Page 1

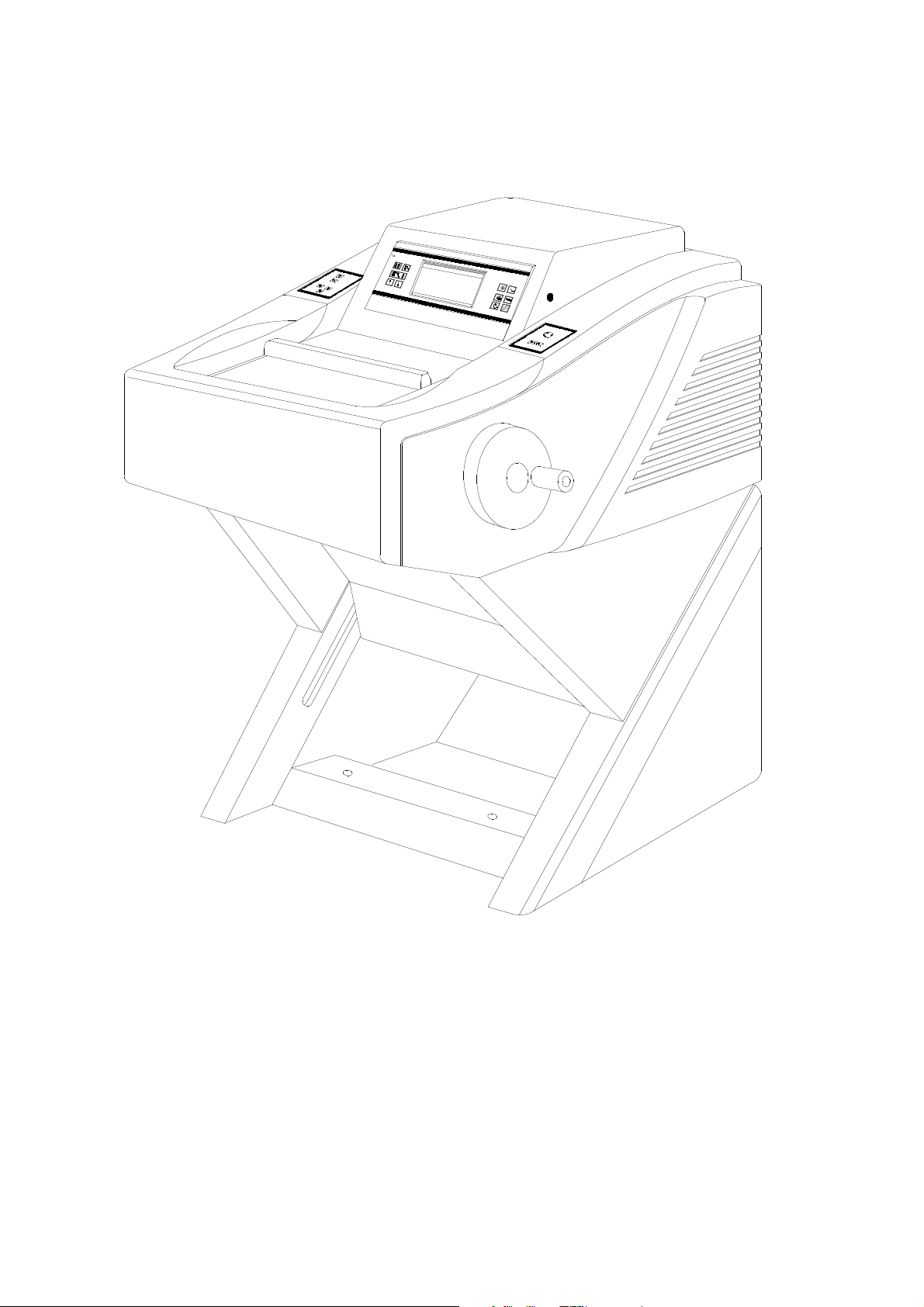

Thermo Scientific Cryostat Microm Cryo Star HM 560

Thermo Scientific

Microtome Cryostat

Microm Cryo-Star HM 560

INSTRUCTION MANUAL

Microm International GmbH

part of Thermo Fisher Scientific

Robert-Bosch-Str. 49

69190 Walldorf / Germany

387 500 - English

1

Page 2

Thermo Scientific Cryostat Microm Cryo Star HM 560

2

Microm International GmbH

part of Thermo Fisher Scientific

Robert-Bosch-Str. 49

69190 Walldorf / Germany

387 500 - English

Page 3

Thermo Scientific Cryostat Microm Cryo Star HM 560

CERTIFICATION

Thermo Fisher Scientific Microm International GmbH certifies that this instrument

has been tested and checked carefully. Its technical data was verified before

shipment to be in accordance with the published specifications.

The instrument complies with applicable international safety regulations.

WARRANTY

This Thermo Fisher Scientific product is warranted against defects in material and

workmanship for a period of 1 year. Parts which prove to be defective during the

warranty period will be repaired or replaced free of charge by the manufacturer. No

other warranty is expressed or implied. Unauthorized modification or repair by third

party persons will void the warranty.

The warranty will expire in case of improper or wrong use of the instrument and in

case the warning and precautionary messages are not observed. Thermo Fisher

Scientific is not liable for any occurring damage.

Errors and omissions excepted. Subject to amendment and improvement without

further notice.

This instruction manual will be supplied together with each instrument. Further

copies can be ordered at the nearest Thermo Fisher Scientific sales office by giving

the serial number of the instrument, the number of the instruction manual and the

date of issue.

This instruction manual is available in the following languages:

Cat. No.

German: 387 490

English: 387 500

French: 387 510

Microm International GmbH

part of Thermo Fisher Scientific

Robert-Bosch-Str. 49

69190 Walldorf / Germany

387 500 - English

3

Page 4

Thermo Scientific Cryostat Microm Cryo Star HM 560

INTENDED USE

Dear valued Customer,

Thank you for buying this Thermo Fisher Scientific instrument.

Before putting the instrument into operation, please read these operating

instructions carefully to familiarize you with its proper operation and

functions.

Only skilled or specially trained personnel must operate the microtome

cryostat HM 560, i.e. clamping the specimen, trimming, sectioning and taking

off the sections from the instrument. The listed and marked safety measures

as well as the regulations and hygiene measures of your respective lab must

strictly be observed.

Serial No.: __________________

Please check the Serial No. on the type plate, which is placed on the rear

side of your instrument and enter this number here. This way, questions and

service can be handled faster.

Instruction Manual No. 387500

Issued on February 03rd, 2009

Microm International GmbH

part of Thermo Fisher Scientific

Robert-Bosch-Strasse 49

69190 Walldorf

Germany

Phone: +49.(0)6227.836-0

Fax: +49.(0)6227.836-111

Email: info.dxd.dewal@thermofisher.com

Internet: www.ap-walldorf.com

4

Microm International GmbH

part of Thermo Fisher Scientific

Robert-Bosch-Str. 49

69190 Walldorf / Germany

387 500 - English

Page 5

Thermo Scientific Cryostat Microm Cryo Star HM 560

Intended Use

Table of Contents

Safety Precautions

PART 1 INTRODUCTION

1-1 Description of the Cryo-Star HM 560

1-2 Technical data Cryo-Star HM 560

PART 2 OPERATING INSTRUCTIONS

2-1 Setting up the cryostat

2-2 Initial turn-on

2-3 Basic operational rules

2-4 Setting section thickness and trimming thickness

2-5 Specimen and knife cooling

2-5-1 Actual and set value of the specimen temperature

2-5-2 Actual and set value of the knife temperature

2-5-3 Function fast freezing

2-5-4 Programming temperature parameters

2-6 Cutting movement and retraction

2-7 Feed

2-7-1 Knife carrier coarse feed

2-7-2 Speed of the knife carrier coarse feed

2-7-3 Automatic approach system

2-7-4 Trimming and first cuts

2-7-5 Fine feed

2-8 Setting the cutting window

2-9 Hand wheel brake

2-10 Detaching the specimen

2-11 Indication of cutting processes

2-11-1 Section counter

2-11-2 Section thickness sum

2-11-3 Remaining travel to front end position

2-11-4 Real time

2-12 Setting the real time, WAKE time and ACTIVE time

2-12-1 Setting the real time

2-12-2 Setting the WAKE time

2-12-3 Setting the ACTIVE time

Microm International GmbH

part of Thermo Fisher Scientific

Robert-Bosch-Str. 49

69190 Walldorf / Germany

387 500 - English

5

Page 6

Thermo Scientific Cryostat Microm Cryo Star HM 560

2-13 Defrosting

2-13-1 Setting the defrost time

2-13-2 Defrosting cycle

2-13-3 Interrupting a defrosting cycle

2-14 Turning off the function retraction

2-15 Customer-specific settings

2-15-1 Setting the contrast

2-15-2 Selecting the language

2-16 Turning off the cooling function

2-17 Illumination of the cooling chamber

2-18 Adjusting the operating panel

2-19 Specimen holder, freezing-on and specimen orientation

2-19-1 Specimen holder, freezing-on

2-19-2 Specimen orientation

2-20 Knife carriers

2-20-1 Standard knife carrier SM

2-20-2 Disposable blade holder SE

2-20-3 Modification from standard knife carrier SM to disposable blade holder SE

2-21 Error code indication

2-21-1 Definition of the error codes

2-22 Accessories

2-22-1 Standard equipment

2-22-2 Additional equipment

PART 3 Theory of operation

3-1 Specimen and knife carrier cooling, defrost cycle

3-2 Cutting movement

3-3 Knife carrier coarse feed and trimming stages

3-4 Automatic approach system

PART 4 Working with the cryostat

4-1 Preparations on the microtome and inside the cooling chamber

4-2 Freezing on the specimen

4-4 Orientation and trimming of specimens

4-5 Sectioning and taking off sections

4-6 How to avoid malfunctions

6

Microm International GmbH

part of Thermo Fisher Scientific

Robert-Bosch-Str. 49

69190 Walldorf / Germany

387 500 - English

Page 7

Thermo Scientific Cryostat Microm Cryo Star HM 560

PART 5 Maintenance of the cryostat

5-1 Shutting-off for cleaning

5-2 Cleaning and care of the microtome

5-3 Changing the fluorescent lamp

5-4 Disposal of the instrument after final shutdown

Microm International GmbH

part of Thermo Fisher Scientific

Robert-Bosch-Str. 49

69190 Walldorf / Germany

387 500 - English

7

Page 8

Thermo Scientific Cryostat Microm Cryo Star HM 560

SAFETY PRECAUTIONS

WARNING SIGNALS AND SYMBOLS

The installation and routine use of the Cryo-Star HM 560 is easy and safe if the instructions in this manual are

being observed.

However, the situations which might be risky for the personnel or equipment are specially marked in this

manual with the following symbols and messages.

Note:

Special instructions regarding operation of the instrument.

Caution:

Special precautionary measures to prevent damage to equipment. For a long lifetime of the

equipment, please observe these instructions carefully.

Danger:

Special warning messages to prevent harm to persons and/or serious damage to equipment. For

your own safety, please observe these instructions carefully.

Biohazard:

Warning of biological danger.

Separate taking back of electrical and electronic instruments in the countries of the

European Union:

This is to be applied in the countries of the European Union and other European countries with a

separate collecting system within the waste management.

This product, being an electro and/or electronic instrument, must be treated separately within the

waste management process (WEEE).

8

Microm International GmbH

part of Thermo Fisher Scientific

Robert-Bosch-Str. 49

69190 Walldorf / Germany

387 500 - English

Page 9

Thermo Scientific Cryostat Microm Cryo Star HM 560

SAFETY PRECAUTIONS

A T T E N T I O N !

The operator's safety is affected, when the instrument is not operated in

accordance with this instruction manual.

Please observe the following general precautions during operation of this

instrument. Failure to comply with these precautions violates safety standards and

the intended use of the instrument. Thermo Fisher Scientific is not liable for misuse

of the instruments and failure to comply with basic safety requirements.

INSTRUMENT GROUNDING

To avoid injury from electrical current, the instrument must be connected with the safety ground. The

instrument is equipped with a three wire ground plug. The power outlet must be connected to the safety

ground and must meet the International Electrotechnical Commission (IEC) regulations.

CAUTION: MAINS VOLTAGE

Never remove instrument covers during operation. Component replacements as well as adjustments must

only be made by trained service personnel. Unplug the unit before removing or opening the covers.

DANGER IN EXPLOSIVE ENVIRONMENT

The instrument must not be operated in the presence of flammable gases.

HAZARD OF FROSTBITE

Avoid permanent touching of metal parts inside the cryostat microtome chamber as frostbite may occur at

unprotected hands and arms.

HAZARD OF RADIOACTIVE RADIATION

When working with radioactive specimens observe all applicable radiation safety procedures. When working

with radioactive contaminated material, appropriate safety and disinfection measures must be carried out.

According to the rules and regulations concerning the handling of radioactive contaminated material of the

respective laboratory, safety clothing (e.g. particle mask, gloves, protective shoe covers) must be worn.

Radioactive contaminated waste must be disposed of according to the respective regulations.

Microm International GmbH

part of Thermo Fisher Scientific

Robert-Bosch-Str. 49

69190 Walldorf / Germany

387 500 - English

9

Page 10

HAZARD OF INFECTION

Thermo Scientific Cryostat Microm Cryo Star HM 560

Use the appropriate safety and disinfection measures when working with infectious specimens.

According to the rules and regulations concerning the handling of infectious/radioactive contaminated

material of the respective laboratory, safety clothing (e.g. particle mask, gloves, protective shoe covers) must

be worn.

HAZARD OF BIOLOGICAL DANGER

Specimens used during the intended operation of the instrument might potentially be infectious. For this

reason, it is recommended to observe the general laboratory regulations concerning protection against

danger of infection.

Information on decontamination media, their use, dilution and effective range of application can be read in the

Laboratory Biosafety Manual : 1984 of the World Health Organization.

CAUTION: DANGER OF SQUEEZING

When placing the microtome cryostat HM 560 onto the height adjustable stage, it is absolutely necessary that

the stage is in its upper position or in case of a mechanical stage that the rear wall will be removed. Not

observing this leads to the risk of squeezing your hands between the rear carrying handles and the stage

housing.

HAZARD OF MALFUNCTION

To avoid the hazard of malfunction of an instrument, it must only be operated in a controlled electromagnetic

environment. This means, that transmitters such as mobile phones must not be operated in their close

vicinity.

CARE IN USING MICROTOME KNIFE

To diminish the danger of being injured by the knife or blade, use the knife guard when adjusting

specimen and knife. If possible, the specimen should be clamped in before the knife is inserted

into the knife holder. Before changing the knife holder, always remove blade or knife! Unused

knives should always be kept in a knife case. Never place the knife with the cutting edge upwards.

Never try to catch a dropping knife!! Never check the sharpness of the cutting edge with your fingers. The

cutting edge is extremely sharp!

WASTE DISPOSAL

All debris, waste as well as infectious and radioactive contaminated material from operation must be

disposed of in accordance with the respective regulations of the lab. Disinfection and cleaning liquids as well

as section waste must be disposed of according to the respective regulations for special waste!

10

Microm International GmbH

part of Thermo Fisher Scientific

Robert-Bosch-Str. 49

69190 Walldorf / Germany

387 500 - English

Page 11

Thermo Scientific Cryostat Microm Cryo Star HM 560

Fig. 1

Microm International GmbH

part of Thermo Fisher Scientific

Robert-Bosch-Str. 49

69190 Walldorf / Germany

387 500 - English

11

Page 12

Thermo Scientific Cryostat Microm Cryo Star HM 560

1 INTRODUCTION

1-1 DESCRIPTION OF THE

CRYO-STAR HM 560

Open top cryostat. Modular design. Stainless

steel cooling chamber. Temperature regulation

variable down to -50°C for specimen holder

and down to -35°C for knife carrier. Graphic

LC-display of preset and actual temperatures,

electronic control with user-oriented touchpad

keyboard, battery-buffered memory and selfdiagnostic system. Standby and sleep status

for noise reduction and energy savings.

Automatic evaporator defrosting and in addition

a manual defrost cycle which can be activated

when needed. Defrost interrupt on keystroke

request. Integrated rapid freezing device with

controlled cooling element down to -60°C.

Freezing device temperature independent of

cryo-chamber temperature. Detach function to

remove used specimen from specimen chucks.

Sliding window with heater and integrated,

position adjustable fluorescent lamp for cryochamber. Storage space inside the cryochamber. Flat storage space on top of the

housing.

HM-Rotary Microtome with backlash and

maintenance-free cross roller bearings in

stainless steel. Electro-motorized feed system.

Section thickness setting from 0,5 to 100

microns;

up to 2 µm in 0,5 µm-increments,

up to 10 µm in 1 µm-increments,

up to 20 µm in 2 µm-increments,

up to 50 µm in 5 µm-increments and

up to 100 µm in 10 µm-increments.

Trimming thickness setting from 5 to 500

microns;

up to 10 µm in 5 µm-increments,

up to 100 µm in 10 µm-increments,

up to 200 µm in 20 µm-increments and

up to 500 µm in 50 µm-increments.

Specimen retraction during the return stroke

with optical indication. Horizontal feed range 48

mm. Vertical specimen stroke 60 mm. Max.

specimen size 75 x 55 mm.

Motorized coarse feed in two directions with

three speed selections. Limit indication and

automated switch off at front and rear limits of

horizontal travel. Automatic approach system

for exact and safe approach of specimen

towards the knife edge.

Section counter and indication of sum of

section thicknesses with reset-button.

Indication of remaining travel. Hand wheel

brake in any position. Fine orientation of

specimen on two axes. Rotatable on Z-axis,

360°.

Basic outfit with three specimen chucks, cryocompound, 100 ml cryostat oil, brush shelf and

section waste tray.

A multi-use knife carrier is available. The

standard knife carrier is designed so the knives

as well as the disposable blade holder can be

easily clamped in place and adjusted.

Depending on the version, the disposable

blade holders SE take up low or high profile

blades. The corresponding anti-roll guides

facilitate taking off sections.

12

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

Page 13

Thermo Scientific Cryostat Microm Cryo Star HM 560

1-2 TECHNICAL DATA CRYO-STAR HM 560

Specimen temperature control: .......................................................................... +10°C to -50°C

Knife carrier control: ................................................................................ -10°C to -35°C

Fast freezing station: ................................................................................. down to -60°C

Defrosting: automatic defrosting, adjustable with temperature control

manual immediate defrosting

Microtome: Section thickness range: ............................................. 1 - 500 µm

Fine section thickness range: .................................... 0,5 - 100 µm

Resolution: .................................................. 0,5 µm for 0,5 - 2 µm

.......................................................................... 1 µm for 2 - 10 µm

........................................................................ 2 µm for 10 - 20 µm

........................................................................ 5 µm for 20 - 50 µm

.................................................................... 10 µm for 50 - 100 µm

Trimming thickness range: ........................................... 5 - 500 µm

Resolution: ........................................................ 5 µm for 5 - 10 µm

.................................................................... 10 µm for 10 - 100 µm

.................................................................. 20 µm for 100 - 200 µm

.................................................................. 50 µm for 200 - 500 µm

Knife carrier retraction during return travel ...........................40 µm

Horizontal knife carrier range ............................................ 48 mm

Vertical specimen stroke ................................................... 60 mm

Read-outs: Graphical LC display: section thicknesses, section counter, sum of

section thicknesses, remaining travel to front end position, size of

the cutting window

Specimen approach: .......................................................................... automatic function

........................................ alternatively manual with variable speed

Temperature parameter: ............................... temperature set values can be stored in pairs

Size of chucks: .......................................................................................30, 40 mm

............................................................. special sizes upon request

Specimen orientation: x - and y - axes: ......................................................... universal 8°

z - axis: ......................................................................... up to 360°

Coarse feed: ........................................... motorized, graduated and continuous

Cooling chamber illumination: ................................................ with variable illumination position

Sliding window: ............................................................................................. heated

Cutting speed: .................................................................................. 0 - 250 mm/s

Hand wheel brake: ................................................................................. in any position

All temperatures refer to an ambient temperature of +20°C!

Cont'd on page -2-

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

13

Page 14

Thermo Scientific Cryostat Microm Cryo Star HM 560

1-2 TECHNICAL DATA CRYO-STAR HM 560

Storage

temperature range: ......................................................................... -20°C up to +50°C

Operating conditions: ....................... +5°C up to +35°C (at a max. rel. humidity of 60%)

........................................................... altitude up to 2000 m M.S.L.

.......................................................................... for indoor use only

Power requirements: ....................................................... 100 V 12 A +/-10% 50...60 Hz

............................................................... 115 V 12 A +/-10% 60 Hz

................................................. 220...230 V 6 A +/-10% 50...60 Hz

................................................................. 240 V 6 A +/-10% 50 Hz

Pollution degree: ...................................................................................................... 2

Overvoltage category: ...................................................................................................... II

Acoustic pressure: ......................................................................................... 45 dB(A)

............................... measured with 1 m distance to the instrument

Dimensions: .. Wide (w/o Hand wheel): 769 mm, deep: 932 mm, high: 578 mm

Weight: ............................................................................................. 141 kg

All temperatures refer to an ambient temperature of +20°C!

page -2-

14

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

Page 15

Thermo Scientific Cryostat Microm Cryo Star HM 560

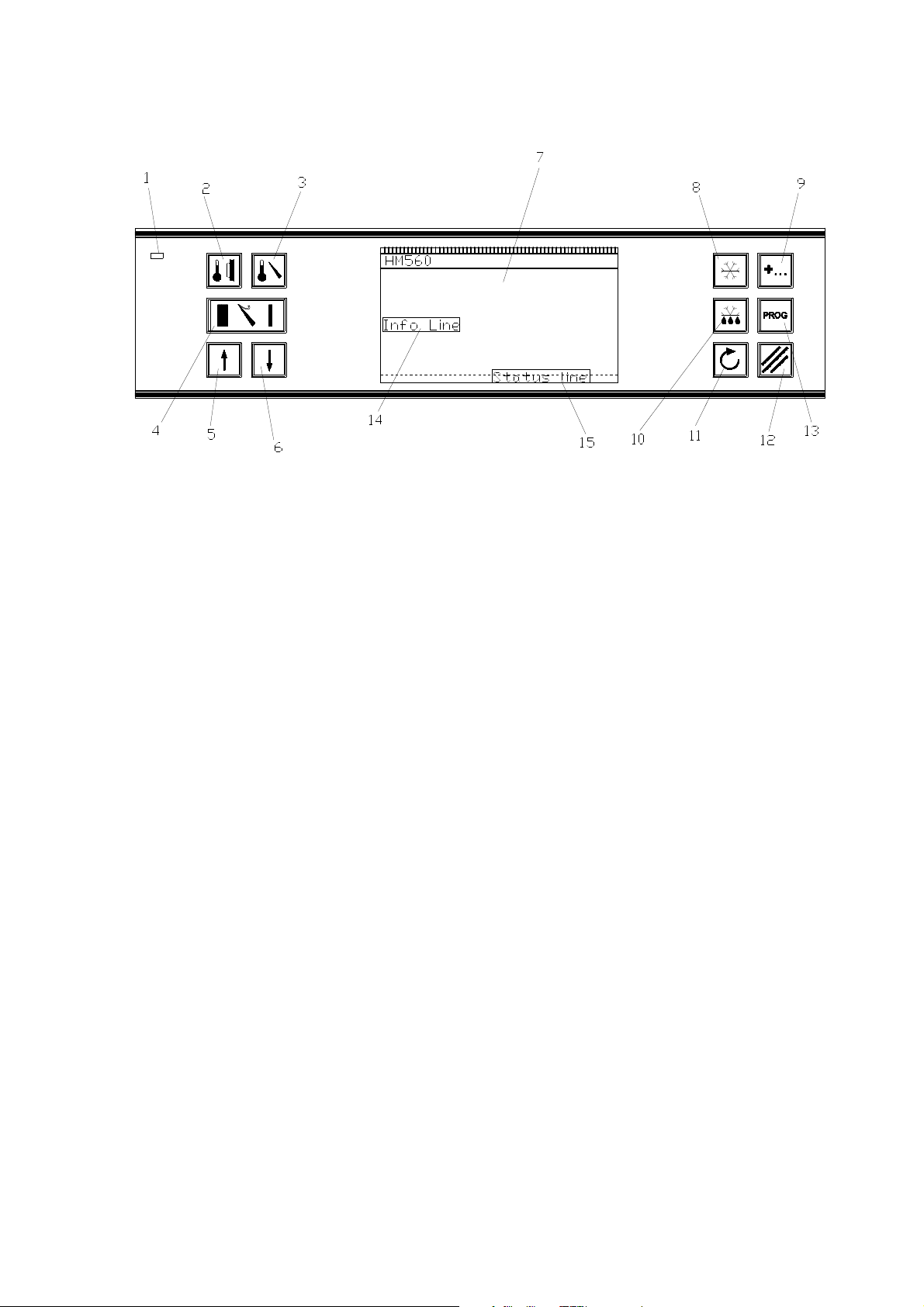

1 = On indication (sleep status)

2 = Button specimen temperature

3 = Button knife temperature

4 = Button TRIM/FEED

5 = Button UP

6 = Button DOWN

7 = LC display

8 = Button fast freezing

Fig. 2

9 = Button options

10 = Button detaching

11 = Scroll button

12 = Button RESET

13 = Button PROG

14 = Info line

15 = Status line

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

15

Page 16

Thermo Scientific Cryostat Microm Cryo Star HM 560

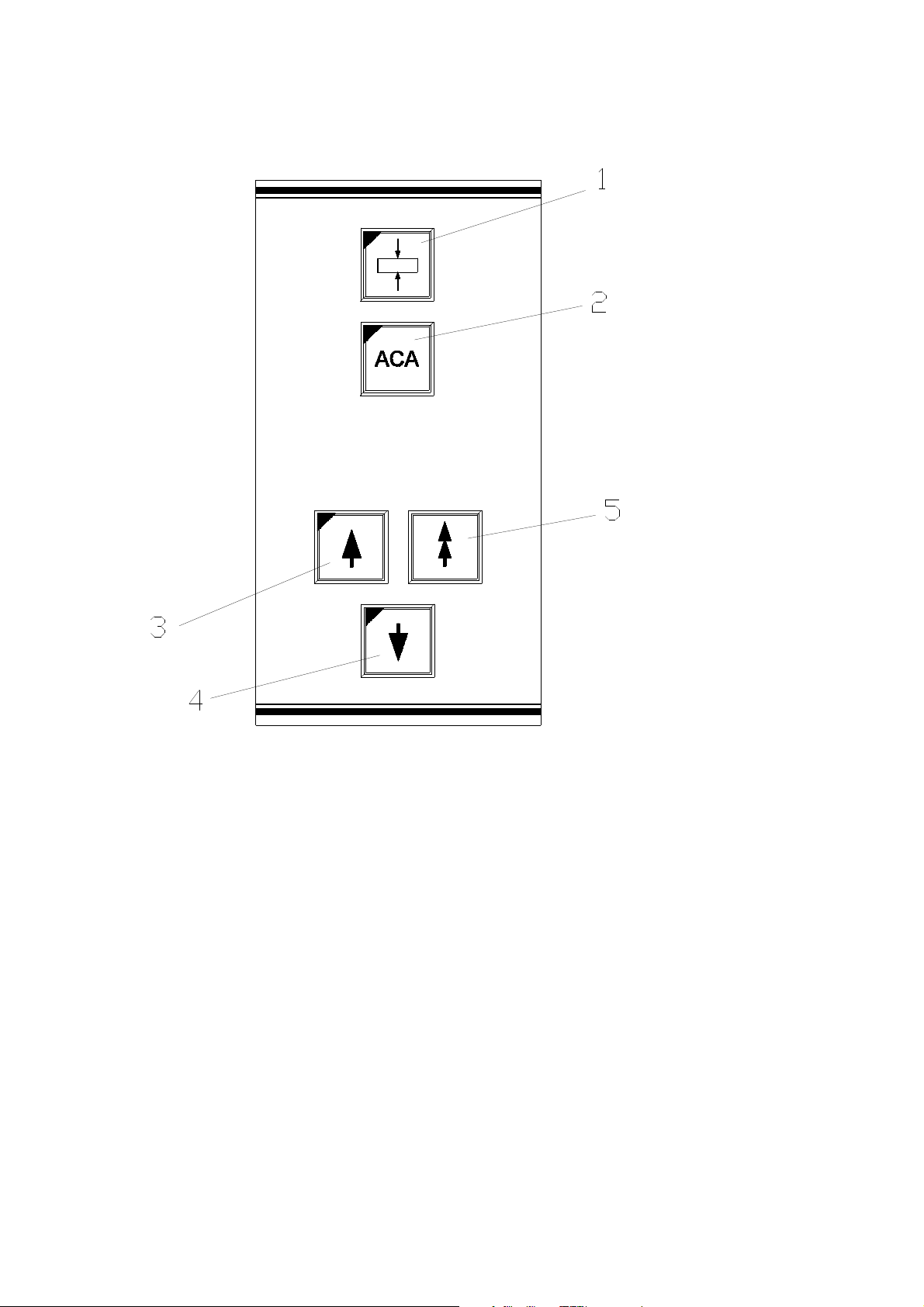

1 = Button cutting window

2 = Button ACA

3 = Button coarse feed, forwards

4 = Button coarse feed, backwards

5 = Button TRIM

16

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

Fig. 3

Page 17

Thermo Scientific Cryostat Microm Cryo Star HM 560

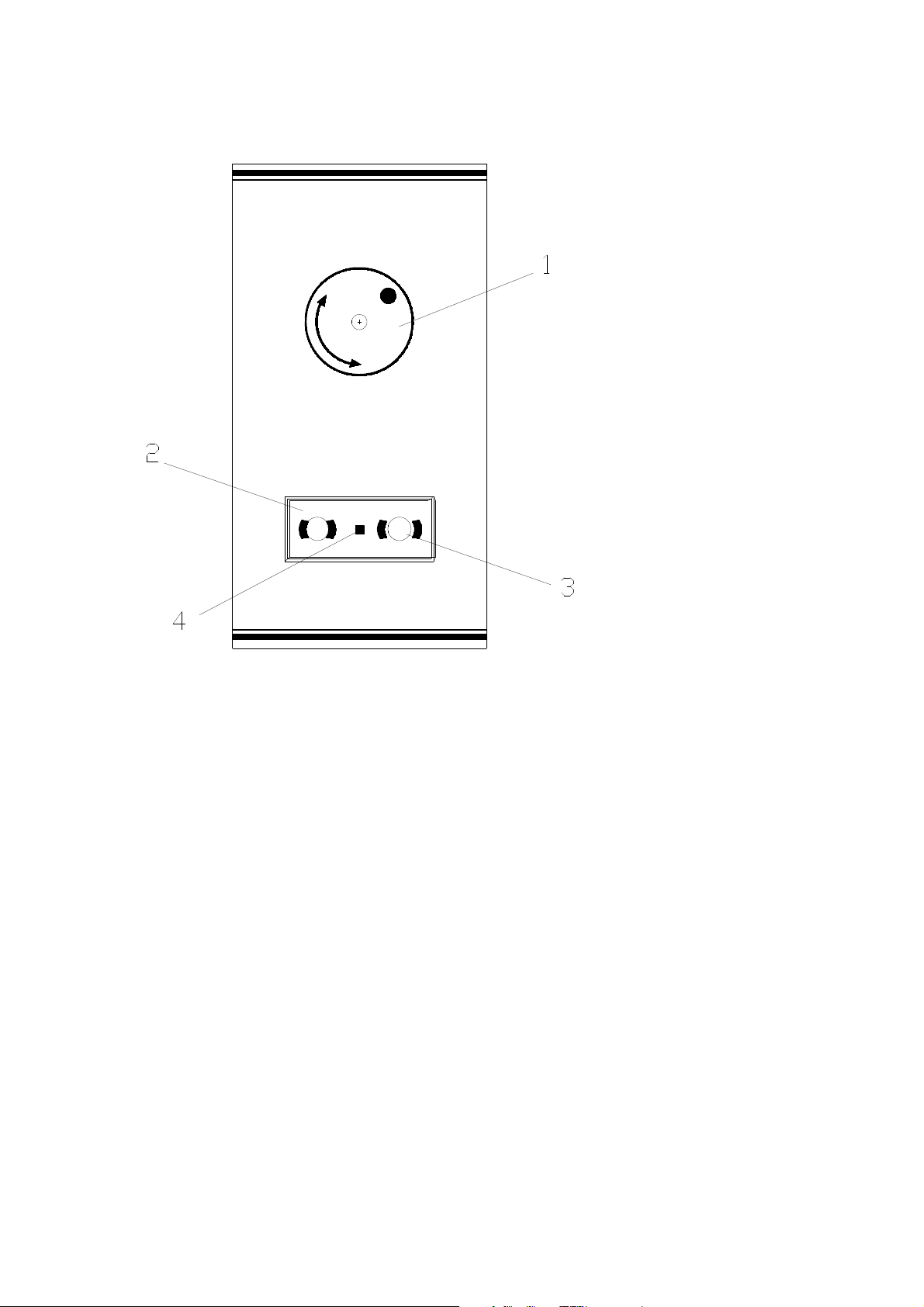

1 = Symbol Hand wheel

2 = Button to activate the Hand wheel brake

3 = Button to loosen the Hand wheel brake

4 = Brake LED

Fig. 4

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

17

Page 18

Thermo Scientific Cryostat Microm Cryo Star HM 560

2 OPERATING INSTRUCTIONS

2-1 SETTING UP THE CRYOSTAT

Note:

If the microtome cryostat is supplied

with an extra height-adjustable stage,

first unpack and set up this stage

according to the separate instruction manual.

Unpacking the instrument:

• Loosen and remove the four tightening

straps.

• Lift and remove the wooden top of the

packing.

• Remove the foam parts upwards.

• The four side parts of the packing, which are

connected with each other, can now be

removed upwards.

• Slightly tilt the cryostat to the side and

remove the right and left lower foam parts

one after the other.

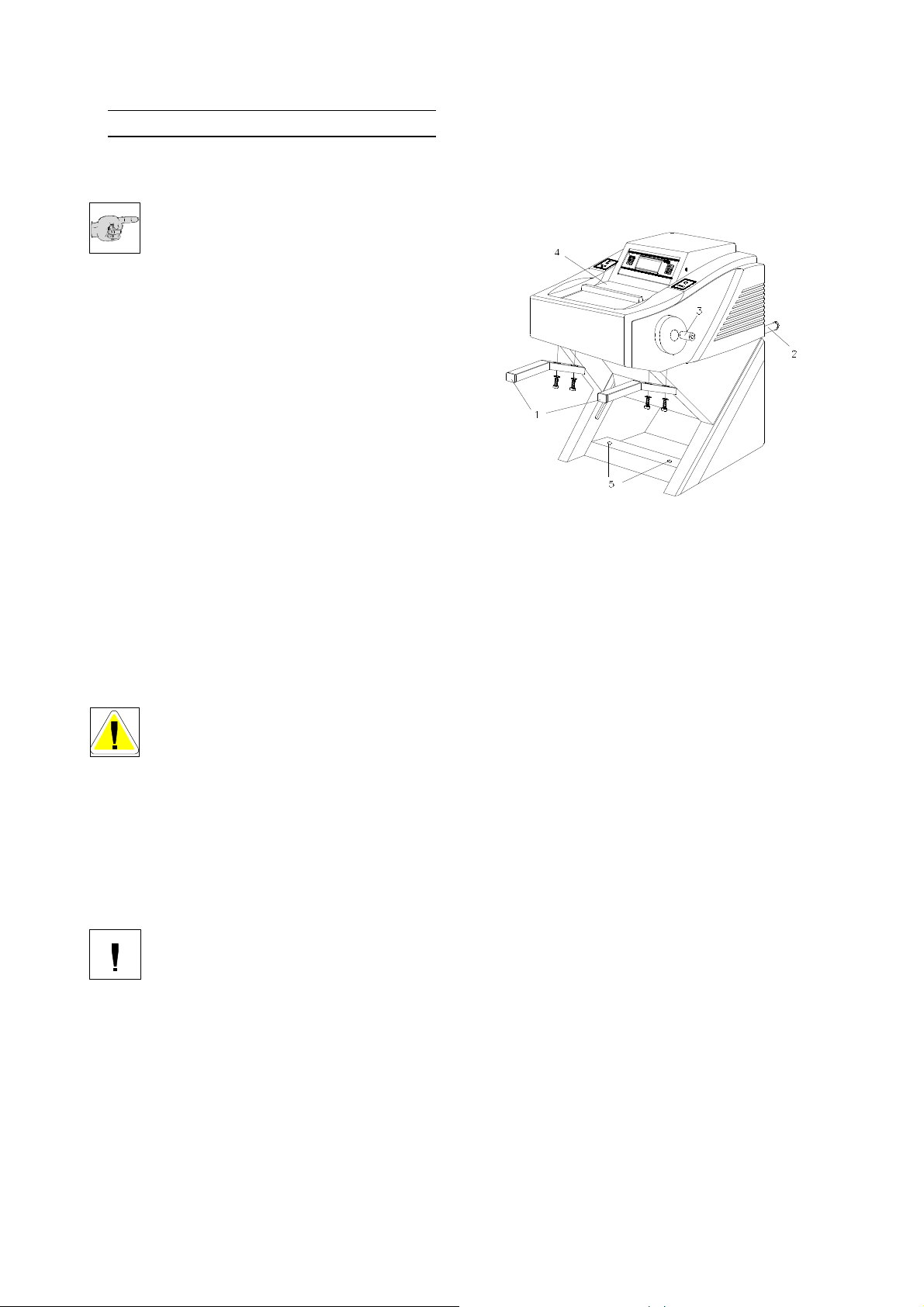

• Lift the cryostat by the carrying handles (fig.

5.1 and 5.2) from the pallet.

• In case the handles are not installed, securely

install the attached carrying handles (fig. 5.1

and 5.2) at the front and rear side of the

instrument and carry the instrument to the

site of installation (table according to the

customer's choice) or place it onto the heightadjustable stage.

Danger:

When placing the microtome cryostat

HM 560 onto the height adjustable

stage, it is absolutely necessary that

the stage is in its upper position.

Not observing this leads to the risk of

squeezing your hands between the rear

carrying handles and the stage housing.

• Remove the handles (fig. 5.1 and 5.2).

cryostat, as when lowering the heightadjustable stage, the handles will hit the stage

and cause damage to the stage.

Caution:

Before the initial set-up of the height-

adjustable stage, it is absolutely

necessary to dismount the two rear

carrying handles (fig. 5.2) on the

Fig. 5

18

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

Page 19

Thermo Scientific Cryostat Microm Cryo Star HM 560

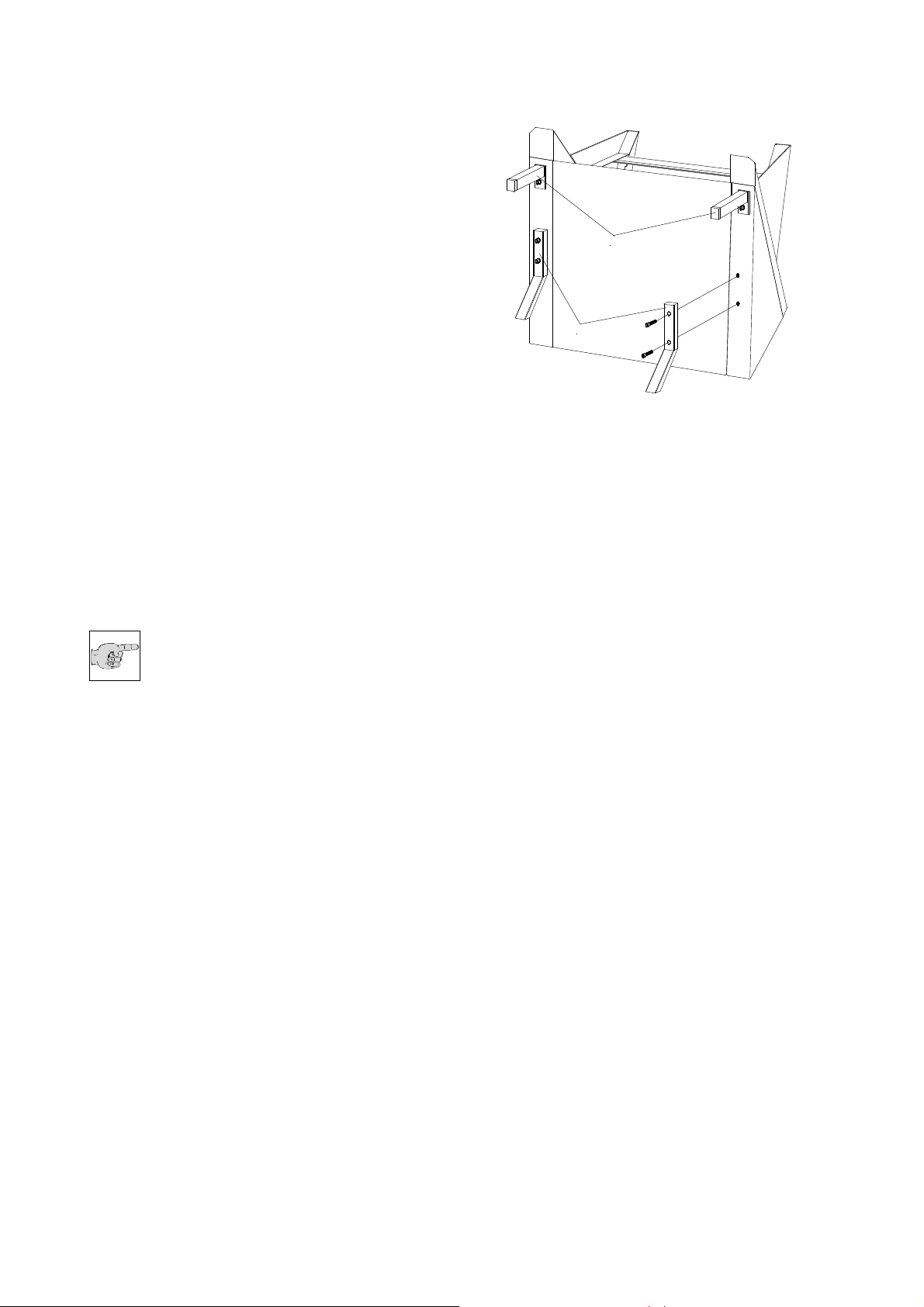

• Adjust the handles of the cryostat (fig. 5a.1

and 5a.2) on the rear side of the cryostat

stage.

• Carefully keep the shipping container for

possible return shipments.

Choose installation site that

• enough ventilation for the cooling system is

guaranteed.

• the distance between wall and rear panel is

approx. 10 - 15 cm.

• the suction areas on either side are kept free.

Moreover, the installation site must be free

from:

• draught by open doors or by air conditioning

systems.

• direct exposure to sunlight into the cooling

chamber.

Note:

Both measures reduce the formation of

frost and therefore result in more

favourable work conditions. A high air

moisture as well as high ambient temperatures

reduce the maximum performance of the

instrument.

In case the instrument is equipped with the

height-adjustable stage, turn the screws (fig.

5.5) on the front foot ends to fix the complete

unit.

Afterwards:

• Install the attached Hand wheel handle (fig.

5.3).

1

2

Fig. 5a

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

19

Page 20

Thermo Scientific Cryostat Microm Cryo Star HM 560

2-2 INITIAL TURN-ON

As already mentioned in part 2-1, the heightadjustable stage, if equipped, must be set up

according to the separate instruction manual

before the initial turn-on of the microtome

cryostat.

Caution:

Before turning on the instrument for the

first time, please check if the power

requirements indicated on the type

plate (fig. 7) correspond to the power supply

voltage being used.

• No other instruments should be connected to

the circuit used for the cryostat, as the

compressor needs high surge currents when

started.

• Do not use multi-socket power outlets and

extension lines for the supply of the stage.

• Connect the power line of the instrument to

the power outlet.

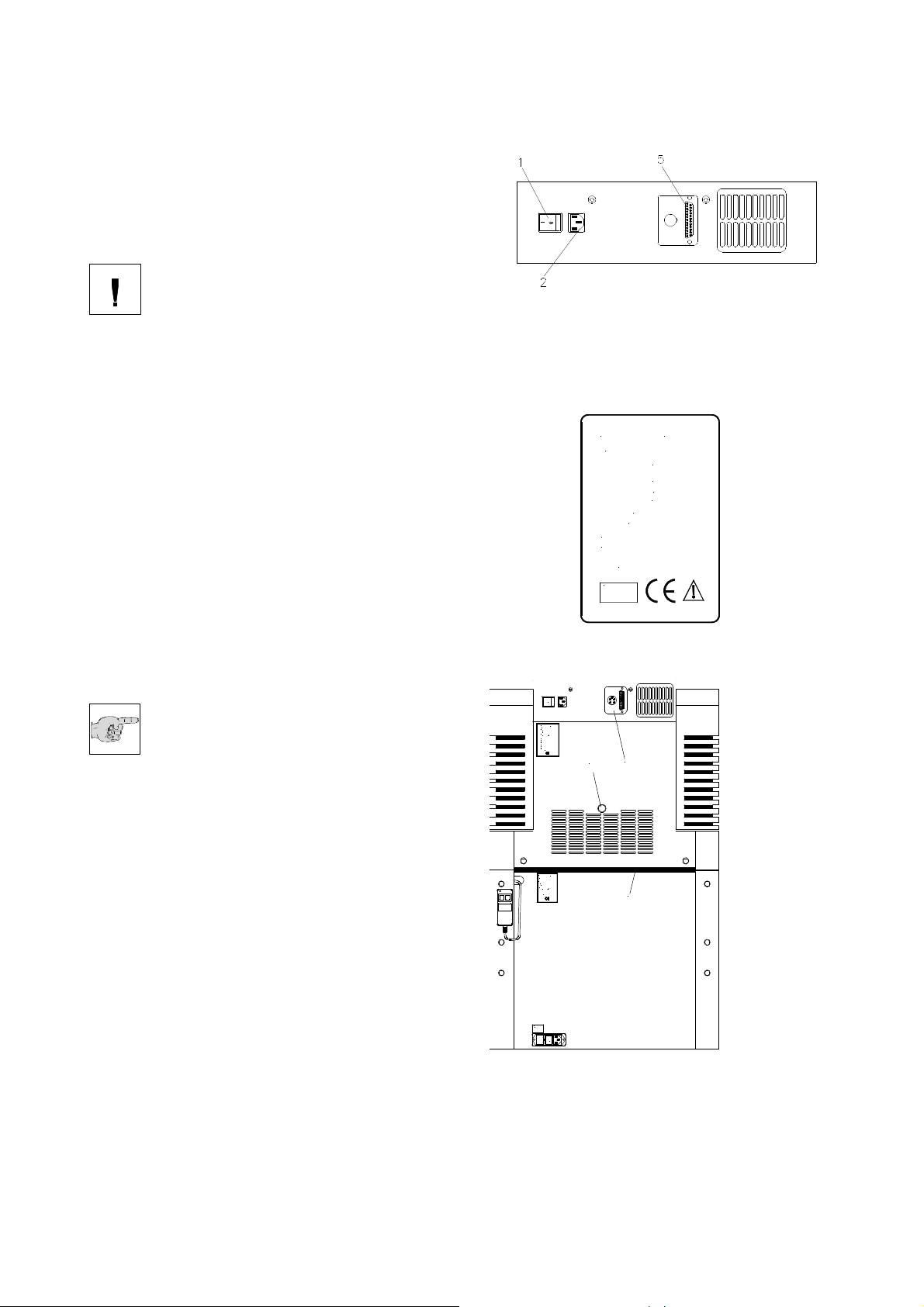

• Turn on the power switch (fig. 6.1) on the rear

side of the instrument.

• Close the heated sliding window (fig. 5.4) and

cool down the instrument.

Note:

To avoid frost built-up on the

specimen, the specimen temperature

is controlled to a temperature of +10°C

until the knife has reached a temperature

of -10°C.

The cooling phase will take approx. 1 to 2 h

depending on the set knife temperature

between -15°C and -30°C.

1 = Power switch

2 = Mains plug

5 = Socket for option Vacutome/Disinfection

MICROM

69190 Walldorf, Germany

GmbH

Type HM 560V

Ser. No.XXXXX

Cat. No. 956320

220...230V 6A 50...60Hz

Cooling System

Refr.: R 404a

Amount: 0,275 kg

Max. Press.: 2300 kPa

Made in Germany

I V D

I

0

GmbH

MICROM

69190 Walldorf, Germany

Type HM 560 MV

Ser. No.____

Cat. No. ______

__A / ___ V + 10% __Hz

Fuse 2 x __AT

HP Circuit

Refr.: R 134a

Amount: 0,180kg

Max. Press.: 2300kPa

LP Circuit

Refr.: R 404a

Amount: 0,270kg

Max. Press.: 2300kPa

Made in Germany

1

4

GmbH

MICROM

69190 Walldorf, Germany

Type Stage f. HM 560 HV

Ser. No. __ __

Cat. No. ______

_A /___V +10% __Hz

Fuse 2x __AT

Made in Germany

3

Fig. 6

Fig. 7

20

~___V

F1/F2

2x __AT

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

I

0

Fig. 8

Page 21

Thermo Scientific Cryostat Microm Cryo Star HM 560

2-3 BASIC OPERATIONAL RULES

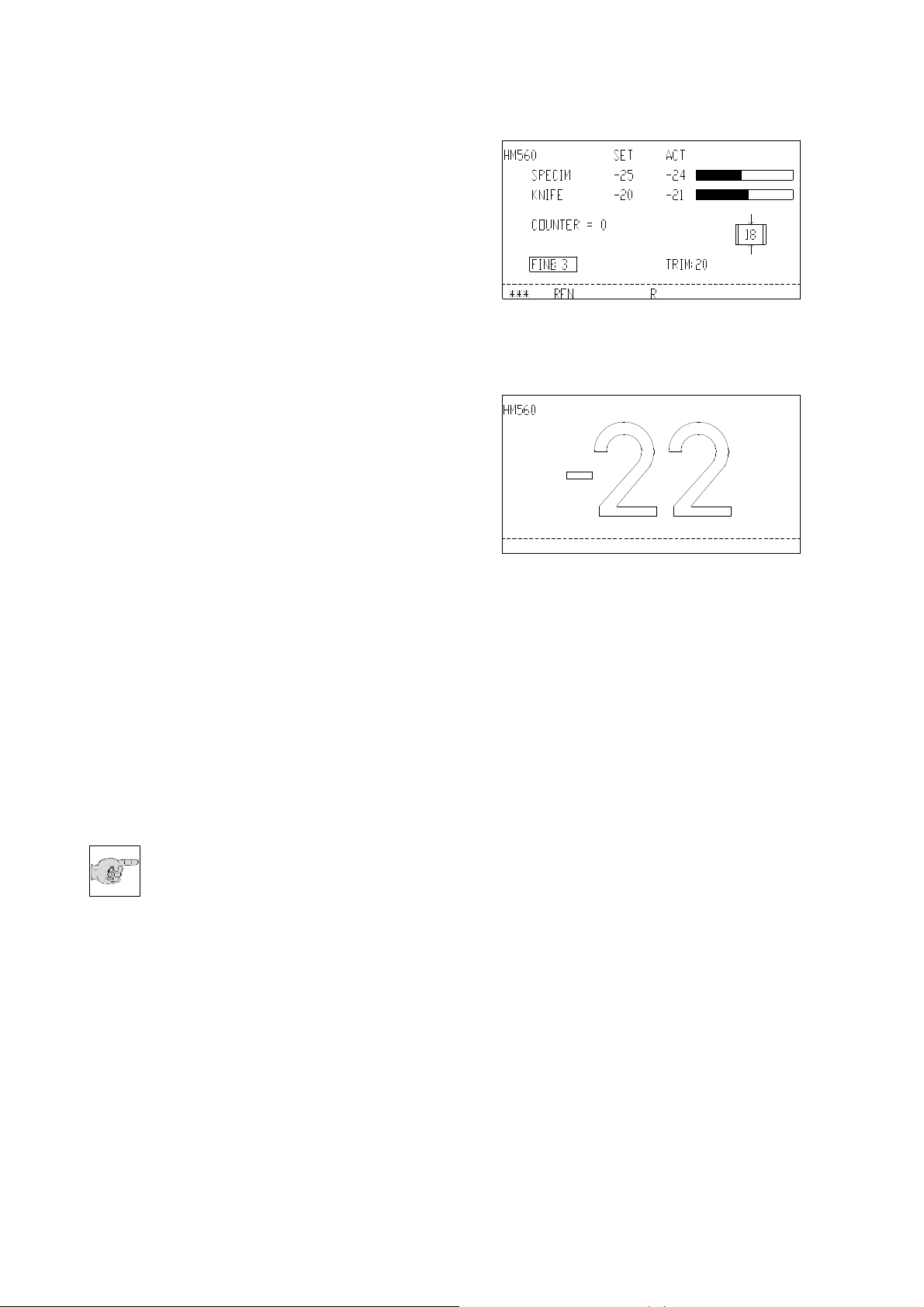

When turning on the instrument, the

display shows:

• the configuration of the instrument

• the section thickness selection

• the specimen and knife temperatures with the

corresponding set and actual values

• the symbol for the cutting window

This is the display (fig. 9) while the instrument

is in its active status.

To save energy and extend the lifetime of

some instrument components, the instrument

has two more operative status:

• Standby status

• Sleep status

The instrument switches to the standby status

when it is turned on, but not operated for more

than a pre-selected active time (see part 2-12-

3) between 1 and 9 h. The chamber

illumination goes off and the display (fig. 10)

switches to a large indication of the knife actual

temperature. This is the clear sign for the

standby status and gives the operator

information on the knife temperature, also from

a greater distance.

When the instrument is not operated for

another hour, the cryostat switches to the

sleep status. The display illumination goes off.

However, the equipment-on indicator (fig. 2.1)

then lights up and shows that the instrument is

still on.

Note:

While in the sleep status, the

temperature control of the knife

temperature features a reduced control

accuracy.

The specimen temperature in the sleep status

is always kept at -15°C. The set temperature of

the knife carrier is kept constant.

This does not only save energy, but also

reduces the formation of frost on the specimen

clamping.

Fig. 9

Fig. 10

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

21

Page 22

Thermo Scientific Cryostat Microm Cryo Star HM 560

• To return to the active operating state, press

any key on the control panels, move the

Hand wheel or wait until the WAKE time (see

2-12-2) has been reached.

The WAKE time is used to trigger the

instrument back into the active state.

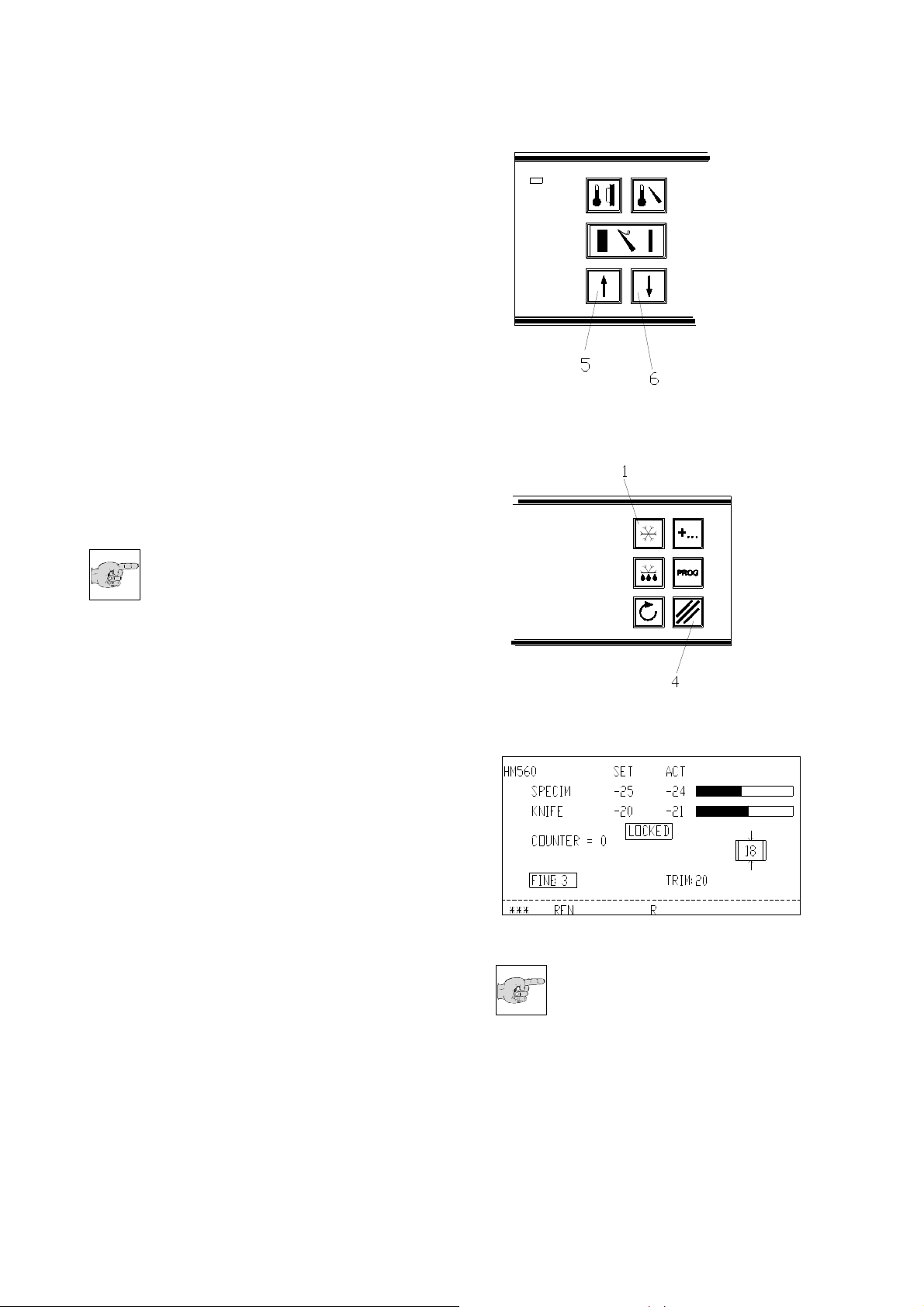

UP/DOWN buttons

These two buttons (fig. 11.5 and 11.6) are

used to change pre-selected values of different

kinds in connection with the chosen function.

• section thickness

• trimming thickness

• specimen temperature

• knife temperature

• time settings

Note:

To operate the instrument easily and

comfortably with a few buttons only,

please note the following:

After having chosen a function, its pre-selected

values can be changed via the UP or DOWN

buttons.

However, if no entry is made within 2 seconds,

the operating control switches back into its

basic status.

RESET-button

This button (fig. 12.4) is used to reset added

values (e.g. number of sections, sum of section

thicknesses) to zero. In some cases, this

button is used as additional button for doublebutton functions (see part 2-8 and

2-13-3).

Keyboard lock

To lock the keyboards and to block the feed

movement, press the buttons (fig. 12.4 and

12.1) for approx. 2 sec. The display (fig. 12a)

shows LOCKED.

To unlock the keyboards press the buttons (fig.

12.4 and 12.1) again.

Fig. 11

Fig. 12

Fig. 12a

Note:

When the keyboards have been

locked, this leads automatically

after 5 sec. to the standby status and after

another 5 sec. to the sleep status.

22

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

Page 23

Thermo Scientific Cryostat Microm Cryo Star HM 560

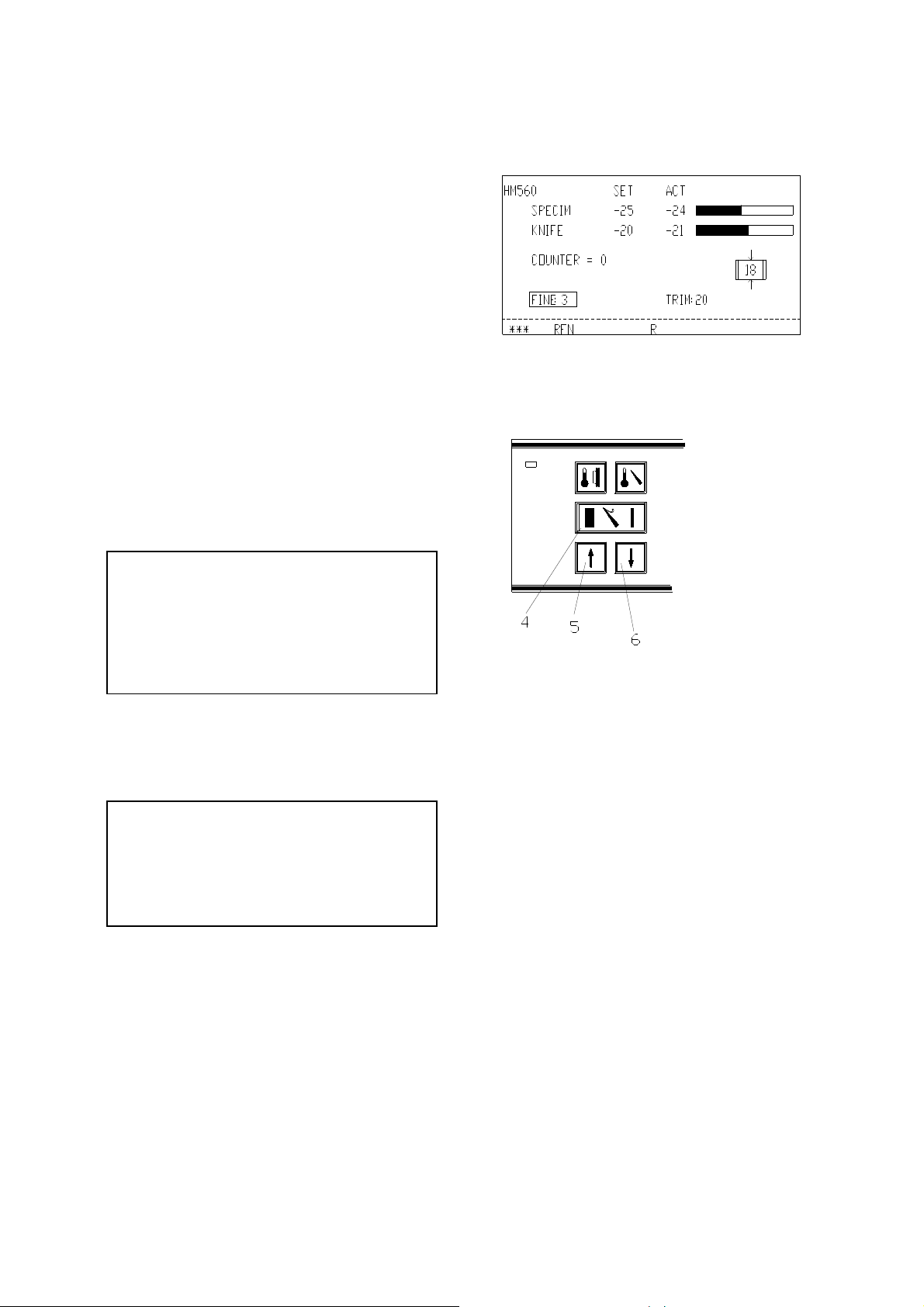

2-4 SETTING SECTION THICKNESS

AND TRIMMING THICKNESS

Basic status of the operating control:

To choose between section thickness and

trimming thickness

• press button (fig. 14.4).

• The selected setting is shown inverted on the

display.

• Then enter the desired section or trimming

thickness via button UP (fig. 14.5) or DOWN

(fig. 14.6).

• The changed values are shown on the

display.

The graduation of the section thicknesses

(which can be pre-selected) is divided into 5

ranges:

range graduation

from 0,5 µm to 2 µm 0,5 µm

from 2 µm to 10 µm 1 µm

from 10 µm to 20 µm 2 µm

from 20 µm to 50 µm 5 µm

from 50 µm to 100 µm 10 µm

The graduation of the trimming thicknesses

(which can be pre-selected) is divided into 4

ranges:

range graduation

from 5 µm to 10 µm 5 µm

from 10 µm to 100 µm 10 µm

from 100 µm to 200 µm 20 µm

from 200 µm to 500 µm 50 µm

Fig. 13

Fig. 14

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

23

Page 24

Thermo Scientific Cryostat Microm Cryo Star HM 560

2-5 SPECIMEN AND KNIFE COOLING

The HM 560 makes it possible to set both the

specimen and the knife temperature.

2-5-1 ACTUAL AND SET VALUE OF

THE SPECIMEN TEMPERATURE

The specimen cooling of the cryostat can be

controlled via the corresponding part of the

operating controls (fig. 16.2).

The actual and set values of the specimen

cooling are shown in °C on the display (fig. 15).

On the right side of the display, the actual

value is shown as on a thermometer.

• Press button (fig. 16.2) for specimen

temperature.

The set value settings are made via the

• UP button (fig. 16.5)

• DOWN button (fig. 16.6)

Note:

The valid range of the set value

goes from +10°C down to -50°C.

• After having chosen the requested values,

the display automatically returns to its basic

indications after three seconds.

Fig. 15

Fig. 16

24

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

Page 25

Thermo Scientific Cryostat Microm Cryo Star HM 560

2-5-2 ACTUAL AND SET VALUE OF

THE KNIFE TEMPERATURE

The knife cooling of the cryostat can be

controlled via the corresponding part of the

operating controls (fig. 16.3).

The actual and set values of the knife cooling

are shown in °C on the display (fig. 17). On the

right side of the display, the actual value is

shown as on a thermometer.

• Press button (fig. 16.3) for knife temperature.

The set value settings are made via the

• UP button (fig. 16.5)

• DOWN button (fig. 16.6)

Note:

The valid range of the set value

goes from -10°C down to -35°C.

• After having chosen the requested values,

the display automatically returns to its basic

indications after three seconds.

2-5-3 FUNCTION FAST FREEZING

To accelerate freezing-on of a specimen on a

specimen chuck, choose the function fast

freezing. If this function is activated in due time

before freezing-on, the fast freezing plate can

achieve a temperature of -60°C.

• For this, press button (fig. 19.1).

• The surface in the front of the fast freezing

station (fig. 59.1) will then be activated for

8 min.

• The course of the changing temperature will

then be shown on the display (fig. 18) as a

figure and as on a thermometer.

• Afterwards, the function fast freezing will

automatically be inactivated.

• If it is necessary to turn off this function within

those 8 min., press button (fig. 19.1) once

more.

Fig. 17

Fig. 18

Fig. 19

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

25

Page 26

Thermo Scientific Cryostat Microm Cryo Star HM 560

2-5-4 PROGRAMMING

TEMPERATURE PARAMETERS

With the cryostat HM 560 it is possible to store

four different combinations of set value

temperatures for the specimen and knife

temperatures. The stored temperatures are of

no direct importance for the respective valid set

value temperatures of knife and specimen.

Note:

The menu for the programs can

only be called when the info line

(fig. 2.14) is also called and values

are shown. To avoid an unintended operation,

see part 2-7-2.

Calling a program:

• Press button (fig. 21.3) to open the menu

for the program lines.

• The first stored program appears in the info

line of the display (fig. 20).

• To choose a program line, press button (fig.

21.5) until the desired program appears.

• To use the stored temperatures as set

values for the active cutting status, press

the UP button (fig. 22.5).

• The program line goes off and the info line

appears again.

• The new set values are now shown in the

set value column and the instrument adjusts

itself to the new temperatures.

Storing a program:

• Open the menu for the programs via the

button (fig. 21.3).

• Via button (fig. 21.5) call this program line

which the new set value temperatures are

supposed to be stored in.

• Store the actual set value temperatures into

the program via the DOWN button (fig.

22.6).

• Then, the info line is shown again on the

display.

Note:

If nothing is changed in the

programs and they are called only

for information purposes, this menu

can be closed again via the button (fig. 21.4).

Fig. 20

Fig. 21

Fig. 22

26

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

Page 27

Thermo Scientific Cryostat Microm Cryo Star HM 560

2-6 CUTTING MOVEMENT AND

RETRACTION

• Turn the Hand wheel in a clockwise direction

so the cutting movement is carried out.

• As the specimen moves down, sections are

produced.

• Continue turning the Hand wheel clockwise to

bring the specimen back up.

• To protect the knife and specimen during

return travel, the knife carrier is retracted

electro-mechanically.

• This is shown by the letter "R" in the status

line (fig. 2.15) on the display.

X=selected section thickness,

1=specimen,

2=cutting movement

3=knife

R=retraction

F=cutting window

Fig. 23

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

27

Page 28

Thermo Scientific Cryostat Microm Cryo Star HM 560

2-7 FEED

2-7-1 KNIFE CARRIER COARSE FEED

For the fast forward and backward travel

between knife and specimen, the cryostat

microtome has a motorized coarse feed

system.

The approach between knife and specimen

can also be carried out by means of an

automatic function (see part 2-7-3).

Return travel of the knife carrier

• Press button (fig. 24.4). Pressing the button

briefly leads to short return travels only.

• Press the button (fig. 24.4) for more than

approx. 2 seconds, the function is carried out

continuously. The knife carrier will entirely be

moved backwards.

Note:

The rear end position is defined as

that position which has the longest

distance to the specimen.

• To stop this function, briefly press button (fig.

24.4) once more.

• When the rear end position of the knife

carrier is reached, the coarse feed turns off.

• The LED in button (fig. 24.4) blinks, which

means that the knife carrier is in its rear end

position.

Feed travel of the knife carrier

• The continuous forward travel is only carried

out as long as the button (fig. 24.3) is being

pressed.

• Press button (fig. 24.5). Briefly press this

button, to carry out a forward travel of that

trimming section thickness which was chosen

via the control panel and shown on the

display.

Caution:

With the function coarse feed forwards

knife and specimen are adjusted very

quickly. To avoid damage to specimen

and knife, the following points are of utmost

importance!

Fig. 24

28

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

Page 29

Thermo Scientific Cryostat Microm Cryo Star HM 560

• Take note that the knife edge and specimen

do not come in contact with each other.

• Carefully observe the narrowing gap between

knife edge and specimen to stop the function

coarse feed forwards in time before the knife

touches the specimen.

When the instrument is just carrying out the

retraction movement and the function coarse

feed forwards is selected, the coarse feed

movement is carried out and the retraction is

annulled.

• When the front end position of the knife

carrier is reached, the coarse feed turns off.

• The LED in button (fig. 24.3) lights up and

shows that the knife carrier has reached its

front end position.

2-7-2 SPEED FOR KNIFE CARRIER

COARSE FEED

The speed for the knife carrier coarse feed can

be selected in three different settings.

The selected setting is shown in the status line

(fig. 2.15) on the display by one, two or three

little stars. Three stars means the fastest

coarse feed setting.

Setting the speed:

• Make sure that there is no information in the

info or program line. For this press the scroll

button until this line is blank.

• Press button (fig. 25.3) until the desired

speed is selected.

• The number of the shown stars determines

the speed.

Fig. 25

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

29

Page 30

Thermo Scientific Cryostat Microm Cryo Star HM 560

2-7-3 AUTOMATIC APPROACH

SYSTEM

The automatic approach system performs the

fast and exact approach of the specimen

towards the knife edge and can be applied

between -5°C and -35°C. Beyond these

temperature limits, the automatic approach

system is blocked (see error code 'OUT OF

TEMPERATURE').

Danger:

For your personal safety, before

activating the automatic approach

system, move the anti-roll plate onto

the blade against possible splintering of the

blade. This might be caused by an incorrect

approach.

Danger:

When using different freezing

techniques, for example by means of

the fast freezing stations, liquid

nitrogen, CO2 and the like, which generate a

freezing temperature of below -35°C, the

automatic approach system can only be

applied after the specimen will have adjusted

itself to the respective temperature of the

specimen holder which must be between the

temperature range of -5°C and -35°C.

As a safety measure, place the anti-roll plate

onto the blade, otherwise an incorrect

approach will be carried out and the blade

might splinter.

Starting the automatic approach

• Use the Hand wheel to make sure that the

most protruding point of the specimen is

opposite the knife edge. This position must

be within the selected cutting window (see

part 2-8).

Note:

If the button cutting window is

pressed twice and the cutting

window is thus inactive, the

automatic approach can be released in any

position.

• Press button (fig. 27.2) to start the automatic

approach process.

• The red LED in this button (fig. 27.2) lights up

and confirms the chosen function and

AUT.APPROACH is shown in the status line

(fig. 2.15) on the display (fig. 26).

• The knife carrier moves forwards until the

knife edge touches the specimen.

Fig. 26

Fig. 27

30

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

Page 31

Thermo Scientific Cryostat Microm Cryo Star HM 560

• Immediately afterwards, this forward travel of

the knife carrier is stopped and moved

backwards by a safety distance of 200 µm.

AUT.APPROACH is still shown on the display

as the process of the automatic approach

has not yet been finished.

• When passing the next upper reversal point,

the knife carrier automatically moves

forwards again by 200 µm.

• The red LED in button (fig. 27.2) goes off as

well as the term AUT.APPROACH

disappears.

• The specimen is now in position to start

sectioning.

Cancellation of the automatic approach

• Press button (fig. 27.2) or

• pass upper or lower reversal point via Hand

wheel.

When an automatic approach has been carried

out, another approach can be started

immediately, if needed.

This might become necessary, when the

specimen has been oriented again.

Error codes during an automatic approach

process

• Error code 'AMPLIFIER ERROR'

is shown on the status line (fig. 2.15) on the

display, in case the activating signal for the

automatic approach has already been

recognized before the automatic approach

movement has been started.

• Possible cause: the specimen has already

been in contact with the knife edge, e.g. by

protruding fibers.

• Press button (fig. 27.2), remove the cause

for the error and press button (fig. 27.2)

again, to start the automatic approach once

more.

• However, if there is no obvious explanation

for this error code, e.g. frost built-up, please

call a service technician.

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

31

Page 32

Thermo Scientific Cryostat Microm Cryo Star HM 560

• Error code 'OUT OF TEMPERATURE'

appears in the status line (fig. 2.15) on the

display, if the actual temperature for the

knife or the specimen is outside the

temperature range of -5° and -35°C, which

is valid for the automatic approach function

only.

• Press button (fig. 27.2). The error message

goes off.

Note:

In this case the function automatic

approach cannot work. The

approach between knife edge and

specimen must be carried out via the coarse

feed button (fig. 24.3) (see part 2-7-1).

32

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

Page 33

Thermo Scientific Cryostat Microm Cryo Star HM 560

2-7-4 TRIMMING AND FIRST CUTS

After the specimen and the knife are adjusted,

further gradual feed for trimming can be carried

out using the function trimming.

For different sectioning series, deeper layers of

the specimen can be reached with the function

trimming.

• Make sure that the trimming thickness setting

is selected via the button (fig. 28.4). Trimming

thickness is shown inverted on the display.

• Press the button UP (fig. 28.5) or DOWN (fig.

28.6) to select the desired trimming value.

• Turn the Hand wheel in a clockwise direction

to carry out the trimming feed in the upper

reversal point of the cutting movement.

2-7-5 FINE FEED

After having adjusted knife and specimen as

well as having trimmed the specimen,

sectioning can be started.

• Make sure that the section thickness setting

is selected via the button (fig. 28.4). Section

thickness is shown inverted on the display.

• Press the button UP (fig. 28.5) or DOWN (fig.

28.6) to select the desired value.

• Turn the Hand wheel in a clockwise direction

to feed the specimen at the selected section

thickness.

Fig. 28

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

33

Page 34

Thermo Scientific Cryostat Microm Cryo Star HM 560

2-8 SETTING THE CUTTING WINDOW

To activate an automatic approach process, it

is necessary to set a cutting window first (see

part 2-7-3).

The instrument automatically detects the

cutting window. It is shown on the display (fig.

29) in the status line with the letters "AW"

(automatic window).

The size of this window is then shown in the

symbol cutting window.

When passing the cutting window this symbol

is shown inverted on the display.

During this automatic function, the cutting

window adjusts itself to the size of the

specimen.

Note:

The automatic window is only

possible within the temperature

range of -5°C and -35°C. Beyond

these temperature limits the automatic window

turns off automatically and the manual setting

is possible only.

Manual setting:

• If necessary, the cutting window can be

determined by manual entries.

• For this, turn off the automatic cutting window

registration. As a precondition for this

process, values must be shown in the info

line (fig. 2.14).

• For this, press button (fig. 30.4) and while this

button (fig. 30.4) is still being pressed, press

button (fig. 31.1). The letters "AW" disappear

from the display.

• Turn the Hand wheel so that the lower edge

of the specimen is positioned slightly above

the knife edge.

• Press button (fig. 31.1) to set the upper limit

of the cutting window.

Fig. 29

Fig. 30

34

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

Page 35

Thermo Scientific Cryostat Microm Cryo Star HM 560

• Continue turning the Hand wheel clockwise to

place the upper edge of the specimen just

below the knife edge.

• Press button (fig. 31.1) to set the lower limit

of the cutting window.

• The LED in button (fig. 31.1) lights up during

each further passing through of the cutting

window. The length of the cutting window is

shown in mm within the cutting window

symbol on the display.

• To activate the automatic cutting window

again, press button (fig. 30.4) and while this

button (fig. 30.4) is still being pressed, also

press the button (fig. 31.1).

• Then the letters "AW" are shown on the

display again.

Note:

A cutting window should only be set

while the specimen is moved

downwards. If, by mistake, a cutting

window limit is set during return travel of the

specimen, the set limits are applied to the

cutting movement accordingly.

Note:

In case the cutting window limits

are set incorrectly, please repeat

above-mentioned process again.

Note:

If no cutting window is needed,

briefly press the button (fig. 31.1)

twice. The automatic approach

system can now be released in any position.

Fig. 31

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

35

Page 36

Thermo Scientific Cryostat Microm Cryo Star HM 560

2-9 HAND WHEEL BRAKE

Unintended movements of the specimen

holder can be avoided via the Hand wheel

brake.

This reduces the danger of being injured while

adjusting specimen clamp and knife carrier!

Caution:

When the instrument is turned off, the

Hand wheel brake is not operative.

Caution:

For your personal safety, the Hand

wheel brake should be turned on when

working on the specimen holder or

knife carrier.

Activating the brake

• Activate the function Hand wheel brake via

button (fig. 35.2).

• The red LED (fig. 35.4) lights up.

Releasing the brake

• To release the Hand wheel brake, press

button (fig. 35.3).

Fig. 35

36

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

Page 37

Thermo Scientific Cryostat Microm Cryo Star HM 560

2-10 DETACHING THE SPECIMEN

To detach a frozen specimen from the

specimen chuck, choose the detach function.

• For this, press button (fig. 40.6).

• The plate of the fast freezing station warms

up.

• Place the specimen chuck onto the plate.

• After a corresponding warm-up, the

specimen can be removed from the

specimen chuck.

• If the temperature is higher than +5°C, this

function is turned off automatically.

Fig. 39

Fig. 40

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

37

Page 38

Thermo Scientific Cryostat Microm Cryo Star HM 560

2-11 INDICATION OF CUTTING

PROCESSES

Further information on the cutting processes

can be seen on the display.

Press the scroll button (fig. 41.5), to show the

various functions one after the other.

The following information on the carried-out

cutting processes of the instrument can be

read on the info line of the display:

• number of sections

• sum of section thicknesses

• remaining travel to the front end position

• real time

• Press the scroll button (fig. 41.5) until the

required information lights up on the display.

• If no information is required in this line of the

display, press button (fig. 41.5) until this line

is blank.

2-11-1 SECTION COUNTER

• The section counter adds up the number of

sections produced.

• After each downward movement of the

specimen holder, the number on the section

counter increases by 1.

• The counter can be reset to zero via button

(fig. 41.4).

2-11-2 SUM OF SECTION THICKNESSES

• This value shows the sum in microns of the

sections already cut.

• Trimming values as well as sectioning values

are added up.

• This value can be reset to zero via button (fig.

41.4).

Fig. 41

Fig. 42

38

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

Fig. 43

Page 39

Thermo Scientific Cryostat Microm Cryo Star HM 560

2-11-3 REMAINING TRAVEL TO FRONT

END POSITION

• This value shows the distance in microns,

which is left for sectioning.

• When the knife carrier is in the rear end

position, the display shows 48 000 µm. This

number decreases the closer the knife carrier

moves towards the front.

Note:

If no further feed is possible

anymore, the display automatically

shows the remaining travel,

independently which information on the

sectioning processes, e.g. number of sections

or sum of section thicknesses, was chosen

before.

2-11-4 REAL TIME

The real time is shown here.

Fig. 44

Fig. 45

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

39

Page 40

Thermo Scientific Cryostat Microm Cryo Star HM 560

2-12 SETTING THE REAL TIME,

WAKE TIME AND ACTIVE TIME

2-12-1 SETTING THE REAL TIME

• Press button (fig. 47b.2) once.

• To change the instrument's real time at

intervals of one minute, press the UP or

DOWN button (fig. 47d.5 or 47d.6).

2-12-2 SETTING THE WAKE TIME

• Press button (fig. 47b.2) three times.

• To change the WAKE time at intervals of 15

minutes, press the UP or DOWN button (fig.

47d.5 or 47d.6).

After having reached the WAKE time, the

instrument switches over to the active status.

2-12-3 SETTING THE ACTIVE TIME

• Press button (fig. 47b.2) four times.

• To change the ACTIVE time at intervals of

1-hour-steps (1 to 9 h), press the UP or

DOWN button (fig. 47d.5 or 47d.6).

The set ACTIVE time is only valid when the

instrument has left the sleep status after having

reached the START time. Then the set

ACTIVE time will be prolonged whenever

pressing a key or turning the Hand wheel.

Note:

If the ACTIVE time has been

passed and the instrument is in the

sleep status and has been activated

afterwards by the operator, the default value of

1 h is now valid again.

Note:

Further menu steps are relevant for

service technicians only.

Fig. 46

Fig. 46a

40

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

Page 41

Thermo Scientific Cryostat Microm Cryo Star HM 560

2-13 DEFROSTING

2-13-1 SETTING THE DEFROSTING TIME

• Press button (fig. 47b.2) twice.

• To change the instrument's defrosting time at

intervals of 15 minutes, press the UP or

DOWN button (fig. 47d.5 or 47d.6).

Note:

Defrosting can only be carried out

at the set defrosting time, if the real

time is set correctly (see part 2-12).

2-13-2 DEFROSTING CYCLE

Every 24 hours the evaporator in the rear part

of the microtome chamber is defrosted

automatically.

• During the defrosting cycle, the display (fig.

47a) shows DEFROST in the upper line.

• It is advisable to set the time of the

defrosting cycle not during routine working

time (see part 2-13-1).

• According to the frost built-up, a defrosting

cycle normally takes approx. 40 min.

• Immediate defrosting can be carried out at

any time by pressing the RESET button (fig.

47b.4) and additionally the button (fig.

47d.2) (specimen temperature).

• Before starting the immediate defrosting, it

is absolutely necessary to remove section

waste.

Note:

When an immediate defrosting is

carried out, the instrument is

"actively heated", i.e. the heatings

of the instrument are turned on. Knife carrier,

specimen clamping as well as the fast freezing

stations are heated.

Caution:

Remove the specimen from the

chamber when defrosting is carried

out. The temperature inside the

chamber rises considerably and thus the

specimen would be damaged.

Fig. 47

Fig. 47a

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

41

Page 42

Thermo Scientific Cryostat Microm Cryo Star HM 560

2-13-3 INTERRUPTING A DEFROSTING

CYCLE

If needed, the daily defrosting can be

interrupted or cancelled.

• For this, press button (fig. 47d.3) (knife

temperature) together with the RESET

button (fig. 47b.4).

• The interrupted defrost cycle is indicated

with INTR. in the status line (fig. 2.15) of the

display (fig. 47c).

Note:

A cancelled or interrupted defrost

cycle must be repeated later on, as

otherwise the evaporator will cover

completely with frost and cannot cool anymore

(see immediate defrosting, part 2-13-2).

For this reason, the function INTERRUPT is

automatically reset at the end of an interrupted

defrosting (max. time approx. 1 h), i.e. the next

defrosting is carried out again at the preselected defrosting time.

While INTR. is active, neither the defrosting

time nor the real time can be changed.

When INTR.ACT appears in the status line,

this means that INTERRUPT was selected

while defrosting should otherwise be carried

out and the next defrosting is carried out again

at the next pre-selected defrosting time.

Fig. 47b

Fig. 47c

42

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

Fig. 47d

Page 43

Thermo Scientific Cryostat Microm Cryo Star HM 560

2-14 TURNING OFF THE

FUNCTION RETRACTION

If needed, the function retraction can be turned

off.

Turning off

To turn the function retraction off, the following

preparation is necessary:

• Via the scroll button (fig. 48.5) select the

blank status line (fig. 2.15) on the display.

• Then press the RESET-button (fig. 48.4) to

turn the retraction off.

• The letters "REN" on the display go off.

Note:

The letter "R", however, might still

be on. This function goes off only

after having passed from the return

travel again to the cutting movements via the

Hand wheel.

Activating

• Via the scroll button (fig. 48.5) select the

blank status line on the display.

• Then press the RESET-button (fig. 48.4) to

turn the retraction on.

• The letters "REN" appear on the display.

Fig. 48

Fig. 49

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

43

Page 44

Thermo Scientific Cryostat Microm Cryo Star HM 560

2-15 CUSTOMER-SPECIFIC SETTINGS

The information on the display can be shown in

various contrasts and in four different

languages.

2-15-1 SETTING THE CONTRAST

• To set the contrast higher or lower, press

the RESET-button (fig. 50.4). While the

RESET-button is still being pressed, also

activate button (fig. 53.4).

• Then the word CONTRAST is shown on the

display (fig. 52.).

• To set the contrast lower, press the button

DOWN (fig. 53.6).

• To set the contrast higher, press the button

UP (fig. 53.5).

• To acknowledge the desired contrast, press

the RESET-button (fig. 50.4).

• The display returns to its basic indication.

Fig. 50

Fig. 52

Fig. 53

44

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

Page 45

Thermo Scientific Cryostat Microm Cryo Star HM 560

2-15-2 SELECTING THE LANGUAGE

The information on the display can be shown in

four different languages.

The following languages are available:

- German

- English

- French

- Spanish

• To select or change one of these languages,

first turn off the power switch (fig. 6.1) of the

instrument.

• When turning on the instrument again, keep

the scroll button (fig. 54.5) pressed.

• The user enters the menu mentioned in part

2-15.

• Confirm the contrast setting via the RESET-

button (fig. 54.4).

Now the desired language can be selected:

• The display shows as the first suggestion:

LANGUAGE DEUTSCH (fig. 55).

• To choose another language, press the scroll

button (fig. 54.5) until the desired language is

shown in the respective national language on

the display.

• Acknowledge the desired language via the

button (fig. 54.4).

• Then the main menu for the service routine

(fig. 56) is shown as well as "Next with

SCROLL, confirm with RES." To quit the

menu, please press the button (fig. 54.4).

• The display now shows the terms in the

desired language.

Note:

If the menu has been used beyond

the a.m. settings, the user enters

service routine programs which can

be operated by trained service technicians

only.

Fig. 54

Fig. 55

Fig. 56

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

45

Page 46

Thermo Scientific Cryostat Microm Cryo Star HM 560

2-16 TURNING OFF THE COOLING

FUNCTION

With this OFF-function (fig. 56a), it is possible

to turn off the major electric assemblies of the

instrument (e.g. the compressors, the fast

freezing element, the temperature control)

without having to turn off the instrument on the

main switch.

Consequently, the temperature in the cooling

chamber increases. Now, the instrument can

be used with certain restrictions in the same

way as a rotary microtome under ambient

conditions.

Turning on and off the cooling function:

• First press the RESET button (fig. 56b.4).

• While the RESET button is still being

pressed, also press the button (fig. 56b.6).

• To activate the cooling function of the

instrument again, press the buttons (fig.

56b.4) and (fig. 56b.6) once more.

For further specimen processing, let the

instrument cool down accordingly.

Fig. 56a

Fig. 56b

46

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

Page 47

Thermo Scientific Cryostat Microm Cryo Star HM 560

2-17 ILLUMINATION OF THE

COOLING CHAMBER

To illuminate the cooling chamber, a

fluorescent lamp is located in the handle of the

sliding window.

• The fluorescent lamp is automatically turned

on when the instrument is turned on.

• The lamp remains on as long as the

instrument is in its active status (see standby

status, part 2-3).

• Used lamps can be changed by the user

himself (see part 5-3).

2-18 ADJUSTING THE

OPERATING PANEL

For better looking at the display and for the

ergonomical operation of the buttons, the user

can adjust the angle of the console up to

approx. 15°.

• Press the knob (fig. 57.1) on the right side

of the console.

• Then take the console on the right and left

side in your hands and swivel the console

forwards or backwards into the desired

position.

Fig. 57

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

47

Page 48

Thermo Scientific Cryostat Microm Cryo Star HM 560

2-19 SPECIMEN HOLDER, FREEZING-ON

AND SPECIMEN ORIENTATION

2-19-1 SPECIMEN HOLDER,

FREEZING-ON

There are several possibilities to freeze on

specimens.

Various specimen chucks are available. Round

specimen chucks can be supplied with a

diameter of 30 mm and 40 mm and rectangular

specimen chucks with a size of 50, 55, 60 and

70 mm. Special sizes on request. Fig. 58

shows a variety of specimen chucks and cryo

molds. (See 2-22-2).

Note:

Besides the usual method of freezing

specimens from above on the

specimen chuck, it is highly

recommendable to apply the below-described

method by using cryo-molds (fig. 58).

• Put the cryo mold (fig. 59.2) onto the

freezing station (fig. 59.1).

• Place fresh tissue into the sparing of the

cryo mold (fig. 59.2). The surface of the

tissue has direct contact with the cold fast

freezing plate (fig. 59.1).

• Fill freezing compound into the cryo mold

(fig. 59.2) so that the sparing is filled well.

• Put the chuck with the clinging grooves

downwards (fig. 59.3) onto the cryo mold

(fig. 59.2) which is filled with tissue and

freezing compound.

• To accelerate the freezing, put the heat

extractor (fig. 59.4) onto the specimen

chuck (fig. 59.3) from above.

Note:

Within approx. 40 sec. the tissue will

be frozen through.

• Remove the specimen chuck (fig. 59.3)

together with the cryo mold (fig. 59.2) from

the fast freezing plate.

• Insert the chuck with the cryo mold into the

specimen holder on the microtome and

clamp it.

• Open the cryo mold (fig. 59.2) by pressing

the two grips (fig. 59.5) and remove it from

the chuck with specimen.

Fig. 58

Fig. 59

48

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

Page 49

Thermo Scientific Cryostat Microm Cryo Star HM 560

• After having oriented the specimen (see

part 2-19-2), the specimen can be

sectioned.

Note:

The upper side of the freezing station

must not be covered by frost or ice. To

avoid this, use acetone, ethanol or the

like.

2-19-2 SPECIMEN ORIENTATION

In many cases, the orientation of the specimen

in relation to the cutting edge would be

advantageous.

This can easily be done by means of the

orienting specimen holder on the microtome.

• Before the specimen chuck can be inserted,

loosen the clamping lever (fig. 60.2)

upwards.

• Insert the specimen chuck and clamp it via

the clamping lever (fig. 60.2).

Note:

The clamping mechanism can be

adjusted in case the chucks cannot be

clamped properly.

• For this, turn the adjusting ring (fig. 60.5) by

means of the enclosed pin (fig. 60.6) (see

standard equipment part 2-22-1).

• For a tighter clamping, turn the ring to the

right side.

• For a looser clamping, turn the ring to the

left side.

• To orient the specimen, loosen the orienting

lever (fig. 60.1).

• Via the adjusting knobs (fig. 60.3 and 60.4),

the specimen clamping can be moved into

various directions.

Note:

When the adjusting knob (fig. 60.4) for

specimen orientation is activated a

slight lock-in position can be noticed

during each rotation. The entire adjusting

range includes four rotations in either direction.

The middle lock-in position marks the zero

position.

3

2

1

4

5

6

Fig. 60

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

49

Page 50

Thermo Scientific Cryostat Microm Cryo Star HM 560

• After having oriented and aligned the

specimen, press the orienting lever (fig.

60.1) upwards.

For the further specimen orientation, the

specimen chuck can be rotated by 360°.

• Slightly loosen the clamping lever (fig. 60.2)

upwards.

• Turn the specimen chuck with specimen as

needed.

• Then bring the clamping lever (fig. 60.2)

back in its clamping position.

• Pull the adjusting knob (fig. 60.3) upwards

to facilitate the taking off of sections by

means of a slide.

50

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

Page 51

Thermo Scientific Cryostat Microm Cryo Star HM 560

2-20 KNIFE CARRIERS

2-20-1 STANDARD KNIFE CARRIER SM

The standard knife carrier SM takes up commercially available conventional knives with c- and dprofiles as well as the disposable blade holder SE.

2

1b

8

4

8

1a

3

5

9

6

7

Fig. 61

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

51

Page 52

Thermo Scientific Cryostat Microm Cryo Star HM 560

Inserting the knife:

• The knife is inserted into the knife carrier

from above.

• For this, swivel both knife guards (fig. 61.1a

and 61.1b) over the knife carrier towards

the microtome.

• Via the knob (fig. 61.3), remove the anti-roll

plate (fig. 61.2) together with the finger

protecting bow adapted to the anti-roll hood

(fig. 61.4) from the knife carrier.

• Insert the knife.

Danger:

When the knife guards are open, the

fixing force for the knife is strongly

reduced. However, the knife is still

pulled towards the magnetic surfaces with

some force. Be careful, when inserting the

knife.

• Swivel the knife guards (fig. 61.1a and

61.1b) back over the knife.

Note:

With this movement, the holding

magnets, which clamp the knife in

place, are brought into their correct

position. The knife is now fixed in its position.

• Via the knob (fig. 61.3) put the anti-roll plate

(fig. 61.2) against the knife.

• Place the knife guard middle part (fig. 61.4)

over the knife blade.

If the cutting area of the knife is no longer

usable, the knife can be moved:

• Open the knife guards (fig. 61.1a and

61.1b) and move the knife to the left or right

side as required.

• Clamp and fix the knife again via the knife

guards (fig. 61.1a and 61.1b).

Danger:

To avoid the danger of injury on the

knife during adjustment of specimen,

always position the knife guards (fig.

61.1a and 61.1b as well as fig. 61.4) over the

blade edge.

52

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

Page 53

Thermo Scientific Cryostat Microm Cryo Star HM 560

Height adjustment of the knife:

• Open the knife guards (fig. 61.1) to loosen

the fixation of the knife.

• Via the knurled screws (fig. 61.8) adjust the

height of the knife so that the blade

corresponds with the red marking line.

Note:

Please note the parallel alignment of

knife edge and edge of the anti-roll

plate.

Putting the anti-roll device holder against

the non-cutting edge of the knife:

• Loosen the knurled screws (fig. 61.9) to put

the anti-roll device holder against the noncutting edge of the knife.

• Press the anti-roll device holder onto the

knife.

• Fasten the knurled screws (fig. 61.9) again.

Fine adjustment of the anti-roll device:

• The fine adjustment of the anti-roll device is

carried out via the knurled screw (fig. 61.5).

• The parallel positioning between knife edge

and anti-roll plate is carried out via another

knurled screw on the right side of the

knurled screw (fig. 61.5).

Selecting the clearance angle:

• Loosen the levers (fig. 61.6).

• Swivel the upper part of the knife carrier on

the base (fig. 61.7) until the desired

clearance angle is reached.

• The clearance angle can be read on the

scale on the left side on the base.

• Bring the levers (fig. 61.6) into clamping

position.

• The selected clearance angle is now fixed

in its position.

Note:

Usable cuts are only achieved at a

clearance angle of 8° to 12°!

Adjusting the flat lever handles (fig. 61.6)

The position of the flat lever handles (fig. 61.6)

can be adjusted in 30° steps.

• Slightly pull out the handles and turn them

further into a more favorable position.

• The the handles must lock into place again.

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

53

Page 54

Thermo Scientific Cryostat Microm Cryo Star HM 560

2-20-2 DISPOSABLE BLADE HOLDER SE

The disposable blade holder SE takes up all commercially available low profile blades with a dimension

of 80 x 8 mm and a facette angle of approx. 35° and as another version it takes also up high profile

blades.

The disposable blade holder SE is inserted into the standard knife carrier SM.

2

1b

4

1a

3

9

5

6

7

Fig. 62

54

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

387 500 - English

Page 55

Thermo Scientific Cryostat Microm Cryo Star HM 560

Inserting the blade:

• Open the left and right knife guard (fig.

62.1a and 62.1b).

• Open the clamping lever (fig. 62.8)

upwards.

• Insert the blade from the left side into the

slot behind the clamping plate (fig. 62.9) as

far as possible.

• Use the attached brush or a similarly