Page 1

Thermo Scientific

Dionex Aquion RFIC Ion

Chromatography System

Operator’s Manual

22176-97006 Revision 01 March 2019

Page 2

© 2019 Thermo Fisher Scientific Inc. All rights reserved.

Chromeleon, ERS, and OnGuard are registered trademarks of Thermo Fisher Scientific Inc. in the United

States. Microsoft and Windows are registered trademarks of Microsoft Corporation in the United States and

other countries.

KIMWIPES is a registered trademark of Kimberly-Clark Corporation in the United States and possibly other

countries.

PEEK is a trademark of Victrex PLC. Rheodyne is a trademark of IDEX Health & Science LLC.

All other trademarks are the property of Thermo Fisher Scientific Inc. and its subsidiaries.

Thermo Fisher Scientific Inc. provides this document to its customers with a product purchase to use in the

product operation. This document is copyright protected and any reproduction of the whole or any part of this

document is strictly prohibited, except with the written authorization of Thermo Fisher Scientific Inc.

The contents of this document are subject to change without notice. All technical information in this

document is for reference purposes only. System configurations and specifications in this document supersede

all previous information received by the purchaser.

This document is not part of any sales contract between Thermo Fisher Scientific Inc. and a purchaser. This

document shall in no way govern or modify any Terms and Conditions of Sale, which Terms and Conditions of

Sale shall govern all conflicting information between the two documents.

Release history: Revision 01 released March 2019; initial system release

Software version: Chromeleon 7.2.9 DUa and later

For Research Use Only. Not for use in diagnostic procedures.

Page 3

C

Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vi

Safety and Special Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vi

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Regulatory Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Notice on Lifting and Handling of Thermo Scientific Instruments . . . . . . . .viii

Notice on the Proper Use of Thermo Scientific Instruments . . . . . . . . . . . . .viii

Notice on the Susceptibility to Electromagnetic Transmission. . . . . . . . . . . .viii

WEEE Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .viii

Deionized Water Requirements for IC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Contacting Us . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Chapter 1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Introduction to Ion Chromatography (IC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Overview of the Dionex Aquion RFIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Chapter 2 Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Operating Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Top Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Component Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Flow Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Flow Description for KOH, LiOH, NaOH, or MSA Eluent

Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Flow Description for Carbonate Eluent Generation . . . . . . . . . . . . . . . . . . . 17

Chromeleon Chromatography Data System . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Thermo Scientific Dionex Aquion RFIC Operator’s Manual i

Page 4

Contents

System Component Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Vacuum Degas Assembly (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Eluent Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Eluent Generator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Injection Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Auxiliary Valve (Optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Column Heater (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Suppressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

DS6 Heated Conductivity Cell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Chapter 3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Operation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Sample Processing Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Turning On the System Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Connecting to Chromeleon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Setting Up the Eluent Reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Checking All Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Priming the Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Setting System Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Equilibrating the System and Verifying Operational Status . . . . . . . . . . . . . . . . 39

Preparing Samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Collecting and Storing Samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Pretreating Samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Diluting Samples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Loading and Injecting Samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Processing Samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Manual Sample Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Automated (Batch) Sample Processing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Chapter 4 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Daily Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Weekly Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Semiannual Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Annual Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Chapter 5 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Troubleshooting Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

ii Dionex Aquion RFIC Operator’s Manual Thermo Scientific

Page 5

Contents

Troubleshooting System Component Symptoms. . . . . . . . . . . . . . . . . . . . . . . . 59

Liquid Leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Pump Difficult to Prime or Loses Prime . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Pump Does Not Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

No Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Erratic Flow and/or Pressure Reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Excessive System Backpressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Peak Ghosting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Nonreproducible Peak Height or Retention Time. . . . . . . . . . . . . . . . . . . . . 65

Abnormal Retention Time or Selectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

No Cell Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

High Cell Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Baseline Noise or Drift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Hardware Not Present. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Leak Sensor Wet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Vacuum Degas Assembly Does Not Run. . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Chapter 6 Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Isolating a Restriction in the Liquid Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Replacing Tubing and Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Rebuilding the Injection Valve or Auxiliary Valve . . . . . . . . . . . . . . . . . . . . . . . 74

Replacing the Auxiliary Valve Pod. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Cleaning and Replacing the Pump Check Valves. . . . . . . . . . . . . . . . . . . . . . . . 76

Replacing a Pump Piston Seal and Piston Rinse Seal . . . . . . . . . . . . . . . . . . . . . 78

Replacing a Pump Piston. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Replacing the Waste Valve or Priming Valve O-Ring . . . . . . . . . . . . . . . . . . . . 83

Replacing the Suppressor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Replacing the Eluent Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Replacing the Leak Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Priming the Pump (Standard Procedure). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Priming the Pump with Isopropyl Alcohol . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Replacing the Dionex EGC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Replacing a KOH, LiOH, NaOH, or MSA Cartridge. . . . . . . . . . . . . . . . . . 93

Replacing a Carbonate Cartridge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Replacing the Dionex CR-TC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Replacing the Dionex EGC 500 Carbonate Mixer . . . . . . . . . . . . . . . . . . . . . 112

Replacing the Dionex EGC Holder and Degas Assembly . . . . . . . . . . . . . . . . 116

Changing the Main Power Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Appendix A Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

Appendix B TTL and Relay Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .131

TTL and Relay Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Controlling TTL and Relay Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Thermo Scientific Dionex Aquion RFIC Operator’s Manual iii

Page 6

Contents

Appendix C Reordering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .137

Appendix D FAQ. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .141

Appendix E Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .145

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .151

iv Dionex Aquion RFIC Operator’s Manual Thermo Scientific

Page 7

P

Preface

This manual provides instructions for the operation of the Thermo Scientific™ Dionex™

Aquion™ RFIC™ Ion Chromatography System.

Contents

• Related Documentation

• Safety Information

• Regulatory Compliance

• Deionized Water Requirements for IC

• Contacting Us

Related Documentation

In addition to this manual, the following documents are available on the Thermo Fisher

Scientific website or from your local office:

• Dionex Aquion RFIC Ion Chromatography System Installation Instructions

(Document No. 22176-97005)

• Manuals for consumable products (including columns, suppressors, and eluent generator

cartridges)

• Chromeleon 7 Installation Guide (Document No. 7229.0003); also provided on the

Thermo Scientific™ Dionex™ Chromeleon™ 7 Chromatography Data System DVD

• Dionex AS-AP Autosampler Operator’s Manual (Document No. 065361)

• Dionex AS-DV Autosampler Operator’s Manual (Document No. 065259)

Thermo Scientific Dionex Aquion RFIC Operator’s Manual v

Page 8

Preface

Safety Information

The Dionex Aquion RFIC is manufactured for Thermo Fisher Scientific at the following

location:

Jabil Circuit de Chihuahua S. de R.L. de C.V.

Complejo Industrial Chihuahua

Av. Alejandro Dumas No. 11341

31109 Chihuahua, Chihuahua

Mexico

The Dionex Aquion RFIC is designed for IC (ion chromatography) applications and should

not be used for any other purpose. Operation of a Dionex Aquion RFIC in a manner not

specified by Thermo Fisher Scientific may result in personal injury.

If there is a question regarding appropriate usage, contact Technical Support for Dionex

products. In the U.S. and Canada, call 1-800-532-4752. Outside the U.S. and Canada, call

the nearest Thermo Fisher Scientific office.

Safety and Special Notices

Make sure you follow the precautionary statements presented in this manual. Safety notices

and special notices appear in boxes. These notices include the following:

DANGER Indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury. Each DANGER notice is accompanied by an appropriate

DANGER symbol.

CAUTION Highlights hazards to humans, property, or the environment. Each CAUTION

notice is accompanied by an appropriate CAUTION symbol.

IMPORTANT Highlights information necessary to prevent damage to the system or

software, loss of data, or invalid test results; or might contain information that is critical

for optimal performance of the system.

Note Highlights information of general interest.

Tip Highlights helpful information that can make a task easier.

vi Dionex Aquion RFIC Operator’s Manual Thermo Scientific

Page 9

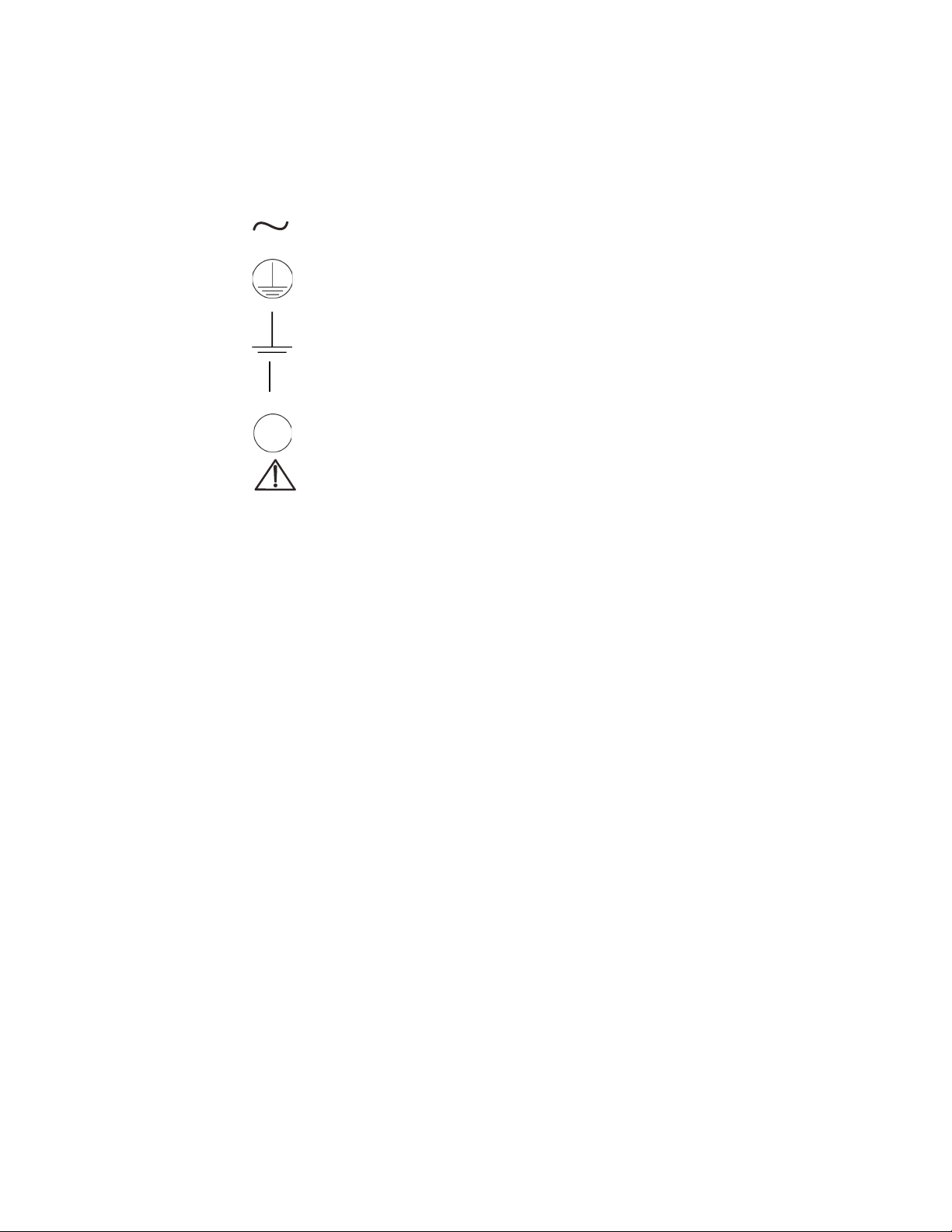

Safety Symbols

Preface

These symbols appear on the Dionex Aquion RFIC or on labels affixed to the system:

Alternating current

Primary protective conductor terminal

Secondary protective conductor terminal

Power supply is on

Power supply is off

Indicates a potential hazard. Refer to this manual for an explanation of the

hazard and how to proceed.

Regulatory Compliance

Thermo Fisher Scientific performs complete testing and evaluation of its products to ensure

full compliance with applicable domestic and international regulations. When the system is

delivered to you, it meets all pertinent electromagnetic compatibility (EMC) and safety

standards as described in this section.

Changes that you make to your system may void compliance with one or more of these EMC

and safety standards. Changes to your system include replacing a part or adding components,

options, or peripherals not specifically authorized and qualified by Thermo Fisher Scientific.

To ensure continued compliance with EMC and safety standards, replacement parts and

additional components, options, and peripherals must be ordered from Thermo Fisher

Scientific or one of its authorized representatives.

The regulatory symbols on the Dionex Aquion RFIC model/data label indicate that the

system is in compliance with the following EMC and safety standards:

• EN 61010-1:2010

• UL 61010-1:2012

• CAN/CSA-C22.2 No. 61010-1-12

• EN 61326-1:2013

The CE mark on the Dionex Aquion RFIC model/data label indicates that the system is in

compliance with the following European Community Directives as is evidenced by

compliance to the associated standard where appropriate:

• Low Voltage/Safety Directive: 2014/35/EU by conforming to EN61010-1:2013

Thermo Scientific Dionex Aquion RFIC Operator’s Manual vii

Page 10

Preface

• EMC Directive: 2014/30/EU by conforming to EN61326-1:2013

Notice on Lifting and Handling of Thermo Scientific Instruments

For your safety, and in compliance with international regulations, the physical handling of

this Thermo Fisher Scientific instrument requires a team effort to lift and/or move the

instrument. This instrument is too heavy and/or bulky for one person alone to handle safely.

Notice on the Proper Use of Thermo Scientific Instruments

In compliance with international regulations: This instrument must be used in the manner

specified by Thermo Fisher Scientific to ensure protections provided by the instrument are

not impaired. Deviations from specified instructions on the proper use of the instrument

include changes to the system and parts replacement. Accordingly, order replacement parts

from Thermo Fisher Scientific or one of its authorized representatives.

Notice on the Susceptibility to Electromagnetic Transmission

WEEE Compliance

Your instrument is designed to work in a controlled electromagnetic environment. Do not use

radio frequency transmitters, such as mobile phones, in close proximity to the instrument.

For manufacturing location, see the label on the instrument.

This product complies with the European Union’s Waste Electrical & Electronic Equipment

(WEEE) Directive 2002/96/EC. It is marked with the following symbol:

Thermo Fisher Scientific is registered with B2B Compliance (B2Bcompliance.org.uk) in the

UK and with the European Recycling Platform (ERP-recycling.org) in all other countries of

the European Union and in Norway.

If this product is located in Europe and you want to participate in the Thermo Fisher

Scientific B2B (Business-to-Business) Recycling Program, send an email request to

weee.recycle@thermofisher.com with the following information:

• WEEE product class

• Name of the manufacturer or distributor (where you purchased the product)

• Number of product pieces, and the estimated total weight and volume

viii Dionex Aquion RFIC Operator’s Manual Thermo Scientific

Page 11

Conformité DEEE

Preface

• Pick-up address and contact person (including contact information)

• Appropriate pick-up time

• Declaration of decontamination, stating that all hazardous fluids or material have been

removed from the product

For additional information about the Restriction on Hazardous Substances (RoHS) Directive

for the European Union, search for RoHS on the Thermo Fisher Scientific European language

websites.

Ce produit est conforme avec la directive européenne (2002/96/EC) des Déchets

d'Equipements Electriques et Electroniques (DEEE). Il est marqué par le symbole suivant:

WEEE Konformität

Thermo Fisher Scientific s'est associé avec une ou plusieurs sociétés de recyclage dans chaque

état membre de l’Union Européenne et ce produit devrait être collecté ou recyclé par

celle(s)-ci. Pour davantage d'informations, rendez-vous sur la page

www.thermoscientific.fr/rohs.

Dieses Produkt entspricht der EU Waste Electrical & Electronic Equipment (WEEE)

Richtlinie 2002/96/EC. Es ist mit dem folgenden Symbol gekennzeichnet:

Thermo Fisher Scientific hat Vereinbarungen mit Verwertungs-/Entsorgungsfirmen in allen

EU-Mitgliedsstaaten getroffen, damit dieses Produkt durch diese Firmen wiederverwertet

oder entsorgt werden kann. Weitere Informationen finden Sie unter

www.thermoscientific.de/rohs.

Thermo Scientific Dionex Aquion RFIC Operator’s Manual ix

Page 12

Preface

Deionized Water Requirements for IC

For electrolytic eluent generation, or when manually preparing eluent and regenerant, use

ASTM Type I (18 megohm-cm) filtered and deionized water that meets the specifications

listed in Ta bl e 1 .

.

Table 1. ASTM filtered, Type I deionized water specifications for ion chromatography

Contaminant Specification

Ions–Resistivity >18.0 megohm-cm

Organics–TOC <10 ppb

Iron/Transition Metals* <1 ppb

Pyrogens <0.03 (Eu/mL)

Particulates > 0.2 μm <1 (units/mL)

Colloids–Silica <10 ppb

Bacteria <1 (cfu/mL)

Contacting Us

* Iron/transition metal content not specified for ASTM Type I water

For Technical Support for Dionex products

In the U.S. and Canada, call 1-800-532-4752.

Outside the U.S. and Canada, call the nearest Thermo Fisher Scientific office.

For additional contact information

Go to www.thermofisher.com/us/en/home/technical-resources/contact-us.html.

x Dionex Aquion RFIC Operator’s Manual Thermo Scientific

Page 13

Risque de choc électrique : l’instrument utilise des

tensions susceptibles de provoquer une électrocution

et/ou des blessures corporelles. Il doit être arrêté et

Riesgo de descargas eléctricas: Este instrumento

utiliza voltajes que pueden causar descargas

eléctricas y/o lesiones personales. Antes de revisar o

débranché de la source de courant avant toute

intervention. Ne pas utiliser l’instrument sans ses

couvercles. Ne pas enlever les capots de protection des

cartes à circuit imprimé (PCBA).

reparar el instrumento, apáguelo y desconéctelo de la

red eléctrica. Mantenga colocadas las cubiertas

mientras se utiliza el instrumento. No retire las

cubiertas protectoras del circuito impreso completo

(PCBA).

Danger lié aux produits chimiques : porter des gants

et d’autres équipements de protection appropriés pour

manipuler les produits chimiques toxiques, cancérigènes,

mutagènes, corrosifs ou irritants. Utiliser des récipients

homologués et des procédures adéquates pour la mise au

Peligro por sustancias químicas: Cuando

manipule sustancias químicas, tóxicas,

carcinogénicas, mutágenas, corrosivas o irritantes,

utilice guantes y otro equipo de protección. Utilice

siempre recipientes homologados y siga los

rebut des huiles usagées et lors de la manipulation des

pièces de l’instrument en contact avec l’eau.

procedimientos adecuados cuando deseche aceite

residual o manipule partes mojadas del instrumento.

Surface chaude : laisser refroidir les composants

chauffés avant toute manipulation.

Superficies calientes: Antes de tocar los

componentes calientes, espere a que se enfríen.

Danger lié aux substances inflammables : agir avec

précaution lors de l’utilisation du système en présence de

substances inflammables.

Peligro por sustancias inflamables: Tenga mucho

cuidado cuando utilice el sistema cerca de sustancias

inflamables.

Risque de lésion oculaire : les projections chimiques,

les particules en suspension dans l’air et les objets

tranchants peuvent entraîner des lésions oculaires. (Les

objets tranchants pouvant être installés par les clients

dans l’instrument comprennent les tubes en silice fondue,

les aiguilles du passeur automatique, etc.). Porter des

lunettes de protection lors de toute manipulation de

produit chimique ou intervention sur l’instrument.

Danger d’ordre général : indique la présence d’un

Riesgo de lesiones oculares: Las salpicaduras de

sustancias químicas, las partículas flotantes en el

aire y los objetos afilados pueden causar lesiones

oculares. (Entre los objetos afilados que los clientes

pueden instalar en el instrumento se encuentran

tubos de sílice fundida, agujas del muestreador

automático, etc.). Para manipular sustancias

químicas o realizar tareas de mantenimiento, utilice

gafas de seguridad.

Peligro general: Existen peligros que no se incluyen

risque n’appartenant pas aux catégories citées plus haut.

Ce symbole figure également sur l’instrument. Pour plus

de détails sur ce danger potentiel, se reporter au manuel

de l’instrument.

Si la sûreté d’une procédure est incertaine, contacter

l’assistance technique pour les produits Thermo Scientific

Sunnyvale.

en las otras categorías. Este símbolo también

aparece en el instrumento. Si desea obtener más

información sobre estos peligros, consulte el manual

del instrumento.

En caso de duda sobre la seguridad de un procedimiento,

póngase en contacto con el personal de servicio técnico

de los productos Thermo Scientific Sunnyvale.

CAUTION Symbol CAUTION VORSICHT PRECAUCIÓN MISE EN GARDE

Stromschlaggefahr: Dieses Gerät arbeitet mit

Spannungen, die Stromschläge und/oder

Personenverletzungen verursachen können. Vor

Risk electric shock: This instrument uses

voltages that can cause electric shock and/or

personal injury. Before servicing, shut down the

Wartungsarbeiten muss das Gerät abgeschaltet

und vom Netz getrennt werden. Betreiben Sie das

Gerät nicht mit abgenommenen Abdeckungen.

Nehmen Sie die Schutzabdeckungen von

instrument and disconnect it from line power.

While operating the instrument, keep covers on.

Do not remove the protective covers from the

printed circuit board assemblies (PCBAs).

Leiterplatten nicht ab.

Gefahr durch Chemikalien: Tragen Sie beim

Chemical hazard: Wear gloves and other

Umgang mit toxischen, karzinogenen, mutagenen,

ätzenden oder reizenden Chemikalien

Schutzhandschuhe und weitere geeignete

Schutzausrüstung. Verwenden Sie bei der

Entsorgung von verbrauchtem Öl und beim Umgang

mit medienberührenden Komponenten die

vorgeschriebenen Behälter, und wenden Sie

protective equipment, as appropriate, when

handling toxic, carcinogenic, mutagenic, corrosive,

or irritant chemicals. Use approved containers and

proper procedures to dispose of waste oil and

when handling wetted parts of the instrument.

ordnungsgemäße Verfahren an.

Heiße Oberflächen: Lassen Sie heiße

Komponenten vor der Berührung abkühlen.

Hot surface: Before touching, allow any heated

components to cool.

Gefahr durch entzündbare Substanzen:

Beachten Sie die einschlägigen Vorsichtsmaßnahmen,

Flammable substances hazard: Use care when

operating the system in the presence of flammable

wenn Sie das System in Gegenwart von entzündbaren

substances.

Umgang mit Chemikalien oder bei der Wartung des

Gerätes eine Schutzbrille.

Allgemeine Gefahr: Es besteht eine weitere

Gefahr, die nicht in den vorstehenden Kategorien

beschrieben ist. Dieses Symbol wird auch auf dem

Gerät angebracht. Einzelheiten zu dieser Gefahr

finden Sie in den Gerätehandbüchern.

Wenn Sie sich über die Sicherheit eines Verfahrens

im Unklaren sind, setzen Sie sich, bevor Sie

fortfahren, mit dem technischen Support für

Thermo Scientific Sunnyvale Produkte in

Substanzen betreiben.

Augenverletzungsrisiko: Verspritzte

Chemikalien, Schwebstoffpartikel oder scharfe

Objekte können Augenverletzungen verursachen.

(Scharfe Objekte, die Kunden möglicherweise im

Gerät installieren, sind z. B. Quarzglas-Kapillaren,

die Nadel des Autosamplers, usw.) Tragen Sie beim

General hazard: A hazard is present that is not

included in the other categories. This symbol also

appears on the instrument. For details about the

hazard, refer to the instrument manual.

When the safety of a procedure is questionable,

Risk of eye injury: Eye injury could occur from

splattered chemicals, airborne particles, or sharp

objects. (Sharp objects that customers might install

in the instrument include fused-silica tubing, the

autosampler needle, and so on.) Wear safety

glasses when handling chemicals or servicing the

instrument.

contact Technical Support for Thermo Scientific

Verbindung.

Sunnyvale products.

Page 14

Danger lié au laser : l’instrument utilise un laser

Peligro por láser: Este instrumento utiliza un láser

susceptible de provoquer des blessures corporelles. Ce

que puede producir lesiones personales. Este símbolo

symbole figure également sur l’instrument. Pour plus de

también aparece en el instrumento. Si desea obtener

détails sur ce danger potentiel, se reporter au manuel de

más información sobre el peligro, consulte el manual

l’instrument.

Danger lié aux rayons ultraviolets : ne jamais

del instrumento.

Peligro por luz ultravioleta: No mire directamente

regarder directement la lumière ultraviolette (UV) ou la

source d’UV. Une exposition peut entraîner des lésions

a una luz ultravioleta (UV) ni a una fuente UV. La

exposición puede causar daños oculares. Lleve

Si la sûreté d’une procédure est incertaine, contacter

l’assistance technique pour les produits Thermo Scientific

En caso de duda sobre la seguridad de un pro cedimiento,

póngase en contacto con el personal de servicio técnico

Sunnyvale.

de los productos Thermo Scientific Sunnyvale.

oculaires. Porter des protections oculaires anti-UV.

Objet tranchant : éviter tout contact physique avec

l’objet.

protección ocular para UV.

Objeto puntiagudo: Evite el contacto físico con el

objeto.

Risque de pincement : éloigner les mains de cette zone.

Puntos de pinzamiento: Mantenga las manos

apartadas de esta área.

Objet lourd : ne jamais soulever ou déplacer l’instrument

seul sous peine de blessure corporelle ou

d’endommagement de l’instrument. Pour obtenir des

instructions de levage spécifiques, se reporter au manuel

de l’instrument.

Risque de trébuchement : faire attention aux câbles,

Objeto pesado: Nunca levante ni mueva el

instrumento por su cuenta, podría sufrir lesiones

personales o dañar el equipo. Para obtener

instrucciones específicas sobre levantamiento,

consulte el manual del instrumento.

Tropiezo con obstáculos: Tenga en cuenta los cables,

tuyaux et autres objets situés sur le sol.

mangueras u otros objetos colocados en el suelo.

CAUTION Symbol CAUTION VORSICHT PRECAUCIÓN MISE EN GARDE

Gefahr durch Laserstrahlen: Der in diesem Gerät

verwendete Laser kann zu Verletzungen führen.

Laser hazard: This instrument uses a laser that is

capable of causing personal injury. This symbol

Dieses Symbol wird auch auf dem Gerät

also appears on the instrument. For details about

angebracht. Einzelheiten zu dieser Gefahr finden

Sie in den Gerätehandbüchern.

Gefahr durch UV-Licht: Richten Sie Ihren Blick

nicht direkt auf ultraviolettes Licht (UV-Licht) oder

in die UV-Quelle. Dies kann zu Augenschäden

the hazard, refer to the instrument manual.

Ultra violet light hazard: Do not look directly at

the ultra-violet (UV) light or into the UV source.

Exposure can cause eye damage. Wear UV eye

führen. Tragen Sie eine UV-Schutzbrille.

protection.

Scharfes Objekt: Vermeiden Sie den physischen

Kontakt mit dem Objekt.

Sharp object: Avoid physical contact with the

object.

Bereich fern.

Pinch point: Keep hands away from this area. Quetschgefahr: Halten Sie Ihre Hände von diesem

Schweres Objekt: Bewegen und heben Sie das

Gerät niemals allein an; dies kann zu Verletzungen

oder zur Beschädigung des Geräts führen.

Spezifische Anweisungen zum Anheben finden Sie

im Gerätehandbuch.

Stolpergefahr: Achten Sie auf Kabel, Schläuche

und andere Objekte auf dem Fußboden.

Heavy objects: Never lift or move the instrument

by yourself; you can suffer personal injury or

damage the equipment. For specific lifting

instructions, refer to the instrument manual.

Trip obstacle: Be aware of cords, hoses, or other

objects located on the floor.

fortfahren, mit Ihrer lokalen technischen

Unterstützungsorganisation für Thermo Scientific

Wenn Sie sich über die Sicherheit eines Verfahrens

im unklaren sind, setzen Sie sich, bevor Sie

When the safety of a procedure is questionable,

contact Technical Support for Thermo Scientific

Sunnyvale Produkte in Verbindung.

Sunnyvale products.

Page 15

普通危险:未归入其他类别的危险。此符号也会在仪器上出现。有关此

危险的详细信息,参阅适当的仪器手册。若对任何步骤的安全事项有疑

触电危险:本仪器所用电压可能导致电击或人身伤害。进行维修服务

前,务必关闭仪器电源并断开其电源连接。操作此仪器时,不要卸下

顶盖。勿卸下印刷电路板组件 (PCBA)的保护盖。

化学品危险:当处理毒性、致癌性、致突变性、腐蚀性或者刺激性化学

品时,佩戴手套和其他保护性设备。当处理浸湿的仪器部件以及废油

时,使用认可的容器和合适的步骤。

易燃物危险:在有易燃物质的场地操作该系统时,务必小心谨慎。

眼睛伤害风险:眼睛受伤可能源自飞溅的化学品、空气中的颗粒,

或者锋利的物体。(安装在仪器内的锋利物体包括熔融石英管、

自动进样器的进样针等。)处理化学品或对仪器进行维修服务时,

务必戴上防护眼镜。

问,联系 Thermo Scientific Sunnyvale 产品的技术支持中心。

警告 危险警告

CAUTION Symbol CAUTION

Risk electric shock: This instrument

感電の危険性 : この機器では、感電および / または身体傷害を引き起こ

uses voltages that can cause electric

すおそれのある電圧を使用しています。整備点検の前には、機器の電

shock and/or personal injury. Before

源を切り、電源コードを抜いてください。機器の作動中は、カバーを

付けたままにしてください。プリント基板アセンブリ (PCBA) から保護

カバーを取り外さないでください。

servicing, shut down the instrument and

disconnect it from line power. While

operating the instrument, keep covers on.

Do not remove the protective covers from

the printed circuit board assemblies

(PCBAs).

化学的危険性 : 毒性、発癌性、変異原性、腐食性、または刺激性のある

化学薬品を取り扱うときは、必要に応じて手袋などの保護具を着用し

ます。廃油を処分したり、機器の接液部品を取り扱うときは、認可さ

れた容器を使用し、適切な手順に従います。

Chemical hazard: Wear gloves and

other protective equipment, as

appropriate, when handling toxic,

carcinogenic, mutagenic, corrosive, or

高温面 : 触れる前に、加熱した部品を冷ましてください。 热表面:待高温部件冷却之后再进行维修。

irritant chemicals. Use approved

containers and proper procedures to

dispose of waste oil and when handling

wetted parts of the instrument.

Hot surface: Before touching, allow any

heated components to cool.

可燃性物質の危険性 : 可燃性物質があるところでシステムを作動させる

Flammable substances hazard: Use

care when operating the system in the

場合は十分注意してください。

presence of flammable substances.

ては、機器のマニュアルを参照してください。

手順の安全性にご不明な点がある場合は、Thermo Scientific Sunnyvale 製品の

眼外傷の危険性 : 飛散した化学薬品、浮遊粒子、または鋭利な物体に

よって眼外傷を負うおそれがあります (機器に取り付けられる可能性が

ある鋭利な物体は、ヒューズドシリカ、オートサンプラーニードルな

どです )。化学薬品を取り扱ったり、機器を整備点検するときは、保護

メガネを着用します。

Risk of eye injury: Eye injury could occur

from splattered chemicals, airborne

particles, or sharp objects. (Sharp objects

that customers might install in the

instrument include fused-silica tubing, the

autosampler needle, and so on.) Wear

一般的な危険性 : それぞれのカテゴリーに当てはまらない危険がありま

safety glasses when handling chemicals

or servicing the instrument.

General hazard: A hazard is present that

テクニカルサポートまでお問い合わせください。

す。この標識記号は機器にも表示されています。この危険の詳細につい

is not included in the other categories.

This symbol also appears on the

instrument. For details about the hazard,

refer to the instrument manual.

When the safety of a procedure is

questionable, contact Technical Support

for Thermo Scientific Sunnyvale products.

Page 16

警告 危险警告

激光危险:本仪器所用激光会导致人身伤害。此符号也会在仪器上出

レーザー光線の危険性 : この機器では、身体傷害を引き起こすおそれ

现。有关此危险的详细信息,参阅适当的仪器手册。

のあるレーザーを使用しています。この標識記号は機器にも表示され

ています。この危険の詳細については、機器のマニュアルを参照して

ください。

紫外光危险:不要直视紫外 (UV)光或者紫外光源。直视可能导致眼

睛伤害。佩戴紫外线防护眼镜。

紫外光の危険性 : 紫外 (UV) 光または UV 光源を直接見ないでください。照

射によって眼損傷を引き起こすおそれがあります。UV 保護メガネを着用

重物:切勿独自提起或移动本仪器;可能遭受人身伤害或损坏仪器。

有关具体的提起说明,参阅仪器手册。

します。

鋭利な物体 : 物体との身体的接触を避けてください。 锋利物体:避免直接接触锋利的物体。

ピンチポイント : この部分には手を挟まれないようにしてください。 夹点:勿将手放在此部位。

重量物 :1 人で機器を持ち上げたり移動しないでください。身体傷害を

負ったり、機器を損傷するおそれがあります。具体的な持ち上げ方法

については、機器のマニュアルを参照してください。

绊倒危险:注意地面上的线、管或其他物品。

作業の障害物 : 床にあるコード、ホース、その他の物体に注意してく

如对安全程序有疑问,联系 Thermo Scientific Sunnyvale 产品的技术支持

中心。

ださい。

手順の安全性にご不明な点がある場合は、Thermo Scientific Sunnyvale 製品の

テクニカルサポートまでお問い合わせください。

Laser hazard: This instrument uses a

laser that is capable of causing personal

injury. This symbol also appears on the

instrument. For details about the hazard,

refer to the instrument manual.

Ultra violet light hazard: Do not look

directly at the ultra-violet (UV) light or into

the UV source. Exposure can cause eye

damage. Wear UV eye protection.

Sharp object: Avoid physical contact

with the object.

CAUTION Symbol CAUTION

Pinch point: Keep hands away from this

area.

Heavy objects: Never lift or move the

instrument by yourself; you can suffer

personal injury or damage the equipment.

For specific lifting instructions, refer to the

instrument manual.

Trip obstacle: Be aware of cords, hoses,

or other objects located on the floor.

When the safety of a procedure is

questionable, contact Technical Support

for Thermo Scientific Sunnyvale products.

Page 17

1

Introduction

Eluent

Separator

column

Waste

Guard column

(optional)

Injection valve

2. Sample injection

1. Eluent delivery

3. Separation

4. Detection

5. Data analysis

Cell

Suppressor

(optional)

Pump

Waste

Sample

P

L

S

W

C

L

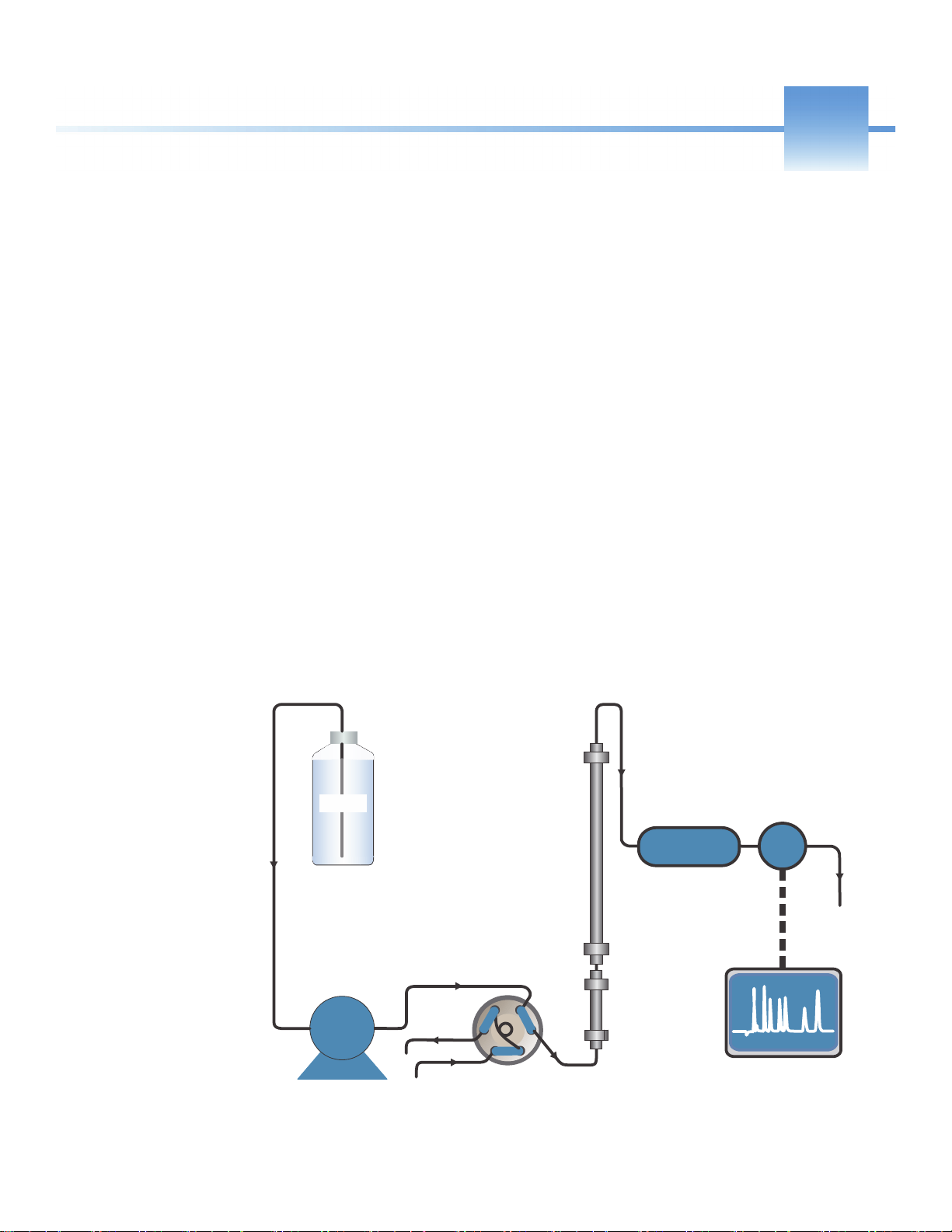

Introduction to Ion Chromatography (IC)

The Dionex Aquion RFIC performs ion analyses using suppressed or non-suppressed

conductivity detection. An ion chromatography system typically consists of a liquid eluent, a

high-pressure pump, a sample injector, a guard and separator column, a chemical suppressor, a

conductivity cell, and a data collection system.

Before running a sample, the ion chromatography system is calibrated using a standard

solution. By comparing the data obtained from a sample to that obtained from the known

standard, sample ions can be identified and quantitated. The data collection system, typically

a computer running chromatography software, produces a chromatogram (a plot of the

detector output vs. time). The chromatography software converts each peak in the

chromatogram to a sample concentration and produces a printout of the results. A typical IC

analysis consists of six stages (see Figure 1).

Figure 1. Ion process analysis

Thermo Scientific Dionex Aquion RFIC Operator’s Manual 1

Page 18

1

Introduction

Introduction to Ion Chromatography (IC)

1. Eluent Delivery

2. Sample Injection

• Eluent, a liquid that helps to separate the sample ions, carries the sample through the

ion chromatography system. The Dionex Aquion RFIC includes an eluent generator,

which generates eluent online from deionized water.

• The system can operate in two eluent delivery modes. In isocratic mode, the eluent

composition and concentration remain constant throughout the run. In the one-step

gradient mode, the eluent concentration changes over time. The delivery mode is

defined in the Chromeleon Instrument Method Wizard. For more information, refer

to the Chromeleon Help.

• The liquid sample is loaded into a sample loop manually or automatically (if an

automated sampler is installed). When triggered, the Dionex Aquion RFIC injects

the sample into the eluent stream.

• The pump pushes the eluent and sample through the guard and separator columns

(chemically-inert tubes packed with a polymeric resin). The guard column removes

contaminants that might poison the separator column.

3. Separation

• As the eluent and sample are pumped through the separator column, the sample ions

are separated. In the Dionex Aquion RFIC, the mode of separation is called ion

exchange. This is based on the premise that different sample ions migrate through the

IC column at different rates, depending upon their interactions with the ion

exchange sites.

4. Suppression

• After the eluent and sample ions leave the column, they flow through a suppressor

that selectively enhances detection of the sample ions while suppressing the

conductivity of the eluent.

5. Detection

• A conductivity cell measures the electrical conductance of the sample ions as they

emerge from the suppressor and produces a signal based on a chemical or physical

property of the analyte.

6. Data Analysis

• The conductivity cell transmits the signal to a data collection system.

• The data collection system (for the Dionex Aquion RFIC, this is the Chromeleon 7

Chromatography Data System) identifies the ions based on retention time, and

quantifies each analyte by integrating the peak area or peak height. The data is

quantitated by comparing the sample peaks in a chromatogram to those produced

from a standard solution. The results are displayed as a chromatogram and the

concentrations of ionic analytes can be automatically determined and tabulated.

2 Dionex Aquion RFIC Operator’s Manual Thermo Scientific

Page 19

Overview of the Dionex Aquion RFIC

The Dionex Aquion RFIC is an integrated ion chromatography system containing an eluent

generator, pump, injection valve, and conductivity detector. Other system components,

including a guard column, separator column, and suppressor vary, depending on the analyses

to be performed.

If necessary, the Dionex Aquion RFIC can be configured with a column heater for

temperature control of the column.

Dionex Aquion RFIC operation is controlled remotely by a personal computer running the

Microsoft® Windows® 10, Windows 8.1, or Windows 7 operating system and Chromeleon

software (version 7.2.9 DUa or later). Chromeleon also provides data acquisition and data

processing functions.

For communication with Chromeleon, the Dionex Aquion RFIC must be connected to a

USB (Universal Serial Bus) port on the computer or a USB hub. For details, refer to the

Dionex Aquion RFIC installation instructions.

1

Introduction

Overview of the Dionex Aquion RFIC

Thermo Scientific Dionex Aquion RFIC Operator’s Manual 3

Page 20

1

Introduction

Overview of the Dionex Aquion RFIC

4 Dionex Aquion RFIC Operator’s Manual Thermo Scientific

Page 21

2

Description

This chapter describes key features of the Dionex Aquion RFIC and introduces the

Chromeleon user interface.

Contents

• Operating Features

• Flow Schematics

• Chromeleon Chromatography Data System

• System Component Details

Thermo Scientific Dionex Aquion RFIC Operator’s Manual 5

Page 22

2

Status LEDs

Power LED

Injection port

Description

Operating Features

Operating Features

Front Panel

Figure 2. Dionex Aquion RFIC front panel

Injection Port

The sample to be analyzed can be injected manually into the injection port, using a syringe.

For automated sample injection, the Dionex Aquion RFIC must be connected to an

autosampler. For more information about sample injection, see “Operation Overview” on

page 32.

LEDs

The Power LED indicates whether the Dionex Aquion RFIC power is on. Other LEDs

indicate the status of various system functions. For details, see Tab le 2 .

6 Dionex Aquion RFIC Operator’s Manual Thermo Scientific

Page 23

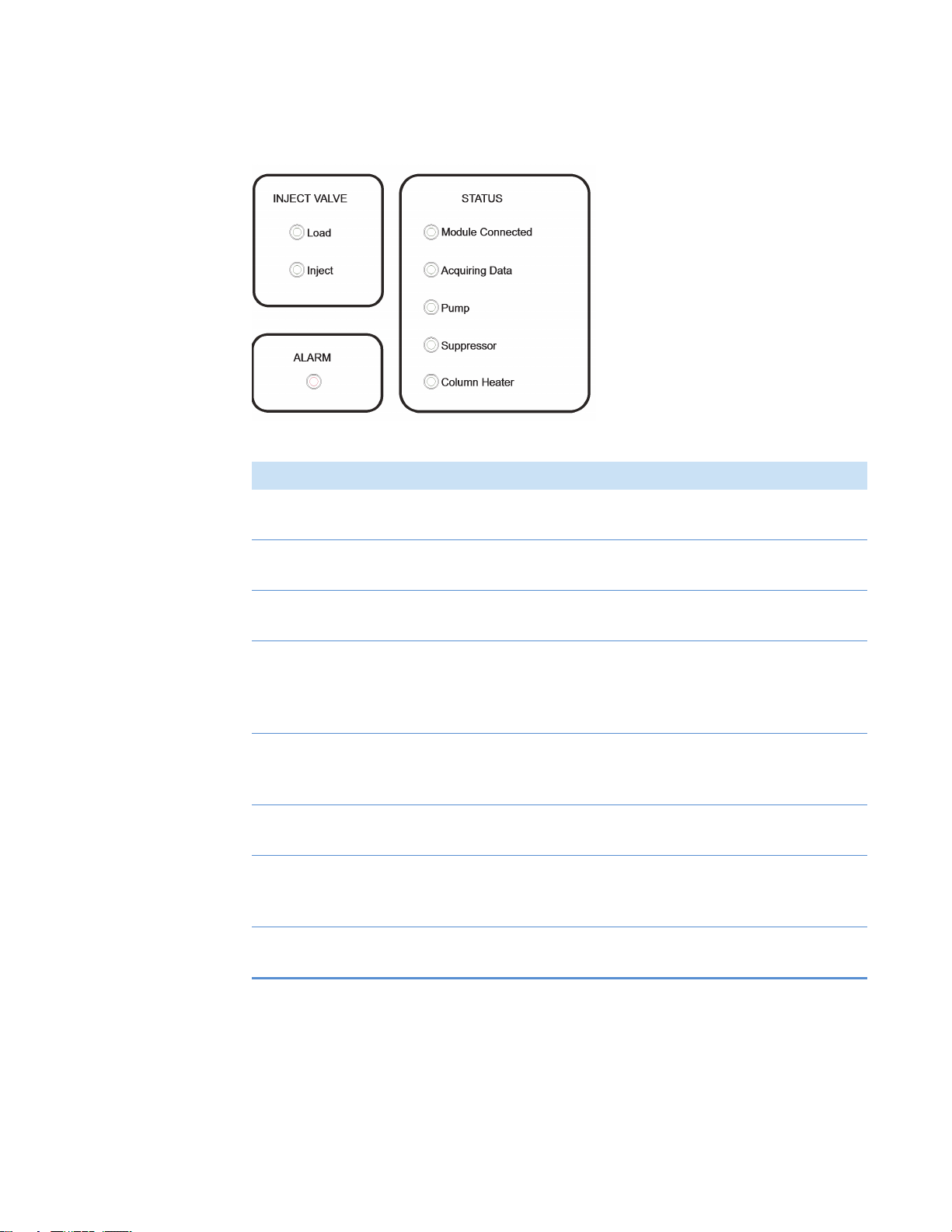

Figure 3. Dionex Aquion RFIC front panel LEDs

Table 2. Dionex Aquion RFIC front panel LED states

LED label If on (green) If flashing

2

Description

Operating Features

Load Injection valve is in

Valve error detected

Load position

Inject Injection valve is in

Valve error detected

Inject position

Alarm LED has no “on”

(green) state

Module Connected Dionex Aquion

Error detected; check the Chromeleon audit

trail for the cause

LED does not flash

RFIC is connected

to a Chromeleon

instrument

Acquiring Data Sequence or manual

data acquisition is in

Sequence stopped because an error was

detected

progress

Pump Pump is on High or low pressure limit exceeded (pump is

turned off)

Suppressor Suppressor is on and

current is being

applied to it

Column Heater Column heater is at

set temperature

Continuity check failed, or suppressor is over

the voltage, current, or power limit

(suppressor is turned off)

Column heater is transitioning to new

temperature

Thermo Scientific Dionex Aquion RFIC Operator’s Manual 7

Page 24

2

EGC service area

EGC and CR-TC power

supply connectors

EGC holder

Tubing chase

(under connectors)

Deionized

water

EGC

Description

Operating Features

Top Cover

Figure 4 shows the top cover of the Dionex Aquion RFIC.

Figure 4. Dionex Aquion RFIC top cover

• Storage area for eluent generator cartridge and eluent reservoirs

– The Dionex EGC (eluent generator cartridge) is installed in a holder that fits into the

rear of the storage area. For more information about the Dionex EGC, see page 23.

– Up to three 2-L plastic reservoirs (P/N 046548) or one 4-L plastic reservoir

(P/N 039164) can be installed in the storage area.

• Power supply connectors

– The electrical cable from the Dionex EGC connects to the EGC connector.

– The electrical cable from the Thermo Scientific™ Dionex™

Continuously Regenerated

Trap Column connects to the CR-TC connector. For more information about the

Dionex CR-TC, see page 25.

– The tubing chase under the connectors routes tubing from the eluent reservoir and

Dionex EGC holder to the front of the Dionex Aquion RFIC.

• Dionex EGC service area

– The service area holds the Dionex EGC during installation and replacement.

8 Dionex Aquion RFIC Operator’s Manual Thermo Scientific

Page 25

Component Panel

Mounting brackets for

second suppressor

Tubing chase

Column heater

(optional)

Eluent valve

Suppressor

DS6 conductivity cell

Injection valve

Tubing chase

Pump head

Pressure transducer

Leak sensor

Pump head

Site for auxiliary valve

(optional)

2

Description

Operating Features

Figure 5 shows the user-accessible components installed on the component panel behind the

Dionex Aquion RFIC front door.

Figure 5. Dionex Aquion RFIC component panel

Pressure Transducer

Leak Sensor

The pressure transducer measures the system backpressure.

A leak sensor is installed in the drip tray at the bottom of the component panel. If liquid

accumulates in the tray, the front panel Alarm LED flashes and an error message is logged in

the Chromeleon audit trail.

Thermo Scientific Dionex Aquion RFIC Operator’s Manual 9

Page 26

2

Description

Operating Features

Pump Heads

The Dionex Aquion RFIC includes a dual-piston serial pump. The flow rate can be set to

0.00 mL/min or to between 0.05 and 5.00 mL/min. For optimum performance, set the flow

rate to between 0.40 and 2.00 mL/min. Setting the flow rate to 0.00 mL/min turns off the

pump. For more information, see “Pump” on page 21.

Injection Valve

The injection valve is a 6-port, electrically-activated Rheodyne™ valve. A 25-μL sample loop

(P/N 042857) is installed on the valve at the factory. For more information, see “Injection

Valv e” on page 25.

Auxiliary Valve (Optional)

The auxiliary valve is a 2-position, electrically-activated Rheodyne valve. The valve is available

in 6-port and 10-port models. For more information, see “Auxiliary Valve (Optional)” on

page 26.

DS6 Heated Conductivity Cell

The flow-through conductivity cell measures the electrical conductance of analyte ions as they

pass through the cell. A heat exchanger inside the cell regulates the temperature, which can be

set to between 30 and 55 °C. For optimum performance, set the temperature to at least 7 °C

above the ambient temperature and 5 °C above the column oven temperature. For more

information, see “DS6 Heated Conductivity Cell” on page 10.

Suppressor

The suppressor reduces the eluent conductivity and enhances the conductivity of the sample

ions, thereby increasing detection sensitivity. The following suppressors can be used with the

Dionex Aquion RFIC:

• Thermo Scientific™ Dionex™ DRS™ Dynamically Regenerated Suppressor

• Thermo Scientific™ Dionex™ ERS™ 500 Electrolytically Regenerated Suppressor

For more information, see “Suppressor” on page 28.

Separator and Guard Columns

Both the separator and guard columns are packed with resin and perform the separation of the

sample ions. The main function of the guard column is to trap contaminants and remove

particulates that might damage the separator column.

10 Dionex Aquion RFIC Operator’s Manual Thermo Scientific

Page 27

Column Heater (Optional)

Upper tubing chase

Analog output connector

Waste lines (3)

Main power receptacle

USB connectors

TTL and Relay connector strip

Lower tubing chase

Power switch

Tubing clips

The column heater controls the temperature of the separator and guard columns. The

temperature can be set to between 30 and 60 °C; however, it must be set to at least 5 °C above

the ambient temperature. For more information, see “Column Heater (Optional)” on

page 27.

Eluent Valve

The eluent valve controls the flow from the eluent reservoir. The eluent valve opens

automatically when the pump is started and closes when the pump is turned off. For more

information, see “Eluent Valve” on page 21.

Tubing Chases

The upper tubing chase routes tubing from the top cover to the component panel. The lower

tubing chase routes tubing from the component panel, through the interior of the system, to

the rear panel.

2

Description

Operating Features

Rear Panel

Figure 6 shows the Dionex Aquion RFIC rear panel.

Figure 6. Dionex Aquion RFIC rear panel

Thermo Scientific Dionex Aquion RFIC Operator’s Manual 11

Page 28

2

Description

Operating Features

Analog Output Connector

The analog output connector outputs conductivity data (as a 0 to 1 V signal) to an integrator

or recording device. For connection and setup information, refer to the Dionex Aquion RFIC

installation instructions.

USB Connectors

The USB receptacle provides a connection to the Chromeleon computer. Two USB ports are

available for connecting to other USB devices. For connection instructions, refer to the

Dionex Aquion RFIC installation instructions.

TTL and Relay Connector

The TTL and Relay connector strip provides two TTL outputs, two relay outputs, and four

TTL inputs. The outputs can be used to control functions in other TTL- or relay-controllable

devices. The inputs can be used to switch the injection valve position, turn on the pump,

perform an autozero command, and send an event mark to the analog output. For connection

instructions, see “TTL and Relay Control” on page 131.

Tubing Chase

The lower tubing chase routes tubing from the rear panel to the component panel.

Tubing Clips

The tubing clips hold tubing routed from the top cover in place.

Power Switch

The power switch provides on/off control of power to the Dionex Aquion RFIC.

Main Power Receptacle

The power supply cord plugs into the AC power receptacle.

CAUTION The power supply cord is used as the main disconnect device. Verify that the

socket-outlet is near the Dionex Aquion RFIC and is easily accessible.

MISE EN GARDE Le cordon d'alimentation principal est utilisé comme dispositif

principal de débranchement. Veillez à ce que la prise de base soit située/installée près du

module et facilement accessible.

12 Dionex Aquion RFIC Operator’s Manual Thermo Scientific

Page 29

VORSICHT Das Netzkabel ist das wichtigste Mittel zur Stromunterbrechung. Stellen Sie

sicher, daß sich die Steckdose nahe am Gerät befindet und leicht zugänglich ist.

Flow Schematics

• Figure 7 illustrates the liquid flow path when the components required for producing

• Figure 8 illustrates the liquid flow path when the components required for producing

2

Description

Flow Schematics

KOH, LiOH, NaOH, or MSA eluent are installed. The required components include the

corresponding type of Dionex EGC III Eluent Generator Cartridge and a Dionex

CR-TC.

carbonate eluent are installed. The required components include a Dionex EGC 500

K

Eluent Generator Cartridge and aThermo Scientific™ Dionex™ EGC 500

2CO3

Carbonate Mixer.

Thermo Scientific Dionex Aquion RFIC Operator’s Manual 13

Page 30

2

Description

Flow Schematics

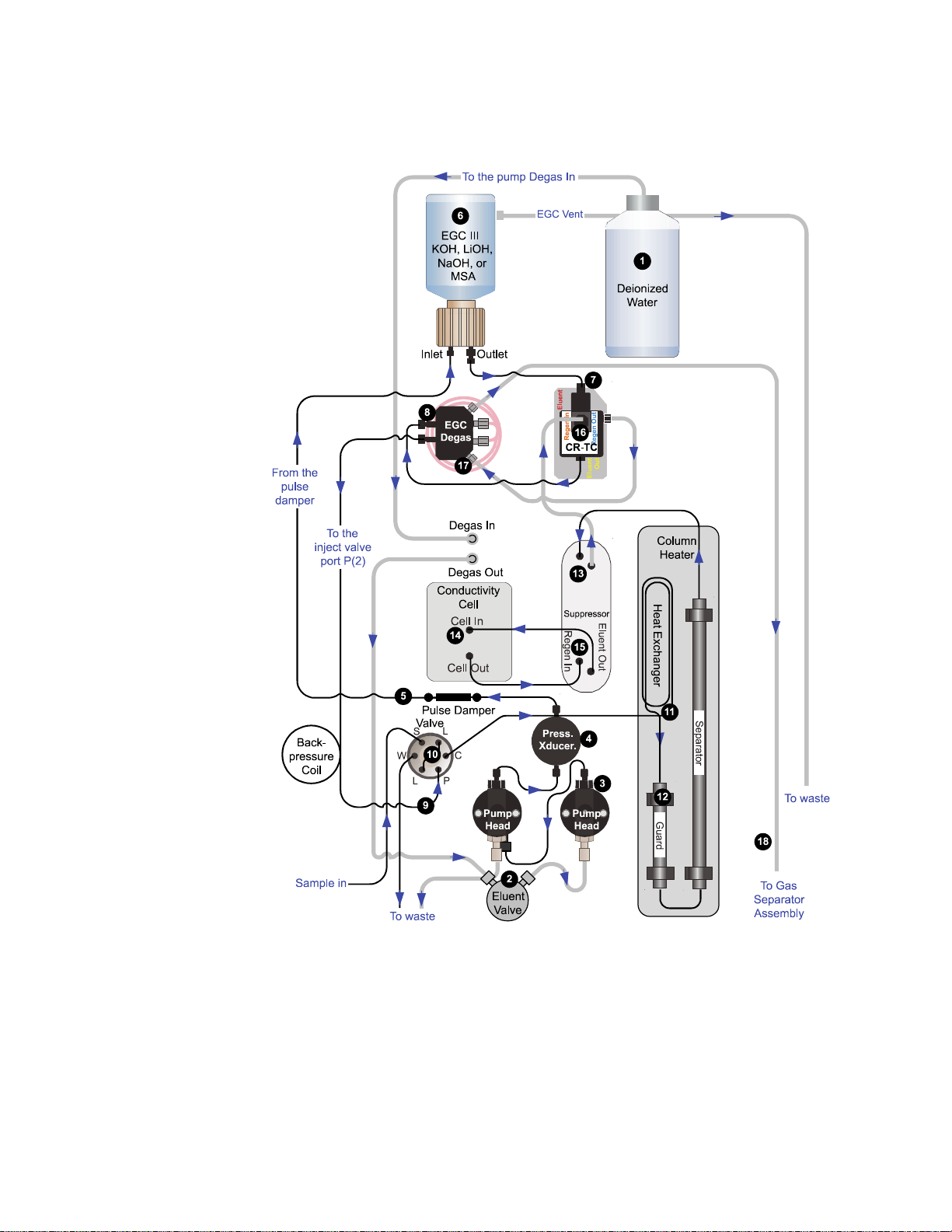

Figure 7. Dionex Aquion RFIC flow schematic: KOH, LiOH, NaOH, or MSA eluent generation

14 Dionex Aquion RFIC Operator’s Manual Thermo Scientific

Page 31

Flow Description for KOH, LiOH, NaOH, or MSA Eluent Generation

11121314151617

18

See Figure 7 for an illustration of the flow path described below.

2

Description

Flow Schematics

• Deionized water from the reservoir

then through the eluent valve

pressure transducer

through a pulse damper

, which measures the system pressure. From there, the water flows

, which smooths minor pressure variations from the pump to

flows first through the pump degas assembly, and

to the pump . The water is then pushed through the

minimize baseline noise.

• Water then flows into the eluent generator cartridge (Dionex EGC)

, which generates

the programmed concentration of eluent. Eluent exits the cartridge and flows through the

Dionex CR-TC

tubing assembly

• After sample is loaded into the sample loop

(which traps ionic contaminants), through the Dionex EGC degas

, and on to the injection valve .

and the injection valve is toggled to the

Inject position, eluent passes through the sample loop.

• The eluent/sample mixture is pumped through the heat exchanger , which heats the

mixture to the column heater temperature. The mixture then goes to the guard and

separator columns and through the suppressor .

• From the suppressor, the mixture flows through the conductivity cell , where the

analytes are detected. A digital signal is sent to Chromeleon software. Analog output can

be collected simultaneously.

• The mixture flows out of the conductivity cell and is recycled back into the suppressor ,

where it is the water source for the regenerant chamber.

• Regenerant waste from the suppressor is directed back to the Dionex CR-TC , and

then to the Dionex EGC degas tubing , where any released hydrogen or oxygen gas is

removed before it is sent to the gas separator assembly and then to waste .

Thermo Scientific Dionex Aquion RFIC Operator’s Manual 15

Page 32

2

Description

Flow Schematics

Figure 8. Dionex Aquion RFIC flow schematic: carbonate eluent generation

16 Dionex Aquion RFIC Operator’s Manual Thermo Scientific

Page 33

Flow Description for Carbonate Eluent Generation

11121314151617

See Figure 8 for an illustration of the flow path described below.

2

Description

Flow Schematics

• Deionized water from the reservoir

then through the eluent valve

pressure transducer

through a pulse damper

minimize baseline noise.

• Water then flows into the eluent generator cartridge (Dionex EGC)

the programmed concentration of carbonate eluent. Eluent exits the cartridge and flows

through the Dionex EGC degas tubing assembly

EGC 500 Carbonate Mixer

on to the injection valve

• After sample is loaded into the sample loop

Inject position, eluent passes through the sample loop.

• The eluent/sample mixture is pumped through the heat exchanger , which heats the

mixture to the column heater temperature. The mixture then goes to the guard and

separator columns and through the suppressor .

• From the suppressor, the mixture flows through the conductivity cell , where the

analytes are detected. A digital signal is sent to Chromeleon software. Analog output can

be collected simultaneously.

• The mixture flows out of the conductivity cell and is recycled back into the suppressor ,

where it is the water source for the regenerant chamber.

, which measures the system pressure. From there, the water flows

, which smooths minor pressure variations from the pump to

(to ensure a homogeneous eluent concentration), and then

.

flows first through the pump degas assembly and

to the pump. The water is then pushed through the

, which generates

. Eluent then goes to the Dionex

and the injection valve is toggled to the

• Regenerant waste from the suppressor is directed back to the Dionex EGC degas

tubing , where any released hydrogen or oxygen gas is removed before it is sent to the

gas separator assembly and then to waste .

Thermo Scientific Dionex Aquion RFIC Operator’s Manual 17

Page 34

2

Description

Chromeleon Chromatography Data System

Chromeleon Chromatography Data System

Chromeleon software is used to control the Dionex Aquion RFIC and to acquire and process

data. There are two modes of software control:

•With automated control, you create a list of control commands to be executed in

chronological order.

•With direct control, you use the controls on the Chromeleon ePanel Set (see Figure 9) to

issue commands and enter operating parameters. Direct control commands and

parameter settings are executed as soon as they are entered.

The Home ePanel of the Chromeleon ePanel Set includes system status information, a

signal plot, and controls for the most commonly used system functions. Click the tabs at

the top of the ePanel to access detailed status and control functions for each system

component (pump, detector, and so on).

For instructions on how to connect to the ePanel Set, see “Connecting to Chromeleon”

on page 35.

Figure 9. Example Chromeleon ePanel Set

If the function to be performed is not available on the ePanel Set, click the Command

icon on the Instrument toolbar above the ePanel Set (or press the F8 key) to open the

Chromeleon Command window (see Figure 10). From there, you can access all commands

available for the system.

18 Dionex Aquion RFIC Operator’s Manual Thermo Scientific

Page 35

Figure 10. Chromeleon Command window

2

Description

System Component Details

System Component Details

This section provides details about Dionex Aquion RFIC system components, including the

vacuum degas assembly (optional), pump, eluent generator, injection valve, column heater

(optional), suppressor, and conductivity cell.

Vacuum Degas Assembly (Optional)

The vacuum degas assembly provides online eluent degassing at a user-specified time and

duration. The assembly, which must be installed in the Dionex Aquion RFIC at the factory,

consists of:

• A single-channel degas chamber (with degas membranes) with internal capacity of 17 mL

• A dual-stage diaphragm vacuum pump

• A solenoid valve

• An on-board vacuum sensor

• The electronics required to operate the vacuum pump

• Tubing, fittings, and other accessories

Thermo Scientific Dionex Aquion RFIC Operator’s Manual 19

Page 36

2

Description

System Component Details

To select the degas operating mode

By default, the Dionex Aquion RFIC monitors the degas pressure reading and turns the degas

pump on and off as required. (This is the Monitor mode.) Follow the instructions here to

select a different operating mode.

1. Open the Chromeleon Instrument Configuration Manager.

2. Double-click the Aquion IC System icon under the instrument.

3. In the Properties dialog box, click the Options tab (see Figure 11).

Figure 11. Properties dialog box: Options tab page

4. Select the preferred options.

• Always Off: The degas pump is always off.

• Always On: The degas pump is always on.

IMPORTANT Never select the Always On option for routine operation. The Always

On option is intended for testing purposes only.

• Cycle: The degas pump cycles on and off. In the On field, specify for how long the

degas pump should run during a cycle. In the Off field, specify the time between

cycles.

• Monitor: (default mode) The Dionex Aquion RFIC monitors the degas pressure

reading and turns the degas pump on and off as required.

20 Dionex Aquion RFIC Operator’s Manual Thermo Scientific

Page 37

Eluent Valve

2

Description

System Component Details

The eluent valve (see Figure 12) controls the flow from the eluent reservoir. The valve opens

automatically when the pump is started and closes when the pump is turned off.

You can also open and close the valve manually, using controls on the Chromeleon ePanel (see

“Chromeleon Chromatography Data System” on page 18). This lets you perform service

procedures on pump components without eluent leaks occurring.

Figure 12. Eluent valve

Pump

Primary Pump Head

The Dionex Aquion RFIC pump is a microprocessor-based eluent delivery system. Its variable

speed, dual-piston series design ensures pulse-free pumping for the most demanding

applications.

The primary pump head pumps eluent into the secondary pump head (see Figure 13). The

check valves, which prevent reverse flow through the pump, are on the bottom (inlet) and top

(outlet) of the primary pump head. The priming valve is on the front of the pump head.

To open the priming valve, turn the knob one-quarter to one-half turn counterclockwise.

When the priming valve is open, liquid can flow into and out of the primary pump head via

the port on the front of the valve.

Note The priming valve must be open when the pump is being primed with a syringe (see

“Priming the Pump (Standard Procedure)” on page 90) or with isopropyl alcohol (see

“Priming the Pump with Isopropyl Alcohol” on page 92).

Thermo Scientific Dionex Aquion RFIC Operator’s Manual 21

Page 38

2

Secondary

pump head

Waste valve

Pressure

transducer

Outlet check valve

Primary pump head

Priming valve

Inlet check valve

Description

System Component Details

Secondary Pump Head

The secondary pump head delivers eluent to the remainder of the chromatography system

(the injection valve, column, and detector). The waste valve is on the front of the secondary

pump head (see Figure 13).

To open the waste valve, turn the knob one-quarter to one-half turn counterclockwise. When

the waste valve is in the open position, all pump flow is directed to waste.

Note The waste valve must be open when the pump is being primed using the Prime

button (see “Priming the Pump (Standard Procedure)” on page 90).

Figure 13. Secondary pump head

Pressure Transducer

Pulse Damper

Flow exiting the secondary pump head is directed to the pressure transducer (see Figure 13),

which measures the system pressure.

Pressure readings are displayed on the Chromeleon ePanel. Monitor readings periodically to

check that the pumping system is delivering smooth, accurate flow.

The system pressure should remain consistent, with no more than a 3% difference from one

pressure reading to the next. High and low pressure limits can be used to stop the pump flow

if a limit is exceeded. You can set the pressure limits from either the Chromeleon Instrument

Configuration Manager or the ePanel. For instructions on what to do if a pressure limit is

exceeded, see “Troubleshooting Error Messages” on page 51.

Flow output from the pressure transducer continues to the pulse damper, which smooths

minor pressure variations. From there, flow is directed to the injection valve and then to the

remainder of the chromatography system.

22 Dionex Aquion RFIC Operator’s Manual Thermo Scientific

Page 39

Piston Seal Wash

Eluent Generator

2

Description

System Component Details

The pump includes a piston seal wash assembly that can be set up to continuously rinse the

back of the piston seals to remove salt crystals and prolong the life of the seals. To use this

feature, an external wash solution must be connected to the system. The wash solution is

either ASTM filtered, Type I (18 megohm-cm) deionized water or a combination of deionized

water and 10% or 20% isopropyl alcohol. For connection instructions, refer to the Dionex

Aquion RFIC installation instructions.

For continued protection of the pump, replace the piston rinse seals and O-rings in the pump

housing every 6 months, or whenever you replace the main piston seals (see “Replacing a

Pump Piston Seal and Piston Rinse Seal” on page 78).

The eluent generator produces high-purity eluents online, using only deionized water as the

carrier. The eluent generator consists of an eluent generator cartridge (Dionex EGC) for

eluent generation, as well as a high-pressure degas tubing assembly for removal of the

electrolysis gases created during eluent generation.

Note The waste, gas separator tube (P/N 045460) should be connected to the system

waste line during installation. For more information, refer to the Dionex Aquion RFIC

installation instructions.

Several eluent generator cartridge types are available for use with the Dionex Aquion RFIC

(see Ta b le 3 ). Each cartridge contains 900 mL of the appropriate electrolyte concentrate

solution for eluent generation. For more information, refer to the Dionex EGC manual.

Table 3. Dionex EGC cartridges for the Dionex Aquion RFIC

Eluent generator cartridge P/N Description

Dionex EGC III KOH 074532 Generates potassium hydroxide eluent for

anion exchange separations

Dionex EGC III LiOH 074534 Generates lithium hydroxide eluent for

anion exchange separations

Dionex EGC III NaOH 074533 Generates sodium hydroxide eluent for

anion exchange separations

Dionex EGC III MSA 074535 Generates methanesulfonic acid eluent for

cation exchange separations

Dionex EGC 500 K

2CO3

088453 Generates potassium carbonate eluent for

anion exchange separations; requires

installation of a Dionex EGC 500

Carbonate Mixer

Thermo Scientific Dionex Aquion RFIC Operator’s Manual 23

Page 40

2

Description

System Component Details

Select the concentration of eluent to be generated on the Chromeleon ePanel. The allowable

eluent concentration depends on the flow rate, suppressor type, and cartridge type (see

Ta bl e 4 ).

Table 4. Eluent concentration ranges

Eluent generator cartridge Eluent concentration range

Dionex EGC III KOH 0.1 to 100 mM at 0.1 to 1.0 mL/min flow

0.1 to X mM at 1.0 to 3.0 mL/min flow

where X = 100/flow in mL/min

Dionex EGC III LiOH 0.1 to 80 mM at 0.1 to £ 1.0 mL/min flow

0.1 to X mM at 1.0 to £ 3.0 mL/min flow

where X = 80/flow in mL/min

Dionex EGC III NaOH 0.1 to 100 mM at 0.1 to 1.0 mL/min flow

0.1 to X mM at 1.0 to 3.0 mL/min flow

where X = 100/flow in mL/min

Dionex EGC III MSA 0.1 to 100 mM at 0.1 to 1.0 mL/min flow

0.1 to X mM at 1.0 to 3.0 mL/min flow

where X = 100/flow in mL/min

Dionex EGC 500 K

2CO3

Eluent Generator Cartridge (Dionex EGC) Holder

The Dionex EGC is installed in a cartridge holder mounted on the top cover of the Dionex

Aquion RFIC (see Figure 4). The cartridge holder also houses a high-pressure degas tubing

assembly. Tubing and fittings for plumbing the cartridge, degas assembly, and Dionex CR-TC

are included with the holder. For more information, refer to the Dionex Aquion RFIC

installation instructions.

Backpressure Coil (Optional)

The Dionex EGC requires at least 14 MPa (2000 psi) of system backpressure for removal of

electrolysis gas from the eluent produced by the cartridge. A system backpressure of 16 MPa

(2300 psi) is ideal.

If the system backpressure is too low, Thermo Fisher Scientific recommends connecting a

backpressure coil (P/N 053765) between the injection valve and the Dionex EGC

OUT port. For more information, refer to the Dionex Aquion RFIC installation instructions.

0.1 to 15 mM at 0.1 to 1.0 mL/min flow

0.1 to X mM at 1.0 to 2.0 mL/min flow

where X = 15/flow in mL/min

ELUENT

24 Dionex Aquion RFIC Operator’s Manual Thermo Scientific

Page 41

Continuously Regenerated Trap Column (Dionex CR-TC)

To W aste

Sample In

To Co l umn

From Pump

Sample

Loop

LOAD POSITION

To W aste

Sample In

From Pump

Sample

Loop

INJECT POSITION

To Column

The Dionex CR-TC is a high-pressure electrolytically-regenerated trap column. The column

is designed to remove anionic or cationic contaminants in the eluent or deionized water and

to reduce drift during gradient separations. The following columns can be used with the

Dionex Aquion RFIC:

• CR-ATC Continuously Regenerated Anion Trap Column (P/N 060477)

• CR-CTC II Continuously Regenerated Cation Trap Column (P/N 060262)

For more information, refer to the column manual.

Carbonate Mixer

To ensure a homogeneous eluent concentration, the carbonate eluent generated by the Dionex

EGC 500 K

to the injection valve. The mixer is included in the following kits:

• Dionex EGC 500 Carbonate Mixer Kit, 2 mm (P/N 088467)

flows through a Dionex EGC 500 Carbonate Mixer before being delivered

2CO3

2

Description

System Component Details

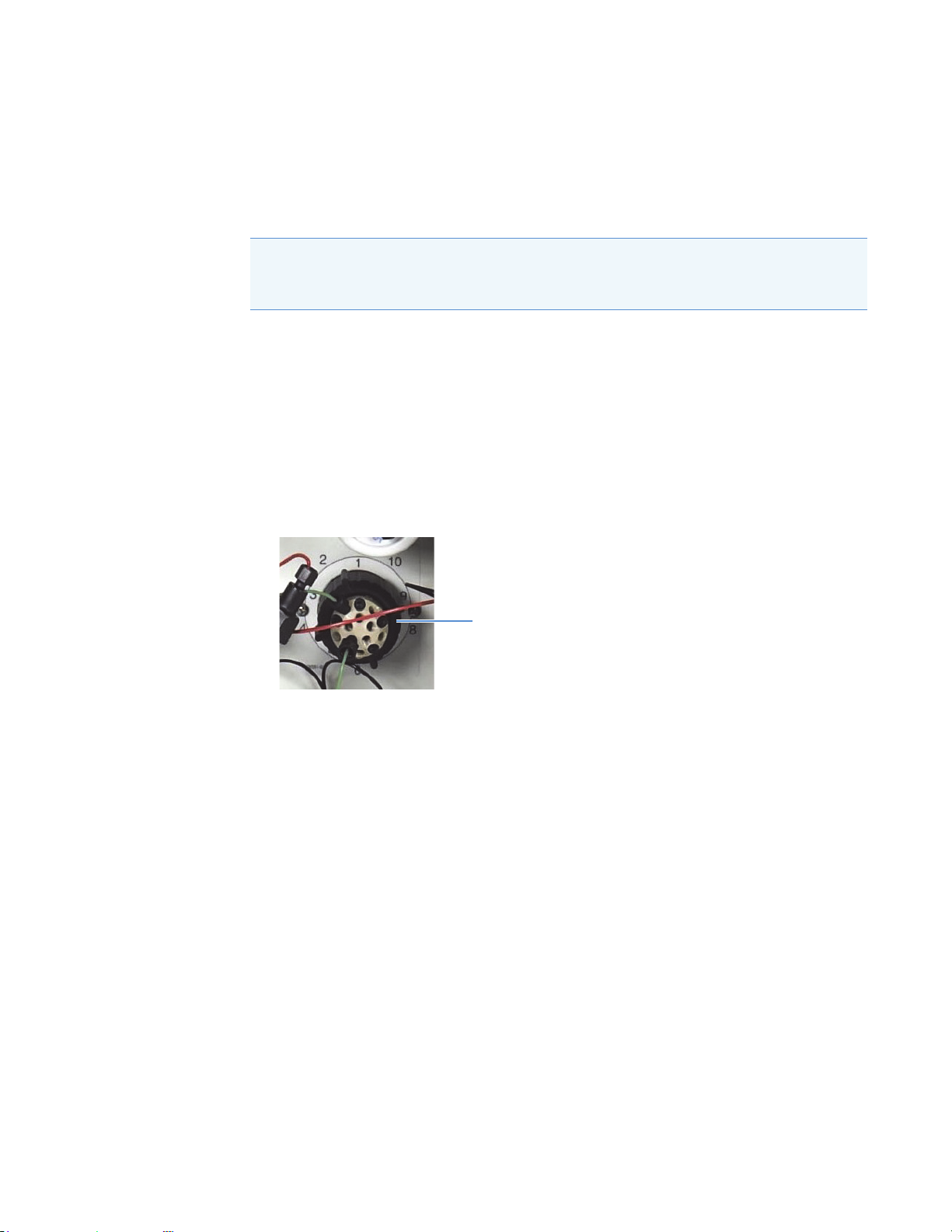

Injection Valve

• Dionex EGC 500 Carbonate Mixer Kit, 4 mm (P/N 088468)

The injection valve (P/N 057968) is a 6-port, electrically-activated valve. A 25-μL sample

loop (P/N 042857) is installed on the valve at the factory.

The valve has two operating positions: Load and Inject (see Figure 14).

Figure 14. Injection valve flow schematics

Thermo Scientific Dionex Aquion RFIC Operator’s Manual 25

Page 42

2

Description

System Component Details

Eluent flows through the Load or Inject path, depending on the valve position.

• Load position: Sample is loaded into the sample loop, where it is held until injection.

Eluent flows from the pump, through the valve, and to the column, bypassing the sample

loop. Sample flows from the syringe or automated sampler line (if installed), through the

valve, and into the sample loop. Excess sample flows out to waste.

• Inject position: Sample is swept to the column for analysis. Eluent flows from the pump,

through the sample loop, and on to the column, carrying the contents of the sample loop

with it. For more information, see “Loading and Injecting Samples” on page 41.

Figure 15 shows the injection valve connections. The injection valve is plumbed at the factory

with all tubing and fittings for connection to the pump, injection port, column, and waste. A

25-μL PEEK™ (polyether ether ketone) sample loop (P/N 042857) is installed between ports

L (1) and L (4). If necessary, replace the pre-installed 25-μL loop with a loop that has a

different sample injection volume. Thermo Fisher Scientific offers sample loops in various

sizes.

Figure 15. Injection valve plumbing

Auxiliary Valve (Optional)

The auxiliary valve is a 2-position, electrically-activated, high-pressure Rheodyne valve. The

PEEK valve is available in two models: a 6-port valve and a 10-port valve. The auxiliary valve

must be installed on-site by Thermo Fisher Scientific field service personnel.

When installed, the valve enables a variety of sample preparation activities, including:

• Online filtration

• Matrix elimination (for example, the removal of high backgrounds of chloride or organic

material)

• Concentrator-based techniques

• Conditional injections (large loop/small loop applications where the data system

monitors sample concentration and reinjects the sample, using the smaller loop, if the

concentration is too high)

26 Dionex Aquion RFIC Operator’s Manual Thermo Scientific

Page 43

• AutoNeutralization™

• Matrix diversion prior to MS (mass spectrometry) detection

Column Heater (Optional)

The column heater (see Figure 16) provides temperature control for the separator and guard

columns.

Figure 16. Column heater

2

Description

System Component Details

The heater temperature can be set to between 30 °C and 60 °C. The set temperature must be

at least 5 °C above the ambient temperature. Setting the temperature to 0 °C turns off the

column heater.

A thermistor mounted in the heater block monitors the temperature. If the temperature

exceeds 65 °C, the column heater is shut off and an error message is displayed in the

Chromeleon audit trail. For troubleshooting guidance, see “Column heater exceeds safe

temperature” on page 51.

The column heater can be installed at the factory or installed on-site by Thermo Fisher

Scientific field service personnel.

Thermo Scientific Dionex Aquion RFIC Operator’s Manual 27

Page 44

2

Description

System Component Details

Suppressor

The suppressor reduces the eluent conductivity and enhances the conductivity of the sample