Page 1

Instruction Manual

Thermo Scientific Savant

®

SPD131DDA SpeedVac Concentrator

Page 2

©

2008 Thermo Fisher Scientific. All rights reserved.

®

“Suva

” is a registered trademark of DuPont.

All other trademarks are the property of Thermo Fisher Scientific Inc. and

its subsidiaries.

Page 3

Contents

Section Overview Page

1.0 Overview of SPD131 DDA Unit 1

1.1 Cover Lock Override 2

1.2 Installation of the SPD131 DDA 3

1.3 How to Hook Up the SPD131 DDA 3

Section Control Panel Page

2.0 The Control Panel 4

2.1 Description of the Control Panel 4

Section Manual Run Page

3.0 The Manual Run 5-6

3.1 The Auto Run 6

Section Rotor Selection Page

4.0 Rotor Selection Guide 7

Section Guidelines Page

5.0 Guideline for Solvent Choice 8

Section Maintenance Page

6.0 Maintenance & Service 9

Section Specifications Page

7.0 Specifications & Warranty

Appendix 1 – Additional SPD131DDA System Set-ups

Appendix 2 – Additional SPD131DDA System Set-ups

For DMSO

Appendix 3 – RS232 Port Specifications

Disclaimer:

All statements, information and data given he rein are believed to be accurate and reliab le but are presented without guarant ee, or responsibi lity of any kind, expresse d or implied. Statements or suggestions

possible use of our products are made without representation that a ny such use is free of patent infringement and are not recommendatio ns to infringe any patent. The user should not assume that all

indicated, or that other measures may not be required.

13

Page 4

Overview of the SPD131 DDA Unit

Figure 1 = Front View

2

Figure 2 = Side View

Figure 3 = Back View

Fig. 1

1. Top Radiant Cover

2. Control Panel

3. Front Panel

4. Left Side Panel

5. Anti Skid/Vibration

6. Right Side Panel

Fig. 2

7. Chamber View Window

8. Vacuum Port

9.* Vacuum Tubing

10. Main On/Off Switch

11. Manual Cover Lock Release

12. Rear Access Panel

13. RS232 Port

14. AC Receptacle

*Tubing that carries vapors to

cold trap is larger in diameter.

11 (See page 2)

Fig. 3

1

Page 5

COVER LOCK OVERRIDE

To Open The Top Cover During Power Failure:

Remove the philips screw holding the cover lock, release cord and lightly pull it as shown, whil e lifting

the cover.

2

Page 6

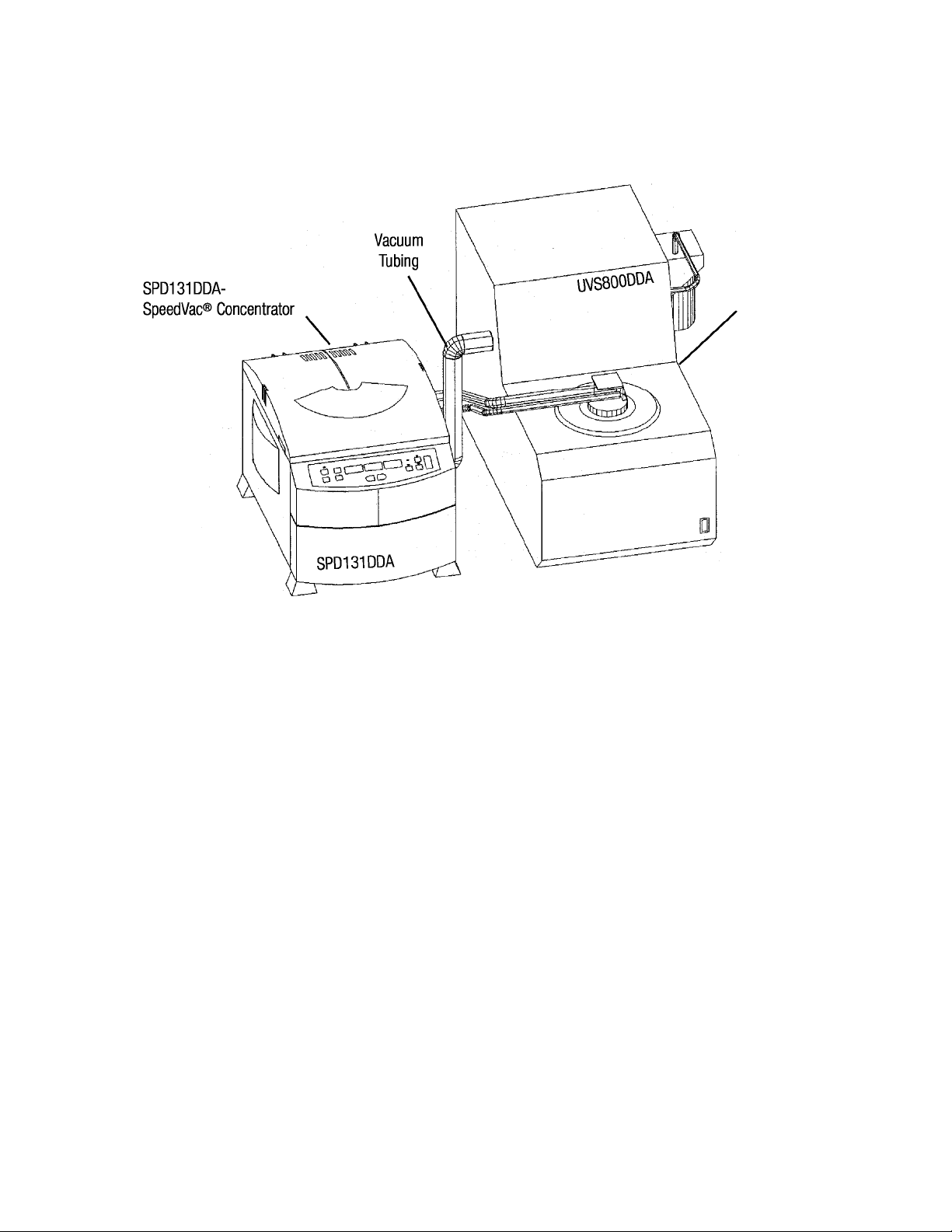

INSTALLATION OF THE SPD131DDA

Figure 4-Front View of System

UVS800DDA

Unviersal Vacuum Source

What it should look like:

How To Hook Up The SPD131DDA SpeedVac

1. Unpack unit from the box and verify that all the parts match packing list.

2. Read instruction manual carefully! If assistance is required, contact Customer Service.

3. If the unit is part of a larger system, use the vacuum tubing supplied to hook up unit (See Figure 4).

4. Vacuum clamps must be put on vacuum ports of pump and SPD unit (See item 8 on Figure 2 and

Figure 4).

5. If the unit is being connected to an existing system, attach vacuum tubing to various components as

illustrated above and in Appendix 1.

CAUTION - Cold trap should be in line between the vacuum source

and the SPD Unit.

®

System

3

Page 7

CONTROL PANEL

1

Pre-

Heat

RC

On/Off

3

Select

View

10

11

Modify Setpoints

12

Level

Ramp

Vacuu

m

7

Manual

Run

Auto

Run

8

2

9

4

5

6

Description of Control Panel

1. PRE-HEAT - use to pre-heat chamber to 45 °C prior to beginning or between runs.

Once run is initiated the pre-heat stops.

2. RC ON/OFF - Use to add radiant heat to chamber. Manually activate by pressing

ON/OFF at any point during run. Will activate as long as there is time left on the

heat timer. Will turn off when heat timer=0.00

3. SELECT - Press this button to select the parameters to be modified. Selection is

from left to right. GREEN light indicates the parameter to be modified.

4. MODIFY SET POINTS UP/DOWN - Modifies selected parameter.

5. VACUUM SET - (VACUUM CONTROLLER) - Selects either “Level” or “Ramp” in

the VAC display.

Level: Allows users to select a pre-set vacuum level. Once this level is obtained,

the microprocessor will regulate and maintain this vacuum level. The

vacuum level can be set from 20 torr to 100 mtorr.

Ramp:The rate at which vacuum is achieved can be set for preventing bumping.

5 adjustable levels can be set as required depending upon your solvent.

Setting Vacuum Rate (approximate

)

5 70 torr/min (Maximum setting)

4 50 torr/min

3 40 torr/min

2 30 torr/min

1 5 torr/min

6. AUTO RUN - Starts an ‘Automated’ run.

7. MANUAL RUN - Starts a “Manual” run.

8. STOP - Terminates “Manual” or “Auto” run.

9. VIEW - Press to view. Displays preset parameters when pressed during a run.

10. TEMPERATURE DISPLAY - Indicates set temperature or actual temperature

during a run in

°C.

4

Page 8

11. TIME DISPLAYS - Indicates heat timer or run timer set-points. In the

process of a run it indicates elapsed time or time left. Set from

0.01 [1 min.] to 9.59 [9 hours, 59 minutes] or “CCC” [continuous].

12. VACUUM PRESSURE DISPLAY - Displays vacuum level or ramp.

Chamber vacuum is displayed in torrs or millitorrs by shifting a decimal point.

“Hpr.” represents atmospheric pressure. No decimal point

indicates microns. Ramp can be set to five (5) adjustable levels.

NOTE - The unit will sound an audible beep, every time a button is pressed.

EXAMPLE OF A MANUAL RUN

1. Connect the unit to its required voltage.

2. The cover lock disengages, allowing the top cover to be opened.

The display lights up, showing the following default values:

Temperature: 45

°C in RED

RunTime: 2.00 HRS. in GREEN

Vacuum Pressure: 01.0 in AMBER

3. Using the “SELECT” button and the up/down keys, setTEMPERATURE

between 45

°C and 80 °C, or “no”, for no heat.

4. Using the “SELECT” button and the up/down keys select and modif

“HEATTIME” to between 0.01 and 9.59 hours or CCC (for continual

heating). When the heat timer expires, the heater will shut off, no

matter what the temperature setpoint reads (except if CCC).

5. Select Run Time: Since this a manual run no time adjustment is needed.

6. To select a VACUUM LEVEL, press “VACUUM SET” to illuminate LEVEL

and use th up/down keys to set vacuum to desired level. To select a

vacuum ramp rate, press “Vacuum Set” to illuminate RAMP and use the

up/down keys to set a ramp rate (5=highest, 1=lowest).

7. Place the sample tubes in the rotor and ensure that the load is balanced.

Secure rotor with the supplied knob. Close cover.

8. Pre-heat may be selected at this time, to warm chamber to 45

°C.

9. Press the “MANUAL RUN” button.The cover locks and rotor starts

turning. The decimal point blinks and the “RUN TIME” display counts up.

The temperature rises to the set temperature. The “HEAT TIME” will count

down and vacuum will be applied to the chamber.The vacuum level

begins falling.

NOTE: If the cover is not closed, the display will show “Lid” and the run

will not start.

5

Page 9

10. Press R/C for radiant chamber heat. Press at any time to turn OFF and ON.

(As long as there is time left in the heat timer).

11. To end the manual run, press “STOP” button.The display will show “End”, the

valves will click, isolating the chamber from the vacuum pump and also allowing

air to bleed into the chamber.

12. After the rotor stops spinning, the cover lock disengages and the display reverts

to last set parameters, and the unit will sound several audible beeps.

13. Open the cover and remove samples.

GENERAL:

press “VIEW” button and “SELECT”. The display will revert temporarily to set points.

During the run, display shows actual parameters. To check set parameters

EXAMPLE OF AN AUTO RUN

1. Refer to the “MANUAL RUN” section for start up.

2. To execute an AUTO “TIMED” RUN:

a) Use “SELECT” button and the up/down keys to select and modify

“TEMPERATURE, “HEATTIME, “RUN TIME” parameters. RUN and

HEATTIME can be set from 0.01 to 9.59 hours (HEATTIME also has

“CCC” for continuous use).

b) To set a VACUUM LEVEL, press “VACUUM SET” to illuminate

LEVEL up/down keys to set vacuum to desired level.

To select a vacuum ramp rate, press “Vacuum Set” to illuminate

RAMP and use the up/down keys to set a ramp rate (5=highest,

1=lowest).

3. Place the sample tubes in rotor so load is balanced. Secure rotor with

supplied knob. Close cover.

a) Press “AUTO RUN” button to start the run.The cover locks and the

rotor starts spinning.The time display is counting down in 1 minute

Intervals and the decimal point blinks. The heat time is counting

down (use select button to view “HEAT TIME”). The temperature

rises in 1

begins decrementing down from “HPr” (atmospheric pressure),

after both SAV valves actuate, applying vacuum to the chamber.

b) The vacuum display will indicate vacuum pressure in the chamber.

NOTE: If the cover is not closed, the display will show “Lid” and

the run will not start.

°C increments to set temperature.The vacuum pressure

6

Page 10

c) Press R/C for radiant chamber heat. Press at any time to turn OFF and

ON. (As long as there is time left in the heat timer).

d) Once the time decrements to 0.00 HRS. the run will automatically stop,

the display will show “End”,the SAV valves will click, also allowing air to

bleed into the chamber.

e) After the rotor stops spinning, the cover unlocks and the display reverts

to last set parameters, and the UNIT will sound several audible beeps.

f) Open the cover and remove samples.

GENERAL

press “VIEW” button and “SELECT”. The display will revert temporarily to set points.

: During the run, display shows actual parameters. To check set parameters

7

Page 11

Rotor Selection Guide

8

Page 12

GUIDELINES FOR SOLVENT CHOICE

Part I Solvents suited for the SPD 131 DDA unit

• Ethanol

• Methanol

• Formic Acid

• Water

• Acetonitrile

• Methylene Chloride

• Chloroform

• Ethyl Acetate

• Hydrochloric Acid

• Trifluoroacetic Acid

• DMSO (Special set-up required-see Appendix 2)

In the event that your choice of solvents and applications are unique and not listed above, please contact Customer

Support for advice.

MAINTENANCE/SERVICE

1. Maintenance: The SPD131DDA SpeedVac requires no scheduled maintenance.

2. Cleaning: The SPD131DDA SpeedVac should be cleaned if solvent, spills on or inside

the unit. Cl

Always wear gloves when cleaning and dispose used of paper

towel in appropriate designated refuse containers.

ean up any spills immediately using absorbent towels.

3. Replace chamber seal if cracked (Part number is 197-6020-01).

4. Outside of unit can be cleaned with di

5. For any other maintenanc

e or service issues or service problems, contact Customer Service

lute solution of soap and water.

.

9

Page 13

1

Page 14

SPECIFICATIONS

Model:

Bleeder Valve:

Temperature Range:

Volume Range/Tube:

Tube Capacity:

Maximum Carrier Capacity:

Dimensions: (W x D x H) in.:

cm:

Weight: lbs. (kg)

Power requirements:

SPD131DDA

Integrated Automatic Bleeder lve

45°

C-80°C

18 x 150 mm*

6*

2 x (96-deepwell plates)

14 x 18 x 13

36 x 45 x 33

31 (14)

115 VAC/60Hz, 5.0A (Part number

SPD131 DDA-115)

or 230 VAC/50Hz, 3.0A (Part

number SPD131 DDA-230)

All Thermo products mentioned in this manual (except glassware) are warranted against defects

in material and workmanship for one year after the date of delivery to the original purchaser.

Thermo’s warranty is limited to defective materials and workmanship, and does not cover

incidental or consequential damages. Warranty work is subject to our inspection of the unit.

No instruments, equipment, or accessories will be accepted without a Return Material

Authorization (RMA) number issued by Thermo. Costs of shipping the unit are not covered under

warranty. The warranty obliges you to follow the precautions in this manual. It is the responsibility

of the user to dispose of ALL materials in a manner in accordance with all federal, s ta te an d lo ca l

regulations. ALL RETURNED UNITS MUST BE DECONTAMINATED AND FREE O F

RADIOACTIVITY AND SHOULD BE ACCOMPANIED WITH A DECONTAMINATION FORM. PLEASE

CONTACT THERMO TO HAVE THIS FORM FAXED TO YOU!

Under no circumstances shall Thermo be liable for damages due to the improper handling or

use of its products. Thermo assumes no liability, express or implied, for your use of this

equipment.

* This is an example of volume range and tube capacities, please see page 6 for other tubes and capacities available.

11

Page 15

A

APPENDIX 1

Additional SPD 131 DDA System Set-ups

*Vacuum Tubing Carrying Vapors From

SPD131 DDA to RVT405DDA

*Vacuum tubing MUST be connected so that

there is no dips or bends that will collect

condensed DMSO.

SpeedVac® Concentrator

SPD131DDA

(Back view of Concentrator)

NT100

Exhaust recovery

post trap

UVS800DDA

Universal Vacuum Source

*Vacuum Tubing Carrying Vapors From

SPD131 DDA to RVT405DDA

*Vacuum tubing MUST be connected so that

there is no dips or bends that will collect condensed DMSO.

________________

SpeedVac® Concentrator

SPD131DDA

(Back view of Concentrator)

SEMI-INTEGRATED SYSTEM-HVSU131 DDA

Vacuum Tubing

From SPD131 DDA to

Vacuum Tubing From RVT405DD

to the RVT4104 Cold Trap

A

VLP80

Vacuum Tubing

From RVT4104 to

SPD131DD

A

COMPONENT HIGH VACUUM SYSTEM-HVS131 DDA

12

Page 16

APPENDIX 2

Additional SPD 131 DDA System Set-ups for DMSO Applications

SpeedVac® Concentrator

SPD131DDA

(Back view of Concentrator)

*Vacuum Tubing Carrying Vapors

From SPD131 DDA to RVT405DDA

*Vacuum tubing MUST be connected so

that there is no dips or bends that will

collect condensed DMSO.

SPD131DDA

RVT405DDA RVT4104

Vacuum Tubing From RVT405DDA

to the RVT4104 Cold Trap

Vacuum Tubing

Vacuum Tubing OFP400

From RVT4104 to

SPD131DDA

OFP400

From SPD131 DDA to

LOW VACUUM SYSTEM-LVS131 DDA

13

12

Page 17

APPENDIX 3

RS232 Port Specifications

Baud Rate: 9600

Parity : None

Bits: 8

Stop Bit: 1

Data Format:

*ALL X’s are numerals from 0-9.

X X__

repeats

The first field (XX) indicates temperature in

supplied.

The second field (X.XX) indicates heater time, hours.minutes. The display “C.CC” denotes a

continuous heat run. The display “E.nd” denotes the end of the heat run

The third field (X.XX) indicates run time, hours.minutes. The display “E.nd” denotes the end

of the run.

The fourth field indicates vacuum in torr units. If the vacuum is less than 1 torr, the format is

.XXX. If it is greater than 1 torr, the format is XX.X

For example:

56__

repeats)

This represents a temperature of 56

of 3 hours and 59 minutes and vacuum level of 15.8 torr.

(space) _X.XX(space) X.XX (space) __ XX.X(space) sequence

(space) _3.30 (space) __3.59 ________(space) 15.8 (space) (sequence

°C. The display “no” denotes no heat being

°C, a heater time of 3 hours and 30 minutes, a run time

Page 18

WEEE Compliance

WEEE Compliance. This product is required to comply with the European

Union’s Waste Electrical & Electronic Equipment (WEEE) Directive 2002/96EC.

It is marked with the following symbol. Thermo Fisher Scientific has contracted

with one or more recycling/disposal companies in each EU Member State, and this

product should be disposed of or recycled through them. Further information on

our compliance with these Directives, the recyclers in your country, and

information on Thermo Scientific products which may assist the detection of

substances subject to the RoHS Directive are available at www.thermo.com/

WEEE Konformittät. Dieses Produkt muss die EU Waste Electrical & Electronic

Equipment (WEEE) Richtlinie 2002/96EC erfüllen. Das Produkt ist durch

folgendes Symbol gekennzeichnet. Thermo Fisher Scientific hat Vereinbarungen

getroffen mit Verwertungs-/Entsorgungsanlagen in allen EU-Mitgliederstaaten

und dieses Produkt muss durch diese Firmen widerverwetet oder entsorgt werden.

Mehr Informationen über die Einhaltung dieser Anweisungen durch Thermo

Scientific, dieVerwerter und Hinweise die Ihnen nützlich sein können, die Thermo

Fisher Scientific Produkte zu identizfizieren, die unter diese RoHS.

Anweisungfallen, finden Sie unter www.thermo.com/

Great Britain

Deutschland

Conformità WEEE. Questo prodotto deve rispondere alla direttiva dell’ Unione

Europea 2002/96EC in merito ai Rifiuti degli Apparecchi Elettrici ed Elettronici

(WEEE). È marcato col seguente simbolo.Thermo Fischer Scientific ha stipulato

contratti con una o diverse società di riciclaggio/smaltimento in ognuno degli Stati

Membri Europei. Questo prodotto verrà smaltito o riciclato tramite queste

medesime. Ulteriori informazioni sulla conformità di Thermo Fisher Scientific con

queste Direttive, l’elenco delle ditte di riciclaggio nel Vostro paese e informazioni

sui prodotti Thermo Scientific che possono essere utili alla rilevazione di sostanze

soggette alla Direttiva RoHS sono disponibili sul sito www.thermo.com/

Conformité WEEE. Ce produit doit être conforme à la directive euro-péenne

(2002/96EC) des Déchets d’Equipements Electriques et Electroniques (DEEE). Il

est marqué par le symbole suivant. Thermo Fisher Scientific s’est associé avec une

ou plusieurs compagnies de recyclage dans chaque état membre de l’union

européenne et ce produit devraitêtre collecté ou recyclé par celles-ci. Davantage

d’informations sur laconformité de Thermo Fisher Scientific à ces directives, les

recycleurs dans votre pays et les informations sur les produits Thermo Fisher

Scientific qui peuvent aider le détection des substances sujettes à la directive

RoHS sont disponibles sur www.thermo.com/

Italia

France

Page 19

Important

For your future reference and when contacting the factory, please have the

following information readily available:

Model Number:

Serial Number:

Date Purchased:

The above information can be found on the dataplate attached to the

equipment. If available, please provide the date purchased, the source of

purchase (manufacturer or specific agent/rep organization), and purchase

order number.

IF YOU NEED ASSISTANCE:

SALES DIVISION

Phone: 1-866-984-3766

1-866-9-THERMO

LABORATORY PARTS and SERVICE

Phone: 1-800-438-4851

TECHNICAL SUPPORT

Phone: 1-800-438-4851

Page 20

Thermo Fisher Scientific Inc.

275 Aiken Road

Asheville, NC 28804

United States

www.thermofisher.com

197-3003-00 Rev G

Loading...

Loading...