Page 1

Thermo Scientific Barnstead

Pretreatment System

Installation and Operation

50157886 • Revision A • October 2018

Page 2

IMPORTANT Read this instruction manual. Failure to follow the instructions in this manual can result in

damage to the unit, injury to operating personnel, and poor equipment performance.

CAUTION All internal adjustments and maintenance must be performed by qualified service personnel.

Material in this manual is for informational purposes only. The contents and the product it describes are

subject to change without notice. Thermo Fisher Scientific makes no representations or warranties with

respect to this manual. In no event shall Thermo be held liable for any damages, direct or incidental, arising

from or related to the use of this manual.

© 2018 Thermo Fisher Scientific Inc. All rights reserved.

Page 3

Contents

Preface ........................................................................ 1

Legal Information...................................................... 1

Warranty .................................................................. 1

Explanatory Notes on the Operating Instructions...... 1

Safety Precautions ................................................... 2

Transport and Packaging............................................. 3

Examination on Receipt............................................ 3

Complaints............................................................... 3

Packaging for Return Shipment................................ 3

Intended Use of the Device .......................................... 4

Technical Specifications............................................... 5

The Installation Area..................................................... 7

Installation.................................................................... 8

Wall Mounting Instructions for

Pretreatment System ............................................... 8

Connections of the Pretreatment System ................. 8

Typical Installation........................................................ 10

Corrective measures ................................................ 10

Flow Chart ................................................................... 11

How the Pretreatment System Functions ..................... 12

Initial start up ............................................................... 13

Putting the system into operation ............................. 13

Operating Elements.................................................. 13

Page 4

Maintenance ................................................................ 14

Maintenance Intervals............................................... 14

Waste Disposal............................................................ 15

Troubleshooting........................................................... 16

Replacement Parts ...................................................... 17

Replacement: Consumables .................................... 17

Maintenance Record.................................................... 18

Page 5

Preface

These operating instructions are protected by copyright.

Rights resulting thereof, particularly reprint, photomechanical

or digital post-processing or reproduction, even in part, are

only allowed with the written consent of Thermo Fisher

Scientific. This regulation does not apply to reproductions for

in-plant use. The contents of this operating instructions

manual may change at any time and without any prior notice.

In case of conflicting translations into foreign languages the

English- language version of these operating instructions shall

be binding.

Read through the information given in these operating

instructions on installing and operating the system before you

begin installation and use of your water purification system.

This is of particular importance, as we, the manufacturer, do

not assume any liability for damage due to incorrect operation

or use of the system other than the intended use.

Thermo Fisher Scientific Inc. provides this document to its

customers with a product purchase to use in the product

operation. This document is copyright protected. Any

reproduction of the whole or any part of this document is

strictly prohibited, except with the written authorization of

Thermo Fisher Scientific Inc. The contents of this document

are subject to change without notice. All technical information

in this document is for reference purposes only. System

configurations and specifications in this document supersede

all previous information received by the purchaser.

Warranty

Thermo Fisher Scientific warrants the operational safety and

functions of the Thermo Scientific Barnstead Pretreatment

systems only under the condition that:

• The system is installed and operated as per the operation

manual. Do not use this product for anything other than

its intended use.

• The system is not modified.

• Only original spare parts and accessories that have been

approved by Thermo Fisher Scientific are used (thirdparty spares without Thermo Fisher Scientific approval

will void the limited warranty).

• Inspections and maintenance are performed at the

specified intervals.

• An installation verification test is performed on

commissioning the system for the first time and repeated

after each preventative maintenance and repair activity.

The warranty is valid from the date of delivery of the

system to the customer.

• The above mentioned warranty conditions are subject to

the general terms and conditions of sale, in effect at the

time of purchase, which apply as well.

Thermo Fisher Scientific Inc. makes no representations that

this document is complete, accurate or error-free and

assumes no responsibility and will not be liable for any errors,

omissions, damage or loss that might result from any use of

this document, even if the information in the document is

followed properly.

This document is not part of any sales contract between

Thermo Fisher Scientific Inc. and a purchaser. This document

shall in no way govern or modify any Terms and Conditions of

Sale, which Terms and Conditions of Sale shall govern all

conflicting information between the two documents.

Legal Information

Note: Specifications, terms and pricing are subject to

change. Not all products are available in all countries. consult

your local sales representative for details.

Explanatory Notes on the

Operating Instructions

CAUTION: This symbol, in the context of a

CAUTION, indicates a potentially hazardous

situation which if not avoided could result in minor

to moderate injury or damage to the equipment.

WARNING: This symbol, in the context of a

WARNING, indicates potentially hazardous

situations which, if not avoided, could result in

serious injury or death.

DANGER: This symbol, in the context of a

DANGER, indicates potentially hazardous

situations which, if not avoided, could result in

serious injury or death.

This symbol indicates a need to use gloves during

the indicated procedures.

Pretreatment system Preface | 1

Page 6

This symbol indicates a need to wear protective

goggles gloves during the indicated procedures.

This symbol indicates a situation in which

breathing protection must be used.

Note: Is used for application hints and useful information.

This information is valid for the system that is received. For

quick and correct service, include the following information on

all inquiries and replacement parts orders which relate to your

system:

• The serial number (located on the right side of the system

on the nameplate)

• The catalog number

Safety Precautions

Observe these safety precautions for your own safety!

CAUTION: To avoid the risk of pinching, crushing,

cutting, never perform maintenance on the system

without its protective housing, or while it is in

operation. Maintenance work on the system may

only be performed by trained, authorized

specialists.

CAUTION: The Thermo Scientific Barnstead

Pretreatment system is a modern water

purification system intended solely for the

treatment of potable water. The water it produces

is not fit for drinking.

• Do not install or operate the system until you have

carefully read through these operating instructions and

the notes and notices contained therein.

• Lifting and carrying the Pretreatment system, e.g. to the

installation location, can be carried out by one person. To

do this, lift the system at the two corner points beneath

the bottom plate.

• Always observe the applicable, pertinent codes and

regulations valid at the installation location of the system

and follow all applicable accident prevention regulations.

• If the system is not to be operated for an extended

period, e.g., over extended weekend, or during a

vacation period, close the feed-water inlet (close the

feed-water tap)

• When installing the pretreatment system, always ensure

that there is adequate space all around the system (refer

to the table “Accessibility to Pretreatment system” in

section Technical Specifications) to ensure that ease

of use or easy replacement of materials (e.g., filter

change, connection) is possible at all times.

• Visually inspect the system at regular intervals. Clean up

any water or spills found around the system immediately.

2 | Preface Pretreatment system

Page 7

Transport and Packaging

DANGER: Do not pull the plastic foil over your

head. Risk of suffocation. Use the plastic foil only

for packaging.

Pretreatment systems are carefully inspected and packed

prior to shipping, but damage could still possibly occur during

transport. Lifting and carrying the Thermo Scientific

Barnstead Pretreatment system, e.g. to the installation

location, can carried out by one person.

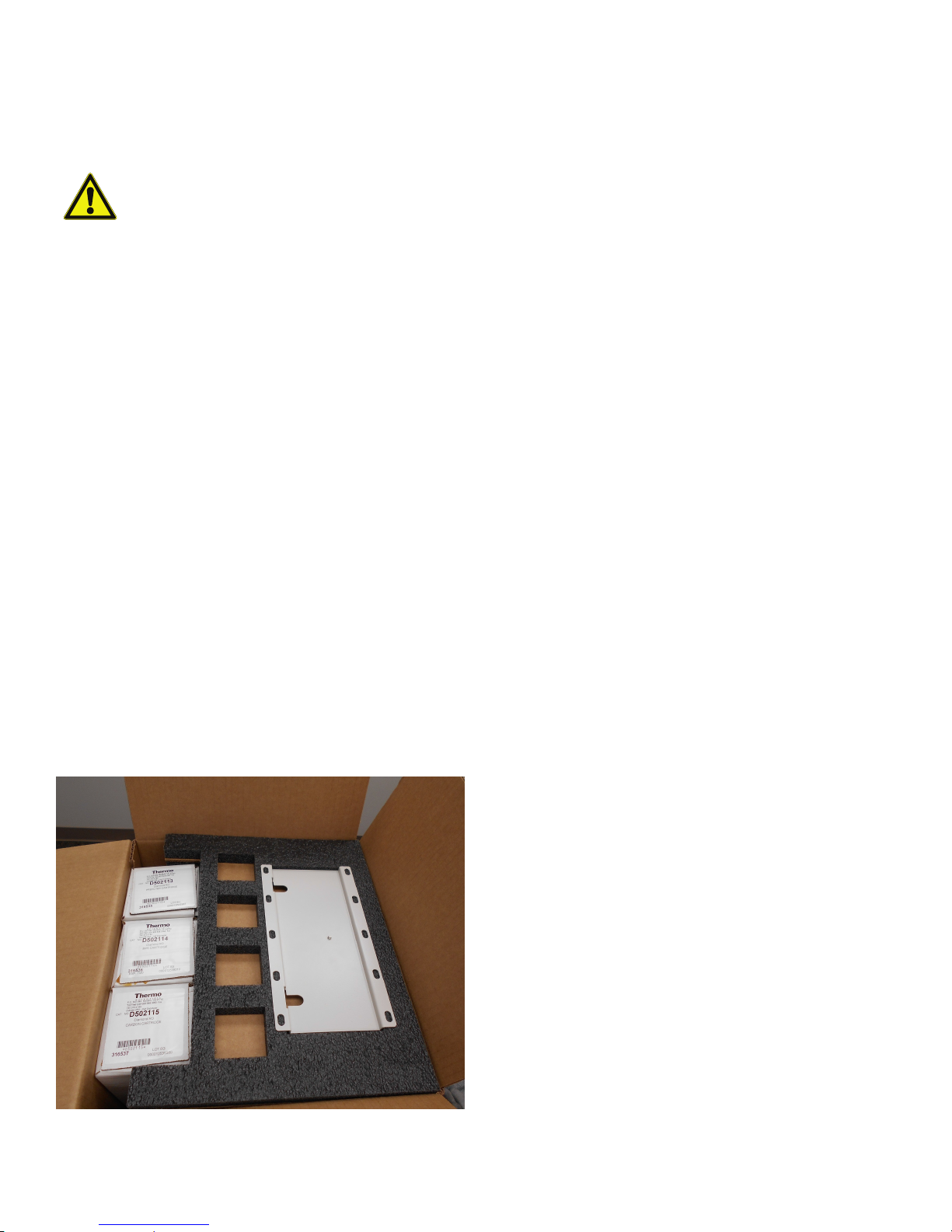

Examination on Receipt

1. Ensure all components for complete system were

ordered and received. This should include:

• Pretreatment system - 50157886

•1 μm Prefilter - D502113

• MPS Cartridge - D502114

• Carbon Cartridge - D502115

• Wall bracket (if wall mounting)

• TU494X4 6 ft (1.8 m) of ¼ OD tubing

• Feed-water Connection kit - 25.0071

2. Carefully unpack system and inspect system for damage.

Note: If the packaging show signs of damage, inspect the

system for damage.

Complaints

If there has been any damage occurred to the goods during

transportation:

• Immediately contact your delivery transport agency.

• Save the complete packaging, including the cardboard

box, for a possible inspection of them and/or return

shipment of the system.

Packaging for Return

Shipment

If possible, use the original box and packaging material. When

these are no longer available, then:

• Protect the system from shock by packing it in bubble

wrap and/or packaging foam and a strong cardboard

box.

Note: The time limit for claims is 6 days from the time of

receipt of the goods. The right to claim for damages ceases

when this time has elapsed.

Note:

• Only a trained person should take the system out of

operation.

• Prior to sending back an operated device, empty the

water, dry the system and take out the cartridges.

Figure 1. Unpacking

Pretreatment system Transport and Packaging | 3

• Pack the cartridges into a bubble wrap and/or packaging

foam and put it into the package of the Pretreatment

system.

Page 8

Intended Use of the Device

Outlet Inlet

The Thermo Scientific Barnstead Pretreatment system is

laboratory systems used for the treatment of water.

The Thermo Scientific Barnstead Water systems are designed

to be installed and used in the following application areas:

• Laboratories for cell biological and biotechnological work

with the safety levels L1, L2 and L3.

• Medical and microbiological laboratories according to

DIN EN 12128.

• Laboratories in the central area of clinics and hospitals.

The system must not be operated outside of the

specifications as described in the operating manual. In

particular, the system should not be used for production of

drinking water and drugs manufacturing. The system must

not be used as a medical device and outside of laboratories.

Note: Pretreatment system will operate with all Smart2Pure

and Pacific series water purification systems.

Figure 2. Front view of Pretreatment system

4 | Intended Use of the Device Pretreatment system

Page 9

Technical Specifications

Note: Check at regular intervals the quality of your feed-water.

Feed-water requirements

Source Potable tap water

Silt density index (SDI) <5

Turbidity <1 NTU

Conductivity (reference

temperature +25°C)

Chlorine Max. 3 ppm

Iron content Max. 0.5 ppm

pH range 4 - 11

Temperature +2°C - +35°C

Pressure

Feed-water supply ¾” NPT (adapts to ¼” NPT male or female)

Tubing Connections

Inlet Tubing Tube ¼” outer diameter

Outlet Tubing Tube ¼” outer diameter

1500 μS/cm (670 Ω·cm)

2 - 6.9 bar / 29 - 100 PSI (at a pressure >6.9 bar / 100 PSI a pressure reducer must

be installed upstream of the system.

Accessibility to Pretreatment system

Space to the Left & Right of Unit 15 cm / 6 inch

Space to the Front of the Unit 30 cm / 12 inch

Pretreatment system Technical Specifications | 5

Page 10

Figure 3. Dimensions of Pretreatment system

Dimensions and weight of Pretreatment system

Height / Height with Wall Bracket 15.58 inch / 15.17 inch

Width 11 inch

Depth / Depth with Wall Bracket 7.00 inch / 7.38 inch

Dry Weight 24.5 lbs (11.1 kg)

Wet Weight (during operation) 29 lbs (13.2 kg)

6 | Technical Specifications Pretreatment system

Page 11

The Installation Area

Note: The operator is obliged to ensure, that the installation of

the pretreatment system and its operation are carried out in

compliance with all national and international guidelines,

applicable and valid for the place of installation.

Note: If necessary, measures to protect the water have to be

taken by installing appropriate components.

Take the following criteria into consideration when selecting

the installation area:

• Feed-water pressure (potable tap water) not be less than

2 bar (29 PSI) and not greater than 6.9 bar (100 PSI).

• There must be a feed-water shut off valve installed ahead

of the Smart2Pure Pro system.

CAUTION: The feed-water pressure to

Pretreatment system must not be allowed to go

above 6.9 bar. Install an additional pressure

reducer when the feed-water pressure is higher.

• You must protect your system from frost. The

temperature at the installation area must be between

+2°C and +40°C.

• The surface on which the system is installed must be

level and stable. It should not exceed a maximum of 2%

deviation from evenness is recommended.

• A smooth wall is required when the system is to be wall

mounted. The bench or wall surface must have an

adequate load-carrying capacity (check the maximum

capacity of load the wall can sustain and the stability of

the wall). The dry and wet weight of the system is given

under section Technical Specifications.

• A low pressure check valve is recommended in the

feed-water line to prevent back flow of feed-water from

the water system. Refer to local building codes.

• Easy access for operation and control of the system.

Pretreatment system The Installation Area | 7

Page 12

Installation

Screw Mounting Holes

Screw Mounting Holes

Wall Bracket Slots

#8-32 UNC

(For Locking Screw)

Mounting Pins

(For Locking Screw)

#8-32 UNC

1. Requirements for installation:

• Screws and fasteners for wall bracket (if wall

mounting pretreatment)

• Tap water supply with shut off valve and ¾” NPT

male adapter

2. Locate Pretreatment system within 6 feet of Water

Purification system.

Wall Mounting Instructions

for Pretreatment System

Note: Before you begin mounting the system on the wall, you

must check that the strength of the wall to ensure it is suitable

for supporting the system (refer to the table “Dimensions and

weight of Pretreatment system” in the section Technical

Specifications).

Note: The system does not include screws and fasteners for

mounting, and requires minimum 4 fasteners (2 on top, 2 on

bottom).

3. Place Pretreatment system onto bracket by sliding the

mounting pins into the wall bracket slots (refer Figure 5).

4. Lock Pretreatment system into place by opening front

door and locating the locking screw hole. Fasten #8-32

locking screw from Pretreatment system to the wall

bracket (refer Figure 5).

The countertop base can be removed before wall mounting.

To remove the coutertop base, remove the 4 screws from the

bottom of unit.

1. Locate the wall bracket. Hold the wall bracket at the

desired position on the wall and check for levelness.

Mark four boreholes for fixing the wall bracket.

Figure 4. Wall mount bracket

2. Drill holes for fasteners, or drill screws directly into

backing board and attach wall bracket securely to the

wall.

Figure 5. Locking wall mount

Connections of the

Pretreatment System

Following connections are required for pretreatment system

to work:

1. 1 micro Prefilter cartridge quick disconnects

2. MPS anti-scalent cartridge quick disconnects

3. Extruded carbon filter quick disconnects

4. Outlet connector for outer diameter ¼” tube

5. Inlet connector for outer diameter ¼” tube

Note: If you remove any of the cartridges, water flow will stop.

In order to operate, all five connections above must be made,

and feed-water must be turned ON.

Tubing Installation:

Note: Use tube cutter to ensure ends of tubing are flat and

free of burrs (prickles).

8 | Installation Pretreatment system

Page 13

1. Mark from end of tube the length of insertion (1.75 cm /

Typical Fitting

Tubing

Collect

1.75 cm (11/16”)

Thumb Pad

Male Adapter

Dirt Screen

¾” Union Nut

Outer Diameter

¼” Tube

Fitting

11/16 inch)

2. Wet the tube end and insert the tube straight into the

fitting until it bottoms out on the interior shoulder and the

insertion mark is no longer visible. ()fa;sdujfa;oisd

Figure 6. Inserting tube into fittings

3. Install the MPS cartridge (D502114) by inserting into the

upper middle and lower middle quick disconnects. Push

firmly into place.

4. Install the Carbon filter (D502115) by inserting into the

upper left and lower left quick disconnects. Push firmly

into place.

Quick Disconnect Fittings:

These fittings are found on the Prefilter, MPS and Carbon

cartridges. To insert the cartridges:

1. Press on metal thumb pad on unit to ensure fitting is

open

1. Insert the male adapter into fitting and release your

thumb. Push the connector until your hear a click. Gently

pull the cartridge to ensure the connection is secure.

2. To remove cartridges, press on metal thumb pad to

release fitting and pull cartridge out.

Figure 8. Cartridge installation

Inlet / Outlet Connections:

1. Outlet Connection: Connect ¼” outer diameter tubing

to outlet connector on left side of Pretreatment system.

Then connect to the water purification system (i.e.

Smart2Pure Pro) as shown in the Typical Installation

section.

2. Inlet Connection: Connect ¼” outer diameter tubing to

the inlet connector on right side of the Pretreatment

system.

3. Feed-Water Connection: Using Feed-water fitting kit

from Smart2Pure Pro installation kit, connect inlet tubing

to the ¾” NPT feed-water connection.

4.

Figure 7. Quick disconnect fittings

Cartridge/Filter Installation:

1. Open the Front Door.

2. Install the Prefilter (D502113) by inserting into the upper

right and lower right quick disconnects. Push firmly into

place.

Pretreatment system Installation | 9

Figure 9. Feed-water fitting

Page 14

Typical Installation

Figure 10. Bench setup

Corrective measures

• All tubing and cartridges must be checked for their

correct position on the system and that no leakage or

blockage after opening the feed-water supply.

• To avoid tripping, ensure that the tubing does not lay over

the floor.

10 | Typical Installation Pretreatment system

Page 15

Flow Chart

Note: The following flow chart describes the Pretreatment system water flow path.

F1: Prefilter PS1: Prefilter Inlet Gauge

F2: MPS Cartridge PS2: Prefilter Outlet Gauge

F3: Carbon Filter PS3: Carbon Outlet Gauge

F4: FLX31 Pressure Gauge Filter, 25 μm V1: Pressure Regulator

Pretreatment system Flow Chart | 11

Page 16

How the Pretreatment System

Functions

When the system is in operation, tap water with a maximum

pressure of 6.9 bar flows into the system through the

feed-water Inlet connection on the bottom of the right side

panel.

The feed-water pressure is regulated to 30 psi via an internal

pressure regulator. This regulated pressure can be seen on

the Prefilter Inlet gauge.

The water then flows (upward) through the 1 μm Prefilter. The

Prefilter is used to remove particulates from your feed-water

which can damage/plug an RO Membrane downstream from

the system. A Prefilter Outlet pressure gauge shows the

pressure drop across the Prefilter by comparing the Prefilter

Inlet and Prefilter Outlet gauge. A pressure drop of > 10 psi

indicates a plugged Prefilter (which can reduce flow through

the Pretreatment system) and replacement is necessary.

Next the water flows into the MPS Anti-Scalent cartridge. The

MPS cartridge contains a slow dissolving anti-scalent material

which is designed to prevent hard water scale buildup on

down stream RO Membranes. Replace this cartridge when

the anti-scalent material is half dissolved.

After the MPS cartridge, the water flows into the Extruded

Carbon cartridge. The carbon cartridge removes chlorine

from your feed-water, which can damage RO Membranes.

Replace the carbon cartridge every 6 months. The Carbon

Outlet pressure gauge displays the pressure after the carbon

cartridge. Compare the Carbon Outlet gauge to the Prefilter

Outlet gauge to determine the pressure drop across the

carbon cartridge. Pressure drops of > 15 psi indicates the

carbon cartridge is blocked and needs replacement.

The water exits the Pretreatment system via the Outlet

connector on the bottom of the left side panel. Use a ¼” outer

diameter tube to connect to an RO system, such as the

Thermo Scientific Barnstead Smart2Pure or Pacific Series

water systems.

12 | How the Pretreatment System Functions Pretreatment system

Page 17

Initial start up

Putting the system into

operation

CAUTION: Check that all connections have been

made as described in the Installation section.

• Verify if all connections are secure and correct.

• Turn the feed-water ON. Verify no leaks are present in the

tubing, connectors, cartridges, etc. Turn the water

purification system (i.e. Smart2Pure Pro) downstream of

the Pretreatment system ON. Check for leaks once the

downstream water purification system starts production.

• Verify that all pressure gauges are showing pressure

readings.

• If no leaks or blockages are found, close the

Pretreatment system’s front door and allow operation to

continue.

Operating Elements

1. Prefilter Inlet

• Indicates water pressure after the regulator, before

entering the Prefilter

2. Prefilter Outlet

• Indicates water pressure after the Prefilter

3. Carbon Filter Outlet

• Indicates water pressure after the carbon filter

Figure 11. Pretreatment system gauge

Pretreatment system Initial start up | 13

Page 18

Maintenance

Regular servicing of the system ensures that the quality of the

treated water will remain constant. To ensure that your

system is serviced properly we recommend that you obtain a

maintenance contract with Thermo Fisher Scientific or factory

authorized service provider. You can then be certain that your

system will have a high degree of operational reliability and

dependability.

To ensure that your system functions without any errors it

must be checked, maintained and serviced at regular

intervals, as described in these operating instructions. The

operating instructions must therefore be kept in an easily

accessible location for anyone who is using or servicing the

system.

Material

Prefilter F1 D502113 6 months

MPS Cartridge F2 D502114 6 months Or when material is half dissolved

Carbon Filter F3 D502115 6 months

Flow

chart no.

Item No. Interval Other problems

Maintenance Intervals

Wear parts must be replaced in accordance with the following

table. The intervals have been established for the user and

depend on the actual, exact water quality and the volume of

water that is used daily.

Or when pressure drop exceeds 10 psi as indicated

by difference of Prefilter Inlet and Prefilter Outlet

gauges

Or when pressure drop exceeds 15 psi as indicated

by difference of Prefilter Outlet and Carbon Outlet

gauges

Note: The lifetime of the wear parts is a direct function of the quality of the feed-water and the daily volume of water that is

used.

14 | Maintenance Pretreatment system

Page 19

Waste Disposal

Note: Before returning your Thermo Scientific Barnstead

Pretreatment systems for waste disposal, contact your local

waste disposal company for proper disposal of the system

and its components. Only specially trained personal can take

the system out of operation and dispose it properly.

When the packaging is no longer needed it can be disposed

of as household waste. Systems are in conformity with EEC

Guideline 2011/65/EC.

The system is not to be thrown away as household waste but

must be properly disposed of. It can be returned to the

manufacturer for safe disposal according to EEC Guideline

2011/65/EC. We therefore request our customers in

Germany and other member States in the European

Economic Area to contact our local service center or our

headquarters.

weee.recycle@thermofisher.com

WEEE-Reg.-no.: DE 12471402

In countries outside of the European Economic Area, contact

your local authorities or waste disposal company.

Pretreatment system Waste Disposal | 15

Page 20

Troubleshooting

Note: Contact the service department if you cannot rectify these error.

Problem Cause Solution

Low Flow out of system

No Flow out of system No feed-water flow

Leakage in the system

Gauges not working

Plugged cartridge(s)

Low feed-water pressure

Tubing connector, Cartridge or

tubing

Faulty gauge

Blocked cartridge

No feed-water

Check Pressure gauges to determine if Prefilter or

Carbon cartridge is plugged.

Ensure feed-water is at least 2 bar

Verify feed-water is on, check for pressure on

Prefilter Inlet Gauge

Verify tubing is properly connected.

Verify cartridges are installed properly and are not

cracked.

Replace broken tubing or connectors. Call

Service

Replace faulty gauge

Try bypassing cartridges using 3/8" tubing with

CUX9 tubing connectors installed to check gauge

Turn on feed-water, or remove blockage

16 | Troubleshooting Pretreatment system

Page 21

Replacement Parts

Note: The use of spare parts, accessories or wear parts from other manufacturers will nullify the warranty for this unit.

Figure 12. Replacement part list for Pretreatment system

Drawing

ID

3 Feet 321191

4 Pressure Gauge MEX196

5 Pressure Regulator 02280

6 Inlet Connector PMX206

7 Outlet Connector PMX206

8 TEE Union PMX222

9 Elbow Union 212-00001

10 Elbow Stem PMX235

11 Male Connector 212-00002

12 Female Connector PMX236

13 Quick Disconnect Coupling 212-00003

14 25 Micron Tube Filter FLX31

Part

Part

Number

Drawing

ID

15 Wall Bracket 700-00006

Not shown:

• TU494X4 6 feet (1.8 meters) of ¼ OD tubing)

• 25.0071 Feed Water Connection kit

Replacement:

Consumables

Consumable Item No.

Prefilter Cartridge D502113

MPS Cartridge D502114

Carbon Cartridge D502115

Part

Part

Number

Pretreatment system Replacement Parts | 17

Page 22

Maintenance Record

Customer address:

Location:

System type:

Serial no.:

Manufacturing Year:

Date

Prefilter Replaced?

Y/N

MPS Replaced?

Y/N

Carbon Replaced?

Y/N

The following points must be observed in order to ensure the quality of the system.

• 1x/Weekly, enter measured values.

18 | Maintenance Record Pretreatment system

Page 23

WEEE Compliance

Great Britain

Deutschland

Italia

France

España

WEEE Compliance. This product is required to comply with the European Union’s Waste Electrical &

Electronic Equipment (WEEE) Directive 2012/19/EU. It is marked with the following symbol. Thermo

Fisher Scientific has contracted with one or more recycling/disposal companies in each EU Member

State, and this product should be disposed of or recycled through them. Further information on our

compliance with these Directives, the recyclers in your country, and information on Thermo Scientific

products which may assist the detection of substances subject to the RoHS Directive are available at

www.thermofisher.com under Services & Support.

WEEE Konformittät. Dieses Produkt muss die EU Waste Electrical & Electronic Equipment (WEEE)

Richtlinie 2012/19/EU erfüllen. Das Produkt ist durch folgendes Symbol gekennzeichnet. Thermo

Fisher Scientific hat Vereinbarungen getroffen mit Verwertungs-/Entsorgungsanlagen in allen EUMitgliederstaaten und dieses Produkt muss durch diese Firmen widerverwetet oder entsorgt werden.

Mehr Informationen über die Einhaltung dieser Anweisungen durch Thermo Scientific, dieVerwerter

und Hinweise die Ihnen nützlich sein können, die Thermo Fisher Scientific Produkte zu identizfizieren,

die unter diese RoHS. Anweisungfallen, finden Sie unter www.thermofisher.com unter Services &

Support.

Conformità WEEE. Questo prodotto deve rispondere alla direttiva dell’ Unione Europea 2012/19/EU

in merito ai Rifiuti degli Apparecchi Elettrici ed Elettronici (WEEE). È marcato col seguente simbolo.

Thermo Fischer Scientific ha stipulato contratti con una o diverse società di riciclaggio/smaltimento in

ognuno degli Stati Membri Europei. Questo prodotto verrà smaltito o riciclato tramite queste

medesime. Ulteriori informazioni sulla conformità di Thermo Fisher Scientific con queste Direttive,

l’elenco delle ditte di riciclaggio nel Vostro paese e informazioni sui prodotti Thermo Scientific che

possono essere utili alla rilevazione di sostanze soggette alla Direttiva RoHS sono disponibili sul sito

www.thermofisher.com in Servizi e Supporto.

Conformité WEEE. Ce produit doit être conforme à la directive euro-péenne (2012/19/EU) des

Déchets d’Equipements Electriques et Electroniques (DEEE). Il est marqué par le symbole suivant.

Thermo Fisher Scientific s’est associé avec une ou plusieurs compagnies de recyclage dans chaque

état membre de l’union européenne et ce produit devraitêtre collecté ou recyclé par celles-ci.

Davantage d’informations sur laconformité de Thermo Fisher Scientific à ces directives, les recycleurs

dans votre pays et les informations sur les produits Thermo Fisher Scientific qui peuvent aider le

détection des substances sujettes à la directive RoHS sont disponibles sur www.thermofisher.com

sous Services et Assistance.

Cumplimiento de la directiva RAEE. Este producto está obligado a cumplir con la Directiva de la

Unión Europea sobre residuos de aparatos eléctricos y electrónicos (RAEE) 2012/19/EU. Está

marcado con el siguiente símbolo. Thermo Fisher Scientific ha contratado a una o varias empresas de

reciclado/disposición de residuos en cada estado miembro de la UE, y este producto debe reciclarse

o desecharse a través de dichas empresas. Para obtener más información sobre nuestro

cumplimiento con estas directivas, las empresas de reciclaje de su país, así como información sobre

los productos Thermo Scientific que pueden ayudarle a detectar sustancias sujetas a la directiva

RoHS, visite www.thermofisher.com/WEEERoHS en la sección Servicios y Asistencia.

Page 24

IF YOU NEED ASSISTANCE:

Thermo Fisher Scientific products are backed by a global technical support team ready to support your applications. We offer

cold storage accessories, including remote alarms, temperature recorders, and validation services.

Visit

www.thermofisher.com or call:

Countries Sales Services

North America +1 866 984 3766 (800) 438-4851

India 1800 22 8374, +91 22 6716 2200 +91 22 6716 2200

China +800 810 5118, +400 650 5118 +8621 68654588

Japan +81 3 5826 1616 +81 3 3816 3355

Australia +61 39757 4300 1 300 735 292

Austria +43 1 801 40 0 +43 1 801 40 0

Belgium +32 53 73 42 41 +32 2 482 30 30

France +33 2 2803 2180 +33 2 2803 2180

Germany 0800 1 536 376, +49 6184 90 6000 0800 1 536 376

Italy +32 02 95059 552 +39 02 95059 552, 432 254 375

Netherlands +31 76 579 55 55 +31 76 571 4440

Nordic/Baltic/CIS +358 9 329 10200 +358 9 329 100

Russia +7 812 703 4215 +7 812 703 4215

Spain/Portugal +34 93 223 09 18 +34 93 223 09 18

Switzerland +41 44 454 12 22 +41 44 454 12 12

UK/Ireland +44 870 609 9203 +44 870 609 9203

New Zealand +64 9 980 6700 +64 9 980 6700

Other Asian Countries +852 2885 4613 +852 2885 4613

Countries not listed +49 6184 90 6000 +49 6184 90 6000

Thermo Fisher Scientific Inc.

275 Aiken Road

Asheville, NC 28804

United States

Find out more at thermofisher.com

© 2018 Thermo Fisher Scientific Inc. All rights reserved. All trademarks are the property of

Thermo Fisher Scientific and its subsidiaries unless otherwise specified. 50157886 1018

Loading...

Loading...