Page 1

Analyze •Detect•Measure •Control

™

Orion 94-16

Orion 96-16 ionplus

Orion Silver/Sulfide

Electrode

INSTRUCTION MANUAL

Ag

/S

+

-

2

Page 2

AQUAfast, Cahn, EZ Flash, Ionalyzer, ionplus, KNIpHE, No Cal, ORION, perpHect,

PerpHecT, PerpHecTion, pHISA, pHix, pHuture, Pure Water, Sage, Sensing the

Future, SensorLink, ROSS Ultra, Sure-Flow, TEA Analyzer, Titrator PLUS, TURBO2

and Wine Master are registered trademarks of Thermo Electron Corporation.

1-888-pHAX-ION, A+, All in One, Aplus, AQUAsnap, AssuredAccuracy,

AUTO-BAR, AUTO-CAL, AUTO DISPENSER, Auto-ID, AUTO-LOG, AUTO-READ,

AUTO-STIR, Auto-Test, BOD AutoEZ, Cable-Free, CERTI-CAL, CISA, DataCOLLECT,

DataPLUS, digital LogR, DirectCal, DuraProbe, Environmental Product Authority,

Extra Easy/Extra Value, FAST QC, Flash Titration, Flash Titrator, GAP, GLPcal,

GLPcheck, GLPdoc, ISEasy, KAP, LabConnect, LogR, Low Maintenance Triode,

Minimum Stir Requirement, MSR, NISS, One-Touch, One-Touch Calibration, OneTouch Measurement, Optimum Results, Pentrode, pHuture MMS, pHuture

Pentrode, pHuture Quatrode, pHuture Triode, Quatrode, QuiKcheK, rf link,

ROSS, ROSS Resolution, SAOB, Smart CheK, Stacked, Stat Face, The Enhanced

Lab, ThermaSense, Triode, TRIUMpH, Unbreakable pH, Universal Access are

trademarks of Thermo.

Guaranteed Success and The Technical Edge are service marks of Thermo.

PerpHecT meters are protected by U.S. patent 6,168,707.

PerpHecT ROSS are protected by U.S. patent 6,168,707.

ORION Series A meters and 900A printer are protected by U.S. patents

5,108,578, 5,198,093 and German patents D334,208 and D346,753.

Sure-Flow electrodes are protected by European Patent 278,979

and Canadian Patent 1,286,720.

ionplus electrodes and Optimum Results solutions are protected by

US Patent 5,830,338.

ROSS Ultra electrodes have patents pending.

ORION ORP Standard is protected by US Patent 6,350,367.

ORION Series A conductivity meters are protected by US Patent 5,872,454.

© Copyright 2003, Thermo Electron Corporation. All rights reserved. Question

everything, and Analyze.Detect.Measure.Control are trademarks of Thermo

Electron Corporation.

The specifications, descriptions, drawings, ordering information and part

numbers within this document are subject to change without notice.

This publication supersedes all previous publications on this subject.

Page 3

TABLE OF CONTENTS

General Information 1

Introduction 1

Required Equipment 2

Required Solutions 3

Before Using The Electrode 6

Electrode Preparation 6

Checking Electrode Operation (Slope) 9

Helpful Information 10

Units of Measurement 10

Sample Requirements 10

GLP Measuring Hints 11

Choosing the Right Measuring Technique 13

Silver Measurement Procedures 15

Direct Measurement 16

Low-Level Measurements 19

Known Addition 23

Low-Level Chloride Titration 30

Low-Level Cyanide Indicator Method 32

Sulfide Measurement Procedures 36

Direct Measurement 36

Analate Subtraction Measurements 40

Sulfide Titration 44

Electrode Storage 46

Electrode Maintenance 47

Troubleshooting 49

Troubleshooting Checklist 49

Troubleshooting Guide 53

Electrode Characteristics 56

Electrode Response 56

Reproducibility 56

Temperature Effects 57

Interferences 58

pH Effects 59

Complexation 59

Theory of Operation 60

Warranty 62

Ordering Information 66

Specifications 67

Page 4

Page 5

GENERAL INFORMATION

Introduction

The Orion 94-16 Silver/Sulfide Half-Cell Electrode and Orion 96-16

Sure-Flow

™

Combination Silver/Sulfide Electrode measure silver and

sulfide ions in aqueous solutions quickly, simply, accurately, and

economically. Because of the extreme insolubility of silver sulfide,

the two ions are virtually never present in solution together. This

electrode also performs low-level cyanide and halide titrations.

The Orion 96-16 offers additional benefits from the Sure-Flow

Combination reference design. With this electrode, a separate

reference electrode is unnecessary, making it convenient to use with

small sample volumes. The free-flowing liquid junction assures

stable, drift-free potentials. When measuring dirty samples which

would clog conventional electrode junctions, the Sure-Flow junction

can be opened and flushed clean simply by pressing the cap. The

Orion 900200 Double Junction Reference electrode, when used with

the 9416 Silver/Sulfide Half-Cell Electrode, also offers the benefits

of the Sure-Flow junction design.

General analytical procedures, required solutions, electrode

characteristics, and electrode theory are discussed in this manual.

Operator instructions for Orion meters are given in the meter

instruction manual.

Thermo Electron Corporation’s The Technical Edge for Customer

Service and Support for Orion Products can be consulted for

assistance and troubleshooting advice. Please refer to

Troubleshooting for information on contacting Thermo Electron.

1

Page 6

Required Equipment

Meter – The easiest to use are direct concentration readout specific

ion meters (ISE meters), such as Orion EA 940, 920A, 720A, 710A,

or 290A. If unavailable, a pH/mV meter with readability to 0.1 mV,

such as Orion 420A, 520A, or 525A is recommended.

Reference Electrode Orion

For use with Orion 94-16:

Orion 90-02 Double Junction 900200

Reference Electrode, includes:

Inner Chamber Filling Solution 900002

Outer Chamber Filling Solution 900003

For use with Orion 96-16:

The 96-16 Combination n/a

Silver/Sulfide Electrode does

not require a separate reference electrode.

Magnetic Stirrer, Stir Bars – Recommended for

laboratory measurements.

Graph Paper – 4 cycle semi-logarithmic paper for preparing

calibration curves (for use with pH/mV laboratory meters).

Plastic Labware – For low-level silver measurements.

Polishing Strips – Orion 948201. To clean the silver/sulfide

sensing element.

2

Page 7

Required Solutions

Distilled or Deionized Water – To prepare all solutions and

standards. Water to prepare sulfide standards should also

be deaerated.

Reference Filling Solution Orion

Optimum Results

™

B 900062

(for 96-16 Combination

Silver/Sulfide Electrode)

Inner Chamber Filling Solution 900002

(for use with 90-02

Reference Electrode)

Outer Chamber Filling Solution 900003

(for use with 90-02

Reference Electrode)

Silver Solutions Orion

Standard solution Customer

0.1 M or 1000 ppm as silver Prepared

(see below)

Low-level Chloride Titrant Customer

2.82 x 10

-3

M AgNO

3

Prepared

(see below)

Ionic Strength Adjustor (ISA): 940011

To adjust ionic strength of samples

and standards, 5M NaNO

3

Sulfide Solutions Orion

Sulfide Anti-Oxidant 941609

Buffer (SAOB ll) Reagent Pack

Lead Perchlorate Solution (0.1M) 948206

For titration of sulfide standard solutions

Sulfide Standard: Customer

100 ppm as S

2-

Prepared

(see below)

3

Page 8

Customer Prepared Solutions

Silver Stock Standard Solutions

Required Chemicals:

Silver Nitrate, Reagent Grade, pulverized and dried in oven at

150 °C for one hour.

Distilled Water

Preparation:

0.1 M AgNO

3

solution:

dry pulverized, reagent grade silver nitrate at 150 °C for one

hour. In a 1-liter flask, place 16.99 g of the dried silver nitrate.

Dissolve the solid, and dilute to volume with distilled water.

Store in an opaque bottle in a dark place.

1000 ppm silver solution:

weigh out 1.57 g of reagent grade silver nitrate, dried as above,

in a 1-liter volumetric flask. Dissolve and dilute to volume with

distilled water. Store in an opaque bottle in a dark place.

Low-level Chloride Titrant:

2.82 x 10

-3

M AgNO3(equivalent to 100 ppm chloride).

For titrations of low-level chloride. Dry reagent grade silver

nitrate as directed above. Place 0.479 g dried silver nitrate in

a 1 liter volumetric flask. Dissolve and dilute to volume with

distilled water. Store in an opaque bottle.

4

Page 9

Customer Prepared Solutions

Sulfide Standard Solutions

Required Chemicals:

Sodium Sulfide, reagent grade SAOB II, Orion 941609 Lead

Perchlorate, Orion 948206 Distilled, deaerated water.

NOTE: Water must be deaerated to prevent oxidation

of sulfide.

Preparation:

Prepare a stock solution of saturated sodium sulfide by

dissolving approximately 100 g of reagent-grade Na

2

S•9H2O in

100 mL distilled, deaerated water. Shake well and let stand

overnight. Store in a tightly stoppered bottle in a hood.

Prepare a sulfide standard weekly by pipetting 10 mL of the stock

solution into a l liter volumetric flask. Add 500 mL SAOB II and

dilute to volume with distilled, deaerated water. Determine the exact

concentration, C, by titrating 10 mL of the standard with 0.1 M

lead perchlorate, using the electrode(s) as the end point indicator,

and calculate:

C= 3206 (V

t/Vs

)

where:

C= concentration as ppm sulfide

Vt = volume of titrant at end point

Vs = volume of standard (10 mL)

Prepare other standards daily by serial dilution of the weekly

standard. To do a ten-fold dilution, pipet 10 mL of the standard into

a 100 mL volumetric flask, add 45 mL SAOB II and dilute to volume

with distilled, deaerated water.

5

Page 10

6

BEFORE USING THE ELECTRODE

Electrode Preparation

Orion 94-16 – Silver/Sulfide Half-Cell Electrode

Remove the rubber cap covering the electrode tip.

Orion 9002 – Double Junction Reference Electrode

Fill this reference electrode according to the instructions in the

reference electrode instruction manual. Fill the inner chamber with

Orion 900002 Filling Solution. Fill the outer chamber with Orion

900003 Filling Solution.

Add filling solution each day before using the electrode. The filling

solution level should be at least one inch above the level of sample

in the beaker to ensure a proper flow rate. If the filling solution is

less than one inch above the sample solution level, electrode

potentials may be erratic.

Orion 96-16 – Sure-Flow Combination

Silver/Sulfide Electrode

Orion offers a line of filling solutions designed specifically for your

application. Chose the Optimum Results

™

filling solution specially

formulated for your measuring requirements. See Temperature

Effects for a discussion on the benefits of Optimum Results

solutions. See Table 1.

Optimum Results B (Orion 900062) supplied with this electrode is

designed to minimize junction potentials and silver/sulfide ion

contamination of the sample and can be used for most silver/sulfide

measurements.

Optimum Results C (Orion 900067) is recommended for precise

silver measurements, providing optimum temperature and time

response.

Optimum Results A (Orion 900061) is recommended when precise

sulfide measurements, providing optimum temperature and time

response.

Page 11

7

Table 1

Choosing the correct filling solution for 96-16

Sure-Flow Combination Silver/Sulfide Electrode

Description Orion Purpose

Optimum

Results A 900061 Sulfide measurements

Variable sample

temperatures

Optimum

Results B 900062 Titration

Measurement of both

Ag

+

and S

2-

Constant sample

temperature

Low-level silver

measurement

Cyanide indicator method

Optimum

Results C 900067 Silver measurements

Variable sample

temperatures

Page 12

8

The 96-16 Silver/Sulfide Sure-Flow Combination Electrode is

shipped without filling solution in the reference chamber. To fill

from the flip-spout bottle:

1. Lift the spout to a vertical position.

2. Insert the spout into the fill hole in the outer sleeve and add a

small amount of filling solution to the chamber. Tip the electrode

to moisten the O-ring at the top and return electrode to a

vertical position.

3. Holding the electrode by the barrel with one hand, use the thumb

to push down on the electrode cap, allowing a few drops of

filling solution to drain and wet the inner cone.

4. Release sleeve. If sleeve does not return to its original position

immediately, check to see if the O-ring is moist enough and

repeat steps 2 - 4 until the sleeve has returned to original

position. Add filling solution up to the fill hole.

Page 13

9

Checking Electrode Operation (Slope)

This procedure measures electrode slope. Slope is defined as the

change in millivolts observed with every ten-fold change in

concentration. Obtaining the slope value provides the best means

for checking electrode performance.

These are general instructions that can be used with most meters to

check electrode operation. See individual meter instruction manuals

for more specific information.

1. If electrode(s) have been stored dry, prepare the electrode(s) as

described in Electrode Preparation.

2. Connect the electrode(s) to the meter as described in the meter

instruction manual. Non-Orion meters may require special

adapters. Consult your meter instruction manual.

3. For Silver:

Place 100 mL distilled water into a 150 mL beaker. Add

2 mL ISA, (Orion 940011). Stir thoroughly. Use 0.1 M or 1000

ppm silver standard in the following steps.

For Sulfide:

Place 50 mL distilled water into a 150 mL beaker. Add 50 mL

SAOB II (Orion 941609). Stir thoroughly.

Use 100 ppm sulfide standard in the following steps.

4. Set the meter to the mV mode.

5. Rinse electrode(s) with distilled water, blot dry, and place in the

solution prepared in Step 3 above.

6. Select the appropriate standard. Pipet 1 mL of the standard into

the beaker. Stir thoroughly. When a stable reading is displayed,

record the electrode potential in millivolts.

7. Pipet 10 mL of the same standard into the same beaker. Stir

thoroughly. When a stable reading is displayed record the

electrode potential in millivolts.

8. The difference between the first and second potential reading

is defined as the slope of the electrode. The difference

should be in the range of (+) 54-60 mV/decade (silver) or

(-) 25-30 mV/decade (sulfide) when the solution temperature is

between 20 and 25 °C. If the slope is not within the appropriate

range refer to the Troubleshooting section.

Page 14

HELPFUL INFORMATION

Units of Measurement

Silver or sulfide ions can be measured in units of moles per liter,

parts per million, or any other convenient unit (see Table 2).

Table 2

Concentration Unit Conversion Factors

For silver: troy oz.

Moles/Liter g/L ppm Ag

+

per gallon

1 107.9 107900 13.128

1 x 10

-3

1.08 x 10

-1

107.9 1.31 x 10

-2

9.27 x 10

-3

1 1000 1.22 x 10

-1

9.27 x 10

-6

1.0 x 10

-3

1 1.22 x 10

-4

7.62 x 10

-2

8.22 8216.9 1

For sulfide:

Moles/Liter g/L ppm S

2-

Normality

1 32.06 32060 2.00

1 x 10

-3

3.21x10

-2

32.06 2.0 x 10

-3

3.12 x 10

-2

1 1000 6.24 x 10

-2

3.12 x 10

-5

1.0 x 10

-3

1 6.24 x 10

-5

0.5 16.03 16030 1

Sample Requirements

The epoxy electrode body is resistant to attack by inorganic

solutions. The electrode may be used intermittently in solutions

containing methanol or ethanol. Consult The Technical Edge for use

of the electrode in other organic solvents (see Assistance).

Samples and standards should be at the same temperature.

Temperature must be less than 100 °C.

Silver samples must be below pH 8 to avoid reaction with hydroxide

ion. Acidify silver samples with 1 M HNO

3

if necessary.

Sulfide samples must be buffered to pH above 12 with SAOB II so

that HS

-

and H2S are converted to S2-.

Dissolved mercury compounds must be absent from silver samples.

Because of the insolubility of HgS and Hg

2

S, no dissolved mercury

ions will be present in sulfide samples.

10

Page 15

11

GLP Measuring Hints

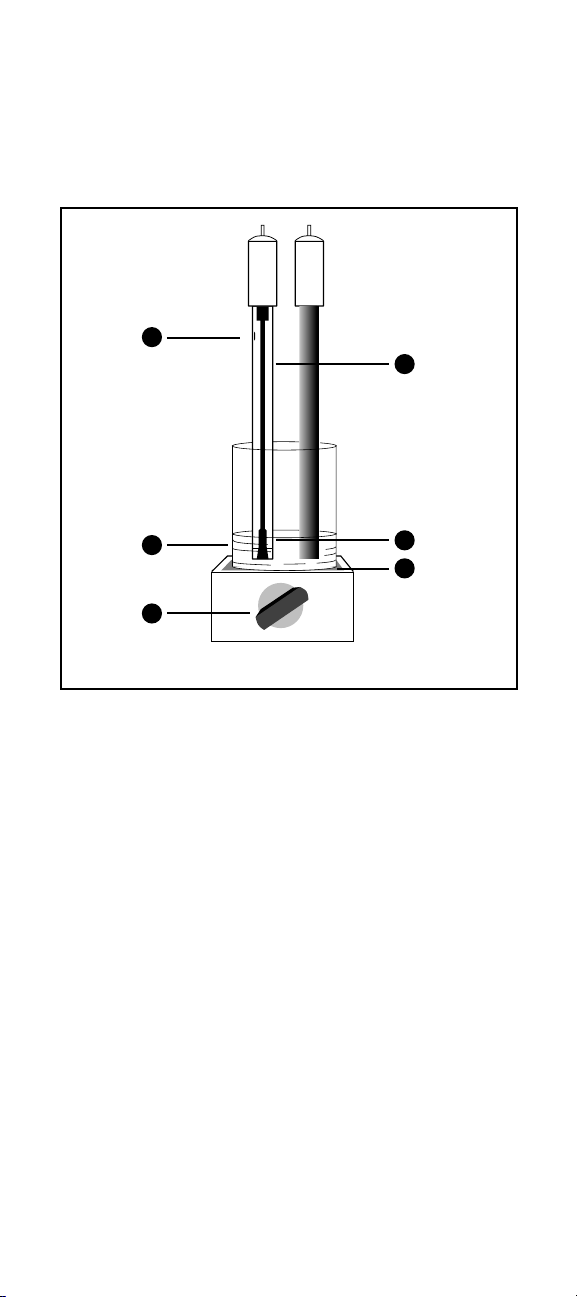

See Figure 1.

– Stir all standards and samples at a uniform rate during

measurement. Magnetic stirrers may generate sufficient heat to

change solution temperature. Place a piece of insulating material

such as cork, cardboard, or Styrofoam between the stirrer

and sample beaker.

– Prepare fresh working standards for calibration daily.

– Always rinse electrode(s) with distilled water between

measurements. Shake after rinsing to prevent solution

carryover. Blot dry.

– Allow all standards and samples to come to the same

temperature for precise measurement.

_ The 90-02 reference electrode (when used with the 94-16

Silver/Sulfide Half-Cell Electrode) should be submerged to the

same depth as the silver/sulfide electrode.

_ Concentrated samples (> 1 M silver or sulfide) should be diluted

before measurement.

– After immersion in solution, check electrode(s) for any air

bubbles on the sensing element and remove by gently tapping

the electrode(s).

– For high ionic strength samples, prepare standards with

composition similar to that of the sample.

Page 16

12

1. Filling hole should be uncovered (90-02 or 96-16)

2. Fresh standard

3. Stir all samples and standards

4. Filling solution level must be higher than sample level

5. Reference junction must be immersed

6. Place insulation between stirrer and beaker

1

2

3

4

5

6

Figure 1 GLP Measuring Hints

Page 17

13

CHOOSING THE RIGHT

MEASURING TECHNIQUE

A variety of analytical techniques are available to the analyst.

Direct Measurement is a simple procedure for measuring a large

number of samples. Only one meter reading is required for each

sample. Calibration is performed in a series of standards. The

concentration of the samples is determined by comparison to the

standards. ISA or SAOB II is added to all solutions to ensure that

samples and standards have similar ionic strength, proper pH, and

to reduce the effect of interfering ions.

Low-Level Measurement is a similar method to Direct

Measurement. This method is recommended when the expected

sample concentration is less than 0.5 ppm or 4.6 x 10

-6

M Ag+or

0.32 ppm or 1 x 10-5M S2-. A minimum three point calibration is

recommended to compensate for the electrode’s non-linear

response at these concentrations. A special procedure describes

the best means of preparing low-level calibration standards.

Known Addition is a useful method for measuring samples, since

calibration is not required. This method is recommended when

measuring only a few samples, or when samples have a high

(> 0.1 M) ionic strength, or a complicated background matrix.

Refer to Theory of Operation for explanation of these effects. The

electrodes are immersed in the sample solution and an aliquot of a

standard solution containing the measured species is added to the

sample. From the change in potential before and after the addition,

the original sample concentration is determined. As in direct

calibration, any convenient concentration unit can be used.

Analate Subtraction is also a useful method for measuring

samples, since calibration is not required. The electrodes are

immersed in a reagent solution that contains a species that the

electrode senses, and that reacts with the samples. It is useful

when sample size is small, for samples for which a stable standard

is difficult to prepare, and for viscous or very concentrated samples.

The method is not suited for very dilute samples. It is also

necessary to know the stoichiometric ratio between standard

and sample.

Page 18

14

Titrations are quantitative analytical techniques for measuring the

concentration of a species by incremental addition of a reagent

(titrant) that reacts with the sample species. Sensing electrodes

can be used for determination of the titration endpoint. Ionselective electrodes are useful as endpoint detectors, because they

are unaffected by sample color or turbidity. Titrations are

approximately 10 times more precise than direct calibration, but are

more time-consuming. For sulfide measurements, titrations

produce an extremely sharp endpoint, even at low levels of

sulfide. Titration is the recommended measurement method for

sulfide samples.

Indicator Titration Methods are useful for measuring ionic species

where an ion-specific electrode does not exist. With these methods

the electrodes sense a reagent species that has been added to the

sample before titration. A procedure for measuring low levels of

cyanide ion down to 0.03 ppm, using the silver electrode, is

described in the Low-Level Cyanide Indicator Method.

Page 19

15

SILVER MEASUREMENT

PROCEDURES

Direct Measurement

The following direct measurement procedures are recommended for

“high-level” measurements. All samples must be in the electrode’s

linear range, greater than 0.5 ppm or 4.6 x 10

-6

M Ag+. A two point

calibration is sufficient, though more points can be used if desired.

With ISE meters, such as the Orion 920A, 720A, 710A, or 290A,

sample concentrations can be read directly from the meter. Refer

to the meter instruction manual for calibration details. When using

a mV meter, a calibration curve can be prepared on semilogarithmic graph paper, or a linear regression (against logarithmic

concentration values) can be performed at the user’s discretion

using a spreadsheet or graphing program.

Measuring Hints

– Standard concentrations should bracket the expected

sample concentrations.

– Always add 2 mL ISA per 100 mL of silver standard or sample.

– For high ionic strength samples, having an ionic strength of 0.1

M or greater, prepare standards with a composition similar to

that of the samples, or measure the samples using the known

addition method.

– During calibration, measure the least concentrated standard first,

and work up to the most concentrated.

– The best method for preparation of standards is by serial

dilution. This procedure involves preparing an initial standard

that is diluted, using volumetric glassware, to prepare a second

standard solution. The second is similarly diluted to prepare a

third standard, and so on, until the desired range of standards

has been prepared.

– Store all silver samples and standards away from light.

– Verify this procedure by measuring a standard of known

concentration as an unknown or by spiking a sample with

silver standard.

– Review section entitled GLP Measuring Hints.

Page 20

16

Direct Measurement Procedure using ISE Meter

See individual meter instruction manuals for more specific

calibration information.

1. Prepare electrode(s) as described in Electrode Preparation.

2. Connect electrode(s) to the meter, and adjust the meter to

measure concentration.

3. Prepare two standards that bracket the expected sample range

and differ in concentration by a factor of ten. Standards can be

prepared in any concentration unit to suit the particular analysis

requirement. All standards should be at the same temperature

as the samples. For details on temperature effects on electrode

performance, refer to Temperature Effects.

4. Measure 100 mL of each standard and sample into separate

150 mL beakers. Add 2 mL ISA to each beaker.

NOTE: Other solution volumes may be used, as long as the

ratio of solution to ISA remains 50:1. Stir thoroughly.

5. Rinse electrode(s) with distilled water, blot dry and place into the

beaker containing the most dilute standard. Wait for a stable

reading, then calibrate the meter to display the value of the

standard as described in the meter instruction manual.

6. Rinse electrode(s) with distilled water, blot dry, and place into

the beaker with the next standard. Wait for a stable reading, then

adjust the meter to display the value of this standard, as

described in the meter instruction manual.

7. Repeat step 6 for all standards, working from the least

concentrated to most concentrated standard.

8. Rinse electrode(s) with distilled water, blot dry, and place into

sample. The concentration will be displayed on the meter.

Page 21

17

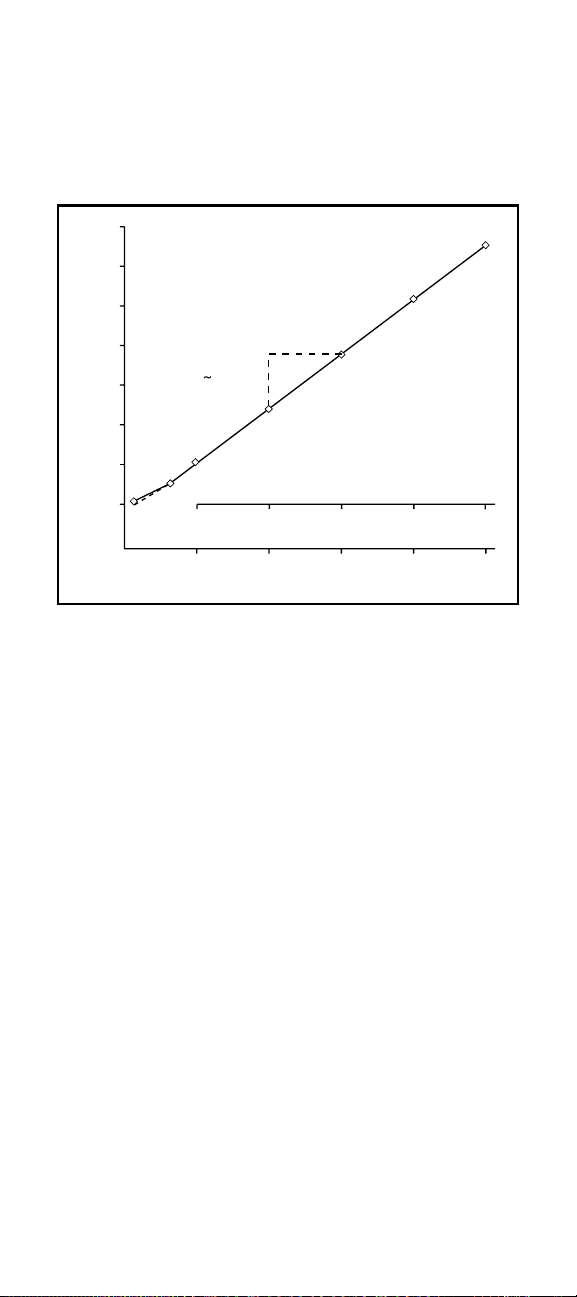

Figure 2

Typical Silver Calibration Curve

In the direct measurement procedure, a calibration curve is

constructed on semi-logarithmic paper. Electrode potentials of

standard solutions are measured and plotted on the linear axis

against their concentrations on the log axis. In the

linear regions of the curves, only two standards are needed

to determine a calibration curve. In nonlinear regions, more points

must be taken. The direct measurement procedures

in this manual are given for concentrations in the region

of linear response. Low-level measurement procedures are given

for measurements in the non-linear region. This curve is only used

as an example. Actual mV values may differ.

550.0

450.0

400.0

350.0

300.0

250.0

200.0

10

-5

11010210

3

10

4

Molarity

ppm silver

10

-4

10

-3

10

-2

10

-1

500.0

Electrode potential

(mV)

57 mV

10-fold change

Page 22

18

Direct Measurement Procedure using a meter with

mV readout

1. Prepare electrode(s) as described in Electrode Preparation.

2. Connect electrode(s) to the meter, and adjust the meter to

measure mV.

3. Prepare two standards that bracket the expected sample range

and differ in concentration by a factor of ten. Standards can be

prepared in any concentration unit to suit the particular analysis

requirement. All standards should be at the same temperature

as the samples. For details on temperature effects on electrode

performance, refer to Temperature Effects.

4. Measure 100 mL of each standard and sample into separate

150 mL beakers. Add 2 mL ISA to each beaker.

NOTE: Other solution volumes may be used, as long as the

ratio of solution to ISA remains 50:1. Stir thoroughly.

5. Rinse electrode(s) with distilled water, blot dry and place into the

beaker containing the most dilute standard. When a stable

reading is displayed,record the mV value and corresponding

standard concentration.

6. Rinse electrode(s) with distilled water, blot dry, and place

into the beaker with the next standard. When a stable reading

is displayed, record the mV value and corresponding

standard concentration.

7. Repeat step 6 for all standards, working from the

least concentrated to most concentrated standard.

8. Using semi-logarithmic graph paper, prepare a calibration curve

by plotting the millivolt values on the linear axis and the

standard concentration values on the logarithmic axis.

See Figure 2.

9. Rinse electrode(s) with distilled water, blot dry, and place into

sample. When a stable reading is displayed, record the

mV value.

10.Using the calibration curve prepared in step 8, determine the

unknown sample concentration.

Page 23

19

Low-Level Measurements

These procedures are for solutions with a silver concentration of

less than 0.5 ppm or 4.6 x 10-6M Ag+, those within the non-linear

range of the silver electrode. See Figure 2. In low-level

measurements, at least three standards are required for calibration

to compensate for the electrode’s non-linearity.

Measuring Hints

– Use plastic labware for low-level silver measurements.

– For solutions low in silver but high in total ionic strength

(greater than 10

-1

M), perform the same procedure with one

change: prepare a calibration solution with a composition similar

to the sample.

– The choice of standard concentrations is important for obtaining

the best electrode performance and most rapid analysis time.

Here are some guidelines:

• Ideally, standard concentrations should bracket the

expected sample concentrations.

• When measuring sub-ppm levels with Orion 920A, 720A,

710A, or 290A, take advantage of the autoblank feature.

It does not require a zero standard, but can perform

blank correction as long as the lowest standard

concentration is in the non-linear range of the electrode.

Electrodes are very slow in the absence of a measurable

concentration and a multipoint calibration generally will

be less accurate when “zero” is included as a standard.

Standard concentrations should be chosen such that the

lowest standard value is larger than the blank value

obtained, and the second lowest standard should be at

least twice that of the lowest. See your A-Series meter

instruction manual for additional information on blank

correction.

Page 24

20

• If using an ISE meter, such as the Orion EA 940, that

allows a blank solution value to be entered, it is

recommended to do so. A blank solution is prepared

with the same dilution water and ISA used when

preparing calibration standards. This solution corrects

for the curves non-linearity as well as for any background

ion contamination that might be present in the standard

solutions. When a blank value is entered, it represents

the zero point of the curve, and each standard is

measured against that blank.

• When not using an ISE meter, a calibration curve can be

drawn on semi-logarithmic graph paper, or the data can

be processed at the discretion of the user by means of a

spreadsheet or graphing program with a non-linear curve

fitting feature.

• When using an ISE meter, such as the Orion 920A, 720A,

710A, or 290A, three calibration points are sufficient. If a

calibration curve is prepared manually, additional points

may be helpful to facilitate drawing the curve.

– Remember to stir all standards and samples at a uniform rate.

– Typical response time for this electrode is approximately 1

minute. Low-level measurements may take longer to stabilize.

Wait for 3 minutes or the meter’s “ready” signal, whichever

takes longer, before calibrating the meter or recording the

sample value.

– Review section entitled GLP Measuring Hints.

Page 25

21

Low-Level Measurement Procedure using ISE Meter

Follow the above procedure entitled Direct Measurement

Procedure using ISE Meter except substitute low-level ISA (see

page 18). Use at least three calibration standards. Read the

Measuring Hints section on pg. 21 in order to select appropriate

standard concentrations. Refer to the meter instruction manual for

detailed calibration procedures. If not using an Orion 920A, 720A,

710A, or 290A with the autoblank feature, preparation of a blank

solution is recommended to ensure

accurate results.

Low-Level Measurement Procedure using a meter with mV

readout (see Table 3)

Set Up

1. Prepare electrode(s) as described in Electrode Preparation.

2. Connect electrode(s) to the meter. Set the meter to read mV.

3. Select a standard solution. Use either a 10 ppm silver standard

or a 10

-4

M silver solution.

4. Prepare a low-level ISA solution by diluting 20 mL of the

silver ionic strength adjustor, Orion 940011, to 100 mL with

distilled water.

NOTE: use this low-level ISA for low-level

measurements only.

Measurement

1. Measure 100 mL distilled water into 150 mL beaker. Add 1 mL

low-level ISA.

2. Rinse electrode(s) with distilled water, blot dry, and place into

beaker. Stir thoroughly.

3. Add increments of the 10 ppm or 10

-4

M standard to the beaker

using steps outlined in Table 3. Record stable millivolt reading

after each increment. On semi-logarithmic paper, plot the

concentration (log axis) against the millivolt potential (linear

axis). See Figure 2. Prepare a new calibration curve with

fresh standards each day.

Page 26

22

4. Measure 100 mL of sample into a beaker. Add 1 mL low-level

ISA. Rinse the electrode(s) with distilled water, blot dry, and

place into the sample.

5. Stir thoroughly. When a stable reading is displayed, record the

mV value.

6. Determine the sample concentration corresponding to the

measured potential from the low-level calibration curve.

Table 3

Preparing a Calibration Curve For Low-Level

Measurements making 10 ppm silver additions

Graduated

Pipet Added Concentration

Step Size Volume ppm

11 mL 0.1 mL 0.01

21 mL 0.3 mL 0.04

31 mL 0.6 mL 0.10

42 mL 2.0 mL 0.30

Preparing a Calibration Curve For Low-Level

Measurements making 10

-4

M silver additions

Graduated

Pipet Added Concentration

Step Size Volume Molarity

11 mL 0.1 mL 1.0 x 10

-7

21 mL 0.3 mL 4.0 x 10

-7

31 mL 0.6 mL 1.0 x 10

-6

42 mL 2.0 mL 3.0 x 10

-6

Additions of 10 ppm or 10-4M standard to 100 mL distilled water,

plus 1 mL low-level ISA.

Page 27

23

Known Addition

Known addition is a convenient technique for measuring samples in

the linear range, greater than 0.5 ppm Ag+, because no calibration

curve is needed. The sample potential is measured before and after

addition of a standard solution. Many meters, such as the Orion

920A, have the known addition algorithms preprogrammed. This

programming allows multiple standard additions to be made to the

sample, thereby allowing the meter to calculate the electrode slope

as well. Having the ability to read the sample concentration directly

from the meter is a great convenience and ensures accuracy.

Measuring Hints

– Sample concentration should be known within a factor of three.

– Concentration should approximately double as a result of the

first standard addition.

– With double or multiple known addition, the final addition should

be 10 to 100 times the sample concentration.

– All samples and standards should be at the same temperature.

– Add 2 mL ISA to every 100 mL of sample before analysis.

– Standard addition volume should be no more than 10% of the

sample volume, or standard should be pre-treated with ISA in a

50:1 ratio. See Table 4.

– Review section entitled GLP Measuring Hints.

Set-up

1. Prepare electrode(s) as described in Electrode Preparation.

2. Connect electrode(s) to the meter.

3. Prepare a standard solution that, upon addition to the sample,

will cause the concentration of silver to double. Refer to Table 4

as a guideline.

4. Determine the slope of the electrode by performing the

procedure under Checking Electrode Operation (Slope).

Page 28

24

Known Addition Measurement Procedure using an ISE meter

with KA program

See individual meter instruction manual for more

specific information.

1. Set the meter to measure in the known addition mode.

2. Measure 100 mL of sample into a beaker. Add 2 mL ISA. Stir

thoroughly. Rinse electrode(s) with distilled water, blot dry, and

place in sample solution.

3. When a stable reading is displayed, program the meter as

described in the meter instruction manual.

4. Pipet the appropriate amount of standard solution into the

beaker. Stir thoroughly.

5. When a stable reading is displayed, record the

sample concentration.

Table 4

Standard Addition volumes

Volume

of Addition Concentration of Standard

1 mL 100 x sample concentration

5 mL 20 x sample concentration

10 mL* 10 x sample concentration

* Most convenient volume to use.

Page 29

25

Known Addition Measurement Procedure using a meter with

mV readout

1. Set the meter to millivolt mode.

2. Measure 100 mL of the sample into a 150 mL beaker.

Add 2 mL ISA. Stir thoroughly.

3. Rinse electrode(s) with distilled water, blot dry, and place

into beaker. When a stable reading is displayed, record the

mV value as E

1

.

4. Pipet the appropriate amount of standard solution into the

beaker. See Table 4. Stir thoroughly.

5. When a stable reading is displayed, record the mV value as E

2

.

Subtract the first reading from the second to find DE.

6. From Table 6, find the value Q, that corresponds to the change

in potential, DE. To determine the original sample concentration,

multiply Q by the concentration of the added standard:

Csam = Q*Cstd

where:

Cstd = standard concentration

Csam = sample concentration

Q = reading from known addition table

The table of Q values is calculated for a 10% volume change for

electrodes with slopes of 57, 58, 59, 60 mV/ decade for silver. The

equation for the calculation of Q for different slopes and volume

changes is given below:

Q= p * r

(1+p)(10

∆E/S

)-1

where:

Q = reading from known addition table

∆E = E

2

- E

1

S = slope of the electrode

p = (volume of standard) / (volume of sample & ISA)

r = (volume of sample & ISA) / (volume of sample)

Page 30

26

If it is more convenient, a simple spreadsheet can be set up to

calculate known addition results, using any ratio of sample to

addition. A typical worksheet is shown in Table 5. The numbers

shown are examples, but the formulas and their locations should be

copied exactly.

Table 5

Calculating known addition for silver samples using Lotus, Excel,

or Quattro Spreadsheet

A B C

1 Enter Value

2 Vol. of Sample & ISA, mL: 102

3 Vol. of Addition, mL: 10

4 Concentrn. of Addition: 10

5 Vol. of Sample 100

6 Initial mV Reading 45.3

7 Final mV Reading 63.7

8 Electrode Slope 59.2

9

10 Derived Values

11 Delta E +C7 - C6

12 Solution Vol. Ratio +C3/C2

13 Antilog Term +10^ (C11/C8)

14 Sample Vol. Ratio +C2/C5

15 Q Term +C12*C14/

{

[(1 +C12)*C13]-1

}

16 Calculated Initial Conc. in

same units as addition: +C15*C4

NOTE: for Excel, use = instead of + at start of formula

Page 31

27

Table 6

Known Addition Table for an added volume one-tenth the total

volume. Slopes, in the column headings, are in units of

mV/decade.

Q, Concentration Ratio

(slope)

-∆E 57.2 58.2 59.2 60.1

5.0 0.2917 0.2957 0.2996 0.3031

5.2 0.2827 0.2867 0.2906 0.2940

5.4 0.2742 0.2781 0.2820 0.2854

5.6 0.2662 0.2700 0.2738 0.2772

5.8 0.2585 0.2623 0.2660 0.2693

6.0 0.2512 0.2550 0.2586 0.2619

6.2 0.2443 0.2480 0.2516 0.2548

6.4 0.2377 0.2413 0.2449 0.2480

6.6 0.2314 0.2349 0.2384 0.2416

6.8 0.2253 0.2288 0.2323 0.2354

7.0 0.2196 0.2230 0.2264 0.2295

7.2 0.2140 0.2174 0.2208 0.2238

7.4 0.2087 0.2121 0.2154 0.2184

7.6 0.2037 0.2070 0.2102 0.2131

7.8 0.1988 0.2020 0.2052 0.2081

8.0 0.1941 0.1973 0.2005 0.2033

8.2 0.1896 0.1927 0.1959 0.1987

8.4 0.1852 0.1884 0.1914 0.1942

8.6 0.1811 0.1841 0.1872 0.1899

8.8 0.1770 0.1801 0.1831 0.1858

9.0 0.1732 0.1762 0.1791 0.1818

9.2 0.1694 0.1724 0.1753 0.1779

9.4 0.1658 0.1687 0.1716 0.1742

9.6 0.1623 0.1652 0.1680 0.1706

9.8 0.1590 0.1618 0.1646 0.1671

10.0 0.1557 0.1585 0.1613 0.1638

10.2 0.1525 0.1553 0.1580 0.1605

10.4 0.1495 0.1522 0.1549 0.1573

10.6 0.1465 0.1492 0.1519 0.1543

10.8 0.1437 0.1463 0.1490 0.1513

11.0 0.1409 0.1435 0.1461 0.1485

11.2 0.1382 0.1408 0.1434 0.1457

11.4 0.1356 0.1382 0.1407 0.1430

11.6 0.1331 0.1356 0.1381 0.1404

11.8 0.1306 0.1331 0.1356 0.1378

12.0 0.1282 0.1307 0.1331 0.1353

12.2 0.1259 0.1283 0.1308 0.1329

12.4 0.1236 0.1260 0.1284 0.1306

12.6 0.1214 0.1238 0.1262 0.1283

12.8 0.1193 0.1217 0.1240 0.1261

13.0 0.1172 0.1195 0.1219 0.1239

13.2 0.1152 0.1175 0.1198 0.1218

13.4 0.1132 0.1155 0.1178 0.1198

13.6 0.1113 0.1136 0.1158 0.1178

13.8 0.1094 0.1117 0.1139 0.1159

Page 32

28

Table 6 (continued)

Q, Concentration Ratio

(slope)

-∆E 57.2 58.2 59.2 60.1

14.0 0.1076 0.1098 0.1120 0.1140

14.2 0.1058 0.1080 0.1102 0.1121

14.4 0.1041 0.1063 0.1084 0.1103

14.6 0.1024 0.1045 0.1067 0.1086

14.8 0.1008 0.1029 0.1050 0.1069

15.0 0.0992 0.1012 0.1033 0.1052

15.5 0.0953 0.0973 0.0994 0.1012

16.0 0.0917 0.0936 0.0956 0.0974

16.5 0.0882 0.0902 0.0921 0.0938

17.0 0.0850 0.0869 0.0887 0.0904

17.5 0.0819 0.0837 0.0856 0.0872

18.0 0.0790 0.0808 0.0825 0.0841

18.5 0.0762 0.0779 0.0797 0.0813

19.0 0.0736 0.0753 0.0770 0.0785

19.5 0.0711 0.0727 0.0744 0.0759

20.0 0.0687 0.0703 0.0719 0.0734

20.5 0.0664 0.0680 0.0696 0.0710

21.0 0.0642 0.0658 0.0673 0.0687

21.5 0.0621 0.0637 0.0652 0.0666

22.0 0.0602 0.0617 0.0631 0.0645

22.5 0.0583 0.0597 0.0612 0.0625

23.0 0.0564 0.0579 0.0593 0.0606

23.5 0.0547 0.0561 0.0575 0.0588

24.0 0.0530 0.0544 0.0558 0.0570

24.5 0.0514 0.0528 0.0541 0.0553

25.0 0.0499 0.0512 0.0525 0.0537

25.5 0.0484 0.0497 0.0510 0.0522

26.0 0.0470 0.0483 0.0495 0.0507

26.5 0.0456 0.0469 0.0481 0.0492

27.0 0.0443 0.0455 0.0468 0.0479

27.5 0.0431 0.0443 0.0455 0.0465

28.0 0.0419 0.0430 0.0442 0.0452

28.5 0.0407 0.0418 0.0430 0.0440

29.0 0.0395 0.0407 0.0418 0.0428

29.5 0.0385 0.0396 0.0407 0.0417

30.0 0.0374 0.0385 0.0396 0.0406

30.5 0.0364 0.0375 0.0385 0.0395

31.0 0.0354 0.0365 0.0375 0.0384

31.5 0.0345 0.0355 0.0365 0.0374

32.0 0.0335 0.0345 0.0356 0.0365

32.5 0.0327 0.0336 0.0346 0.0355

33.0 0.0318 0.0328 0.0337 0.0346

33.5 0.0310 0.0319 0.0329 0.0337

34.0 0.0302 0.0311 0.0320 0.0329

34.5 0.0294 0.0303 0.0312 0.0321

35.0 0.0286 0.0295 0.0305 0.0313

35.5 0.0279 0.0288 0.0297 0.0305

Page 33

29

Table 6 (continued)

Q, Concentration Ratio

(slope)

-∆E 57.2 58.2 59.2 60.1

36.0 0.0272 0.0281 0.0290 0.0298

36.5 0.0265 0.0274 0.0282 0.0290

37.0 0.0258 0.0267 0.0275 0.0283

37.5 0.0252 0.0260 0.0269 0.0276

38.0 0.0246 0.0254 0.0262 0.0270

38.5 0.0240 0.0248 0.0256 0.0263

39.0 0.0234 0.0242 0.0250 0.0257

39.5 0.0228 0.0236 0.0244 0.0251

40.0 0.0223 0.0230 0.0238 0.0245

40.5 0.0217 0.0225 0.0232 0.0239

41.0 0.0212 0.0219 0.0227 0.0234

41.5 0.0207 0.0214 0.0221 0.0228

42.0 0.0202 0.0209 0.0216 0.0223

42.5 0.0197 0.0204 0.0211 0.0218

43.0 0.0192 0.0199 0.0206 0.0213

43.5 0.0188 0.0195 0.0202 0.0208

44.0 0.0183 0.0190 0.0197 0.0203

44.5 0.0179 0.0186 0.0192 0.0198

45.0 0.0175 0.0181 0.0188 0.0194

45.5 0.0171 0.0177 0.0184 0.0190

46.0 0.0167 0.0173 0.0179 0.0185

46.5 0.0163 0.0169 0.0175 0.0181

47.0 0.0159 0.0165 0.0171 0.0177

47.5 0.0156 0.0162 0.0168 0.0173

48.0 0.0152 0.0158 0.0164 0.0169

48.5 0.0148 0.0154 0.0160 0.0166

49.0 0.0145 0.0151 0.0157 0.0162

49.5 0.0142 0.0147 0.0153 0.0158

50.0 0.0139 0.0144 0.0150 0.0155

50.5 0.0135 0.0141 0.0146 0.0151

51.0 0.0132 0.0138 0.0143 0.0148

51.5 0.0129 0.0135 0.0140 0.0145

52.0 0.0126 0.0132 0.0137 0.0142

52.5 0.0124 0.0129 0.0134 0.0139

53.0 0.0121 0.0126 0.0131 0.0136

53.5 0.0118 0.0123 0.0128 0.0133

54.0 0.0116 0.0120 0.0125 0.0130

54.5 0.0113 0.0118 0.0123 0.0127

55.0 0.0110 0.0115 0.0120 0.0125

55.5 0.0108 0.0113 0.0118 0.0122

56.0 0.0106 0.0110 0.0115 0.0119

56.5 0.0103 0.0108 0.0113 0.0117

57.0 0.0101 0.0106 0.0110 0.0114

57.5 0.0099 0.0103 0.0108 0.0112

58.0 0.0097 0.0101 0.0105 0.0110

58.5 0.0095 0.0099 0.0103 0.0107

59.0 0.0093 0.0097 0.0101 0.0105

59.5 0.0091 0.0095 0.0099 0.0103

60.0 0.0089 0.0093 0.0097 0.0101

Page 34

30

Low-Level Chloride Titration

The electrode is a highly sensitive endpoint detector for titration of

silver samples with a halide standard (or vice versa). The low-level

chloride titration is an example of this type of measurement.

Titrations are more time-consuming than direct electrode

measurement, but results are more accurate and reproducible.

With careful technique, titrations accurate to ± 0.1% of the total

chloride ion concentration of the sample can be performed. The

Orion 960 Autochemistry System may be used to automate these

titrations.

Figure 3

Typical Titration of 25 mL (before dilution) 0.001 M Chloride

Sample with 0.01 M AgNO

3

10-fold change

500

mV

400

300

200

ml 0.01 M AgNO

3

0 1 2 3 4 5 6 7 8 9 10

Page 35

31

Set-up

1. Prepare electrode(s) as described in Electrode Preparation.

2. Connect electrode(s) to the meter.

3. Prepare a titrant solution 10 - 20 times as concentrated as the

sample by dilution of the 0.1 M silver solution.

Measurement

1. Place 50 mL of sample into a 150 mL beaker. Place electrode(s)

in the sample. Stir thoroughly.

2. Using a 10 mL burette, add increments of titrant and plot

electrode potential against mL of titrant added. The endpoint is

the point of greatest slope (inflection point). See Figure 3.

3. Calculate the sample concentration before dilution:

C

sam

= Ct(Vt/V

sam

)

where:

C

sam

= sample concentration

C

t

= titrant concentration

V

sam

= sample volume

V

t

= titrant volume added at endpoint.

Page 36

32

Low-Level Cyanide Indicator Method

The Ag/S electrode can be used for cyanide measurements down to

0.03 ppm CN-. A small amount of KAg(CN)2is added to the

solution as an indicator. The ion Ag(CN)

2

-

dissociates to form some

silver and cyanide ions, and the electrode measures the silver

concentration. Since the degree of dissociation of the ion depends

on the free cyanide concentration, measurement of the silver

concentration is an indirect measure of the cyanide concentration.

Cyanide complexed by copper, nickel, cobalt, or iron cannot be

measured directly with this method. These complexes may be

broken by distillation according to ASTM Method D 2036,

Section 12.2.

Sulfide ion is an interference for the method, but it can be removed

by precipitation with cadmium.

Set-up

1. Prepare electrode(s) as described in Electrode Preparation.

2. Connect electrode(s) to the meter.

3. Prepare the following solutions:

Ethylemediamine – anhydrous (98% purity or better) for the

removal of formaldehyde.

Silver Nitrate Titrant – (1 mL = 1 mg CN

-

) Crush approximately

5 g of reagent grade silver nitrate (AgNO3) crystals and dry at

150 °C for 1 hour. Dissolve 3.265 g in distilled water and dilute

to 1 liter.

NaOH Diluent – Dissolve 25 g reagent grade sodium hydroxide

(NaOH) in distilled water and dilute to 1 liter. For diluting

cyanide standard solutions.

Silver Potassium Cyanide [KAg(CN)

2

] – Reagent grade or

equivalent. Available from suppliers of electroplating chemicals.

Indicator/Buffer – Add 33 g of reagent grade disodium hydrogen

phosphate (Na

2

HPO4 • 7H2O) in about 80 mL water. Stir for

about one half hour to saturate the solution with phosphate.

Add 2.2 g of reagent grade sodium hydroxide (NaOH),

0.1 g of silver potassium cyanide [KAg(CN)2], and 3.4 mL of

ethylemediamine, and dissolve by thorough mixing with distilled

water. Dilute to 100 mL with distilled water. Check the

solution before use for precipitation of any solids; discard if a

precipitate appears.

Page 37

33

Potassium Cyanide – Stock solution (1000 ppm,

1 mL = approximately 1 mg CN

-

) Dissolve approximately 2 g of

reagent grade sodium hydroxide (NaOH) and 2.51 g of reagent

grade potassium cyanide (KCN) in 1 liter of distilled water.

CAUTION: KCN is highly toxic. Avoid contact or inhalation.

Standardization of KCN Stock Solution

1. Standardize the KCN stock solution by titration with silver nitrate

titrant. Pipet 20 mL of the KCN stock solution into a 150 mL

beaker. Immerse the electrode(s) and stir gently.

2. Fill a 25 mL burette with the silver nitrate titrant.

3. Add increments of 0.5 to 1 mL in the beginning of the titration

and about 0.1 to 0.25 mL in the region of the endpoint.

Continue the titration 3 - 4 mL past the endpoint.

4. Record the solution potential after each addition of titrant and

plot mL of titrant added versus mV readings on standard graph

paper. The point of inflection is taken as the endpoint.

5. Prepare a blank solution by dissolving 2 g reagent grade NaOH

per liter. Titrate 20 mL of blank solution according to

instructions above.

6. Calculate the cyanide concentration of the stock

solutions follows:

CN

-

, (ppm) = (A - B) x 1000/ C

where:

A = mL of titrant added at the endpoint

(cyanide solution)

B = mL of titrant added at the endpoint (blank)

C = mL of cyanide stock solution used for

the titration

7. Standardize the stock solution each week because the solution

loses strength gradually.

8. Prepare a 100 ppm cyanide standard daily by dilution of the

stock solution with NaOH diluent. The 100 ppm solution is

prepared by pipetting a volume, V, into a 100 mL volumetric

flask. The volume, V, is calculated from:

V = 10000/D

where D = concentration (ppm) of cyanide stock solution

9. Prepare 10 and 1 ppm standards daily by serial dilution with

the NaOH diluent. For lower levels of cyanide, prepare 0.1 and

0.01 ppm standards as well.

Page 38

34

Measurement of Sample

Set-up

1. Prepare electrode(s) as described in Electrode Preparation.

2. Connect electrode(s) to the meter.

3. Use the two standards prepared in step 9. Standards should be

at the same temperature as the samples. For details on

temperature effects on electrode performance, refer to

Temperature Effects.

Indicator method procedure using ISE Meter

See individual meter instruction manual for more specific

calibration information.

1. Measure 100 mL of each standard and sample into separate

150 mL beakers. Add 2 mL Indicator/ Buffer to each beaker.

Stir thoroughly.

2. Rinse electrode(s) with distilled water, blot dry and place into the

beaker containing the most dilute standard. Wait for a stable

reading, then calibrate the meter to display the value of the

standard as described in the meter instruction manual.

3. Rinse electrode(s) with distilled water, blot dry, and place into

the beaker with the next standard. Wait for a stable reading, then

adjust the meter to display the value of this standard, as

described in the meter instruction manual.

4. Repeat step 3 for all standards, working from the least

concentrated to most concentrated standard. Slope will be

between -116 to -122 mV/decade.

5. Rinse electrode(s) with distilled water, blot dry, and place into

sample. The concentration will be displayed on the meter.

Page 39

35

Indicator method procedure using a meter with mV readout

1. Measure 100 mL of each standard and sample into separate

150 mL beakers. Add 2 mL Indicator/ Buffer to each beaker.

Stir thoroughly.

2. Rinse electrode(s) with distilled water, blot dry and place into the

beaker containing the most dilute standard. When a stable

reading is displayed, record the mV value and corresponding

standard concentration.

3. Rinse electrode(s) with distilled water, blot dry, and place

into the beaker with the next standard. When a stable reading

is displayed, record the mV value and corresponding

standard concentration.

4. Repeat step 3 for all standards, working from the least

concentrated to most concentrated standard.

5. Using semi-logarithmic graph paper, prepare a calibration curve

by plotting the millivolt values on the linear axis and the

standard concentration values on the logarithmic axis.

See Figure 3.

6. Rinse electrode(s) with distilled water, blot dry, and place

into sample. When a stable reading is displayed, record the

mV value.

7. Using the calibration curve prepared in step 5, determine the

unknown sample concentration.

Page 40

36

SULFIDE MEASUREMENT

PROCEDURES

Direct Measurement

The following direct measurement procedures are recommended for

“high-level” measurements. All samples must be in the electrode’s

linear range, greater than 0.32 ppm or 10

-5

M S2-. A two point

calibration is sufficient, though more points can be used if desired.

With ISE meters, such as the Orion 920A, 720A, 710A, or 290A,

sample concentrations can be read directly from the meter. Refer

to the meter instruction manual for calibration details. When using

a mV meter, a calibration curve can be prepared on semilogarithmic graph paper, or a linear regression (against logarithmic

concentration values) can be performed at the user’s discretion

using a spreadsheet or graphing program.

Measuring Hints

– Standard concentrations should bracket the expected

sample concentrations.

– Always dilute samples and standards in a 1:1 ratio with SAOB II.

For example, 25 mL of sample and 25 mL of SAOB II.

– For high ionic strength samples, having an ionic strength of

0.1 M or greater, prepare standards with a composition similar

to that of the samples, or measure the samples using the known

addition method.

– During calibration, measure the least concentrated standard first,

and work up to the most concentrated.

– The best method for preparation of standards is by serial

dilution. This procedure involves preparing an initial standard

that is diluted, using volumetric glassware, to prepare a second

standard solution. The second is similarly diluted to prepare a

third standard, and so on, until the desired range of standards

has been prepared.

– Dilute sulfide samples 1:1 with SAOB II as they are collected,

except when analate subtraction is the measurement technique.

NOTE: If samples have been preserved with

SAOB II DO NOT add more SAOB II before measuring.

– Always use deaerated water when preparing sulfide standards to

prevent the oxidation of sulfide.

– Verify this procedure by measuring a standard of known

concentration as an unknown or by spiking a sample with

sulfide standard.

– Review section entitled GLP Measuring Hints.

Page 41

37

Direct Measurement Procedure using ISE Meter

See individual meter instruction manuals for more specific

calibration information.

1. Prepare electrode(s) as described in Electrode Preparation.

2. Connect electrode(s) to the meter, and adjust the meter to

measure concentration.

3. Prepare two standards that bracket the expected sample range

and differ in concentration by a factor of ten. Standards can be

prepared in any concentration unit to suit the particular analysis

requirement. All standards should be at the same temperature

as the samples. For details on temperature effects on electrode

performance, refer to Temperature Effects.

4. Measure 25 mL of each standard and sample into separate

150 mL beakers. Add 25 mL SAOB II to each beaker.

NOTE: Other solution volumes may be used, as long as the

ratio of solution to SAOB II remains 1:1.

Stir thoroughly.

5. Rinse electrode(s) with distilled water, blot dry and place into

the beaker containing the most dilute standard. Wait for a stable

reading, then calibrate the meter to display the value of the

standard as described in the meter instruction manual.

6. Rinse electrode(s) with distilled water, blot dry, and place into

the beaker with the next standard. Wait for a stable reading, then

adjust the meter to display the value of this standard, as

described in the meter instruction manual.

7. Repeat step 6 for all standards, working from the least

concentrated to most concentrated standard.

8. Rinse electrode(s) with distilled water, blot dry, and place into

sample. The concentration will be displayed on the meter.

Page 42

38

Figure 4

Typical Sulfide Calibration Curve

In the direct measurement procedure, a calibration curve is

constructed on semi-logarithmic paper. Electrode potentials

of standard solutions are measured and plotted on the linear axis

against their concentrations on the log axis. In the linear regions

of the curves, only two standards are needed to determine a

calibration curve. In nonlinear regions, more points must be taken.

This curve is only used as an example. Actual mV values

may differ.

-790.0

-780.0

-770.0

-760.0

-750.0

-740.0

-730.0

10

-5

0.1 1 10 10

2

10

3

Molarity

ppm sulfide

10

-4

10

-3

10

-2

10

-1

-800.0

-840.0

-830.0

-820.0

-810.0

-850.0

Electrode

potential

(mV)

-28 mV

10-fold change

Page 43

39

Direct Measurement Procedure using a meter with

mV readout

1. Prepare electrode(s) as described in Electrode Preparation.

2. Connect electrode(s) to the meter, and adjust the meter to

measure mV.

3. Prepare two standards that bracket the expected sample range

and differ in concentration by a factor of ten. Standards can be

prepared in any concentration unit to suit the particular analysis

requirement. All standards should be at the same temperature

as the samples. For details on temperature effects on electrode

performance, refer to Temperature Effects.

4. Measure 25 mL of each standard and sample into separate

150 mL beakers. Add 25 mL SAOB II to each beaker.

NOTE: Other solution volumes may be used, as long as the

ratio of solution to SAOB II remains 1:1.

Stir thoroughly.

5. Rinse electrode(s) with distilled water, blot dry and place into the

beaker containing the most dilute standard. When a stable

reading is displayed, record the mV value and corresponding

standard concentration.

6. Rinse electrode(s) with distilled water, blot dry, and place

into the beaker with the next standard. When a stable reading

is displayed, record the mV value and corresponding

standard concentration.

7. Repeat step 6 for all standards, working from the least

concentrated to most concentrated standard.

8. Using semi-logarithmic graph paper, prepare a calibration

curve by plotting the millivolt values on the linear axis and the

standard concentration values on the logarithmic axis.

See Figure 4.

9. Rinse electrode(s) with distilled water, blot dry, and place

into sample. When a stable reading is displayed, record the

mV value.

10.Using the calibration curve prepared in step 8, determine the

unknown sample concentration.

Page 44

40

Analate Subtraction Measurements

Analate subtraction is recommended for occasional sulfide

measurements because it uses a silver standard solution rather than

the easily oxidized sulfide standard solution. The sample must not

contain species that react with silver (e.g., halide ions or SAOB II).

All concentration units are moles per liter. Use Table 2 to convert

to ppm after measurement.

NOTE: DO NOT dilute sample with SAOB II for

this procedure.

Set-up

1. Prepare electrode(s) as described in Electrode Preparation.

2. Connect electrode(s) to the meter.

3. Prepare a silver standard solution about one to one half the

expected sample sulfide concentration by diluting 0.1 M silver

nitrate standard. Add 2 mL ISA (Orion 940011) to every 100 mL

of standard.

Analate subtraction procedure using an ISE meter

See individual meter instruction manuals for more

specific information.

1. Measure 100 mL of the silver standard into a beaker. Rinse

electrode(s) with distilled water, blot dry, and place in standard

solution. Stir thoroughly.

2. When a stable reading is displayed, calibrate the meter as

described in the meter instruction manual.

3. Pipet 10 mL of sulfide sample into the silver standard.

Stir thoroughly.

4. When a stable reading is displayed, record the

sample concentration.

Page 45

41

Analate subtraction procedure using a meter with mV readout

1. Adjust the meter to measure mV.

2. Measure 100 mL of the silver standard into a beaker. Rinse

electrode(s) with distilled water, blot dry, and place in standard

solution. Stir thoroughly.

3. When a stable reading is displayed, record the mV value.

4. Pipet 10 mL of sulfide sample into the silver standard.

Stir thoroughly.

5. When a stable reading is displayed, record the mV value.

6. Determine the potential change, ∆E, by subtracting the first

reading from the second.

7. Find the concentration ratio, Q, corresponding to the potential

change, E, in Table 7. Calculate the sample sulfide

concentration in moles per liter:

Csam = 0.5QC

std

where:

C

sam

= sample concentration

Q= concentration ratio from Table 7

C

std

= concentration of silver standard in moles/liter

Page 46

42

Table 7

Analate Subtraction Table Slopes, in the column headings, are in

units of mV/decade

Q, Concentration Ratio

(slope)

-∆E 57.2 58.2 59.2 60.1

5.0 0.503 0.487 0.472 0.458

5.2 0.539 0.523 0.507 0.493

5.4 0.575 0.558 0.542 0.527

5.6 0.610 0.593 0.576 0.561

5.8 0.645 0.628 0.611 0.595

6.0 0.680 0.662 0.645 0.629

6.2 0.715 0.696 0.679 0.662

6.4 0.749 0.730 0.712 0.695

6.6 0.783 0.764 0.745 0.728

6.8 0.817 0.797 0.778 0.761

7.0 0.851 0.830 0.811 0.793

7.2 0.884 0.863 0.843 0.825

7.4 0.917 0.896 0.876 0.857

7.6 0.950 0.928 0.908 0.888

7.8 0.982 0.960 0.939 0.920

8.0 1.014 0.992 0.971 0.951

8.2 1.046 1.024 1.002 0.982

8.4 1.078 1.055 1.033 1.012

8.6 1.109 1.086 1.064 1.043

8.8 1.141 1.117 1.094 1.073

9.0 1.172 1.148 1.124 1.103

9.2 1.202 1.178 1.154 1.133

9.4 1.233 1.208 1.184 1.162

9.6 1.263 1.238 1.214 1.191

9.8 1.293 1.268 1.243 1.221

10.0 1.323 1.297 1.272 1.249

10.2 1.352 1.326 1.301 1.278

10.4 1.381 1.355 1.330 1.306

10.6 1.410 1.384 1.358 1.334

10.8 1.439 1.412 1.386 1.362

11.0 1.468 1.441 1.414 1.390

11.2 1.496 1.469 1.442 1.418

11.4 1.524 1.497 1.470 1.445

11.6 1.552 1.524 1.497 1.472

11.8 1.580 1.552 1.524 1.499

12.0 1.607 1.579 1.551 1.526

12.2 1.634 1.606 1.578 1.552

12.4 1.661 1.633 1.605 1.579

12.6 1.688 1.659 1.631 1.605

12.8 1.715 1.685 1.657 1.631

13.0 1.741 1.712 1.683 1.656

13.2 1.767 1.737 1.709 1.682

13.4 1.793 1.763 1.734 1.707

13.6 1.819 1.789 1.759 1.732

13.8 1.844 1.814 1.784 1.757

14.0 1.870 1.839 1.809 1.782

14.2 1.895 1.864 1.834 1.806

14.4 1.920 1.889 1.859 1.831

14.6 1.944 1.913 1.883 1.855

14.8 1.969 1.938 1.907 1.879

15.0 1.993 1.962 1.931 1.903

15.5 2.053 2.021 1.990 1.961

16.0 2.112 2.080 2.048 2.019

16.5 2.169 2.137 2.105 2.076

17.0 2.226 2.193 2.161 2.131

17.5 2.281 2.248 2.215 2.185

Page 47

43

Q, Concentration Ratio

(slope)

-∆E 57.2 58.2 59.2 60.1

18.0 2.335 2.302 2.269 2.239

18.5 2.388 2.355 2.322 2.291

19.0 2.440 2.406 2.373 2.342

19.5 2.491 2.457 2.424 2.393

20.0 2.541 2.507 2.473 2.442

20.5 2.590 2.556 2.522 2.491

21.0 2.638 2.604 2.570 2.538

21.5 2.685 2.651 2.617 2.585

22.0 2.731 2.697 2.663 2.631

22.5 2.777 2.742 2.708 2.676

23.0 2.821 2.786 2.752 2.720

23.5 2.864 2.829 2.795 2.763

24.0 2.907 2.872 2.837 2.805

24.5 2.949 2.914 2.879 2.847

25.0 2.990 2.954 2.920 2.888

25.5 3.030 2.995 2.960 2.928

26.0 3.069 3.034 2.999 2.967

26.5 3.107 3.072 3.038 3.006

27.0 3.145 3.110 3.076 3.044

27.5 3.182 3.147 3.113 3.081

28.0 3.218 3.183 3.149 3.117

28.5 3.254 3.219 3.185 3.153

29.0 3.289 3.254 3.220 3.188

29.5 3.323 3.288 3.254 3.222

30.0 3.356 3.322 3.288 3.256

31.0 3.421 3.387 3.353 3.321

32.0 3.483 3.449 3.416 3.384

33.0 3.543 3.509 3.476 3.445

34.0 3.601 3.567 3.534 3.503

35.0 3.656 3.623 3.590 3.560

36.0 3.709 3.676 3.644 3.614

37.0 3.760 3.728 3.696 3.666

38.0 3.809 3.777 3.745 3.716

39.0 3.856 3.824 3.793 3.764

40.0 3.901 3.870 3.839 3.811

41.0 3.944 3.914 3.884 3.855

42.0 3.986 3.956 3.926 3.898

43.0 4.026 3.996 3.967 3.940

44.0 4.064 4.035 4.007 3.979

45.0 4.101 4.073 4.045 4.018

46.0 4.137 4.109 4.081 4.055

47.0 4.171 4.143 4.116 4.090

48.0 4.203 4.177 4.150 4.124

49.0 4.235 4.209 4.182 4.157

51.0 4.294 4.269 4.243 4.219

52.0 4.322 4.297 4.272 4.249

53.0 4.349 4.324 4.300 4.277

54.0 4.374 4.351 4.327 4.304

55.0 4.399 4.376 4.352 4.330

56.0 4.423 4.400 4.377 4.355

57.0 4.446 4.423 4.401 4.380

58.0 4.467 4.446 4.424 4.403

59.0 4.488 4.467 4.446 4.425

60.0 4.509 4.488 4.467 4.447

Page 48

44

Sulfide Titration

Sulfide may be titrated with a lead perchlorate standard solution.

For sulfide measurements, titrations produce an extremely sharp

endpoint, even at low levels of sulfide. Titration is the

recommended measurement method for sulfide samples. Titrations

are more time-consuming than direct electrode measurement, but

results are more accurate and reproducible. With careful technique,

titrations accurate to ± 0.1% of the total sulfide ion concentration of

the sample can be performed. The Orion 960 Autochemistry

System may be used to automate these titrations.

Figure 5

Typical Titration of 25 mL (before dilution) 0.03 M Sulfide

Sample with 0.1 M Pb(ClO

4)2

Set-up

1. Prepare electrode(s) as described in Electrode Preparation.

2. Connect electrodes to the meter.

3. Prepare a lead titrant solution 10 - 20 times as concentrated as

the sample by dilution of the Orion 0.1 M lead perchlorate

solution, 948206.

10-fold change

-800

mV

-700

-600

-500

ml 0.1 M Pb(ClO

4)2

0 1 2 3 4 5 6 7 8 9 10

Page 49

45

Measurement

1. Place 50 mL of sample (previously diluted 1:1 with SAOB II)

into a 150 mL beaker. Place electrode(s) in the sample.

Stir thoroughly.

2. Using a 10 mL burette, add increments of titrant and plot

electrode potential against mL of titrant added. The endpoint is

the point of greatest slope (inflection point). See Figure 5.

3. Calculate the sample concentration before dilution:

Csam = C

t(Vt/Vsam

)

where:

C

sam

= sample concentration

C

t

= titrant concentration

V

sam

= sample volume

V

t

= titrant volume added at endpoint.

Page 50

46

ELECTRODE STORAGE

Orion 94-16 Silver/Sulfide Half-Cell Electrode

Orion 94-16 Silver/Sulfide Half-Cell Electrode should be rinsed

thoroughly and stored in distilled water or in the air. When storing

for long periods of time, replace the cap to protect the sensing

element and store dry.

Orion 96-16 Sure-Flow Combination Silver/Sulfide Electrode

The solution in the Orion 96-16 Combination Silver/Sulfide

Electrode should not be allowed to evaporate,

causing crystallization.

For short periods of time (up to one week):

Store the electrode in distilled water.

For storage longer than one week:

Drain the electrode, flush the inside with distilled water and store

dry with the cap on to protect the sensing element.

Orion 90-02 Double Junction Reference Electrode

Orion 90-02 Reference Electrode may be stored in air between

sample measurements (up to two hours).

For short periods of time (up to one week):

90-02 should be stored in filling solution. Distilled water is also an

acceptable storage solution. The solutions inside the electrode

should not be allowed to evaporate causing crystallization.

For storage longer than one week:

Drain both chambers of the reference electrode, flush the inside

with distilled water, and store dry.

Page 51

47

ELECTRODE MAINTENANCE

Silver/Sulfide Electrode Cleaning Procedure

Place a drop of liquid dish detergent on a moist cloth or tissue and

gently rub over the sensing element. Rinse with distilled water.

Silver/Sulfide Electrode Polishing Procedure

To be used when electrode becomes sluggish or drifty and above

cleaning procedure does not improve electrode response.

1. Cut off a 1-inch length of the polishing strip, Orion 948201.

2. Hold electrode with the sensing element facing upwards.

3. Place a few drops of distilled water on the sensing

element surface.

4. With the frosted side down, place the polishing strip on the

sensing element using light finger pressure.

5. Rotate the electrode for about 30 seconds.

6. Rinse and soak in a 1 ppm or 10

-5

M silver standard solution for

about two minutes before use.

Disassembly and Cleaning of 96-16 Sure-Flow Combination

Silver/Sulfide Electrode

Disassembly is not normally required or recommended. When the

area between the electrode sleeve and inner cone becomes clogged

with sample or precipitate from filling solution, the chamber can be

cleaned by flushing out with filling solution. (Hold the electrode by

the cap with one hand and push the outer sleeve of the electrode

up into the cap to drain the chamber.) If the chamber is not

completely clean, repeat the procedure. Refill with the appropriate

filling solution.

Page 52

48

If a more thorough cleaning is required, the electrode can be

disassembled using the following instructions:

1. Rinse the outer body under warm running water.

2. Hold the electrode body by the cap with one hand and

push the outer sleeve of the electrode up into the cap to drain

the chamber.

3. Unscrew the cap, slide the cap and epoxy-coated spring up

along the cable.

4. Hold the outer sleeve with one hand and firmly push down on

the threaded portion with the thumb and forefinger to separate

the inner body from the sleeve.

5. Grasp the cone with a clean tissue and withdraw the body from

the sleeve with a gentle twisting motion.

NOTE: Do not touch the AgCl pellet above the cone as it

may cause damage to the pellet.

Rinse the outside of the electrode body and the entire sleeve

with distilled water. Allow to air dry.

Reassemble

1. Moisten the O-ring on the electrode body with a drop of filling

solution. Insert screw-thread end of the electrode body into the

tapered, ground end of sleeve.

2. Push body into sleeve with a gentle twisting motion until bottom

surface of inner cone is flush with the tapered end of the sleeve.

3. Place the spring on the electrode body and screw on the cap.

Refill with filling solution. The electrode is now ready for use.

Page 53

49

TROUBLESHOOTING

Troubleshooting Checklist

Symptom Possible Causes

Off-scale or Defective meter

Over-range Defective electrode

reading Electrodes not plugged in properly

Reference electrode junction is dry

Reference electrode chamber not filled

Air bubble on electrode

Electrodes not in solution

Noisy or Defective meter

unstable Meter or stirrer improperly grounded

readings Air bubble on electrode

(readings Wrong reference electrode

continuously ISA/SAOB II not used

or rapidly

changing)

Drift (Reading Samples and standards at different

slowly changing temperatures

in one direction) Sensing element dirty or etched

Sulfide being oxidized

(drift in positive direction)

Incorrect reference filling solution

Page 54

50

Solution

Check meter with shorting strap

(See meter instruction manual)

Refer to Troubleshooting Guide

Unplug electrodes and reseat

Hold reference electrode and push cap to expel a few

drops of filling solution

Be sure reference electrode chamber is filled.

See Electrode Preparation.

Remove air bubble on electrode by gently tapping it.

Put electrodes in solution

Check meter with shorting strap

(See meter instruction manual)

Check meter and stirrer for grounding

Check Using the Electrode

Remove air bubble on electrode by gently tapping it.

Use appropriate reference electrode.

See Required Equipment.

Do not use calomel or Ag/AgCl

(frit-or fiber-type) reference electrode

Use recommended ISA, Orion 940011, for silver analyses

or SAOB II, Orion 941609, for sulfide analyses. Use

prepared indicator buffer for cyanide analyses.

Allow solutions to come to room temperature

before measurement

Polish sensing element (see Electrode Maintenance)

Use recommended filling solution.

See Electrode Preparation.

Page 55

51

Troubleshooting Checklist (Con‘t)

Symptom Possible Causes

Low slope Electrodes not properly conditioned

or No slope Standards contaminated or incorrectly made

ISA or SAOB II not used

Standard used as ISA

Electrode exposed to interferences

“Wrong Answer” Incorrect scaling of semilog paper

(But calibration Incorrect sign

curve is OK) Incorrect standards

Wrong units used

Complexing agents in sample

Page 56

52

Solution

Prepare fresh standards

Use recommended ISA, Orion 940011, or SAOB II, Orion

941609

Use ISA!

Refer to Troubleshooting Guide

Plot millivolts on the linear axis. On the log axis, be sure

concentration numbers within each decade are