Page 1

Xcalibur

Ion Trap Series

Hardware Manual

120425-00HW Revision B November 30, 2009

Page 2

© 2009 Thermo Fisher Scientific Inc. All rights reserved. Xcalibur™, DSQ, DSQ II, TRACE DSQ, TRACE

GC, TRACE GC Ultra, FOCUS GC, PolarisQ, and ITQ are trademarks and/or product names of Thermo

Fisher Scientific. Microsoft® is a registered trademark of Microsoft. Adobe® is a registered trademark of Adobe

Systems Incorporated in the United States and/or other countries. Septum BTO® is a registered trademark of

Chromatography Research Supplies, Inc. Swagelok® is a registered trademark of Swagelok Company. ETP is an

SGE product. All other trademarks are the property of Thermo Fisher Scientific and its subsidiaries.

Ion Trap series refers to ITQ and PolarisQ instruments. DSQ series refers to all DSQ and DSQ II instruments.

Information about the TRACE GC and FOCUS GC instruments is included in this document.

NSTRUMENT USAGE: Thermo Scientific systems operate safely and reliably under carefully controlled

I

environmental conditions. If the equipment is used in a manner not specified by the manufacturer, the

protections provided by the equipment may be impaired. If you maintain a system outside the specifications

listed in this guide, failures of many types may occur. The repair of such failures is specifically excluded from

the standard Warranty and service contract coverage.

Thermo Fisher Scientific Inc. provides this document to its customers with a product purchase to use in the

product operation. This document is copyright protected and any reproduction of the whole or any part of this

document is strictly prohibited, except with the written authorization of Thermo Fisher Scientific Inc.

The contents of this document are subject to change without notice. All technical information in this

document is for reference purposes only. System configurations and specifications in this document supersede

all previous information received by the purchaser.

Thermo Fisher Scientific Inc. makes no representations that this document is complete, accurate or errorfree and assumes no responsibility and will not be liable for any errors, omissions, damage or loss that might

result from any use of this document, even if the information in the document is followed properly.

This document is not part of any sales contract between Thermo Fisher Scientific Inc. and a purchaser. This

document shall in no way govern or modify any Terms and Conditions of Sale, which Terms and Conditions of

Sale shall govern all conflicting information between the two documents.

Release history: Rev A, April 29, 2008, Rev B, November 30, 2009.

For Research Use Only. Not regulated for medical or veterinary diagnostic use by U.S. Federal Drug

Administration or other competent authorities.

Page 3

Reader’s Survey

Ion Trap Series Hardware Manual, 120425-00HW, Revision B

Free gift for your returned Reader’s Survey. Please help us improve the quality of our documentation by completing

and returning this survey. Circle one number for each statement:

fold

fold

Strongly

Agree

Agree Neutral Disagree

Strongly

Disagree

The manual is well organized. 12345

The manual is clearly written. 12345

The manual contains all the information I need.12345

The instructions are easy to follow. 12345

The instructions are complete. 12345

The technical information is easy to

understand.

12345

Examples of operation are clear and useful.12345

The figures are helpful. 12345

I was able to operate the system using this

manual.

12345

If not, please comment below. Attach additional sheets if necessary.

__________________________________________________________ __________________________________________________________________

__________________________________________________________ __________________________________________________________________

__________________________________________________________ __________________________________________________________________

__________________________________________________________ __________________________________________________________________

__________________________________________________________ __________________________________________________________________

__________________________________________________________ __________________________________________________________________

__________________________________________________________ __________________________________________________________________

__________________________________________________________ __________________________________________________________________

__________________________________________________________ __________________________________________________________________

__________________________________________________________ __________________________________________________________________

Customer Registration Card

Register now…and receive all the privileges associated with being a Thermo Fisher Scientific product user including customer

support, application reports, and technical reports.

MY ORGANIZATION IS: (Check only one) MY PRIMARY APPLICATION IS: (Check only one)

❏ Commercial (for profit) lab ❏ Analytical

❏ Government lab ❏ Biomedical

❏ Hospital/Clinic ❏ Clinical/Toxicology

❏ Industrial lab ❏ Energy

❏ Research Institute ❏ Environmental

❏ University/College ❏ Food/Agricultural

❏ Veterinary ❏ Forensic/Toxicology

❏ Other______________________ ❏ Pharmaceutical

❏ Research/Education

MY PRIMARY JOB FUNCTION IS: (Check only one)

❏ Administration

❏ Lab management

❏ Operator

❏ Other______________________

❏ Other______________________

Name __________________________________________________Title__________________________________________________________________

Company __________________________________________________ __________________________________________________________________

Address ___________________________________________________ __________________________________________________________________

City/State _________________ ________________________Postal Code____ ______________________________________________________________

Country ___________________________________________________ __________________________________________________________________

Telephone_______________________________________________ Ext. __________________________________________________________________

Serial Number __________________________________ Date purchased __________________________________________________________________

Fold and mail or email to: techpubsaustin@thermofisher.com

Page 4

Page 5

Regulatory Compliance

Thermo Fisher Scientific performs complete testing and evaluation of its products to ensure full compliance with

applicable domestic and international regulations. When the system is delivered to you, it meets all pertinent

electromagnetic compatibility (EMC) and safety standards as described below.

EMC Directive 89/336/EEC

EMC compliance has been evaluated by Professional Testing.

• PolarisQ, ITQ, and Ion Trap Series standards: EMC EN 55011:1998 + EN 50082-1:1998,

Safety EN 61010-1:1990 + A1:1992 + A2:1995

• DSQ standards: EMC EN 61326-1:1998 + A1:1998. Safety EN 61010-1:1990 + A1:1992 + A2:1995

• DSQ II standards: EMC EN 61326-1:1997 + A1:1998 + A2:2001. Safety EN 61010-1:2001

• Direct Probe Controller (DPC) standards: EMC EN 55011:1991 + EN 50082-1:1992. Safety EN 61010-1:1994

Low Voltage Safety Compliance

This device complies with Low Voltage Directive 73/23/EEC and harmonized standard EN 61010-1:2001. Changes

that you make to your system may void compliance with one or more of these EMC and safety standards. Changes to

your system include replacing a part or adding components, options, or peripherals not specifically authorized and

qualified by Thermo Fisher Scientific. To ensure continued compliance with EMC and safety standards, replacement

parts and additional components, options, and peripherals must be ordered from Thermo Fisher Scientific or one of its

authorized representatives.

FCC Compliance Statement

Certifications, FCC part 15, Class A

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates, uses,

and can radiate radio frequency energy. If it is not installed and used in accordance with the instruction

manual, it may cause harmful interference to radio communication. Operation of this equipment in a

residential area is likely to cause harmful interference. In this case, users will be required to correct the

interference at their own expense. Detailed installation requirements are in the respective instrument’s

preinstallation guide.

Page 6

WARNING Read and understand the various precautionary notes, signs, and symbols

contained inside this manual pertaining to the safe use and operation of this product

before using the device.

Notice on Lifting and Handling of Thermo Scientific Instruments

For your safety, and in compliance with international regulations, the physical handling of this Thermo Fisher Scientific

instrument requires a team effort to lift and/or move the instrument. This instrument is too heavy and/or bulky for one

person alone to handle safely.

Notice on the Proper Use of Thermo Scientific Instruments

In compliance with international regulations: Use of this instrument in a manner not specified by Thermo Fisher

Scientific could impair any protection provided by the instrument.

Notice on the Susceptibility to Electromagnetic Transmissions

Your instrument is designed to work in a controlled electromagnetic environment. Do not use radio frequency

transmitters, such as mobile phones, in close proximity to the instrument.

For manufacturing location, see the label on the instrument.

WEEE Compliance

This product is required to comply with the European Union’s Waste Electrical & Electronic Equipment (WEEE)

Directive 2002/96/EC. It is marked with the following symbol:

Thermo Fisher Scientific has contracted with one or more recycling or disposal companies in each European Union

(EU) Member State, and these companies should dispose of or recycle this product. See www.thermo.com/

Page 7

WEEERoHS for further information on Thermo Fisher Scientific’s compliance with these Directives and the recyclers

in your country.

WEEE Konformität

Dieses Produkt muss die EU Waste Electrical & Electronic Equipment (WEEE) Richtlinie 2002/96/EC erfüllen. Das

Produkt ist durch folgendes Symbol gekennzeichnet:

Thermo Fisher Scientific hat Vereinbarungen mit Verwertungs-/Entsorgungsfirmen in allen EU-Mitgliedsstaaten

getroffen, damit dieses Produkt durch diese Firmen wiederverwertet oder entsorgt werden kann. Mehr Information

über die Einhaltung dieser Anweisungen durch Thermo Fisher Scientific, über die Verwerter, und weitere Hinweise, die

nützlich sind, um die Produkte zu identifizieren, die unter diese RoHS Anweisung fallen, finden sie unter

www.thermo.com/WEEERoHS

.

Conformité DEEE

Ce produit doit être conforme à la directive européenne (2002/96/EC) des Déchets d'Equipements Electriques et

Electroniques (DEEE). Il est marqué par le symbole suivant:

Thermo Fisher Scientific s'est associé avec une ou plusieurs compagnies de recyclage dans chaque état membre de

l’union européenne et ce produit devrait être collecté ou recyclé par celles-ci. Davantage d'informations sur la

conformité de Thermo Fisher Scientific à ces directives, les recycleurs dans votre pays et les informations sur les produits

Thermo Fisher Scientific qui peuvent aider la détection des substances sujettes à la directive RoHS sont disponibles sur

www.thermo.com/WEEERoHS

.

Page 8

Page 9

Contents

C

Reader’s Survey . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Customer Registration Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiii

About Your System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiii

Power Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiv

Safety Alerts and Special Notices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiv

Safety Symbols and Signal Words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Contacting Us . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xvi

To contact Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xvi

To contact Customer Service for ordering information . . . . . . . . . . . . . . . . .xvi

To suggest changes to documentation or to Instrument Help . . . . . . . . . . . .xvi

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

Chapter 1 Routine Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Installing a GC Column . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Removing a GC Column . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Starting Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Shutting Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter 2 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Main Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Recommended Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Removing the Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Assembling the Ion Source and Ion Trap. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Cleaning Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Cleaning the Ion Source Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Cleaning the Ion Trap. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Maintaining the Ion Detector System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Maintaining a High-Vacuum Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Maintaining a Rotary-Vane Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Finding Components and Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Replacing the Analog PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Replacing a Fuse on the Analog PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Balun PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Replacing the Calibration Gas Flow Module. . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Thermo Scientific Ion Trap Series Hardware Manual ix

Page 10

Contents

Adding Calibration Compound. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Replacing the CI Reagent Gas Flow Module . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Replacing the Conversion Dynode/Electron Multiplier Power Supply . . . . . . . 88

Replacing the Convectron Gauge and Foreline Adapter . . . . . . . . . . . . . . . . . . 90

Replacing the Digital PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Replacing the Electrometer PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Replacing the Variable Damping Gas Regulator . . . . . . . . . . . . . . . . . . . . . . . . 95

Replacing the Damping Gas Flow Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Replacing the Ion Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Replacing the Lens Interface PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Replacing the Low Pass Filter PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Replacing the Power Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Replacing the Rear Cooling Fans. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Replacing the RF Detector PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Replacing the RF Generator PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Replacing a Fuse on the RF Generator PCB . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Replacing the Transfer Line. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Replacing the Turbomolecular Pump Power Supply . . . . . . . . . . . . . . . . . . . . 117

Replacing the Vacuum Control PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Replacing the Vent Valve Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Chapter 3 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Running Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Communication Symptoms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Contamination Symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Filament and Lens Control Symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Heated Zone Symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

High Vacuum Symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Linearity Symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Power Supply Symptoms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

RF Control Symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Sensitivity Symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Stability Symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Tuning Symptoms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Chapter 4 Vacuum System and Gas Inlets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .153

Vacuum System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Convectron Gauge and Foreline Adapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

High Vacuum Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Turbomolecular Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Ion Gauge (Upgrade Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Rotary-Vane Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Expansion Volume (Upgrade Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .160

Vacuum Manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

x Ion Trap Series Hardware Manual Thermo Scientific

Page 11

Contents

Gas Inlets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Calibration Gas Flow Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

CI Reagent Gas Flow Module (Upgrade Option) . . . . . . . . . . . . . . . . . . . . . . 164

Damping Gas Flow Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Vent Valve Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Chapter 5 Ion Source Components and Inlet Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .167

Ion Source Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Filament Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Ion Source Block Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Ion Volume Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Ion Source Lenses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Magnets and Magnet Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Inlet Valve (Upgrade Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Ball Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Guide Bar Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

I/R Tool and Guide Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Inlet Valve Plug. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Inlet Valve Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Chapter 6 Ion Trap System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .183

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Chapter 7 Ion Detector Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .187

Electron Multiplier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Appendix A Replaceable Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .191

Vacuum Manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Analyzer Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Ion Source. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Ion Source Lenses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Ion Trap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Gas Inlets and Gauges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

PCBs and Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Turbomolecular Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Inlet Valve (Upgrade Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Installation Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Miscellaneous Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Appendix B Functional Block Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .221

Vacuum System and Gas Inlets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Electronic Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Power Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Thermo Scientific Ion Trap Series Hardware Manual xi

Page 12

Contents

Abbreviations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .227

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .231

xii Ion Trap Series Hardware Manual Thermo Scientific

Page 13

Preface

This guide contains instructions to operate and maintain the instrument. It is also designed to

increase understanding and knowledge of the mass spectrometer assembly and theory of

operations.

About Your System

Thermo Fisher Scientific systems provide the highest caliber gas chromatography/mass

spectrometry (GC/MS) instrumentation available on today’s market.

P

GC/MS represents a combination of two powerful analytical techniques: GC, which acts as a

separation technique and MS, which acts as a detection technique. Complex mixtures of

individual compounds can be injected into the GC, either manually or through the use of an

optional autosampler, and then separated for presentation to the MS. The MS will then

generate a mass spectrum of the GC eluent and its components, which can be used for

qualitative identification as well as accurate and precise quantification of the individual

compounds present in the sample.

IMPORTANT Thermo Fisher Scientific systems are designed to optimize both the

separation and detection capabilities of GC/MS techniques and combine them in a

synergistic fashion to provide high performance analytical capabilities for both research

and routine applications. More information on the use of this system can be found in

related documentation sources and through the provided contact information.

WARNING Thermo Fisher Scientific systems operate safely and reliably under carefully

controlled environmental conditions. If the equipment is used in manner not specified by

the manufacturer, the protections provided by the equipment may be impaired. If you

maintain a system outside the specifications listed in this guide, failures of many types,

including personal injury or death, may occur. The repair of instrument failures caused by

operation in a manner not specified by the manufacturer is specifically excluded from the

Standard Warranty and service contract coverage.

Thermo Scientific Ion Trap Series Hardware Manual xiii

Page 14

Preface

Power Ratings

Power Ratings

Mass Spectrometer (MS)

• 120 V ac +6/-10%, 50/60 Hz, 15 A max

• 230 V ac ±10%, 50/60 Hz, 10 A max

Gas Chromatograph (GC)

• 120 V ac +6%/-10%, 50/60 Hz, 16 A max

• 230 V ac ±10%, 50/60 Hz, 16 A max

Detailed instrument specifications are in the Product Specification or Product Brochure.

Safety Alerts and Special Notices

Make sure you follow the precautionary notices presented in this guide. Safety and other

special notices appear in boxes and include the following:

WARNING A warning safety alert is used to prevent actions that could cause personal

injury. It highlights hazards to humans or the environment. When you see a safety alert on

your instrument or in the documentation, carefully follow the safety instructions before

proceeding.

CAUTION A cautionary safety alert is used to prevent actions that may cause personal

injury or instrument damage. We use it to highlight information necessary to prevent

personal injury or damage to software, loss of data, or invalid test results; or might contain

information that is critical for optimal system performance. When you see a safety alert on

your instrument or in the documentation, carefully follow the safety instructions before

proceeding.

IMPORTANT Highlights information necessary to prevent damage to software, loss of

data, or invalid test results; or might contain information that is critical for optimal

performance of the system.

Note Emphaizes important information about a task.

Tip Helpful information that can make a task easier.

xiv Ion Trap Series Hardware Manual Thermo Scientific

Page 15

Safety Symbols and Signal Words

All safety symbols are followed by WARNING or CAUTION, which indicates the degree of risk

for personal injury and/or instrument damage. Cautions and warnings are following by a

descriptor, such as BURN HAZARD. A WARNING is intended to prevent improper actions that

could cause personal injury. Whereas, a CAUTION in intended to prevent improper actions

that may cause personal injury and/or instrument damage. The following safety symbols may

be found on your instrument and/or in this guide:

BURN HAZARD. This symbol indicates a hot surface that could or may cause

burn injuries.

ELECTRICAL SHOCK HAZARD. This symbol indicates that an electrical shock

could or may occur.

FIRE HAZARD. This symbol indicates a risk of fire or flammability, or that

fire/flammability damage could or may occur.

FLAMMABLE GAS HAZARD. This symbol alerts you to gases that are

compressed, liquefied or dissolved under pressure and can ignite on contact

with an ignition source. This symbol indicates this risk could or may cause

physical injury.

GLOVES REQUIRED. This symbol indicates that you must wear gloves when

performing a task or else physical injury could or may occur.

HAND AND CHEMICAL HAZARD. This symbol indicates that chemical

damage or physical injury could or may occur.

INSTRUMENT DAMAGE. This symbol indicates that damage to the

instrument or module may occur. This damage may not be covered under the

standard warranty.

LIFTING HAZARD. This symbol indicates two or more people are required to

lift the object to prevent a physical injury that could or may occur.

MATERIAL AND EYE HAZARD. This symbol indicates that eye damage could

or may occur.

RADIOACTIVE. This symbol indicates the presence of radioactive material

could or may occur.

READ MANUAL. This symbol alerts you to carefully read your instrument’s

operational instructions before usage to ensure your safety and the

instrument’s operational ability. Failing to carefully read the instructions could

or may put you at risk for a physical injury.

Preface

Safety Alerts and Special Notices

TOXIC SUBSTANCES HAZARD. This symbol indicates that exposure to a

toxic substance will, could, or may cause personal injury or death.

This is the general warning symbol that the ISO 3864-2 standard refers to as

the general warning signal to prevent personal injury. It is a triangle with an

exclamation mark that precedes the WARNING safety alert word. In the

vocabulary of ANSI Z535 signage, this symbol indicates a possible personal

injury hazard exists if the instrument is improperly used or if unsafe actions

occur. We use this symbol and another appropriate safety symbol to alert to

an imminent or potential hazard that could cause personal injury.

Thermo Scientific Ion Trap Series Hardware Manual xv

Page 16

Preface

Contacting Us

Contacting Us

There are several ways to contact Thermo Fisher Scientific.

Y To contact Technical Support

Phone 800-532-4752

Fax 561-688-8736

E-mail US.Techsupport.Analyzer@thermofisher.com

Find software updates and utilities to download at http://mssupport.thermo.com.

Y To contact Customer Service for ordering information

Phone 800-532-4752

Fax 561-688-8731

Web site http://www.thermo.com/com/cda/resources/resources_

detail/1,,12512,00.html

Y To suggest changes to documentation or to Instrument Help

• Fill out a reader survey online at www.thermo.com/lcms-techpubs.

• Send an e-mail message to the Technical Publications Editor at

techpubsaustin@thermofisher.com.

Related Documentation

In addition to this guide, Thermo Scientific provides the following documents for the ITQ

Series. These documents are also available on a “Print-By-Request” basis.

Ion Trap Series Document Set, PN 120425-0ALL

• ITQ Preinstallation Guide, PN 120425-00PI

• Ion Trap Series Hardware Manual, PN 120425-00HW

• Ion Trap Series User’s Guide, PN 120425-USER

Instrument Help is available from within the software.

xvi Ion Trap Series Hardware Manual Thermo Scientific

Page 17

Routine Operations

This chapter describes how to use the Ion Trap Series mass spectrometer. This mass

spectrometer uses ion trap technology that gives analysts, technicians, and technical directors

a powerful tool for mass spectrometry and complete control when using the Xcalibur

software.

Contents

• “Installing a GC Column” on page 2

• “Removing a GC Column” on page 13

• “Starting Up” on page 14

1

• “Shutting Down” on page 16

Thermo Scientific Ion Trap Series Hardware Manual 1

Page 18

1

Routine Operations

Installing a GC Column

Installing a GC Column

To install a column, you will need:

• Capillary column, 5MS, 30 m, 0.25 mm i.d., 0.25 μm (PN A0012-08143), or similar

• Column measuring tool (PN 119640-0550), optional

• Gloves, clean, lint- and powder-free

• Injector ferrule, for 0.25 mm column (PN 290 134 88)

• Leak detector (Thermo Scientific GLD Pro PN 66002-001 or equivalent)

• Lint-free tissue

• Magnifying glass

• Methanol or other suitable solvent

• Scoring wafer (or sapphire scribe) to cut capillary column

• Transfer Line ferrule, 0.4 mm i.d. (PN A0101-18100)

• Wrench, open-ended, 5/16-in.

• Wrench, two, open-ended, 7/16-in.

• Wrench, open-ended, 6 mm

Refer to the documentation supplied with your GC for additional setup information.

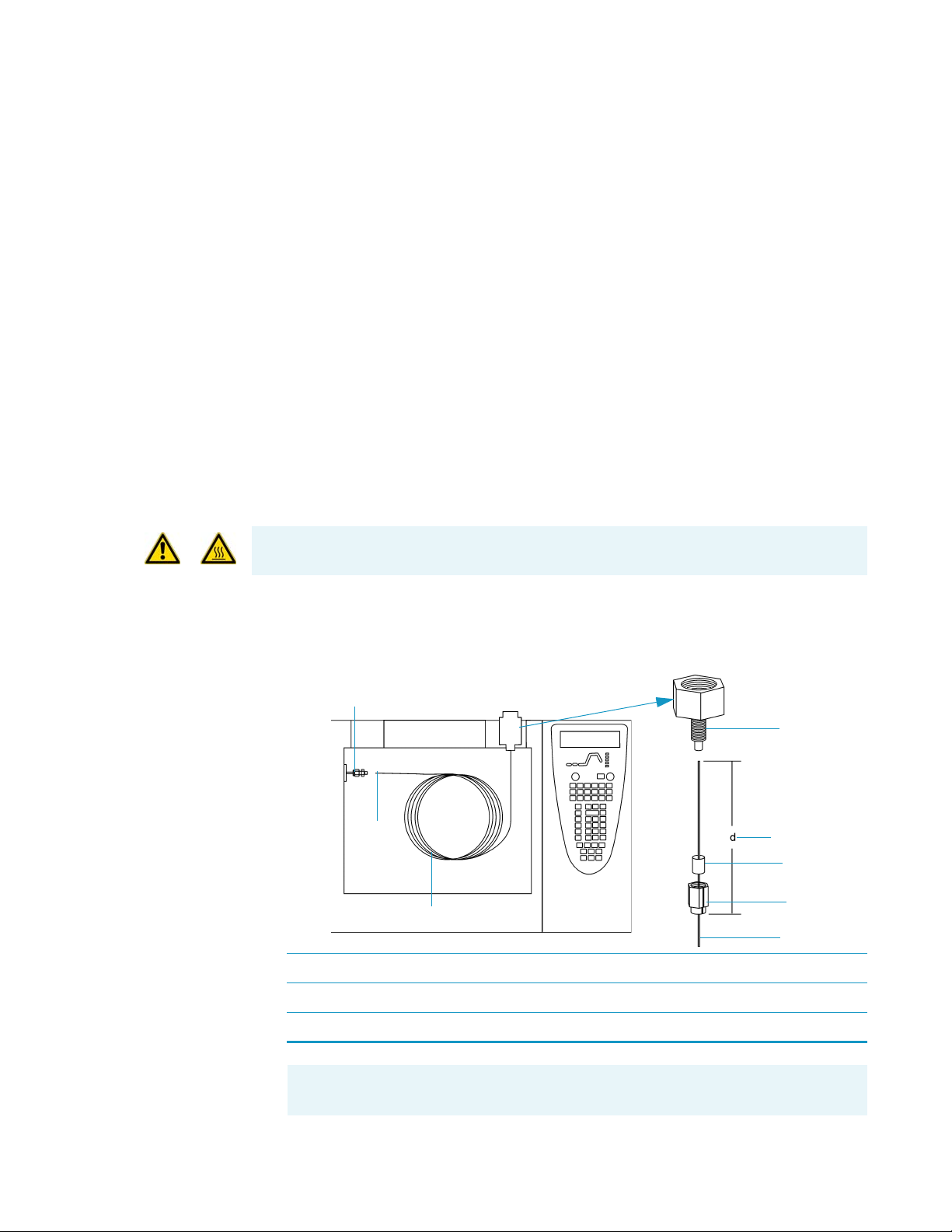

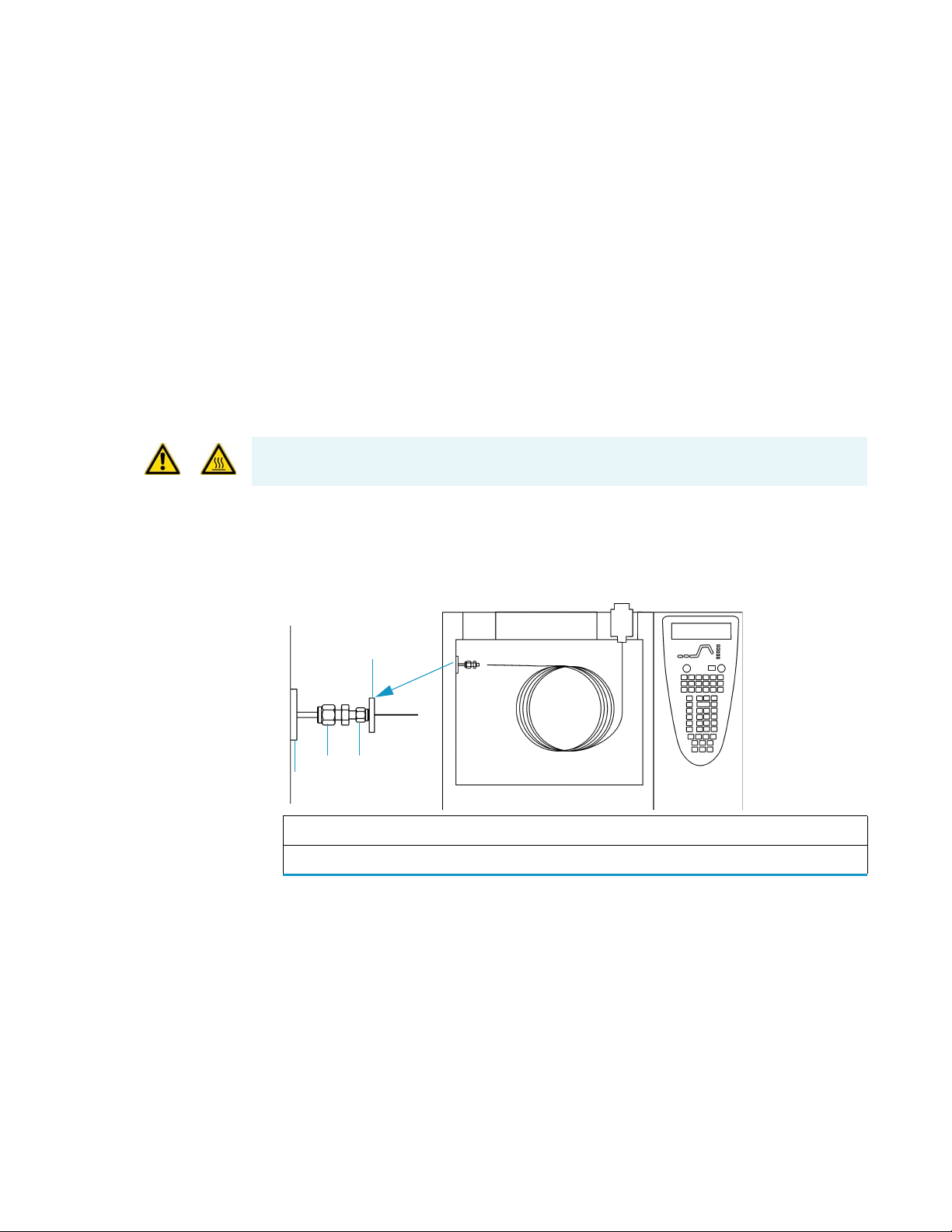

WARNING - BURN HAZARD. The injector, oven, and transfer line may be hot. Allow

them to cool to room temperature before touching them.

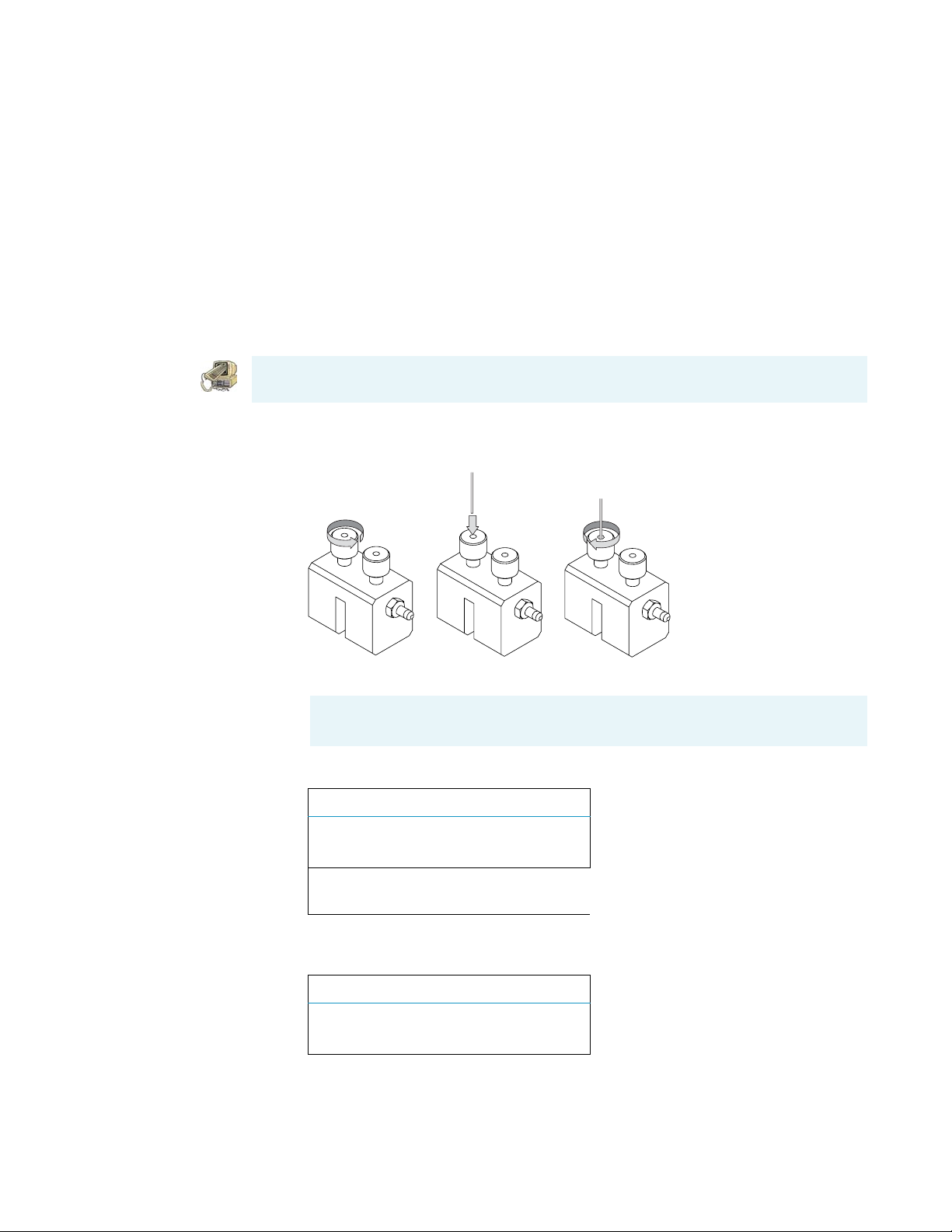

1. Connect the column to the injector, as shown in Figure 1.

Figure 1. GC Injector (Front)

6

1

5

4

Distance

2

3

4

1Injector 4Column

2Injector Ferrule 5Column Outlet

3 Injector Nut 6 Transfer Line

Note Wear clean, lint- and powder-free gloves when you handle the column and

injector ferrule.

2 Ion Trap Series Hardware Manual Thermo Scientific

Page 19

1

Routine Operations

Installing a GC Column

a. Unwind about half a turn of the column.

b. Wipe about 100 mm (4 in). of the column with a tissue soaked in methanol.

c. Insert the column through the injector nut and ferrule (open end up).

Note Sliding a septum on the column before the injector nut will help you

measure the proper distance between the nut and the end of the column.

d. Wipe the column again with a tissue soaked in methanol.

e. Score and then break the column about 2.5 cm (1 in). from the end with a scoring

wafer. With the magnifying glass, check for an even, flat cut. Repeat if necessary.

f. Insert the column into the injector so that the end of the column is the proper

distance from the back of the injector nut. Proper distances are as follows:

splitless = 64 mm, split = 40 mm, PTV = 30 mm.

g. Tighten the injector nut by hand and then turn it an additional quarter turn with the

wrench.

h. Turn on the gas chromatograph.

2. Set up the gas chromatograph.

a. Set the oven and injector temperatures to 40 °C.

b. Set the injector flow to 1.0 mL/min.

c. Turn off vacuum compensation (under the right or left carrier menu).

d. Dip the column outlet in a small vial of methanol. Bubbles indicate there is flow

through the column.

e. Allow the column

to purge for at least 10 minutes.

3. Perform column characterization.

a. Raise the oven and injector temperatures to 50 °C and allow them to stabilize. Then

confirm that the carrier gas is on.

CAUTION - INSTRUMENT DAMAGE. Do not allow the clear plastic component to

exceed 80 °C. Otherwise, it will melt and damage the instrument.

Thermo Scientific Ion Trap Series Hardware Manual 3

Page 20

1

Routine Operations

Installing a GC Column

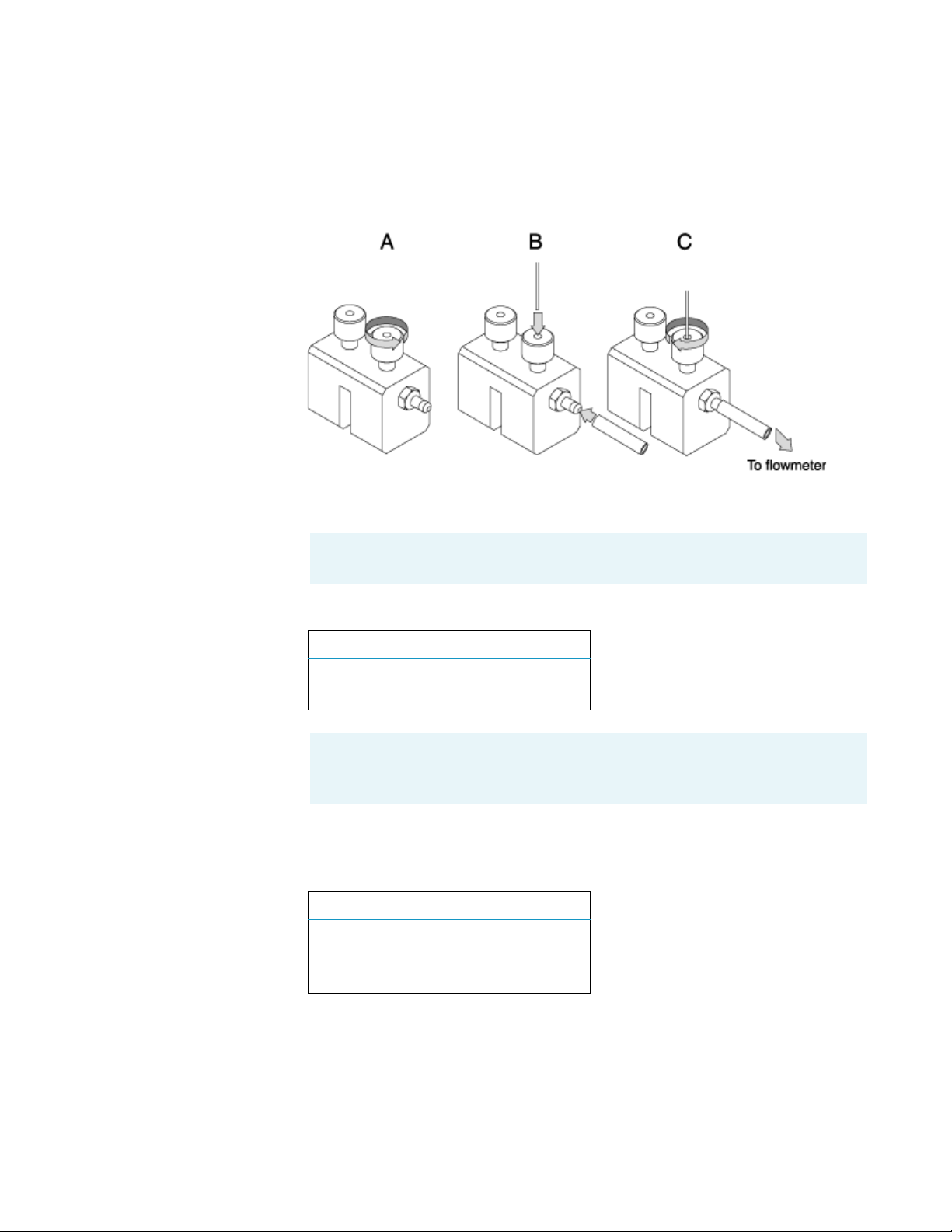

b. Carefully push the capillary column end into the flowmeter section of the

column-flow meter connector, as shown in Figure 2.

Figure 2. Flow Measure

c. Connect the flowmeter to the dedicated fitting on the column flow meter connector.

Note The available options (Right column or Left column) will differ depending

on the configuration of your GC.

d. Press Column Eval to open the following menu:

COLUMN INFORMATION

Right column

Left column <

Note Make sure the Vacuum Compensation parameter is set to OFF in the

Carrier menu, which is accessed by pressing the Left Carrier or Right Carrier

button. Otherwise an accurate column evaluation cannot be performed.

e. Scroll to the Right or Left column to evaluate and press Enter. The following menu

appears if you select the left column and and use the settings below to set the physical

characteristics of the column.

LEFT1 COLUMN INFO

Length (m) 15.00

ID (mm) 0.25

Film th. (um) 0.25

1. These settings could also apply to a right

column.

4 Ion Trap Series Hardware Manual Thermo Scientific

Page 21

1

Routine Operations

Installing a GC Column

f. Select Pre/post column? yes (Y) or no (N).

• If a pre-/post-column is not present, select N.

• If a pre-/post-column is present, select Y. You must set the length and nominal

internal diameter of the pre-/post-column in the same valid ranges for the

column. The following two lines are added to the menu.

Pre/post column? Y

P/p col. L 10.00

P/p col. ID 0.530

g. According to the physical characteristics of the column, the system calculates and

displays the relevant Column K-factor.

1

LEFT

COLUMN INFO

Column K= (0.8087)

Calc’d ID (0.0000)

Run Column eval?

1. These settings could also apply to a right

column.

h. To evaluate the column, scroll to Run column eval.? and press ENTER.

The system will set the Column K factor by pressurizing the column to obtain a

nominal carrier flow of 5 mL/min. The display shows the pressure.

i. Using the flowmeter, measure the carrier gas flow at the outlet of the column. Scroll

to Measured Flow and set the value of the flow.

EVALUATING L COLUMN

Pressure (162)

Measured Flow: 4.90

Use <STOP> to abort

Note To abort column evaluation, you can press STOP.

j. The following message will display if the operation was successful.

L. COL. EVALUATION

COMPLETED

Calc’d ID 0.242

K. 0.9020

Thermo Scientific Ion Trap Series Hardware Manual 5

Page 22

1

Routine Operations

Installing a GC Column

k. Expect a K-factor of about 0.7 – 0.9 for a 15 m, 0.25 mm i.d. column (1.3 – 2.0 for

a 30 m, 0.25 mm i.d. column). If the column does not report a K-factor within this

range or within 0.1 units of the previous stored value, check for a leak or broken

column using the leak detector. The K-factor is a measured resistance for the column.

A K-factor that is too low may indicate a leak in the system, while a K-factor that is

too high may indicate a blockage.

4. Perform a column leak check.

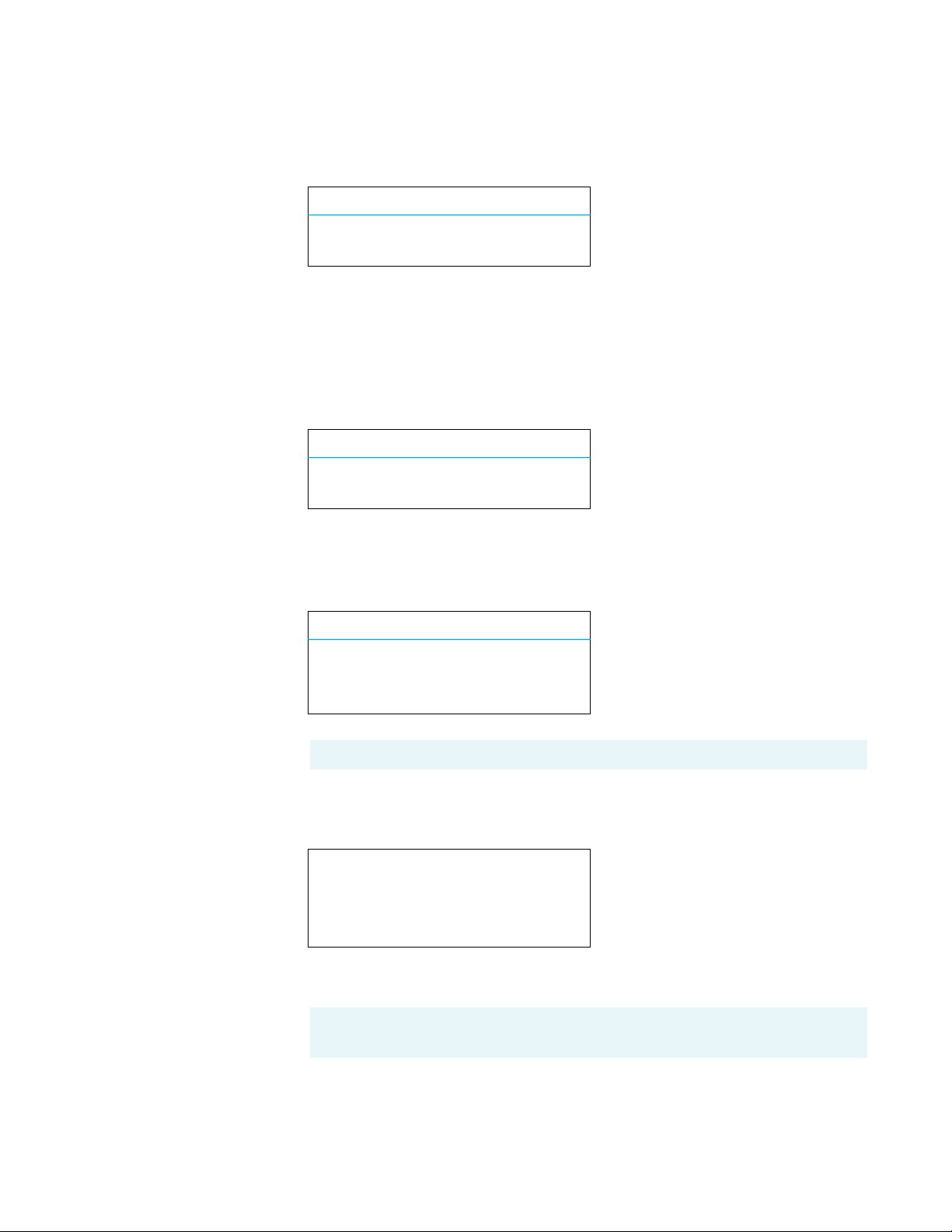

a. Carefully push the capillary column end into the column section of the column-flow

meter connector, as shown in Figure 3.

CAUTION - INSTRUMENT DAMAGE. Do not allow the clear plastic component to

exceed 80 °C. Otherwise, it will melt and damage the instrument.

Figure 3. Leak Check

A B C

b. Press Leak Check to access the Leak Check Columns menu.

Note The available options (Right column or Left column) will differ depending

on the configuration of your GC.

LEAK CHECK COLUMN

Right column

Left column <

1. This item appears if the relevant channel is

present and configured.

c. Scroll to a channel to open the left or right column’s leak check menu.

L. COL. LEAK CHECK

Start Leak Check

Leak Check Settings

6 Ion Trap Series Hardware Manual Thermo Scientific

Page 23

1

Routine Operations

Installing a GC Column

d. Scroll to Leak Check Settings.

L. COL. SETT.

Check Leak press 200

Sensitivity 5.0

e. In the Check at press line, set the pressure at which the leak check will be performed.

The value must be between 10 and 999 kPa (1.45 and 145 psi).

f. In the Sensitivity line, set the maximum pressure drop that is allowed during the test.

The value must be between 1 and 10 kPa (0.145 and 1.45 psi).

g. Press CLEAR to exit the Leak Check Settings menu and return to the previous menu.

L. COL. LEAK CHECK

Start leak check

Leak Check settings

h. Select Start leak check to begin operation. The split and purge valves of the selected

channel are automatically closed and the channel is pressurized with carrier gas to the

leak check set point.

CHECKING L COLUMN

Pressure (200)

Elapsed time 0.90

Use <STOP> to abort

Note To abort a leak check, you can press STOP.

i. The system monitors the pressure for one minute. If the pressure does not drop more

than the maximum allowed sensitivity value, then the leak check will pass.

R/L.LEAK CHECK

COMPLETED

SUCCESSFULLY

Leak check passed.

If the leak check did not pass, you should use the leak detector to find and fix the

leaks.

Tip Leaks can be caused by not tightening the fitting on the clear plastic

component. We recommend that you check that fitting before looking elsewhere.

j. Repeat the column evaluation and leak check until no leaks are indicated.

Thermo Scientific Ion Trap Series Hardware Manual 7

Page 24

1

Routine Operations

Installing a GC Column

5. Disconnect the column from the clear plastic component.

6. Remove the clear plastic component, including its fittings, from the oven and set it aside.

7. Condition the column before inserting it into the mass spectrometer.

CAUTION INSTRUMENT DAMAGE. The material released from the column during the

conditioning (column bleed) will contaminate the ion source if the column is inserted

into the transfer line. The ion source must then be cleaned.

a. Raise the injector temperature to the desired temperature (normally 250 °C).

b. Run the slow temperature program that is recommended by the manufacturer. For

example, hold the column at 40 °C for 15 minutes, then ramp it to 10 °C per minute

up to 10 °C above the maximum temperature at which you will operate the column

(normally 300+10 °C = 310 °C). Hold the column at this temperature for two hours.

CAUTION INSTRUMENT DAMAGE. Never exceed the column manufacturer’s maximum

operating temperature.

8. Connect the column to the transfer line.

a. Shut down and vent the mass spectrometer, as described in “Shutting Down” on

page 16.

b. Lower the oven temperature to 40 °C and allow it to cool before continuing.

WARNING - BURN HAZARD. The injector, oven, and transfer line may be hot. Allow

them to cool to room temperature before touching them.

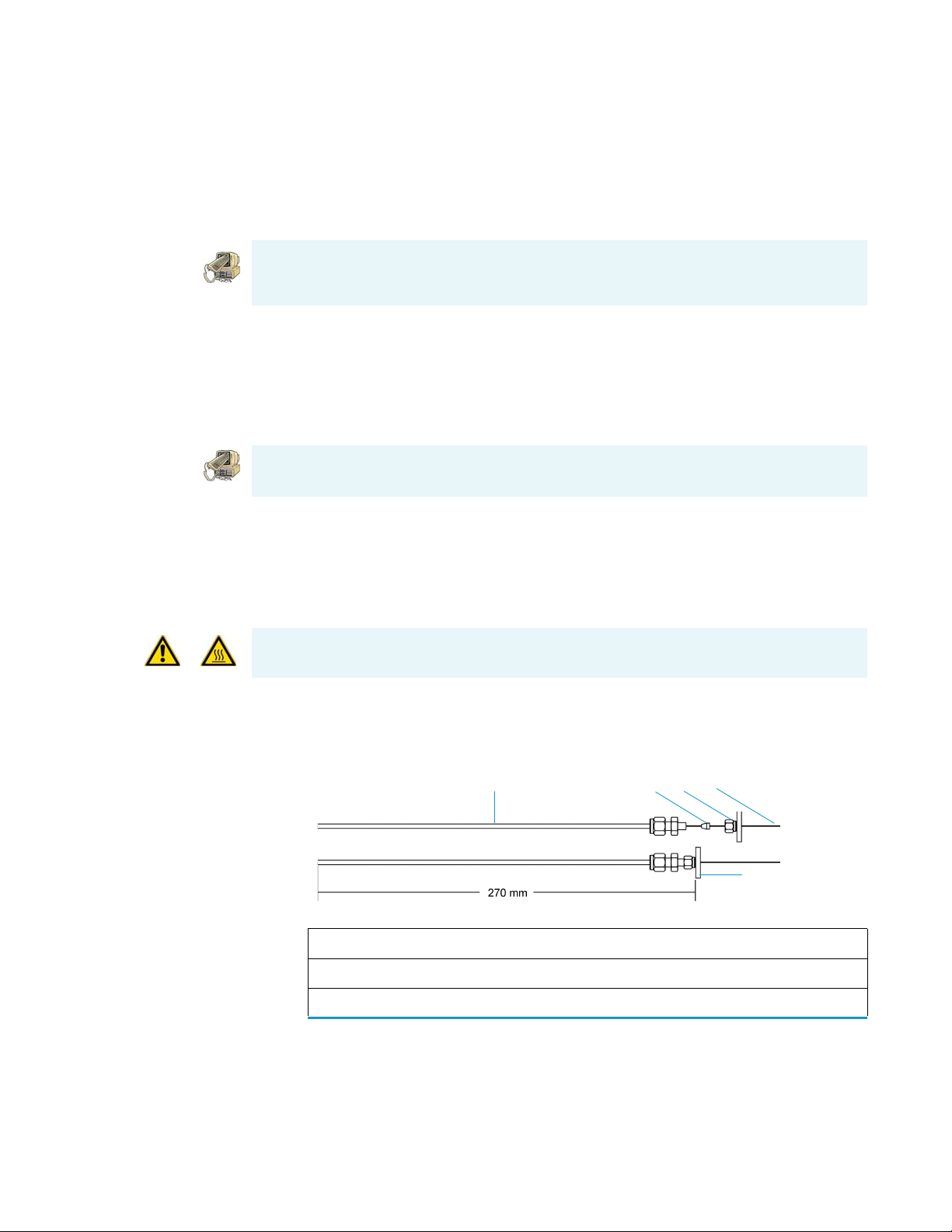

c. Unwind about one turn of the column (shown in Figure 4) from the column outlet

end.

Figure 4. Column Measuring Tool

1

3

2

4

5

1 Column Measuring Tool* 4 Column

2 Transfer Line Ferrule 5 Septum

3Transfer Line Nut

* The Column Measuring Tool is sold separately and can be purchased through

Thermo Fisher Scientific using part number 119640-0550.

8 Ion Trap Series Hardware Manual Thermo Scientific

Page 25

1

Routine Operations

Installing a GC Column

Note Wear clean, lint- and powder-free gloves when you handle the column and

transfer line ferrule.

d. Wipe about 300 mm (12 in). of the column with a tissue soaked in methanol.

e. Insert the column through the septum, transfer line nut, and ferrule. Wipe the

column again with a tissue soaked in methanol.

Note Sliding a septum on the column before the transfer line nut will help you

measure the proper distance between the nut and the end of the column. The

column should extend approximately 1–2 mm past the end of the transfer line.

f. Score and break the end of the column with a scoring wafer. With the magnifying

glass, check for an even, flat cut. Repeat, if necessary.

g. Insert the column into the transfer line using one of the following methods: Method

One, Method Two, or Method Three.

Method One

If you have a column measuring tool, follow these steps to insert the column:

1. Screw the transfer line nut onto the column measuring tool

1

.

2. Push the column past the end of the column measuring tool and score and break the end

of the column with a scoring wafer. With the magnifying glass, check for an even, flat cut.

Repeat if necessary.

3. Pull the column back so that it is flush with the end of the column measuring tool and

tighten the transfer line nut.

4. Slide the septum up to the back of the transfer line nut.

5. Remove the column, transfer line nut and ferrule from the column measuring tool, as

shown in Figure 5.

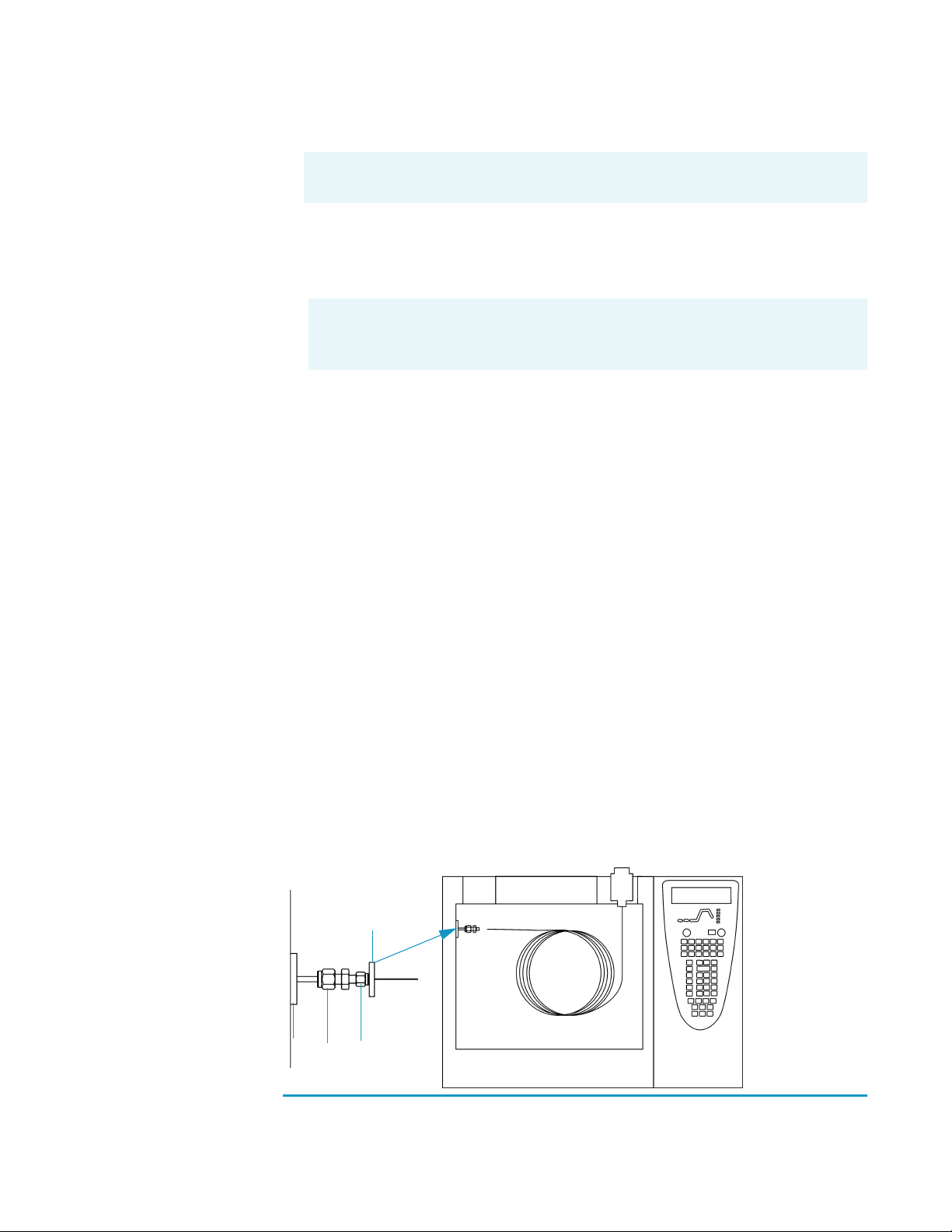

Figure 5. Transfer Line (Front)

1

2

3

4

1

Purchase the Column Measuring Tool PN 119640-0550 from Thermo Fisher Scientific.

Thermo Scientific Ion Trap Series Hardware Manual 9

Page 26

1

Routine Operations

Installing a GC Column

Figure 5. Transfer Line (Front)

1 Septum 5 Transfer Line Union

2 Transfer Line Nut 4 Transfer Line

a. Insert the column into the transfer line. Be careful not to move the septum.

b. Tighten the transfer line nut and the transfer line union.

6. Condition the transfer line ferrule. Graphite/vespel ferrules like the transfer line ferrule

require conditioning to ensure a leak-tight seal.

a. Raise the oven temperature to the maximum temperature you will operate the

column (normally 300 °C).

b. Wait 10 minutes.

c. Lower the oven temperature to 40 °C and allow it to cool before continuing.

WARNING - BURN HAZARD. The injector, oven, and transfer line may be hot. Allow

them to cool to room temperature before touching them.

Method Two

d. Re-tighten the transfer line nut and the transfer line union.

7. Set up the gas chromatograph.

a. Make sure the column does not have any sharp bends and that it does not touch any

metal objects or walls inside the oven.

b. Raise the oven temperature to the initial temperature you will use (normally 40 °C).

c. Turn on the vacuum compensation (under the right or left carrier menu).

If you have the optional inlet valve, follow these steps to insert the column:

Tip Slide a septum on the column before adding the transfer line nut to make it easier to

measure the proper distance between the nut and the end of the column. You can also use

a white marker to mark the position of the column and nut.

1. Remove the mass spectrometer front cover so you can get a better view of the column.

2. Using the I/R tool, remove the ion volume, as described in “Cleaning the Ion Source

Components” on page 37.

3. Insert the column into the transfer line and tighten the transfer line nut by hand.

4. Push the column in until you can see it through the inlet valve.

5. Pull the column back just far enough that you cannot see it.

6. Tighten the transfer line nut and transfer line union.

10 Ion Trap Series Hardware Manual Thermo Scientific

Page 27

1

Routine Operations

Installing a GC Column

7. Using the I/R tool, replace the ion volume, as described in “Cleaning the Ion Source

Components” on page 37.

8. Condition the transfer line ferrule. Graphite/vespel ferrules like the transfer line ferrule

require conditioning to ensure a leak-tight seal.

a. Raise the oven temperature to the maximum temperature you will operate the

column (normally 300 °C).

b. Wait 10 minutes.

c. Lower the oven temperature to 40 °C and allow it to cool before continuing.

WARNING - BURN HAZARD. The injector, oven, and transfer line may be hot. Allow

them to cool to room temperature before touching them.

d. Re-tighten the transfer line nut and the transfer line union.

9. Set up the gas chromatograph.

a. Make sure the column does not have any sharp bends and that it does not touch any

metal objects or walls inside the oven.

Method Three

b. Raise the oven temperature to the initial temperature you will use (normally 40 °C).

Note Turn on vacuum compensation (under the Right or Left Carrier menu).

If you do not have an inlet valve, follow these steps to insert the column:

1. Remove the front and top covers so you can get a better view of the column.

2. Remove the vacuum manifold cover, as described in “Removing the Vacuum Manifold

Cover” on page 28.

3. Remove the ion source assembly, as described in“Cleaning the Ion Source Components”

on page 37.

4. Adjust the column so that it extends 1–2 mm past the end of the transfer line.

5. Tighten the transfer line nut and transfer line union.

6. Condition the transfer line ferrule. Graphite/vespel ferrules like the transfer line ferrule

require conditioning to ensure a leak-tight seal.

a. Raise the oven temperature to the maximum temperature you will operate the

column (normally 300 °C).

b. Wait 10 minutes.

c. Lower the oven temperature to 40 °C and allow it to cool before continuing.

Thermo Scientific Ion Trap Series Hardware Manual 11

Page 28

1

Routine Operations

Installing a GC Column

WARNING - BURN HAZARD. The injector, oven, and transfer line may be hot. Allow

them to cool to room temperature before touching them.

d. Re-tighten the transfer line nut and the transfer line union.

7. Replace the ion source assembly, as described in “Cleaning the Ion Source Components”

on page 37.

8. Replace the vacuum manifold cover.

9. Replace the front and top covers.

10. Condition the transfer line ferrule. Graphite/vespel ferrules like the transfer line ferrule

require conditioning to ensure a leak-tight seal.

a. Raise the oven temperature to the maximum temperature you will operate the

column (normally 300 °C).

b. Wait 10 minutes.

c. Lower the oven temperature to 30 °C and allow it to cool before continuing.

WARNING - BURN HAZARD. The oven may be hot. Allow it to cool to room temperature

before opening it. The injector will still be hot, so do not touch it.

d. Re-tighten the transfer line nut and the transfer line union.

11. Set up the gas chromatograph.

a. Make sure the column does not have any sharp bends and that it does not touch any

metal objects or walls inside the oven.

b. Raise the oven temperature to the initial temperature you will use (normally 40 °C).

Note Turn on vacuum compensation (under the Right or Left Carrier menu).

12 Ion Trap Series Hardware Manual Thermo Scientific

Page 29

Removing a GC Column

To remove a GC column, you will need:

• Gloves, clean, lint- and powder-free

• Wrench, open-ended, 5/16-in.

• Wrench, open-ended, 7/16-in.

• Wrench, open-ended, 6 mm

1. Shut down the mass spectrometer.

a. Shut down and vent the mass spectrometer, as described in “Shutting Down” on

page 16.

b. Lower the oven, injector, and transfer line temperatures to 30 °C and allow them to

cool before continuing.

WARNING - BURN HAZARD. The injector, oven, and transfer line may be hot. Allow

them to cool to room temperature before touching them.

c. Once the oven, injector, and transfer line are cool, turn off the gas chromatograph.

1

Routine Operations

Removing a GC Column

2. Remove the column from the transfer line, as shown in Figure 6.

Figure 6. Transfer Line (Front)

1

2

3

4

1 Septum 3 Transfer Line Union

2 Transfer Line Nut 4 Transfer Line

a. Unscrew the transfer line nut.

b. Remove the column from the transfer line.

Thermo Scientific Ion Trap Series Hardware Manual 13

Page 30

1

Routine Operations

Starting Up

3. Remove the column from the injector, as shown in Figure 7.

Figure 7. Injector (Front)

6

5

1

Distance

2

3

Starting Up

4

4

1Injector 4Column

2 Injector Ferrule 5 Column Outlet

3 Injector Nut 6 Transfer Line

a. Unscrew the injector nut.

b. Remove the column from the injector.

1. Set up the mass spectrometer.

a. Install the GC column, as described in “Installing a GC Column” on page 2.

b. Verify that the gas chromatograph is on and there is carrier gas flowing through the

column into the mass spectrometer.

WARNING - INSTRUMENT DAMAGE. Damage may occur if you turn on the mass

spectrometer without column flow. This forces air to be drawn through the column. This

large air leak into the mass spectrometer may cause the ion source to require cleaning as

well as potentially damaging the column.

c. Plug in the mass spectrometer power cord.

14 Ion Trap Series Hardware Manual Thermo Scientific

Page 31

2. Turn on the mass spectrometer.

a. Switch the main circuit breaker (shown in Figure 8) to ON (I), which causes:

• The rotary-vane pump to power on

• The fore pressure to reach the proper operating pressure

• The turbomolecular pump to power on

Figure 8. Main Circuit Breaker (Rear)

1

Routine Operations

Starting Up

b. Set the transfer line to the desired operating temperature (normally 300 °C).

3. Start Xcalibur.

a. Check the heater status shown in the heater tab of the mass spectrometer status

window. If the ion source is not set to the desired temperature (normally 200 °C),

change it in Tune.

b. Check the vacuum status shown in the Vacuum tab of the mass spectrometer status

window. Within 10 minutes of powering on the detector, vacuum should read OK. If

it does not read OK, refer to “Troubleshooting” on page 123.

c. Allow the mass spectrometer to stabilize for at least 30 minutes before running

samples.

Thermo Scientific Ion Trap Series Hardware Manual 15

Page 32

1

Routine Operations

Shutting Down

Shutting Down

1. Cool the gas chromatograph.

Note If you do not plan to change the column or perform maintenance on the gas

chromatograph, you do not have to lower the injector temperature.

2. Lower the oven, injector, and transfer line temperatures to 30 °C.

3. Shut down the mass spectrometer.

a. From the Instrument Setup window, click Tune to display the Tune window.

b. Choose Instrument | Shutdown to start the automatic shutdown procedure:

• Tune Shut Down screen displays

• Calibration gas and CI reagent gas are turned off

• Voltages are turned off to the ion source, ion trap, and ion detector assembly

• Ion source heater turns off

• Turbomolecular pump turns off

• Tune waits ten minutes for the turbomolecular pump to slow down

• Tune waits for the ion source to cool to < 175

parts when they are exposed to air

4. Wait for the transfer line to cool below < 175

o

C to prevent oxidizing the hot

o

C

16 Ion Trap Series Hardware Manual Thermo Scientific

Page 33

1

Routine Operations

5. Turn off the mass spectrometer.

a. Look for a prompt indicating that it is safe to turn off the main power to the mass

spectrometer and then click OK.

b. Switch the main circuit breaker (shown in Figure 9) to OFF (0), which turns off the

rotary-vane pump. Approximately three seconds later, the vent valve opens and the

vacuum manifold vents to atmospheric pressure. This takes approximately three to

four minutes.

Figure 9. Main Circuit Breaker (Rear)

Shutting Down

c. Unplug the mass spectrometer power cord.

d. STOP HERE

if you are planning to perform system maintenance on only the mass

spectrometer (for example, to clean the ion source). You do not need to turn off the

gas chromatograph, data system and autosampler. In this case, the shutdown

procedure is complete.

6. Wait for the GC oven, injector, and transfer line to cool to room temperature.

7. Turn off all instruments.

a. Turn off the gas chromatograph using the GC main circuit breaker.

b. Turn off the GC helium supply at the tank.

c. Turn off the optional autosampler by using the main power On/Off switch.

Thermo Scientific Ion Trap Series Hardware Manual 17

Page 34

1

Routine Operations

Shutting Down

18 Ion Trap Series Hardware Manual Thermo Scientific

Page 35

Maintenance

This chapter describes how to maintain the essential components of the mass spectrometer.

Performing periodic maintenance increases laboratory productivity and helps you get the

most out of your instrument.

Contents

2

• “Main Components” on page 20

• “Recommended Maintenance Schedule” on page 21

• “Removing the Covers” on page 24

• “Removing the Vacuum Manifold Cover” on page 28

• “Assembling the Ion Source and Ion Trap” on page 30

• “Cleaning Parts” on page 32

• “Stainless Steel Parts” on page 33

• “Non-Stainless Steel or Hybrid Parts” on page 35

• “Cleaning the Ion Source Components” on page 37

• “Cleaning the Ion Trap” on page 61

• “Maintaining the Ion Detector System” on page 65

• “Maintaining a High-Vacuum Pump” on page 70

• “Maintaining a Rotary-Vane Pump” on page 71

• “Finding Components and Assemblies” on page 75

Thermo Scientific Ion Trap Series Hardware Manual 19

Page 36

2

Maintenance

Main Components

Main Components

Figure 10. Maintenance Components (Top View)

20 Ion Trap Series Hardware Manual Thermo Scientific

Page 37

Recommended Maintenance Schedule

You can perform most maintenance yourself. For your safety, be sure to read the instructions

carefully before using any procedure.

The frequency of maintenance depends on the types and amounts of sample and solvents you

use. See Ta bl e 1 for more information. To perform maintenance, you will need:

•Clean, dry gas

• Gloves, clean, lint- and powder-free

• Gloves, latex, impermeable

• Lint-free cloth or paper

• Nut driver, 5.5 mm

• Protective eyewear

• Screwdriver, Phillips #2

• Screwdriver, flat blade

• Wrench, adjustable

• Wrench, Allen, 2 mm, 2.5 mm, 3 mm, 4 mm, 5/32-in., 5/64-in., 1/16-in.

• Wrench, open-ended, 1/4-in., 5/16-in., 7/16-in. (2),

1/2-in., 9/16-in.

• Wrench, socket, 1/2-in.

2

Maintenance

Recommended Maintenance Schedule

Thermo Scientific Ion Trap Series Hardware Manual 21

Page 38

2

Maintenance

Recommended Maintenance Schedule

Ta b le 1 contains a recommended routine maintenance schedule. Time estimates are based on

running multiple samples in an 8-hour day. Adapt the schedules according to how clean your

samples are and how many analyses you plan to conduct per day. Keep a record of system

maintenance and performance to identify deviations from normal operation, which can be

used to determine how to take corrective action.

Table 1. Recommended Routine Maintenance Schedule

Item 1 Mth 4 Mth 1 Y 2 Y *As needed

Ion Source Components

“Cleaning the Ion Source Components” on page 37.

“Cleaning the Ion Volume with an Inlet Valve” on page 38.

“Cleaning the Ion Source Lenses” on page 53.

“Cleaning the Ion Source” on page 56.

“Replacing the Ion Source Filament” on page 59.

Ion Trap Components

“Cleaning the Ion Trap” on page 61.

Ion Detector System Components

“Cleaning the Ion Detector System” on page 66.

“Cleaning or Replacing the Anode” on page 67 or “Maintaining a

High-Vacuum Pump” on page 70.

Rotary Vane Pump

“Checking the Oil Level of a Rotary-Vane Pump” on page 71.

“Adding Oil to a Rotary-Vane Pump” on page 72

“Purging Gas from the Oil in a Rotary-Vane Pump” on page 73.**

Miscellaneous

“Adding Calibration Compound” on page 85.

“Replacing the Rear Cooling Fans” on page 108.

* As needed depends on how close the component is to the sample introduction point. For example, the Ion Volume is

closer to the sample introduction point than any other component and requires the most frequent cleaning.

** Perform every month if you use ammonia as a chemical ionization reagent gas.

22 Ion Trap Series Hardware Manual Thermo Scientific

Page 39

2

Maintenance

Recommended Maintenance Schedule

Figure 11 illustrates the sequence to follow when performing routine maintenance on the

mass spectrometer.

Figure 11. Sequence of Routine Maintenance (no inlet valve)

Thermo Scientific Ion Trap Series Hardware Manual 23

Page 40

2

Maintenance

Removing the Covers

Removing the Covers

Disassembling the mass spectrometer to access internal components requires removing the

necessary covers. The covers overlap each other, so you must first remove the front cover, then

the top cover, and finally the right and/or left cover. In some cases, you need only remove the

cover concealing the components you wish to service.

Removing the Front Cover

To remove the front cover:

1. Prepare the mass spectrometer for maintenance.

a. Prepare a clean work area by covering the area with lint-free cloth.

b. Shut down and vent the mass spectrometer (“Shutting Down” on page 16).

WARNING - ELECTRICAL SHOCK HAZARD. Unplug the mass spectrometer before

proceeding.

2. If your system is equipped with an inlet valve, remove the inlet valve lever by pulling it

free.

3. Grasp the cover by the left- and right-hand slots, as indicated in Figure 12. Pull the cover

toward you and it will snap out of the connectors located on the top and bottom of the

mass spectrometer.

Figure 12. Removing the Front Cover

Left-Hand Slot

Right-Hand Slot

4. Reverse these steps to reinstall the cover.

24 Ion Trap Series Hardware Manual Thermo Scientific

Page 41

Removing the Top Cover

To remove the top cover, you will need a Phillips #2 screwdriver.

1. Prepare the mass spectrometer for maintenance.

a. Prepare a clean work area by covering the area with lint-free cloth.

b. Shut down and vent the mass spectrometer (“Shutting Down” on page 16).

)

WARNING - ELECTRICAL SHOCK HAZARD. Unplug the mass spectrometer before

proceeding.

2. Remove the front cover.

3. Loosen the fastener located on the front of the mass spectrometer that attaches the top

cover to the chassis, as illustrated in Figure 13.

Figure 13. Removing the Top Cover

Top Cover Fastener

2

Maintenance

Removing the Covers

4. Slide the top cover forward about 2.5 cm (1-inch).

5. Lift the top cover up and away from the mass spectrometer.

6. Reverse these steps to reinstall the mass spectrometer top cover.

Thermo Scientific Ion Trap Series Hardware Manual 25

Page 42

2

Maintenance

Removing the Covers

Removing the Right Cover

To remove the right cover, you will need a Phillips #2 screwdriver and a 2.5 mm Allen wrench.

)

1. :Prepare the mass spectrometer for maintenance.

a. Prepare a clean work area by covering the area with lint-free cloth.

b. Shut down and vent the mass spectrometer (“Shutting Down” on page 16).

WARNING - ELECTRICAL SHOCK HAZARD. Unplug the mass spectrometer before

proceeding.

2. Remove the front and top covers.

3. Remove the capillary column, as described in“Removing a GC Column” on page 13.

4. Remove the two screws holding the top cover to the chassis (Figure 14).

Figure 14. Removing the Right Cover

Screws holding the right cover

5. Slide the cover towards the back and pull it away from the instrument.

6. Reverse these steps to reinstall the mass spectrometer right cover.

26 Ion Trap Series Hardware Manual Thermo Scientific

Page 43

Removing the Left Cover

To remove the left cover, you will need a Phillips #2 screwdriver.

1. Prepare the mass spectrometer for maintenance.

a. Prepare a clean work area by covering the area with lint-free cloth.

b. Shut down and vent the mass spectrometer (“Shutting Down” on page 16).

)

WARNING - ELECTRICAL SHOCK HAZARD. Unplug the mass spectrometer before

proceeding.

2. Remove the front and top covers.

3. Remove the single screw located at the rear of the mass spectrometer that holds the left

cover against the chassis (Figure 15).

Figure 15. Removing the Left Cover

2

Maintenance

Removing the Covers

WARN ING

HIGH VOLTAGE

AND HOT SURFACES

CAUTION

Screw holding

left cover in

place

REV

Thermo Scientific Ion Trap Series Hardware Manual 27

Page 44

2

Maintenance

Removing the Covers

4. Slide the cover toward the rear of the mass spectrometer until the tabs come to the end of

the grooved slots and then pull the cover away from the mass spectrometer.

CAUTION INSTRUMENT DAMAGE. The analog and digital PCBs are behind the left

cover, so the left cover is significantly heavier than the right cover. Also, several cables

connect the PCBs to other parts of the instrument. Do not pull the cover too far away

from the instrument or damage to cables may occur.

5. Reverse these steps to reinstall the mass spectrometer left cover.

Removing the Vacuum Manifold Cover

Located inside the vacuum manifold are the ion source, ion trap, and ion detector system. To

perform maintenance inside the vacuum manifold, you must remove the vacuum manifold

cover, ion source and ion trap assembly.

To remove the vacuum manifold cover, you will need:

•Clean, dry gas

• Gloves, clean, lint- and powder-free

• Lint-free cloth

• Screwdriver, Phillips #2

CAUTION INSTRUMENT DAMAGE. You should always put the vacuum manifold cover

back in place to prevent dust and debris from collecting in the vacuum manifold. Even

small amounts of dust on the electron multiplier and conversion dynode feedthrough can

cause excessive noise in the mass spectra.

1. Prepare the mass spectrometer for maintenance.

a. Prepare a clean work area by covering the area with lint-free cloth.

b. Shut down and vent the mass spectrometer (“Shutting Down” on page 16).

WARNING - ELECTRICAL SHOCK HAZARD. Unplug the mass spectrometer before

proceeding.

c. )Remove the front and top covers, as described in “Removing the Covers” on

page 24.

Note Completely vent the instrument to atmospheric pressure for approximately

four minutes, or the cover will be difficult to remove.

28 Ion Trap Series Hardware Manual Thermo Scientific

Page 45

d. Remove the vacuum manifold cover (Figure 16).

Figure 16. Vacuum Manifold Cover

Vacuum Manifold Cover

2

Maintenance

Removing the Covers

2. Reattach the vacuum manifold cover.

a. Check the O-ring (PN 3814-6500) for signs of wear and replace if necessary.

b. Verify that there are no particles on the O-ring. Wipe it off with a lint-free cloth, if

necessary.

c. Clean the electron multiplier and ion trap with clean, dry gas. Do not use liquids to

clean the ion detector System.

CAUTION INSTRUMENT DAMAGE. Even the smallest amount of dust or lint on the

electron multiplier, or ion trap can cause spectral noise or instrument damage.

3. Replace the vacuum manifold cover.

4. Replace the covers.

5. Restart your system.

Thermo Scientific Ion Trap Series Hardware Manual 29

Page 46

2

Maintenance

Assembling the Ion Source and Ion Trap

Assembling the Ion Source and Ion Trap

This procedure contains instructions on how to assemble and disassemble the ion source and

ion trap.

To disassemble/assemble the ion source and ion trap, you will need:

•Clean, dry gas

• Gloves, clean, lint- and powder-free

• Lint-free cloth

• Screwdriver, Phillips #2

1. Remove the ion source and ion trap assembly.

a. Shut down and vent the mass spectrometer, as described in “Shutting Down” on

page 16.

WARNING - ELECTRICAL SHOCK HAZARD. Unplug the mass spectrometer before

proceeding.

b. Remove the front and top covers, as described in“Removing the Covers” on page 24.

c. Remove the vacuum manifold cover, as described in “Removing the Vacuum

Manifold Cover” on page 28.

d. Remove the 8-pin cable from the ion source and the 3-pin lens cable. Be careful not

to pull the cable by the wires.

Note Wear clean, lint- and powder- free gloves when you handle parts inside the

vacuum manifold.

e. Use your left hand to apply pressure to the base of the magnet yoke and slide it

towards the left of the mass spectrometer. With your right hand, grasp the exit lens

mounting bracket and move it left and right as you slide the magnet yoke to the left.

2. Replace the ion source and ion trap.

30 Ion Trap Series Hardware Manual Thermo Scientific

Page 47

Figure 17. Ion Source and Ion Trap Assembly

1

5

4

2

Maintenance

Assembling the Ion Source and Ion Trap

2

3

1Helium Supply Line 43-Pin Lens Cable

2 12-Pin Cable 5 Exit and Entrance Endcap Cables

38-Pin Source Cable

a. Loosen the two thumbscrews holding the ion source and ion trap together.

b. Rotate the exit endcap so the helium supply is pointing directly to the right.

c. Place the ring electrode groove over the RF Pin and make sure the pin does not

scratch the spacers.

d. Slide the ion source into its space in the vacuum manifold by applying pressure to the

base of the magnet yoke with your left hand and sliding it towards the right of the

mass spectrometer.

e. Align the helium supply with the helium inlet on the exit endcap and the transfer line

with the ion source.

f. Tighten the two thumbscrews just enough so that the exit and entrance endcaps

cannot be easily rotated.

g. Connect the 12-pin cable to the right side of the vacuum manifold.

CAUTION INSTRUMENT DAMAGE. Overtightening the thumbscrews can cause the ion

trap spacers or the ceramic lens holders to crack when the ion source is heated. The

thumbscrews should only be tight enough to prevent the endcap electrodes from rotating.

Thermo Scientific Ion Trap Series Hardware Manual 31

Page 48

2

Maintenance

Cleaning Parts

Cleaning Parts

A large part of maintaining your mass spectrometer consists of making sure that all the

components are clean. Use the cleaning procedures listed in this section to clean stainless steel

and non-stainless steel parts. However, use caution when doing so, as some components can

be damaged by exposure to liquids.

When your mass spectrometer is clean and in good working order, perform benchmark tests

and record the results. A good benchmark test is a solution of octafluoronaphthalene (OFN)

for EI Systems or decafluorobenzophenone (DFBZ) for CI systems. Both are available from

Thermo Fisher Scientific. When the tested performance of your system decreases significantly

from your benchmark test results, clean the ion volume. If this does not restore performance,

clean the lenses.

How often you clean the mass spectrometer depends on the types and amounts of samples

and solvents you introduce into the system. In general, the closer a component is to the

sample introduction point, the more rapidly it becomes dirty. For example, you will clean the

ion volume more often than other parts. If you just want to change or clean the ion volumes

and the mass spectrometer is equipped with an inlet valve, there is no need to shut down the

system.

Many parts can be removed and disassembled by hand. Make sure you have all the tools

needed before using each procedure. You can purchase items without part numbers at a local

hardware store.

Note This section is not intended to relate strictly to the parts and components in this

chapter. These procedures can be used to clean other stainless steel, ceramic, aluminum,

and gold-plated parts within the mass spectrometer. However, use caution when doing so,

as some components can be damaged when exposed to liquids.

32 Ion Trap Series Hardware Manual Thermo Scientific

Page 49

Stainless Steel Parts

Stainless steel parts located on your mass spectrometer require special cleaning to enhance and

ensure quality performance.

To clean stainless steel parts, such as the ion volume, ion source, and lenses you will need:

• Acetone, reagent grade (or other suitable polar solvent)

• Aluminum oxide abrasive, number 600 (PN 32000-60340)

• Applicators, cotton-tipped (PN A0301-02000)

• Beaker, 450 mL

•Clean, dry gas

•De-ionized water

• Detergent (Alconox, Micro, or equivalent)

• Dremel rotary tool or equivalent (recommended)

• Foil, aluminum

•Forceps

• Gloves, clean, lint- and powder-free

• Gloves, latex, impermeable

• Glycerol, reagent grade

• Lint-free cloth

• Protective eyewear

•Tap water

• Toothbrush, soft

• Ultrasonic cleaner

2

Maintenance

Cleaning Parts

CAUTION INSTRUMENT DAMAGE. Please do NOT use this procedure to clean ceramic,

aluminum, or gold plated parts. Also, this procedure should not be used on the ion trap,

electron multiplier, conversion dynode feedthrough, or anode feedthrough.

WARNING - MATERIAL AND EYE HAZARD. Wear impermeable laboratory gloves and eye

protection when performing cleaning procedures.

1. Remove contamination from all the surfaces you are cleaning.

a. Use a slurry of number 600 aluminum oxide in glycerol and a cleaning brush or

cotton-tipped applicator. Contamination usually appears as dark or discolored areas,

but sometimes is not visible. The heaviest contamination is usually found around the

apertures, such as the electron entrance hole on an ion volume.

b. Clean each part thoroughly, even if no contamination is visible.

c. Use the wooden end of an applicator cut at an angle to clean the inside corners.

Thermo Scientific Ion Trap Series Hardware Manual 33

Page 50

2

Maintenance

Cleaning Parts

d. Use a Dremel® tool at its lowest speed with an applicator to increase cleaning

efficiency. To prevent personal injury, be sure to keep the Dremel tool away from

possible hazards, such as standing water or flammable solvents.

WARNING - BURN HAZARD. The Dremel tool uses an electric motor that may generate