, AGITATE) can be run as single process steps. More

information on the single process steps: „Operational Sequence for Antiglobulin Test“ on page 37.

Step Operation Description

1 Switch on MANUAL. MANUAL lights up.

2 Press FEED once or multiple times to set

the desired process manually.

The LED of the set PROCESS lights up.

3 Switch on STA RT. START lights up.

Upon finish of the selected process The end buzzer sounds and the door is opened.

NOTICE The door is automatically opened after the rotor is stopped by pressing STOP in the middle of operation.

NOTICE When power fails during operation and then it is restored, or when POWER is switched off during operation and

then turned on again, the automatic-mode operation is set (AUTO lights up) and the cell washer stops. In such cases, set

the desired process again and perform operation in the manual mode.

The CENTRIFUGE process is set preferentially.

Possible process steps:

1. DECANT - Pressing FEED once (1x) will set the DECANT process. The

according LED lights up.

2. AGITATE - Pressing FEED twice (2x) will set the AGITATE process. The

according LED lights up.

3. WASH - Pressing FEED three times (3x) will set the WASH process. The

according LED lights up.

4. CENTRIFUGE - Pressing FEED four times (4x) will set the CENTRIFUGE

process as set preferentially when MANUAL is pressed. The according LED

lights up.

Make sure that the desired values on the condition-setting panel for the

manually set process step are set.

STA RT lights o.

4. 2. 3. Agitation-Centrifugation

Step Operation Description

1 Switch on AGI/CENT. AGI/CENT lights up.

2 Switch on STA RT. STA RT lights up.

To stop the cell washer temporarily in the middle of a process, press STOP. For

restarting the process, press START.

3 Upon finish of the process The end buzzer sounds and STAR T lights o.

AGI/CENT lights up and the door is opened.

36 | CW3 Thermo Scientic

Page 38

4. 2. 4. Operational Sequence for Antiglobulin Test

➍

Operation Modes

3000

➊ Rotor speed (rpm)

➊

1200

400

➋

➌

Process Operation Description

➎

WASH A fixed amount of saline is pumped into the

distributor when the rotor speed reaches

1200rpm. The saline is injected by centrifgual

force from the distributor into the test tubes. The

blood cells in the test tubes are suciently

suspended in the saline.

CENTRIFUGE Blood cells are centrifuged.

The standard centrifugation time is 35 sec.

(selectable). Before the rotor decelerates, the

injection of saline continues to overflow the test

tubes.

(Overflow is also selectable.)

➋ Process (details below)

➌ 1 cycle

➍ Time

➎ Injection of saline

Reference

Illustration

Washing cycle

repeated 3 or 4 times

DECANT The rotor spins at low speed with the rotor holder

kept at an angle to slightly open its top end by

magnetic force. By this operation only the saline

decants from the test tubes and the blood cells

remain.

AGITATE The rotor repeats rotation and stops at short, quick

intervals to disentangle the remaining blood cells.

CENTRIFUGE The rotor spins about 5 seconds to collect the

blood cells adhered to the wall surfaces of the test

tubes at the bottom. This is done to ensure the

reaction with the Antiglobulin reagent. This

operation is performed at the end of the washing

cycle.

Thermo Scientic CW3 | 37

Page 39

Cleaning

5. Maintenance

WARNING

Cell washer, rotor or accessories can be contaminated by samples.

Decontaminate according to good laboratory procedures and methods.

WARNING

If there is a possibility that the cell washer, rotor, or an accessory is contaminated by samples that might impair

human health (for example, samples that are toxic or radioactive, or blood samples that are pathogenic or infectious),

it is your responsibility to sterilize or decontaminate the cell washer, rotor, or the accessory correctly before requesting repairs from Thermo Fisher Scientific service. Note that Thermo Fisher Scientific can not repair the cell washer,

rotor or the accessory unless sterilization or decontamination is completed.

WARNING

It is your responsibility to sterilize and/or decontaminate the cell washer, rotor, or parts correctly before returning

them. In such cases copy the decontamination sheet at the end of this manual, fill it out and attach it to the item to

be returned. Thermo Fisher Scientific may ask you about the treatment for the cell washer, rotor or the part if the

decontamination is checked and judged as insufficient by Thermo Fisher Scientific. It is your responsibility to bear the

cost of sterilization or decontamination. Note that Thermo Fisher Scientific can not repair or inspect the cell washer,

rotor or the accessory unless sterilization or decontamination is completed.

CAUTION

Do not operate the cell washer in any manner not described in this instruction manual. Should you have any troubles

with the cell washer, call Thermo Fisher Scientific service.

5. 1. Cleaning

NOTICE

Information provided is to be considered as general guideline and may vary depending on the usage of the unit.

If you use other cleaning methods than those described here, make sure that the necessary cleanliness is achieved

according to your requriements.

38 | CW3 Thermo Scientic

Page 40

5. 1. 1. Pump, Tank and Tubing

CAUTION If saline is contaminated by bacteria, it may cause hemolysis or poor result.

Wash the inside of the tank and the tubing on a regular basis.

If the cell washer is not used for a long period, drain out saline from the tank, tubing and pump.

Check the volume of saline inside the tank before operation. Connect the tube securely to the saline tank and

the pump inlet connector with the hose bands. When the tube is loose, replace it.

Make sure that all tubing is connected and free from obstructions.

Washing

1. Fill up the saline tank with washing solution (0.5% Sodium Hypochlorite Solution).

2. Fill up the fluid passage with washing solution according to the same procedure as pump ventilation (“4. 1. 1.

Injection Volume Adjustment and Pump Ventilation” on page 33).

3. Flush the tubing by running through four wash cycles. Do not run wash cycles without the rotor and distributor

installed. Damage to the bearing may result.

Replace the washing solution in saline tank with distilled water

4. Flow distilled water 2 to 3 liters from the saline tank according to the same procedure as pump bleeding.

Cleaning

5. Exchange distilled water in the saline tank with saline.

6. Flow saline 2 to 3 liters from the saline tank in the same manner as described in point 4.

5. 1. 2. Rotor, Distributor and Bowl

After operation remove the rotor, distributor and bowl. Wash and dry them well.

To remove the bowl hold it with both hands. Remove the bowl by lifting it. Slowly rotating the bowl makes it easier to lift it.

See the following table for cleaning.

Part Cleaning

Rotor

Distributor, bowl

CAUTION The distributor is made of polycarbonate. For cleaning make sure that you use washing solution (0.5% sodium

hypochlorite solution) or the distributor might deteriorate. Use neutral detergent (pH 6 to 8). Do not dip the distributor in

the diluted detergent solution for a long time or the strength of the distributor can decrease.

Thermo Scientic CW3 | 39

Soak in washing solution (0.5% sodium hypochlorite solution). Wash and dry.

Soak in washing solution (0.5% sodium hypochlorite solution) within 1 hour.

Wash and dry.

Page 41

Cleaning

5. 1. 3. Chamber, Splash Guard, Drain Cover and Door Stopper Parts

Remove the splash guard and the drain cover from the cell washer. Wash and dry them well.

Use washing solution (0.5% sodium hypochlorite solution) for cleaning. When washing the inside of the chamber, be

careful not to pour washing solution on the decantation coil. Wipe the decantation coil with a cloth or paper moistened

with washing solution.

5. 1. 4. 4. Drain Cover

Removing

1. Slide the pins in direction of the arrows at both sides.

2. Pull the drain cover forward to remove it.

Mounting

1. Insert the drain cover into the drain cover holder to install it.

2. Push the pins in the door safely until a click is heard.

CAUTION When installing the drain cover, check that the nozzle at the center of the door is put through the hole of the

drain cover. Install the drain cover correctly.

5. 1. 5. 5. Splash Guard

Removing

1. Remove the drain cover. See “5. 1. 4. 4. Drain Cover” on page 40.

2. Remove the distributor, rotor and bowl.

3. Remove the splash guard by pulling it up.

Mounting

1. Insert the splash guard.

2. Install the distributor, rotor and bowl. See “3. 6. Setting Up” on page 21.

3. Mount the drain cover. See “5. 1. 4. 4. Drain Cover” on page 40.

CAUTION Do not store washing solution in the chamber. Do not spill washing solution on the decantation coil or liquid

can leak into the cell washer causing a failure.

If a test tube is broken, be sure to remove the fragments inside the chamber and the drain tube of the drain cover thoroughly with a brush.

5. 1. 6. 6. Checking and Replacing the Door Stopper Parts

If you observe the below, call a service technician.

1. The rubber mount cracks or deteriorates.

2. The door keeps being wide-open after you open the door.

If the door keeps being wide-open, drops of waste liquid on the drain cover might fall on the rear of the cell washer.

40 | CW3 Thermo Scientic

Page 42

Preventive Maintenance

5. 2. Preventive Maintenance

Replace the drain tube and the tube every 1 to 3 years depending on the degree of discoloration.

The pump is a replacement part. Liquid may leak from the bellows of the pump because of deterioration.

Deterioration depends on the installation environment such as ultraviolet rays and temperature. We highly recommended to replace the bellows of the pump (S413230A) every three years.

Replace the carbon brushes of the motor after 7 years of use (assuming 30 runs per day).

5. 3. Shipping and Disposal

WARNING

When removing the centrifuge and accessories from use for disposal

you have to clean and if necessary disinfect or decontaminate the entire system. In doubt contact the Thermo Fisher

Scientific customer service.

For the disposal of the centrifuge mind the regulations in your country. Contact the Thermo Fisher Scientific Customer

Service for the disposal of the centrifuge. For contact information check the backpage of this manual or visit www.ther-

mofisher.com/centrifuge

For the countries of the European Union the disposal is regulated by the European Union’s Waste Electrical & Electronic

Equipment (WEEE) Directive 2002/96/EC.

Mind the information on transport and shipping (“3. Transport and Set Up” on page 20, “3. 8. Shipping” on page 32).

Thermo Scientic CW3 | 41

Page 43

Mechanical Emergency Door Release

6. Troubleshooting

6. 1. Mechanical Emergency Door Release

Opening the door while the rotor spins is very dangerous. Never unlock the door while the rotor spins. If the door

is opened while the rotor still spins, close the door immediately. Do not run the cell washer with the allen wrench

inserted in the hole of the cell washer.

The door can not be opened and closed except when the cell washer is switched on and the rotor has stopped. If the door

can not be opened because of a power failure, open the door according to the following procedure.

1. Check that the rotor does not spin.

Listen carefully to make sure that no spinning sound is heard.

It takes about one minute until the rotor spinning at 3,000 rpm (maximum speed) stops completely. Wait for a

sufficient time.

2. Insert the attached allen wrench into the small hole to unlock the door.

A small hole is provided on both sides of the cell washer.

Insert the attached allen wrench straight into the small hole and push it in until a click is heard. Then insert the allen

wrench into the small hole of the other side in the same manner. The door unlocks and opens.

CAUTION

42 | CW3 Thermo Scientic

Page 44

6. 2. Error Codes

If any abnormality occurs during operation, corresponding error code blinks on the TIME indicator, the alarm buzzer sounds,

and the cell washer stops. Take the action described in the following table or contact Thermo Fisher Scientific service.

Error code Desciption Troubleshooting

E1 The door is open. Close the door safely and press STA RT.

E2 The saline tank needs to be refilled. Refill the tank and press STOP to clear the error code. In the manual

mode, CENTRIFUGE and DECANT processes can be executed even when

this error code is shown.

The liquid level sensor may be faulty if the alarm buzzer sounds even

though there is enough saline. Contact a Thermo Fisher Scientific

authorized sales/service representative for repair. The error code can be

temporarily cleared by pressing MANUAL and STOP simultaneously for

three seconds or more (operation in automatic mode is possible). It returns

to the original state by turning on and o the power switch.

E3 A power failure occurs. If a power failure occurs while the cell washer is running, the cell washer

stops spinning after the power failure and the error code “E3” is shown.

In order to clear the error code, press any of the switches on the control

panel after a lapse of one minute or more from when the error code is

indicated. If the error persists, contact Thermo Fisher Scientific service.

This error can be caused by voltage drop if your cell washer is connected

to an outlet to which multiple appliances are connected when the rotor

accelerates. Turn o the cell washer power and connect the cell washer to

an outlet that can supply stable voltage to the cell washer.

E4 The power supply is incorrect. The frequency of the power supply is incorrect. Turn o the power switch

and on again. If the error persists, contact Thermo Fisher Scientific

service.

E5 The rotor overspeeds. This error code is shown when the rotor runs at a speed higher than the

specified speed. Contact Thermo Fisher Scientific service.

E6 An incorrect current flows. This error code is shown when an incorrect current flows in the circuit.

Contact Thermo Fisher Scientific service.

E7 The speed sensor is defective. The sensor to detect the rotor speed is defective. Contact Thermo Fisher

Scientific service.

E8 The current sensor is defective. The sensor to detect the current is defective. Contact Thermo Fisher

Scientific service.

E9 The RAM is defective. Turn o and on the power switch. If the error persists, the microcomputer

of the cell washer to control its operation is defective. Contact Thermo

Fisher Scientific service.

E10 The rotor overspeeds (hardware detection). This error code is shown when the rotor runs at a speed higher than the

specified speed. Contact Thermo Fisher Scientific service.

E11 The triac is defective. The element on the circuit board is defective. Contact Thermo Fisher

Scientific service.

E14 Set up might be wrong, lid lock not

engaging.

E16 Set up might be wrong, motor not turning. Check if the rubber gasket and the bowl are installed correctly. „Check

Others System error Contact Thermo Fisher Scientific service.

Check if the rubber gasket and the bowl are installed correctly. „Check

rubber gasket“ on page 24 and „Install bowl“ on page 25. If the error

still occurs, contact Thermo Fisher Scientific service.

rubber gasket“ on page 24 and „Install bowl“ on page 25. If the error

still occurs, contact Thermo Fisher Scientific service.

Error Codes

Thermo Scientic CW3 | 43

Page 45

Troublshooting when no Error Code is indicated

6. 3. Troublshooting when no Error Code is

indicated

Unauthorized disassembly of the cell washer except by Thermo Fisher Scientific service is strictly prohibited.

No. Symptom Possible cause Remedy

1 POWER does not light its LED even if it

is turned on.

2 The cell washer does not start

operation.

3 Injection of saline does not take place. 1. No saline is in the tank.

4 Saline (waste liquid) scatters in the

chamber.

1. The amount of blood cells after

washing is less than before.

2. No washing is executed.

3. Washing is executed.

5 No decantation is executed. The coil is disconnected. Contact Thermo Fisher Scientific

6 Abnormal noise is heard.

1. Contacting noise

2. Others

7 The cell washer intensely vibrates. 1. Imbalance operation.

8 A test tube breaks. 1. The test tube is not strong.

9 Hemolysis is found in the blood cells. 1. Density of saline is improper.

WARNING

1. A power failure occurs.

2. The power cord is

disconnected.

1. The door is not closed.

2. The door switch is defective.

2. The pump is not filled with

saline.

3. The pump is defective.

4. The pump connector is loose.

1. Injection volume is excessive

and the test tubes are overflown

with solution.

2. The nozzle is out of position and

fails to supply the distributor

with solution.

3. The drain cover is broken.

1. The bowl and the rotor contact

the drain cover.

2. The bearing and the locking

screw for the decantation coil

are defective.

2. The bowl, rotor and distributor

are not set correctly.

3. The center packing is not

mounted correctly.

4. Others.

2. The test tube is dierent in size.

3. The rotor holder is deformed.

2. Sample is contaminated by

bacteria.

3. Fragments of a test tube are

mixed.

1. Wait until power is restored.

2. Contact Thermo Fisher Scientific

service.

1. Close the door.

2. Contact Thermo Fisher Scientific

service.

1. / 2. For the the first two possible

causes: refill the tank with saline to

fill the pump.

3. Contact Thermo Fisher Scientific

service.

4. Retighten it securely.

1. Adjust the injection volume

correctly.

2. / 3. Contact Thermo Fisher

Scientific service.

service.

1. Set the bowl and the rotor correctly.

2. Contact Thermo Fisher Scientific

service.

1. Balance correctly.

2. Set the bowl, rotor and distributor

correctly.

3. Mount the center packing correctly.

4. Contact Thermo Fisher Scientific

service.

1. Use test tubes strong enough to

bear the centrifugal force.

2. Use applicable-sized test tubes.

3. Contact Thermo Fisher Scientific

service.

1. Exchange for saline of proper

density (0.9%).

2. Clean the tank, tube and pump

(especially the inside of the tank).

3. Remove glass fragments in the

chamber and the drain cover.

44 | CW3 Thermo Scientic

Page 46

Troublshooting when no Error Code is indicated

Decontamination Information

Certificate

INSTRUCTIONS

When an instrument used with radioactive, pathogenic, or otherwise hazardous materials requires servicing by Thermo

Fisher Scientific personnel either at the customer’s laboratory or at Thermo Fisher Scientific facilities, the following procedure must be complied with to insure safety of our personnel:

1. The instrument or part to be serviced shall be cleaned of all blood and other encrusted material and decontaminated

prior to servicing by our representative.

No radioactivity shall be detectable by survey equipment.

2. A Decontamination Information Certificate shall be completed and attached to the instrument or part.

If an instrument or part to be serviced does not have a Decontamination Information Certificate attached to it, and, in our

opinion, presents a potential radioactive or biological hazard, our representative will not service the equipment until proper

decontamination and certification has been completed.

If an instrument is received at our service facilities and, in our opinion, poses a radioactive or biological hazard, the sender

will be contacted for instructions as the equipment is to be disposed. Disposition costs will be borne by the sender.

Additional certificates are available from your local technical or customer service representative. In the event these certificates are not available, a written statement certifying that the instrument or part has been correctly decontaminated and

outlining the procedures used will be acceptable.

NOTE Thermo Fisher Scientific Service representatives will indicate on a Customer Service Repair Report if

decontamination was required, and if so, what the contaminate was and what procedure was used. If no decontamination

was required, it should be stated.

Decontamination Information Certificate

Complete and attach to equipment BEFORE servicing.

Decontamination

Certified By title/Position

Phone fAX dePArtment

institution Address

City stAte ZiP

instrument seriAl numBer

rotor seriAl numBer

PArt PArt numBer

hAZArdous ContAminAnt(s) deContAminAtion dAte

deContAminAtion method(s)

deContAminAtion

Certifier‘s signAture: dAte:

Thermo Scientic CW3 | 45

Page 47

Troublshooting when no Error Code is indicated

Chemical Compatibility

™

™

, tefLon

™

PoLysuLfone

PoLyvyniL chLoriDe

ruLon A

siLicone ruBBer

stainLess steeL

titanium

tygon™viton

noryL™nyLon

,cLear crimP

™

, PoLycLear

¹

PET

PoLyaLLomer

PoLycarBonate

PoLyester, gLass thermoset

PoLythermiDe

PoLyethyLene

PoLyProPyLene

MATERIAL

CHEMICAL

2-merCAPtoethAnol s s u / s m s / s u s s u s s / s s s s u s s s s s s

ACetAldehyde s / u u / / / m / u / / / m u u u m m / m s u / s / u

ACetone m s u u s u m s s u u s u s u u u s s u u s m m s u u

ACetonitrile s s u / s m s / s s u s u m u u / s m u u s s s s u u

™

AlConoX

Allyl AlCohol / / / u / / s / / / / s / s s m s s s / m s / / s / /

Aluminum Chloride u u s s s s u s s s s m s s s s / s s s s s m u u s s

formiC ACid (100%) / s m u / / u / / / / u / s m u u s s / u s / u s / u

Ammonium ACetAte s s u / s s s / s s s s s s s u / s s s s s s s s s s

Ammonium CArBonAte m s u s s s s s s s s s s s u u / s s s s s s m s s s

Ammonium hydroXide (10%) u u s u s s m s s s s s / s u m s s s s s s s s s m s

Ammonium hydroXide (28%) u u s u s u m s s s s s u s u m s s s s s s s s s m s

Ammonium hydroXide (ConC.) u u u u s u m s / s / s u s u u s s s / m s s s s / u

Ammonium PhosPhAte u / s / s s s s s s s s / s s m / s s s s s s m s s s

Ammonium sulfAte u m s / s s u s s s s s s s s s / s s s s s s u s s u

Amyl AlCohol s / m u / / s s / m / s / m s s s s m / / / u / s / m

Aniline s s u u s u s m s u u u u u u u / s m u u s s s s u s

sodium hydroXide (<1%) u / m s s s / / s m s s / s m m s s s s s s m s s / u

sodium hydroXide (10%) u / m u / / u / m m s s u s u u s s s s s s m s s / u

BArium sAlts m u s / s s s s s s s s s s s m / s s s s s s m s s s

BenZene s s u u s u m u s u u s u u u m u m u u u s u u s u s

BenZyl AlCohol s / u u / / m m / m / s u u u u u u u / m s m / s / s

BoriC ACid u s s m s s u s s s s s s s s s u s s s s s s s s s s

Cesium ACetAte m / s / s s s / s s s s / s s / / s s s s s s m s s s

Cesium Bromide m s s / s s s / s s s s s s s / / s s s s s s m s s s

Cesium Chloride m s s u s s s / s s s s s s s / / s s s s s s m s s s

Cesium formAte m s s / s s s / s s s s s s s / / s s s s s s m s s s

Cesium iodide m s s / s s s / s s s s s s s / / s s s s s s m s s s

Cesium sulfAte m s s / s s s / s s s s s s s / / s s s s s s m s s s

Chloroform u u u u s s m u s u u m u m u u u m m u u s u u u m s

ChromiC ACid (10%) u / u u s u u / s s s u s s m u m s s u m s m u s s s

ChromiC ACid (50%) u / u u / u u / / / s u u s m u m s s u m s / u m / s

Cresol miXture s s u / / / s / s u u u u u u / / u u / u s s s s u s

CyCloheXAne s s s / s s s u s u s s u u u m s m u m m s u m m u s

deoXyCholAte s s s / s s s / s s s s s s s / / s s s s s s s s s s

distilled WAter s s s s s s s s s s s s s s s s s s s s s s s s s s s

deXtrAn m s s s s s s / s s s s s s s s s s s s s s s m s s s

diethyl ether s s u u s s s u s u u s u u u u u u u u u s s s s m u

diethyl Ketone s / u u / / m / s u / s / m u u u m m / u s / / s u u

diethylPyro-CArBonAte s s u / s s s / s s u s u s u / / s s s m s s s s s s

dimethylsulfoXide s s u u s s s / s u s s u s u u / s s u u s s s s u u

dioXAne m s u u s s m m s u u s u m u u / m m m u s s s s u u

ferriC Chloride u u s / / / m s / m / s / s / / / s s / / / m u s / s

ACetiC ACid (glACiAl) s s u u s s u m s u s u u u u u m s u m u s u u s / u

ACetiC ACid (5%) s s m s s s m s s s s s m s s s s s s s m s s m s s m

ACetiC ACid (60%) s s u u s s u / s m s u u m u s m s m s m s m u s m u

ethyl ACetAte m m u u s s m m s s u s u m u u / s s u u s m m s u u

ethyl AlCohol (50%) s s s s s s m s s s s s u s u s s s s s s s s m s m u

ethyl AlCohol (95%) s s s u s s m s s s s s u s u / s s s m s s s u s m u

ethylene diChloride s / u u / / s m / u u s u u u u u u u / u s u / s / s

ethylene glyCol s s s s s s s s s s s s / s u s s s s s s s s m s m s

ethylene oXide VAPor s / u / / u / / s u / s / s m / / s s s u s u s s s u

fiColl-hyPAque

aLLuminum

anoDic coating for aLuminum

Buna n

ceLLuLose acetate Butyrate

PoLyurethane rotor Paint

comPosite carBon fiBer/ePoxy

DeLrin™ethyLene ProPyLene

gLass

neoPrene

u u s / s s s / s s s s s s m s s s s s s s s s s s u

™

m s s / s s s / s s s s / s s / s s s s s s s m s s s

™

46 | CW3 Thermo Scientic

Page 48

Troublshooting when no Error Code is indicated

™

™

, tefLon

™

PoLysuLfone

PoLyvyniL chLoriDe

ruLon A

siLicone ruBBer

stainLess steeL

titanium

tygon™viton

noryL™nyLon

,cLear crimP

™

, PoLycLear

¹

PET

PoLyaLLomer

PoLycarBonate

PoLyester, gLass thermoset

PoLythermiDe

PoLyethyLene

PoLyProPyLene

MATERIAL

CHEMICAL

hydrofluoriC ACid (10%) u u u m / / u / / u u s / s m u s s s s m s u u u / /

hydrofluoriC ACid (50%) u u u u / / u / / u u u u s u u u s s m m s u u u / m

hydroChloriC ACid (ConC.) u u u u / u u m / u m u u m u u u / s / u s u u u / /

formAldehyde (40%) m m m s s s s m s s s s m s s s u s s m s s s m s m u

glutArAldehyde s s s s / / s / s s s s s s s / / s s s / / s s s / /

glyCerol m s s / s s s s s s s s s s s s / s s s s s s s s s s

guAnidine hydroChloride u u s / s s s / s s s s s s s / / s s s s s s u s s s

™

hAemo-sol

heXAne s s s / s s s / s s u s u m u s s u s s m s u s s u s

isoButyl AlCohol / / m u / / s s / u / s u s s m s s s / s s s / s / s

isoProPyl AlCohol m m m u s s s s s u s s u s u m s s s s s s s m m m s

iodoACetiC ACid s s m / s s s / s m s s m s s / m s s s s s m s s m m

PotAssium Bromide u s s / s s s / s s s s s s s s s s s / s s s m s s s

PotAssium CArBonAte m u s s s s s / s s s s s s u s s s s s s s s s s s s