Thermo Scientifi? Dionex Chemically Regenerated Suppressor 500 Series, Dionex CRS 500 Series, Dionex ACRS 500, Dionex CCRS 500 Product Manual

Page 1

Part of Thermo Fisher Scientific

Thermo Scientific

Dionex CRS 500

Product Manual

P/N: 031727-07 March 2015

Page 2

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 2 of 40

Product Manual

for

Dionex Chemically Regenerated Suppressor 500

Dionex ACRS 500, 4 mm, (P/N 085090)

Dionex CCRS 500, 4 mm, (P/N 085092)

Dionex ACRS 500, 2 mm, (P/N 085091)

Dionex CCRS 500, 2 mm, (P/N 085093)

031727-07

Page 3

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 3 of 40

© 2015 Thermo Fisher Scientific Inc. All rights reserved.

Thermo Fisher Scientific Inc. provides this docu ment to its customers with a product purchase to use in the product

operation. This document is copyright protected and any reproduction of the whole or any part of this document is

ede all previous

Revision History:

All trademarks are the property of Thermo Fisher Scientific Inc. and its subsidiaries.

strictly prohibited, except with the written authorization of Thermo Fisher Scientific Inc.

The contents of this docu ment ar e subj ect to change without notice. All tech nical infor mati on in this d ocu ment is for

reference purposes only. System configurations and specifications in this document supers

information received by the purchaser.

Thermo Fisher Scientific Inc. makes no representations that this document is complete, accurate or error free and

assumes no responsibility and will not be liable for any errors, o missions, da mage or loss that might result from any

use of this document, even if the information in the document is followed properly.

This document is not part of any sales contract between Thermo Fisher Scientific Inc. and a purchaser. This

document shall in no way govern or modify any Terms and Conditions of Sale, which Terms and Conditions of Sale

shall govern all conflicting information between the two documents.

For Research Use Only. Not for Use in Diagnostic Procedures.

Revision 06, January, 2015 – Rebranded for Thermo Scientific. Product name changed from Dionex MMS 300 to

CRS 500.

Revision 07, March, 2015 – Typo and formatting corrections.

031727-07

Page 4

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 4 of 40

Indicates a potentially hazardous situation which, if not avoided, could result in death or

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

!

!

!

NOTE

!

Safety and Special Notices

Make sure you follow the precautionary statements presented in this guide. The safety and

other special notices appear in boxes.

Safety and special notices include the following:

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in damage to

equipment.

IMPORTANT

Tip

moderate injury. Also used to identify a situation or practice that may seriously damage the

instrument, but will not cause injury.

Indicates information o f general interest.

Highlights information necessary to prevent damage to software, loss of data, or invalid test

results; or might contain information that is critical for optimal performance of the system.

Highlights helpful inform ation that can make a task easier.

031727-07

Page 5

Contents

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 5 of 40

Contents

1. Introduction ......................................................................................................... 7

1.1 Chemically Regenerated Suppressor .............................................................................................. 7

1.2 Dionex Chemically Regenerated Suppressor Assembly Schematic ............................................... 9

1.3 Chemical Suppression Schematic ................................................................................................. 11

1.4 Shipment and Storage ................................................................................................................... 12

1.4.1 Shipment ............................................................................................................................................. 12

1.4.2 Storage ................................................................................................................................................ 12

1.5 Overview of Suppression Modes .................................................................................................. 13

1.6 Mode of Operation Selection ........................................................................................................ 14

1.6.1 The Displacement Chemical Regeneration (DCR) Mode ................................................................... 15

1.6.2 The External Chemical Mode ............................................................................................................. 16

1.6.3 The AutoRegen Suppres s i on Mode ..................................................................................................... 17

2. Installation .........................................................................................................18

2.1 System Requirements ................................................................................................................... 18

2.2 Back Pressure Coils for the Dionex CRS 500 .............................................................................. 19

2.3 Plumbing for Displacement Chemical Regeneration (DCR) Mode of Operation ........................ 21

2.4 Plumbing for External Chemical Mode of Operation ................................................................... 23

2.5 Peristaltic Pump installation ......................................................................................................... 24

2.6 Plumbing for AutoRegen Suppression Mode of Operation .......................................................... 25

3. Operation ...........................................................................................................27

3.1 Chemical Purity Requirements ..................................................................................................... 27

3.1.1 Inorganic Che mic a l s ............................................................................................................................ 27

3.1.2 Solvents ............................................................................................................................................... 27

3.1.3 Deionized Water.................................................................................................................................. 27

3.2 Start Up ......................................................................................................................................... 28

3.3 Optimizing Regenerant Concentration and Flowrate ................................................................... 29

3.3.1 Anion Regenerant Concentration for Optimized Operation in

External Chemical and AutoRegen Modes ......................................................................................... 29

3.3.2 Cation Regenerant Concentration for Optimized Operation for

External Chemical and AutoRegen Modes ......................................................................................... 30

3.3.3 Calculations for Regenerant Concentration......................................................................................... 32

3.3.4 Regenerant Concentrat ion for DCR Mode .......................................................................................... 33

3.4 Storage .......................................................................................................................................... 33

3.4.1 Short Term Storage (1 to 5 days) ........................................................................................................ 33

3.4.2 Long Term Storage ............................................................................................................................. 33

031727-07

Page 6

Contents

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 6 of 40

4. Troubleshooting Guide .....................................................................................34

4.1 Small Analyte Peak Areas ............................................................................................................ 34

4.2 High Background Conductivity .................................................................................................... 34

4.3 Drifting Baseline........................................................................................................................... 35

4.4 Decreased Sensitivity ................................................................................................................... 36

4.5 System Back Pressure Increases Over Time ................................................................................ 36

4.6 Liquid Leaks ................................................................................................................................. 37

5. Suppressor Cleanup ..........................................................................................38

5.1 Base-Soluble Contaminants or Precipitates with the Dionex CRS 500 ........................................ 39

5.2 Organic Contaminants with the Dionex ACRS 500 or Dionex CCRS 500 .................................. 40

031727-07

Page 7

1 – Introduction

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 7 of 40

1. Introduction

Suppressor: The role of a suppressor in Ion Chromatography is to remove the eluent and sample

counterions and replace this with regenerant ions thereby converting the eluent to a weakly

dissociated form prior to detection. Detection of analyte ions particularly with conductivity

detection is therefore feasible against a low background. The suppressor not only reduces the

background signal but also the noise associated with the signal. Furthermore, the analytes are

converted to the more conductive acid or base form, which enhances the signal, particularly for

fully dissociated species. Thus overall i mprovement in detection limits as observed from the

signal to noise ratio is achieved. When compared to single column ion chromatography, i.e.,

applications that do not use a suppressor, the improvement in noise with suppressed ion

chromatography far exceeds the noise performance of single column chromatography

applications. Hence the suppressor has become an integral part of the ion chromatography

instrument.

The suppressors from Thermo Fisher Scientific are designed for continuous operation and do

not require any switchin g or offline r egeneratio n. Furthermore , the standar ds and the s amples

are always exposed to the same suppressor device when pursuing ion analysi s, thus ensuring

that the analytical parameters are consistent between calibration and analysis. From a simplistic

perspective there are two types of suppressors offered for continuous operation, namely,

electrolytically regenerated suppressors and chemically regenerated suppressors. The

electrolytic suppressors operate continuously with a water source as a regenerant. In the recycle

mode of operation the water source is derived from the suppressed eluent, thereby making the

suppressor operation facile. The chemical suppressors operate continuously with an external

regenerant source.

The electrolytic suppressor also is a device that permits recycle of the eluent when installed in a

system with Eluent Recycle (ER) s ys t em.

1.1 Chemically Regenerated Suppressor

The T hermo Scientific™ Dionex™ Chemically Regenerated Suppressor (Dionex CRS™ 500)

replaces the Dionex MicroMembrane Suppressor (MMS 300 ) product line. The Dionex CRS

500 is a chemical suppressor with a new hardware design that allows the suppressor to be more

pressure tolerant than previous generation suppressor devices. The suppressor flow pathway has

been redesigned to optimize band dispersion, improve the flow and sealing properties. The

Dionex CRS 500 continues to use the same cleaned ion exchange components (screens and

membranes) as the Dionex MMS 300 suppressor devices; however the Dionex CRS 500 eluent

channel uses an ion exchange resin bed as opposed to a gasketed screen.

The Chemically Regenerated Suppressor (CRS 500) is available in two versions: the Anion

Chemically Regenerated Suppressor (Dionex ACRS™ 500) or Cation Chemically Regenerated

Suppressor (Dionex CCRS™ 500) to support anion and cation analysis applications.

031727-07

Page 8

1 – Introduction

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 8 of 40

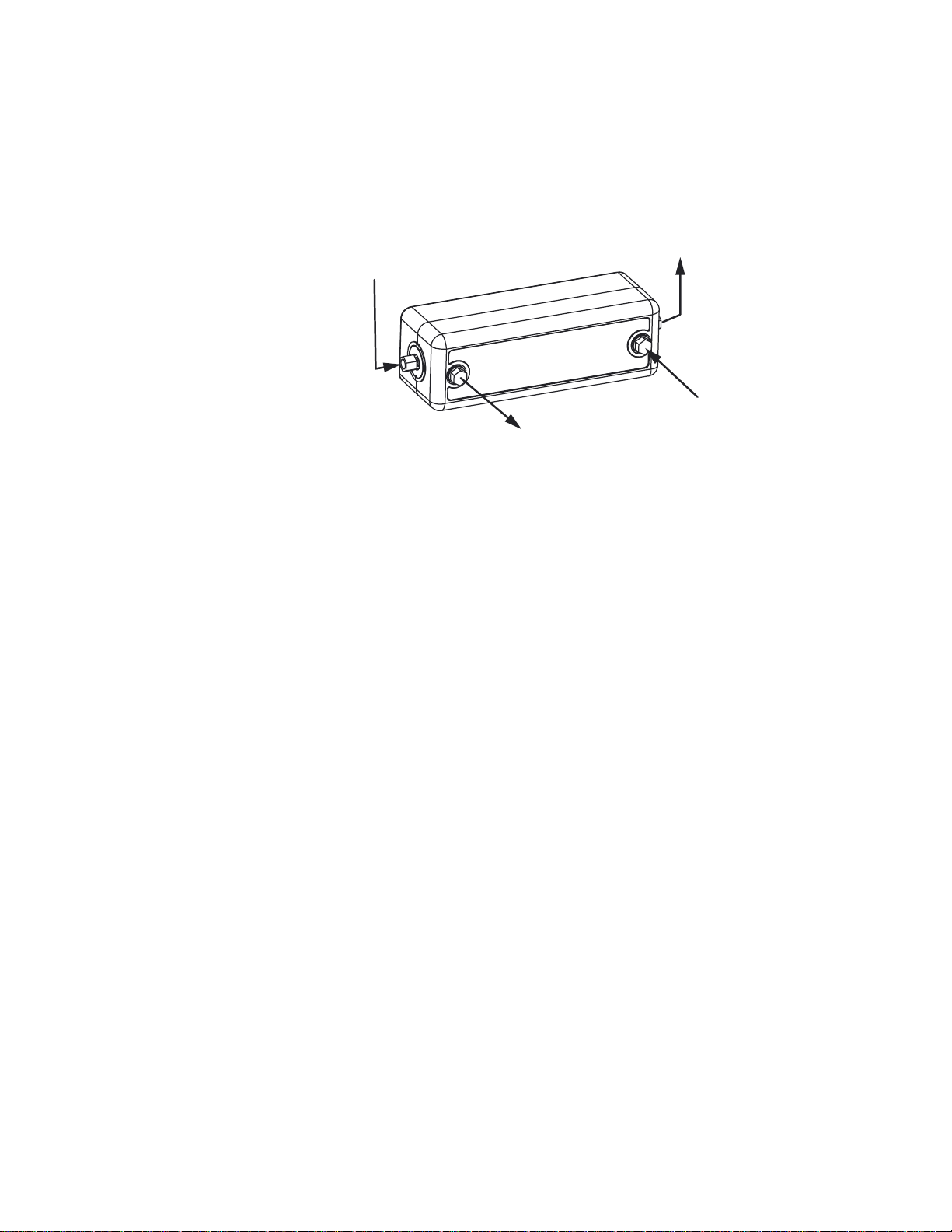

Regenerant is pumped in

Regenerant is Diverted to Waste

or

Recycled to AutoRegen Module

Eluent In

From Analytical Column

Eluent Out

To Detector Cell

with Back Pressure Coils

and then to Waste

or

to DCR Reservoir

Figure 1 The Chemical Suppression System

The Dionex Chemically Regenerated Suppressors, Dionex Anion Chemically Regenerated

Suppressor (Dionex ACRS 500) and the Dionex Cation Chemically Regenerated Suppressor

(Dionex CCRS 500), provide a high performance, highly reliable, low maintenance chemical

suppression system for Ion Chromatography.

The chemical suppression system consists of the Dionex CRS 500 and a source of chemical

regenerant. Through an ion exchange based neutralization reaction in the Dionex CRS 500

Suppressor device, the eluent is converted to a weakly dissociated lower conductivity form

while the analytes are converted typically to a more conductive form.

The Dionex CRS 500 is a non-electrolytic device and therefore requires no power supply.

Installation of equipment (either the Displacement Chemical Regeneration (DCR) kit, a

pressurized bottle delivery s ystem, additional pump or the AutoRegen Accessory) is needed in

conjunction with the Dionex CRS 500. This equipment facilitates the delivery of the regenerant

to the Dionex CRS 500 suppressor. A regenerant controller Thermo Scientific™ Dionex

TM

SRD-10 Suppressor Regenerant Detector is reco mmended to monitor the chemical regenerant

flow and trigger when to replace the chemical regenerant. If the regenerant flow is restricted or

stops the SRD-10 auto matically disables the eluent pump.

The Dionex CRS 500 provides high capacity suppression while adding minimum dead volume

to the analytical system. The ability of the Dionex ACRS 500 to provide continuous suppression

of traditional eluents, and more concentrated eluents up to 100 mM NaOH, significantly

expands the capabilities and simplifies the operation of anion exchange Ion Chromatography.

The ability of the Dionex CCRS 500 to provide continuous suppression of traditional eluents,

and more concentrated eluents up to 75 mM HCl, significantly expands the capabilities and

simplifies the operation of cation exchange Ion Chromatography.

The Dionex ACRS 500 and Dionex CCRS 500 are available in both 4 mm and 2 mm formats

for use with 4 mm and 2 mm Ion Chromatography columns and systems respectively. The 4 mm

Dionex CRS 500 is designed to ensure optimum performance with 4 and 5 mm columns. The 2

mm Dionex CRS 500 is designed with reduced internal volume to ensure optimum performance

with, 2 and 3 mm columns and systems.

031727-07

Page 9

1 – Introduction

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 9 of 40

NOTE

!

For assistance, contact Technical Support for Dionex Products. In the U.S., call 1-800346-6390. Outside the U.S., call the nearest Thermo Fisher Scientific office.

1.2 Dionex Chemicall y Regen erat ed Suppressor Assembly Schematic

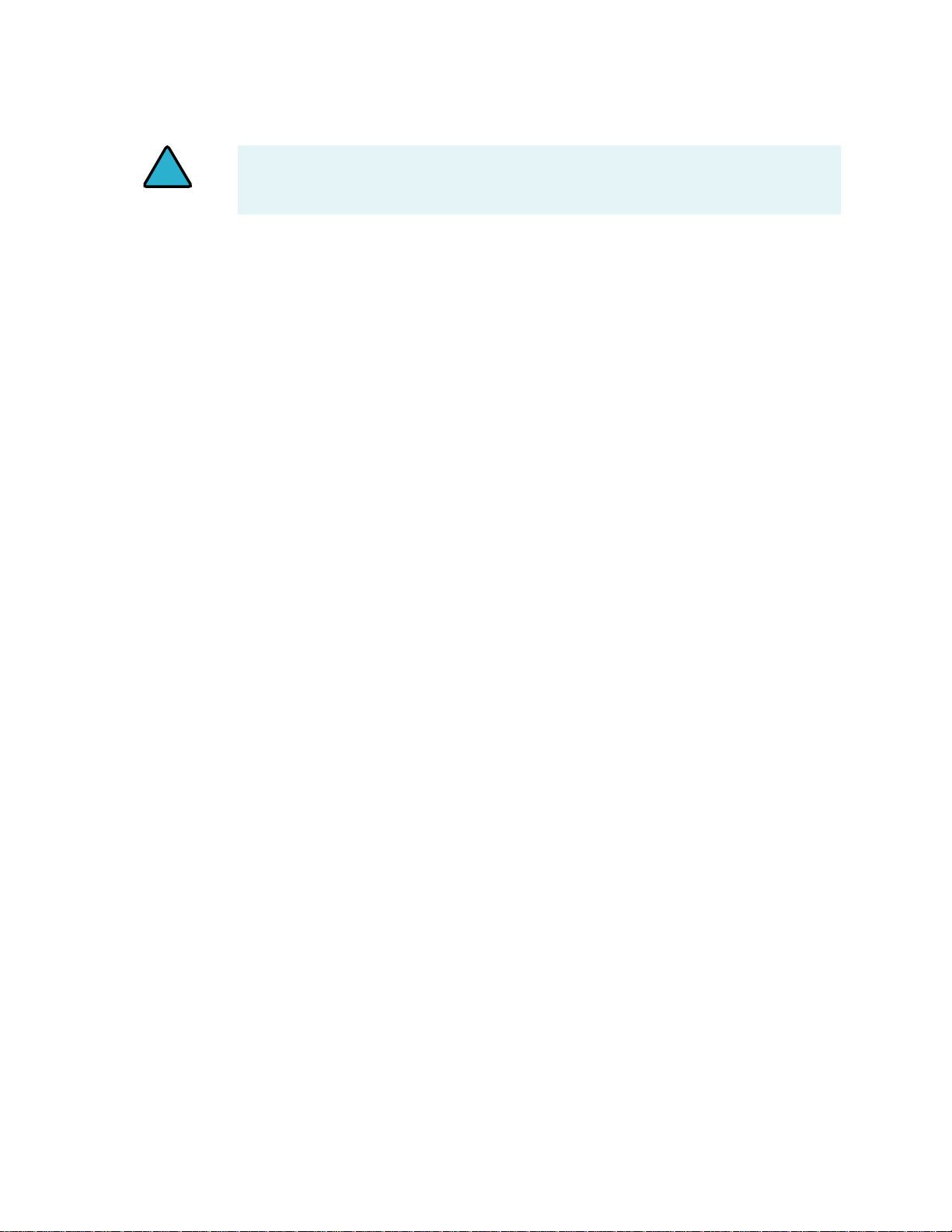

The Dionex CRS 500 includes two regenerant compartments and one eluent compartment

separated by ion exchange membranes. The central channel is the eluent channel and the two

side channels are regenerant channels. Two PEEK plates form the outer walls of the regenerant

channels and have t he ¼-28 port s for co nnecti ng the r egene rant li quid li nes. T he elue nt cha nnel

is defined by a PEEK plate that seals against the ion exchange membrane and a thin elastomeric

o-ring installed on the regenerant PEEK plates. The eluent in and out ports are independent

ports that define the fluidic pa thwa y, which i s simi lar to a co lumn The regenerant flo w dir ectio n

is opposite to the elue nt flow direction. This orie ntation ensures complete regeneratio n of the

device.

The regenerant channels are flushed with a regenerant tha t supplies hydronium or hydroxide

ions that are required for the suppression reaction. For the Dionex ACRS 500, the ion e xc han ge

membranes provide the transport pathwa y for the hydronium ions into the eluent channel while

providing a transport pathway for the sodium or potassium ions out o f the eluent cha nnel. For

the Dionex CCRS 500, the ion exchange membranes provide the transport pathway for the

hydroxide ions into the eluent channel while providing a transport pathway for the sulfate or

MSA ions out of the eluent channel. In the Dionex CRS 500 the rege nerant channel is fitted

with unfunctionalized neutral regenerant screens that facilitate excellent transport of ions to and

from the ion exchange membranes without any retention in the regenerant channel. The net

result for both the Dionex ACRS 500 and t he Dionex CCRS 500 is suppression o r conversion of

the eluent from a hi ghly conduc tive for m to a wea kly cond uctive for m and conversion of most

analytes into highly conductive forms.

For example, for the Dionex ACRS 500, sodium hydroxide eluent with residual carbonate is

converted to water and a weakly conductive carbonic acid background, while sodium chloride

analyte is converted to a highly conductive hydrochloric acid form. Thus the analyte, chloride, is

detected as the highly conductive HCl form against a low conductivity water and residual

carbonic acid background. For the Dionex CCRS 500, methanesulfonic acid eluent is converted

to water and the analyte, sodium chloride, is converted to sodium hydroxide. Thus sodium is

detected as the highly conductive NaOH form against a low conductivity water bac kground. It

should be noted that the background of the suppressed eluent may be elevated due to chemical

leakage of the regenerant into the eluent; therefore optimization of the regenerant type,

concentration and flow rate may be needed to minimize this effect.

031727-07

Page 10

1 – Introduction

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 10 of 40

Regen In

Regen Out

Eluent In

Eluent Out

Figure 2 Membrane and Flow Chamber Configuration in the Dionex Chemically

Regenerated Suppressors

031727-07

Page 11

1 – Introduction

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 11 of 40

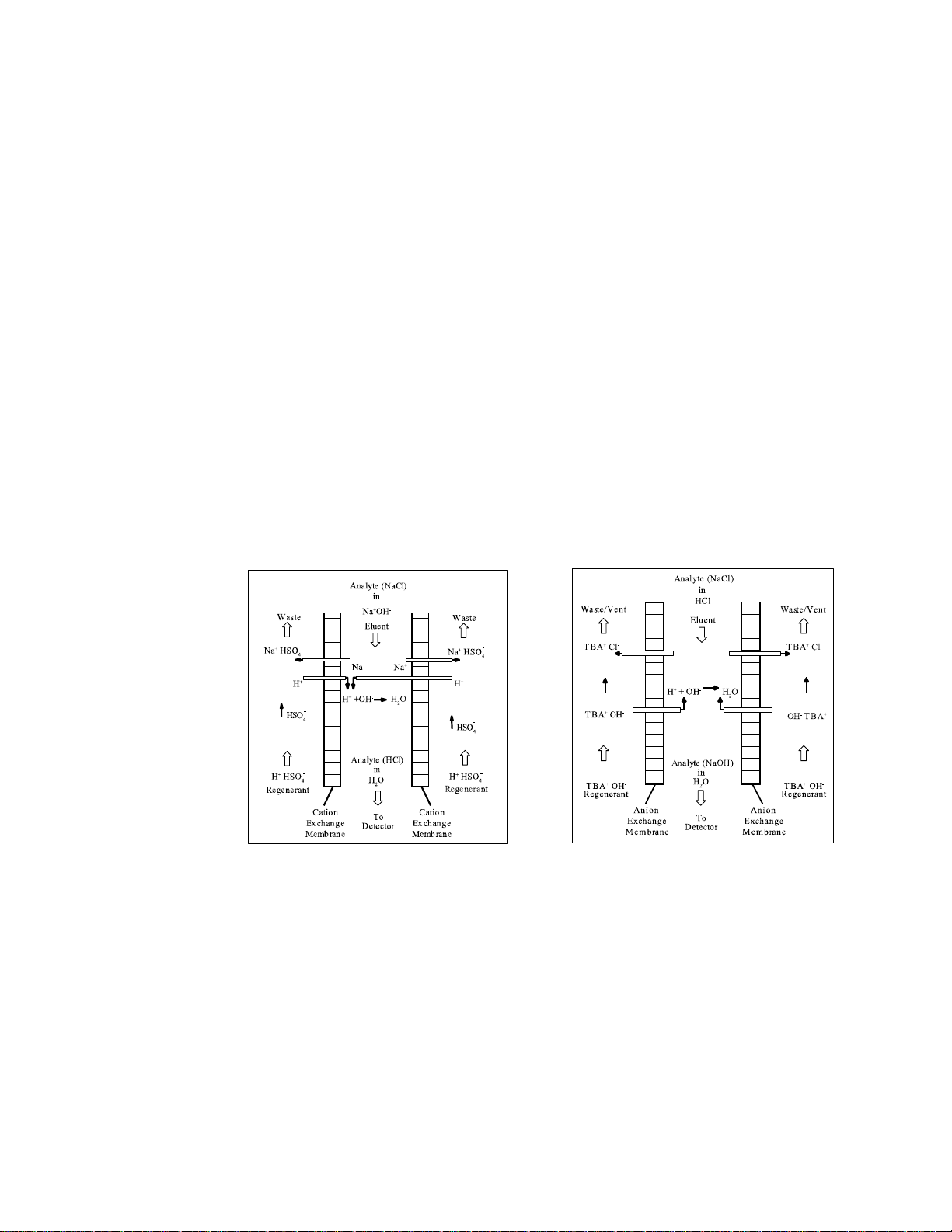

1.3 Chemical Suppression S chematic

Chemical Suppression with the Dionex ACRS 500 is a neutralization reaction and selective

desalting process carried out across a pair of cation exchange membranes. The cation exchange

membranes facilitate the selective exchange of cations in the suppressor. With sodium

hydroxide as the eluent, sodium ions are continuously exchanged for hydronium ions from the

regenerant acid and combine with the eluent hydroxide to form water. The sodium ions are

removed continuously from the suppressor by the regenerant acid stream thus effecting

continuous suppression.

Chemical Suppression with the Dionex CCRS 500 is a neutralization reaction and selective

desalting process carried out across a pair of anion exchange membrane s.. The a nion excha nge

membranes facilitate the selective exchange of anio ns in the supp ressor. Wi th methanes ulfonic

acid as the eluent, the methanesulfonate ions are continuously exchanged for hydroxide ions

from the regenerant base (TBAOH) and combine with the eluent hydronium to form water. The

methanesulfonate anions are removed continuously from the suppressor by the regenerant base

stream thus effecting continuous suppression.

Figure 3 Figure 4

Chemical Suppression with the Chemical Suppression with the

Dionex Anion Chemically Regenerated Dionex Cation Chemically Regenerated

Suppressor (Dionex ACRS 500) Suppressor (Dionex CCRS 500)

031727-07

Page 12

1 – Introduction

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 12 of 40

storage or

Ensure the suppressor is stored in a temperature controlled environment away from direct

!

!

1.4 Shipment and Storage

1.4.1 Shipment

The Dionex Chemically Regenerated Sup pressors (Dionex ACRS 500 and Dionex CCRS

500) should not be subjected to temperatures above 60°C during shipment,

operation for extended periods of time.

1.4.2 Storage

exposure to sunlight or other sources of heat. Do not store the suppressor in a nontemperature controlled environment where temperatures in excess of 40°C are commonly

experienced, such as a parked car, a tool shed, or a lab-bench in close proximity to an open

window with direct sunlight.

031727-07

Page 13

1 – Introduction

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 13 of 40

1.5 Overview of Suppressio n Modes

Three basic modes of suppression can be used with the Dionex Chemically Regenerated

Suppressor (Dionex CRS 500):

Displacement Chemical Regeneration Mode:

This mode is a se lf-co nta ined mean s of d is pens ing r ege ner ant i nto the Dionex CRS 500 without

any added pumps or delivery systems. The suppressed effluent from the suppressor is directed

from the cell outlet into a closed bottle containing the regenerant. A second line is connected

back from the bottle into the REGEN IN port of the suppressor. Thus t he ce ll e f fl ue nt d r i ves t he

regenerant out of the bottle and into the Dionex CRS 500; the difference in density of the eluent

and regenerant solutions prevent mixing of the two. In this mode, the eluent flow rate

determine s t he regenerant flow rate.

The density of the cell effluent and the regenerant determines the exact location of the line

inside the bottle. For detailed plumbing and operation instructio ns refer to the DCR Kit M anual

(Document No. 031664).

External Chemical Mode:

This mode in the simplest form uses an external regenerant reservoir that is gas pressurized and

dispenses regenerant into the suppressor. The pressure on the container, the liquid level and the

back pressure of the Dionex CRS 500 suppressor and associated tubing determines the flow rate

of the regenerant into the suppressor. An external pump could also be used to dispense the

regenerant, provided the pump is substantially pulse free or has a suitable pulse damper

installed.

AutoRegen Suppression Mode:

This mode has been discontinued by Thermo Scientific and is only included here for legacy

operators.

AutoRegen Suppression mode recycles the regenerant thus enabling continuous operation. A

pump is required in this mode to pump the expended regenerant back into an AutoRegenerant

cartridge to exchange the cations for hydronium ions (Dionex ACRS 500) or the anions for

hydroxide ions (Dionex CCRS 500). Thus, fresh regenerant is made available for the

suppression function.

The following sections explain which mode to use for an application. Once the mode of

operation is determined, more detailed plumbing configuration and operating instructions can be

found in Section 3, “Dionex Chemically Regenerated Suppressor (Dionex CRS 500)

Operation.”

031727-07

Page 14

1 – Introduction

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 14 of 40

Eluent

Displacement Chemical

External Chemical

AutoRegen

Aqueous El uents

Yes

Yes

Yes

Eluents Co ntaining

Yes

Yes

Yes

Eluents Co ntaining

Yes

Yes

Yes

1.6 Mode of Operation Selection

The Dionex ACRS 500 uses sulfuric acid as the preferred regenerant to achieve eluent

suppression. The Dionex CCRS 500 uses tetrabutylammonium hydroxide (TBAOH) as the

preferred regenerant to achieve eluent suppression. Both the Dionex ACRS 500 and Dionex

CCRS 500 mode of operation is highly dependent on the ionic strength or concentration of the

eluent used and the analysis sensitivity requirements.

Table 1 Eluent Composition and Suppression Mode Compatibility

Composition

Organic Solvents

Ion Pair Reagents

with/without Solvents

Regeneration Mode

Mode

Suppression

031727-07

Page 15

1 – Introduction

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 15 of 40

Regenerant

Regen

IN

Regen

OUT

Eluent

OUT

Eluent

IN

Injection

Valve

Guard

Column

Analytical

Column

Waste

Cell

1.6.1 The Displacement Chemical Regeneration (DCR) Mode

The DCR Mode is the easiest mode to implement and provides convenient and economical

operation in which the regenerant is displaced from the regenerant reservoir using the

conductivity cell effluent. T his mode delivers regenerant to the suppressor at a flow rate equal to

the eluent flow rate. In this mode the regenerant bottle is completely filled with regenerant upon

startup. As the cell effluent is p umped into r eservoir it displa ces the rege nerant solu tion into the

Dionex CRS regenerant chambers. No additional pump or pressure is required. Eluent and

regenerant bottles are of equivalent volumes ensuring that the regenerant solution lasts as long

as the eluent; thus new regenerant needs to be prepared only when new eluent is prepared.

The DCR Mode is recommended for low to medium suppression applications (< 50 ueq/min)

and provides adequate dynamic capacity for the majority of applications. Because regenerant

flow rate is limited to the same flow rate as the eluent, the concentration of the regenerant may

need to be adjusted to achieve full suppression; this may result in increased background

conductivity compared to other modes where the flow rate can be adjusted. As a general rule the

regenerant concentration in mN should be 2 to 5 times the eluent concentration in mN.

Figure 5 The Displacement Chemical Regeneration (DCR) Mode Diagram

031727-07

Page 16

1 – Introduction

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 16 of 40

Regenerant

Regen

IN

Regen

OUT

Eluent

OUT

Eluent

IN

Injection

Valve

Guard

Column

Analytical

Column

Waste

Cell

Gas Pressure

25 psi max

Coil #1

Coil #2

1.6.2 The External Chemical Mode

The External Chemical Mode is an easy to implement configuration that dispenses regenerant

using a pressurized regenerant reservoir directly into the suppressor. The concentration of the

regenerant dictates the leakage into the eluent stream therefore lower concentration of the

regenerant is preferred in this mode. The flow rate needs to be adjusted to provide the equivalent

concentration required for suppression. Generally higher flow rates are employed in this

mode resulting in higher waste generation. The regenerant dynamic concentration (mN x

mL/min) should be approximately 7 times the eluent dynamic concentrati on (mN x mL/ min).

The External Chemical Mode is highly recommended for high suppression applications (> 70

µeq/min) and provides the highest dynamic capacities required for these applications.

An external pump could be used for dispensing the regenerant provided the pump is

substantially pulse dampened using a suitable pulse damper. Thermo Scientific recommends the

use of a Peristaltic Pump P/N 064230 along with a Peristaltic Pump Kit (P/N 064911) for this

application.

Figure 6 The External Chemical Mode with the Dionex Chemically Regenerated

Suppressor (Dionex CRS 500)

031727-07

Page 17

1 – Introduction

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 17 of 40

1.6.3 The AutoRegen Suppression Mode

This mode has been discontinued by Thermo Scientific and is only incl uded here for legacy

operators.

The Auto Regen Suppression Mo de is another mode for implementing chemical suppression.

This mode is designed to recycle the regenerant and reduce regenerant consumption for high

suppression applications. For the Dionex ACRS 500, the AutoRe ge n Sup p re ssi o n mod e r eq ui re s

the installat io n of the Auto Re gen Acc e ssor y equip pe d with an A uto Rege n Re gener ant Car tri dge

to convert the spent regenerant back to sulfuric acid regenerant. For the Dionex CRS 500, the

AutoRegen S uppression mode r equires the installat ion of the AutoRege n Accessory equipp ed

with an AutoRegen Regenerant Cartridge to convert the spent regenerant back to TBAOH

regenerant. The AutoRegen Suppression Mode is recommended for applications that require

continuous operation without user intervention. The AutoRegen Mode however, is not

recommend ed for appl i cations requiring low no i s e or high sensi tivity.

031727-07

Page 18

2 – Installation

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 18 of 40

Required Installation Components

P/N

Description

Back pressure coils:

45877

Backpressure coil 4 mm

45878

Backpressure coil 2 mm

Also Found in:

46297

ED40 Shipkit

46298

CD20 Shipkit

45935

CDM-3 On-Line Ship Kit

50130

DX-120 Ship Kit

Tubing for 4 mm systems:

45825

Standard tubing

(containing tubing, fittings and 4 mm backpressure coils required for plumbing a

4 mm systems)

Tubing for 2 mm / 3 mm systems:

52324

Microbore tubing

(containing tubing, fittings and 2 mm backpressure coils required for plumbing a

2 mm and 3 mm systems)

Regenerant Options:

Pressurized Water Delivery System (used with the External Pressurized Bottle

Mode, the Chemical Suppression Mode, or the MPIC Suppression Mode)

38018

Dionex CRS/SRS Installation Kit

64230

Peristaltic Pump

64911

Peristaltic Pump Kit

AutoRegen Accessory (used with the Chemical Suppr ession Mode)

39594

115 V ac Version

39608

230 V ac Version

39564

Anion Regenerant Cartr idge

39563

Cation Regenerant Cartridge

Displacement Regeneration Kit

56882

Displacement Regeneration 2 Liter K it

56884

Displacement Regeneration 4 Liter K it

2. Installation

2.1 System Requirement s

The Dionex Anion or Cation Chemically Regenerated Suppressor (Dionex CRS 500) is

designed to be run on any Dionex Ion Chromatograph (IC) equipped with an ion exchange

column set and suppressed conductivity detection. The Dionex CRS 500 is installed

immediately after the analytical column and before the conductivity detector cell. The

following components are req uired for the installation o f the Dionex CRS 500 in a Dionex Ion

Chromatograph:

031727-07

Page 19

2 – Installation

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 19 of 40

, it may be necessary to

NOTE

!

!

During the course of installing and using the Dionex CRS 500

assemble 1/4-28 or 10-32 ferrule/bolt style liquid lines. See , “Dio nex Liquid Line Fittings,”

for complete details.

2.2 Back Pressure Coils for the Dionex CRS 500

All detector cells require enough back pressure to prevent eluent in the cell from out-gassing

due to abrupt volume changes between the small inner diameter of the connecting t ube and the

relatively larger volume of the cell. Out-gassing creates bubbles in the cell and disrupts detector

responsiveness. Back pressure coils help to prevent gases from out-gassing and prevents

formation of bubbles in the detector cell. For example, carbonate eluent is suppressed to

carbonic acid which is CO

if adequate pressure is not applied. The above out-gassing can trap bubbles in the cell causing

high noise. Therefore Dionex recommends addition of 30-40 psi of backpressure for most

applications.

Back pressure coil components are located in the detector Ship Kits as part of the Gas Separator

Waste Tube Assembly/Back Pressure Coils Kit, P/N 045825. For 4 mm systems, locate

assembly P/N 045877. For 2 mm systems, the backpressure coils are available in the microbore

tubing kit, P/N 052324. For 2 mm syste ms, locate assembl y P/N 04 5878. Alte rnativel y, lengt hs

and diameters of tubing necessary for proper back pressure are given in Table 2, “Coils for

Dionex CRS 500 Back Pressure Requirements.” Adjust the tubing length to achieve a

backpressure of approximately 40 psi.

gas in equilibri um with DI water; CO2 gas can come out of solution

2

If back pressure coils become damaged or plugged, they may cause irreversible damage to

the suppressor.

Assemble as fol l ows:

A. Slip PEEK liquid line bolts and ferrules onto the ends of the tubing. Refer to Table 2,

“Coils for Dionex CRS 500 Back Pressure Requirements,” and determine the correct

number of coils required for your application based on the eluent flow rate.

B. After assembly of the coils, see Figure 8, “Configuration of the External Chemical

Mode with the Dionex CRS 500 Suppressor,” for the proper placement of the

assembled coils and couplers after the detector cell and before the waste container.

031727-07

Page 20

2 – Installation

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 20 of 40

Dionex

Flow Rate

I.D. of

Appropriate

Number

4 mm

0.5–1.5 ml/min

0.010" (Black)

2.5 feet

2

4 mm

1.5–3.0 ml/min

0.010" (Black)

2.5 feet

1

2 mm

0.12–0.25 ml/min

0.005" (Red)

6.0 inches

2

2 mm

0.25–0.75 ml/min

0.005" (Red)

6.0 inches

1

!

Table 2 Coils for Dionex CRS 500 Back Pressure Requirements

CRS III

Type

The above recommended length of tubing may vary depending on the I.D. of the tubing.

The correct amount of back pressure for optimum operation is 40 psi.

Back pressure over 150 psi after the Dionex CRS 500 can cause irreversible damage!

Tubing

Length of

Each Coil

of Coils

031727-07

Page 21

2 – Installation

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 21 of 40

Regenerant

Regen

IN

Regen

OUT

Eluent

OUT

Eluent

IN

Injection

V

alve

Guard

Column

Analytical

Column

Waste

Cell

2.3 Plumbing for Displacement Chemical Regeneration (DCR) Mode of Operation

Figure 7 The Displacement Chemical Regeneration (DCR) Mode Plumbing Diagram

The Displacement Chemical Regeneration Mode is the easiest method of operation. As the

eluent passes through the suppressor, it is neutra lized to pr oduce its weakly ionized form. After

passing through the conductivity cell, this effluent can be redirected to the regenerant bottle,

thus displac ing t he regene rant (see Figure 7, “The Displacement Chemical Regeneration (DCR)

Mode Plumbing Diagram”). The main advantage of this mode is its simplicity and ease of use. It

is not necessary to use a pump or pressurized bottle.

Depending on the specific components (analytical column, conductivity cell, back pressure

coils) in the system, 1/4-28 or 10-32 ferrule/bolt liquid lines may be required. All necessary

tubing and fittings are supplied in the detector or Ship Kits. To purchase or assemble 1/4-28 or

10-32 ferrule/bolt liquid lines, refer to , “Dionex Liquid Line Fittings.” Always use 0.005" i.d.

PEEK tubing with 10-32 ferrule/bolt fitti ngs on 2 mm systems. Wherever possible use 0.010"

i.d. PEEK tubing with 10-32 ferrule/bolt fittings on 4 mm systems.

031727-07

Page 22

2 – Installation

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 22 of 40

egenerant. Refer to the DCR Kit Manual

NOTE

!

A. Install the Dionex Chemically Regenerated Suppressor (Dionex CRS 500) in the

Chromatography Module.

B. Connect the outlet of the analytical column to the ELUENT IN of the Dionex CRS

500. See Figure 7, “The Displacement Chemical Regeneration (DCR) Mode Plumbing

Diagram.” To avoid adding dead volume to the system, make the length of all eluent

lines as short as practically possible. Be sure to butt the tubing tight in the end fitting as

the fitting is tightened.

C. Connect the ELUENT OUT port of the Dionex CRS 500 to the inlet of the

conductivity cell. See Figure 7, “The Displacement Chemical Regeneration (DCR)

Mode Plumbing Diagram.” To avoid adding dead volume to the system, make the

length of all eluent lines as short as practicall y possible. Refer to the DCR Kit Manual

(P/N 031664) for DCR plumbing details.

D. Connect the back pressure line from the cell to the DCR bottle. Connect the second

line from the DCR bottle to the REGEN IN port on the suppressor

The correct tubing orientation in the DCR bottle d epe nds on the d iff erence in the d ensity of

the cell effluent versus the chemical r

(P/N 031664)

031727-07

Page 23

2 – Installation

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 23 of 40

Regenerant

Regen

IN

Regen

OU

T

Eluent

OU

T

Eluent

IN

Injection

V

alve

Guard

Column

Analytical

Column

Waste

Cell

Gas Pressure

25 psi max

Coil #1

Coil #2

2.4 Plumbing for External Chemical Mode of Operation

Figure 8 Configuration of the External Chemical Mode with the Dionex CRS 500

Suppressor

The Dionex CRS/ERS Installation Kit (P/N 038018) contains all of the components needed to

install and operate the Dionex CRS 500 with a pressurized regenerant reservoir. The kit contains

the Installat ion Part s Kit (P/N 039055), a 25 psi regulator (P/N 038201) and a 4-liter reservoir

(P/N 039164).

A. Make the following air line connections:

1. Locate the pieces of red 1/8" o.d. plastic tubing (P/N 030089) supplied in the

Installation Parts Kit.

2. Push the end of one piece of 1/8" o.d. tubing over the barbed fitting of the

regulator. Connect the other end of the tubing to the source of air pressure.

3. Push one end of the second piece of 1/8" o.d. tubing over the other barbed fitting of

the regulator. Push the other end of this tubing over the barbed fitting (P/N

030077) in the pressure inlet of the plastic reservoir. See Figure 8, “Configuration

of the External Chemical Mode with the Dionex CRS 500 Suppressor.”

031727-07

Page 24

2 – Installation

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 24 of 40

NOTE

!

B. Make the following liquid line connections. See Figure 8, “Configuration of the

External Chemical Mode with the Dionex CRS 500 Suppressor.”

1. Use a coupler (P/N 039056) to connect one end of the 30" tubing assembly (P /N

035727) that comes in the Installation Kit to t he water re servoir. Con nect the other

end of this tubing to the REGEN IN port of the D ionex Chemi cally Rege nerated

Suppressor.

2. Using a coupler (P/N 039056) and a 1/8" o.d. piece of tubing (P/N 035728) from

the Installation Kit, connect one end of this tubing to the REGEN OUT port and

direct the other end to waste.

C. Fill the regenerant reservoir with the recommended regenerant (Refer to Tables 3

or 4, “Matching the Regenerant concentration and flow rate to eluent

concentration and flow rate”). Make sure that the O-ring is inside the cap of the

reservoir before screwing the cap onto the reservoir. Screw the cap onto the reservoir

tightly and place the reservoir near the Chromatography Module.

D. Adjust the regenerant flow rate to approximately 5–10 mL/min. for the Dionex

CRS 500 4 mm and 5–8 mL /min f or the Dionex CRS 500 2 mm.

A safety relief valve on the reservoir regulator prevents pressure grea ter than 25 p si from

being applied to the reservoir.

2.5 Peristaltic Pump installation

For detailed installation i nstructions plea se refer to t he MAST ERFLEX® C/L® Peristaltic Pump

Quick Start Guide (Document No. 065203)

031727-07

Page 25

2 – Installation

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 25 of 40

Regenerant

2.6 Plumbing for AutoRegen Suppression Mode of Operation

Figure 9 Configuration of the Dionex CRS 500 Suppressor Using AutoRegen

Injection

Valve

Coil #2

Guard

Column

Waste

Coil #1

Analytical

Column

Eluent

IN

Regen

OUT

Regenerant

Slip-on

Filter

Pressure

Relief

Assembly

Pump

Regen

IN

Cell

Three-way

Manifold

Eluent

OUT

Cartridge

031727-07

Page 26

2 – Installation

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 26 of 40

This mode has been discontinued by Thermo Scientific and is only incl uded here for legacy

operators.

The AutoRegen Suppression Mode requires the use of an acid regenerant to neutralize the

eluent. Choose the appropriate sulfuric acid concentration as described in Tables 3 or 4,

"Matching R egenerant Conc entration and Flow Rate to E luent Concentr ation and Flo w Rate."

The following installation instructions assume that your system is configured with an

AutoRegen Ac ce sso r y eq uip p ed with an A nio n Aut oR e ge n Re ge ne ra nt Ca r tr id ge.

To save regenerant preparation time, consumption, and waste, it is recommended that the

AutoRegen Accessory (115 V ac version, P/N 039594; 230 V ac version P/N 039608) be

purchased. The AutoRegen Accessory is designed to be used specifically with Dionex

Chemically Regenerated Suppressors. The AutoRegen Accessory should be equipped with

either an Anio n AutoRegen Regenerant Cartridge (P/N 039564) for the Dionex ACRS 500 or

with a Cati on A uto Re gen Regener ant Ca r tr id ge ( P /N 0 39 5 64 ) for the Dionex CRS 500. Refer to

the AutoRegen Accessory Manual (Document No. 032853) for complete installation

instructions.

A. Connect the 1/8" o.d. tubing fr om the top of the Auto Regen Regenera nt Cartridge to

the REGEN IN port of the Dionex Chemically R egenerate d Suppressor.

B. Connect the 1 /8" o.d. tubing from the regener ant reservoir cap to the REGEN OUT

port of the Dionex Chemically Regenerate d Suppressor.

C. Turn ON the ON/OFF switch on the front of the pump. The unit is ready for

equilibration and operation.

031727-07

Page 27

3 – Operation

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 27 of 40

3. Operation

This section provides instructions for the start-up and operation of the Dionex Chemically

Regenerated Suppressor (Dionex CRS 500). The selection and description of each of the

suppression modes of operation are covered.

3.1 Chemical Purity Requiremen t s

Obtaining precise and accurate results requires eluents that are free of ionic impurities.

Chemicals and deionized water used to prepare eluents must have the purities described below.

Low trace impurities a nd lo w p articulate le vels i n elue nts a nd r egenera nts a lso help p rote ct your

Dionex CRS 500 a nd syste m compone nts fro m contami nation. Dionex cannot guarantee proper

Dionex CRS 500 performance when the quality of the chemicals and water used to prepare

eluents has been compromised.

3.1.1 Inorganic Chemicals

Reagent Grade inorganic chemicals should always be used to prepare ionic eluents. Whenever

possible, inorganic chemicals that meet or surpass the latest American Chemical Society

standard for purity (universally accepted standard for reagents) should be used. These inorganic

chemicals will detail the purity by having an actual lot analysis on each label.

For ease of regenerant preparation and guaranteed purity, use Dionex Anion Regenerant

Concentrat e (P/Ns 03 7164, 039601 ). Sulfuric aci d is the recomme nded regene rant for us e with

the Dionex ACRS 500. Wit h the DCR Kit, use Anion Regenera nt Concent rate 75 mL o f 2.0 N

Sulfuric Ac id (P/N 057559) or the 4-Pak (P/N 057555).

Tetrabutylammonium hydroxide (TBAOH) is the recommended regenerant for use with the

Dionex CRS 500. For ease of regenerant preparation and guaranteed purity, use Dionex Ca tion

Regenerant Concentrate ( P/N 039602 ). With the DCR Ki t, use Cation Re generant Conc entrate

100 mL of 2.06 M TBAOH (P/N 057561) or the 4-Pak (P/N 057556).

3.1.2 Solvents

Since solvents used with the Dionex CRS 500 are added to ionic eluents to modify the ion

exchange process or improve sample solubility, the solvents used must be free of ionic

impurities. However, since most manufacturers of solvents do not te st for ionic impurities, it is

important t hat the highest gr ade of solvents available be used. Currently, several manufacturers

are making ultrahigh purity solvents that are compatible for HPLC and spectrophotometric

applicati ons. These ultrahigh purity solve nts will usually ensure that your chromatography is not

affected by ionic impurities in the solvent. Currently at Thermo Fisher Scientific, we have

obtained c onsistent results using High Puri ty Solvents manufa ctured by Burd ick and Jackson

and Optima™ Solvents by Fishe r Chemical.

3.1.3 Deionized Water

The deionized water used to prepare eluents should be degassed Type I Reagent Grade Water

with a specific resistance of 18.2 megohm-cm. The deionized water should be free of ionized

impurities, organics, microorganisms and particulate matter larger than 0.2 µm. It is good

practice to filter eluents thro ugh a 0.2 µm filter whenever po ssible. Bottled HP LC-Grade Water

should not be used since most bottled water contai ns an unacceptable le vel of ionic impurities.

Finally, thoroughly degas all deionized water prior to preparing any eluents or regenerants.

031727-07

®

Page 28

3 – Operation

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 28 of 40

This requirement is achieved by

maintaining the regenerant cavities full of the appropriate regenerant solution to ensure that

e membranes remain properly hydrated. Occasionally some of the regenerant solution

long term storage. Before starting an analysis, install your new

!

!

3.2 Start Up

The Dionex CRS 500 is installed in the column compartment of the chromatography module

after the analytical column and before the conductivity detector cell. On all Dionex Ion

Chromatogr aphy Syste ms instru ments, the Dionex CRS 500 mounts o n tabs on the co mponent

panel. Orie nt the Dionex CRS 500 accord ing to the flow d iagram provided with your syste m;

align the slots on the back of the Dionex CRS 500 with the t abs on t he pa nel . Pr ess i n, a nd t hen

slide to lock t he Dionex CRS 500 in place. Slide a nd pull out to re move the Dionex CRS 500.

Make sure the Dionex CRS 500 is plumbed properly, according to the selected mode of

operation. Refer to Section 2, “Installation,” for complete installation instructions.

The membranes, resin and screens in the Dionex CRS 500 must be completely hydrated to

maintain liquid seals and chromatographic performance.

th

evaporates during mid to

Dionex CRS 500 and pump regenerant solution through the suppressor until you see no more

bubbles. Turn off the flow and let the Dionex CRS 500 sit for at least 20 minutes to ensure

that the membranes are fully hydrated before pumping eluent through the suppressor.

The correct amount of back pressure for optimum operation is 40 – 60 psi. Connect the

back pressure coil(s) appropriate for your column I.D. and flow rate. Back pres sures over

150 psi after the Dionex CRS 500 can cause poor peak shapes. Back pressure s o ve r 300 psi

after the Dionex CRS 500 can cause irreversible damage!

031727-07

Page 29

3 – Operation

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 29 of 40

Eluent Flow Rat e

Regenerant Fl o w Rate

Regenerant Co nc

Eluent

(mL/min)

(mL/min)

(mN H2SO4)

1.8 mM Na2CO3/1.7 mM NaHCO

0.5–2.0

3–5

25

9.0 mM Na2CO3 0.5–2.0

3–5

50

1.0 - 100 mM NaOH

0.5–1.5

3–10

50–100

1.0 - 100 mM KOH

0.5–1.5

3–10

50–100

20 - 50 mM Na2B4O

0.5 - 1.5

5–10

50-100

Eluent Flow Rat e

Regenerant Fl o w Rate

Regenerant Co nc

Eluent

(mL/min)

(mL/min)

(mN H2SO4)

1.8 mM Na2CO3/1.7 mM NaHCO

0.10–0.50

3–5

25

2.7 mM Na2CO3/0.3 mM NaHCO

0.10–0.50

3–5

25

9.0 mM Na2CO3 0.10–0.50

3–5

50

1.0 - 100 mM NaOH

0.10–0.50

3–8

50

100 - 150 mM NaOH

0.10–0.50

5–8

50–100

1.0 - 100 mM KOH

0.10–0.50

3–8

50

100 - 150 mM KOH

0.10–0.50

5–8

50–100

30 - 75 mM Na2B4O

0.10–0.38

5–8

50–100

3.3 Optimizing Regenerant Concentration and Flowrate

3.3.1 Anion Regenerant Concentration for Optimized Operation i n Exte r nal Chemical and AutoRegen Modes

The Dionex ACRS 500 has the ability to provide continuous suppression of eluents using

chemical regeneration with an acid such as sulfuric acid (H

Regenerant Concentration and Flow Rate to Eluent Concentration and Flow Rate”, list the

eluent concentrations and flow rates of standard eluents used in anion separations and the

regenerant concentrations and flow rates required to suppress them. Optimal operation of the

Dionex ACRS 500 requires a constant flow of the regenerant over the membrane, in a direction

that is countercurrent to the flow of the eluent. A standard regenerant flow rate of 5–10 mL/min

is recommended for the External Chemical Mode of operation.

This flow rate is adequate for most applications. For applications that require stronger than

typical eluent strengths, the regenerant flow rate may be increased. The level of chemical

leakage increases with increasing concentration hence it is critical that the concentration of

regenerant be as low as possible in order to achieve low backgrounds.

Table 3 Matching Regenerant Concentration and Flow Rate to Eluent Concentration

and Flow Rate for the 4 mm Dionex ACRS 500 in the Chemical Suppression

Mode

). Tables 3 or 4, “Matching

2SO4

3

2.7 mM Na2CO3/0.3 mM NaHCO

3.5 mM Na2CO3/1.0 mM NaHCO

1.0 - 20 mM Na2B4O

7

7

3

3

Table 4 Matching Regenerant Concentration and Flow Rate to Eluent Concentration

3

3

3.5 mM Na2CO3/1.0 mM NaHCO

1.0 - 30 mM Na2B4O

7

7

3

0.5–2.0 3–5 25

0.5–2.0 3–5 25

0.5–2.0 5–10 50

and Flow Rate for the 2 mm Dionex SCRS 500 in the Chemical Suppression

Mode

0.10–0.50 3–5 25

0.10–0.50 5–8 50

031727-07

Page 30

3 – Operation

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 30 of 40

Maximum Eluent

Regenerant

Eluent Flow Rate

Concentration

Concentration

Eluent

(mL/min)

(mM)

(mM TBAOH)

MSA

1

65

100

Hydrochloric acid 1 75

100

Sulfuric Acid 1 30

100

Nitric Acid 1 50

150

HSA

1 5 100

HSA + 10% ACN 1 7

100

OSA

1 2 100

OSA + 10% ACN 1 2

100

NOTE

!

For the lower eluent concentration in a given range, choose lower corresponding

regenerant concentration; for higher eluent concentration choose higher regenerant

concentration.

Most solve nts suc h as me than ol have l ittle or no e ffect o n the Anio n Rege nerant Solut ion when

using an AutoRegen Accessory unit.

For the best s ignal-to-noise ratio and the best overall perfo rmance when using an Aut oRegen

Cartridge to supply regenera nt, Dionex reco mmends that the A nion Regenerant So lution used

with the Dionex ACRS 500 be replaced on a regular basis. The time interval between changing

the regenerant will depend o n both the time that the instrument is in ope ration and the specific

application. As a guideline, the regenerant should be replaced whenever the background

conductivity drifts to higher levels than t hose observed in the initial chromatogra ms. See the

Installation Instructions and Troubleshooting Guide for the analytical column being used in your

application for a guideline on the expected background conductivity. Tables 3 or 4, “Matching

Regenerant Concentration and Flow Rate to Eluent Concentration and Flow Rate,” list the

appropriate regenerant concentration for selected eluents.

3.3.2 Cation Regenerant Concentration for Optimized Operation for External Chemical and AutoRegen Modes

The Dionex CCRS 500 has the ability to provide continuous suppression of eluents using

chemical regeneration with a base. Tables 5 or 6, “Practical Maximum Eluent Concentration

Suppression Guidelines,” list the practical maximum eluent concentrations and flow rates of

standard el uents used in cation separations versus the regener ant conce ntrations a nd flow rate s

required to suppress them. The operation of the Dionex CCRS 500 requires a constant flow of

the regenerant over the membrane, in a direction that is countercurrent to the flow of the eluent.

A standard regenerant flow rate of 5–10 mL/min is recommended for the External Chemical

Mode of operation.

This flow rate is adequate for most applications. For applications that require stronger than

typical eluent strengths, the regenerant flow rate may be increased. The level of leakage

increases with increasing concentration hence it is critical that the concentration of regenerant

be as low as possible in order to achieve low backgrounds.

Table 5 Dionex CCRS 500 4 mm Practical Maximum Eluent Concentration

Suppression Guidelines Regenerant Flow Rate = 10 mL/min

* For suppressing higher concentrations then listed above, the regenerant concentrations may be increased to 150 mM TBAOH

031727-07

Page 31

3 – Operation

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 31 of 40

Maximum Eluent

Regenerant

Eluent Flow Rate

Concentration

Concentration

Eluent

(mL/min)

(mM)

(mM TBAOH)

MSA

0.5

45

100

MSA

0.3

70

100

MSA

0.25

95

100

Hydrochloric acid

0.5

75

100

Hydrochloric acid

0.3

100

100

Hydrochloric acid

0.25

110

100

Sulfuric Acid

0.5

20–25

100

Sulfuric Acid

0.3

25–30

100

Sulfuric Acid

0.25

30–35

100

Nitric Acid

0.25

75

100

HSA

0.25 5 100

HSA + 10% ACN

0.25 7 100

OSA

0.25 2 100

OSA + 10% ACN

0.25 2 100

Eluent Flow Rate

Regenerant Flow Rate

Regenerant Conc

Eluent

(mL/min)

(mL/min)

(mM TBAOH)

5-25 mM HCl

1.0–3.0

3–5

50

25-50 mM HCl

0.5–1.5

5–10

100

25 mM HCl/ 0.25 mM DAP

1.0–2.0

3–5

50

40-50 mM HCl/2-8 mM DAP

0.5–1.5

5–10

100

Eluent Flow Rate

Maximum Suppressible

Regenerant Conc

Eluent

(mL/min)

(mM)

(mM TBAOH)

5-25 mM HCl

0.1–0.50

3–5

50

25-50 mM HCl

0.1–0.50

5–10

100

50-75 mM HCl

0.1–0.40

5–10

100

25 mM HCl/0.25 mM DAP

0.1–0.50

3–5

50

40-60 mM HCl/2-10 mM DAP

0.1–0.40

5–10

100

Table 6 Dionex CCRS 500 2 mm Practical Maximum Eluent Concentration

Suppression Guidelines Regenerant Flow Rate = 8 mL/min

For customers with older systems that use HCl·DAP eluents, the following tables list the practical eluent

concentrations and flow rates of standard DAP/HCL eluents versus the regenerant concentrations and flow rates

required to suppress them.

Table 7 Dionex CCRS 500 4 mm Regenerant Concentration and Flow Rate Versus

Eluent Concentration and Flow Rate for DAP/HCl Eluents

Table 8 Dionex CCRS 500 2 mm Regenerant Concentration and Flow Rate Versus

Eluent Concentration and Flow Rate for DAP/HCl Eluents

031727-07

where:

DAP = DL-2,3-Diaminopropionic acid monohydrochloride (P/N 039670)

Page 32

3 – Operation

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 32 of 40

For the lower eluent concentration in a given range, choose lower corresponding

rate arrived at by using the above equations is necessarily the

optimum flow rate. Instead, consider it a good starting point. By monitoring the suppressor

performance, background and noise and by either increasing or decreasing the flow rate as

NOTE

!

NOTE

!

regenerant concentration; for higher eluent concentration choose higher regenerant

concentration.

For the best signal-to-noise ratio and the best overall performance, when using an AutoRegen

Cartridge to supply regenera nt, Dionex reco mmends that the Cation Regenera nt Solution used

with the Dionex CRS 500 b e replaced on a regular basis. The time interval between changing

the regenerant will depend o n both the time that the instrument is in ope ration and the specific

application. As a guideline, the regenerant should be replaced whenever the background

conductivity drifts to higher levels than t hose observed in the i nitial chromatogra ms. See the

Product Manual for the analytical column being used in your application for a guideline on the

expected background conductivity.

3.3.3 Calculations for Regenerant Concentration

The regenerant dynamic concentration (mN x mL/min) should be approxi mately 7 times the

eluent dynamic concentration.

7.(eluent mN)(eluent mL/min)=(regenerant mN)(regenerant mL/min)

Therefore:

(

regenerant mL/min)=

Example #1 Eluent: 50 mN NaOH

Eluent Flow Rate: 1.5 mL/min

A. Regenerant Concentration = 50 mN H2SO4

(

regenerant mL/min)=

B. Regenerant Concentration = 100 mN H2SO4

(

regenerant mL/min)=

Example #2 Eluent: 2.8 mM NaHCO3/2.2 mM Na2CO3

Eluent Flow Rate: 2.0 mL/min

A. Regenerant Concentration = 50 mN H2SO4

Eluent Concentration = 2.8 mN + (2 x 2.2) mN = 7.2 mN

(

regenerant mL/min)=

7.(eluent mN)(eluent mL/min

(

regenerant mN

7.(50 mN)(1.5 mL/min

7.(50 mN)(1.5 mL/min

7.(7.2 mN)(2.0 mL/min

(

50 mN

(

100 mN

(

50 mN

)

)

)

)

=10 mL/min

)

)

=5 mL/min

)

)

=2 mL/min

Do not assume that the flow

required, you should be able to determine the optimum flow rate.

031727-07

Page 33

3 – Operation

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 33 of 40

NOTE

!

B. Dionex Anion Regenerant Concentrate (P/Ns 037164, 039601) should be used to make

regenerants for the Dionex Anio n Chemically Regenerated Sup pressors beca use of its

ease of use and guaranteed high purity. With the DCR Kit, use Anion Regenerant

Concentrate 75 mL of 2.0 N Sulfuric Acid (P/N 057559) or the 4-Pak (P/N 057555).

C. Solutions such as methanol and acetonitrile, have little or no effect on the Anion

Regenerant Solution using an AutoRegen System. And, most solvents such as

methanol have little or no effect on the Cation Regenerant Solution when using an

AutoRegen Ac ce sso r y uni t.

D. For the best signal to noise ratio and the best over all pe rformance, Dionex recommends

that the Anion Regenerant Solution used with the Dionex Anion Chemically

Regenerated Suppressors be replaced on a regular basis. Tables 3 or 4, “Matching

Regenerant Co ncentration a nd Flow Rate to Elue nt Concentrat io n and Fl o w Ra te,” list s

the appropriate regenerant concentrations for selected eluents.

3.3.4 Regenerant Concentration for DCR Mode

For anion analysis, X equivalents of eluent requires at least a factor of 2X equivalents of

regenerant in the DCR mode of operation. For catio n analys is, X eq uivale nts of e luent requires

at least a factor of 5X equivalents of regenerant in the DCR mode of operation. Since the flow is

constant, this mode provides improved performance. Refer to DCR Kit Manual (P/N 031664)

for detailed information on the regene rant concentrations.

3.4 Storage

The Dionex Chemically Regenerated Suppressor (Dionex CRS 500) is shipped with DI water as

the storage solution. If a suppressor will not be used for more than one week, prepare it for

storage. The screens and membranes in the Dionex CRS 500 must be completely hydrated to

maintain liquid seal and chromatographic performance.

3.4.1 Short Term Storage (1 to 5 days)

A. Plug both el uent ports. Using a plastic syringe, gently push deio nized water through the

REGEN In port until all bubbles are removed. Plug both regenerant ports.

B. To resume operation, connect the suppressor to the system. Allow the system to

equilibrate before starting you r analysis.

If the eluent last used contained organic so lvents, flush th e Dionex CRS 500 with deio nized

water for 10 minutes through both chambers before plugging the fitting ports.

3.4.2 Long Term Storage

A. Flush the Dionex CRS 500 with deionized water for 10 minutes.

B. Plug the Dionex CRS 500 eluent ports and regenerant ports.

C. To resume operation, connect the suppressor to the system. Turn on the regenerant

flow and al low regene rant to flow un til no mo re bubble s exit the regen o ut port. Turn

off the regenerant flow and allow the suppressor to hydrate for at least 20 minutes.

D. Allow the system to equilibrate befor e starting analysis.

E. If small analyte peak areas are observed when using the DCR mode, perfor m steps A–

C as outlined in APPENDIX B, “QuickStart for the Displacement Regenerant Mode.”

031727-07

Page 34

4 – Troubleshooting Guide

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 34 of 40

4. Troubleshooting Guide

The purpose of the Troubleshooting Guide is to help you solve operating problems that may

arise while using the Dionex Chemica ll y Regener ated Suppressor (Dionex CRS 500). For more

information on problems that originate with the Ion Chromatograph or the specific Anion

exchange column set in use, refer to the Troubleshooting Guide in the appropriate Installation

Manual. If you cannot solve the problem on your own, contact the Dionex Regional Office

nearest you (see, “Dionex Worldwide Offices”).

4.1 Small Analyte Peak Areas

If small peak areas are observed when working with a pressurized reservoir

A. Stop the eluent flow while flowing regenerant flow into the suppressor for 5 minutes

B. If peak respo nse has not reco vered then perfor m quick start p rocedure as outlined in

APPENDIX A, “QuickStart for the External Chemical Mode and the AutoRegen

Mode.”

C. In the DCR mode if the above problem is observed then follow instructions outlined in

APPENDIX B, “QuickStart for the Displacement Regenerant Mode.”

D. If the correct peak areas are not observed following two injections of a standard test

solution, contact the nearest Thermo Scientific Regional Office (see, “Thermo

Scientific Worldwide Offices” ).

4.2 High Background Conductivity

A. Check that the regenerant is flowing from the waste line at the proper flow rate.

1. If there is no flow from the waste line, disconnect the 0.012" i.d. tubing connected

to the waste line. If the regenerant lines and the suppressor are filled with

regenerant and there are no restrictions in the regenerant line, the regenerant shoul d

flow freely from the 1/8" o.d. waste line. If there is no flow, make sure the

reservoir cap is tight and that there are no audible air leaks. Also make sure that the

regenerant reservoir is pressurized. If it is, trace the regenerant lines backward

from the reservoir to find and remove any blockage.

2. If there is flow from the waste line, but it is less than the de sired flo w rate, increase

the flow rate b y shortening the 0.012" i .d. waste line tubi ng or by increasing t he

reservoir pressure. If the flow rate is correct, go on to the next step.

3. If the regenerant is flowing at the desired rate, either the selected regenerant flow

rate is too slow or the regenerant is too dilute to suppress the eluent concen tration

at the set eluent flow rate. Refer to Tables 3 or 4, “Matching Regenerant

Concentration and Flow Rate to Eluent Concentration and Flow Rate,” for the

Dionex ACRS 500 or to Tables 5 and 6, “Practical Maximum Eluent Concentration

Suppression Guidelines,” for the Dionex CCRS 500 and then increase the

regenerant flow rate or increase the regenerant concentration.

031727-07

Page 35

4 – Troubleshooting Guide

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 35 of 40

!

B. Check for eluent flow out of the suppre s s or ELUENT OUT port.

Do NOT attempt to disassemble the Dionex Chemically Regenerated Suppressor!

C. Remake the regenerant to be sure that the concentration is correct and that the solution

D. Remake the eluent to be sure that the concentration is correct. Be sure that chemicals of

E. If the background conductivity remains high, and you cannot solve t he problem on

4.3 Drifting Baseline

1. If there is no flow out of the Dionex CRS 500 ELUENT OUT p o rt , ma ke s ure tha t

eluent is enterin g t he s upp r es s or a t the ELU EN T IN port. If there is no flo w at this

point, trac e the e lue nt flow path back war d t hro ug h t he s ystem to find and r emo ve

the blockage.

2. If there is flow of elue nt into the Dionex CRS 500 but not out, and there are no

visible leaks from the side seams of the supp r esso r, a break in the o-ring seal or t he

membrane is probably allowing eluent to leak into the regenerant. If this is the

case, then the Dionex CRS 500 must be replaced.

3. If there is flow from the ELUENT OUT port, but no eluent suppression, the

membrane may have been contaminated. Try to restore system performance by

cleaning the membrane (see Section 5, “Suppressor Cleanup”).

has been freshly prepared. Be sure that chemicals of the required purity were used to

make the regenerant (see Section 3.1, “Chemical Purity Requirements”). If the

regenerant concentration is too high or too old, it can cause high background

conductivity.

For the Dionex ACRS 500, Dionex recommends the use of D i onex Anion Regenerant

Concentrate (P/Ns 037164, 039601) for the best performa nce. With the DCR Kit, use

Anion Regenerant Concentrate 75 mL of 2.0 N Sulfuric Acid (P/N 057559) or the 4Pak (P/N 057555).

For the Dionex CRS 500, Dionex r ecommends the use of Di onex Cation Regenerant

Concentrate (P/N 039602) for the best performance. With the DCR Kit, use Cation

Regenerant Concentrate 100 mL of 2.06 M TBAOH (P/N 057561) or the 4-Pak (P/N

057556).

the required purity were used to make the eluent (see Section 3.1, “Chemical Purity

Requirements”). If the eluent concentration is t oo high, the Dionex CRS 500 will not

be able to suppress it, resulting in high background conductivity. Refer to Tables 3 or

4, “Matching Regenera nt Concentration and Flow Rate to Eluent Concent ration and

Flow Rate,” for the Dionex ACRS 500 or to Tables 5 and 6, “Practical Maximum

Eluent Concentration Suppres sion Guidelines,” for the Dionex CCRS 500 and then

increase the regenerant flow rate or increase the regenerant concentration.

your own, contact the Thermo Scientific Regional Office nearest you (see, Thermo

Scientific Worldwide Offices).

If the baseline drifts steadily upward, increase the regenerant flow rate, or if using DCR Mode

increase the r egenerant co ncentration to r ed uce the b ac kground conductivity. As t he b a ck gr ound

conductivity decreases, the baseline usually levels.

031727-07

Page 36

4 – Troubleshooting Guide

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 36 of 40

4.4 Decreased Sensitivity

A. Chec k for leak s throughout the syste m. If a fittin g is leakin g, tighten it carefully u ntil

the leak stops. Do not overtighten. If the Dionex CRS 500 is observed to be leaking

from the center or bottom seam, see Section 4.6, “Liquid Leaks.” If you cannot cure the

problem yourself, call the nearest Dionex Regional Office (see, “Dionex Regional

Offices”) for assistance.

B. Ensure that the inj ection valve is operating correctly. Refer to the valve manuals that

accompany the chromatography module for troubleshooting assistance. Be sure to

check the slider port faces for damage.

C. If sensitivity remains low, clean the suppressor membrane (see Section 5, “Suppressor

Cleanup”).

D. Replace the Dionex CRS 500 if cleaning the suppressor membrane does not restore

sensitivity.

E. Chec k the backp ressure co ils. Verif y that they a re not exc eeding 40 p si in the c urrent

plumbing configuratio n and flow rat e.

F. Contact the nearest Thermo Scientific Regional Office (see, “Thermo Scientific

Worldwide Offices”) if you cannot solve the problem on your own.

4.5 System Back Pressure Increases Over Time

A. If the increased back pressure does not affect system performance, no maintenance is

necessary.

B. Check the inlet frits on the guard and analytical column and replace them if necessary.

The most common cause of increasing system back pressure is a contaminated frit in

the analytical or guard colu mn i nlet end fitti ng. The complete instructions for replacing

column bed support assemblies are in column Product Manuals. Recheck the system

back pressure. If it remains high, go on to the next step.

C. Check the backpressure coils. If removing the backpressure coils lowers the pressur e

by more than 40 psi, replace the coils or remove the blockage causing the increased

pressure. Backpressure over 125 psi after the suppressor can cause irreversible damage.

D. Find and eliminate any system blockage. Bypass the Dionex CRS 500 by coupling the

lines attached to the ELUENT IN and ELUENT OUT ports. If the back pressure

decreases by less than 150 psi with the Dionex ACRS 500 out o f line , a b lo c kage i n the

system rather than in the Dionex CRS 500 is causing the high pressure.

E. Remove a blockage from Dionex CRS 500 by r eversing the eluent flow. If the back

pressure decreases by more than 150 psi with the Dionex CRS 500 o ut o f line , t he hig h

pressure may be caused by a blockage in the Dionex Chemically Regenerated

Suppressor. Reverse the direction of flow of the eluent or both the eluent and the

regenerant thro ugh t he Dio nex Chemica lly R ege nerate d Suppressor. After the pressure

drops, allow eluent, or eluent and regenera nt, to flo w to waste for several mi nutes after

the pressure drops. Perform step A of Section 3.2, “Start Up,” and reinstall the Dionex

CRS 500 in the appropriate configuration.

F. Clean the suppressor membranes if reversing the flow thro ugh the Dionex CRS 500

does not decrease the pressure. (See Section 5, “Suppressor Cleanup”).

G. Replace the Dionex CRS 500 if cleaning the suppressor membrane does not reduce the

pressure.

H. Contact the nearest Thermo Scientific Regional Office (see, “Thermo Scientific

Regional Offices”) if you cannot so lve the problem on your own.

031727-07

Page 37

4 – Troubleshooting Guide

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 37 of 40

4.6 Liquid Leaks

A. If there is leakage from the ports of the Dionex CRS 500, c arefully t ighte n the fitt ings

in the ELUENT and REGEN IN and OUT ports – be careful not to over-tighten the

fittings. If tightening the fittin gs does not stop the leak, replace the fittings and ferrules.

B. If there is leakage from the side seam of the Dionex CRS 500, check the cell and

backpressure coil backpressure.

1. If the backpressure is greater than 200 psi, the leaks are caused by excessive

backpressure downstream from the Dionex CRS 500. Find and eliminate the source

of the pressure.

2. If the backp ressure i s less tha n 150 psi, the Dionex CRS 500 is the cause of high

backpressure; follow step C or go to Chapter 5, Suppressor Cleanup. Do not

disassemble the Dionex CRS 500 and attempt to repair it yourself!

C. If the Dionex CRS 500 is leaking due to excessive internal backpressure (>200 psi), the

suppressor may need to be back-flushed.

1. Turn off the pump.

2. Disconnect the Column Out line from the Suppresso r Eluent In port. Disconnect

the Suppressor Eluent O ut port.

3. Connect the Column Out line to the Suppressor Eluent Out port.

4. Connect a piece of tubing to the Suppressor Eluent In port and run this line to

waste.

5. Turn the p ump on and pump eluent through the suppressor at the standa rd flow rate

for 5 minutes; ensure the po wer to the suppressor is turned off during this step.

6. Turn off the pump.

7. Reconnect the Eluent In and Eluent Out connections in their correct orientation.

D. For issues with DCR operation, refer to the DCR Kit Man ual (P/N 031664).

E. For i ssues with AutoRe gen operatio n, refer to the Auto Regen Cartrid ge Manual (P/N

032852).

031727-07

Page 38

5 – Suppressor Cleanup

Thermo Scientific

Product Manual for Dionex CRS 500 Suppressor

Page 38 of 40

Bypassing internal pump manifolds when temporarily pumping high concentration

NOTE

!

5. Suppressor Cleanup

This section describes routine cleanup procedures for the Dionex Chemically Regenerated

Suppressors (Dionex CRS 500) in the case of contamination. Consult the Troubleshooting

Guide (see Section 4, “Troubleshooting G uide”) to first determine that the system is operating

properly. If the Dionex CRS 500 is determined to be the source of higher than normal back