Page 1

Thermo Scientific

Forma Environmental Chambers

Controlled Temperature Storage Solutions

Optimum uniformity

plus a wide temperature range

Page 2

A Choice of Environmental Chambers

to Meet Your Specific Needs

From stability testing to cell culturing, CO2, RH, and refrigeration control

to temperature-only, and 11.0 to 29.0 cu. ft., Thermo Scientific™ Forma™

environmental chambers are built to last and will meet your needs now

and in the future.

If you require a high precision cabinet to meet ICH,

FDA, TAPPI, ASTM or national testing standards our

3920/3940/3911 Series is the ideal choice.

• Uniformity and a wide temperature range

for easy compliance with regulatory requirements

• Rugged construction and durable shelving designed for long life

• Broad range of options to create the perfect fit for

your applications

At-A-Glance Chamber Comparison

Thermo Scientific

Type

Stability

Cat. No. Temp Range Uniformity RH

3940 (3949) 0°C TO 60°C ±0.3°C @ 25°C to 37°C Above ambient to 95% @ 37°C 29.0 Optional Optional*

3920 0°C TO 60°C ±0.3°C @ 25°C to 37°C N/A 29.0 Optional Optional*

3911 (3913) 0°C TO 60°C ±0.3°C @ 25°C to 37°C Above ambient to 95% @ 37°C 11.0 Optional N/A

3960 (3961)

5°C above

ambient to 60°C

±0.4°C @ 30°C

±0.3°C @ 37°C

±0.5°C @ 45°C

Consider our Thermo Scientific 3960 Reach-In

Incubator/ Environmental Chamber if you are

focused on elevated temperature-only segments of

drug stability and culture.

• Optimum uniformity and an elevated temperature range for

easy compliance with regulatory requirements

• Rugged construction and durable shelving for long life

• Valuable features designed for flexibility and cost-effectiveness

Size

(Cu. Ft.) CO

N/A 29.0 N/A N/A

Lights

2

* Lights (Cat. No. See page 11) do not meet ICH guidelines.

2

Page 3

Thermo Scientific 3920/3940/3911 Series Stability

Chambers for a Multitude of Applications

This series of environmental chambers meets

International Conference on Harmonization (ICH)

guidelines* for drug substance and product storage

testing. The units are ideal for drug stability studies,

shelf life testing for packaged products, and insect

and other large-scale biological research.

Optimum uniformity and a wide

temperature range for easy compliance

with regulatory requirements

These chambers feature a 0°C to 60°C (32°F to 140°F)

temperature range that can be set in 0.1°C

increments. The broad temperature range, and

optimum temperature uniformity and recovery

contribute to an ideal test environment, even when the

chamber contains large product loads and low output,

heat-generating equipment.

Advantages of our directed horizontal

laminar airflow system

Our directed airflow system (shown below) promotes

an ideal growth environment. The enhanced design

includes a positive pressure feed plenum on the right

side of the chamber and a negative pressure return

plenum on the left to distribute the airflow uniformly

throughout the chamber.

This combination directs air across the surface of

each solid shelf. Even when filled with samples or

equipment, each shelf receives a consistent flow of

conditioned air for optimum temperature uniformity

and recovery.

As opposed to our horizontal airflow system, top-tobottom (non-directed) airflow systems use a topmounted fan to push air down through wire shelves.

Temperature uniformity and recovery can deteriorate

quickly when shelves are filled because air movement is

blocked. That variation in temperature, alone or when

combined with frequent door openings, may

compromise environmental conditions or make process

validation difficult.

Standard 4 to 20 milliamp output connects to most

alarm/monitoring systems, allowing you to meet

internal and regulatory product documentation

requirements. Chart recorders are also available.

The Thermo Scientific directed airflow design (left) versus a top-to-bottom, undirected

airflow design (right).

The directed airflow minimizes the risk of product desiccation and loss, and wasted

time and money due to poor temperature uniformity and recovery.

3

Page 4

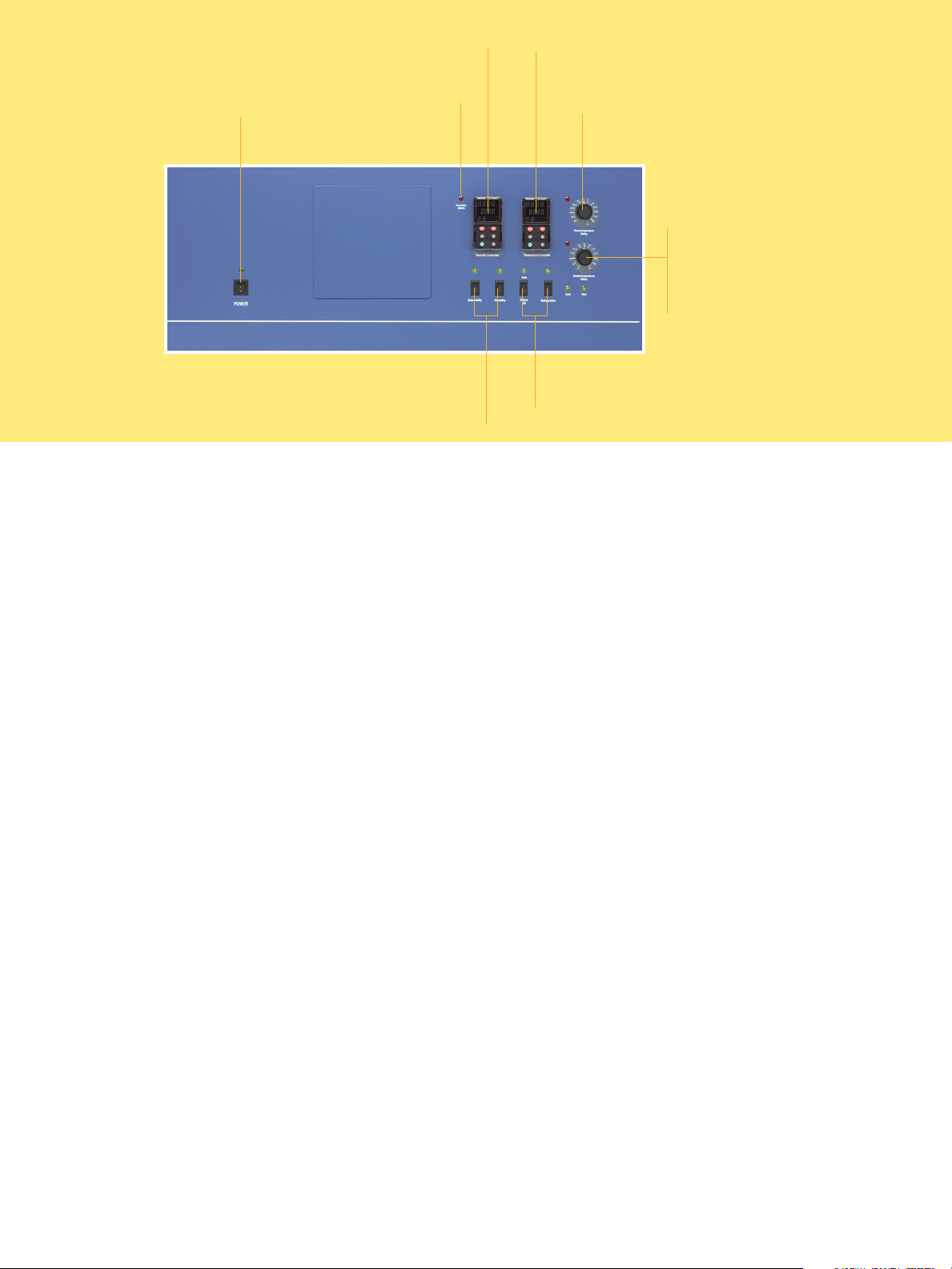

Main Power Switch

and Indicator

Humidity Controller

(3940/3949, 3911/3913) only)

Displays actual RH (%) and setpoint (Ramp and Soak)

Humidity Alarm and Indicator

(3940/3949, 3911/3913 only)

Indicates deviation of cabinet humidity from

set parameters

Temperature Controller

Displays actual chamber temperature and setpoint

(Ramp and Soak)

Over-temperature Safety Thermostat and Indicator

Set over-temp (alarm and light indicate over-temp condition)

Under-temperature

Safety Thermostat

and Indicator

Set under-temp control

(alarm and light indicate

under-temp condition)

Dehumidify and Humidify Switches and Indicators

(3940/3949, 3911/3913 only)

Control humidification and refrigeration systems, show cycle status

(dehumidify switch operates only with optional heatless dryer)

Rugged construction and durable

shelving for long life

• Exterior cabinet is 18 gauge cold-rolled steel, powder

coated for durability and a high quality appearance that

resists scratches and chipping.

• 2.0" (5.1cm) thick, non-CFC, foamed-in-place

polyurethane cabinet insulation provides maximum

product thermal protection and increased rigidity for

reliable daily use.

• Phenolic-coated evaporator protects against corrosive

by-products or agents in the chamber atmosphere

(e.g., secretions from insects such as flies), ensuring

long life.

• Solid, stainless steel interior is more durable and

corrosion-resistant than plastic or painted metal,

ensuring long life and minimizing equipment costs.

• Heavy-duty, solid, stainless steel shelves are easy-to-

clean, saving time and effort; more corrosion-resistant

than coated wire shelves for long life; and adjustable

for convenience.

• 29.0 cu. ft. models include 6 shelves that are

adjustable on 3.0" (7.6cm) centers.

• 11.0 cu. ft. model includes 3 shelves that are

adjustable on 2.0" (5.1cm) centers.

• Reinforced floor/shelf components for 29.0 cu. ft.

models are available so you can use shakers, cell

rollers, or other heavy equipment or product loads

inside the chamber to meet a variety of applications.

• Swivel, locking casters ensure easy mobility during

installation and cleaning. Leveling feet provide stability

and added safety in the lab.

Defrost and Refrigeration Switches and Indicators

Adjustable defrost timer is factory set for two 15 minute

defrost cycles during a 24 hour period

Broad range of options create a perfect fit for your applications

Many options are available so you can tailor this series to your specific applications.

Factory-installed options (ordered separately) include:

• Choice of access ports for inserting data logging sensors or cables.

• Convenience receptacles to run electrical devices in chamber.

• Choice of chart recorders for data logging.

• Choice of data outputs for monitoring/alarm (3960 / 3961 models only).

• Infrared CO2 Control Package for control of a CO2 environment.

• Heatless dryer for low humidity conditions – check temperature / humidity chart (see page 5).

• Door light package for plant growth, seed germination, algae, small animal, insect studies.

• Stainless steel door glass for light sensitive applications.

• Door options include door lock, left-hand door, and Lexan™ inner door.

• Choice of shaker support systems provides system safety.

• Temperature mapping and calibration certificate – customized.

Accessories/on-site options (ordered separately) include:

• Extra and special shelving.

• Reinforced floor options for heavy weights – up to 150 lb.

• Sensaphone™ telephone dialing systems – interfaces with standard touch-tone phone.

• Cell roll system for production of monolayer cell cultures (see page 7).

• On site IQ/OQ/PQ validation services.

Options for the humidity system:

• Condensate pump kit: recommended when the accessible drain on lab wall is well above the

drain on back of environmental chamber.

• Condensate evaporator: external heating device which burns off water that drips out the back

of the unit when there is no drain available.

4

See page 11 for order numbers, model compatibility and additional information.

Page 5

Temperature/Humidity Performance

Chart for 3940 (3949) and 3911 (3913)

The following chart illustrates the maximum and

minimum attainable humidity within the cabinet at

a given set temperature under the following

nominal conditions: refrigeration on, defrost off, no

wet bulb recorder, no air exchange, set for 22.2°C

(72°F) and 50% RH ambient. Optional heatless

dryer is available for lower humidity levels.

Chamber Specifications

% RELATIVE HUMIDITY

TEMPERATURE °C

Effective temperature

and humidity range

Extended range with

optional dryer

Maximum humidity

Minimum humidity

Optional Dryer

Thermo Scientific Cat. No. 3920

Description

Voltage 120V, 60 Hz 208-220V, 60 Hz 220-240V, 50/60 Hz 208-220V, 60 Hz 220-240V, 50/60 Hz

Temperature

Control ±0.1°C @ 25°C to 37°C (77°F to 98.6°F) ±0.1°C @ 25°C to 37°C (77°F to 98.6°F) ±0.1°C @ 25°C to 37°C (77°F to 98.6°F)

Range 0°C to 60°C (32°F to 140°F) 0°C to 60°C (32°F to 140°F) 0°C to 60°C (32°F to 140°F)

Sensor RTD RTD RTD

Controller Microprocessor, PID Microprocessor, PID Microprocessor, PID

Programmability Ramp & Soak (to 40 steps) Ramp & Soak (to 40 steps) Ramp & Soak (to 40 steps)

Setpoint Digital Digital Digital

Display Digital dual LED Digital dual LED Digital dual LED

Readability & Setability 0.1°C 0.1°C 0.1°C

Uniformity* ±0.3°C @ 25°C to 37°C (77°F to 98.6°F) ±0.3°C @ 25°C to 37°C (77°F to 98.6°F) ±0.3°C @ 25°C to 37°C (77°F to 98.6°F)

Temperature Safety

Sensor & Controller Thermostat Thermostat Thermostat

Setpoint Analog reference dial Analog reference dial Analog reference dial

Alarm Audible/visual Audible/visual Audible/visual

Refrigeration

Compressor 1⁄4 HP, air-cooled 1⁄4 HP, air-cooled 1⁄4 HP, air-cooled

Refrigerant Non-CFC, R134A refrigerant Non-CFC, R134A refrigerant Non-CFC, R134A refrigerant

Humidity

Input Water Quality 50K-1Megohm resistance 50K-1Megohm resistance

Input Water Volume 1 gallon/hour 1 gallon/hour

Input Water Pressure Gravity to 40 psi Gravity to 40 psi

RH Above ambient to 95% @ 37°C (98.6°F) ±5.0% RH Above ambient to 95% @ 37°C (98.6°F) ±5.0% RH

Sensor Capacitive – thin film polymer Capacitive – thin film polymer

Controller Microprocessor, PID Microprocessor, PID

Programmability Ramp & Soak (to 40 steps) Ramp & Soak (to 40 steps)

Setpoint Digital (direct set in % RH) Digital (direct set in % RH)

Display Digital, dual LED (direct read in % RH) Digital, dual LED (direct read in % RH)

Readability & Setability 1.0% 1.0%

Steam Generator Initial fill approx. 1 qt. (1 liter) Initial fill approx. 1 qt. (1 liter)

Setable Alarm Audible/visual Audible/visual

Certification cULus cULus CE cULus CE

**

29 cu. ft. Incubated/Refrigerated

Environmental Chamber

**

3940

29 cu. ft. Incubated/Refrigerated Environmental

Chamber with humidity control

3949

**

**

3911

11 cu. ft. Incubated/Refrigerated Environmental

Chamber with humidity control

3913**

*Six shelves in 3920 and 3940 (3949), three shelves in 3911 (3913); uniformity is ±0.5°C at all other temperature parameters.

**All models require a drain unless fitted with the optional Condensate Evaporator (No. 1900031). 3940 (3949) and 3911 (3913)

also require a constant water source.

5

Page 6

Chamber Specifications continued

Thermo Scientific 3920/3940/3911 Series Stability Chambers

Thermo Scientific Cat. No. 3920

Description

Fittings**

Fill Port 1⁄8” female NPT 1⁄8” female NPT

Drain Port (bottom) 3⁄8” FPT & 3⁄8” O.D. P-trap right rear 3⁄8” FPT & 3⁄8” O.D. P-trap right rear 3⁄8” FPT & 3⁄8” O.D. P-trap right rear

Unit Heat Load

115V 5500 BTUH (1600 Watts) 5500 BTUH (1600 Watts) 5500 BTUH (1600 Watts)

220V 6000 BTUH (1750 Watts) 6000 BTUH (1750 Watts) 6000 BTUH (1750 Watts)

Dimensions

Exterior

Width 38.0” (96.5cm) 38.0” (96.5cm) 38.0” (96.5cm)

Height 88.5” (224.8cm) 88.5” (224.8cm) 51.5” (130.8cm)

F-B 32.0” (81.3cm) 32.0” (81.3cm) 32.0” (81.3cm)

Interior

Width 31.0” (78.7cm) 31.0” (78.7cm) 31.0” (78.7cm)

Height 60.0” (152.4cm) 60.0” (152.4cm) 24.0” (60.9cm)

F-B 27.0” (68.6cm) 27.0” (68.6cm) 27.0” (68.6cm)

Shelves

Dimensions 30.6”W x 25.8” F-B (77.8cm x 65.6cm) 30.6”W x 25.8” F-B (77.8cm x 65.6cm) 30.6”W x 25.8” F-B (77.8cm x 65.6cm)

Construction Solid stainless steel, reinforced Solid stainless steel, reinforced Solid stainless steel, reinforced

Surface Area per Shelf 5.4 sq. ft. (0.5 sq. m) 5.4 sq. ft. (0.5 sq. m) 5.4 sq. ft. (0.5 sq. m)

Max. Surface Area

per Chamber

Standard/Maximum

Number of Shelves

Load per Shelf

Construction

Interior Volume 29.0 cu. ft. (821.2 liters) 29.0 cu. ft. (821.2 liters) 11.0 cu. ft. (311.5 liters)

Interior Material Type 304, 2B finish, stainless steel Type 304, 2B finish, stainless steel Type 304, 2B finish, stainless steel

Exterior Material Cold-rolled steel, powder coated Cold-rolled steel, powder coated Cold-rolled steel, powder coated

Outer Door Gasket Four-sided, vinyl compression Four-sided, vinyl compression Four-sided, vinyl compression

Electrical 120V, 60 Hz, 16.0 Amps 3 Wire

Dry Contacts Common, NO, NC Common, NO, NC Common, NO, NC

Data Output 4-20 milliamp, temperature 4-20 milliamp, temperature and RH 4-20 milliamp, temperature and RH

Power Switch 2 Pole 2 Pole 2 Pole

Plug NEMA 5-20P NEMA 14-20P None NEMA 14-20P None

Weight

Net 700 lbs. (317.5 kg) 765 lbs. (347.0 kg) 575 lbs. (260.8 kg)

Shipping (motor) 850 lbs. (385.6 kg) 1,040 lbs. (471.7 kg) 940 lbs. (426.4 kg) 715 lbs. (324.3 kg)

*All models require a drain unless fitted with the optional Condensate Evaporator (No. 1900031). 3940 (3949) and 3911 (3913) also require a constant water source.

**

29 cu. ft. Incubated/Refrigerated

Environmental Chamber

104.3 sq. ft. (9.7 sq. m) 104.3 sq. ft. (9.7 sq. m) 59.4 sq. ft. (5.5 sq. m)

6, 19 6, 19 3, 11

35 lbs. (15.9 kg), slide in/out

50 lbs. (22.7 kg), stationary

(including ground)

**

3940

29 cu. ft. Incubated/Refrigerated Environmental

Chamber with humidity control

35 lbs. (15.9 kg), slide in/out

50 lbs. (22.7 kg), stationary

208-220V, 60 Hz,

15.0 Amps 4 Wire

(including ground)

single phase

**

3949

220-240V,50/60 Hz

14.0 Amps, 3 Wire

(including ground) must

be hardwired to a

lockable fused

disconnect switch

**

3911

11 cu. ft. Incubated/Refrigerated Environmental

Chamber with humidity control

35 lbs. (15.9 kg), slide in/out

50 lbs. (22.7 kg), stationary

208-220V, 60 Hz

15.0 Amps 4 Wire

(including ground)

single phase

3913**

220-240V,50/60 Hz

14.0 Amps, 3 Wire

(including ground) must

be hardwired to a

lockable fused

disconnect switch

6

Page 7

Incubator/Environmental Chamber

for Elevated Temperature Applications

The 29.0 cu. ft. (821.2 liters) 3960 (3961) offers precise temperature

control in a range of 5°C above ambient to 60°C (140°F), making this

unit ideal for clinical applications, elevated temperature stability

3960 (3961) Models

• Large size for high volumes and a broad range of products

• Heated glass door for minimal condensation and a clear view

• Interior and exterior convenience receptacles, and five adjustable shelves

• Thermo Scientific Enviro-Scan

studies, and shelf life testing.

™

controls with easy-to-read display of actual temp

Cell Roll System

The optional cell roll system allows extensive production of monolayer

cell cultures in standard roller culture vessels. Oxygenation and

exposure of the cells to the media growth area are improved.

Culture yields are increased by the uniform temperature control and

cell roll system’s continuous, gentle rotation.

The environmental chamber accommodates a cell roller up to

7 decks high with 5 positions per deck for a maximum total of

35 positions, or bottles.

Achieving maximum capacity requires a 4862 (4868) three tier cell

roller base (15 positions), four add-on tiers (20 positions), and a

reinforced floor/ramp.

All position drive is standard. Adjustable speed control provides

precise speeds of 0.125 to 6.25 RPM with ±1.0% accuracy, based

on 110mm bottles.

Cell Roller System

Model 3961

7

Page 8

Uniformity and an Elevated Temperature Range

for Easy Compliance with Regulatory Requirements

Our directed airflow system promotes an ideal growth environment. The proven design includes a positive

pressure feed plenum and a negative pressure return plenum. This combination directs air across the surface

of each solid shelf. Even when filled with samples or equipment, each shelf receives a consistent flow of

conditioned air for optimum temperature uniformity and recovery. By design, the feed plenum cannot be

blocked by the chamber’s contents. (Refer to the diagram on page 3.)

Intuitive, powerful Enviro-Scan–

a key Forma advantage

> ensures precise temperature control without

complicated programming

> provides audible/visual under-temperature and over-

temperature alarms for peace-of-mind

> includes an easy-to-read display for convenient,

continuous monitoring.

• Enviro-Scan operating modes include Run, Setpoint,

Calibration, and System Configuration.

• Standard remote alarm contacts and available data outputs

allow connection to an in-house monitor/alarm system to track

chamber conditions, helping you meet internal and regulatory

documentation requirements. Chart recorders are available.

8

Page 9

Durable construction and shelving

Valuable features included for cost-

for long life

• Exterior cabinet is 18 gauge cold-rolled steel, powder coated for

durability and a high quality appearance that resists scratches and

chipping.

• Maximum product thermal protection and added cabinet strength for

reliable daily use are provided by the 2.0" (5.1cm) thick fiberglass

cabinet insulation.

• Solid, stainless steel interior is more durable and corrosion-resistant

than plastic or painted metal, ensuring long life and minimizing

equipment costs.

• Five heavy-duty, solid, stainless steel shelves, adjustable on 2.0"

(5.1cm) centers, are easy-to-clean, saving time and effort; more

corrosion-resistant than coated wire shelves for long life; and

adjustable for convenience.

• Reinforced floor/shelf components are available so you can use shakers,

cell rollers, or other heavy equipment or product loads inside the

chamber to meet a variety of applications.

effectiveness and flexibility

Casters, access ports, convenience receptacles, heated glass door, and

remote alarm contacts – all are included up-front. Our 3960 Incubator/

Environmental Chamber is prepared to meet your changing application

needs without the added cost of expensive add-on options.

• Swivel, locking casters ensure easy mobility during installation and

cleaning. Leveling feet provide stability and added safety in the lab.

• Thru-wall access ports, located on the right and left sides of the

chamber, make it possible to add probes, sensors, etc. without altering

the cabinet.

• Interior and exterior accessory receptacles provide a convenient

power source.

– Interior GFCI duplex receptacle on the 115V 3960 unit (Single

European 230V CEE 7 on 3961) located in the upper right corner

of the rear wall, permits the use of shakers, cell rollers, and other

equipment inside the chamber, eliminating the inconvenience of an

extra external power strip.

– Exterior receptacle, located on the upper-right side of the control

panel, is available for connecting an optional recorder or other

Forma accessories.

9

Page 10

Chamber Specifications

Thermo Scientific Cat. No. 3960 3961

Description 29 cu. ft. Incubated Environmental Chamber 29 cu. ft. Incubated Environmental Chamber

Voltage 115V, 50/60 Hz 200-230V, 50/60 Hz

Temperature

Control ±0.1°C ±0.1°C

Range 5°C above ambient to 60°C (140°F) 5°C above ambient to 60°C (140°F)

Uniformity

Low Alarm User programmable and indicator User programmable and indicator

Over-temperature

Sensor Precision thermistor Precision thermistor

Setability 0.1°C 0.1°C

Function User programmable, action (shuts off heat), and indicator User programmable, action (shuts off heat), and indicator

Temperature Safety (Cabinet)

Sensor Independent thermostat Independent thermostat

Type Independent analog electronic Independent analog electronic

Fittings

Access Port With Stopper 2.4” (6.1cm) I.D., one on each side 2.4” (6.1cm) I.D., one on each side

Unit Heat Load

115V/230V 510 BTUH (150 Watts) 129 kcal per hour 510 BTUH (150 Watts) 129 kcal per hour

Shelves

Dimensions 30.6”W x 25.8”F-B (77.7cm x 65.5cm) 30.6”W x 25.8”F-B (77.7cm x 65.5cm)

Construction 2B finish, solid stainless steel 2B finish, solid stainless steel

Surface Area 5.4 sq. ft. (0.5 sq. m) per shelf 5.4 sq. ft. (0.5 sq. m) per shelf

Max. per Chamber 140.4 sq. ft. (13.0 sq. m) 140.4 sq. ft. (13.0 sq. m)

Standard/Maximum No. of Shelves 5, 26 5, 26

Loading

Construction

Interior Volume 29.0 cu. ft. (821.2 liters) 29.0 cu. ft. (821.2 liters)

Interior Material Type 304, 2B finish, stainless steel Type 304, 2B finish, stainless steel

Exterior Material Cold-rolled steel, powder coated Cold-rolled steel, powder coated

Insulation 2.0” (5.1cm) fiberglass 2.0” (5.1cm) fiberglass

Exterior Door Heated, triple pane, tempered glass Heated, triple pane, tempered glass

Outer Door Gasket Molded vinyl Molded vinyl

Electrical

Circuit Breaker/Power Switch 15 Amps; 2 pole 8 Amps; 2 pole

Exterior Convenience Receptacle 75 Watts maximum (matches cabinet voltage) 75 Watts maximum (matches cabinet voltage)

Interior Convenience Receptacle 230 Watts maximum (matches cabinet voltage) 230 Watts maximum (matches cabinet voltage)

Plug 115V: NEMA 5-15P Plug 230V: CEE 7/7 Plug

Alarm Contacts

Data Outputs (opt.) RS-485, 0-1V, 0-5V, 4-20 milliamp RS-485, 0-1V, 0-5V, 4-20 milliamp

Dimensions

Exterior 38.0”W x 80.0”H x 33.0”F-B (96.5cm x 203.2cm x 83.8cm) 38.0”W x 80.0”H x 33.0”F-B (96.5cm x 203.2cm x 83.8cm)

Interior 31.0”W x 60.0”H x 27.0”F-B (78.7cm x 152.4cm x 68.6cm) 31.0”W x 60.0”H x 27.0”F-B (78.7cm x 152.4cm x 68.6cm)

Weight

Net 500 lbs. (226.8 kg) 500 lbs. (226.8 kg)

Shipping (motor) 660 lbs. (299.4 kg) 660 lbs. (299.4 kg)

Certification cULus CE

±0.4°C @ 30°C (86°F) ±0.3°C @ 37°C (98.6°F)

±0.5°C @ 45°C (113°F)

30 lbs. (13.6 kg) per shelf, fully inserted and stationary;

not to exceed 300 lbs. (136.0 kg) total per cabinet

115V, 50/60 Hz, 9.0 Amps (Operating range 90-125V

includes voltage fluctuations)

Temperature deviation and power failure; Common, NO, and NC;

customer connections through RJ11 jack on rear of unit

±0.4°C @ 30°C (86°F) ±0.3°C @ 37°C (98.6°F)

±0.5°C @ 45°C (113°F)

30 lbs. (13.6 kg) per shelf, fully inserted and stationary;

not to exceed 300 lbs. (136.0 kg) total per cabinet

200/230V, 50/60 Hz, 5.0 Amps (Operating range 180-250V

includes voltage fluctuations)

Temperature deviation and power failure; Common, NO, and NC;

customer connections through RJ11 jack on rear of unit

Specifications are based on nominal voltages of 115V or 230V in ambients of 22ºC to 25ºC. Performance is plus or minus

the least significant digit unless otherwise specified.

10

Page 11

Accessories (All are customer installed unless indicated otherwise)

Thermo Scientific

Cat. No Description

Shelving

Stainless Steel Shelves for 3920, 3940 (3949), 3911 (3913), and 3960 (3961)

224139

224155

224161

Shaker Support System, factory installed

1900005*

190761*

Door Options, factory installed

190239

190514

190597 Left-Hand Door Swing Kit for 3920 and 3940 (3949); factory installed

Stainless Steel Door Glass Covers

190591 For 3920, 3940 (3949), and 3960 (3961); factory installed

190892 For 3920, 3940 (3949), and 3960 (3961)**

Door Light Package, factory installed

190032 (220V, 60Hz)

1900604 (120V, 60Hz)

1900605 (220V, 50Hz)

Reinforced Floor Options

500182***

190777*** Same as No. 500182 but factory installed

Access Ports, factory installed

505101

193004 2" nominal ID port with cover

190164 Port for 3960 (3961), 2.4" (6.1 cm) I.D., customer specified location

193005 4" nominal ID port with cover

193006 6" nominal ID port with cover

Convenience Receptacles, factory installed

505099

505094

Data Outputs (select one) for 3960 (3961), factory installed

190523 RS-485 interface (compatible with 1535 Monitor/Alarm only)

190512 4-20 milliamp

190543 0-5V

190544 0-1V

Sensaphone Telephone Dialing Systems, interface with standard touch-tone phone

400047 For up to four input channels

400134 For up to eight input channels

Solid Stainless Steel Shelf and Channels for 3920, 3940 (3949), 3911

(3913), and 3960 (3961)

Perforated Stainless Steel Shelf and Channels for 3920, 3940 (3949),

3911 (3913), and 3960 (3961)

Reinforced Stainless Steel Shelf and Channels for 3920, 3940 (3949),

3911 (3913), and 3960 (3961); two per unit max., not for shakers; 150

lb. (68.0 kg) load maximum with shelf fully inserted and stationary

Two shelf shaker support system without duplex outlet, each shelf will

hold 200 lbs., for 3920, 3940, (3949) and 3960 (3961). Must be ordered

with duplex outlet (505099 or 505094)

Three shelf shaker support system includes duplex outlet, each shelf will

hold 200 lbs., for 3920, 3940, (3949) and 3960 (3961)

Lexan® Inner Door Kit (five doors) for 3920, 3940 (3949), and 3960

(3961); factory installed

Door Lock Assembly for 3920, 3940 (3949), and 3960 (3961); factory

installed

Door light package with 8 fluorescent light bulbs for plant growth, seed

germination, algae, small animal and insect studies for 3920, 3940 and

(3949); A 24-hour timer enables automated light on/off cycles. Intensity of

light can be modified in 4 steps by enabling / disabling from 2 to 8 lights.

Reinforced Floor with Removable Ramp for 3920, 3940 (3949), and 3960

(3961); accommodates a cell roller

Port for 3920, 3940 (3949), and 3911 (3913); 1.5" (3.8 cm) I.D.; on

center right wall

120V Duplex (includes separate line cord) for 3920, 3940, and 3911;

located on center rear wall

230V (includes separate line cord) for 3949, and 3913; located on center

rear wall

Warranty

We confidently back our environmental chambers with a two-year parts and labor warranty.

* Rubber isolators replace casters for maximum stability.

** Must be installed by qualified personnel.

*** Ramp extends approximately 23.0” (58.4cm) in front of the chamber.

****Specification sheets for protocol and field validations are available for review upon request by

calling Pre-Sales at 866-984-3766 or emailing: LPG.presales@thermofisher.com.

Thermo Scientific

Cat. No Description

Chart Recorders and Paper

12", 6 Hour to 31 Day Digital Recorders for 3920, 3940 (3949), and 3911 (3913); draw own

chart as they record; single or dual pen; 120V, 50/60 Hz; factory installed

198036 Left Side

198039 Right Side

198042 Top, adds 20.3" (51.6cm) to cabinet height

197054 Replacement Chart Paper, 100 per box

6", 7 Day Chart Recorders for 3920, 3940 (3949), and 3911 (3913); 0°C to 60°C

(32°F to 140°F); 115V, 50/60 Hz

201144

201147 Dual Pen

6", 7 Day Chart Recorders for 3960 (3961), 0°C to 60°C (32°F to 140°F), single pen

201155 115V, 50/60 Hz

201156 230V, 50/60 Hz

6" Chart Paper for Recorders, 50 per box

180006 For Single Pen, 0°C to 60°C (32°F to 140°F)

197030 For Single Pen, -10°C to 70°C (14°F to 158°F)

197075 For Single or Dual Pen, 0°C to 100°C (32°F to 212°F)

RH System Options

184062

1900031

1900391

1900139

Deionization Cartridge Assembly for chambers with humidity and no DI water source

019-168-00

585-036-00 Replacement DI cartridge

Calibration Certificate and Temperature Mapping with Report

260045 Temperature Mapping Report (factory installed)

260049 Calibration Certificate (specify test parameters)

cGxP Protocols and on site Validation Services****

GLP Level Protocols (IQ OQ)

IOQDOCE89003499 For 3920, 3960

IOQDOCE89003710 For 3940 (3949) 3911 (3913)

GMP Level Protocols (IQ OQ PQ)

IOPQDOCE89003499 For 3920, 3960

IOPQDOCE89003710 For 3940 (3949) 3911 (3913)

GLP Level Field Validation (IQ OQ) Performed at the customer site

(protocol included at no extra charge)

IOQPCKE89003499 For 3920, 3960

IOQPCKE89003710 For 3940 (3949) 3911 (3913)

GMP Level Field Validation (IQ OQ PQ) Performed at the customer site

(protocol included at no extra charge)

IOPQPCKE89003499 For 3920, 3960

IOPQPCKE89003710 For 3940 (3949) 3911 (3913)

Miscellaneous Accessories Infrared CO2 Control Packages, factory installed

1900226 For 3920

1900227 For 3940 (3949) and 3911 (3913)

Cell Roll System

4862

4868 Same as 4862 but 230V, 50/60 Hz

190049

190777

500182 Same as No. 190777 but customer installed

228077 Rotation Alarm System, includes annunciator jack, factory installed

228078

475560 110mm x 285mm Glass Bottles (4 per case)

Single Pen, factory installed201145 Single Pen201146 Dual Pen, factory

installed

Condensate Pump Kit for 3920, 3940 (3949), and 3911 (3913) Elevated

Drains; includes separate line cord, 115V

Condensate Evaporator for 3920, 3940, and 3911; includes separate line

cord; 115V

Condensate Evaporator for 3949 and 3913; includes separate line cord;

240V

Heatless Dryer Kit for 3940 (3949) and 3911 (3913), for sub-ambient

chamber RH, factory installed; The heatless dryer requires an air supply of

90 psi capable of 10 cfm, at minimum. It is recommended that the air

supply be greater than the minimum required by the dryer.

DI cartridge assembly includes DI cartridge, wall bracket, pressure

regulator and gauge and 1/4" flexible tubing

Three Tier Cell Roller Base (15 positions), 120V, 50/60 Hz, 29.8"W x

27.8"H x 24.4"F-B (75.7cm x 70.6cm x 62.0cm)

Add-On Tier (5 positions), 29.8"W x 7.1"H x 24.4"F-B (75.7cm x 18.0cm

x 62.0cm), customer installed

Reinforced Floor with Removable Ramp, ramp extends 23.0" (58.4cm),

factory installed

Battery Back-Up, provides 24 hours of power if a power failure occurs,

factory installed

11

Page 12

thermoscientific.com/chambers

© 2015 Thermo Fisher Scientific Inc. All rights reserved. Sensaphone is a registered trademark of the Sensaphone Company. Lexan is a registered trademark of the

General Electric Company. All other trademarks are the property of Thermo Fisher Scientific Inc. and its subsidiaries. Specifications, terms and pricing are subject to change.

Not all products are available in all countries. Please consult your local sales representative for details.

Australia +61 39757 4300

Austria +43 1 801 40 0

Belgium +32 53 73 42 41

China +800 810 5118 or

+400 650 5118

France +33 2 2803 2180

Germany national toll free 0800 1 536 376

Germany international +49 6184 90 6000

BRFORMACHB 0715

India toll free 1800 22 8374

India +91 22 6716 2200

Italy +39 02 95059 552

Japan +81 3 5826 1616

Netherlands +31 76 579 55 55

New Zealand +64 9 980 6700

Nordic/Baltic/CIS countries

+358 9 3291 0200

Russia +7 812 703 42 15

Spain/Portugal +34 93 223 09 18

Switzerland +41 44 454 12 22

UK/Ireland +44 870 609 9203

USA/Canada +1 866 984 3766

Other Asian countries +852 2885 4613

Countries not listed +49 6184 90 6000

Loading...

Loading...